Fe(Se,Te) Thin Films Deposited through Pulsed Laser Ablation from Spark Plasma Sintered Targets

Abstract

:1. Introduction

2. Materials and Methods

3. Results

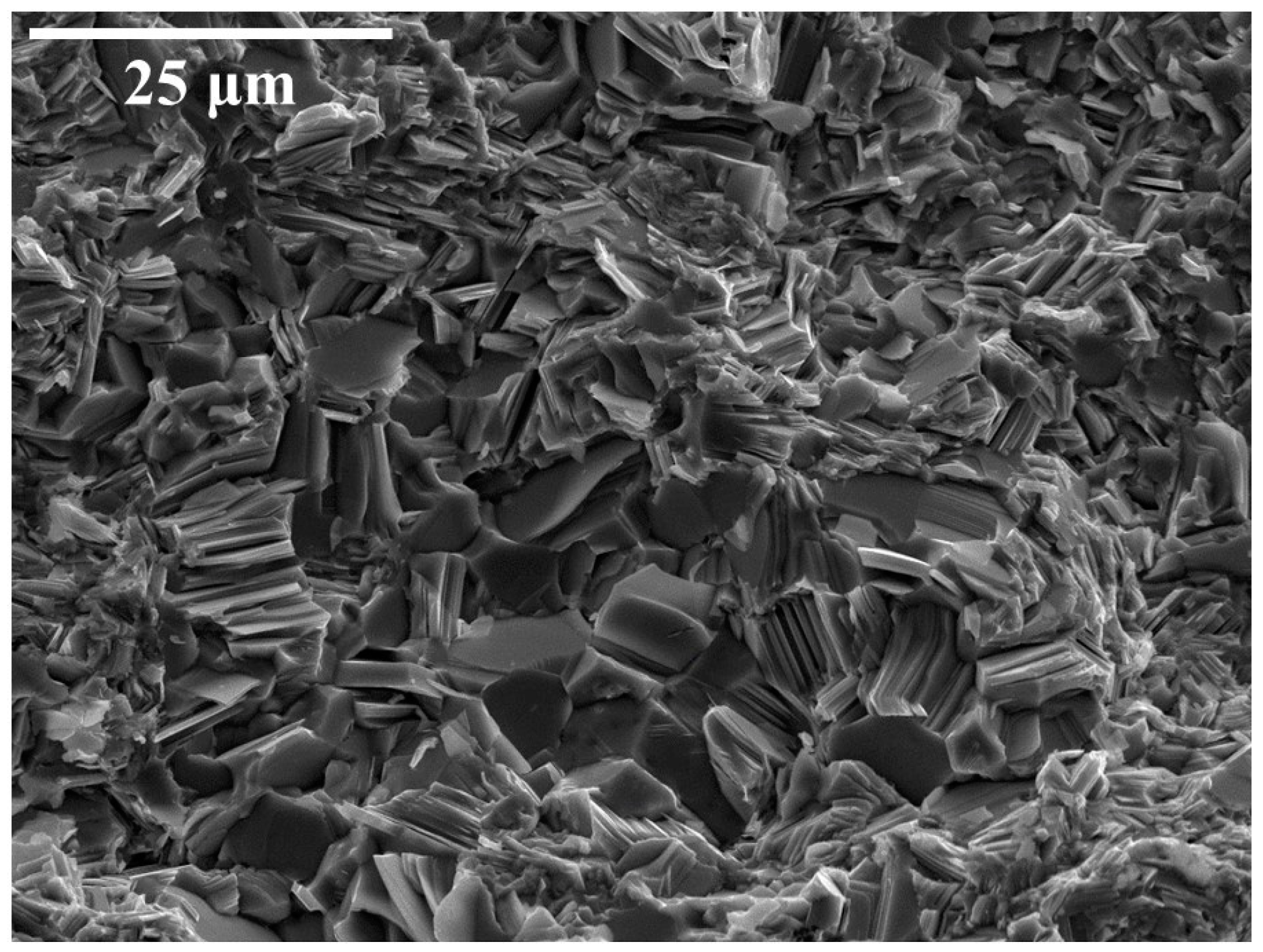

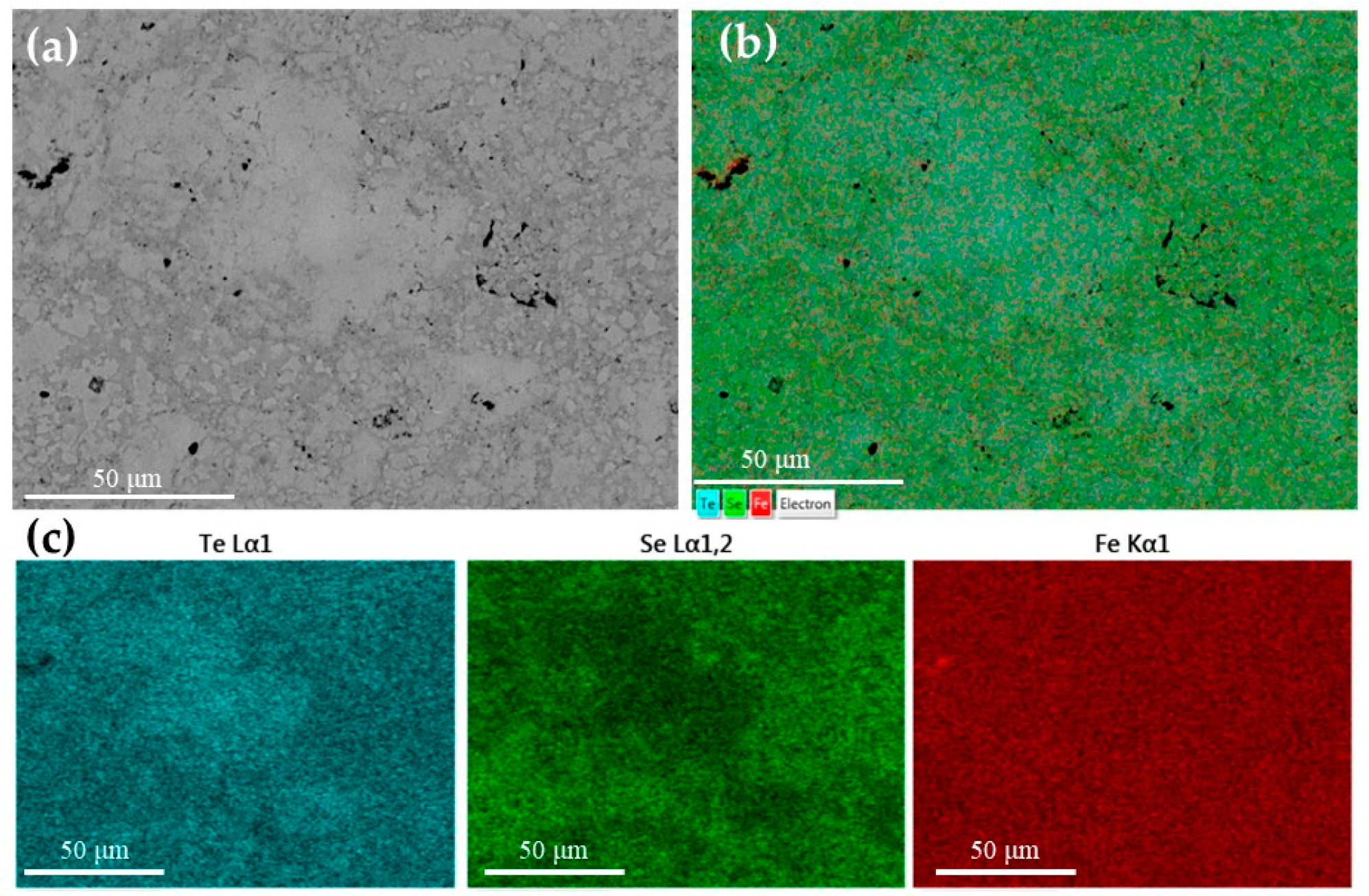

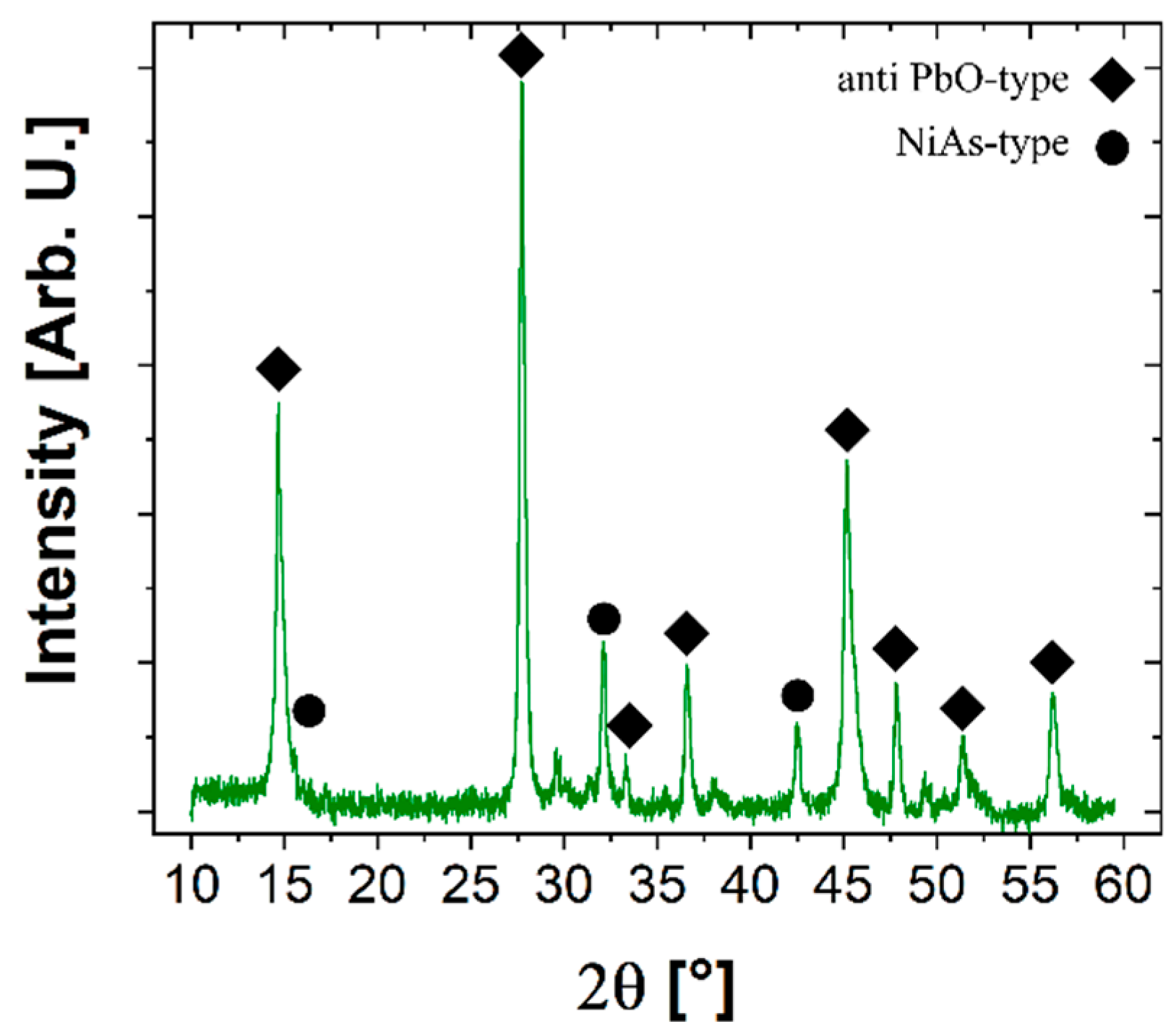

3.1. Pellet

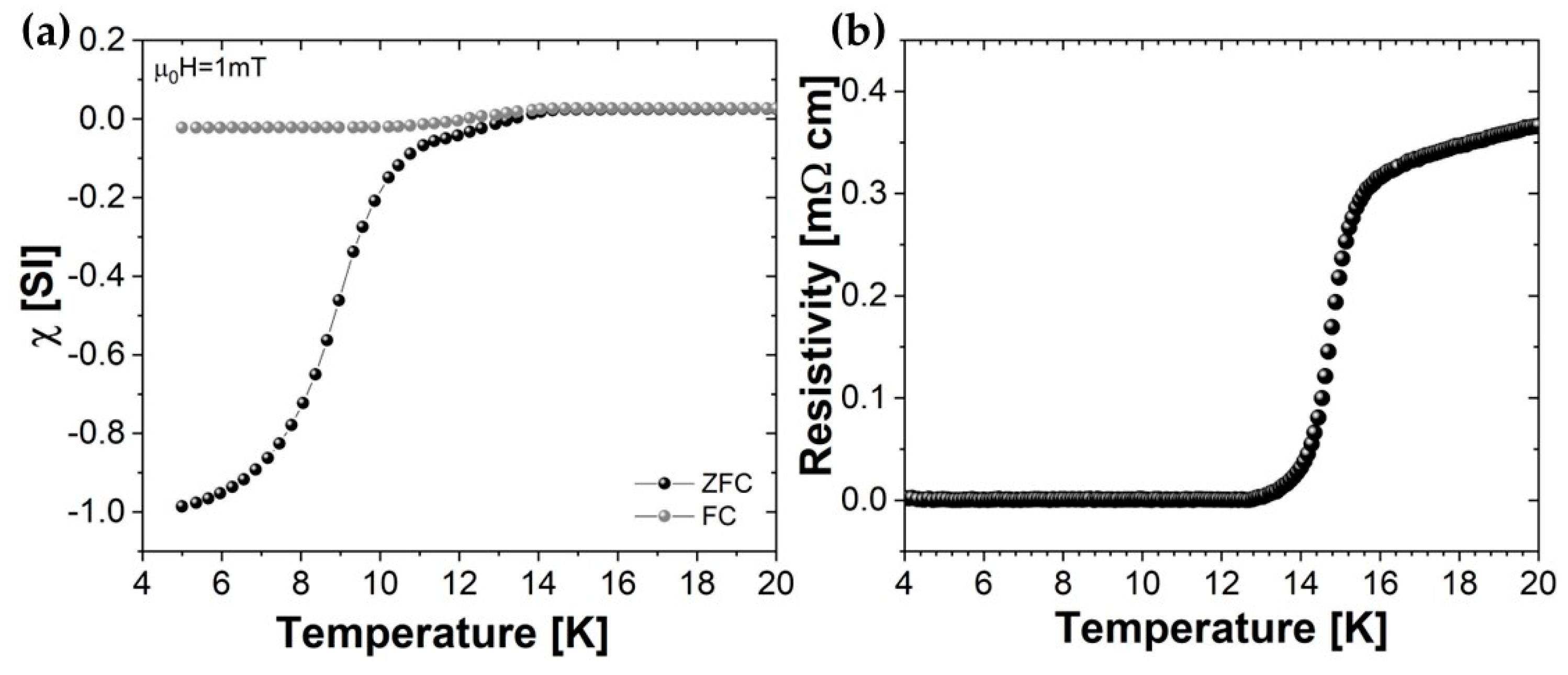

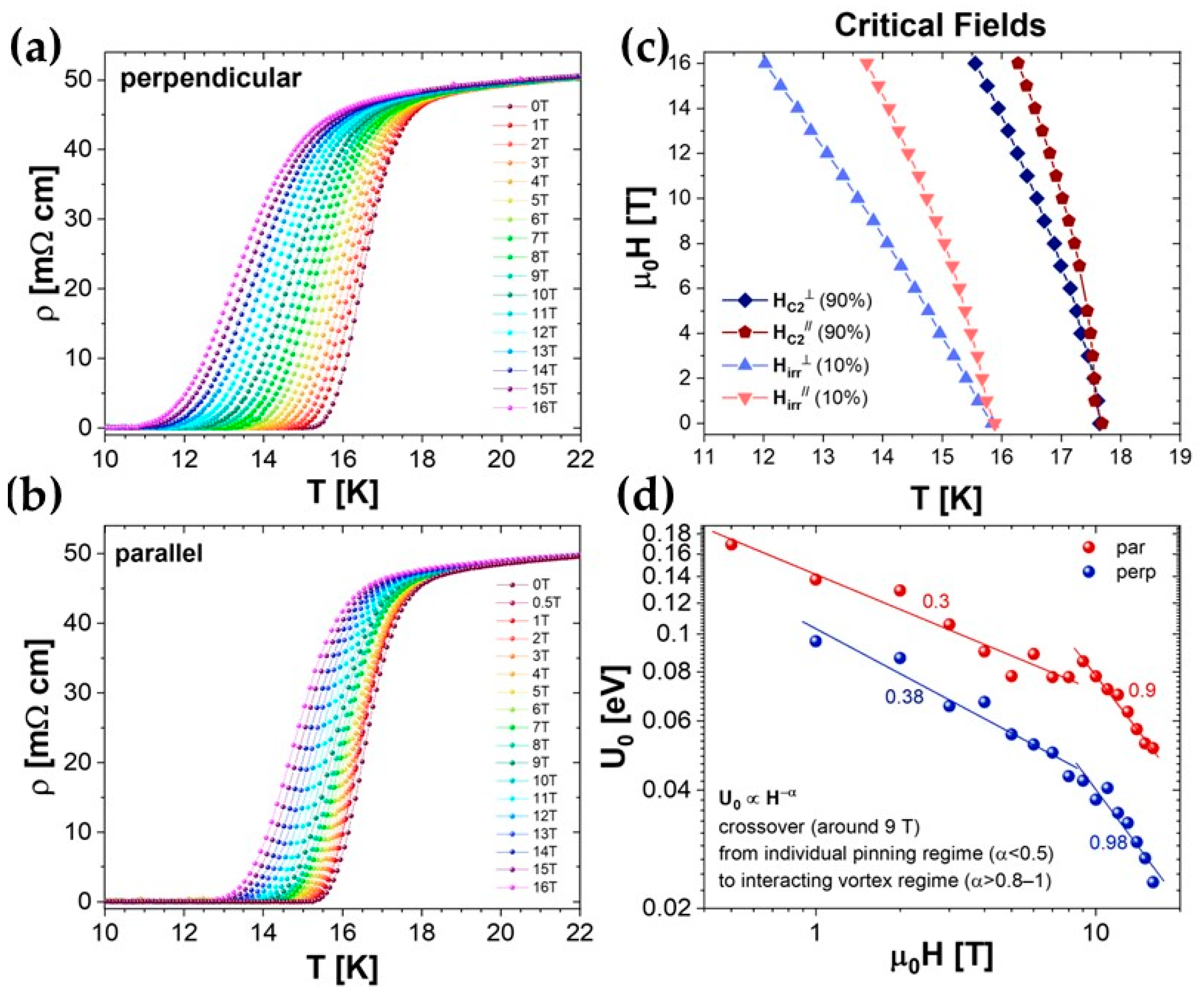

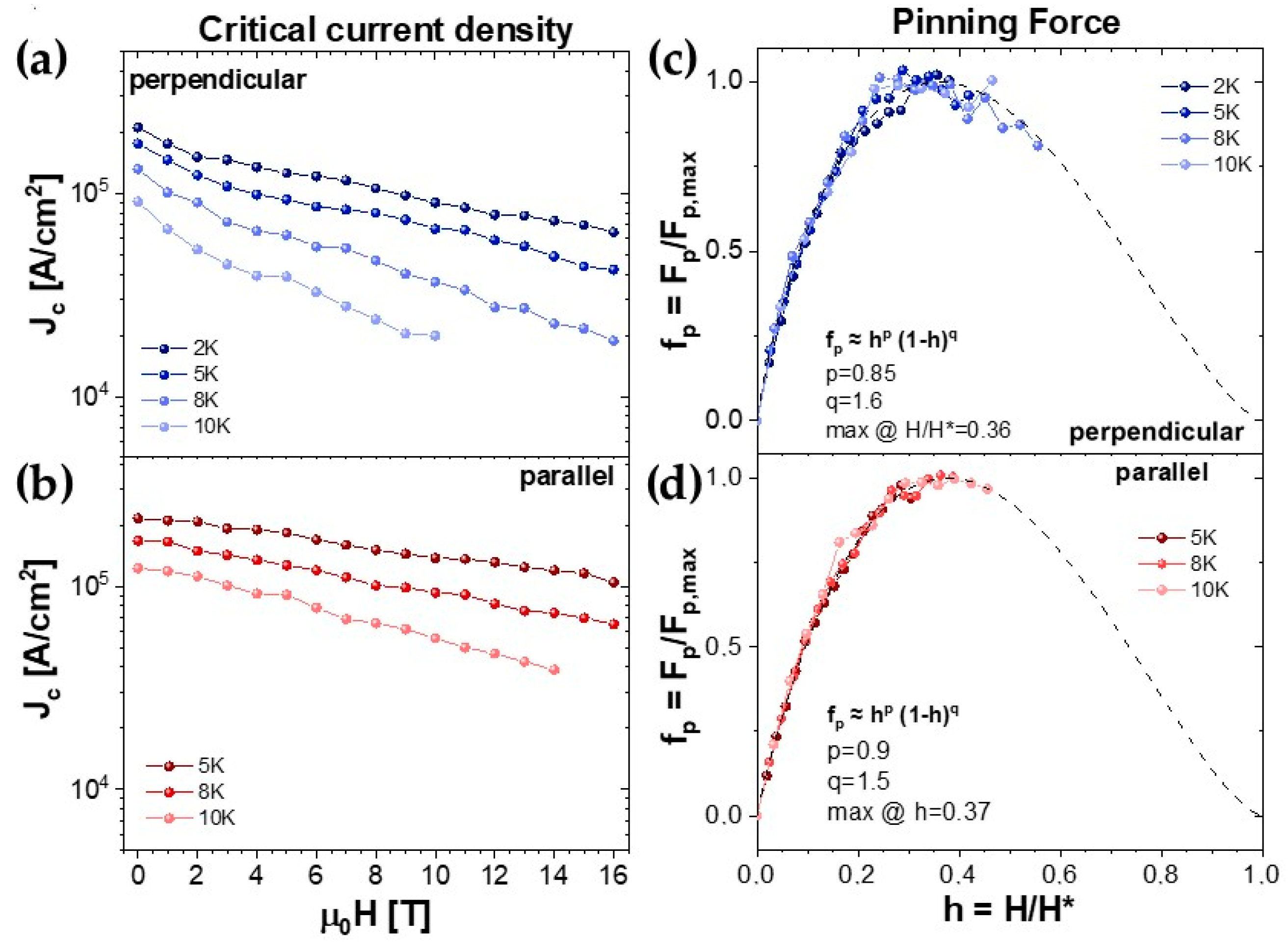

3.2. Film

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kamihara, Y.; Watanabe, T.; Hirano, M.; Hosono, H. Iron-Based Layered Superconductor La[O1-xFx]FeAs (x = 0.05−0.12) with Tc = 26 K. J. Am. Chem. Soc. 2008, 130, 3296. [Google Scholar] [CrossRef] [PubMed]

- Piperno, L.; Vannozzi, A.; Pinto, V.; Augieri, A.; Angisani Armenio, A.; Rizzo, F.; Mancini, A.; Rufoloni, A.; Celentano, G.; Braccini, V.; et al. Chemical CeO2-Based Buffer Layers for Fe(Se,Te) Films. IEEE Trans. Appl. Supercond. 2022, 32, 1–5. [Google Scholar] [CrossRef]

- Bruzzone, P.; Fietz, W.H.; Minervini, J.V.; Novikov, M.; Yanagi, N.; Zhai, Y.; Zheng, J. High temperature superconductors for fusion magnets. Nucl. Fusion 2018, 58, 1030001. [Google Scholar] [CrossRef]

- Hosono, H.; Yamamoto, A.; Hiramatsu, H.; Ma, Y. Recent advances in iron-based superconductors toward applications. Mater. Today 2018, 21, 278–302. [Google Scholar] [CrossRef]

- Pallecchi, I.; Eisterer, M.; Malagoli, A.; Putti, M. Application potential of Fe-based superconductors. Supercond. Sci. Technol. 2015, 28, 114005. [Google Scholar] [CrossRef]

- Bellingeri, E.; Pallecchi, I.; Buzio, R.; Gerbi, A.; Marrè, D.; Cimberle, M.R.; Tropeano, M.; Putti, M.; Palenzona, A.; Ferdeghini, C. Tc = 21 K in epitaxial FeSe0.5Te0.5 thin films with biaxial compressive strain. Appl. Phys. Lett. 2010, 96, 102512. [Google Scholar] [CrossRef]

- Braccini, V.; Kawale, S.; Reich, E.; Bellingeri, E.; Pellegrino, L.; Sala, A.; Putti, M.; Higashikawa, K.; Kiss, T.; Holzapfel, B.; et al. Highly effective and isotropic pinning in epitaxial Fe(Se,Te) thin films grown on CaF2 substrates. Appl. Phys. Lett. 2013, 103, 172601. [Google Scholar] [CrossRef]

- Palombo, M.; Malagoli, A.; Pani, M.; Bernini, C.; Manfrinetti, P.; Palenzona, A.; Putti, M. Exploring the feasibility of Fe(Se,Te) conductors by ex-situ Powder-in-Tube method. J. Appl. Phys. 2015, 117, 213903. [Google Scholar] [CrossRef]

- Si, W.; Han, S.; Shi, X.; Ehrlich, S.N.; Jaroszynski, J.; Goyal, A.; Li, Q. High current superconductivity in FeSe0.5Te0.5-coated conductors at 30 tesla. Nat. Commun. 2013, 4, 1347. [Google Scholar] [CrossRef]

- Si, W.; Zhou, J.; Jie, Q.; Dimitrov, I.; Solovyov, V.; Johnson, P.D.; Jaroszynski, J.; Matias, V.; Sheehan, C.; Li, Q. Iron-chalcogenide FeSe0.5Te0.5 coated superconducting taper for high field applications. Appl. Phys. Lett. 2011, 98, 262509. [Google Scholar] [CrossRef]

- Obradors, X.; Puig, T. Coated conductors for power applications: Materials challenges. Supercond. Sci. Technol. 2014, 27, 044003. [Google Scholar] [CrossRef]

- Iida, K.; Hanisch, J.; Tarantini, C. Fe-based superconducting thin films on metallic substrates: Growth, characreristics, and relevant properties. Appl. Phys. Rev. 2018, 5, 031304. [Google Scholar] [CrossRef]

- Vannozzi, A.; Prili, S.; Sylva, G.; Masi, A.; Angrisani Armenio, A.; Mancini, A.; Pinto, V.; Rufoloni, A.; Piperno, L.; Augieri, A.; et al. Epitaxial Zr-doped CeO2 films by chemical solution deposition as buffer layers for Fe(Se,Te) film growth. Supercond. Sci. Technol. 2020, 33, 084004. [Google Scholar] [CrossRef]

- Sakoda, M.; Iida, K.; Naito, M. Recent progress in thin-film growth of Fe-based superconductors: Superior superconductivity achieved by thin films. Supercond. Sci. Technol. 2018, 31, 093001. [Google Scholar] [CrossRef]

- Sylva, G.; Augieri, A.; Mancini, A.; Rufoloni, A.; Vannozzi, A.; Celentano, G.; Bellingeri, E.; Ferdeghini, C.; Putti, M.; Braccini, V. Fe(Se,Te) coated conductors deposited on simple rollin-assisted biaxially textured substrate templates. Supercond. Sci. Technol. 2019, 32, 084006. [Google Scholar] [CrossRef]

- Sylva, G.; Bellingeri, E.; Bernini, C.; Celentano, G.; Ferdeghini, C.; Leveratto, A.; Lisitskiy, M.; Malagoli, A.; Manca, N.; Mancini, A.; et al. The role of texturing and thickness of oxide buffer layers in the superconducting properties of Fe(Se,Te)Coated Conductors. Supercond. Sci. Technol. 2020, 33, 114002. [Google Scholar] [CrossRef]

- Piperno, L.; Vannozzi, A.; Augieri, A.; Masi, A.; Mancini, A.; Rufoloni, A.; Celentano, G.; Braccini, V.; Cialone, M.; Iebole, M.; et al. High-performance Fe(Se,Te) films on chemical CeO2-based buffer layers. Sci. Rep. 2023, 13, 569. [Google Scholar] [CrossRef] [PubMed]

- Vannozzi, A.; Piperno, L.; Rufoloni, A.; Botti, S.; Bonfigli, F.; Iebole, M.; Savio, L.; Cialone, M.; Masi, A.; Mancini, A.; et al. Zr:CeO2 buffer by CSD on Ni-W substrate for low-cost Fe(Se,Te) coated conductor. IEEE Trans. Appl. Supercond. 2024, 34, 7500305. [Google Scholar] [CrossRef]

- Haindl, S.; Molatta, S.; Hiramatsu, H.; Hosono, H. Recent progress in pulsed laser deposition of iron based superconductors. J. Phys. D Appl. Phys. 2016, 49, 345301. [Google Scholar] [CrossRef]

- Sun, Q.; Xu, Z.; Dong, C.; Huang, H.; Wang, D.; Zhang, X.; Ma, Y. Macroscopically ordered phase separation: A new strategy for improving the superconducting performance in Fe(Se,Te). Mater. Today Adv. 2023, 17, 100354. [Google Scholar] [CrossRef]

- Palenzona, A.; Sala, A.; Bernini, C.; Braccini, V.; Cimberle, M.R.; Ferdeghini, C.; Lamura, G.; Martinelli, A.; Pallecchi, I.; Romano, G.; et al. A new approach for improving global critical current density in Fe(Se0.5Te0.5) polycrystalline materials. Supercond. Sci. Technol. 2012, 25, 115018. [Google Scholar] [CrossRef]

- Tokuta, S.; Hasegawa, Y.; Shimada, Y.; Yamamoto, A. Enhanced critical current density in K-doped Ba122 polycristalline bulk superconductors via fast densification. iScience 2022, 25, 103992. [Google Scholar] [CrossRef]

- Olevsky, E.A.; Bradbury, W.L.; Haines, C.D.; Martin, D.G.; Kapoor, D. Fundamental Aspects of Spark Plasma Sintering: I. ExperimentalAnalysis of Scalabilit. J. Am. Ceram. Soc. 2012, 95, 2406. [Google Scholar] [CrossRef]

- Sylva, G.; Bellingeri, E.; Ferdeghini, C.; Martinelli, A.; Pallecchi, I.; Pellegrino, L.; Putti, M.; Ghigo, G.; Gozzelino, L.; Torsello, D.; et al. Effects of high-energy proton irradiation on the superconducting properties of Fe(Se,Te) thin films. Supercond. Sci. Technol. 2018, 31, 054001. [Google Scholar] [CrossRef]

- Martinelli, A.; Bernardini, F.; Massidda, S. The phase diagrams of iron-based superconductors: Theory and experiments. C. R. Physique 2016, 17, 5–35. [Google Scholar] [CrossRef]

- Sala, A.; Palenzona, A.; Bernini, C.; Caglieris, F.; Cimberle, M.R.; Ferdeghini, C.; Lamura, G.; Martinelli, A.; Pani, M.; Hecher, J.; et al. Evidence of a miscibility gap in the FeTe1-xSex polycrystalline samples prepared with a melting process. J. Phys. Conf. Ser. 2014, 507, 012044. [Google Scholar] [CrossRef]

- Bhatia, V.; Rodriguez, E.E.; Butch, N.P.; Paglionec, J.; Green, M.A. Phase separation and superconductivity in Fe1+xTe0.5Se0.5. Chem. Commun. 2011, 47, 11297–11299. [Google Scholar] [CrossRef] [PubMed]

- Sala, A.; Palenzona, A.; Bernini, C.; Caglieris, F.; Cimberle, M.R.; Ferdeghini, C.; Lamura, G.; Martinelli, A.; Pani, M.; Putti, M. The role of Fe deficiency in FeySe0.5Te0.5 samples prepared by a melting process. Physical C 2013, 494, 69. [Google Scholar] [CrossRef]

- Blatter, G.; Feigelman, M.V.; Geshkenbein, V.B.; Larkin, A.I.; Vinokur, V.M. Vortices in high-temperature superconductors. Rev. Mod. Phys. 1994, 66, 1125. [Google Scholar] [CrossRef]

- Lei, H.; Wang, K.; Hu, R.; Ryu, H.; Abeykoon, M.; Bozin, E.S.; Petrovic, C. Iron chalcogenide superconductors at high magnetic fields. Sci. Technol. Adv. Mater. 2012, 13, 054305. [Google Scholar] [CrossRef]

- Bellingeri, E.; Kawale, S.; Caglieris, F.; Braccini, V.; Lamura, G.; Pellegrino, L.; Sala, A.; Putti, M.; Ferdeghini, C.; Jost, A.; et al. High field vortex phase diagram of Fe(Se,Te) thin films. Supercond. Sci. Technol. 2014, 27, 044007. [Google Scholar] [CrossRef]

- Jaroszynski, J.; Hunte, F.; Balicas, L.; Jo, Y.; Raicevic, I.; Gurevich, A.; Larbalestier, D.C.; Balakirev, F.F.; Fang, L.; Cheng, P.; et al. Upper critical fields and thermally-activated transport of NdFeAsO0.7F0.3 single crystal. Phys. Rev. B 2008, 78, 174523. [Google Scholar] [CrossRef]

- Scuderi, M.; Pallecchi, I.; Leo, A.; Nigro, A.; Grimaldi, G.; Ferdeghini, C.; Spinella, C.; Guidolin, M.; Trotta, A.; Braccini, V. Nanoscale analysis of superconducting Fe(Se,Te) epitaxial thin films and relationship with pinning properties. Sci. Rep. 2021, 11, 20100. [Google Scholar] [CrossRef] [PubMed]

- Bonura, M.; Giannini, E.; Viennois, R.; Senatore, C. Temperature and time scaling of the peak-effect vortex configuration in FeTe0.7Se0.3. Phys. Rev. B 2012, 85, 134532. [Google Scholar] [CrossRef]

- Dew-Hughes, D. Flux pinning mechanisms in type II superconductors. Philos. Mag. 1974, 30, 293–305. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Iebole, M.; Braccini, V.; Bernini, C.; Malagoli, A.; Manca, N.; Martinelli, A.; Cialone, M.; Putti, M.; Singh, S.J.; Latronico, G.; et al. Fe(Se,Te) Thin Films Deposited through Pulsed Laser Ablation from Spark Plasma Sintered Targets. Materials 2024, 17, 2594. https://doi.org/10.3390/ma17112594

Iebole M, Braccini V, Bernini C, Malagoli A, Manca N, Martinelli A, Cialone M, Putti M, Singh SJ, Latronico G, et al. Fe(Se,Te) Thin Films Deposited through Pulsed Laser Ablation from Spark Plasma Sintered Targets. Materials. 2024; 17(11):2594. https://doi.org/10.3390/ma17112594

Chicago/Turabian StyleIebole, Michela, Valeria Braccini, Cristina Bernini, Andrea Malagoli, Nicola Manca, Alberto Martinelli, Matteo Cialone, Marina Putti, Shiv J. Singh, Giovanna Latronico, and et al. 2024. "Fe(Se,Te) Thin Films Deposited through Pulsed Laser Ablation from Spark Plasma Sintered Targets" Materials 17, no. 11: 2594. https://doi.org/10.3390/ma17112594