Evaluation of Major Physical and Mechanical Properties of Trembling Aspen Lumber

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Modulus of Elasticity (MOE)

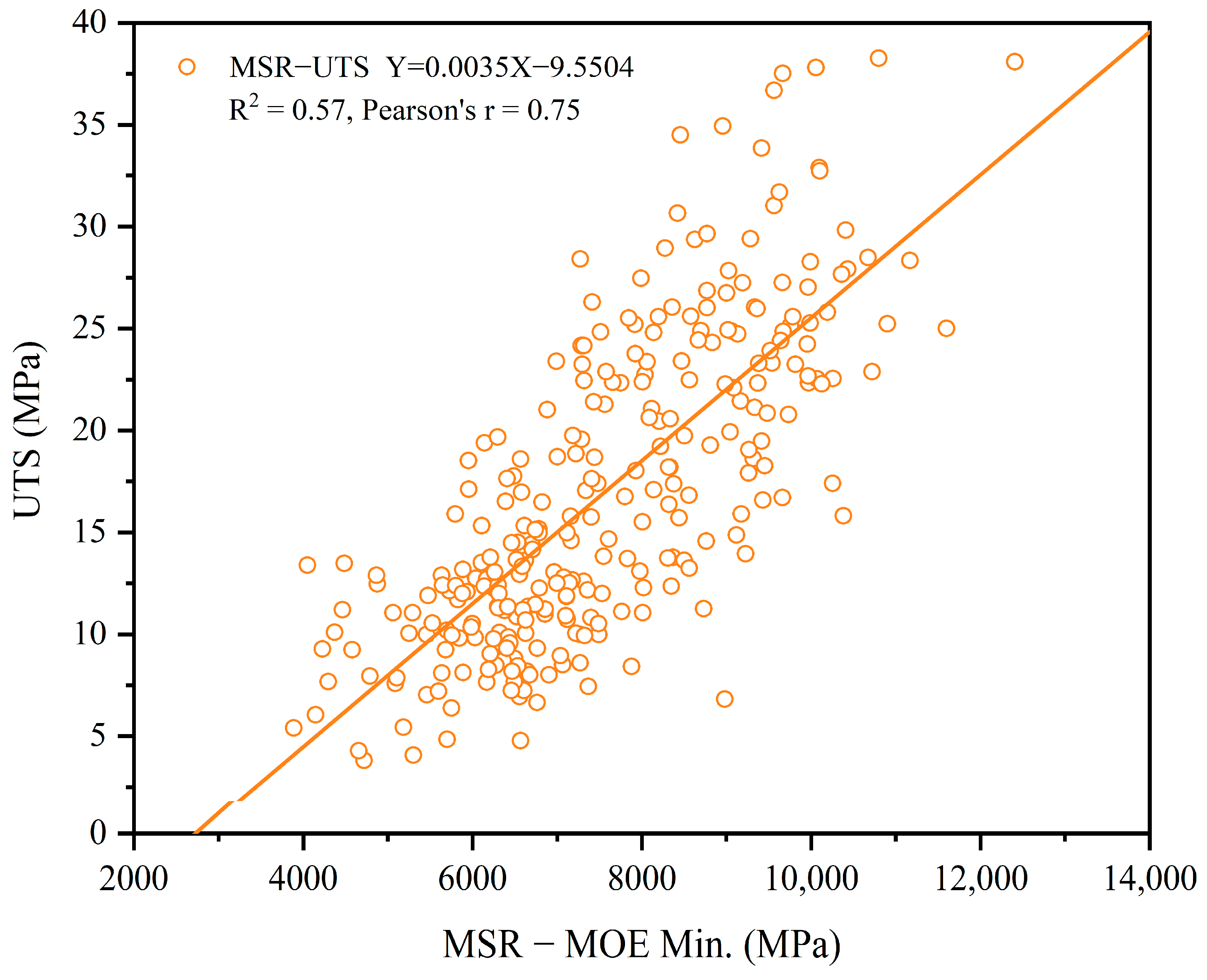

2.2.2. Ultimate Tensile Strength (UTS)

2.2.3. Moisture Content and Specific Gravity (SG)

3. Results and Discussion

3.1. Physical and Mechanical Properties

3.1.1. Moisture Content and Specific Gravity

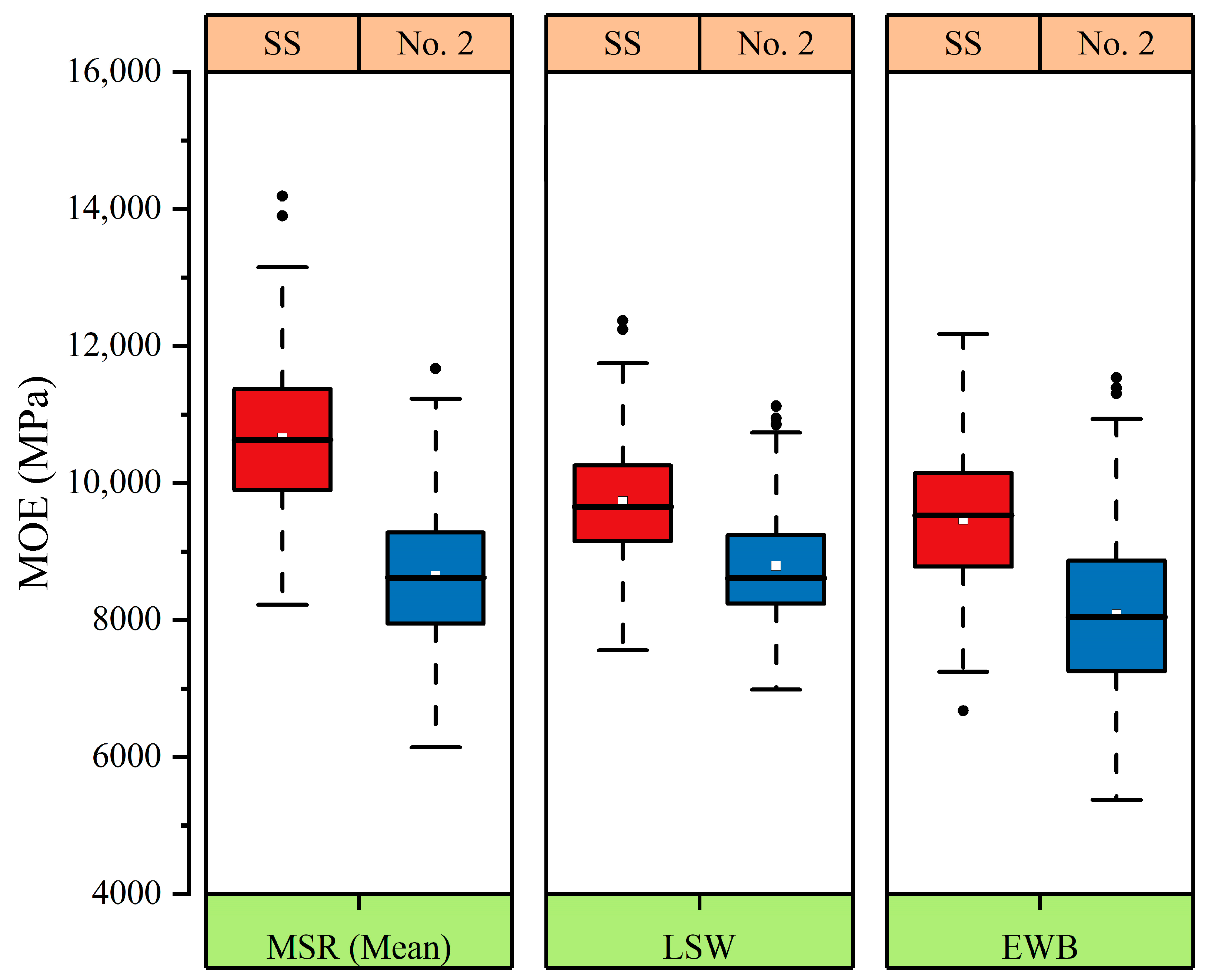

3.1.2. Modulus of Elasticity

3.1.3. Ultimate Tensile Strength and Failure Mode(s)

3.2. Effects of Lumber Length, Knot Size, and Species on Mechanical Properties

3.2.1. Lumber Length

3.2.2. Knot Size

3.2.3. Comparison of MOE and UTS with Spruce–Pine–Fir (S-P-F) Lumber

3.3. Grade-Yield Analysis

4. Conclusions

- It can be observed that, as the maximum knot size increased by a half-inch from one-quarter inch, the MOEmin measured using the MSR, as well as the mean and fifth-percentile UTS, decreased by about 8.8%, 20.1%, and 29.8%, respectively. It is recommended that the maximum knot size be incorporated as a primary factor in trembling aspen lumber sorting criteria, with the initial value of one-quarter inch being incremented by a half-inch.

- Approximately 44% of the trembling aspen lumber met the 1450f-1.3E grade for MSR lumber, and 62% qualified for the 1200f-1.2E grade. Moreover, it exhibited significant potential for manufacturing E3-grade CLT, despite a rejection rate of about 29%.

- The mean UTS and MOE values of the SS-grade trembling aspen lumber were 22.88 MPa and 9519 MPa, respectively, being 25.5% and 11.3% lower than those of the S-P-F lumber. The fifth-percentile UTS and MOE values were 11.57 MPa and 7404 MPa, respectively, marking a decrease of 13.3% and 1.5% compared to that of the S-P-F lumber.

- The oven-dried SG of the trembling aspen wood was 0.40, about 3.5% larger than the value published in the Wood Handbook.

- The length effect of the SS-grade trembling aspen lumber on the mean MOE values, with variations ranging from 0.6% to 4.5%, indicates no significant impact.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Balatinecz, J.J.; Kretschmann, D.E. Properties and Utilization of Poplar Wood. In Poplar Culture in North America; NRC Research Press: Ottawa, ON, Canada, 2001; Part A; pp. 277–291. [Google Scholar]

- Dickmann, D.I.; Isebrands, J.G.; Eckenwalder, J.E.; Richardson, J. (Eds.) Poplar Culture in North America; NRC Research Press: Ottawa, ON, Canada, 2001. [Google Scholar]

- Surmiński, J. Technical properties and uses of poplar wood. In The Poplars (Populus L.); USDA: Washinton, DC, USA, 1976; Volume 12, p. 385. [Google Scholar]

- McKeever, T.; Spelter, H. Wood-Based Panel Plant Locations and Timber Availability in Selected U.S. States; General Technical Report FPL–GTR–103; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1998.

- Youngquist, J.A.; Spelter, H. Aspen Wood Products Utilization: Impact of the Lake States Composites Industry. In Proceedings of the Aspen Symposium 89, Duluth, Minnesota, 25–27 July 1989; NC–GTR–140. U.S. Department of Agriculture, Forest Service, North Central Forest Experiment Station: St. Paul, MN, USA, 1990; pp. 91–102. [Google Scholar]

- Riemenschneider, D.E.; Netzer, D.A.; Berguson, W. Intensive culture of hybrid poplars: What’s new in Minnesota. In Proceedings of the 1st Conference of the Short Rotation Woody Crops Operations Working Group, Paducah, KY, USA, 23–25 September 1996; pp. 53–58. [Google Scholar]

- Riemenschneider, D.E.; Stelzer, H.E.; Foster, G.S. Quantitative genetics of poplars and poplar hybrids. In Biology of Populus and Its Implications for Management and Conservation; NRC Research Press: Ottawa, ON, Canada, 1996; Part I; pp. 159–181. [Google Scholar]

- Holt, D. Properties of hybrid poplar juvenile wood affected by silvicultural treatments. Wood Sci. Technol. 1978, 10, 198–203. [Google Scholar]

- Bendtsen, B.A.; Maeglin, R.R.; Deneke, F. Comparison of mechanical and anatomical properties of eastern cottonwood and Populus hybrid NE-237. Wood Sci. 1981, 14, 1–14. [Google Scholar]

- Hall, R.B.; Hilton, G.D.; Maynard, C.A. Construction lumber from hybrid aspen plantations in the Central States. J. For. 1982, 80, 291–294. [Google Scholar] [CrossRef]

- Brashaw, B.K. Preliminary Evaluation of Hybrid Cottonwood Lumber Mechanical Properties. University of Minnesota, Duluth. Retrieved from the University of Minnesota Digital Conservancy. 1995. Available online: https://hdl.handle.net/11299/256883 (accessed on 12 April 2024).

- Derbowka, D.R.; Andersen, S.; Lee-Andersen, S.; Stenberg, C. Poplar and willow cultivation and utilization in Canada. 2008–2011 Canadian Country Progress Report. In Proceedings of the Canadian Report to the 24th IPC Session, International Poplar Commission, Dehradun, India, 29 October–2 November 2012. [Google Scholar]

- National Forestry Database. Wood Supply, Table 2, Wood Supply Estimates by Ownership and Species Group. 2022. Available online: http://nfdp.ccfm.org/en/data/woodsupply.php (accessed on 15 April 2024).

- Natural Resources Canada, Canadian Forest Service. The State of Canada’s Forests. Annual Report 2022. Available online: https://natural-resources.canada.ca/our-natural-resources/forests/state-canadas-forests-report/16496 (accessed on 16 December 2023).

- McKenney, D.W.; Yemshanov, D.; Pedlar, J.; Allen, D.; Lawrence, K.; Hope, E.; Lu, B.; Eddy, B. Canada’s Timber Supply: Current Status and Future Prospects under a Changing Climate; Information Report GLC-X-15; Natural Resources Canada, Canadian Forest Service, Great Lakes Forestry Centre: Sault Ste. Marie, ON, Canada, 2016; 75p. [Google Scholar]

- Kretschmann, D.E. Structural Lumber Properties of Hybrid Poplar; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1999; Volume 573.

- De la Roche, I.; Dangerfield, J.A.; Karacabeyli, E. Wood products and sustainable construction. NZ Timber Des. J. 2003, 12, 9–13. [Google Scholar]

- Gong, M.; Tu, D.; Li, L.; Chui, Y.H. Planar shear properties of hardwood cross layer in hybrid cross laminated timber. In Proceedings of the International Scientific Conference on Hardwood Processing, Québec, QC, Canada, 15–17 September 2015. [Google Scholar]

- Wang, Z.; Dong, W.; Wang, Z.; Zhou, J.; Gong, M. Effect of macro characteristics on rolling shear properties of fast-growing poplar wood laminations. Wood Res. 2018, 63, 227–238. [Google Scholar]

- Han, Z.; Zhang, R.; Song, B. Evaluation of the bending properties of modified fast-growing poplar glulam based on composite mechanics. BioResources 2018, 13, 7071–7085. [Google Scholar] [CrossRef]

- National Lumber Grades Authority (NLGA). Grading Rules for Canadian Lumber; National Lumber Grades Authority: New Westminster, BC, Canada, 2019. [Google Scholar]

- Boström, L. Machine strength grading. In Comparison of Four Different Systems; Building Technology, SP Report; Swedish National Testing and Research Institute: Boras, Sweden, 1994; Volume 49. [Google Scholar]

- Ross, R.J.; Pellerin, R.F. Non-Destructive Testing for Assessing Wood Members in Structures; Forest Products Laboratory: Madison, WI, USA, 1994.

- Oscarsson, J.; Olsson, A.; Johansson, M.; Enquist, B.; Serrano, E. Strength grading of wet Norway spruce side boards for use as laminations in wet-glued laminated beams. In Proceedings of the Final Conference of COST Action E53, Edinburgh, UK, 4–7 May 2010. [Google Scholar]

- Biechele, T.; Chui, Y.H.; Gong, M. Comparison of NDE techniques for assessing mechanical properties of unjointed and finger-joined lumber. Holzforschung 2011, 65, 397–401. [Google Scholar] [CrossRef]

- ASTM D198-2022a; Standard Test Methods of Static Tests of Lumber in Structural Sizes. American Society for Testing Materials (ASTM): Philadelphia, PA, USA, 2022.

- Barrett, J.D.; Hejja, A. Compression Strength of Canadian Softwood Lumber; Forintek Canada Corp., Western Laboratory: Vancouver, BC, Canada, 1984. [Google Scholar]

- ASTM D4442-07; Standard Test Methods for Direct Moisture Content Measurement of Wood and Wood-Based Materials. American Society of Testing and Materials: Philadelphia, PA, USA, 2020.

- Senalik, C.A.; Farber, B. Chapter 5: Mechanical properties of wood. In Wood Handbook Wood as an Engineering Material; General Technical Report FPL-GTR-282; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 2021; p. 46. [Google Scholar]

- Stamm, A.J. Wood and Cellulose Science; Ronald Press: New York, NY, USA, 1964; 549p. [Google Scholar]

- ASTM D1990-2019; Standard Practice for Establishing Allowable Properties for Visually Graded Dimension Lumber from In-Grade Tests of Full-Size Specimens. American Society of Testing and Materials (ASTM): Philadelphia, PA, USA, 2019.

- Green, D.W.; Evans, J.W. Mechanical Properties of Visually Graded Lumber; U.S. Department of Agriculture, Forest Service, Forest Products Laboratory: Madison, WI, USA, 1987.

- American Forest & Paper Association (AF&PA). National Design Specification (NDS) Supplement: Design Values for Wood Construction 2018 Edition; American Wood Council: Leesburg, VA, USA, 2018. [Google Scholar]

- Malaga-Toboła, U.; Łapka, M.; Tabor, S.; Niesłony, A.; Findura, P. Influence of wood anisotropy on its mechanical properties in relation to the scale effect. Int. Agrophysics 2019, 33, 337–345. [Google Scholar] [CrossRef] [PubMed]

- Fan, S.; Wong, S.W.; Zidek, J.V. Knots and their effect on the tensile strength of lumber: A case study. J. Qual. Technol. 2023, 55, 510–522. [Google Scholar] [CrossRef]

- Hittenrauch, H.R. Response of aspen to various harvest techniques. In Utilization and Marketing as Tools for Aspen Management in the Rocky Mountains; USDA Forest Service General Technical Report RM-29; U.S. Department of Agriculture, Forest Service: Madison, WI, USA, 1976; pp. 41–44. [Google Scholar]

- Hiratsuka, Y.; Loman, A.A. Decay of Aspen and Balsam Poplar in Alberta; Information Report, NOR-X-262; Northern Forest Research Centre: Edmonton, AB, Canada, 1984. [Google Scholar]

- Canadian Wood Council (CWC). Canadian Lumber Properties; Canadian Wood Council: Ottawa, ON, Canada, 1994. [Google Scholar]

- Smith, I.; Chui, Y.H. Derivation of machine settings in machine-controlled stress grading of lumber: Some statistical considerations. J. Inst. Wood Sci. 1994, 13, 449–454. [Google Scholar]

- SPS-2; Special Products Standard for Machine Graded Lumber. National Lumber Grades Authority (NLGA): New Westminster, BC, Canada, 2019.

- ANSI/APA PRG-320; Standard for Performance-Rated Cross-Laminated Timber. The Engineered Wood Association: Tacoma, WA, USA, 2019.

| Dimension | Quantity (Pcs.) | ||||||

|---|---|---|---|---|---|---|---|

| Length | Width | Thickness | SS Grade | No. 2 Grade | |||

| foot | mm | inch | mm | inch | mm | ||

| 8 | 2438 | 3.5 | 89 | 1.5 | 38 | 39 | - |

| 10 | 3048 | 3.5 | 89 | 1.5 | 38 | 49 | - |

| 12 | 3658 | 3.5 | 89 | 1.5 | 38 | 80 | 200 |

| Grade | Length (ft.) | Index | MC (%) | SG |

|---|---|---|---|---|

| SS | 8 | Count | 39 | 39 |

| Mean | 8.3 | 0.43 | ||

| COV (%) | 13.5 | 7.4 | ||

| 10 | Count | 49 | 49 | |

| Mean | 7.5 | 0.41 | ||

| COV (%) | 8.5 | 8.5 | ||

| 12 | Count | 80 | 80 | |

| Mean | 7.4 | 0.41 | ||

| COV (%) | 4.4 | 6.9 | ||

| No. 2 | 12 | Count | 200 | 200 |

| Mean | 7.0 | 0.42 | ||

| COV (%) | 7.3 | 8.9 |

| SS Grade | No. 2 Grade | |

|---|---|---|

| Count (Pcs.) | 114 | 174 |

| Failure at MSRD (Pcs.) | 50 | 102 |

| Reject (Pcs.) | 15 | 26 |

| Mean UTS (MPa) | 22.88 | 12.92 |

| COV (%) | 29.1 | 38.9 |

| Index | Sub-Group | |||

|---|---|---|---|---|

| T1 | T2 | T3 | T4 | |

| Max. Knot Size (any-caused) (inches) | <1/4 (6.35) | 1/4–3/4 (19.05) | 3/4–5/4 (31.75) | >5/4 |

| MSR MOEmin (MPa) | 9026 | 8286 | 7867 | 6842 |

| Mean UTS (MPa) | 26.87 | 20.27 | 17.94 | 13.60 |

| Fifth-Percentile UTS (MPa) | 14.16 | 9.12 | 6.74 | 4.87 |

| Quantity (Pcs.) | 19 | 45 | 89 | 135 |

| Proportion (%) | 6.6 | 15.6 | 30.9 | 46.9 |

| Property | Grade | Sample Size (Pcs.) | Mean (MPa) | Fifth Percentile (MPa) | |||||

|---|---|---|---|---|---|---|---|---|---|

| Aspen | S-P-F | Aspen | S-P-F | Ratio | Aspen | S-P-F | Ratio | ||

| MOE | SS | 153 | 441 | 9519 | 10,730 | 0.89 | 7404 | 7520 | 0.98 |

| No. 2 | 174 | 440 | 8028 | 9490 | 0.85 | 5656 | 6090 | 0.93 | |

| UTS | SS | 114 | 440 | 22.88 | 30.69 | 0.75 | 11.57 | 13.34 | 0.87 |

| No. 2 | 174 | 444 | 12.85 | 22.59 | 0.57 | 4.88 | 7.60 | 0.64 | |

| Combination | High-Grade | Low-Grade | Reject (%) | ||||

|---|---|---|---|---|---|---|---|

| Grade | Setting (MPa) | Yield (%) | Grade | Setting (MPa) | Yield (%) | ||

| 1 | 1650f-1.5E | 9264 | 18 | 1450f-1.3E | 7563 | 26 | 56 |

| 2 | 1650f-1.5E | 9264 | 18 | 1350f-1.3E | 7399 | 30 | 52 |

| 3 | 1450f-1.3E | 7563 | 44 | 1200f-1.2E | 6784 | 18 | 38 |

| Grade | Major-Strength Direction | Minor-Strength Direction | Reject (%) | ||||

|---|---|---|---|---|---|---|---|

| Standard (MPa) | Setting (MPa) | Yield (%) | Standard (MPa) | Setting (MPa) | Yield (%) | ||

| E1 | 11,700 | - | - | 9000 | 9001 | 23 | 77 |

| E3 | 8300 | 8309 | 34 | 6500 | 6511 | 37 | 29 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, D.; Zhang, M.; Gong, M.; Chui, Y.-H. Evaluation of Major Physical and Mechanical Properties of Trembling Aspen Lumber. Materials 2024, 17, 2952. https://doi.org/10.3390/ma17122952

Wang D, Zhang M, Gong M, Chui Y-H. Evaluation of Major Physical and Mechanical Properties of Trembling Aspen Lumber. Materials. 2024; 17(12):2952. https://doi.org/10.3390/ma17122952

Chicago/Turabian StyleWang, Dawei, Mengyuan Zhang, Meng Gong, and Ying-Hei Chui. 2024. "Evaluation of Major Physical and Mechanical Properties of Trembling Aspen Lumber" Materials 17, no. 12: 2952. https://doi.org/10.3390/ma17122952

APA StyleWang, D., Zhang, M., Gong, M., & Chui, Y.-H. (2024). Evaluation of Major Physical and Mechanical Properties of Trembling Aspen Lumber. Materials, 17(12), 2952. https://doi.org/10.3390/ma17122952