Influence of Polypropylene Fiber on Concrete Permeability under Freeze-Thaw Conditions and Mechanical Loading

Abstract

:1. Introduction

2. Experiments

2.1. Materials

2.2. Test Specimens

2.3. Rapid Freeze-Thaw Test

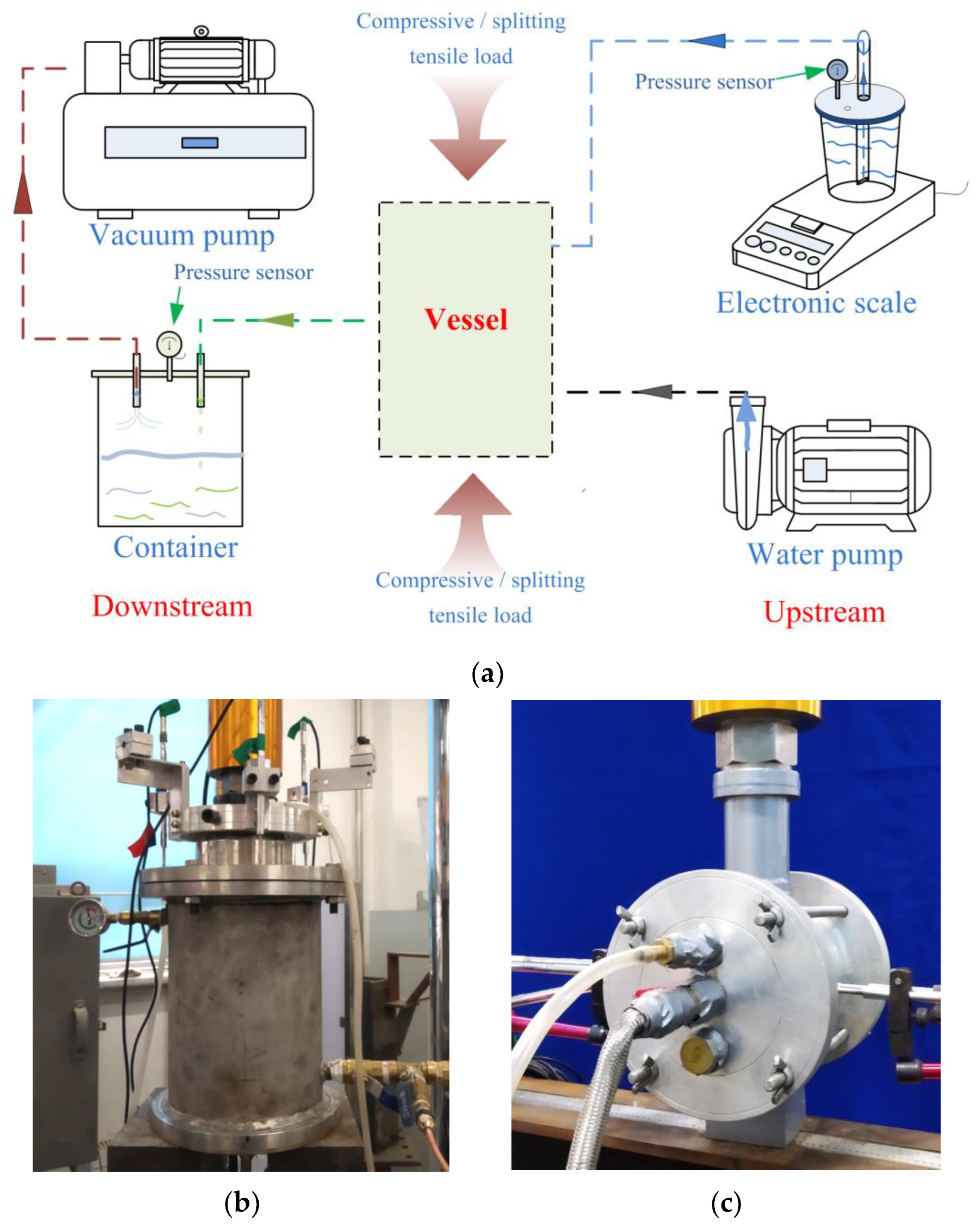

2.4. Permeability Test

2.5. Measurement of Volume Change of PFRC under Compressive Load

3. Results and Discussion

3.1. Test Results of Workability and Compressive Strength

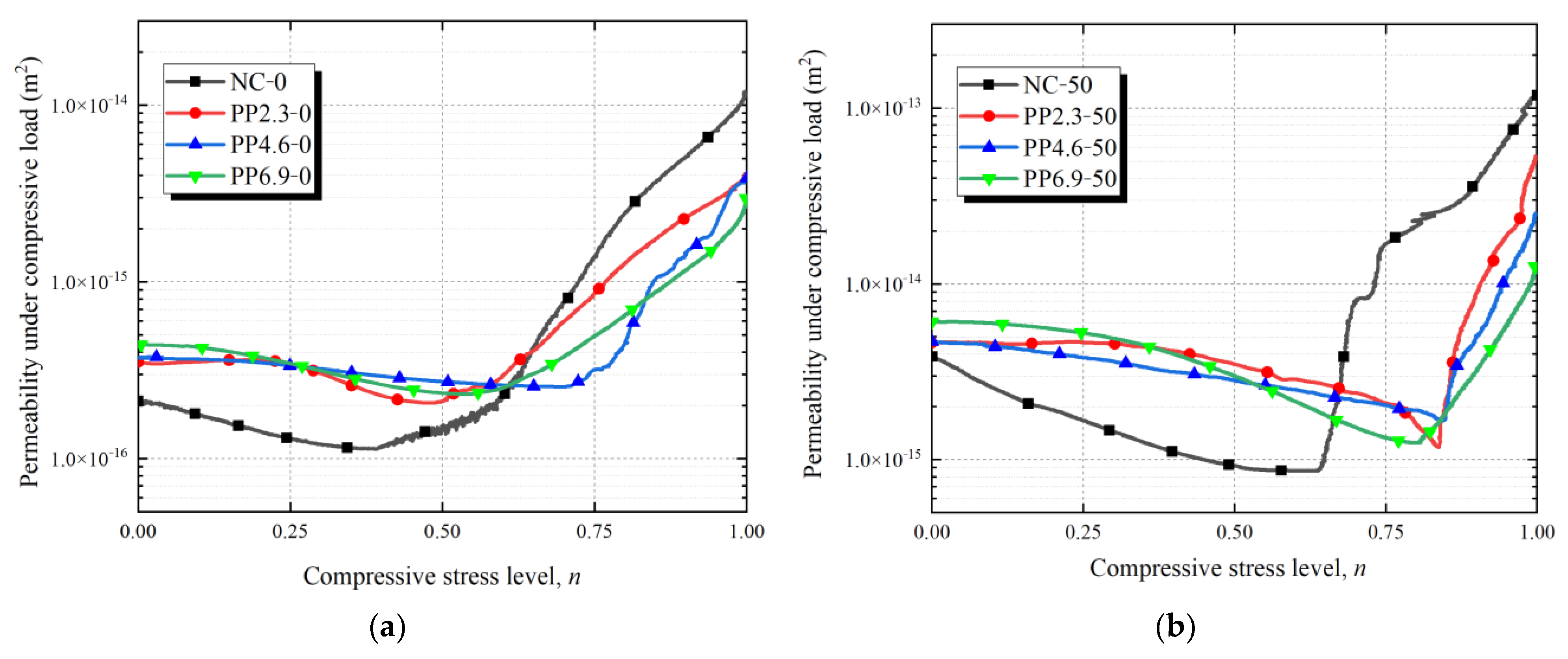

3.2. Concrete Permeability under Compressive Load

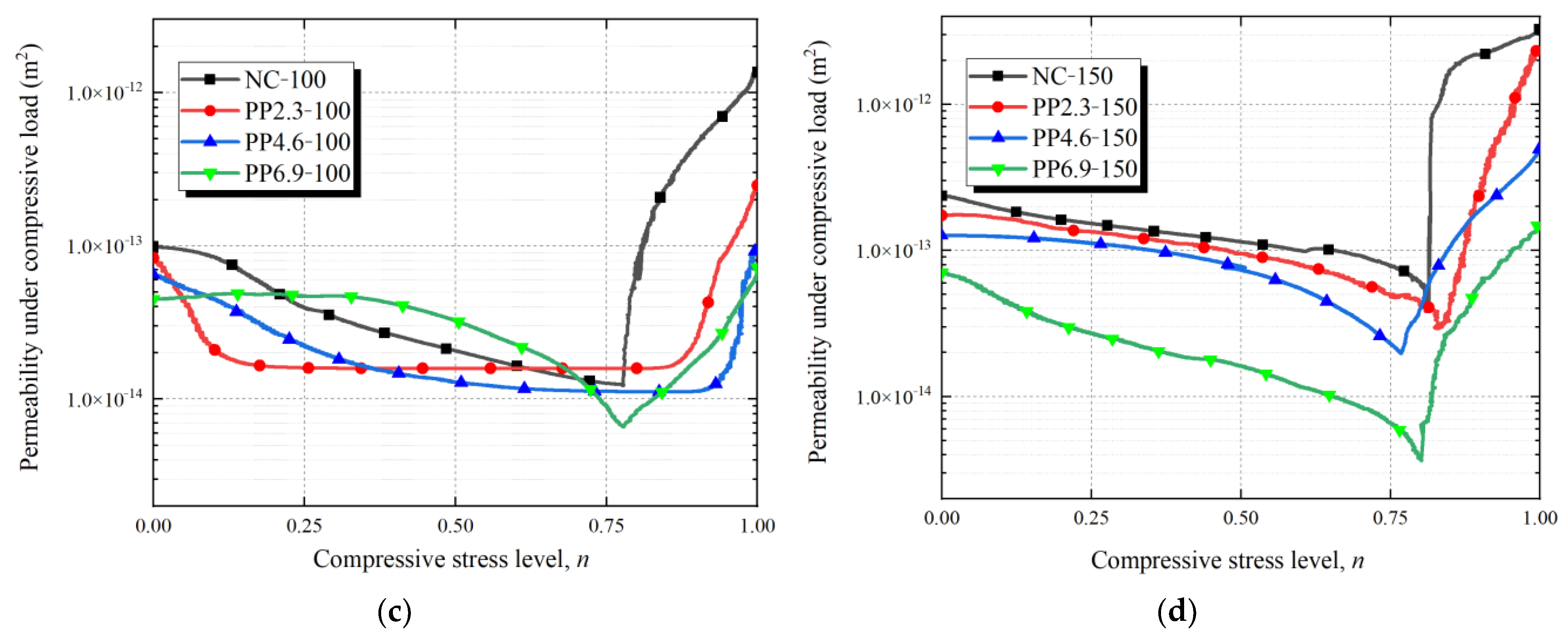

3.3. Volume Change of PFRC under Compressive Load

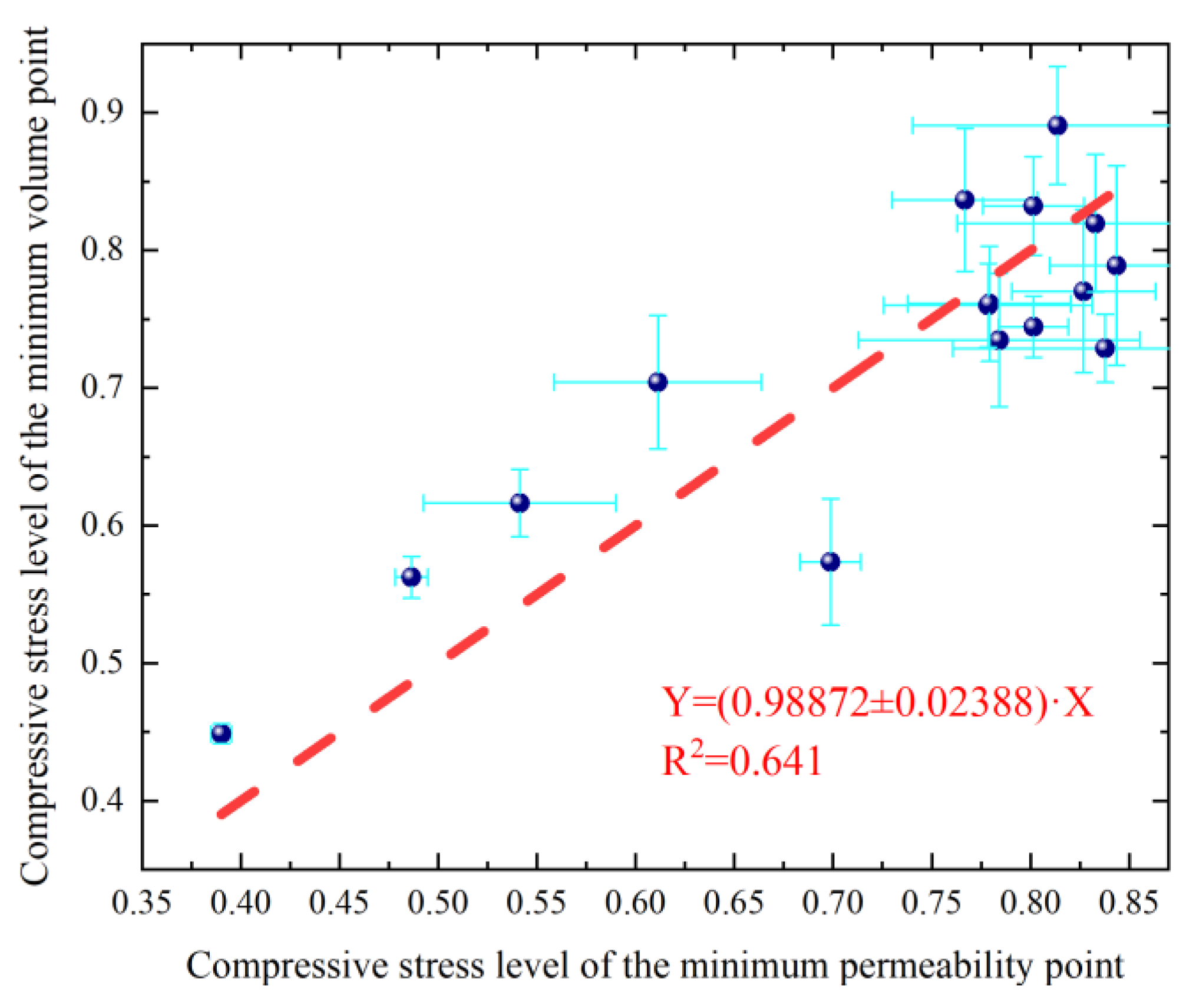

3.4. Relationship of Compressive Stress Levels at the Minimum Permeability and the Minimum Volume Points of PFRC

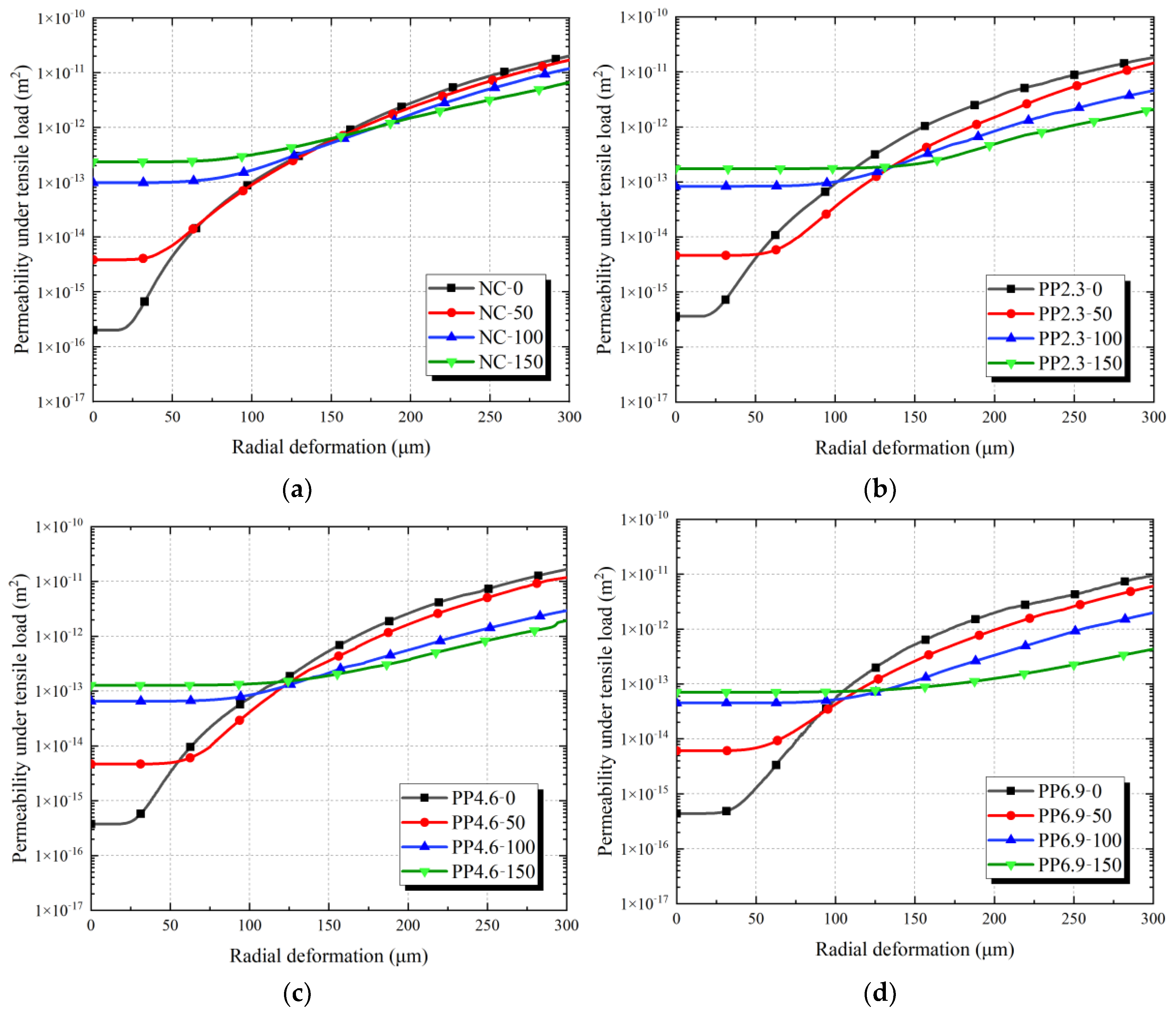

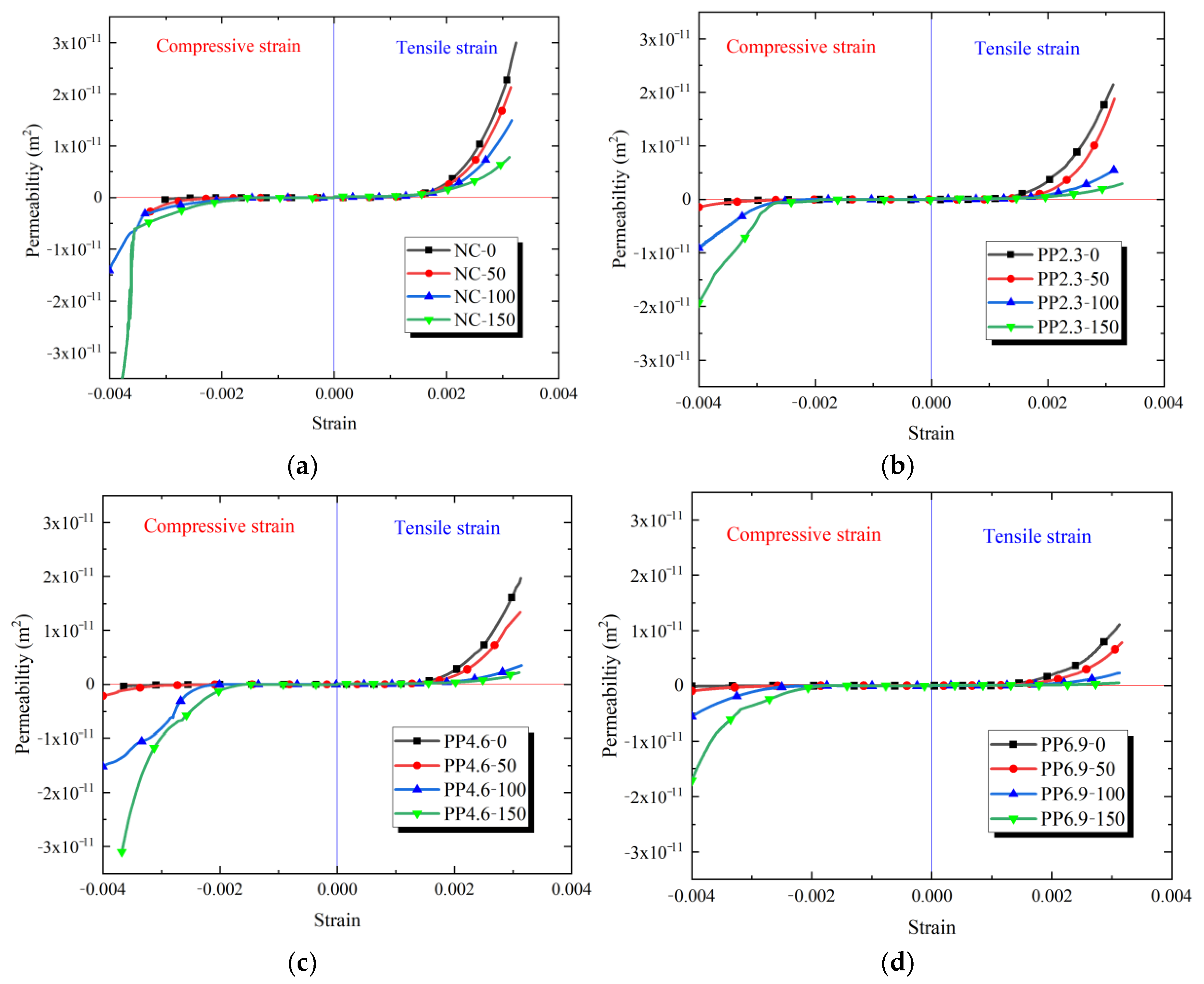

3.5. Permeability of Concrete under Tensile Load and Strain-Permeability Curve under Loading

- (i)

- The concrete permeability of PFRC increased significantly with the increase in both compressive and tensile strains.

- (ii)

- For the specimens subjected to the same number of freeze-thaw cycles, the permeability of PFRC decreased gradually as the PF content increased.

- (iii)

- Under tensile load, as the freeze-thaw cycles increased, the permeability of PFRC decreased gradually. Conversely, as the freeze-thaw cycles increased, the permeability of PFRC increased gradually under compressive load. Under compressive and tensile loads, the permeability trends of PFRC were diametrically opposed.

4. Conclusions

- (1)

- The application of PF increases the porosity of the concrete matrix, negatively affecting the impermeability of the undamaged concrete matrix. However, as the freeze-thaw cycles increase, PF can effectively reduce freeze-thaw damage, resulting in a slower increase in the initial permeability of PFRC compared to NC. The addition of PF demonstrates a positive effect on the impermeability of concrete subjected to freeze-thaw cycles.

- (2)

- Under compressive load, as the stress level increases, the permeability of polypropylene fiber reinforced concrete (PFRC) initially shows a slow decreasing trend, followed by a significant increase. A permeability threshold is observed and divides the evolution of PFRC permeability into two stages. The compressive stress levels at the points of minimum permeability and minimum volume for PFRC exhibit a linear correlation, with the fitted proportional function parameter γ = 0.98872 ± 0.023. This permeability trend is related to the volume changes of the specimens under compressive load. For concrete without freeze-thaw damage, the incorporation of PF enables the concrete to maintain lower permeability over a wider range of compressive stress levels. As the freeze-thaw cycles increase, the threshold stress levels for permeability in both NC and PFRC increase and tend to become similar, extending the range of compressive stress levels that maintain low permeability.

- (3)

- Under tensile load, the radial deformation-permeability curves of PFRC exhibit two stages. In stage I, the permeability of PFRC evolves with increasing radial deformation, with the concrete matrix being the primary water pathway. This results in a relatively small increase in permeability. In stage II, as the radial deformation increases, the crack width in the concrete gradually enlarges, leading to a significant increase in the permeability of PFRC. The addition of PF and the occurrence of freeze-thaw cycles both reduce the permeability of concrete in stage II of the radial deformation-permeability curves under tensile load.

- (4)

- The relationship between strain and permeability of PFRC under both compressive and tensile loads is determined, and it comprises two stages. In stage I, when compressive and tensile strains are low, the permeability of PFRC does not change significantly. The permeability of PFRC gradually increases with increasing tensile strain, while it gradually decreases with increasing compressive strain. Thus, in stage I, the permeability trends of PFRC under compressive and tensile loads are opposite as the strain increases. In stage II, when tensile and compressive strains are high, the permeability of PFRC increases significantly. Under tensile load, the permeability of PFRC decreases with the increasing in freeze-thaw cycles, while under compressive load, the permeability gradually increases with an increasing of freeze-thaw cycles. In stage II, the permeability trends of PFRC under compressive and tensile loads are completely opposite as the freeze-thaw cycles increase. The promotion in concrete impermeability due to the polypropylene fiber subjected to tensile load was larger than that subjected to compressive load. In future research, the relationship between strain and permeability of PFRC can be integrated with its constitutive relationship between stress and strain to provide a reference for the application of PF in the waterproofing of concrete structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- El Ouni, M.-H.; Syed-Haroon-Ali, S.; Asif, A. Mechanical performance, water and chloride permeability of hybrid steel-polypropylene fiber-reinforced recycled aggregate concrete. Case Stud. Constr. Mater. 2022, 16, e831. [Google Scholar] [CrossRef]

- Blazy, J.; Blazy, R. Polypropylene fiber reinforced concrete and its application in creating architectural forms of public spaces. Case Stud. Constr. Mater. 2021, 14, e549. [Google Scholar] [CrossRef]

- Hosseinzadeh, H.; Salehi, A.-M.; Mehraein, M. The effects of steel, polypropylene, and high-performance macro polypropylene fibers on mechanical properties and durability of high-strength concrete. Constr. Build. Mater. 2023, 386, 131589. [Google Scholar] [CrossRef]

- Haq, I.-U.; Elahi, A.; Nawaz, A. Mechanical and durability performance of concrete mixtures incorporating bentonite, silica fume, and polypropylene fibers. Constr. Build. Mater. 2022, 345, 128223. [Google Scholar] [CrossRef]

- Xu, F.; Li, T.; Li, C. Compressive behavior, microstructural properties, and freeze–thaw behavior of tailing recycled aggregate concrete with waste polypropylene fiber addition. Materials 2021, 14, 6712. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Liu, S. Macro polypropylene fiber influences on crack geometry and water permeability of concrete. Constr. Build. Mater. 2020, 231, 117128. [Google Scholar] [CrossRef]

- Ahmed, T.-W.; Mohammed, A.-A.; Zidan, R.-S. Properties of high strength polypropylene fiber concrete containing recycled aggregate. Constr. Build. Mater. 2020, 241, 118010. [Google Scholar] [CrossRef]

- Zhou, W.; Mo, J.; Zeng, L. Fracture behavior of polypropylene fiber reinforced concrete modified by rubber powder exposed to elevated temperatures. Constr. Build. Mater. 2022, 346, 128439. [Google Scholar] [CrossRef]

- Abed, M.-A.; Fořt, J.; Naoulo, A. Influence of polypropylene and steel fibers on the performance and crack repair of self-compacting concrete. Materials 2021, 14, 5506. [Google Scholar] [CrossRef]

- Ghone, M.-O.; Long, G.; Yang, K. Toughness improvement of low strength ceramsite lightweight concrete by polypropylene fiber and recycled rubber particle. Constr. Build. Mater. 2024, 422, 135716. [Google Scholar] [CrossRef]

- Zhu, Y.; Jia, Y. Mechanical properties and microstructure of glass fiber and polypropylene fiber reinforced concrete: An experimental study. Constr. Build. Mater. 2021, 266, 121048. [Google Scholar]

- GB/T 50082-2009; Standard for Test Method of Long-Term Performance and Durability of Ordinary Concrete. China Architecture & Building Press: Beijing, China, 2010.

- ASTM C1202; Standard Test Method for Electrical Indication of Concrete’s Ability to Resist Chloride Ion Penetration. ASTM International: West Conshohocken, PA, USA, 2012.

- BS EN 12390-8; Testing Hardened Concrete-Part 8. Depth of Penetration of Water Under Pressure. BSI: London, UK, 2009.

- Nilson, A.H.; Darwin, D.; Dolan, C. Design of Concrete Structures; McGraw Hill: New York, NY, USA, 2010. [Google Scholar]

- Fib Model Code for Concrete Structures 2010; Wiley-VCH Verlag GmbH & Co. KGaA: Hoboken, NJ, USA, 2013.

- Chen, W.; Han, Y.; Agostini, F. Permeability of a macro-cracked concrete effect of confining pressure and modelling. Materials 2021, 14, 862. [Google Scholar] [CrossRef] [PubMed]

- Mengel, L.; Krauss, H.-W.; Lowke, D. Water transport through cracks in plain and reinforced concrete–Influencing factors and open questions. Constr. Build. Mater. 2020, 254, 118990. [Google Scholar] [CrossRef]

- Akhavan, A.; Shafaatian, S.-M.-H.; Rajabipour, F. Quantifying the effects of crack width, tortuosity, and roughness on water permeability of cracked mortars. Cem. Concr. Res. 2012, 42, 313–320. [Google Scholar] [CrossRef]

- Padilla, A.; Najvani, M.-A.; Knight, E. Correlating damage and cracking with air (gas) permeability in concrete using the Brazilian tension test. Constr. Build. Mater. 2022, 348, 128616. [Google Scholar] [CrossRef]

- Rastiello, G.; Boulay, C.; Dal Pont, S. Real-time water permeability evolution of a localized crack in concrete under loading. Cem. Concr. Res. 2014, 56, 20–28. [Google Scholar] [CrossRef]

- Choinska, M.; Khelidj, A.; Chatzigeorgiou, G. Effects and interactions of temperature and stress-level related damage on permeability of concrete. Cem. Concr. Res. 2007, 37, 79–88. [Google Scholar] [CrossRef]

- Wang, Q.; Banthia, N.; Sun, W. Water permeability of Eco-Friendly Ductile Cementitious Composites (EDCC) under an applied compressive stress. Cem. Concr. Compos. 2020, 107, 103500. [Google Scholar] [CrossRef]

- Xue, W.; Liu, X.; Jing, W. Experimental study and mechanism analysis of permeability sensitivity of mechanically damaged concrete to confining pressure. Cem. Concr. Res. 2020, 134, 106073. [Google Scholar] [CrossRef]

- Matar, P.; Assaad, J.-J. Concurrent effects of recycled aggregates and polypropylene fibers on workability and key strength properties of self-consolidating concrete. Constr. Build. Mater. 2019, 199, 492–500. [Google Scholar] [CrossRef]

- Das, C.-S.; Dey, T.; Dandapat, R. Performance evaluation of polypropylene fibre reinforced recycled aggregate concrete. Constr. Build. Mater. 2018, 189, 649–659. [Google Scholar] [CrossRef]

- Saje, D.; Bandelj, B.; Šušteršič, J. Shrinkage of polypropylene fiber-reinforced high-performance concrete. J. Mater. Civ. Eng. 2011, 23, 941–952. [Google Scholar] [CrossRef]

- Forsdyke, J.-C.; Zviazhynski, B.; Lees, J.-M. Probabilistic selection and design of concrete using machine learning. Data-Centric Eng. 2023, 4, e9. [Google Scholar] [CrossRef]

- ASTM C666; Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing, American Society for Testing and Materials. ASTM International: West Conshohocken, PA, USA, 2003.

- Pereira, V.-M.; Camarini, G. Air permeability of concrete by Thenoz method. Adv. Mater. Res. 2011, 224, 132–136. [Google Scholar] [CrossRef]

- Kaboudan, A.; Naderi, M.; Afshar, M.-A. The efficiency of Darcy and two-dimensional diffusion flow models to estimate water penetration into concrete. J. Build. Eng. 2021, 34, 102012. [Google Scholar] [CrossRef]

- Choinska, M. Effets de la température, du chargement mécanique et de leurs interactions sur la perméabilité du béton de structure, thèse de doctorat. Ph.D. Thesis, Université de Nantes, Nantes, France, 2006. [Google Scholar]

- ASTM C143; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM C231; Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. Annual Book of ASTM standards. ASTM International: West Conshohocken, PA, USA, 2010.

- Qin, Y.; Duan, M.; Ma, W. Experimental study on the damage permeability of polypropylene fiber-reinforced concrete. Constr. Build. Mater. 2021, 286, 122592. [Google Scholar] [CrossRef]

- Metha, P.K.; Monterio, P.J.M. Concrete: Structure, Properties, and Materials, 4th ed.; McGraw-Hill: New York City, NY, USA, 2013. [Google Scholar]

- Filho, S.-T.-M.; Pieralisi, R.; Lofrano, F.-C. Framework to characterize nonlinear flow through pervious concrete. Cem. Concr. Res. 2022, 151, 106633. [Google Scholar] [CrossRef]

- Zeng, W.; Ding, Y.; Zhang, Y. Effect of steel fiber on the crack permeability evolution and crack surface topography of concrete subjected to freeze-thaw damage. Cem. Concr. Res. 2020, 138, 106230. [Google Scholar] [CrossRef]

- Xue, W.; Peng, X.; Alam, M.-S. Pore structure, mechanical property and permeability of concrete under sulfate attack exposed to freeze–thaw cycles. Arch. Civ. Mech. Eng. 2024, 24, 130. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Yin, Z. CT scanning of internal crack mechanism and strength behavior of cement-fiber-tailings matrix composites. Cem. Concr. Compos. 2021, 116, 103865. [Google Scholar] [CrossRef]

- Hubert, M.; Desmettre, C.; Charron, J.-P. Influence of fiber content and reinforcement ratio on the water permeability of reinforced concrete. Mater. Struct. 2015, 48, 2795–2807. [Google Scholar] [CrossRef]

- Yi, S.-T.; Tae-Yang, H.; Kim, J.-K. The effects of hydraulic pressure and crack width on water permeability of penetration crack-induced concrete. Constr. Build. Mater. 2011, 25, 2576–2583. [Google Scholar] [CrossRef]

- Karahan, O.; Atiş, C.-D. The durability properties of polypropylene fiber reinforced fly ash concrete. Mater. Des. 2011, 32, 1044–1049. [Google Scholar] [CrossRef]

- Meng, C.; Li, W.; Cai, L. Experimental research on durability of high-performance synthetic fibers reinforced concrete: Resistance to sulfate attack and freezing-thawing. Constr. Build. Mater. 2020, 262, 120055. [Google Scholar] [CrossRef]

| Mixture ID | Polypropylene Fiber (kg/m3) | Portland Cement (kg/m3) | Fine Aggregate (kg/m3) | Coarse Aggregate (kg/m3) | Water (kg/m3) | Fly Ash (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|

| NC | -- | 390 | 822 | 848 | 272.5 | 155 | 4.0 |

| PP2.3 | 2.3 (0.25 vol.%) | 390 | 822 | 848 | 272.5 | 155 | 4.0 |

| PP4.6 | 4.6 (0.50 vol.%) | 390 | 822 | 848 | 272.5 | 155 | 4.0 |

| PP6.9 | 6.9 (0.75 vol.%) | 390 | 822 | 848 | 272.5 | 155 | 4.0 |

| Sample | Slump (mm) | Air Content (%) | 28-Day Compressive Strength (MPa) |

|---|---|---|---|

| NC | 195 | 1.9 | 37.3 |

| PP2.3 | 192 | 2.2 | 36.5 |

| PP4.6 | 185 | 2.5 | 35.4 |

| PP6.9 | 170 | 2.7 | 37.5 |

| Sample | Minimum Permeability (m2) | Compressive Stress Level of the Minimum Permeability Point | Permeability of Peak Load (m2) | Sample | Minimum Permeability (m2) | Compressive Stress Level of the Minimum Permeability Point | Permeability of Peak Load (m2) |

|---|---|---|---|---|---|---|---|

| NC-0 | 1.13 × 10−16 (Cv = 5.1%) | 0.390 (Cv = 1.3%) | 1.193 × 10−14 (Cv = 8.6%) | NC-100 | 1.23 × 10−14 (Cv = 8.9%) | 0.779 (Cv = 6.8%) | 1.36 × 10−12 (Cv = 5.3%) |

| PP2.3-0 | 2.07 × 10−16 (Cv = 7.9%) | 0.486 (Cv = 1.7%) | 4.090 × 10−15 (Cv = 6.1%) | PP2.3-100 | 1.59 × 10−14 (Cv = 9.5%) | 0.784 (Cv = 9.1%) | 2.48 × 10−13 (Cv = 4.8%) |

| PP4.6-0 | 2.55 × 10−16 (Cv = 4.4%) | 0.699 (Cv = 2.2%) | 3.860 × 10−15 (Cv = 4.7%) | PP4.6-100 | 1.12 × 10−14 (Cv = 7.5%) | 0.833 (Cv = 8.4%) | 9.23 × 10−14 (Cv = 6.2%) |

| PP6.9-0 | 2.32 × 10−16 (Cv = 9.9%) | 0.541 (Cv = 9.0%) | 2.977 × 10−15 (Cv = 9.3%) | PP6.9-100 | 6.59 × 10−15 (Cv = 8.9%) | 0.779 (Cv = 5.3%) | 6.39 × 10−14 (Cv = 2.7%) |

| NC-50 | 8.65 × 10−16 (Cv = 9.7%) | 0.611 (Cv = 8.6%) | 1.188 × 10−13 (Cv = 7.2%) | NC-150 | 4.43 × 10−14 (Cv = 5%) | 0.814 (Cv = 9.0%) | 3.28 × 10−12 (Cv = 2.9%) |

| PP2.3-50 | 1.18 × 10−15 (Cv = 5.5%) | 0.838 (Cv = 9.2%) | 5.333 × 10−14 (Cv = 1.6%) | PP2.3-150 | 2.92 × 10−14 (Cv = 3.6%) | 0.827 (Cv = 4.4%) | 2.33 × 10−12 (Cv = 2.6%) |

| PP4.6-50 | 1.66 × 10−15 (Cv = 2.3%) | 0.844 (Cv = 4.0%) | 2.517 × 10−14 (Cv = 1.2%) | PP4.6-150 | 1.98 × 10−14 (Cv = 8.5%) | 0.767 (Cv = 4.8%) | 4.93 × 10−13 (Cv = 9.0%) |

| PP6.9-50 | 1.25 × 10−15 (Cv = 6.1%) | 0.802 (Cv = 2.2%) | 1.260 × 10−14 (Cv = 3.0%) | PP6.9-150 | 3.63 × 10−15 (Cv = 9.9%) | 0.801 (Cv = 3.2%) | 1.47 × 10−13 (Cv = 3.2%) |

| Sample | Minimum Volume of Specimen (mm3) | Compressive Stress Level | Sample | Minimum Volume of Specimen (mm3) | Compressive Stress Level |

|---|---|---|---|---|---|

| NC-0 | 1,371,085 (Cv = 7.2%) | 0.449 (Cv = 1.6%) | NC-100 | 1,368,312 (Cv = 1.5%) | 0.760 (Cv = 4.0%) |

| PP2.3-0 | 1,371,894 (Cv = 5.3%) | 0.562 (Cv = 2.7%) | PP2.3-100 | 1,369,571 (Cv = 2.0%) | 0.735 (Cv = 6.6%) |

| PP4.6-0 | 1,370,675 (Cv = 3.4%) | 0.574 (Cv = 8.0%) | PP4.6-100 | 1,368,551 (Cv = 7.2%) | 0.819 (Cv = 6.1%) |

| PP6.9-0 | 1,371,452 (Cv = 1.8%) | 0.616 (Cv = 4.0%) | PP6.9-100 | 1,367,150 (Cv = 5.2%) | 0.761 (Cv = 5.5%) |

| NC-50 | 1,370,018 (Cv = 5.6%) | 0.704 (Cv = 6.9%) | NC-150 | 1,367,169 (Cv = 1.8%) | 0.891 (Cv = 4.8%) |

| PP2.3-50 | 1,370,959 (Cv = 5.0%) | 0.729 (Cv = 3.4%) | PP2.3-150 | 1,368,052 (Cv = 4.6%) | 0.770 (Cv = 9.9%) |

| PP4.6-50 | 1,369,009 (Cv = 4.2%) | 0.789 (Cv = 9.2%) | PP4.6-150 | 1,367,017 (Cv = 4.5%) | 0.837 (Cv = 6.2%) |

| PP6.9-50 | 1,369,187 (Cv = 7.7%) | 0.744 (Cv = 3.0%) | PP6.9-150 | 1,366,805 (Cv = 5.4%) | 0.832 (Cv = 4.3%) |

| Sample | Compressive Stress Level | Sample | Compressive Stress Level | ||

|---|---|---|---|---|---|

| Minimum Permeability Point | Minimum Volume Point | Minimum Permeability Point | Minimum Volume Point | ||

| NC-0 | 0.390 (Cv = 1.3%) | 0.449 (Cv = 1.6%) | NC-100 | 0.779 (Cv = 6.8%) | 0.760 (Cv = 4.0%) |

| PP2.3-0 | 0.486 (Cv = 1.7%) | 0.562 (Cv = 2.7%) | PP2.3-100 | 0.784 (Cv = 9.1%) | 0.735 (Cv = 6.6%) |

| PP4.6-0 | 0.699 (Cv = 2.2%) | 0.574 (Cv = 8.0%) | PP4.6-100 | 0.833 (Cv = 8.4%) | 0.819 (Cv = 6.1%) |

| PP6.9-0 | 0.541 (Cv = 9.0%) | 0.616 (Cv = 4.0%) | PP6.9-100 | 0.779 (Cv = 5.3%) | 0.761 (Cv = 5.5%) |

| NC-50 | 0.611 (Cv = 8.6%) | 0.704 (Cv = 6.9%) | NC-150 | 0.814 (Cv = 9.0%) | 0.891 (Cv = 4.8%) |

| PP2.3-50 | 0.838 (Cv = 9.2%) | 0.729 (Cv = 3.4%) | PP2.3-150 | 0.827 (Cv = 4.4%) | 0.770 (Cv = 9.9%) |

| PP4.6-50 | 0.844 (Cv = 4.0%) | 0.789 (Cv = 9.2%) | PP4.6-150 | 0.767 (Cv = 4.8%) | 0.837 (Cv = 6.2%) |

| PP6.9-50 | 0.802 (Cv = 2.2%) | 0.744 (Cv = 3.0%) | PP6.9-150 | 0.801 (Cv = 3.2%) | 0.832 (Cv = 4.3%) |

| Sample | κT−0 (m2) | κT−200 (m2) | Sample | κT−0 (m2) | κT−200 (m2) |

|---|---|---|---|---|---|

| NC-0 | 2.022 × 10−16 (Cv = 3.1%) | 2.791 × 10−12 (Cv = 3.0%) | NC-100 | 9.880 × 10−14 (Cv = 7.9%) | 1.731 × 10−12 (Cv = 1.9%) |

| PP2.3-0 | 3.656 × 10−16 (Cv = 6.1%) | 3.386 × 10−12 (Cv = 9.5%) | PP2.3-100 | 8.371 × 10−14 (Cv = 5.9%) | 8.389 × 10−13 (Cv = 2.4%) |

| PP4.6-0 | 3.760 × 10−16 (Cv = 4.1%) | 2.594 × 10−12 (Cv = 8.7%) | PP4.6-100 | 6.493 × 10−14 (Cv = 9.5%) | 5.576 × 10−13 (Cv = 8.0%) |

| PP6.9-0 | 4.410 × 10−16 (Cv = 8.0%) | 1.980 × 10−12 (Cv = 2.4%) | PP6.9-100 | 4.492 × 10−14 (Cv = 9.3%) | 3.327 × 10−13 (Cv = 3.5%) |

| NC-50 | 3.880 × 10−15 (Cv = 5.9%) | 2.331 × 10−12 (Cv = 2.5%) | NC-150 | 2.371 × 10−13 (Cv = 6.1%) | 1.507 × 10−12 (Cv = 6.7%) |

| PP2.3-50 | 4.640 × 10−15 (Cv = 4.7%) | 1.496 × 10−12 (Cv = 8.0%) | PP2.3-150 | 1.740 × 10−13 (Cv = 5.7%) | 4.881 × 10−13 (Cv = 8.7%) |

| PP4.6-50 | 4.700 × 10−15 (Cv = 7.1%) | 1.639 × 10−12 (Cv = 7.4%) | PP4.6-150 | 1.274 × 10−13 (Cv = 8.1%) | 3.685 × 10−13 (Cv = 3.8%) |

| PP6.9-50 | 6.120 × 10−15 (Cv = 7.6%) | 9.604 × 10−13 (Cv = 1.3%) | PP6.9-150 | 7.050 × 10−14 (Cv = 8.3%) | 1.257 × 10−13 (Cv = 8.1%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zeng, W.; Wang, W.; Wang, Q.; Li, M.; Zhang, L.; Tong, Y. Influence of Polypropylene Fiber on Concrete Permeability under Freeze-Thaw Conditions and Mechanical Loading. Materials 2024, 17, 2945. https://doi.org/10.3390/ma17122945

Zeng W, Wang W, Wang Q, Li M, Zhang L, Tong Y. Influence of Polypropylene Fiber on Concrete Permeability under Freeze-Thaw Conditions and Mechanical Loading. Materials. 2024; 17(12):2945. https://doi.org/10.3390/ma17122945

Chicago/Turabian StyleZeng, Wei, Weiqi Wang, Qiannan Wang, Mengya Li, Lining Zhang, and Yunyun Tong. 2024. "Influence of Polypropylene Fiber on Concrete Permeability under Freeze-Thaw Conditions and Mechanical Loading" Materials 17, no. 12: 2945. https://doi.org/10.3390/ma17122945