Review of the Development of an Unbonded Flexible Riser: New Material, Types of Layers, and Cross-Sectional Mechanical Properties

Abstract

1. Introduction

2. Form, Performance Characteristics, and Configuration Characteristics of an Unbonded Flexible Riser

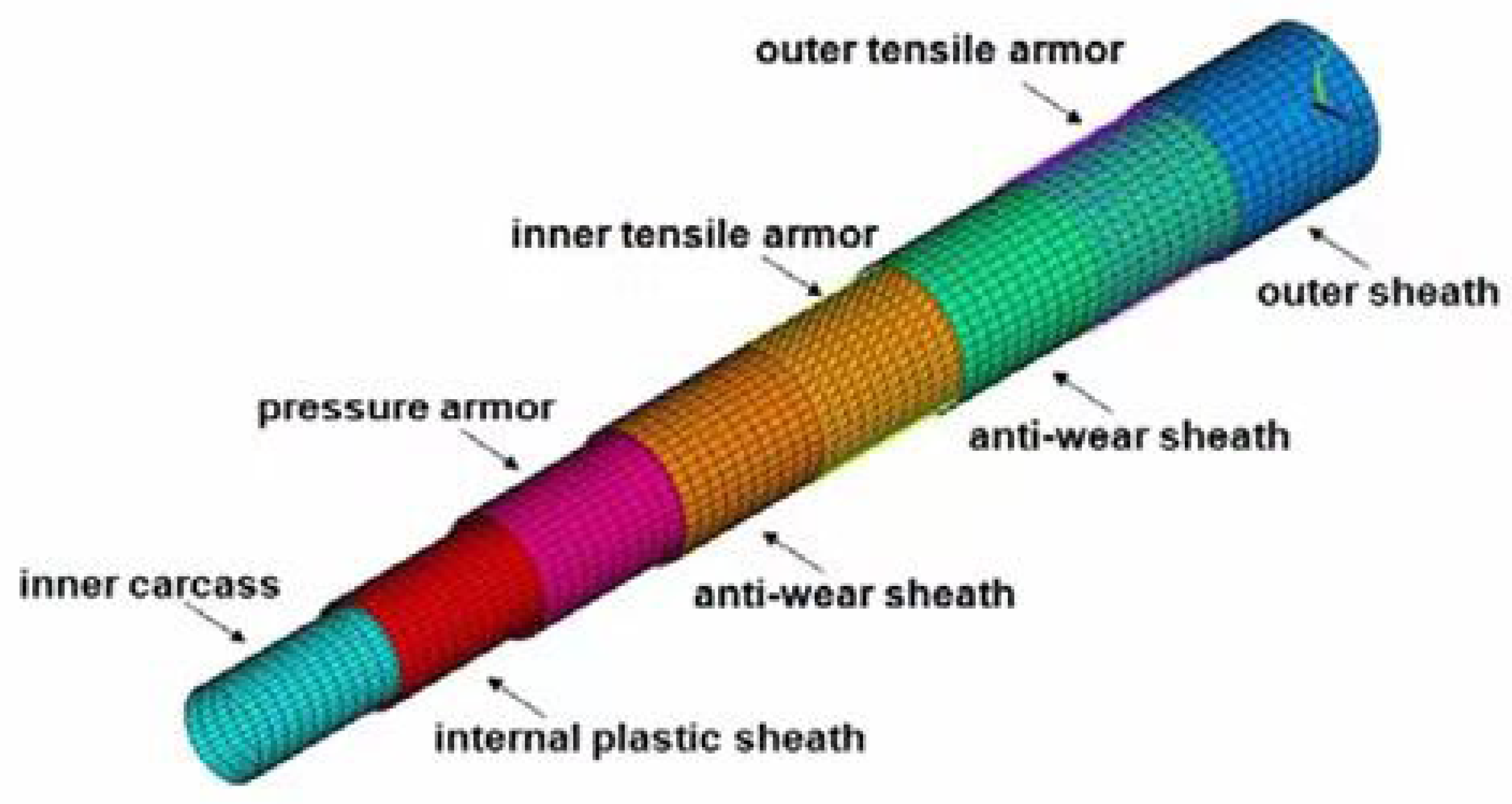

2.1. Form of Interlayers of an Unbonded Flexible Riser

- 1.

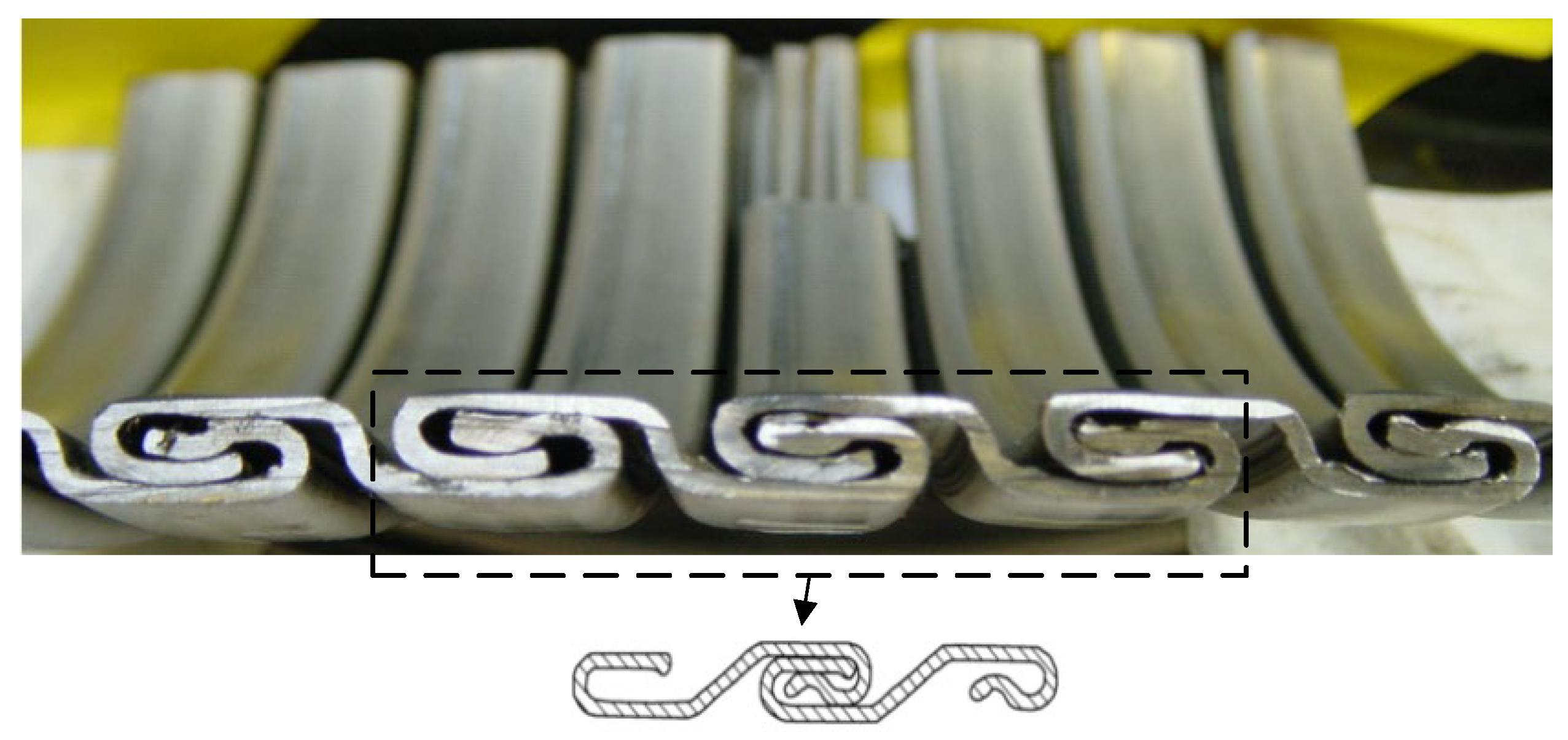

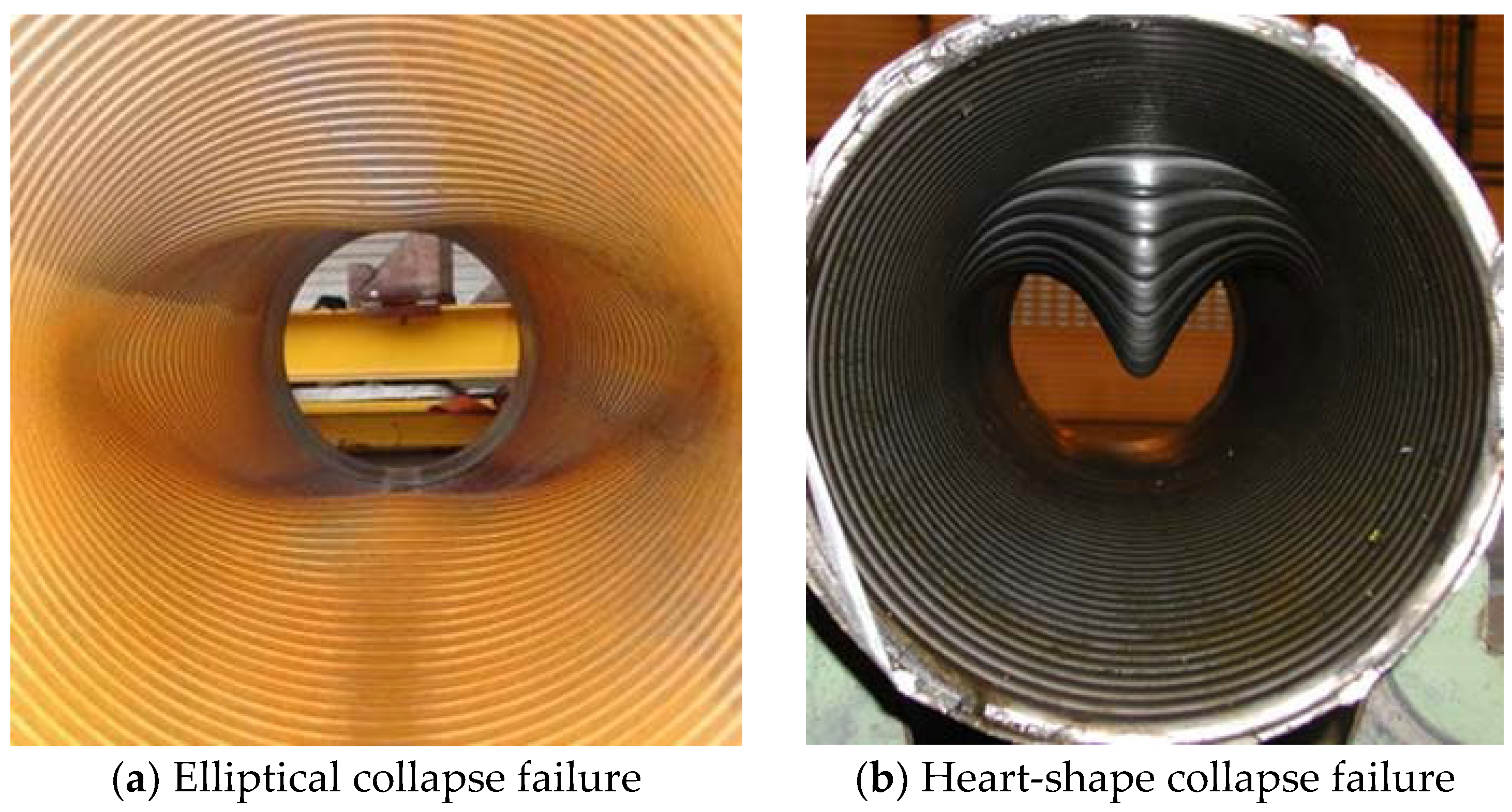

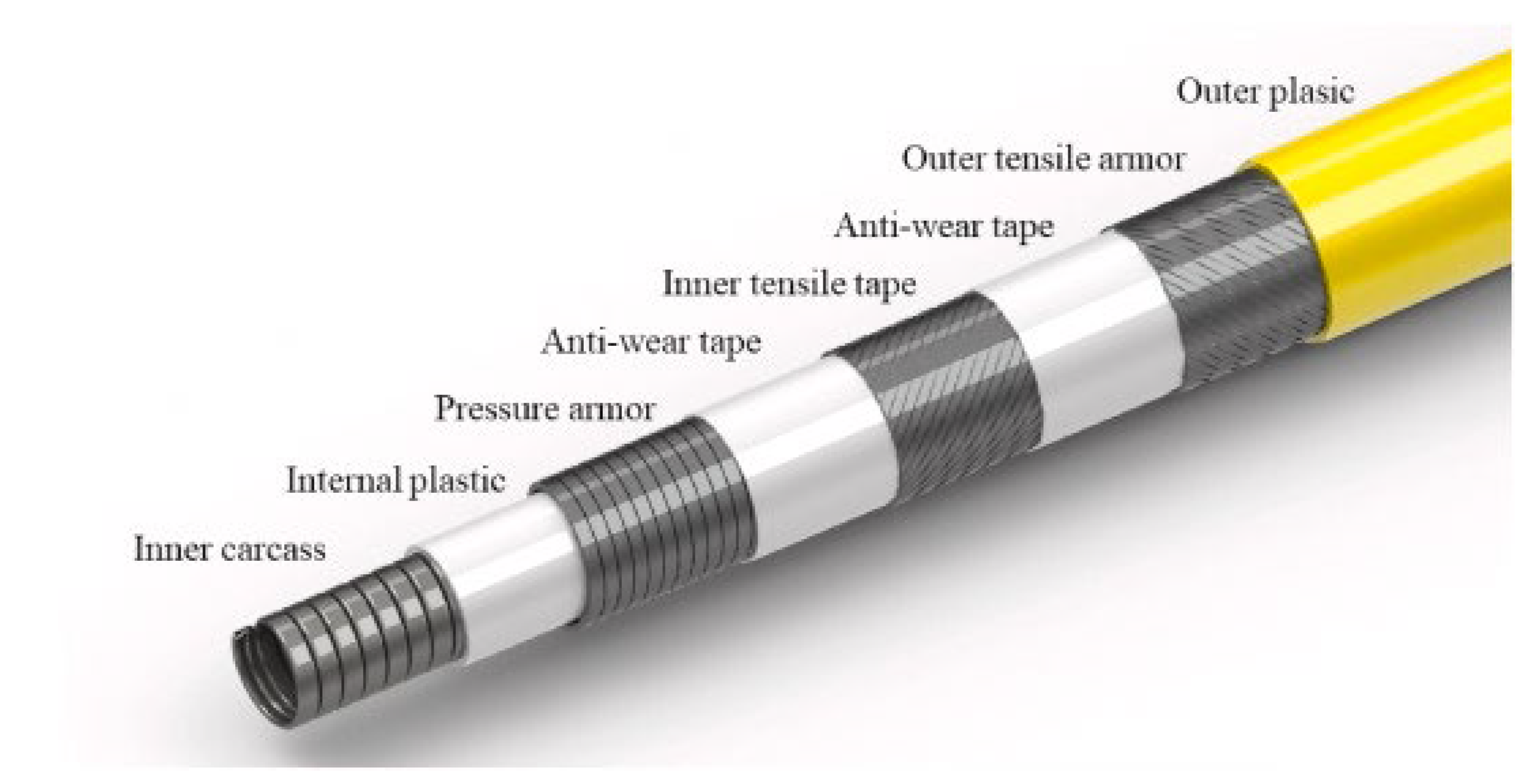

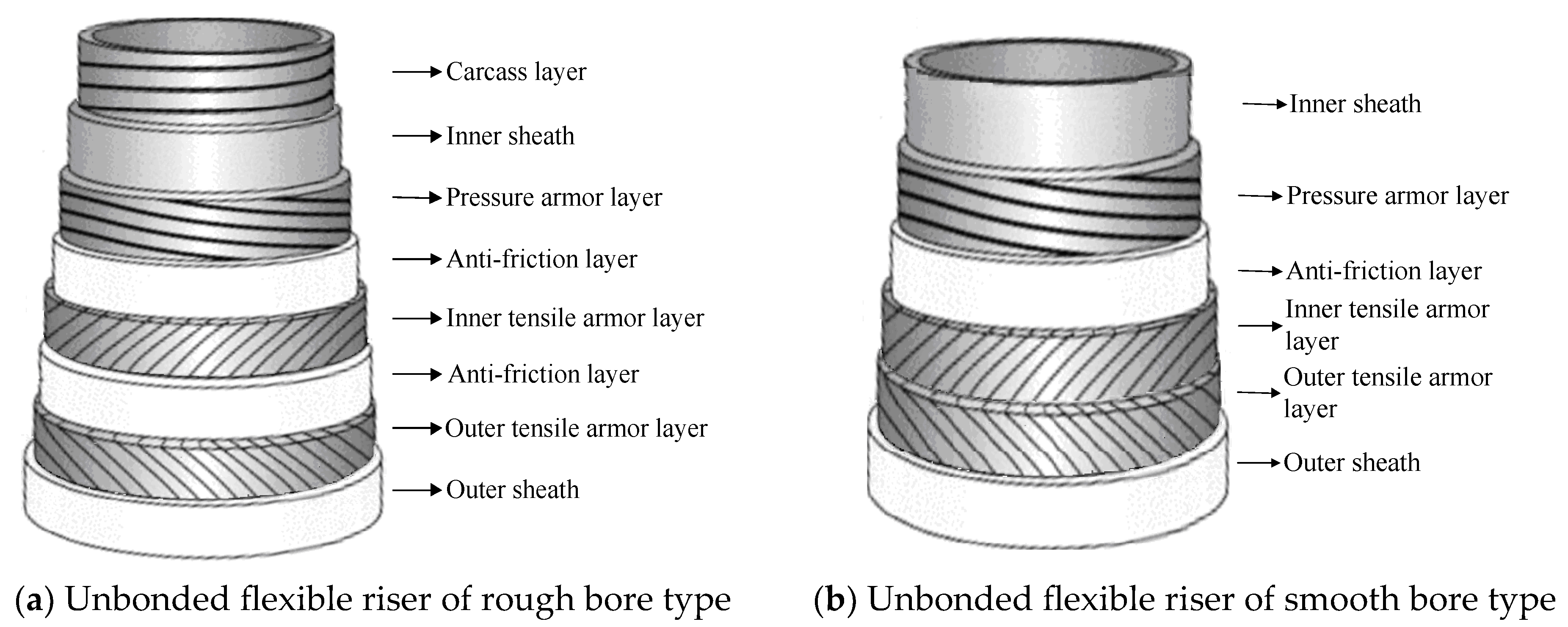

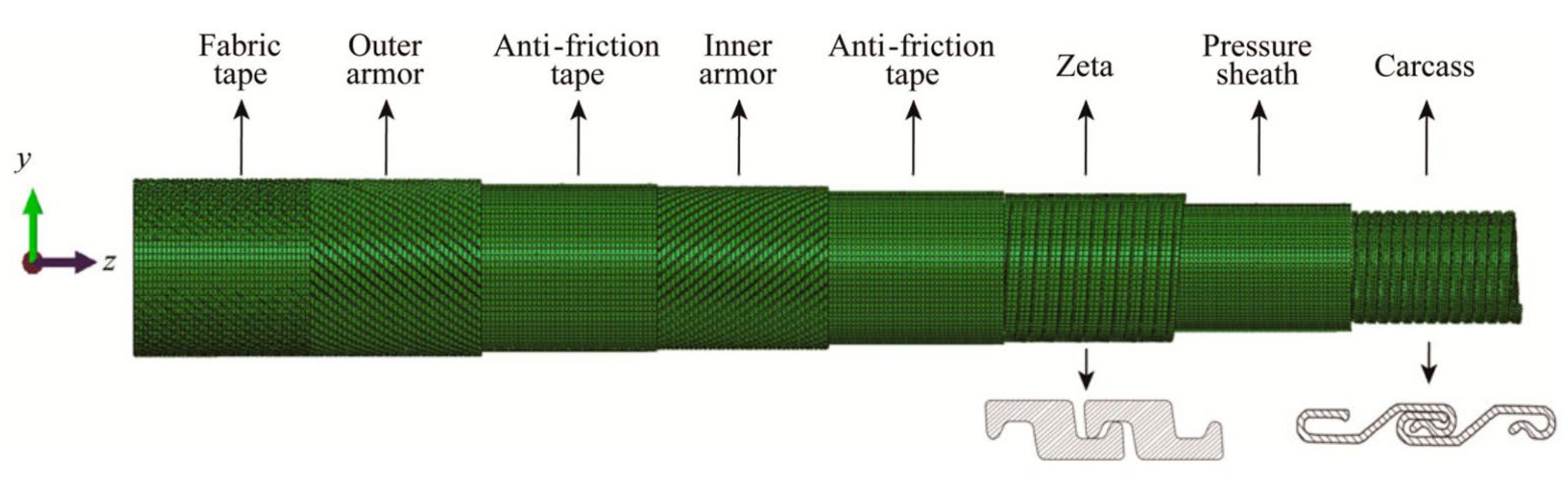

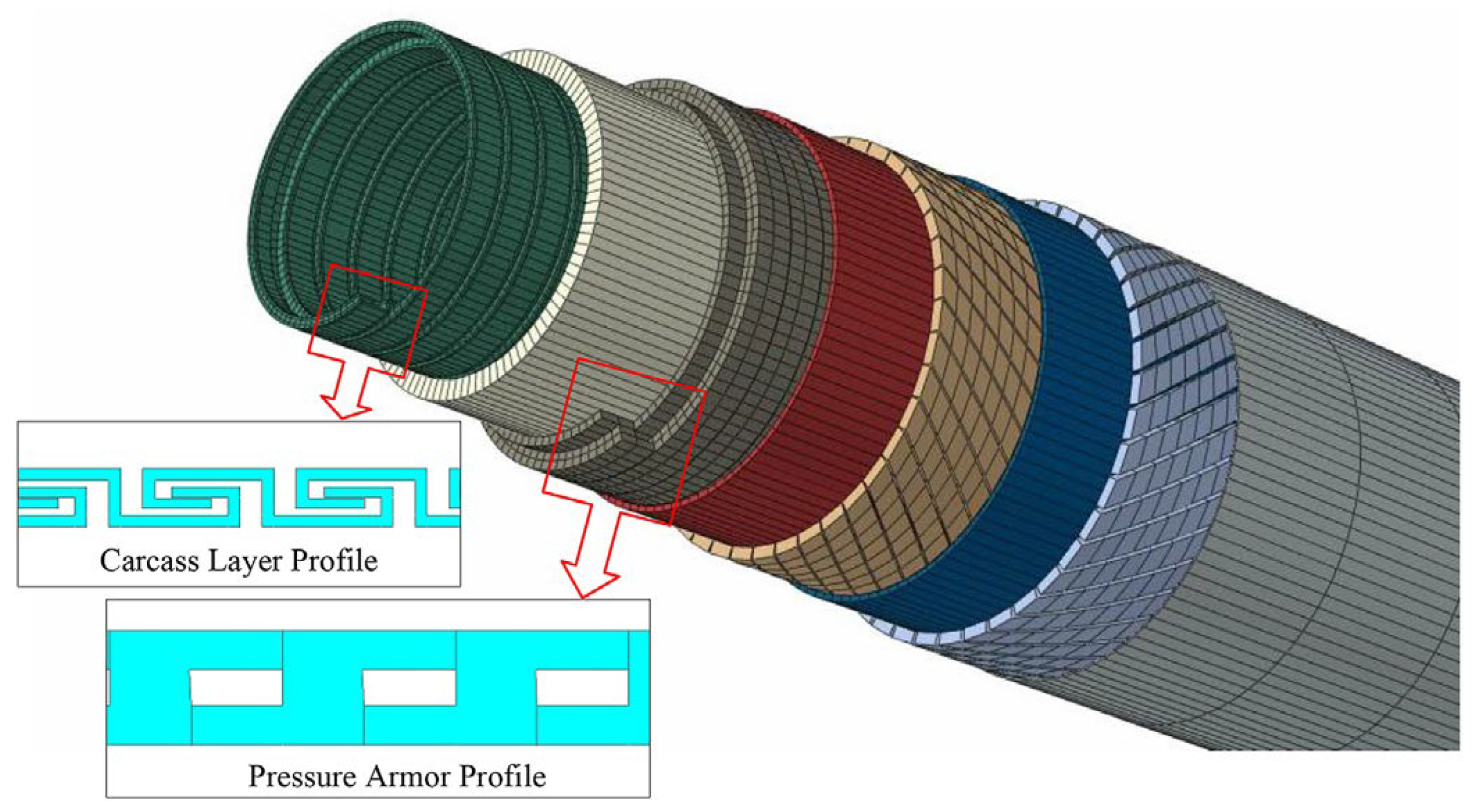

- Carcass layer (Figure 4). The carcass layer is typically composed of carbon steel, stainless steel (austenitic stainless steel AISl304, 304L, 316, 316L, or duplex stainless steel, etc.), corrosion-resistant alloys (resistant to the corrosive effects of H2S, CO2, CL ions, etc.), and other metal materials. The self-locking, non-watertight structure consists of steel material wound at a laying angle of close to 90°, and the cross-section is usually S-shaped, as shown in Figure 4. The special geometric form makes the axial tensile stiffness and torsional stiffness of the skeleton layer very small while ensuring sufficient bending performance but also preventing compression failure caused by external compressive loads. In general, as shown in Table 1, the skeleton layer of unbonded flexible risers features specific dimensional specifications tailored to risers of varying sizes. The typical failure modes of the carcass layer, as well as the pressure armor layer, are presented in Figure 5 [15].

- 2.

- Inner sheath. The internal sheath layer is a closed cylindrical shell structure extruded from polymers, usually nylon 11 (PA-11), nylon 12 (PA-12), cross-linked polyethylene (XLPE), high-density polyethylene (HDPE), etc. The thickness of this layer is usually 5.5 to 18 mm and is used for conveying medium (oil and gas resources). During the design process, the inner sheath layer is mainly considered with the compatibility of the fluid medium, fluid permeability, mechanical and thermal properties, and other factors. It should be noted that there may be gaps between the internal carcass layer and the inner sheath layer, which can lead to an infiltration phenomenon where gaseous substances accumulate in the annular region between these two layers [16].

- 3.

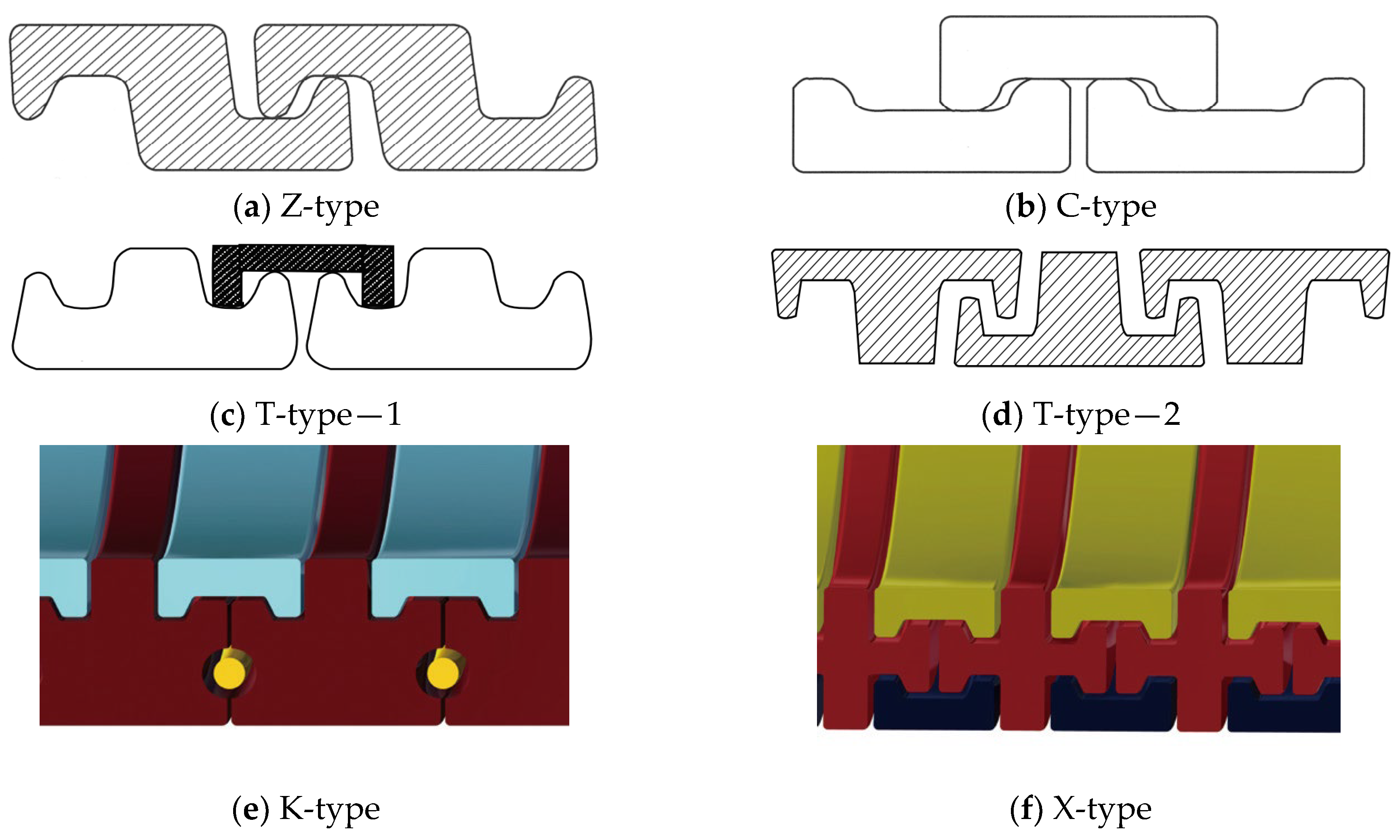

- Pressure armor layer [17,18,19,20,21]. The geometric properties of the pressure armor layer are similar to that of the carcass layer, which is a steel self-locking structure with a high laying angle, where the axial tensile and torsional stiffness can be basically ignored. The thickness of the layer is 4 to 12 mm, and the section geometry is mainly of the Z-type, C-type, or T-type (such as Figure 6a–d). The pressure armor layer mainly provides the radial stiffness of the unbonded flexible riser and carries the riser’s internal and external pressure (mainly carrying the internal pressure load caused by the internal medium). In cases where the riser is subjected to less internal pressure, the riser design can similarly eliminate that layer of the structure. The “Z-type” pressure armor layer is the main cross-section in the unbonded flexible riser industry. The specification parameters and scope of application of the pressure armor layer are presented in Table 2. In addition, there are some special cross-section shapes of the pressure armor layer, as shown in Figure 6e,f. These two structural forms of fatigue performance assessment are complex and do not promote application. Unlocking is the most common failure mode of tensile armor layers due to the fact that they are not completely self-locking like the skeleton layer structure and the asymmetry of the structural cross-section profile. The bearing ability of internal pressure is one of the most important properties of unbonded flexible risers. The burst failure of the pressure armor layer is illustrated in Figure 7.

- 4.

- Anti-friction layer: The anti-friction layer is made of polymer winding or directly formed by a non-metallic thermoplastic sheath cylindrical shell layer, usually PA11/6, PVDF, PP, etc. The anti-friction layer is located between the metal layers, mainly used to reduce and prevent friction between the metal layers, which can enhance the fatigue life of the pipeline and prolong its use.

- 5.

- Tensile armor layer. The tensile armor layer is the most important component layer of an unbonded flexible riser. A traditional unbonded flexible riser tensile armor layer consists of double or four layers of steel tendon with rectangular cross-sections, which are relatively wound. Additionally, the tensile armor layer is mainly used to provide axial stiffness, bearing the role of axial tension and torque, which can ensure the safe operation of the riser when it is subjected to self-weight and other external loads. In order to balance the role of tensile force and circumferential stress, the laying angle of the tensile armor layer can generally vary from 20° to 55°, and the gap between tendons generally accounts for 7~11% of the annular area of the tensile armor layer. The ability of the tensile armor layer directly determines the structural safety of the unbonded flexible riser. Additionally, structural failure is mainly caused by axial force, which mainly contains three failure modes: fracture failure, radial failure (birdcage failure, caused by axial compression, see Figure 8a), and lateral failure (caused by axial compression and wet environment, see Figure 8b).

- 6.

- Other intermediate layer structures (cylindrical layer). The intermediate layer of the unbonded flexible riser can be flexibly designed according to the needs of the actual situation. Additionally, according to the function of these cylindrical layers, they can be divided into an auxiliary layer, a bending-resistant layer, a thermal insulation layer, etc. Most of the intermediate layer structure is composed of a composite material cylindrical layer, such as a H2S gas corrosion-resistant layer and a thermal insulation layer. Some unbonded flexible risers add a layer of higher-strength composite material (typically Kevlar 49) as an anti-birdcage tape on the outside of the tensile armor layer to prevent radial failures from occurring [12].

- 7.

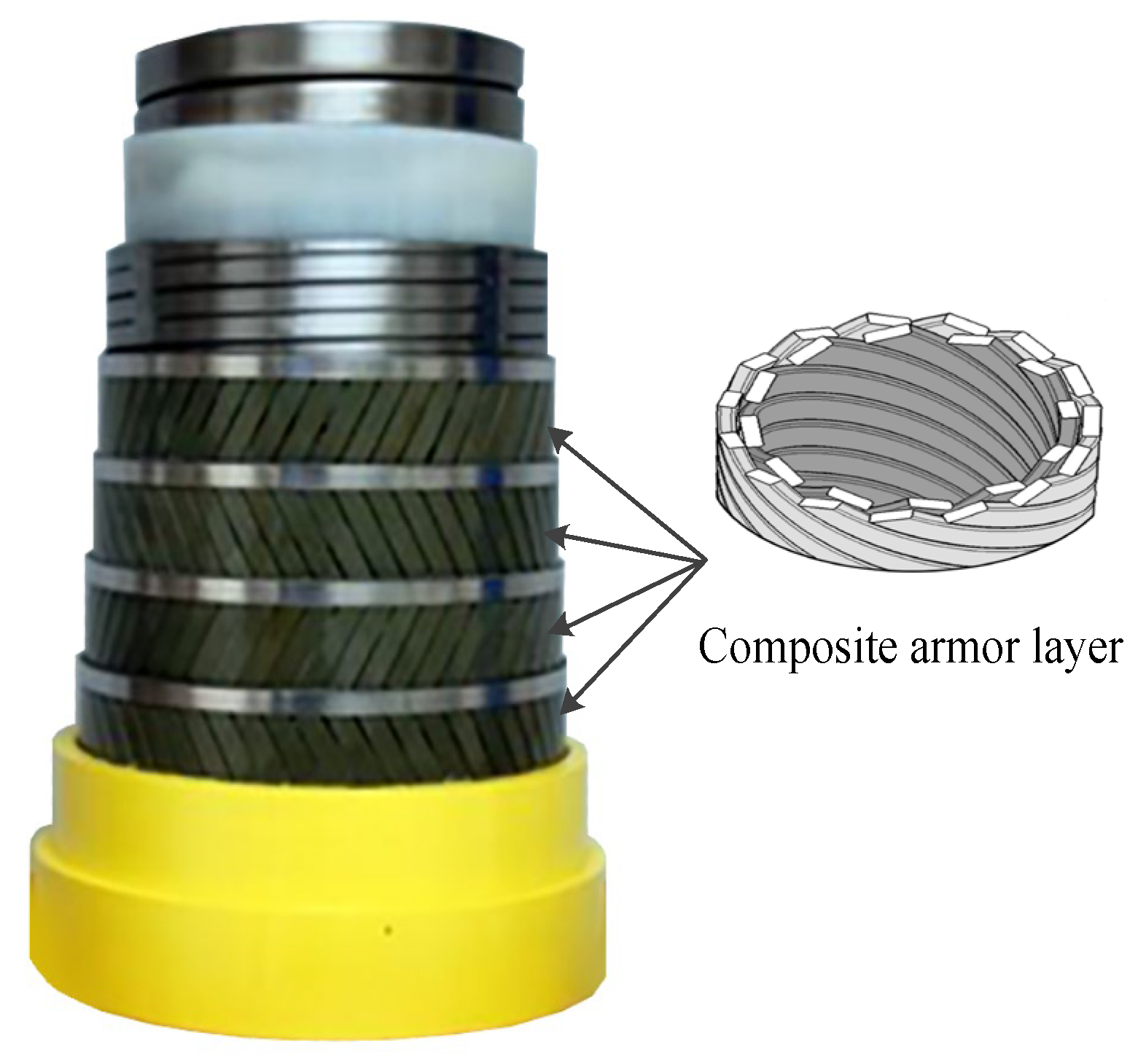

- Composite tensile armor layer [23,24,25,26,27,28]. The composite tensile armor layer is the application of composite materials to manufacture the tensile armor layer structure; its geometry is consistent with the traditional steel tensile armor layer. A schematic diagram containing a composite tensile armor layer of an unbonded flexible riser provided by Technip is presented in Figure 9. Offshore engineering towards ultra-deep waters is the reason that composite armor layers are generated. Beyond 2000 m of water depth, the weight of conventional flexible pipe becomes critical not only for the pipelay equipment and vessel but for the production floater as well. Substituting tensile steel armor with composite armor made from fiber-reinforced polymer has the potential to significantly reduce the weight of the pipe. Due to the high strength/mass ratio of carbon fiber, it can greatly reduce the overall quality of the unbonded flexible riser and improve the fatigue performance of the riser while meeting the strength; at the same time, compared with the steel structure, the composite material has better corrosion resistance, which can reduce the corrosive effect of chemicals and seawater on the risers in oil and gas fields, and it is the future direction of the development of unbonded flexible risers.

2.2. Performance Characteristics

- Flexible. The interlayers of an unbonded flexible riser are relatively independent of each other, and the layers can slip relative to each other; thus, flexibility is the most prominent characteristic of the riser. For example, a typical unbonded flexible hose with an inner diameter of 203.2 mm has a safe bending radius of 2 m. It can fit the seabed terrain well without a large overhang and can be used in floating systems or on an uneven seabed. It is also easily wound, transported, and installed [13,29].

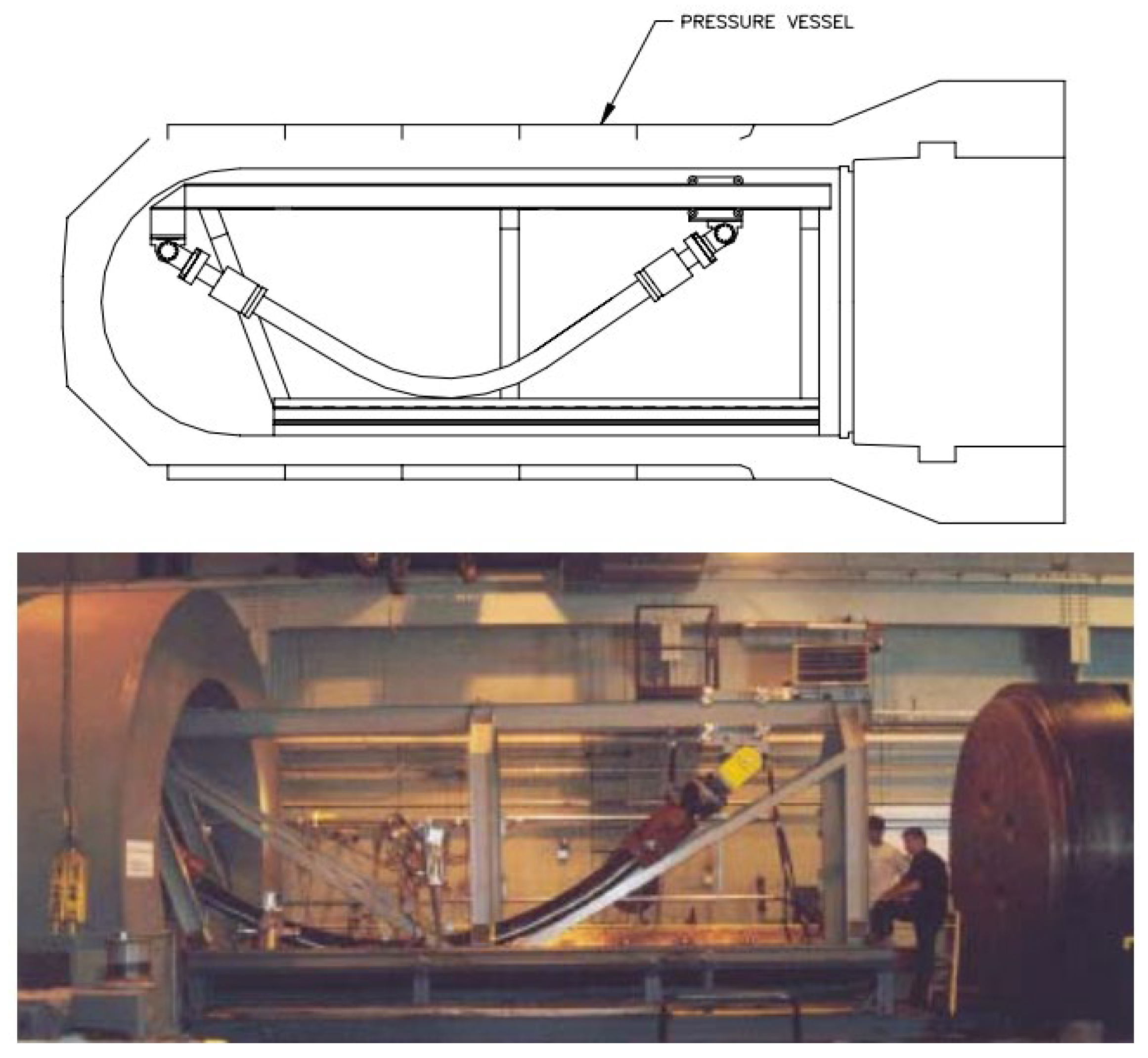

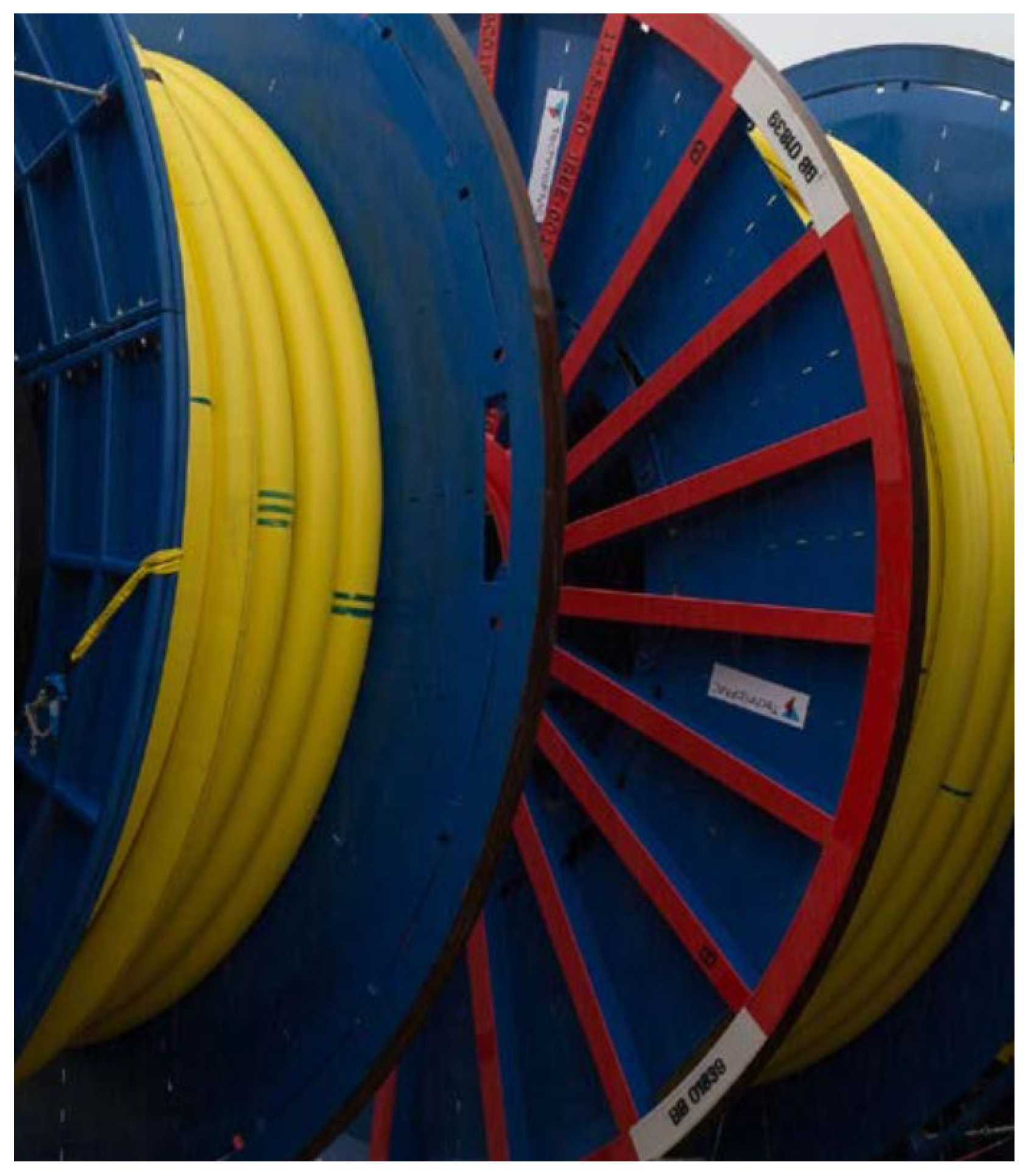

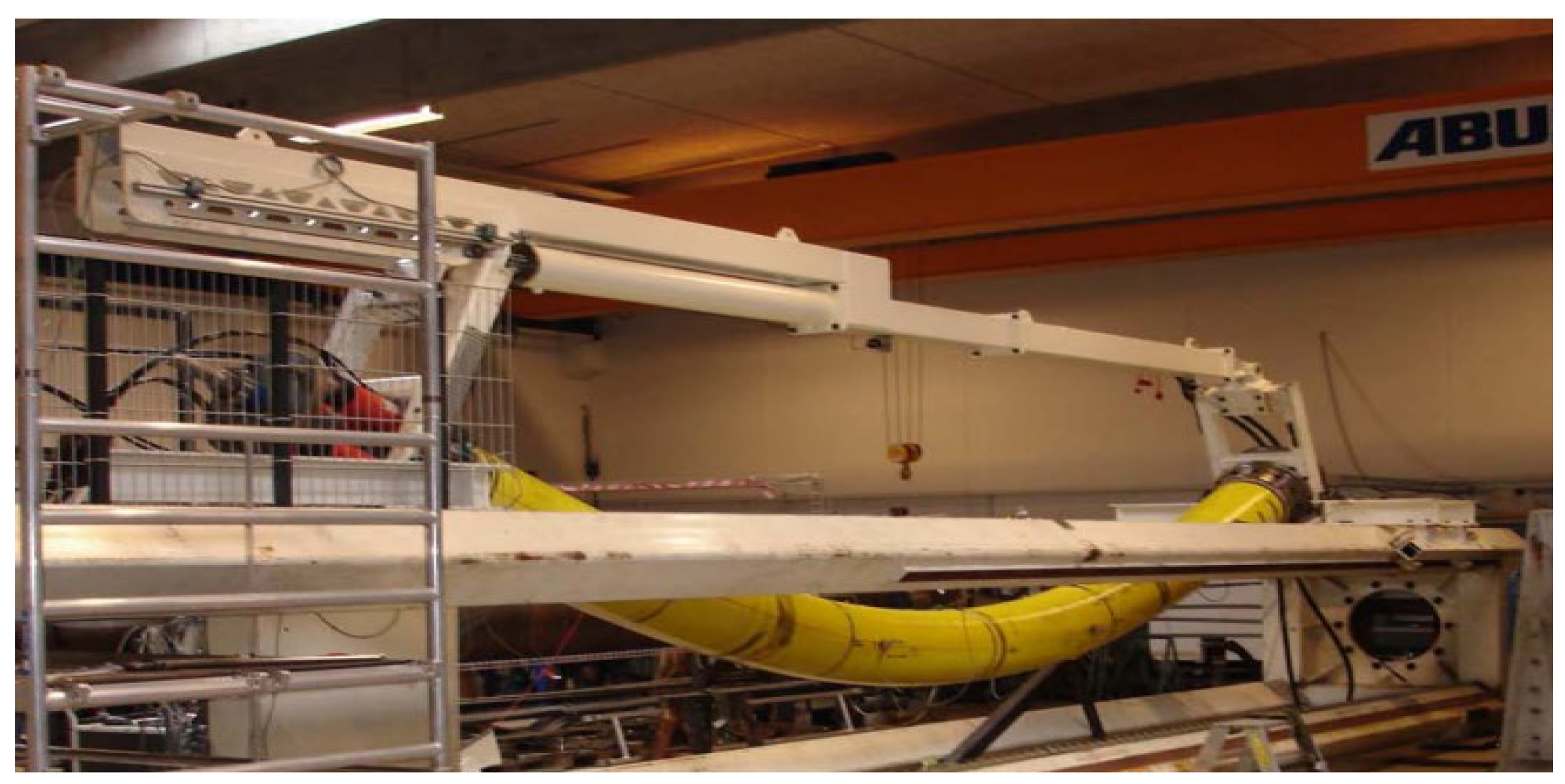

- Convenient installation. Despite the high costs of unbonded flexible risers, installation costs are relatively low. Since conventional steel pipe laying costs are high, the sea welding inspection workload is large, and the laying cycle is long. An unbonded flexible riser has laying safety, convenience, and fast features, meaning the risers can be laid using an ordinary power positioning vessel, and the laying cost of construction compared to conventional steel pipe is reduced by more than 50%. The pipe is continuously wound on a winch, and the entire length of the pipe can be several thousand meters long (see Figure 10). The laying cycle is short, the offshore connection workload is small, and the laying speed is generally 500 m/h on average, which is more than five times the speed of steel pipe laying. Separate sections can be placed on the deck, and connections can be synchronized during installation without the need for other riser-based structures or underwater connection aids.

- 3.

- Modularization. The interlayers of unbonded flexible riser construction are independent of each other, making it possible to realize the exact requirements of a specific development. A simple riser for medium pressure resistance requires only 4 layers, while the most complex riser can have up to 19 layers. In addition to basic liquid leakage and anti-pressure layers, other layers can be sandwiched between the helical steel layers for abrasion resistance or thermal insulation. The modularity of the riser production process facilitates the adjustment of the thickness, cross-sectional shape, and number of layers to meet the different requirements of the customer.

- 4.

- Low corrosion-resistance requirement for steel helical tendons. Since the steel tensile armor of an unbonded flexible riser does not come into direct contact with the conveyed liquid, it does not need to have the same corrosion resistance as a conventional steel pipe. However, the innermost carcass layer of the hose must be in contact with the conveyed liquid and must be corrosion-resistant.

- 5.

- High pressure resistance. Unbonded flexible hose can have both internal and external pressure due to the specific configuration of the carcass layer, anti-pressure armor layer, and tensile armor layer.

- 6.

- Long production cycle life and low maintenance. Conventional steel pipe requires a large number of welded connections, while a sperate unbonded flexible riser is very long with fewer connecting joints in the whole riser, which is not needed for maintenance and repair of welds after being put into production and would not affect the production operation under adverse sea conditions. Additionally, the unbonded flexible riser would meet the requirements of continuous production, which has a longer fatigue life than that of steel pipe.

- 7.

- Recyclable. An unbonded flexible riser is easy to recycle and reuse, thus increasing the deep-sea oil field investment overall and is conductive to the environment.

2.3. Configuration Characteristics

3. Development of Cross-Sectional Properties of an Unbonded Flexible Riser

3.1. Development of Unbonded Flexible Riser under Axisymmetric Loads

3.1.1. Theoretical Method

3.1.2. Numerical Method

3.1.3. Test Method

3.2. Development of an Unbonded Flexible Riser under a Bending Moment

3.2.1. Theoretical Method

3.2.2. Numerical Method

3.2.3. Test Method

3.3. Development of the Study of Typical Failure Characteristics of Unbonded Flexible Risers

3.3.1. Collapse Failure of the Carcass Layer and Pressure Armor Layer

3.3.2. Burst Failure of the Pressure Armor Layer

3.3.3. Failure of the Tensile Armor Layer

3.4. Development of Machine Learning Methods on Unbonded Flexible Risers

4. New Types of Unbonded Flexible Risers and Research Hotspots

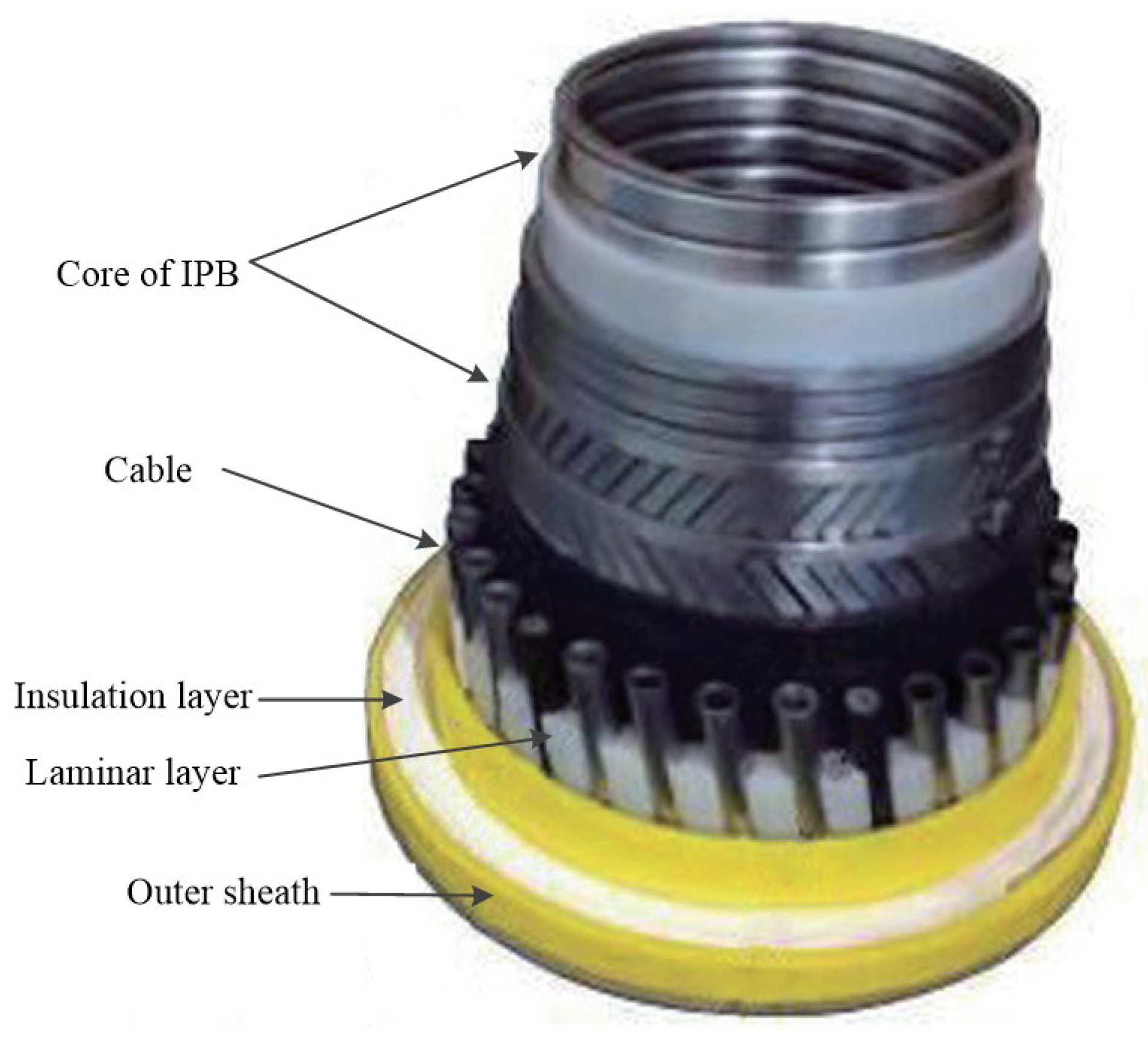

4.1. Integrated Production Bundle, IPB

4.2. An Unbonded Flexible Riser with an Anti-H2S Layer

4.3. Unbonded Flexible Risers with Composite Armor Layers

5. Research Prospect

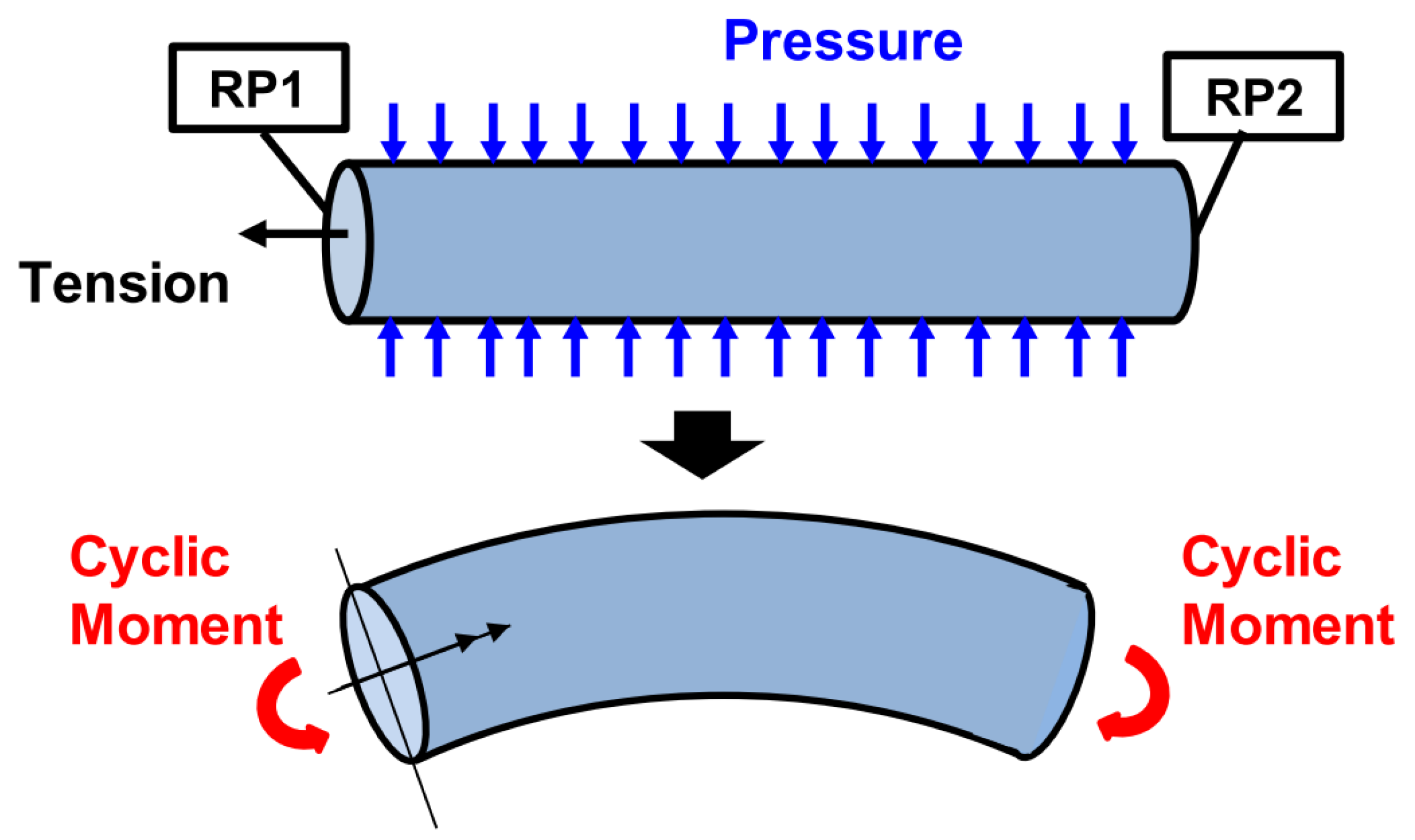

- Experimental research on the cross-sectional mechanical properties of unbonded flexible risers with composite tensile armor layers: Carrying out model tests of unbonded flexible risers with composite tensile armor layers is of great significance for understanding the structural characteristics of composite tensile armor layers and carrying out the design of unbonded flexible risers. In addition, the influence of axisymmetric loads, such as internal and external pressures, on the bending hysteresis effect of unbonded flexible risers is inconclusive; thus, carrying out research on the bending characteristics of unbonded flexible risers with the action of internal and external pressure loads can lead to a better understanding and mastery of the hysteresis characteristics of unbonded flexible risers.

- Failure characteristics of composite tensile armor layers: The failure characteristics of composites and isotropic materials are different. Due to their special structural form, the destructive stress in the axial and radial directions of composites differ greatly. While focusing on the axial tensile destruction of the tensile armor layer of the composite material, it is also necessary to be alert to their destruction under the action of internal and external pressure loads. At the same time, the tensile armor layer might undergo complex radial and lateral failure under axial compression. The replacement of the original steel tensile armor layer with a composite tensile armor layer might also have a certain impact on the failure characteristics. It is recommended that the failure characteristics of composite tensile armor layers under axial force and internal and external pressure loads should be studied by experimental methods and simulated by reasonable numerical methods.

- Theoretical modeling of radial and lateral failure of tensile armor layers: The failure mode of the tensile armor layer structure under axial compression is relatively complex. The current theoretical model is based on the straight and curved beam theory to solve the equilibrium equation of the helical tendon under axial compression. The present theoretical method has made many assumptions, and the relative deviation from the test and numerical calculation results is relatively large. It is suggested to consider the failure path of the helical tendon reasonably under axial compression, thus predicting the ultimate bearing capacity of the tensile armor layer under axial compression more accurately.

- Dynamic response of unbonded flexible risers: Due to the nonlinear bending characteristics of unbonded flexible risers, their dynamic response analysis is very complex and is mostly calculated using Orcaflex commercial software, version 11.4 (OrcaFlex—dynamic analysis software for offshore marine systems (orcina.com)). However, the treatment of unbonded flexible risers using Orcaflex software (version 11.4) is relatively simple and cannot take into account the elongation conditions of risers, which might have a great impact on the results of the dynamic calculations under high tension. It is proposed to carry out the dynamic response study of unbonded flexible risers based on the slender theory, establishing the force balance equation of unbonded flexible risers and the control equation considering the elongation condition. Meanwhile, the bending nonlinearity is taken into account, and the bending stiffness matrix of the unbonded flexible riser element is updated in real-time to carry out the analysis of the overall dynamic response characteristics of unbonded flexible risers in the marine environment.

- Effect of temperature on the mechanical properties of unbonded flexible riser sections: The material properties of the layer structure in unbonded flexible risers, especially the polymer structure, are strongly influenced by temperature, and the effect of temperature on the material should be taken into account to affect the cross-section mechanical properties of unbonded flexible risers.

- Application of artificial intelligence and machine learning: The rise of artificial intelligence (AI) and machine learning (ML) opens up a range of new avenues for solving engineering problems, with rising applications in the field of offshore industry. AI and ML would aid in the structural design of future unbonded flexible risers.

6. Conclusions

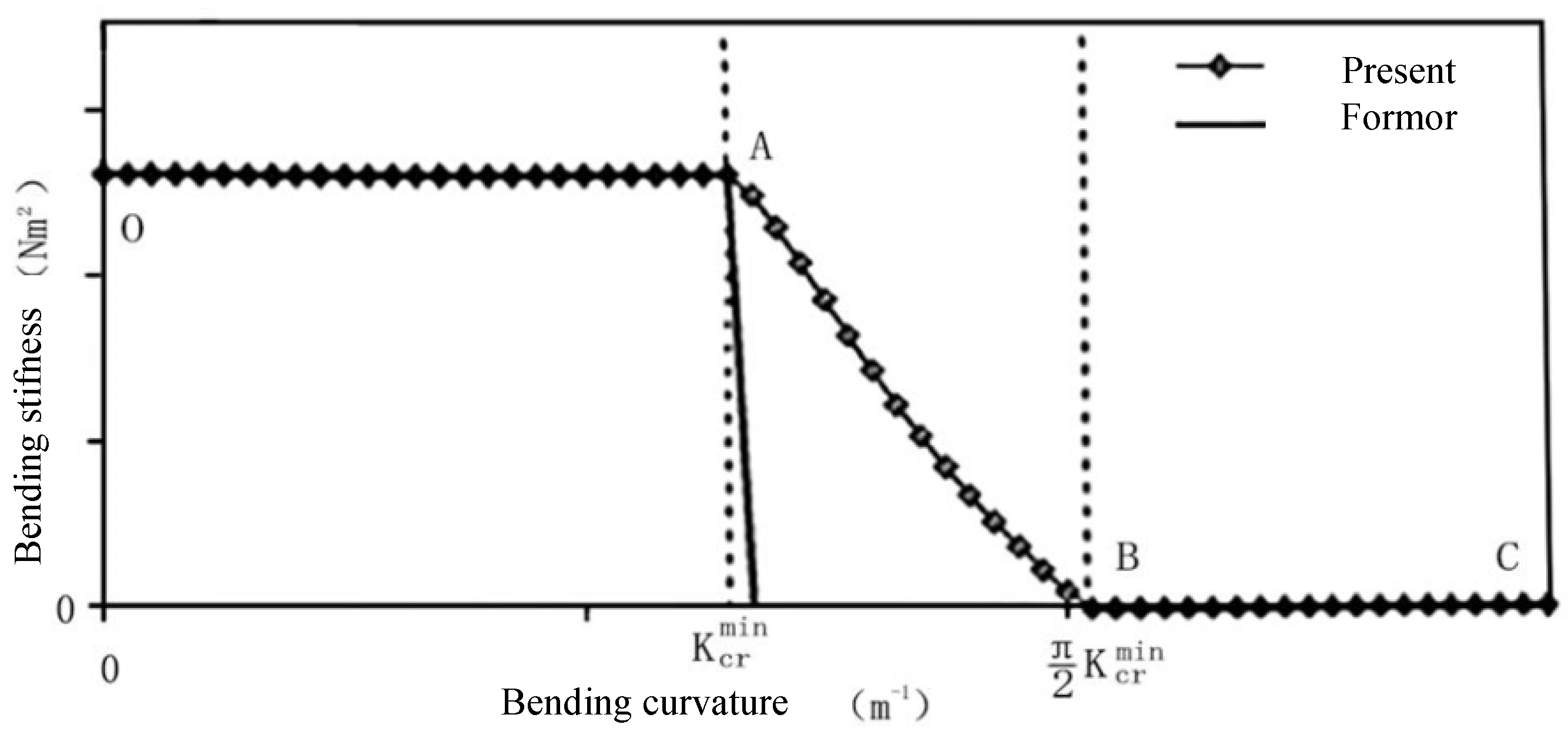

- The theoretical models of unbonded flexible risers are all established based on a large number of strict assumptions. Considering the geometric relationship and based on the functional principle, the load–strain relationship of unbonded flexible risers under axisymmetric loading is basically linear. The theoretical model of unbonded flexible risers under the bending moment is more complicated compared to that under axisymmetric load; the helical tendons of the tensile armor layers are free to slide after overcoming interlayer friction, resulting in a decrease in bending stiffness.

- The establishment of a three-dimensional numerical model of an unbonded flexible riser under axisymmetric loading has roughly gone through development, simplifying part of the layer structure and taking into account the detailed geometrical properties of each layer. Additionally, due to the existence of a large number of geometrical nonlinearities and contact nonlinearities within the numerical model, it is generally solved by explicit algorithms. Applying axisymmetric loads to the numerical model of the unbonded flexible riser is required before applying the bending moment to determine the initial prestressing effect between adjacent layers.

- The introduction of composite materials into the manufacturing of unbonded flexible risers is the current development trend of marine unbonded flexible risers. The mechanical properties of unbonded flexible risers containing composites are extremely complex, although some riser manufacturers have given verification tests of unbonded flexible risers containing composite tensile armor layers. However, the relevant research on the mechanical properties of the cross-section of the composite tensile armor layer is still lacking, and carrying out the relevant research is conducive to the breakthrough of the key technologies for the development of marine oil and gas resources.

- Unbonded flexible risers technology is poised to become even more integral to the marine industry. As deepwater exploration continues to expand, the demand for high-performance, unbonded flexible risers will grow. The long-term vision includes the development of unbonded flexible risers that are not only more robust and reliable but also adaptable to various marine environments and operational demands.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kagoura, T.; Ishii, K.I.; Abe, S.; Inoue, T.; Yamada, T. Development of a flexible pipe for pipe-in-pipe technology. Furukawa Rev. 2003, 24, 69–75. [Google Scholar]

- Ji, Y. Flexible Riser Static Configuration Analysis and Bend Stiffener Design. Master’s Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- Bahtui, A.; Alfano, G.; Bahai, H.; Hosseini-Kordkheili, S.A. On the multi-scale computation of un-bonded flexible risers. Eng. Struct. 2010, 32, 2287–2299. [Google Scholar] [CrossRef]

- Yang, H.; Jiang, H.; Yang, Q. Enhanced multi-layer fatigue-analysis approach for unbonded flexible risers. China Ocean Eng. 2014, 28, 363–379. [Google Scholar] [CrossRef]

- Zhang, X.; Chang, Z. Advance of research of unbonded flexible risers. Appl. Mech. Mater. 2014, 470, 1015–1019. [Google Scholar] [CrossRef]

- Ren, S. Study on Cross-Sectional Mechanical Properties and Typical Failure Characteristics of Unbonded Flexible Risers. Ph.D. Thesis, Shanghai Jiaotong University, Shanghai, China, 2016. [Google Scholar]

- Dong, L. Theoretical Prediction of Cross-Sectional Properties and Fatigue Analysis in the BSR Area for Unbonded Flexible Risers. Ph.D. Thesis, Dalian University of Technology, Dalian, China, 2013. [Google Scholar]

- DNV-OSS-302; Offshore Riser Systems. DNV: Hovik, Norway, 2010.

- American Petroleum Institute. API Recommended Practice 17B, Recommended Practice for Flexible Pipe; API Publishing Services: Washington, DC, USA, 2002. [Google Scholar]

- American Petroleum Institute. API Specification 17J, Specification for Unbonded Flexible Pipe; API Publishing Services: Washington, DC, USA, 2001. [Google Scholar]

- Zhang, H.; Tong, L.; Addo, M.A.; Liang, J.; Wang, L. Research on contact algorithm of unbonded flexible riser under axisymmetric load. Int. J. Press. Vessel. Pip. 2020, 188, 104248. [Google Scholar] [CrossRef]

- Malta, E.R.; Shiri, H.; Martins, C.D. Finite element analysis of flexible pipes under compression. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-23192. [Google Scholar]

- Yu, R.; Yuan, P. Structure and research focus of marine unbonded flexible pipes. Oil Gas Storage Transp. 2016, 35, 1255–1260. [Google Scholar]

- Witz, J. A case study in the cross-section analysis of flexible risers. Mar. Struct. 1996, 9, 885–904. [Google Scholar] [CrossRef]

- Paumier, L.; Averbuch, D.; Felix-Henry, A. Flexible pipe curved collapse resistance calculation. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. Paper No. OMAE2009-79117. [Google Scholar]

- Leroy, J.M.; Estrier, P. Calculation of stresses and slips in helical layers of dynamically bent flexible pipes. Oil Gas Sci. Technol. 2001, 56, 545–554. [Google Scholar] [CrossRef]

- Guo, Y.; Chen, X.; Wang, D.; Fu, S. Analytical and numerical investigation on the structural response of flexible risers under axisymmetric load. Shiyou Xuebao/Acta Pet. Sin. 2015, 36, 504–510+515. [Google Scholar]

- Laycock, M.A.; Latto, J. Flexible Pipe Body and Method of Producting Same. EU Patent EP3060836B2, 25 August 2021. [Google Scholar]

- Glejbøl, K.; Østergaard, R.C. Flexible Pipe and a Method of Producing a Flexible Pipe. U.S. Patent 13/515,362, 1 November 2012. [Google Scholar]

- Rytter, J.; Rytter, N.J.; Nielsen, R.; Glejbøl, K. A novel compression armor concept for unbonded flexible pipes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2002. Paper No. OTC-14059-MS. [Google Scholar]

- Ji, G.; Leira, B.J.; Sævik, S.; Klæbo, F.; Axelsson, G.; Fergestad, D. Integrity assessment of damaged flexible pipe cross-sections. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-24155. [Google Scholar]

- Liu, Q.; Xue, H.; Tang, W. Failure characteristic analysis of tensile armour layer of unbonded flexible riser under axial compression. Ships Offshore Struct. 2019, 14, 187–198. [Google Scholar] [CrossRef]

- Epsztein, T.; Demanze, F.; Lefebvre, X.; Jarrin, J. New anti H2S layer for flexible pipes. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 2–5 May 2011. Paper No. OTC 21371. [Google Scholar]

- Liu, Q.; Xue, H.; Tang, W.; Yuan, Y. Theoretical and numerical methods to predict the behavior of unbonded flexible riser with composite armor layers subjected to axial tension. Ocean Eng. 2020, 199, 107038. [Google Scholar] [CrossRef]

- Liu, Q.; Xue, H.; Tang, W. Behavior of unbonded flexible riser with composite armor layers under coupling loads. Ocean Eng. 2021, 239, 109907. [Google Scholar] [CrossRef]

- Lambert, A.; Do, A.-T.; Felix-Henry, A.; Grosjean, F. Qualification of unbonded dynamic riser with carbon fiber composite armours. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012; Volume 44908, pp. 117–125. [Google Scholar]

- Kalman, M.D.; Yu, L.; Seymour, M.; Erni, J. Qualification of composite armor materials for unbonded flexible pipe. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 30 April–3 May 2012. Paper No. OTC-23185-MS. [Google Scholar]

- Rytter, J. Qualification approach to unbonded flexible pipes with fibre reinforced armour layer. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–25 June 2004; Volume 37440, pp. 757–765. [Google Scholar]

- Vaz, M.; Rizzo, N. A finite element model for flexible pipe armor wire instability. Mar. Struct. 2011, 24, 275–291. [Google Scholar] [CrossRef]

- Tan, Z.; Loper, C.; Hou, Y.; Sheldrake, T. Application of flexible risers in shallow water: Weight added wave configuration. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. Paper No. OMAE2009-79476. [Google Scholar]

- DNV-OS-F101; Submarine Pipeline Systems. DNV: Hovik, Norway, 2007.

- American Petroleum Institute. Design, Construction, Operation, and Maintenance of Offshore Hydrocarbon Pipelines (Limit State Design); American Petroleum Institute: Washington, DC, USA, 1999. [Google Scholar]

- British Standards Institution. Code of Practice for Pipelines. Design and Construction of Steel Pipelines in Land; British Standards Institution: London, UK, 2010. [Google Scholar]

- ASME B31 Committee. Gas Transmission and Distribution Piping Systems: ASME Code for Pressure Piping, B31; American Society of Mechanical Engineers: New York, NY, USA, 1999. [Google Scholar]

- American Bureau of Shipping. Guide for Building and Classing Subsea Pipeline Systems; ABS: Houston, TX, USA, 2004. [Google Scholar]

- Berge, S.; Engseth, A.; Fylling, I.; Fylling, I.; Larsen, C.M.; Leira, B.J.; Nygaard, I.; Olufsen, A. Handbook on Design and Operation of Flexible Pipes; STF70 A92006; SINTEF: Trondheim, Norway, 1992. [Google Scholar]

- DNV-OS-F201; Dynamic Risers—Offshore Standard. Det Norske Veritas: Hovik, Norway, 2010.

- Sødahl, N.; Skeie, G.; Steinkjer, O.; Kalleklev, A.J. Efficient fatigue analysis of helix elements in umbilicals and flexible risers. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. Paper No. OMAE2010-21012. [Google Scholar]

- Fang, J.; Lyons, G.J. Structural damping behaviour of unbonded flexible risers. Mar. Struct. 1992, 5, 165–192. [Google Scholar] [CrossRef]

- Tan, Z.; Quiggin, P.; Sheldrake, T. Time domain simulation of the 3D bending hysteresis behavior of an unbonded flexible riser. J. Offshore Mech. Arct. Eng. 2009, 131, 031301. [Google Scholar] [CrossRef]

- Out, J.; Von Morgen, B. Slippage of helical reinforcing on a bent cylinder. Eng. Struct. 1997, 19, 507–515. [Google Scholar] [CrossRef]

- Li, Z.; Xu, H.; Zhang, G. Calculation methods of the local structure behavior of unbonded flexible pipes. Adv. Mater. Res. 2013, 658, 481–486. [Google Scholar] [CrossRef]

- Edmans, B.; Pham, D.C.; Zhang, Z.; Guo, T.; Narayanaswamy, S.; Stewart, G. Multiscale finite element analysis of unbonded flexible risers. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-24454. [Google Scholar]

- Bahtui, A. Development of a Constitutive Model to Simulate Unbonded Flexible Riser Pipe Elements. Ph.D. Thesis, Department of Mechanical Engineering, Brunel University, London, UK, 2008. [Google Scholar]

- Han, L. Flexible Pipe Stress and Fatigue Analysis. Master’s Thesis, Norwegian University of Science and Technology, Trondheim, Norway, 2012. [Google Scholar]

- Skeie, G.; Sødahl, N.; Steinkjer, O. Efficient fatigue analysis of helix elements in umbilicals and flexible risers: Theory and applications. J. Appl. Math. 2012, 2012, 246812. [Google Scholar] [CrossRef]

- Ramos, R., Jr.; Pesce, C.; Martins, C. A comparative analysis between analytical and FE-Based models for flexible pipes subjected to axisymmetric loads. In Proceedings of the International Offshore and Polar Engineering Conference, Seattle, WA, USA, 27 May–3 June 2000; pp. 80–88. [Google Scholar]

- Pesce, C.P.; Ramos, R., Jr.; da Silveira, L.M.Y.; Tanaka, R.L.; Martins, C.V.D.A.; Takafuji, F.C.M.; Novaes, J.O.P.Z.L.; Godinho, C.A.F. Structural behavior of umbilicals—Part I: Mathematical modeling. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. Paper No. OMAE2010-20892. [Google Scholar]

- Ramos, R., Jr.; Kawano, A. Local structural analysis of flexible pipes subjected to traction, torsion and pressure loads. Mar. Struct. 2015, 42, 95–114. [Google Scholar] [CrossRef]

- Alfano, G.; Bahtui, A.; Bahai, H. Numerical derivation of constitutive models for unbonded flexible risers. Int. J. Mech. Sci. 2009, 51, 295–304. [Google Scholar] [CrossRef]

- Edmans, B.; Alfano, G.; Bahai, H.; Andronicou, L.; Bahtui, A. Local stress assessment of flexible unbonded pipes using FEA. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012. Paper No. OMAE2012-84248. [Google Scholar]

- Bahtui, A.; Bahai, H.; Alfano, G. Numerical and analytical modeling of unbonded flexible risers. J. Offshore Mech. Arct. Eng. 2009, 131, 021401. [Google Scholar] [CrossRef]

- Sævik, S.; Li, H. Shear interaction and transverse buckling of tensile armours in flexible pipes. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–15 June 2013. Paper No. OMAE2013-10130. [Google Scholar]

- Bournazel, C. Calculation of stresses and slip in structural layers of unbonded flexible pipes. J. Offshore Mech. Arct. Eng. 1987, 109, 263–269. [Google Scholar]

- Goto, Y.; Okamoto, T.; Araki, M.; Fuku, T. Analytical study of the mechanical strength of flexible pipes. J. Offshore Mech. Arct. Eng. 1987, 109, 249–253. [Google Scholar] [CrossRef]

- McNamara, J.; Harte, A. Three-Dimensional analytical simulation of flexible pipe wall structure. J. Offshore Mech. Arct. Eng. 1992, 114, 69–75. [Google Scholar] [CrossRef]

- Harte, A.; McNamara, J. Modeling procedures for the stress analysis of flexible pipe cross sections. J. Offshore Mech. Arct. Eng. 1993, 115, 46–51. [Google Scholar] [CrossRef]

- Witz, J.; Tan, Z. On the axial-torsional structural behaviour of flexible pipes, umbilicals and marine cables. Mar. Struct. 1992, 5, 205–227. [Google Scholar] [CrossRef]

- Claydon, P.; Cook, G.; Brown, P.; Chandwani, R. A theoretical approach to prediction of service life of unbonded flexible pipes under dynamic loading conditions. Mar. Struct. 1992, 5, 399–429. [Google Scholar] [CrossRef]

- Kebadze, E. Theoretical Modelling of Unbonded Flexible Pipe Cross-Sections. Ph.D. Thesis, South Bank University, London, UK, 2000. [Google Scholar]

- Kraincani, I.; Kebadze, E. Slip initiation and progression in helical armouring layers of unbonded flexible pipes and its effect on pipe bending behaviour. J. Strain Anal. Eng. Des. 2001, 36, 265–275. [Google Scholar] [CrossRef]

- Dong, L.; Qu, Z.; Zhang, Q.; Huang, Y.; Liu, G. A general model to predict torsion and curvature increments of tensile armors in unbonded flexible pipes. Mar. Struct. 2019, 67, 102632. [Google Scholar] [CrossRef]

- Ramos, R., Jr.; Pesce, C.P. A consistent analytical model to predict the structural behavior of flexible risers subjected to combined loads. J. Offshore Mech. Arct. Eng. 2004, 126, 141–146. [Google Scholar] [CrossRef]

- Ramos, R., Jr.; Martins, C.A.; Pesce, C.P.; Roveri, F.E. Some further studies on the axial–torsional behavior of flexible risers. J. Offshore Mech. Arct. Eng. 2014, 136, 011701. [Google Scholar] [CrossRef]

- Custódio, A.; Vaz, M. A nonlinear formulation for the axisymmetric response of umbilical cables and flexible pipes. Appl. Ocean Res. 2002, 24, 21–29. [Google Scholar] [CrossRef]

- Sævik, S. On Stresses and Fatigue in Flexible Pipes. Ph.D. Thesis, Norges Tekniske Høgskole Trondheim, Trondheim, Norway, 1992. [Google Scholar]

- Li, Z.; Xu, H.; Zhang, G. Analysis of structural parameters for unbonded flexible pipes. Adv. Mater. Res. 2013, 652–654, 1514–1519. [Google Scholar] [CrossRef]

- Knapp, R.H. Derivation of a new stiffness matrix for helically armoured cables considering tension and torsion. Int. J. Numer. 1979, 14, 515–529. [Google Scholar] [CrossRef]

- Sævik, S.; Bruaseth, S. Theoretical and experimental studies of the axisymmetric behaviour of complex umbilical cross-sections. Appl. Ocean Res. 2005, 27, 97–106. [Google Scholar] [CrossRef]

- Liu, J.; Vaz, M.A. Viscoelastic axisymmetric structural analysis of flexible pipes in frequency domain considering temperature effect. Mar. Struct. 2016, 50, 111–126. [Google Scholar] [CrossRef]

- Liu, J.; Vaz, M.A. Axisymmetric viscoelastic response of flexible pipes in time domain. Appl. Ocean Res. 2016, 55, 181–189. [Google Scholar] [CrossRef]

- De Sousa, J.R.M.; Lima, E.; Ellwanger, G.; Papaleo, A. Local mechanical behaviour of flexible pipes subjected to installation loads. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rio de Janeiro, Brazil, 30 January 2001. Paper No. OMAE2001/PIPE-4102. [Google Scholar]

- Ribeiro, E.J.; de Sousa, J.R.; Ellwanger, G.; Lima, E. On the tension-compression behaviour of flexible risers. In Proceedings of the International Offshore and Polar Engineering Conference, Honolulu, HI, USA, 25–30 May 2003; pp. 105–112. [Google Scholar]

- de Sousa, J.R.; Magluta, C.; Roitman, N.; Ellwanger, G.B.; Lima, E.C.; Papaleo, A. On the response of flexible risers to loads imposed by hydraulic collars. Appl. Ocean Res. 2009, 31, 157–170. [Google Scholar] [CrossRef]

- de Sousa, J.R.M.; Magluta, C.; Roitman, N.; Londoño, T.V.; Campello, G.C. A study on the response of a flexible pipe to combined axisymmetric loads. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013. Paper No. OMAE2013-11384. [Google Scholar]

- De Sousa, J.R.M.; Magluta, C.; Roitman, N.; Campello, G.C. On the axisymmetric response of a damaged flexible pipe. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-23984. [Google Scholar]

- De Sousa, J.R.M.; Campello, G.C.; Kwietniewski, C.E.F.; Ellwanger, G.B.; Strohaecker, T.R. Structural response of a flexible pipe with damaged tensile armor wires under pure tension. Mar. Struct. 2014, 39, 1–38. [Google Scholar] [CrossRef]

- De Sousa, J.R.M.; Pinho, A.N.; Ellwanger, G.B.; Lima, E.C. Numerical analysis of a flexible pipe with damaged tensile armor wires. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Honolulu, HI, USA, 31 May–5 June 2009. Paper No. OMAE2009-80014. [Google Scholar]

- Merino, H.C.E.; de Sousa, J.R.M.; Magluta, C.; Roitman, N. Numerical and experimental study of a flexible pipe under torsion. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. Paper No. OMAE2010-20902. [Google Scholar]

- De Sousa, J.R.M. Numerical Analysis of Flexible Pipes through the Finite Element Method. Master’s Thesis, COPPE/Universidade Federal do Rio de Janeiro, Rio de Janeiro, Brazil, 1999. [Google Scholar]

- Cruz, F. Structural Analysis of Flexible Pipes through the Finite Element Method. Master’s Thesis, Escola Politécnica da Universidade de São Paulo, Sao Paulo, Brazil, 1996. [Google Scholar]

- Bahtui, A.; Bahai, H.; Alfano, G. A finite element analysis for unbonded flexible risers under axial tension. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008. Paper No. OMAE2008-57627. [Google Scholar]

- Bahtui, A.; Bahai, H.; Alfano, G. A finite element analysis for unbonded flexible risers under torsion. J. Offshore Mech. Arct. Eng. 2008, 130, 041301. [Google Scholar] [CrossRef]

- Perdrizet, T.; Leroy, J.; Barbin, N.; Le-Corre, V.; Charliac, D.; Estrier, P. Stresses in armour layers of flexible pipes: Comparison of Abaqus models. In Proceedings of the SIMULIA Customer Conference, Barcelona, Spain, 17–19 May 2011; pp. 1–14. [Google Scholar]

- Leroy, J.-M.; Perdrizet, T.E.; Le Corre, V.; Estrier, P. Stress assessment in armour layers of flexible risers. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. Paper No. OMAE2010-20932. [Google Scholar]

- Li, J.; Qiu, Z.; Ju, J. Numerical modeling and mechanical analysis of flexible risers. Math. Probl. 2014, 2015, 894161. [Google Scholar] [CrossRef]

- Liu, M.; Li, J.; Chen, L.; Ju, J. On the response and prediction of multi-layered flexible riser under combined load conditions. Eng. Comput. 2019, 36, 2507–2529. [Google Scholar] [CrossRef]

- Ren, S.; Tang, W.; Guo, J. Behavior of unbonded flexible risers subject to axial tension. China Ocean Eng. 2014, 28, 249–258. [Google Scholar] [CrossRef]

- Ren, S.; Xue, H.; Tang, W. Analytical and numerical models to predict the behavior of unbonded flexible risers under torsion. China Ocean Eng. 2016, 30, 243–256. [Google Scholar] [CrossRef]

- Ren, S.; Tang, W.; Kang, Z.; Geng, H. Numerical study on the axial-torsional response of an unbonded flexible riser with damaged tensile armor wires. Appl. Ocean Res. 2020, 97, 102045. [Google Scholar] [CrossRef]

- Yoo, D.; Jang, B.; Yim, K. Nonlinear finite element analysis of failure modes and ultimate strength of flexible pipes. Mar. Struct. 2017, 54, 50–72. [Google Scholar] [CrossRef]

- Yoo, D.; Jang, B.; Yim, K. A simplified multi-layered finite element model for flexible pipes. Mar. Struct. 2019, 63, 117–137. [Google Scholar] [CrossRef]

- Ramos, R., Jr.; de Arruda Martins, C.V.; Pesce, C.P.; Roveri, F.E. A case study on the axial-torsional behavior of flexible risers. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008. Paper No. OMAE2008-57514. [Google Scholar]

- Vargas-Londoño, T.; de Sousa, J.R.M.; Magluta, C.; Roitman, N. A theoretical and experimental analysis of the bending behavior of unbonded flexible pipes. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-24247. [Google Scholar]

- Zhou, C.; Ye, N.; Sævik, S. Effect of anti-wear tape on behavior of flexible risers. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-24261. [Google Scholar]

- de Sousa, J.R.M.; Viero, P.F.; Magluta, C.; Roitman, N. An experimental and numerical study on the axial compression response of flexible pipes. J. Offshore Mech. Arct. Eng. 2012, 134, 031703. [Google Scholar] [CrossRef]

- Yue, Q.; Lu, Q.; Yan, J.; Zheng, J.; Palmer, A. Tension behavior prediction of flexible pipelines in shallow water. Ocean Eng. 2013, 58, 201–207. [Google Scholar] [CrossRef]

- Sævik, S.; Gjøsteen, J.K. Strength analysis modelling of flexible umbilical members for marine structures. IMA J. Appl. Math. 2012, 2012, 985349. [Google Scholar] [CrossRef]

- Vaz, M.; Aguiar, L.; Estefen, S.; Brack, M. Experimental determination of axial, torsional and bending stiffness of umbilical cables. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Lisbon, Portugal, 5–6 June 1998. Paper No. 98-0423. [Google Scholar]

- Lanteigne, J. Theoretical estimation of the response of helically armored cables to tension, torsion, and bending. J. Appl. Mech. 1985, 52, 423–432. [Google Scholar] [CrossRef]

- Mciver, D.B. A method of modeling the detailed component and overall structural behavior of flexible pipe sections. Eng. Struct. 1995, 17, 254–266. [Google Scholar] [CrossRef]

- Ramos, R., Jr.; Pesce, C.P.; Martins, C.v.A. A new analytical expression to estimate the bending stiffness of flexible risers. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Cancun, Mexico, 8–13 June 2003. Paper No. OMAE2003-37320. [Google Scholar]

- Dong, L.; Huang, Y.; Zhang, Q.; Liu, G. An analytical model to predict the bending behavior of unbonded flexible pipes. J. Ship. Res. 2013, 57, 171–177. [Google Scholar] [CrossRef]

- Wang, K.; Ji, C. Helical wire stress analysis of unbonded flexible riser under irregular response. J. Mar. Sci. Appl. 2017, 16, 208–215. [Google Scholar] [CrossRef]

- Wang, K.; Ji, C.; Xue, H.; Tang, W. Fatigue damage study of helical wires in catenary unbonded flexible riser near touchdown point. J. Offshore Mech. Arct. Eng. 2017, 139, 051701. [Google Scholar] [CrossRef]

- Østergaard, N.H.; Lyckegaard, A.; Andreasen, J.H. A method for prediction of the equilibrium state of a long and slender wire on a frictionless toroid applied for analysis of flexible pipe structures. Eng. Struct. 2012, 34, 391–399. [Google Scholar] [CrossRef]

- Péronne, S.; Izarn, C.; Estrier, P.; Caro, O.; Leroy, J.M.; Charliac, D. Flexible pipe hysteretic bending behavior: Comparison with experimental characterization and finite element method. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, St. John’s, NL, Canada, 31 May–5 June 2015. Paper No. OMAE2015-41281. [Google Scholar]

- Zhang, J.; Tan, Z.; Sheldrake, T. Effective bending stiffness of an unbonded flexible riser. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008. Paper No. OMAE2008-57098. [Google Scholar]

- Witz, J.A.; Tan, Z. On the flexural structural behaviour of flexible pipes, umbilicals and marine cables. Mar. Struct. 1992, 5, 229–249. [Google Scholar] [CrossRef]

- Witz, J.A.; Tan, Z. Rotary bending of marine cables and umbilicals. Eng. Struct. 1995, 17, 267–275. [Google Scholar] [CrossRef]

- Wang, L.; Ye, N.; Yue, Q. A novel helix contact model for predicting hysteretic behavior of unbonded flexible pipes. Ocean Eng. 2022, 264, 112407. [Google Scholar] [CrossRef]

- Tang, M.; Li, S.; Zhang, H.; Bian, X.; Zhao, X. Monitoring the slip of helical wires in a flexible riser under combined tension and bending. Ocean Eng. 2022, 256, 111512. [Google Scholar] [CrossRef]

- Ma, W.; Su, L.; Wang, S.; Yang, Y.; Huang, W. Influence of structural parameters of unbonded flexible pipes on bending performance. Ocean Eng. 2022, 199, 107038. [Google Scholar] [CrossRef]

- Provasi, R.; Toni, F.G.; Martins, C.D.A. Friction coefficient influence in a flexible pipe: A macroelement model. Ocean Eng. 2022, 266, 113109. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, Q.; Huang, Y.; Liu, G. Slip and stress of tensile armors in unbonded flexible pipes close to end fitting considering an exponentially decaying curvature distribution. Ocean Eng. 2021, 225, 108766. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, S.; Ma, W.; Su, L.; Yang, Y. Study on the influence of bending curvature on the bending characteristics of unbonded flexible pipes. Ocean Eng. 2023, 281, 114730. [Google Scholar] [CrossRef]

- Dai, T.; Sævik, S.; Ye, N. An anisotropic friction model in non-bonded flexible risers. Mar. Struct. 2018, 59, 423–443. [Google Scholar] [CrossRef]

- Dai, T.; Sævik, S.; Ye, N. Friction models for evaluating dynamic stresses in non-bonded flexible risers. Mar. Struct. 2017, 55, 137–161. [Google Scholar] [CrossRef]

- Yun, R.; Jang, B.; Kim, J. Improvement of the bending behavior of a flexible riser: Part I—Nonlinear bending behavior considering the shear deformation of polymer layers. Appl. Ocean Res. 2020, 101, 102204. [Google Scholar] [CrossRef]

- Du Kim, J.; Jang, B.S.; Yun, R.H.; Jeong, H.S. Improvement of the bending behavior of a flexible riser: Part ii–hysteretic modeling of bending stiffness in global dynamic analysis. Appl. Ocean Res. 2020, 101, 102249. [Google Scholar] [CrossRef]

- Zhang, M.; Chen, X.; Fu, S.; Guo, Y.; Ma, L. Theoretical and numerical analysis of bending behavior of unbonded flexible risers. Mar. Struct. 2015, 44, 311–325. [Google Scholar] [CrossRef]

- Lu, H.; Vaz, M.A.; Caire, M. Alternative analytical and finite element models for unbonded flexible pipes under axisymmetric loads. Ocean Eng. 2021, 225, 108766. [Google Scholar] [CrossRef]

- Tang, L.; He, W.; Zhu, X.; Zhou, Y. Mechanical analysis of unbonded flexible pipe tensile armor under combined loads. Int. J. Press. Vessel. Pip. 2019, 171, 217–223. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Kenny, S.; Hussein, A. Finite element investigation on the tensile armor wire response of flexible pipe for axisymmetric loading conditions using an implicit solver. J. Offshore Mech. Arct. Eng. 2018, 140, 041402. [Google Scholar] [CrossRef]

- Rahmati, M.T.; Norouzi, S.; Bahai, H.; Alfano, G. Experimental and numerical study of structural behavior of a flexible riser model. Appl. Ocean Res. 2017, 67, 162–168. [Google Scholar] [CrossRef]

- Magluta, C.; Roitman, N.; Viero, P.F.; Rosa, L.F.L. Experimental estimation of physical properties of a flexible riser. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Rio de Janeiro, Brazil, 3–8 June 2001; pp. 255–264. [Google Scholar]

- Bech, A.; Skallerud, B. Structural Damping in flexible pipes: Comparisons between dynamic tests and numerical simulations. International Offshore and Polar Engineering Conference. In Proceedings of the International Society of Offshore and Polar Engineers, San Francisco, CA, USA, 14–19 June 1992. Paper No. ISOPE-I-92-125. [Google Scholar]

- Troina, L.M.B.; Rosa, L.F.L.; Viero, P.F.; Magluta, C.; Roitman, N. An experimental investigation on the bending behaviour of flexible pipes. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Cancun, Mexico, 8–13 June 2003. Paper No. OMAE2003-37200. [Google Scholar]

- Zhao, J.; Tan, Z.; Sheldrake, T. Deep water carcass development effects of carcass profile on collapse resistance. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Nantes, France, 9–14 June 2013. Paper No. OMAE2013-11321. [Google Scholar]

- Neto, A.G.; de Arruda Martins, C. A comparative wet collapse buckling study for the carcass layer of flexible pipes. J. Offshore Mech. Arct. Eng. 2012, 134, 031701. [Google Scholar] [CrossRef]

- Tang, M.G.; Yan, J.; Wang, Y. Collapse estimation of interlocked armour of flexible pipe with strain energy equivalence. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 June 2012. Paper No. OMAE2012-83705. [Google Scholar]

- Lu, J.; Ma, F.; Tan, Z.; Sheldrake, T. Bent collapse of an unbonded rough bore flexible pipe. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Estoril, Portugal, 15–20 June 2008. Paper No. OMAE2008-57063. [Google Scholar]

- Axelsson, G.; Skjerve, H. Flexible riser carcass collapse analyses-sensitivity on radial gaps and bending. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE 2014-23922. [Google Scholar]

- Cooke, N.; Kenny, S. Comparative study on the collapse response of flexible pipe using finite element methods. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-23306. [Google Scholar]

- Kristensen, C.E.; Muren, J.; Skeie, G.; Skjerve, H.; Sødahl, N. Carcass tear out load model for multi-layer pressure sheath risers. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE 2014-24129. [Google Scholar]

- Yuan, S. Ultimate Capacity Study for Unbonded Flexible Pipes under Pressures. Ph.D. Thesis, Zhejiang University, Hangzhou, China, 2017. [Google Scholar]

- Braga, M.P.; Kaleff, P. Flexible pipe sensitivity to birdcaging and armor wire lateral buckling. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–25 June 2004. Paper No. OMAE2004-51090. [Google Scholar]

- Bectarte, F.; Coutarel, A. Instability of tensile armour layers of flexible pipes under external pressure. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, Vancouver, BC, Canada, 20–25 June 2004. Paper No. OMAE2004-51352. [Google Scholar]

- Østergaard, N.H.; Lyckegaard, A.; Andreasen, J.H. On lateral buckling failure of armour wires in flexible pipes. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011. Paper No. OMAE2011-49358. [Google Scholar]

- Sævik, S.; Thorsen, M.J. An analytical treatment of buckling and instability of tensile armors in flexible pipes. J. Offshore Mech. Arct. Eng. 2017, 139, 041701. [Google Scholar] [CrossRef]

- Østergaard, N.H.; Lyckegaard, A.; Andreasen, J.H. On modelling of lateral buckling failure in flexible pipe tensile armour layers. Mar. Struct. 2012, 27, 64–81. [Google Scholar] [CrossRef]

- Østergaard, N.H.; Lyckegaard, A.; Andreasen, J.H. Imperfection analysis of flexible pipe armor wires in compression and bending. Appl. Ocean Res. 2012, 38, 40–47. [Google Scholar] [CrossRef]

- Sertã, O.; Connaire, A.; Tanaka, R.; Barbosa, T.; Godinho, C. Predictions of armour wire buckling for a flexible pipe under compression, bending and external pressure loading. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Rio de Janeiro, Brazil, 1–6 July 2012. Paper No. OMAE2012-83482. [Google Scholar]

- Caleyron, F.; Guiton, M.; Leroy, J.M.; Perdrizet, T.; Charliac, D.; Estrier, P.; Paumier, L. A multi-purpose finite element model for flexible risers studies. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, San Francisco, CA, USA, 8–13 June 2014. Paper No. OMAE2014-23250. [Google Scholar]

- Secher, P.; Bectarte, F.; Felix-Henry, A. Lateral buckling of armor wires in flexible pipes: Reaching 3000 m water depth. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Rotterdam, The Netherlands, 19–24 June 2011. Paper No. OMAE2011-49447. [Google Scholar]

- Zhang, Y.; Chen, B.; Qiu, L.; Hill, T.; Case, M. State of the art analytical tools improve optimization of unbonded flexible pipes for deepwater environments. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 5–8 May 2003. Paper No. OTC 15169. [Google Scholar]

- Tan, Z.; Loper, C.; Sheldrake, T.; Karabelas, G. Behavior of tensile wires in unbonded flexible pipe under compression and design optimization for prevention. In Proceedings of the International Conference on Offshore Mechanics and Arctic Engineering, 4–9 June 2006; Volume 47497, pp. 43–50. [Google Scholar]

- Li, X.; Vaz, M.A.; Custódio, A.B. High strength tape layer modeling for analysis of flexible pipe axisymmetric behavior and birdcaging limit. Ocean Eng. 2021, 234, 109273. [Google Scholar] [CrossRef]

- Gonzalez, G.M.; Sousa, J.R.M.; Sagrilo, L.V.S. A modal finite element approach to predict the lateral buckling failure of the tensile armors in flexible pipes. Mar. Struct. 2019, 67, 102628. [Google Scholar] [CrossRef]

- Hu, H.; Yan, J.; Sævik, S.; Ye, N.; Lu, Q.; Bu, Y. Nonlinear bending behavior of a multilayer copper conductor in a dynamic power cable. Ocean Eng. 2022, 250, 110831. [Google Scholar] [CrossRef]

- Tang, L.; He, W.; Zhu, X. Parameter sensitivity analysis on the buckling failure modes of tensile armor layers of flexible pipe. Eng. Fail. Anal. 2019, 104, 784–795. [Google Scholar] [CrossRef]

- Yang, Z.; Yan, J.; Zhang, L.; Shi, D.; Lu, Q. Research on lateral buckling mechanism of tensile armor wires in unbonded flexible pipe. In Proceedings of the International Conference on Ocean, Offshore and Arctic Engineering, Online, 3–7 August 2020. Paper No. OMAE18204. [Google Scholar]

- Park, Y.I.; Kim, J.H. Artificial neural network-based prediction of ultimate buckling strength of liquid natural gas cargo containment system under sloshing loads considering onboard boundary conditions. Ocean Eng. 2022, 249, 110981. [Google Scholar] [CrossRef]

- Gao, X.; Zhai, L.; Xu, W. Prediction of vortex-induced vibration of flexible cylinder using BP neural network. J. Harbin Eng. Univ. 2020, 41, 1150–1155. [Google Scholar]

- Yuan, L.; Wang, C.; Luo, Q.; Chen, N. Collapse pressure prediction of mechanically lined pipes using FEM and machine learning techniques. Ocean Eng. 2023, 268, 113418. [Google Scholar] [CrossRef]

- Yan, J.; Li, W.; Du, H.; Zhang, H.; Huo, S.; Lu, Q. Data-driven prediction of critical collapse pressure of flexible pipeline carcass layer. Ocean Eng. 2022, 249, 110948. [Google Scholar] [CrossRef]

- Bai, Y.; Xu, W.; Cheng, P.; Wang, N.; Ruan, W. Behaviour of reinforced thermoplastic pipe (RTP) under combined external pressure and tension. Ships Offshore Struct. 2014, 9, 464–474. [Google Scholar] [CrossRef]

- Bai, Y.; Yuan, S.; Tang, J.; Qiao, H.; Cheng, P.; Cao, Y.; Wang, N. Behaviour of reinforced thermoplastic pipe under combined bending and external pressure. Ships Offshore Struct. 2015, 10, 575–586. [Google Scholar] [CrossRef]

| Cross-Sectional Area/mm2 | Thickness/mm | Scope of Application (Riser I.D. Size)/mm |

|---|---|---|

| 0.62 × 28 | 3.25 | 50.8~76.2 |

| 1.00 × 36 | 5.00 | 76.2~127.0 |

| 1.20 × 40 | 6.00 | 152.4~203.2 |

| 1.40 × 55 | 7.00 | 203.2~304.8 |

| 1.60 × 55 | 8.00 | 203.2~304.8 |

| 2.00 × 72 | 10.00 | 304.8~421.6 |

| Cross-Sectional Area/mm2 | Scope of Application (Riser I.D. Size)/mm |

|---|---|

| 50.8~76.2 | |

| 76.2~127.0 | |

| 152.4~203.2 | |

| 203.2~304.8 | |

| 203.2~304.8 |

| Material | Tensile Strength/MPa | Elongation/% | Young’s Modulus/GPa | Densities/g·cm−3 |

|---|---|---|---|---|

| High strength steel | 3.25 | 5 | 210 | 7.8 |

| Corrosion-resistant steel | 5.00 | 10 | 210 | 7.8 |

| Composite | 10.00 | 1.8 | 160 | 1.7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Q.; Qu, Z.; Chen, F.; Liu, X.; Wang, G. Review of the Development of an Unbonded Flexible Riser: New Material, Types of Layers, and Cross-Sectional Mechanical Properties. Materials 2024, 17, 2560. https://doi.org/10.3390/ma17112560

Liu Q, Qu Z, Chen F, Liu X, Wang G. Review of the Development of an Unbonded Flexible Riser: New Material, Types of Layers, and Cross-Sectional Mechanical Properties. Materials. 2024; 17(11):2560. https://doi.org/10.3390/ma17112560

Chicago/Turabian StyleLiu, Qingsheng, Zhongyuan Qu, Feng Chen, Xiaoya Liu, and Gang Wang. 2024. "Review of the Development of an Unbonded Flexible Riser: New Material, Types of Layers, and Cross-Sectional Mechanical Properties" Materials 17, no. 11: 2560. https://doi.org/10.3390/ma17112560

APA StyleLiu, Q., Qu, Z., Chen, F., Liu, X., & Wang, G. (2024). Review of the Development of an Unbonded Flexible Riser: New Material, Types of Layers, and Cross-Sectional Mechanical Properties. Materials, 17(11), 2560. https://doi.org/10.3390/ma17112560