The Impact of Abiotic and Biotic Conditions for Degradation Behaviors of Common Biodegradable Products in Stabilized Composts

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of Materials

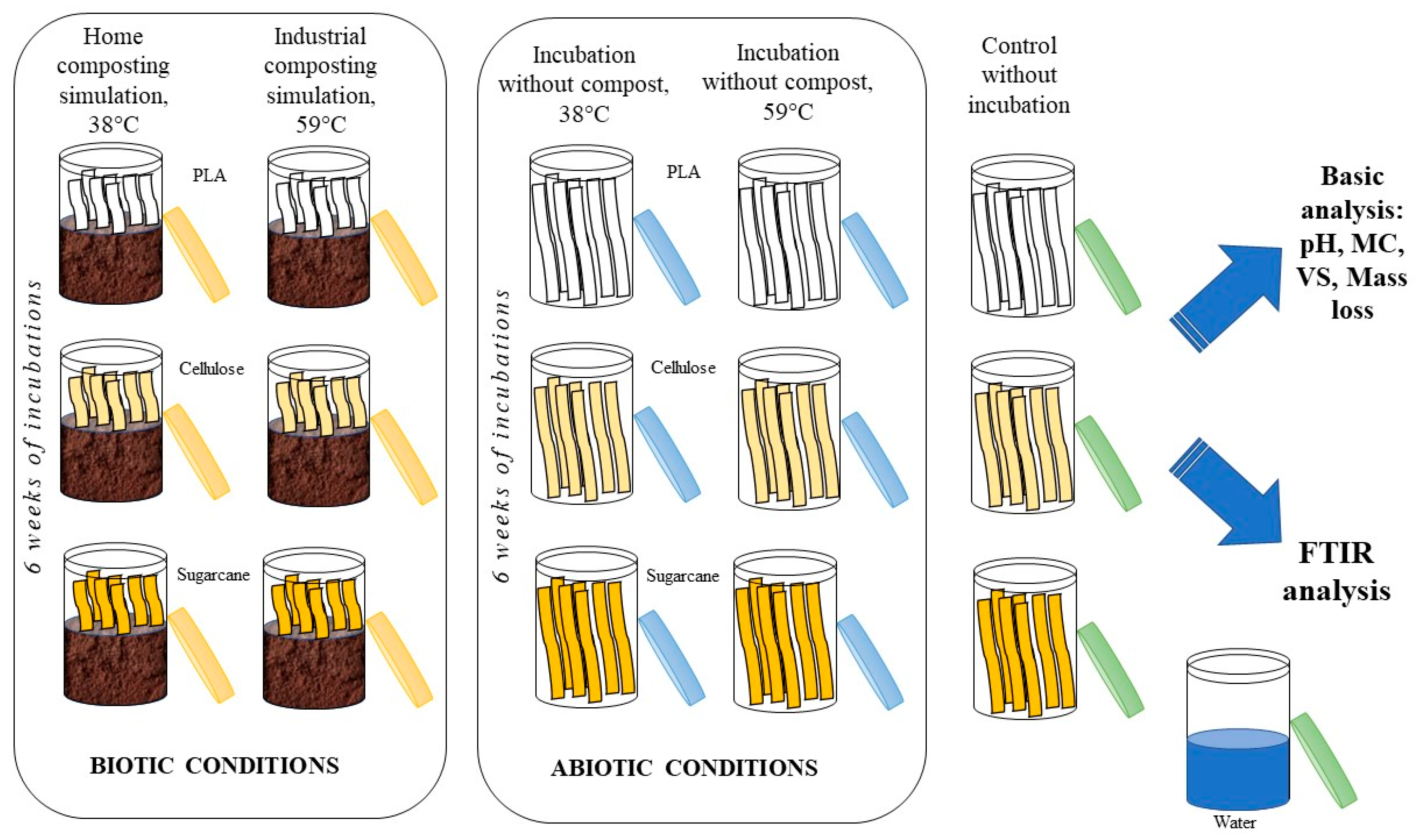

2.2. Experiment Configuration—Biodegradation Tests

2.3. Determination of Physicochemical Properties of Compost Samples

FTIR Spectroscopy

2.4. Statictical Analysis

3. Results and Discussion

3.1. Compost and Biodegradable Products Characterization

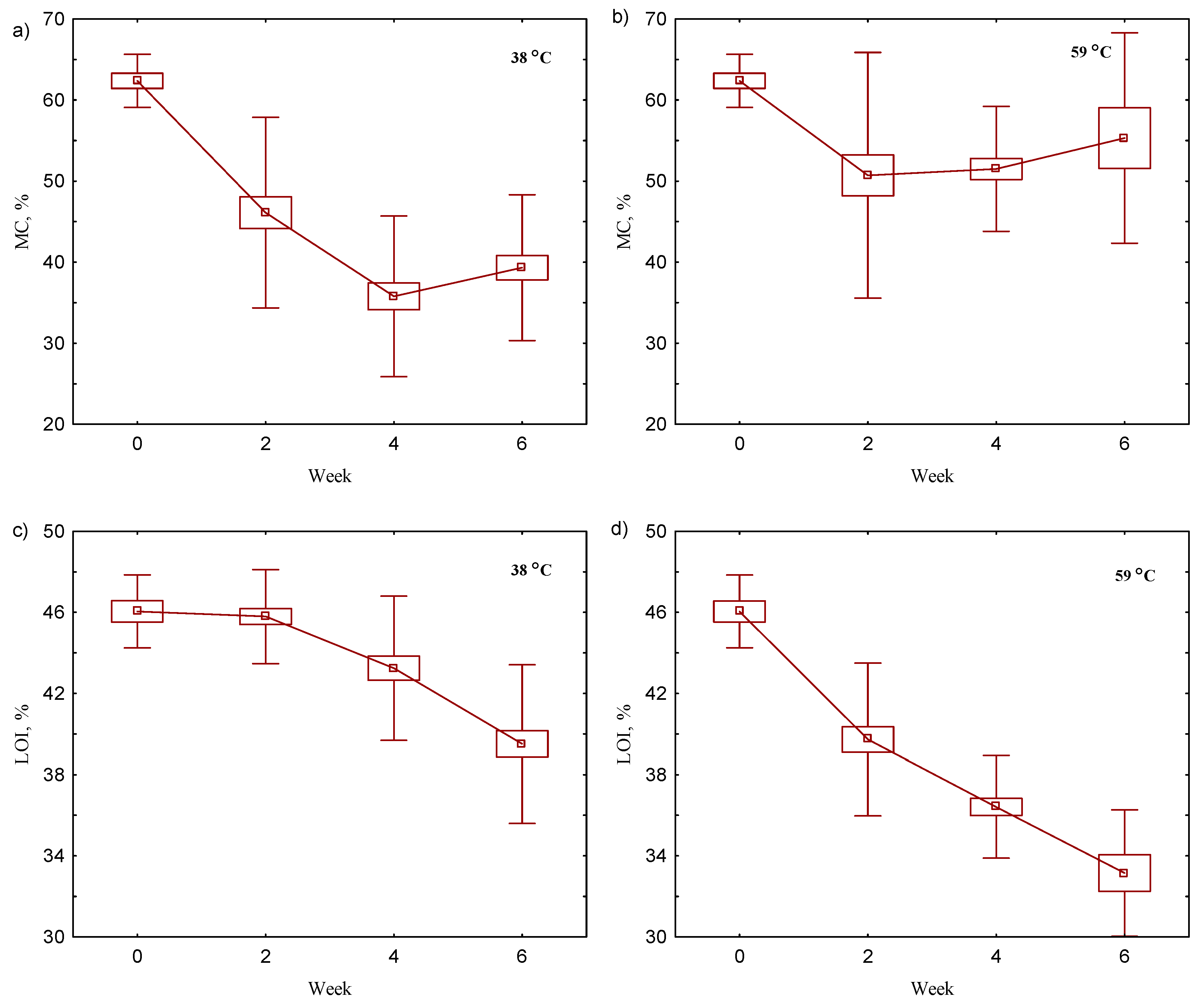

3.2. Changes inPhysicochemical Parameters during Composting

3.3. Degradation Behavior Composting Tests of Biodegradable Products

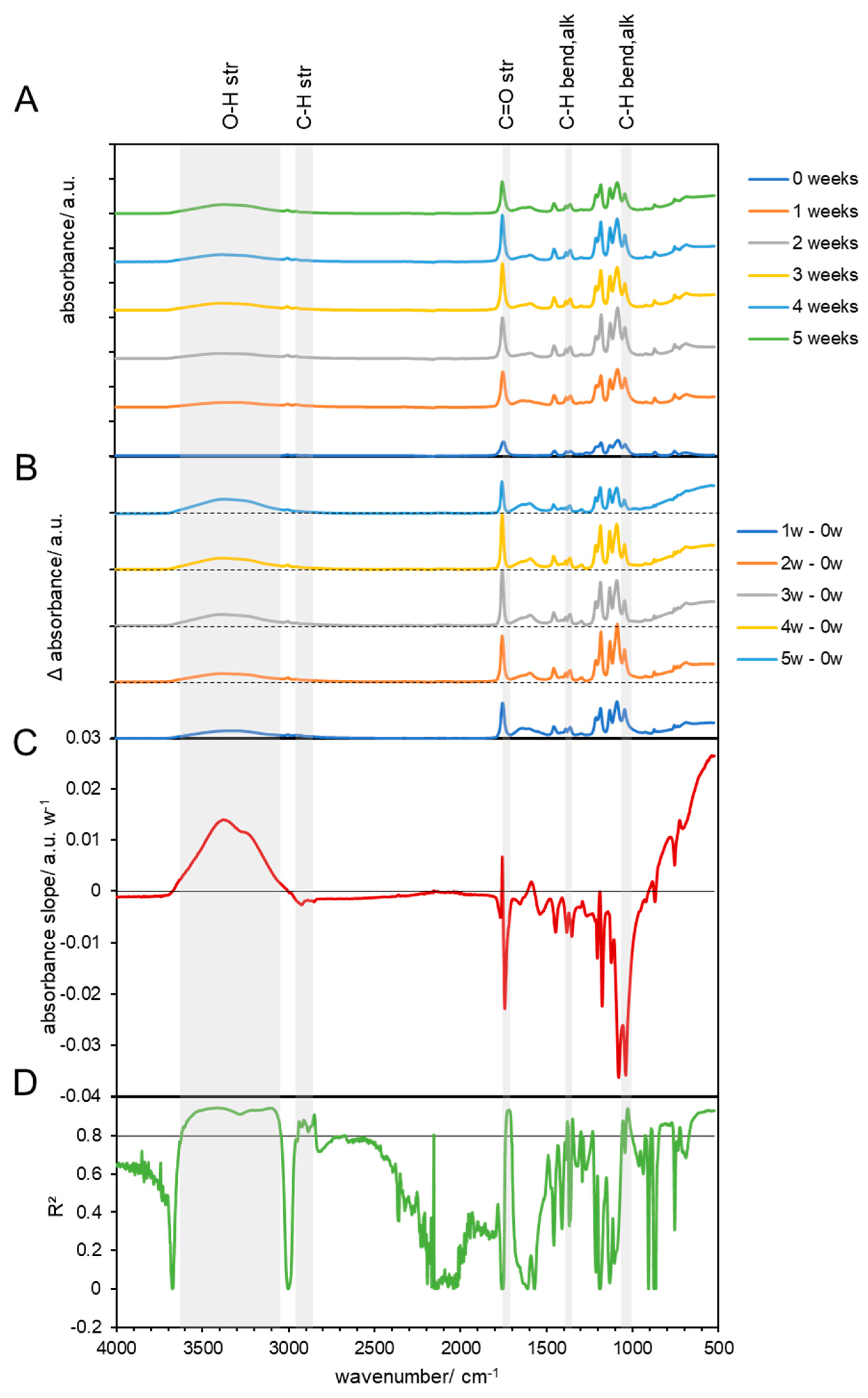

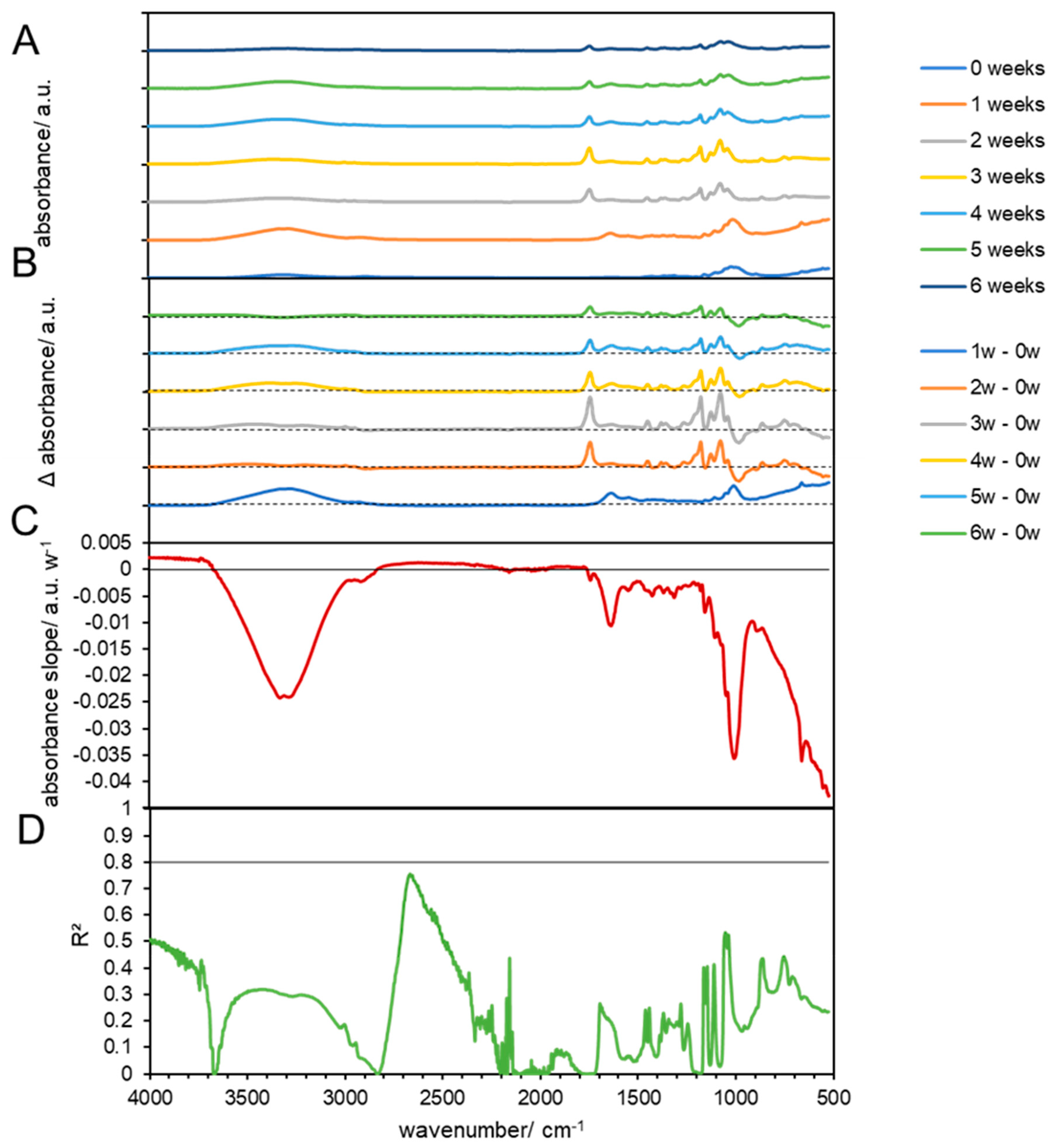

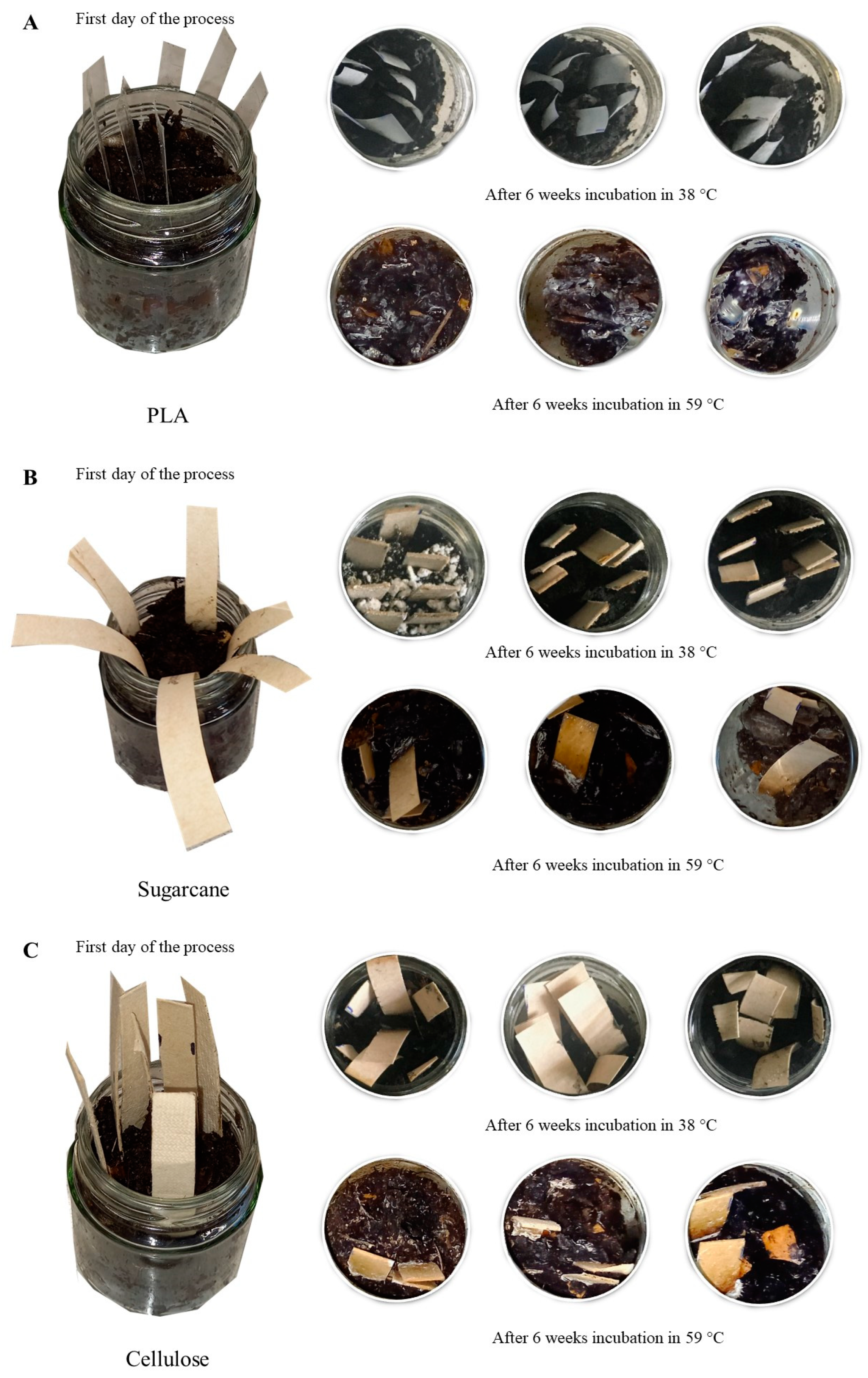

3.3.1. Chemical Changes in Biodegradable Products Made from PLA

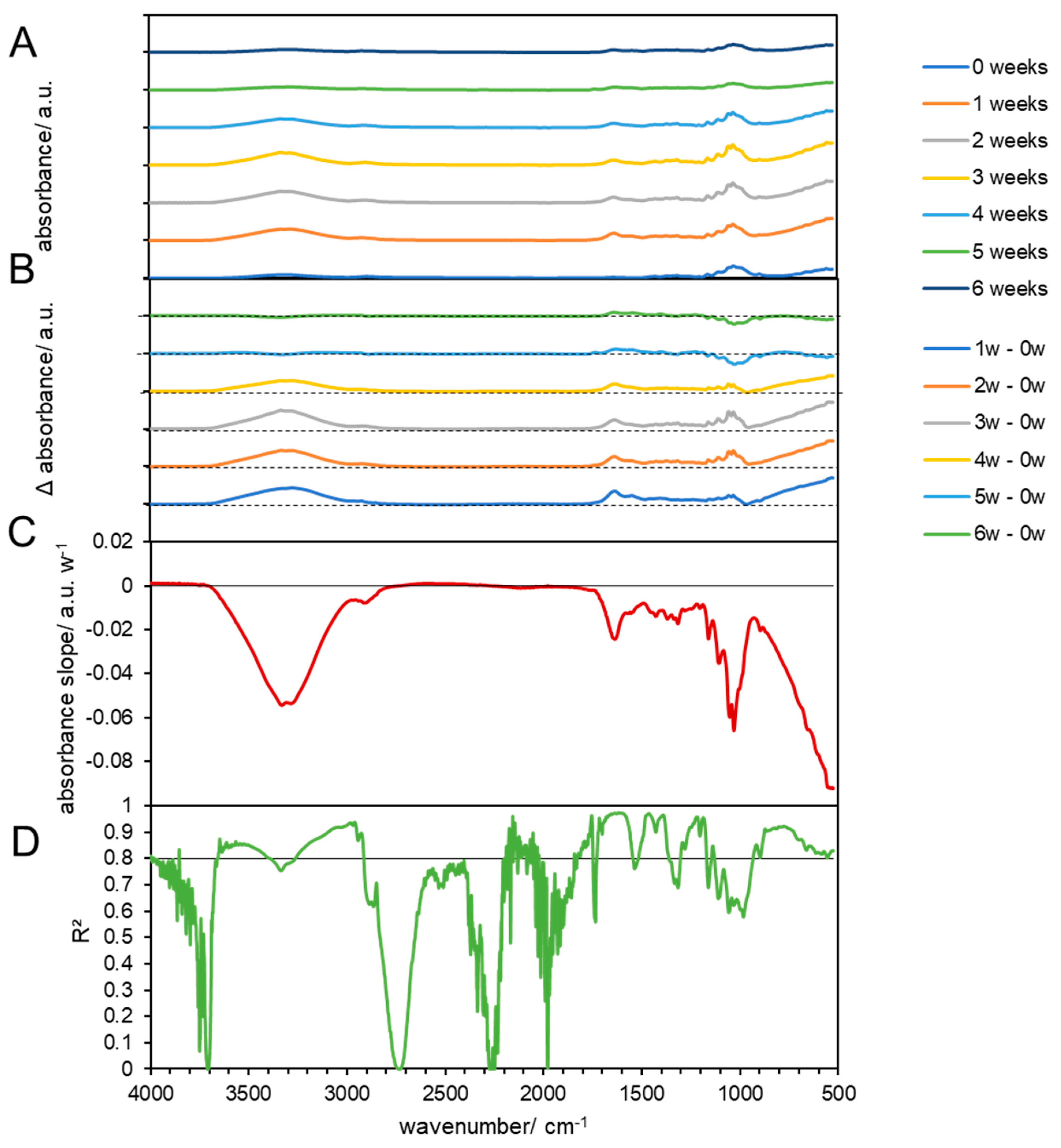

3.3.2. Chemical Changes in Biodegradable Products Made from Cellulose

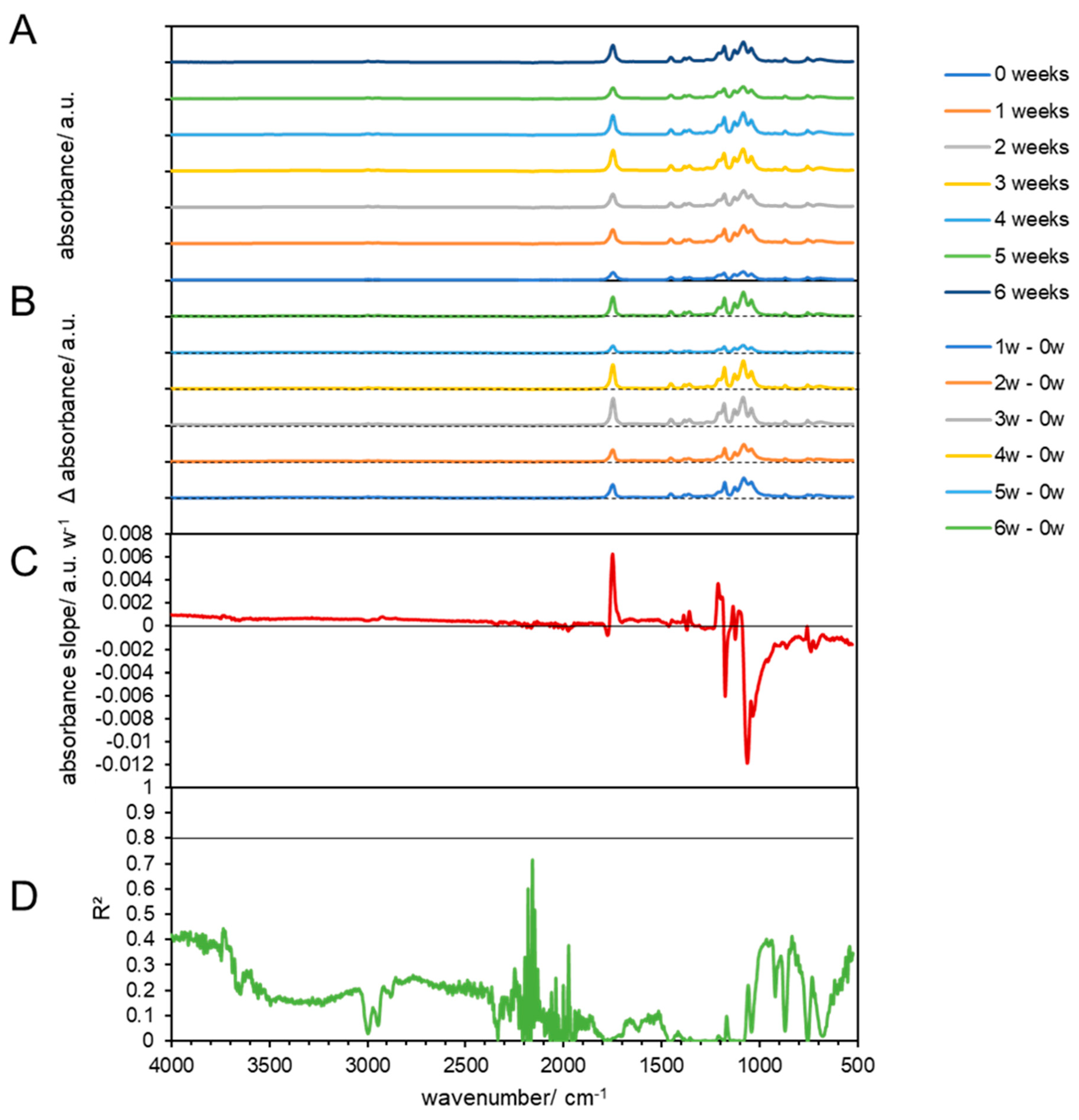

3.3.3. Chemical Changes in Biodegradable Products Made from Sugarcane

3.4. Effect of Abiotic and Biotic Parameters on Disintegrationof Biodegradable Products Made from PLA, Cellulose, and Sugarcane

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rosenboom, J.G.; Langer, R.; Traverso, G. Bioplastics for a Circular Economy. Nat. Rev. Mater. 2022, 7, 117–137. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Awasthi, A.K.; Wei, F.; Tan, Q.; Li, J. Single-Use Plastics: Production, Usage, Disposal, and Adverse Impacts. Sci. Total Environ. 2021, 752, 141772. [Google Scholar] [CrossRef] [PubMed]

- Jariyasakoolroj, P.; Leelaphiwat, P.; Harnkarnsujarit, N. Advances in Research and Development of Bioplastic for Food Packaging. J. Sci. Food Agric. 2020, 100, 5032–5045. [Google Scholar] [CrossRef] [PubMed]

- Woolnough, C.A.; Yee, L.H.; Charlton, T.S.; Foster, L.J.R. A Tuneable Switch for Controlling Environmental Degradation of Bioplastics: Addition of Isothiazolinone to Polyhydroxyalkanoates. PLoS ONE 2013, 8, e75817. [Google Scholar] [CrossRef]

- Wei, R.; Wierckx, N. Editorial: Microbial Degradation of Plastics. Front. Microbiol. 2021, 12, 635621. [Google Scholar] [CrossRef]

- Blinková, M.; Boturová, K. Influence of Bacteria on Degradation of Bioplastics. IOP Conf. Ser. Earth Environ. Sci. 2017, 92, 012004. [Google Scholar] [CrossRef]

- Barrena, R.; Font, X.; Gabarrell, X.; Sánchez, A. Home Composting versus Industrial Composting: Influence of Composting System on Compost Quality with Focus on Compost Stability. Waste Manag. 2014, 34, 1109–1116. [Google Scholar] [CrossRef] [PubMed]

- Markowicz, F.; Szymańska-Pulikowska, A. Analysis of the Possibility of Environmental Pollution by Composted Biodegradable and Oxo-Biodegradable Plastics. Geosciences 2019, 9, 460. [Google Scholar] [CrossRef]

- European Environment Agency Biodegradable and Compostable Plastics—Challenges and Opportunities—European Environment Agency 2020. Available online: https://www.eea.europa.eu/publications/biodegradable-and-compostable-plastics (accessed on 15 June 2024).

- Zafiu, C.; Binner, E.; Hirsch, C.; Vay, B.; Huber-Humer, M. Makro- Und Mikrokunststoffe in Österreichischen Komposten. Österreichische Wasser-und Abfallwirtschaft 2020, 72, 410–420. [Google Scholar] [CrossRef]

- PN-EN 14346:2011; Waste Characteristics. Calculation of Dry Mass on the Basis of Dry Residue or Water Content. Polish Committee for Standardization: Warsaw, Poland, 2013.

- PN-EN 15169:2011; Waste Characteristics. Determination of Organic Matter Content for Waste, Slurry and Sludge. Polish Committee for Standardization: Warsaw, Poland, 2013.

- Świechowski, K.; Rasaq, W.A.; Stegenta-Dąbrowska, S.; Białowiec, A. Characterization of Engineered Biochar: Proximate Analyses, Ultimate Analyses, Physicochemical Analyses, Surface Anal-yses, and Molecular Analyses. In Engineered Biochar: Fundamentals, Preparation, Characterization and Applications; Springer: Singapore, 2022; pp. 127–148. [Google Scholar] [CrossRef]

- Tatàno, F.; Pagliaro, G.; di Giovanni, P.; Floriani, E.; Mangani, F. Biowaste Home Composting: Experimental Process Monitoring and Quality Control. Waste Manag. 2015, 38, 72–85. [Google Scholar] [CrossRef]

- PN-EN ISO 11885:2009; Water Quality: Determination of Selected Elements by Inductively Excited Plasma Optical Emission Spectrometry. Polski Komitet Normalizacji: Warsaw, Poland, 2009.

- Darby, I.; Xu, C.-Y.; Wallace, H.M.; Joseph, S.; Pace, B.; Bai, S.H. Short-term dynamics of carbon and nitrogen using compost, compost-biochar mixture and organo-mineral biochar. Environ. Sci. Pollut. Res. 2016, 23, 11267–11278. [Google Scholar] [CrossRef]

- Azim, K.; Soudi, B.; Boukhari, S.; Perissol, C.; Roussos, S.; Thami Alami, I. Composting Parameters and Compost Quality: A Literature Review. Org. Agric. 2018, 8, 141–158. [Google Scholar] [CrossRef]

- Ravindran, B.; Awasthi, M.K.; Karmegam, N.; Chang, S.W.; Chaudhary, D.K.; Selvam, A.; Nguyen, D.D.; Rahman Milon, A.; Munuswamy-Ramanujam, G. Co-Composting of Food Waste and Swine Manure Augmenting Biochar and Salts: Nutrient Dynamics, Gaseous Emissions and Microbial Activity. Bioresour. Technol. 2022, 344, 126300. [Google Scholar] [CrossRef] [PubMed]

- Prescott, C.E. Litter Decomposition: What Controls It and How Can We Alter It to Sequester More Carbon in Forest Soils? Biogeochemistry 2010, 101, 133–149. [Google Scholar] [CrossRef]

- Castro-Aguirre, E.; Auras, R.; Selke, S.; Rubino, M.; Marsh, T. Enhancing the Biodegradation Rate of Poly(Lactic Acid) Films and PLA Bio-Nanocomposites in Simulated Composting through Bioaugmentation. Polym. Degrad. Stab. 2018, 154, 46–54. [Google Scholar] [CrossRef]

- Torrijos, V.; Calvo Dopico, D.; Soto, M. Integration of Food Waste Composting and Vegetable Gardens in a University Campus. J. Clean. Prod. 2021, 315, 128175. [Google Scholar] [CrossRef]

- Cayuela, M.L.; Sanchez-Monedero, M.A.; Roig, A.; Sinicco, T.; Mondini, C.; Luz Cayuela, M.; Angel Sanchez-Monedero, M.; Roig, A.; Sinicco, T.; Mondini, C. Biochemical Changes and GHG Emissions during Composting of Lignocellulosic Residues with Different N-Rich by-Products. Chemosphere 2012, 88, 196–203. [Google Scholar] [CrossRef] [PubMed]

- Yousefi, J.; Younesi, H.; Ghasempoury, S.M. Co-Composting of Municipal Solid Waste with Sawdust: Improving Compost Quality. Clean Soil Air Water 2013, 41, 185–194. [Google Scholar] [CrossRef]

- Meng, X.; Yan, J.; Zuo, B.; Wang, Y.; Yuan, X.; Cui, Z. Full-Scale of Composting Process of Biogas Residues from Corn Stover Anaerobic Digestion: Physical-Chemical, Biology Parameters and Maturity Indexes during Whole Process. Bioresour. Technol. 2020, 302, 122742. [Google Scholar] [CrossRef] [PubMed]

- Dz.U. 2016 poz. 1395 Rozporządzenie Ministra Środowiska z Dnia 1 Września 2016 r. w Sprawie Sposobu Prowadzenia Oceny Zanieczyszczenia Powierzchni Ziemi 2016. Available online: https://isap.sejm.gov.pl/isap.nsf/DocDetails.xsp?id=wdu20160001395 (accessed on 15 June 2024).

- Adamcová, D.; Zloch, J.; Brtnický, M.; Vaverková, M.D. Biodegradation/Disintegration of Selected Range of Polymers: Impact on the Compost Quality. J. Polym. Environ. 2019, 27, 892–899. [Google Scholar] [CrossRef]

- Ponsa, S.; Pagans, E.; Sanchez, A. Composting of Dewatered Wastewater Sludge with Various Ratios of Pruning Waste Used as a Bulking Agent and Monitored by Respirometer. Biosyst. Eng. 2009, 102, 433–443. [Google Scholar] [CrossRef]

- Seng, B.; Kaneko, H.; Hirayama, K.; Katayama-Hirayama, K. Development of Water Movement Model as a Module of Moisture Content Simulation in Static Pile Composting. Environ. Technol. 2012, 33, 1685–1694. [Google Scholar] [CrossRef] [PubMed]

- Bandini, F.; Taskin, E.; Vaccari, F.; Soldano, M.; Piccinini, S.; Frache, A.; Remelli, S.; Menta, C.; Sandro Cocconcelli, P.; Puglisi, E. Anaerobic Digestion and Aerobic Composting of Rigid Biopolymers in Bio-Waste Treatment: Fate and Effects on the Final Compost. Bioresour. Technol. 2022, 351, 126934. [Google Scholar] [CrossRef] [PubMed]

- Gadaleta, G.; De Gisi, S.; Chong, Z.K.; Heerenklage, J.; Notarnicola, M.; Kuchta, K.; Cafiero, L.; Oliviero, M.; Sorrentino, A.; Picuno, C. Degradation of Thermoplastic Cellulose Acetate-Based Bioplastics by Full-Scale Experimentation of Industrial Anaerobic Digestion and Composting. Chem. Eng. J. 2023, 462, 142301. [Google Scholar] [CrossRef]

- Sikorska, W.; Musioł, M.; Zawidlak-Wȩgrzyńska, B.; Rydz, J. End-of-Life Options for (Bio)Degradable Polymers in the Circular Economy. Adv. Polym. Technol. 2021, 2021, 6695140. [Google Scholar] [CrossRef]

- Cucina, M.; De Nisi, P.; Trombino, L.; Tambone, F.; Adani, F. Degradation of Bioplastics in Organic Waste by Mesophilic Anaerobic Digestion, Composting and Soil Incubation. Waste Manag. 2021, 134, 67–77. [Google Scholar] [CrossRef] [PubMed]

- Gastaldi, E.; Buendia, F.; Greuet, P.; Benbrahim Bouchou, Z.; Benihya, A.; Cesar, G.; Domenek, S. Degradation and Environmental Assessment of Compostable Packaging Mixed with Biowaste in Full-Scale Industrial Composting Conditions. Bioresour. Technol. 2024, 400, 130670. [Google Scholar] [CrossRef] [PubMed]

- Spaccini, R.; Todisco, D.; Drosos, M.; Nebbioso, A.; Piccolo, A. Decomposition of Bio-Degradable Plastic Polymer in a Real on-Farm Composting Process. Chem. Biol. Technol. Agric. 2016, 3, 4. [Google Scholar] [CrossRef]

- Accinelli, C.; Saccà, M.L.; Mencarelli, M.; Vicari, A. Deterioration of Bioplastic Carrier Bags in the Environment and Assessment of a New Recycling Alternative. Chemosphere 2012, 89, 136–143. [Google Scholar] [CrossRef]

- Janczak, K.; Hrynkiewicz, K.; Znajewska, Z.; Dąbrowska, G. Use of Rhizosphere Microorganisms in the Biodegradation of PLA and PET Polymers in Compost Soil. Int. Biodeterior. Biodegrad. 2018, 130, 65–75. [Google Scholar] [CrossRef]

- Ruggero, F.; Gori, R.; Lubello, C. Methodologies to Assess Biodegradation of Bioplastics during Aerobic Composting and Anaerobic Digestion: A Review. Waste Manag. Res. 2019, 37, 959–975. [Google Scholar] [CrossRef] [PubMed]

- Wang, F.; Nan, Z.; Sun, X.; Liu, C.; Zhuang, Y.; Zan, J.; Dai, C.; Liu, Y. Characterization of Degradation Behaviors of PLA Biodegradable Plastics by Infrared Spectroscopy. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2022, 279, 121376. [Google Scholar] [CrossRef] [PubMed]

- Rudnik, E. Compostable Polymer Materials; Elsevier Science: Amsterdam, The Netherlands, 2008; Volume 211. [Google Scholar] [CrossRef]

- Zarei, M.; Hosseini Nikoo, M.M.; Alizadeh, R.; Askarinya, A. Synergistic Effect of CaCO3 Addition and In-Process Cold Atmospheric Plasma Treatment on the Surface Evolution, Mechanical Properties, and In-Vitro Degradation Behavior of FDM-Printed PLA Scaffolds. J. Mech. Behav. Biomed. Mater. 2024, 149, 106239. [Google Scholar] [CrossRef] [PubMed]

- de Castro, L.L.R.L.; Silva, L.G.L.; Abreu, I.R.; Braz, C.J.F.; Rodrigues, S.C.S.; Moreira-Araújo, R.S.d.R.; Folkersma, R.; de Carvalho, L.H.; Barbosa, R.; Alves, T.S. Biodegradable PBAT/PLA Blend Films Incorporated with Turmeric and Cinnamomum Powder: A Potential Alternative for Active Food Packaging. Food Chem. 2024, 439, 138146. [Google Scholar] [CrossRef] [PubMed]

- Lv, S.; Liu, X.; Gu, J.; Jiang, Y.; Tan, H.; Zhang, Y. Effect of Glycerol Introduced into PLA Based Composites on the UV Weathering Behavior. Constr. Build. Mater. 2017, 144, 525–531. [Google Scholar] [CrossRef]

- Maniglia, B.C.; Tapia-Blácido, D.R. Structural Modification of Fiber and Starch in Turmeric Residue by Chemical and Mechanical Treatment for Production of Biodegradable Films. Int. J. Biol. Macromol. 2019, 126, 507–516. [Google Scholar] [CrossRef] [PubMed]

- Brodhagen, M.; Peyron, M.; Miles, C.; Inglis, D.A. Biodegradable Plastic Agricultural Mulches and Key Features of Microbial Degradation. Appl. Microbiol. Biotechnol. 2015, 99, 1039–1056. [Google Scholar] [CrossRef] [PubMed]

- Tanjung, F.A.; Arifin, Y.; Husseinsyah, S. Enzymatic Degradation of Coconut Shell Powder–Reinforced Polylactic Acid Biocomposites. J. Thermoplast. Compos. Mater. 2018, 33, 800–816. [Google Scholar] [CrossRef]

- Doi, Y.; Steinbüchel, A. Biopolymers: Biology, Chemistry, Biotechnology, Applications Polyesters III—Applications and Commercial Products; 2002; 410. Available online: https://www.amazon.com/Polyesters-III-Applications-Commercial-Biopolymers/dp/3527302255 (accessed on 15 June 2024).

- Sedničková, M.; Pekařová, S.; Kucharczyk, P.; Bočkaj, J.; Janigová, I.; Kleinová, A.; Jochec-Mošková, D.; Omaníková, L.; Perďochová, D.; Koutný, M.; et al. Changes of Physical Properties of PLA-Based Blends during Early Stage of Biodegradation in Compost. Int. J. Biol. Macromol. 2018, 113, 434–442. [Google Scholar] [CrossRef] [PubMed]

- Solano, G.; Rojas-Gätjens, D.; Rojas-Jimenez, K.; Chavarría, M.; Romero, R.M. Biodegradation of Plastics at Home Composting Conditions. Environ. Chall. 2022, 7, 100500. [Google Scholar] [CrossRef]

- Badia, J.D.; Strömberg, E.; Kittikorn, T.; Ek, M.; Karlsson, S.; Ribes-Greus, A. Relevant Factors for the Eco-Design of Polylactide/Sisal Biocomposites to Control Biodegradation in Soil in an End-of-Life Scenario. Polym. Degrad. Stab. 2017, 143, 9–19. [Google Scholar] [CrossRef]

- Tomita, K.; Tsuji, H.; Nakajima, T.; Kikuchi, Y.; Ikarashi, K.; Ikeda, N. Degradation of Poly(d-Lactic Acid) by a Thermophile. Polym. Degrad. Stab. 2003, 81, 167–171. [Google Scholar] [CrossRef]

- Kim, M.N.; Park, S.T. Degradation of Poly(L-Lactide) by a Mesophilic Bacterium. J. Appl. Polym. Sci. 2010, 117, 67–74. [Google Scholar] [CrossRef]

- Caputo, D.; Fusco, C.; Nacci, A.; Palazzo, G.; Murgia, S.; D’Accolti, L.; Gentile, L. A Selective Cellulose/Hemicellulose Green Solvents Extraction from Buckwheat Chaff. Carbohydr. Polym. Technol. Appl. 2021, 2, 100094. [Google Scholar] [CrossRef]

- Gómez, E.F.; Michel, F.C. Biodegradability of Conventional and Bio-Based Plastics and Natural Fiber Composites during Composting, Anaerobic Digestion and Long-Term Soil Incubation. Polym. Degrad. Stab. 2013, 98, 2583–2591. [Google Scholar] [CrossRef]

- Pérez, J.; Muñoz-Dorado, J.; de La Rubia, T.; Martínez, J. Biodegradation and Biological Treatments of Cellulose, Hemicellulose and Lignin: An Overview. Int. Microbiol. 2002, 5, 53–63. [Google Scholar] [CrossRef]

- Polman, E.M.N.; Gruter, G.J.M.; Parsons, J.R.; Tietema, A. Comparison of the Aerobic Biodegradation of Biopolymers and the Corresponding Bioplastics: A Review. Sci. Total Environ. 2021, 753, 141953. [Google Scholar] [CrossRef] [PubMed]

- Navarro, D.; Rosso, M.N.; Haon, M.; Olivé, C.; Bonnin, E.; Lesage-Meessen, L.; Chevret, D.; Coutinho, P.M.; Henrissat, B.; Berrin, J.G. Fast Solubilization of Recalcitrant Cellulosic Biomass by the Basidiomycete Fungus Laetisaria Arvalis Involves Successive Secretion of Oxidative and Hydrolytic Enzymes. Biotechnol. Biofuels 2014, 7, 143. [Google Scholar] [CrossRef]

- Littlejohn, D.; Pethrick, R.A.; Quye, A.; Ballany, J.M. Investigation of the Degradation of Cellulose Acetate Museum Artefacts. Polym. Degrad. Stab. 2013, 98, 416–424. [Google Scholar] [CrossRef]

- Cheng, S.; Huang, A.; Wang, S.; Zhang, Q. Effect of Different Heat Treatment Temperatures on the Chemical Composition and Structure of Chinese Fir Wood. Bioresources 2016, 11, 4006–4016. [Google Scholar] [CrossRef]

- Kumar, A.; Negi, Y.S.; Choudhary, V.; Bhardwaj, N.K. Characterization of Cellulose Nanocrystals Produced by Acid-Hydrolysis from Sugarcane Bagasse as Agro-Waste. J. Mater. Phys. Chem. 2014, 2, 1–8. [Google Scholar] [CrossRef]

- Nevoralová, M.; Koutný, M.; Ujčić, A.; Horák, P.; Kredatusová, J.; Šerá, J.; Růžek, L.; Růžková, M.; Krejčíková, S.; Šlouf, M.; et al. Controlled Biodegradability of Functionalized Thermoplastic Starch Based Materials. Polym. Degrad. Stab. 2019, 170, 108995. [Google Scholar] [CrossRef]

- Cucina, M.; de Nisi, P.; Tambone, F.; Adani, F. The Role of Waste Management in Reducing Bioplastics’ Leakage into the Environment: A Review. Bioresour. Technol. 2021, 337, 125459. [Google Scholar] [CrossRef] [PubMed]

- Sikorska, W.; Musiol, M.; Nowak, B.; Pajak, J.; Labuzek, S.; Kowalczuk, M.; Adamus, G. Degradability of Polylactide and Its Blend with Poly[(R,S)-3-Hydroxybutyrate] in Industrial Composting and Compost Extract. Int. Biodeterior. Biodegrad. 2015, 101, 32–41. [Google Scholar] [CrossRef]

- Sintim, H.Y.; Bary, A.I.; Hayes, D.G.; Wadsworth, L.C.; Anunciado, M.B.; English, M.E.; Bandopadhyay, S.; Schaeffer, S.M.; DeBruyn, J.M.; Miles, C.A.; et al. In Situ Degradation of Biodegradable Plastic Mulch Films in Compost and Agricultural Soils. Sci. Total Environ. 2020, 727, 138668. [Google Scholar] [CrossRef] [PubMed]

- Mihai, M.; Legros, N.; Alemdar, A. Formulation-Properties Versatility of Wood Fiber Biocomposites Based on Polylactide and Polylactide/Thermoplastic Starch Blends. Polym. Eng. Sci. 2014, 54, 1325–1340. [Google Scholar] [CrossRef]

- Balaguer, M.P.; Aliaga, C.; Fito, C.; Hortal, M. Compostability Assessment of Nano-Reinforced Poly(Lactic Acid) Films. Waste Manag. 2016, 48, 143–155. [Google Scholar] [CrossRef] [PubMed]

- Kale, G.; Auras, R.; Singh, S.P.; Narayan, R. Biodegradability of Polylactide Bottles in Real and Simulated Composting Conditions. Polym. Test. 2007, 26, 1049–1061. [Google Scholar] [CrossRef]

| No | Lining Material | Color | Volume/Size | Weight/g | Wall Thickness/mm |

|---|---|---|---|---|---|

| 1 | PLA | transparent | 200 | 11.6 | 1.0 |

| 2 | Sugarcane | transparent | 200 | 6.0 | 1.2 |

| 3 | Cellulose | brown | 15.5 × 15.5 cm | 14 | 1.3 |

| Samples | MC/% | LOI/% | C/% | N/% | C/N | pH | EC/mS cm−1 | CEC cmol(+)kg−1 | NO3−-N mg kg−1 DM | NH4+-N mg kg−1 DM |

|---|---|---|---|---|---|---|---|---|---|---|

| Compost | 62.4 ± 1.6 | 46.1 ± 0.9 | 9.21 | 0.73 | 14.71 | 8.69 ± 0.4 | 3.79 ± 1.02 | 143.28 | 1322.03 | 125.85 |

| PLA | 1.9 ± 0.6 | 98.2 ± 0.6 | ||||||||

| Cellulose | 2.9 ± 1.0 | 97.1 ± 1.0 | ||||||||

| Sugarcane | 4.3 ± 1.4 | 95.7 ± 1.4 |

| Sample | pH, - | Conductivity, mS/cm | MC,% | LOI, % |

|---|---|---|---|---|

| 38 °C | ||||

| C | 7.64 | 6.3 | 39.3 ± 4.5 | 39.5 ± 2.0 |

| C + PLA | 9.28 | 5.4 | 39.9 ± 1.2 | 38.8 ± 1.7 |

| C + CELLULOSE | 9.03 | 4.43 | 47.8 ± 2.2 | 37.8 ± 2.2 |

| C + SUGARCANE | 8.14 | 4.46 | 51.1 ± 0.8 | 41.2 ± 1.7 |

| 59 °C | ||||

| C | 9.02 | 6.08 | 55.3 ± 6.5 | 33.2 ± 1.6 |

| C + PLA | 9.03 | 5.74 | 38.8 ± 3.7 | 35.9 ± 1.0 |

| C + CELLULOSE | 8.93 | 5.67 | 31.3 ± 2.0 | 33.3 ± 1.1 |

| C + SUGARCANE | 9.06 | 5.64 | 46.3 ± 1.2 | 43.6 ± 6.9 |

| Sample Name | Weight Loss, % | |||||

|---|---|---|---|---|---|---|

| After 1st Week | After 2nd Week | After 3rd Week | After 4th Week | After 5th Week | After 6th Week | |

| 38 °C | ||||||

| C | 26.9 ± 2.6 | 20.7 ± 1.9 | 40.7 ± 2.4 | 52.3 ± 3.0 | 53.3 ± 3.5 | 54.7 ± 4.0 |

| C + PLA | 14.5 ± 0.9 | 24.8 ± 1.2 | 34.8 ± 2.6 | 41.6 ± 6.0 | 43.4 ± 4.7 | 44.3 ± 4.8 |

| C + CELLULOSE | 7.1 ± 4.4 | 17.4 ± 4.8 | 21.9 ± 5.1 | 23.3 ± 24.8 | 24.8 ± 6.0 | 26.8 ± 6.7 |

| C + SUGARCANE | 23.1 ± 4.7 | 28.8 ± 4.2 | 32.2 ± 4.4 | 34.4 ± 5.6 | 35.4 ± 5.2 | 36.9 ± 5.2 |

| Evaporation (WATER) | 0.99 | 1.04 | 1.07 | 1.08 | ||

| 59 °C | ||||||

| C | 9.4 ± 8.1 | 29.3 ± 20.4 | 37.4 ± 23.7 | 44.6 ± 23.7 | 54.1 ± 22.6 | 54.2 ± 22.5 |

| C + PLA | 17.1 ± 5.3 | 33.82 ± 5.3 | 47.0 ± 6.2 | 47.0 ± 6.2 | 47.3 ± 6.3 | 47.8 ± 6.3 |

| C + CELLULOSE | 13.5 ± 15.2 | 34.7 ± 21.1 | 42.5 ± 22.0 | 42.5 ± 22.0 | 42.9 ± 21.8 | 43.1 ± 21.7 |

| C + SUGARCANE | 2.7 ± 0.3 | 25.0 ± 14.9 | 44.3 ± 21 | 44.3 ± 21.0 | 44.7 ± 20.8 | 45.0 ± 20.6 |

| Evaporation (WATER) | 2.20 | 17.00 | 28.65 | 35.10 | 35.23 | 35.38 |

| Biopolymer | Temperature/MC/Other Parameters | Composting Scale | Time | Results | References |

|---|---|---|---|---|---|

| Paper and cellulose mulch (cellulose) | Moisture: 55–65% Temperature >60 °C in 4 weeks C/N ratio—25–30:1 | Compost, semi-technical scale | 18 weeks | 85% biodegradation in 18 weeks | [63] |

| Organix, BASF ecovio grade M2351, (blend PLA and PBAT) | 85–95% biodegradation in 18 weeks | ||||

| PLA/PHA | Full biodegradation in 5 weeks | ||||

| PLA | Temperature: 58 °C; MC: 60% | Compost, laboratory scale | 30 days | Loss of weight 60% | [64] |

| PLA + clay foil | Temperature: 58 °C; Moisture 55% | Compost, laboratory semi-scale | 130 days | biodegradation in PLA 34% | [65] |

| PLA | Temperature: 58 °C; MC: 48.2% VS: 41.3% pH: 7.9 C/N ratio: 9.9 | Compost, laboratory scale | 10 month | 80% biodegradation in 90 days addition of bioaugmentation | [20] |

| PLA | Temperature: 65 °C pH: 8.5 | Composting, real scale | 58 days | 84% biodegradation in 58 days | [66] |

| Cellulose | Temperature: 65 °C pH: 8.5 | Composting, real scale | 58 days | 86% biodegradation in 58 days | [66] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stegenta-Dąbrowska, S.; Korendał, M.; Kochanowicz, M.; Bondos, M.; Wiercik, P.; Medyńska-Juraszek, A.; Zafiu, C. The Impact of Abiotic and Biotic Conditions for Degradation Behaviors of Common Biodegradable Products in Stabilized Composts. Materials 2024, 17, 2948. https://doi.org/10.3390/ma17122948

Stegenta-Dąbrowska S, Korendał M, Kochanowicz M, Bondos M, Wiercik P, Medyńska-Juraszek A, Zafiu C. The Impact of Abiotic and Biotic Conditions for Degradation Behaviors of Common Biodegradable Products in Stabilized Composts. Materials. 2024; 17(12):2948. https://doi.org/10.3390/ma17122948

Chicago/Turabian StyleStegenta-Dąbrowska, Sylwia, Marek Korendał, Maks Kochanowicz, Marcin Bondos, Paweł Wiercik, Agnieszka Medyńska-Juraszek, and Christian Zafiu. 2024. "The Impact of Abiotic and Biotic Conditions for Degradation Behaviors of Common Biodegradable Products in Stabilized Composts" Materials 17, no. 12: 2948. https://doi.org/10.3390/ma17122948