Impact of Temperature Optimization of ITO Thin Film on Tandem Solar Cell Efficiency

Abstract

1. Introduction

2. Materials and Methods

2.1. ITO Film Deposition

2.2. Fabrication of Solar Cells

- A.

- Silicon Heterojunction solar cell (Subcell)

- B. Perovskite (Top cell) on silicon heterojunction solar cell

- C. Characterization

3. Results

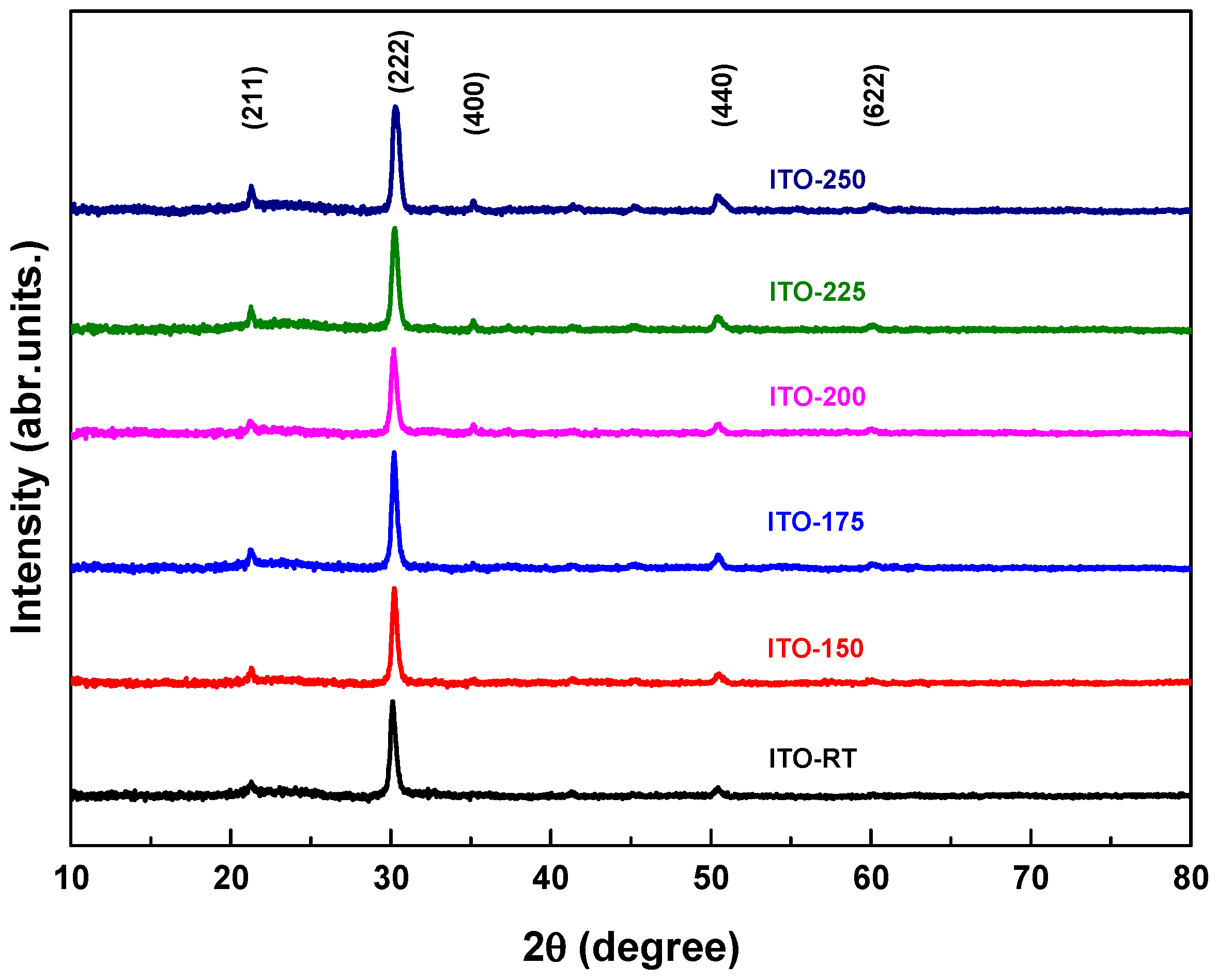

3.1. Effect of Temperature on the Structural Properties of ITO Films

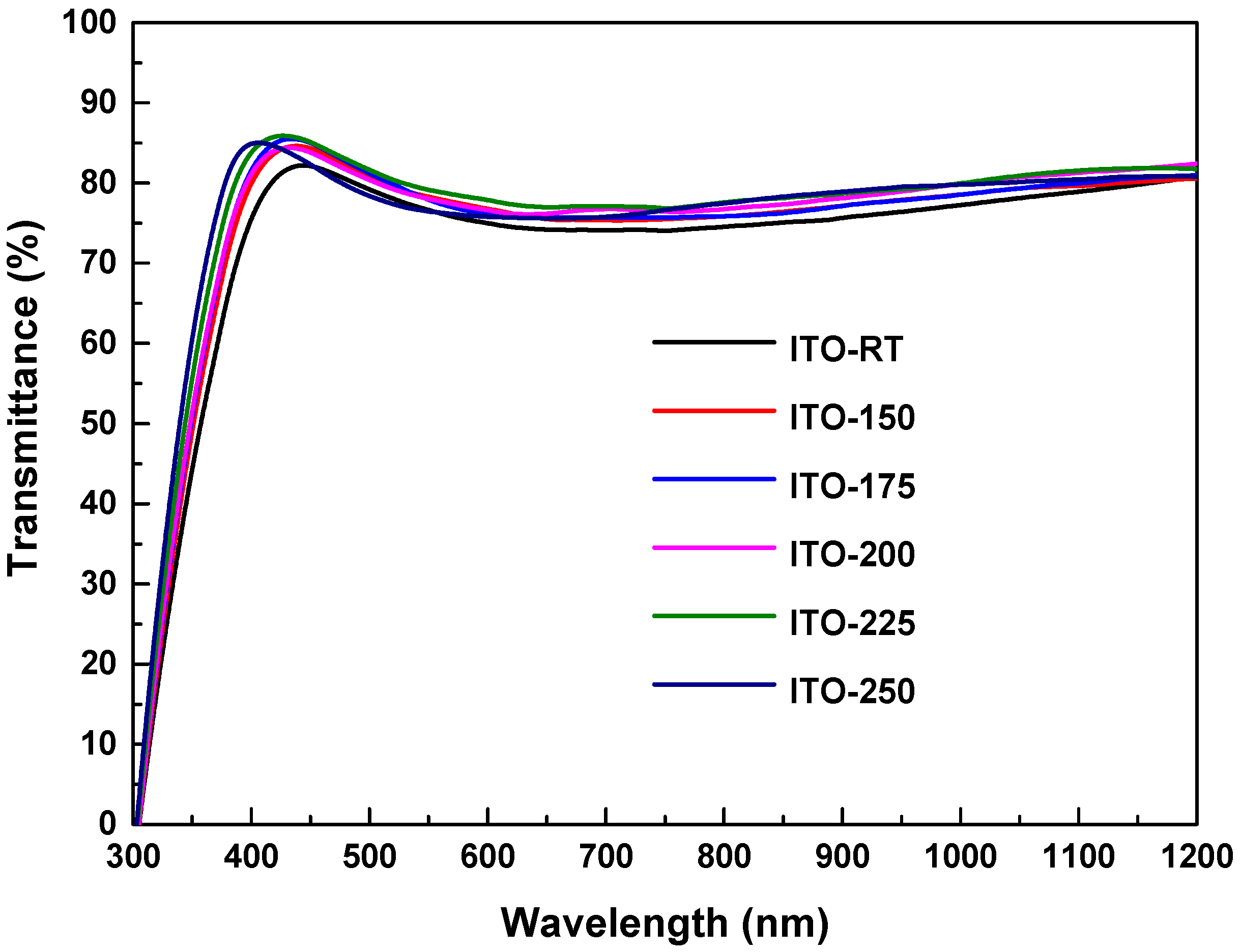

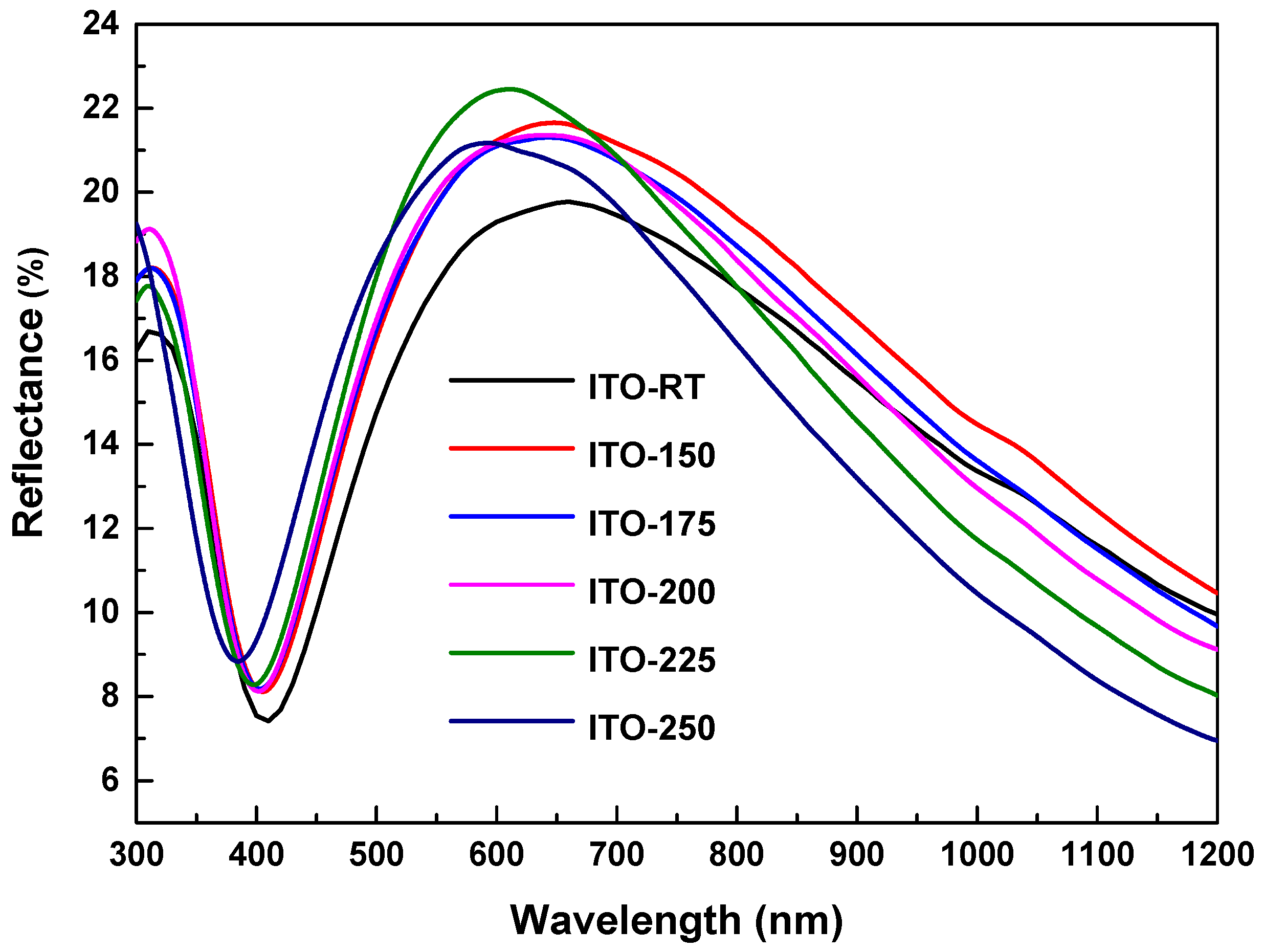

3.2. Effect of Temperature on the Optical Properties of ITO Films

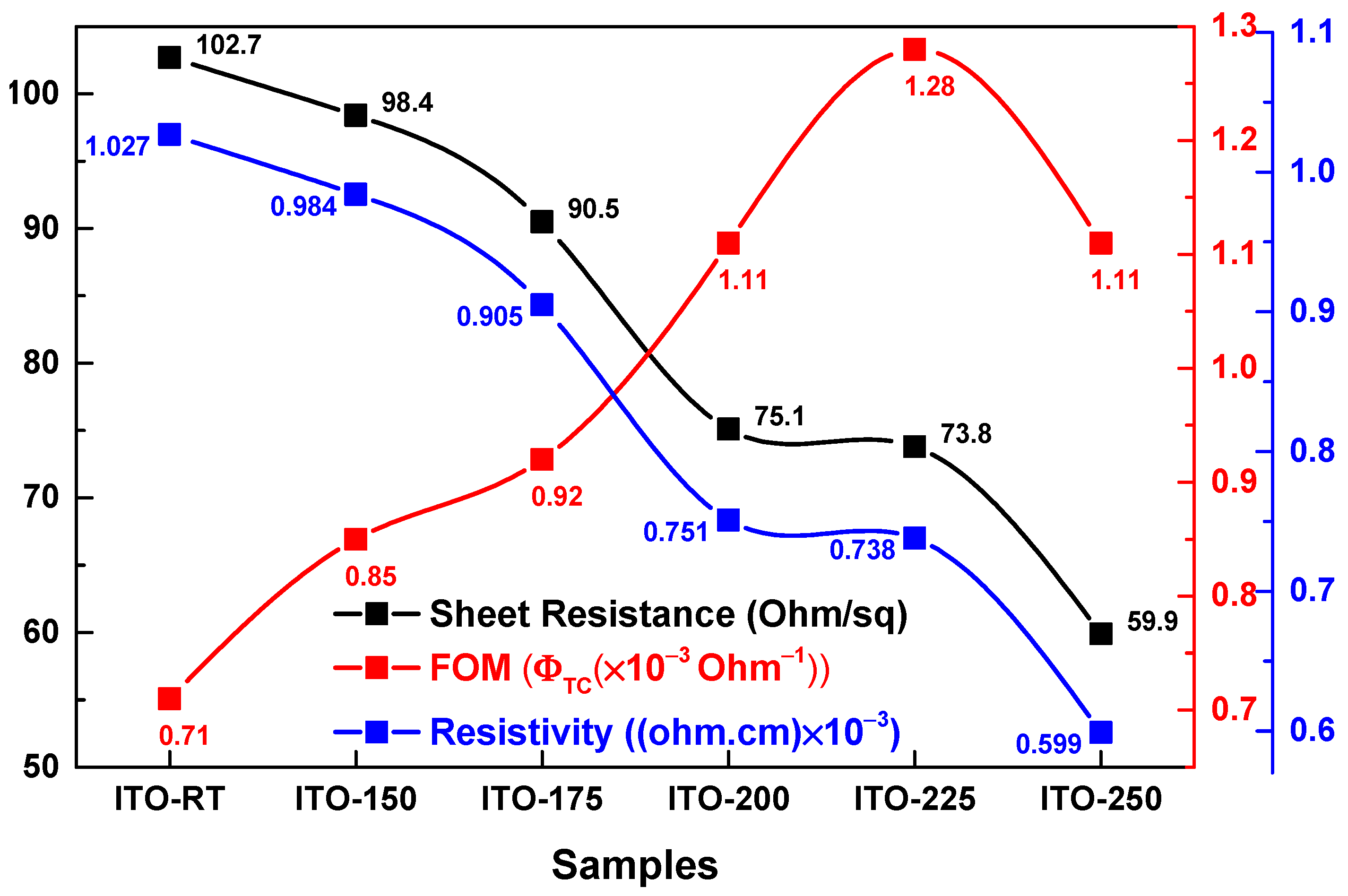

3.3. Effect of Temperature on the Electrical Properties of ITO Films

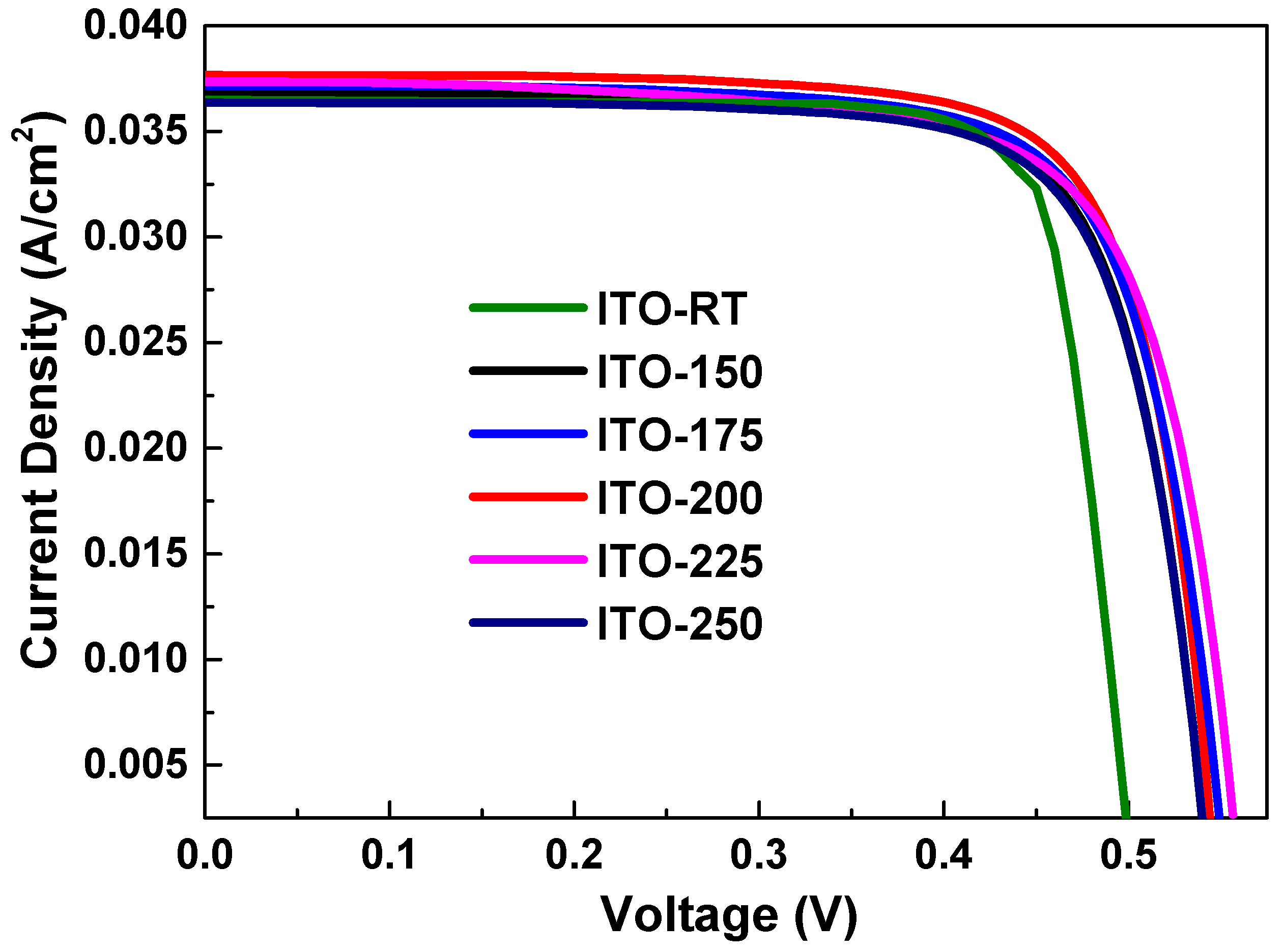

3.4. Effect of Temperature on the HJT Solar Cell Parameters

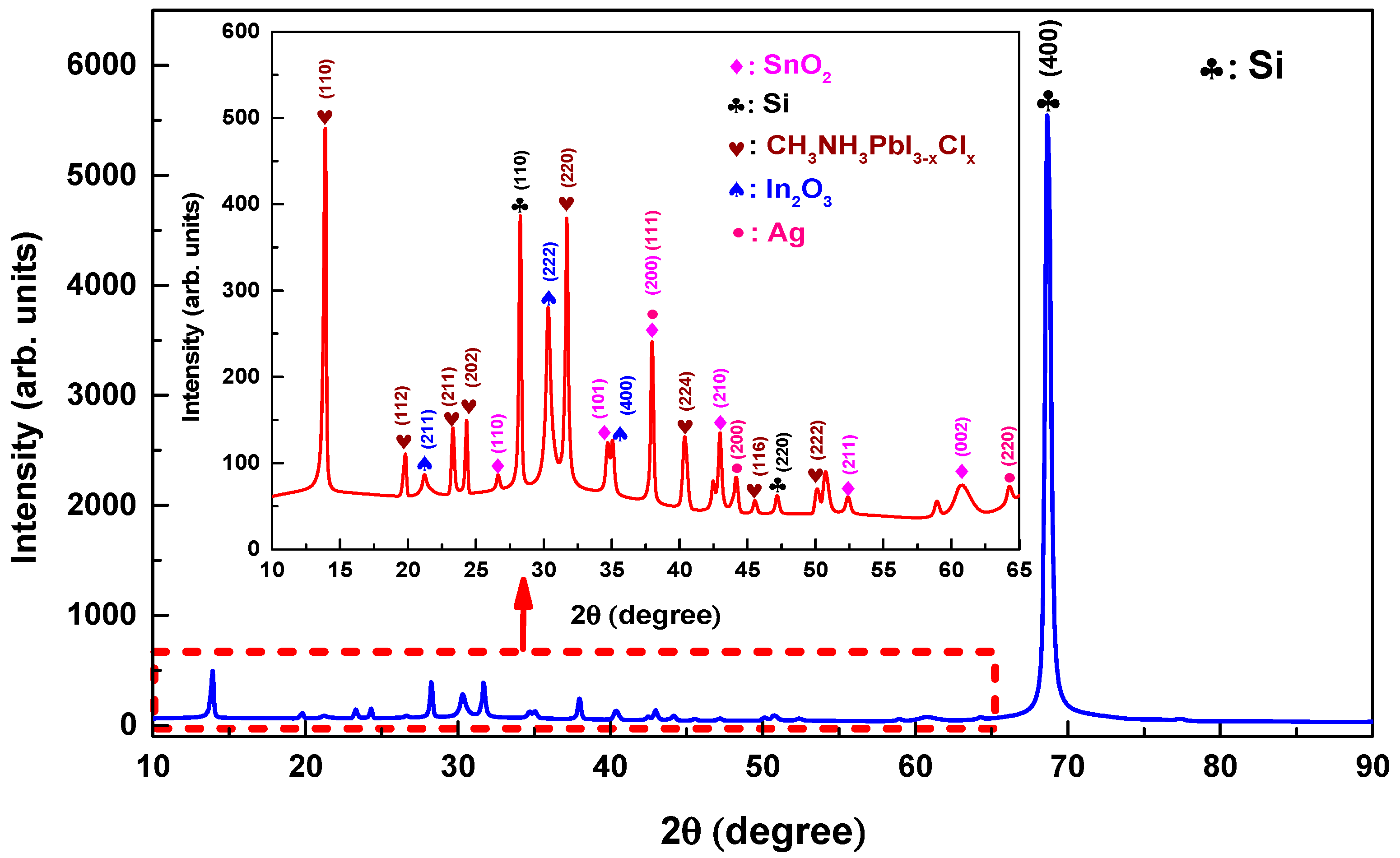

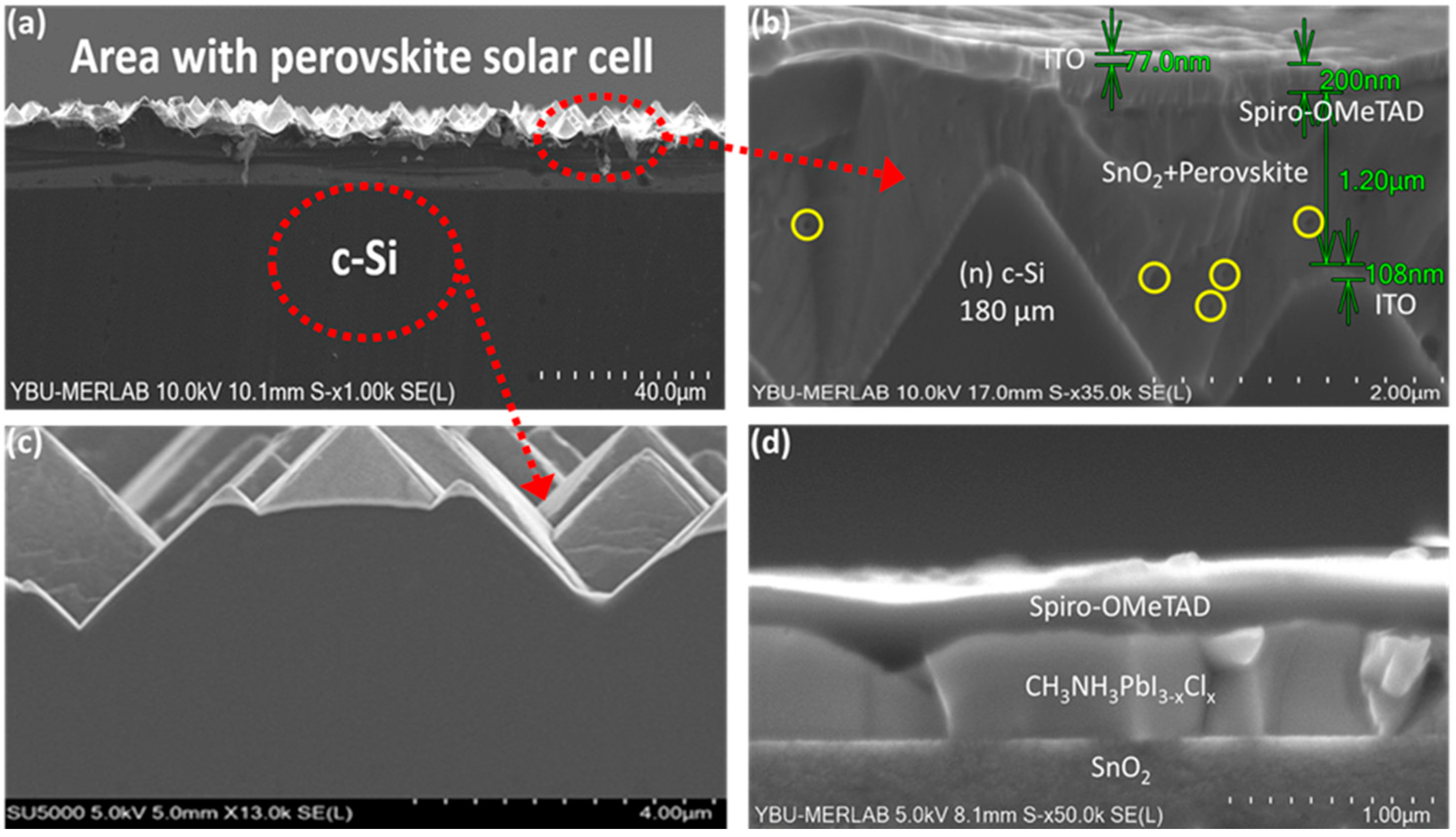

3.5. Structural and Morphological Properties of Monolithic c-Si HJT/perovskite Tandem Solar Cell

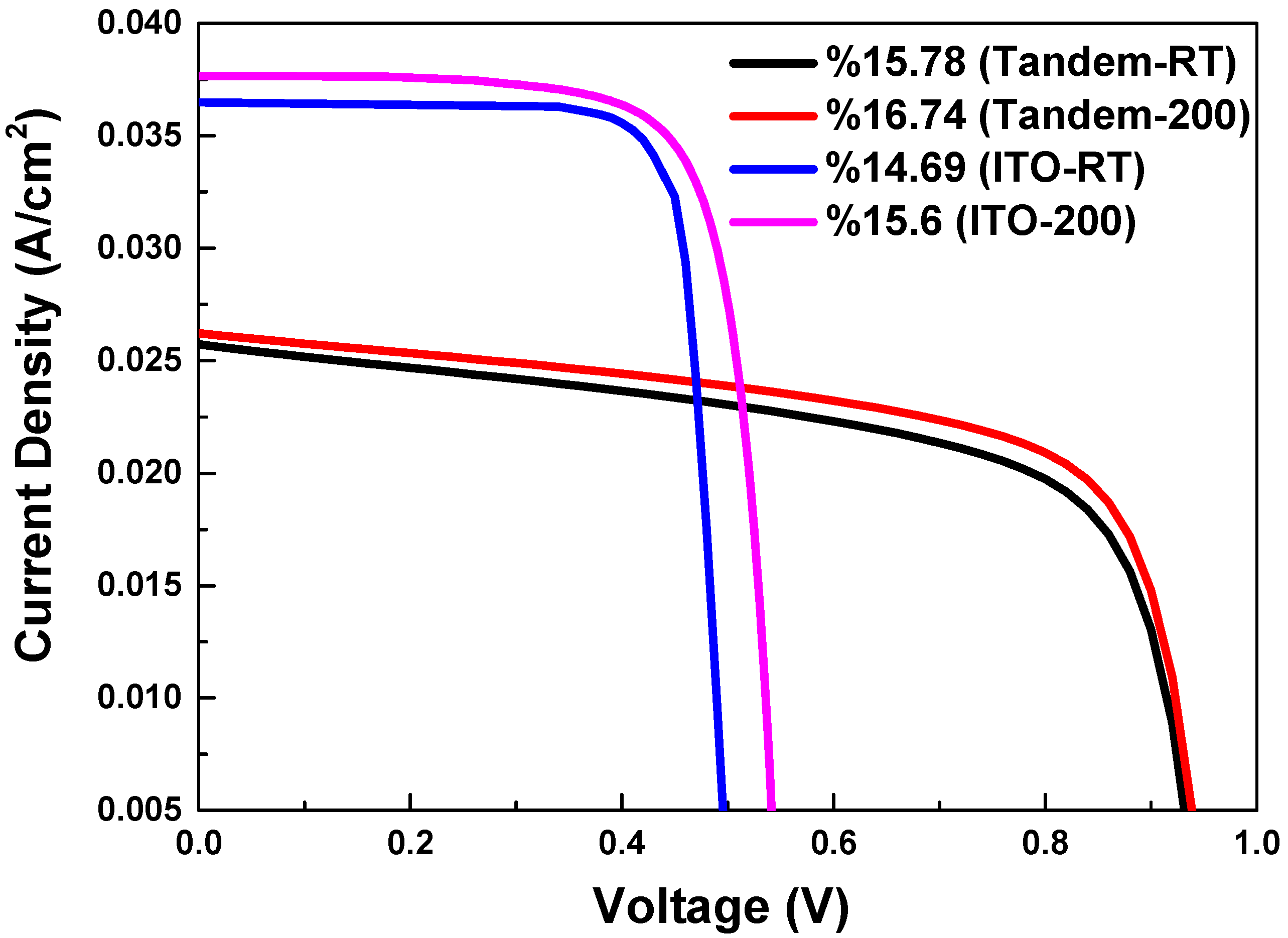

3.6. c-Si HJT and Monolithic c-Si HJT/Perovskite Tandem Solar Cell Efficiency

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fraunhofer Institute for Solar Energy Systems. ISE. Available online: www.cell-to-module.com (accessed on 17 September 2023).

- Hafshejani, M.T.; Keshavarzi, R.; Mirkhani, V.; Moghadam, M.; Tangestaninejad, S.; Mohammadpoor-Baltork, I. Waste Carbon-Based Toner Protection Layer on CsPbBr3 Perovskite Photoanodes for Efficient and Stable Photoelectrochemical Water Oxidation. Int. J. Hydrogen Energy 2024, 59, 82–88. [Google Scholar] [CrossRef]

- NREL Best Research-Cell Efficiency Chart. Available online: www.nrel.gov/pv/cell-efficiency.html (accessed on 16 April 2024).

- Richter, A.; Hermle, M.; Glunz, S.W. Reassessment of the Limiting Efficiency for Crystalline Silicon Solar Cells. IEEE J. Photovolt. 2013, 3, 1184–1191. [Google Scholar] [CrossRef]

- Jacak, J.E.; Jacak, W.A. Routes for Metallization of Perovskite Solar Cells. Materials 2022, 15, 2254. [Google Scholar] [CrossRef] [PubMed]

- Laska, M.; Krzemińska, Z.; Kluczyk-Korch, K.; Schaadt, D.; Popko, E.; Jacak, W.A.; Jacak, J.E. Metallization of Solar Cells, Exciton Channel of Plasmon Photovoltaic Effect in Perovskite Cells. Nano Energy 2020, 75, 104751. [Google Scholar] [CrossRef]

- Jošt, M.; Kegelmann, L.; Korte, L.; Albrecht, S. Monolithic Perovskite Tandem Solar Cells: A Review of the Present Status and Advanced Characterization Methods toward 30% Efficiency. Adv. Energy Mater. 2020, 10, 1904102. [Google Scholar] [CrossRef]

- Sahli, F.; Werner, J.; Kamino, B.A.; Bräuninger, M.; Monnard, R.; Paviet-Salomon, B.; Barraud, L.; Ding, L.; Diaz Leon, J.J.; Sacchetto, D. Fully Textured Monolithic Perovskite/Silicon Tandem Solar Cells with 25.2% Power Conversion Efficiency. Nat. Mater. 2018, 17, 820–826. [Google Scholar] [CrossRef]

- Wu, Y.; Zheng, P.; Peng, J.; Xu, M.; Chen, Y.; Surve, S.; Lu, T.; Bui, A.D.; Li, N.; Liang, W. 27.6% Perovskite/C-Si Tandem Solar Cells Using Industrial Fabricated TOPCon Device. Adv. Energy Mater. 2022, 12, 2200821. [Google Scholar] [CrossRef]

- Bailie, C.D.; McGehee, M.D. High-Efficiency Tandem Perovskite Solar Cells. Mrs Bull. 2015, 40, 681–686. [Google Scholar] [CrossRef]

- Gerritsen, S.; Nguyen, H.V.; Creatore, A. Studying Degradation of Perovskite Solar Cells in Ambient Atmosphere Using Photoluminescence Spectroscopy 2019. Available online: https://api.semanticscholar.org/CorpusID:202609581 (accessed on 19 April 2024).

- Li, B.; Li, Y.; Zheng, C.; Gao, D.; Huang, W. Advancements in the Stability of Perovskite Solar Cells: Degradation Mechanisms and Improvement Approaches. RSC Adv. 2016, 6, 38079–38091. [Google Scholar] [CrossRef]

- Zhao, J.; Wang, A.; Altermatt, P.P.; Green, M.A.; Rakotoniaina, J.P.; Breitenstein, O. High Efficiency PERT Cells on N-Type Silicon Substrates. In Proceedings of the Conference Record of the Twenty-Ninth IEEE Photovoltaic Specialists Conference, New Orleans, LA, USA, 19–24 May 2002; pp. 218–221. [Google Scholar]

- Müller, J.; Rech, B.; Springer, J.; Vanecek, M. TCO and Light Trapping in Silicon Thin Film Solar Cells. Sol. Energy 2004, 77, 917–930. [Google Scholar] [CrossRef]

- Altuntepe, A.; Olgar, M.A.; Erkan, S.; Hasret, O.; Keçeci, A.E.; Kökbudak, G.; Tomakin, M.; Seyhan, A.; Turan, R.; Zan, R. Hybrid Transparent Conductive Electrode Structure for Solar Cell Application. Renew. Energy 2021, 180, 178–185. [Google Scholar] [CrossRef]

- Zan, R.; Olgar, M.A.; Altuntepe, A.; Seyhan, A.; Turan, R. Integration of Graphene with GZO as TCO Layer and Its Impact on Solar Cell Performance. Renew. Energy 2022, 181, 1317–1324. [Google Scholar] [CrossRef]

- Chavan, G.T.; Kim, Y.; Khokhar, M.Q.; Hussain, S.Q.; Cho, E.-C.; Yi, J.; Ahmad, Z.; Rosaiah, P.; Jeon, C.-W. A Brief Review of Transparent Conducting Oxides (TCO): The Influence of Different Deposition Techniques on the Efficiency of Solar Cells. Nanomaterials 2023, 13, 1226. [Google Scholar] [CrossRef] [PubMed]

- Al-Kuhaili, M.F. Transparent-Conductive and Infrared-Shielding WO3/Ag/WO3 Multilayer Heterostructures. Sol. Energy 2023, 250, 209–219. [Google Scholar] [CrossRef]

- Suwanboon, S.; Amornpitoksuk, P.; Haidoux, A.; Tedenac, J.-C. Structural and Optical Properties of Undoped and Aluminium Doped Zinc Oxide Nanoparticles via Precipitation Method at Low Temperature. J. Alloys Compd. 2008, 462, 335–339. [Google Scholar] [CrossRef]

- Zhang, H.; Qu, F.; Li, H. Front Transparent Passivation of CIGS-Based Solar Cells via AZO. Molecules 2022, 27, 6285. [Google Scholar] [CrossRef] [PubMed]

- Hussain, S.Q.; Kim, S.; Ahn, S.; Balaji, N.; Lee, Y.; Lee, J.H.; Yi, J. Influence of High Work Function ITO: Zr Films for the Barrier Height Modification in a-Si: H/c-Si Heterojunction Solar Cells. Sol. Energy Mater. Sol. Cells 2014, 122, 130–135. [Google Scholar] [CrossRef]

- Han, C.; Zhao, Y.; Mazzarella, L.; Santbergen, R.; Montes, A.; Procel, P.; Yang, G.; Zhang, X.; Zeman, M.; Isabella, O. Room-Temperature Sputtered Tungsten-Doped Indium Oxide for Improved Current in Silicon Heterojunction Solar Cells. Sol. Energy Mater. Sol. Cells 2021, 227, 111082. [Google Scholar] [CrossRef]

- Kobayashi, E.; Watabe, Y.; Yamamoto, T.; Yamada, Y. Cerium Oxide and Hydrogen Co-Doped Indium Oxide Films for High-Efficiency Silicon Heterojunction Solar Cells. Sol. Energy Mater. Sol. Cells 2016, 149, 75–80. [Google Scholar] [CrossRef]

- Yao, Z.; Duan, W.; Steuter, P.; Hüpkes, J.; Lambertz, A.; Bittkau, K.; Pomaska, M.; Qiu, D.; Qiu, K.; Wu, Z. Influence of Oxygen on Sputtered Titanium-Doped Indium Oxide Thin Films and Their Application in Silicon Heterojunction Solar Cells. Sol. RRL 2021, 5, 2000501. [Google Scholar] [CrossRef]

- Messmer, C.; Tutsch, L.; Pingel, S.; Erath, D.; Schön, J.; Fell, A.; Goldschmidt, J.C.; Goraya, B.S.; Clement, F.; Lorenz, A. Optimized Front TCO and Metal Grid Electrode for Module-integrated Perovskite–Silicon Tandem Solar Cells. Prog. Photovolt. Res. Appl. 2022, 30, 374–383. [Google Scholar] [CrossRef]

- Ba, L.; Wang, T.; Wang, J.; Shen, W. Perovskite/c-Si Monolithic Tandem Solar Cells under Real Solar Spectra: Improving Energy Yield by Oblique Incident Optimization. J. Phys. Chem. C 2019, 123, 28659–28667. [Google Scholar] [CrossRef]

- Sahoo, N.G. New Generation Transparent Conducting Electrode Materials for Solar Cell Technologies. Mater. Res. Found. 2021, 88, 86–128. [Google Scholar]

- Seyhan, A.; Kartal, E. Optical, Electrical and Structural Properties of ITO/IZO and IZO/ITO Multilayer Transparent Conductive Oxide Films Deposited via Radiofrequency Magnetron Sputtering. Coatings 2023, 13, 1719. [Google Scholar] [CrossRef]

- Kartal, E.; Duran, İ.; Damgaci, E.; Seyhan, A. Investigation of Structural, Optical, and Electrical Properties of Ito Films Deposited at Different Plasma Powers: Enhanced Performance and Efficiency in SHJ Solar Cells. Eurasian J. Sci. Eng. Technol. 2023, 4, 25–35. [Google Scholar] [CrossRef]

- Zan, R.; Altuntepe, A.; Altan, T.; Seyhan, A. Crystalline-Silicon Heterojunction Solar Cells with Graphene Incorporation. In Sustainable Material Solutions for Solar Energy Technologies; Elsevier: Amsterdam, The Netherlands, 2021; pp. 229–257. [Google Scholar]

- Raoufi, D.; Taherniya, A. The Effect of Substrate Temperature on the Microstructural, Electrical and Optical Properties of Sn-Doped Indium Oxide Thin Films. Eur. Phys. J. Appl. Phys. 2015, 70, 30302. [Google Scholar] [CrossRef]

- Lien, S.-Y. Characterization and Optimization of ITO Thin Films for Application in Heterojunction Silicon Solar Cells. Thin Solid Films 2010, 518, S10–S13. [Google Scholar] [CrossRef]

- Ogi, T.; Hidayat, D.; Iskandar, F.; Purwanto, A.; Okuyama, K. Direct Synthesis of Highly Crystalline Transparent Conducting Oxide Nanoparticles by Low Pressure Spray Pyrolysis. Adv. Powder Technol. 2009, 20, 203–209. [Google Scholar] [CrossRef]

- Zhang, K.; Zhu, F.; Huan, C.H.A.; Wee, A.T.S. Effect of Hydrogen Partial Pressure on Optoelectronic Properties of Indium Tin Oxide Thin Films Deposited by Radio Frequency Magnetron Sputtering Method. J. Appl. Phys. 1999, 86, 974–980. [Google Scholar] [CrossRef]

- Mustapha, N.; Alakhras, A.; Idriss, H. Influence of Post-Deposition Annealing on the Indium Tin Oxide Thin Films Grown by Pulsed Laser Deposition. Dig. J. Nanomater. Biostruct. 2020, 15, 1227–1237. [Google Scholar] [CrossRef]

- Thilakan, P.; Kumar, J. Studies on the Preferred Orientation Changes and Its Influenced Properties on ITO Thin Films. Vacuum 1997, 48, 463–466. [Google Scholar] [CrossRef]

- Meng, L.; Dos Santos, M.P. Properties of Indium Tin Oxide Films Prepared by Rf Reactive Magnetron Sputtering at Different Substrate Temperature. Thin Solid Films 1998, 322, 56–62. [Google Scholar] [CrossRef]

- Ezzeldien, M.; Gami, F.; Alrowaili, Z.A.; Shaaban, E.R.; El-Hagary, M. The Influential Role of ITO Heat Treatment on Improving the Performance of Solar Cell N-ITO/p-Si Junction: Structural, Optical, and Electrical Characterizations. Mater. Today Commun. 2022, 31, 103272. [Google Scholar] [CrossRef]

- Sofi, A.H.; Shah, M.A.; Asokan, K. Structural, Optical and Electrical Properties of ITO Thin Films. J. Electron. Mater. 2018, 47, 1344–1352. [Google Scholar] [CrossRef]

- Manzano, C.V.; Rojas, A.A.; Decepida, M.; Abad, B.; Feliz, Y.; Caballero-Calero, O.; Borca-Tasciuc, D.-A.; Martin-Gonzalez, M. Thermoelectric Properties of Bi2Te3 Films by Constant and Pulsed Electrodeposition. J. Solid State Electrochem. 2013, 17, 2071–2078. [Google Scholar] [CrossRef]

- Nisha, M.; Anusha, S.; Antony, A.; Manoj, R.; Jayaraj, M.K. Effect of Substrate Temperature on the Growth of ITO Thin Films. Appl. Surf. Sci. 2005, 252, 1430–1435. [Google Scholar] [CrossRef]

- Tauc, J. Optical Properties and Electronic Structure of Amorphous Ge and Si. Mater. Res. Bull. 1968, 3, 37–46. [Google Scholar] [CrossRef]

- Hamberg, I.; Granqvist, C.G. Evaporated Sn-doped In2O3 Films: Basic Optical Properties and Applications to Energy-efficient Windows. J. Appl. Phys. 1986, 60, R123–R160. [Google Scholar] [CrossRef]

- Park, H.-K.; Jeong, J.-A.; Park, Y.-S.; Kim, H.-K.; Cho, W.-J. Electrical, Optical, and Structural Properties of InZnSnO Electrode Films Grown by Unbalanced Radio Frequency Magnetron Sputtering. Thin Solid Films 2009, 517, 5563–5568. [Google Scholar] [CrossRef]

- Akhmedov, A.K.; Abduev, A.K.; Murliev, E.K.; Belyaev, V.V.; Asvarov, A.S. Transparent Conducting Amorphous IZO Thin Films: An Approach to Improve the Transparent Electrode Quality. Materials 2023, 16, 3740. [Google Scholar] [CrossRef]

- Ali, A.H.; Shuhaimi, A.; Hassan, Z. Structural, Optical and Electrical Characterization of ITO, ITO/Ag and ITO/Ni Transparent Conductive Electrodes. Appl. Surf. Sci. 2014, 288, 599–603. [Google Scholar] [CrossRef]

- Zhu, B.L.; Ma, J.M.; Lv, K.; Wang, C.J.; Wu, J.; Gan, Z.H.; Liu, J.; Shi, X.W. Improvement of Transparent Conductive Properties of GZO/Cu/GZO Tri-Layer Films by Introducing H2 into Sputtering Atmosphere. Superlattices Microstruct. 2020, 140, 106456. [Google Scholar] [CrossRef]

- Lee, S.Y.; Park, Y.S.; Seong, T.-Y. Optimized ITO/Ag/ITO Multilayers as a Current Spreading Layer to Enhance the Light Output of Ultraviolet Light-Emitting Diodes. J. Alloys Compd. 2019, 776, 960–964. [Google Scholar] [CrossRef]

- Haacke, G. New Figure of Merit for Transparent Conductors. J. Appl. Phys. 1976, 47, 4086–4089. [Google Scholar] [CrossRef]

- Ren, H.; Zou, X.; Cheng, J.; Ling, T.; Bai, X.; Chen, D. Facile Solution Spin-Coating SnO2 Thin Film Covering Cracks of TiO2 Hole Blocking Layer for Perovskite Solar Cells. Coatings 2018, 8, 314. [Google Scholar] [CrossRef]

- Satpute, S.D.; Bhujbal, P.K.; Shaikh, S.F.; Patil, S.A.; Jadkar, S.R.; More, S.A. TiO2 Blocking Layer Incorporated TiO2/In2O3-Based Photoanode for DSSC Application. J. Mater. Sci. Mater. Electron. 2023, 34, 2311. [Google Scholar] [CrossRef]

- Chaudhary, D.K.; Kumar, P.; Kumar, L. Realization of Efficient Perovskite Solar Cells with MEH: PPV Hole Transport Layer. J. Mater. Sci. Mater. Electron. 2017, 28, 3451–3457. [Google Scholar] [CrossRef]

- Oku, T. Crystal Structures of Perovskite Halide Compounds Used for Solar Cells. Rev. Adv. Mater. Sci. 2020, 59, 264–305. [Google Scholar] [CrossRef]

- Sewvandi, G.A.; Kodera, K.; Ma, H.; Nakanishi, S.; Feng, Q. Antiferroelectric Nature of CH3NH3PbI3−XClx Perovskite and Its Implication for Charge Separation in Perovskite Solar Cells. Sci. Rep. 2016, 6, 30680. [Google Scholar] [CrossRef]

- Song, W.; Rakocevic, L.; Thiruvallur Eachambadi, R.; Qiu, W.; Bastos, J.P.; Gehlhaar, R.; Kuang, Y.; Hadipour, A.; Aernouts, T.; Poortmans, J. Improving the Morphology Stability of Spiro-OMeTAD Films for Enhanced Thermal Stability of Perovskite Solar Cells. ACS Appl. Mater. Interfaces 2021, 13, 44294–44301. [Google Scholar] [CrossRef]

| Sample Notation | Ar Flow (sccm) | O2 Flow (sccm) | Deposition Power (W) | Deposition Temperature (°C) |

|---|---|---|---|---|

| ITO-RT | 200 | 3.3 | 1850 | RT |

| ITO-150 | 200 | 3.3 | 1850 | 150 |

| ITO-175 | 200 | 3.3 | 1850 | 175 |

| ITO-200 | 200 | 3.3 | 1850 | 200 |

| ITO-225 | 200 | 3.3 | 1850 | 225 |

| ITO-250 | 200 | 3.3 | 1850 | 250 |

| Sample Name | β (Rad) | θ (Degrees) | cosθ | D (nm) | δ (Lines/nm2) (×10−3) | ε (×10−3) | N (nm−2) (×10−2) |

|---|---|---|---|---|---|---|---|

| ITO-RT | 7.90 × 10−3 | 15.0699 | 0.9656 | 18 | 3.1 | 1.9 | 1.7 |

| ITO-150 | 7.20 × 10−3 | 15.1153 | 0.9654 | 20 | 2.5 | 1.7 | 1.3 |

| ITO-175 | 7.30 × 10−3 | 15.1082 | 0.9654 | 19 | 2.8 | 1.8 | 1.5 |

| ITO-200 | 7.90 × 10−3 | 15.0948 | 0.9655 | 18 | 3.1 | 1.9 | 1.7 |

| ITO-225 | 8.20 × 10−3 | 15.1266 | 0.9654 | 17 | 3.5 | 2 | 2 |

| ITO-250 | 8.70 × 10−3 | 15.1621 | 0.9652 | 16 | 3.9 | 3.1 | 2.4 |

| Sample | Diffraction Peaks | |||||

|---|---|---|---|---|---|---|

| (211) | (222) | (400) | (440) | (622) | ||

| ITO-RT | 10.3 | 100 | 30.5 | 37.3 | 27.4 | I0 |

| ITO-150 | 10.3 | 100 | 30.5 | 37.3 | 27.4 | |

| ITO-175 | 10.7 | 100 | 30.6 | 37.1 | 27.4 | |

| ITO-200 | 10.3 | 100 | 30.5 | 37.3 | 27.4 | |

| ITO-225 | 11.1 | 100 | 30.5 | 36.8 | 26.9 | |

| ITO-250 | 11.1 | 100 | 30.5 | 36.8 | 26.9 | |

| ITO-RT | 319.6 | 2373.8 | - | 172.7 | - | Imeans |

| ITO-150 | 364.8 | 1944.7 | - | 225.4 | - | |

| ITO-175 | 470.4 | 2919.7 | - | 318 | 100 | |

| ITO-200 | 302.8 | 2098.4 | 190.8 | 211 | 105.1 | |

| ITO-225 | 533.3 | 2469.8 | 214.3 | 303.7 | 110.8 | |

| ITO-250 | 623.3 | 2128.4 | 217.2 | 356 | 147.3 | |

| ITO-RT | 0.76 | 1.02 | - | 0.65 | - | Texture Coefficient (TC) |

| ITO-150 | 0.87 | 0.84 | - | 0.85 | - | |

| ITO-175 | 1.08 | 1.26 | - | 1.20 | 0.85 | |

| ITO-200 | 0.72 | 0.90 | 0.92 | 0.79 | 0.90 | |

| ITO-225 | 1.18 | 1.06 | 1.03 | 1.16 | 0.96 | |

| ITO-250 | 1.38 | 0.92 | 1.05 | 1.36 | 1.28 | |

| Sample Name | Average Transmittance (%) (400–1200 nm) | Average Reflectance (%) (400–1200 nm) | Eg (eV) | Transmittance (%) (550 nm) |

|---|---|---|---|---|

| ITO-RT | 77 | 15 | 3.9 | 77 |

| ITO-150 | 78 | 16 | 3.91 | 78 |

| ITO-175 | 78 | 16 | 3.91 | 78 |

| ITO-200 | 80 | 15 | 3.91 | 78 |

| ITO-225 | 79 | 15 | 3.92 | 79 |

| ITO-250 | 79 | 14 | 3.93 | 76 |

| Sample Name | Efficiency (%) | Current Density, JSC (A/cm2) | Open Circuit Voltage, VOC (V) | Fill Factor, FF (%) |

|---|---|---|---|---|

| ITO-RT | 14.69 | 0.0365 | 0.5008 | 80.39 |

| ITO-150 | 15.05 | 0.0368 | 0.5430 | 75.40 |

| ITO-175 | 15.30 | 0.0372 | 0.5520 | 74.40 |

| ITO-200 | 15.60 | 0.0377 | 0.5460 | 75.70 |

| ITO-225 | 15.20 | 0.0374 | 0.5590 | 72.50 |

| ITO-250 | 14.90 | 0.0364 | 0.5430 | 75.40 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Damgaci, E.; Kartal, E.; Gucluer, F.; Seyhan, A.; Kaplan, Y. Impact of Temperature Optimization of ITO Thin Film on Tandem Solar Cell Efficiency. Materials 2024, 17, 2784. https://doi.org/10.3390/ma17112784

Damgaci E, Kartal E, Gucluer F, Seyhan A, Kaplan Y. Impact of Temperature Optimization of ITO Thin Film on Tandem Solar Cell Efficiency. Materials. 2024; 17(11):2784. https://doi.org/10.3390/ma17112784

Chicago/Turabian StyleDamgaci, Elif, Emre Kartal, Furkan Gucluer, Ayse Seyhan, and Yuksel Kaplan. 2024. "Impact of Temperature Optimization of ITO Thin Film on Tandem Solar Cell Efficiency" Materials 17, no. 11: 2784. https://doi.org/10.3390/ma17112784

APA StyleDamgaci, E., Kartal, E., Gucluer, F., Seyhan, A., & Kaplan, Y. (2024). Impact of Temperature Optimization of ITO Thin Film on Tandem Solar Cell Efficiency. Materials, 17(11), 2784. https://doi.org/10.3390/ma17112784