Study on the Friction and Wear Properties of Multiple Rare-Earth-Oxide-Reinforced Resin-Based Friction Materials

Abstract

1. Introduction

2. Experimental

2.1. Material Preparation

2.2. Specimen Preparation

- (1)

- An electronic scale was used to weigh each raw material according to the formula in Table 1;

- (2)

- First, aramid fiber was added into a JHF-20 mixer (Zhengzhou jinhe Powder Technology Co., Zhengzhou, China) for 5 min, and then the aramid fiber was opened and dispersed. Then, the other raw materials were put into the mixer for 15 min, and the rotating speed of the blades was 1000 r/min;

- (3)

- The raw materials were mixed and put into the JFY60 hot press (Jilin jida Electromechanical Equipment Co., Changchun, China). The working pressure was set at 15 MPa, and the temperatures of the upper, middle, and lower molds were 150 °C, 160 °C, and 150 °C, respectively. The hardening time was 600 s. Finally, the pressed samples were put into a drying box for heat treatment at 180 °C for 12 h and then cooled down to room temperature. The heat-treated samples were cut using an MQD3220 cutting machine (Jiangsu Jinding Power Tools Group Co., Changzhou, China).

2.3. Testing Proceduce

3. Results and Discussion

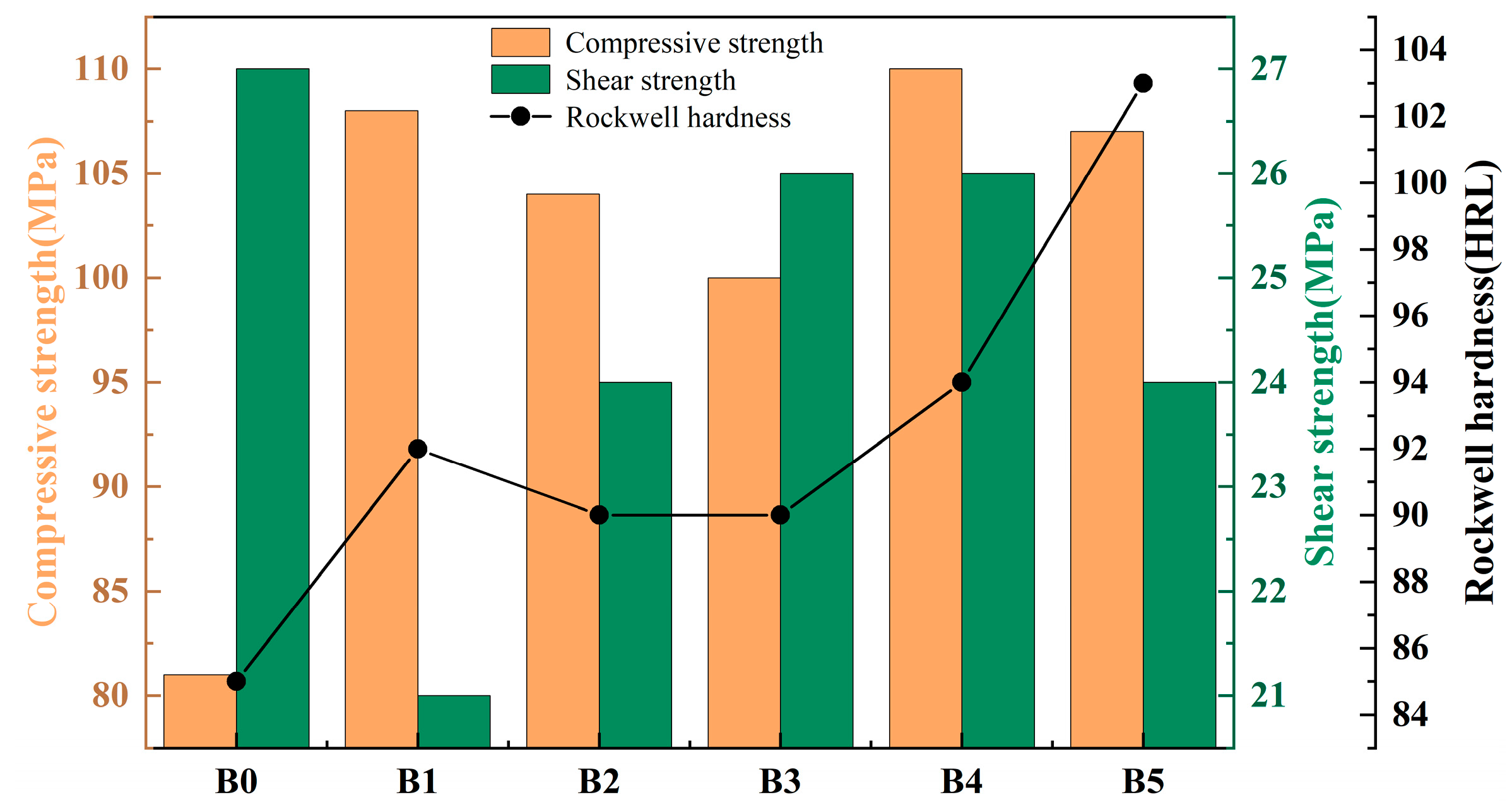

3.1. Mechanical Performance

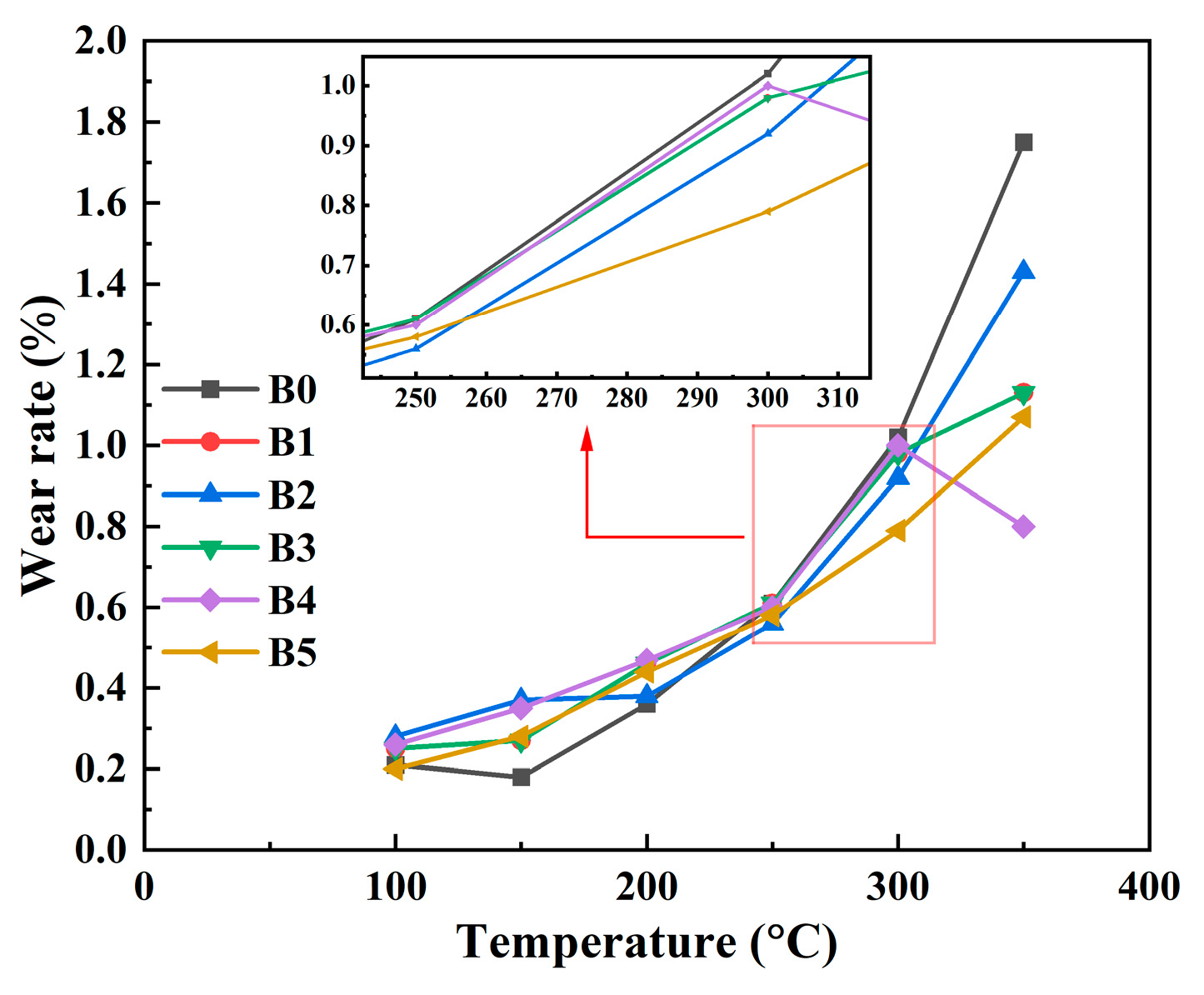

3.2. Tribological Performance

3.2.1. Friction Coefficient

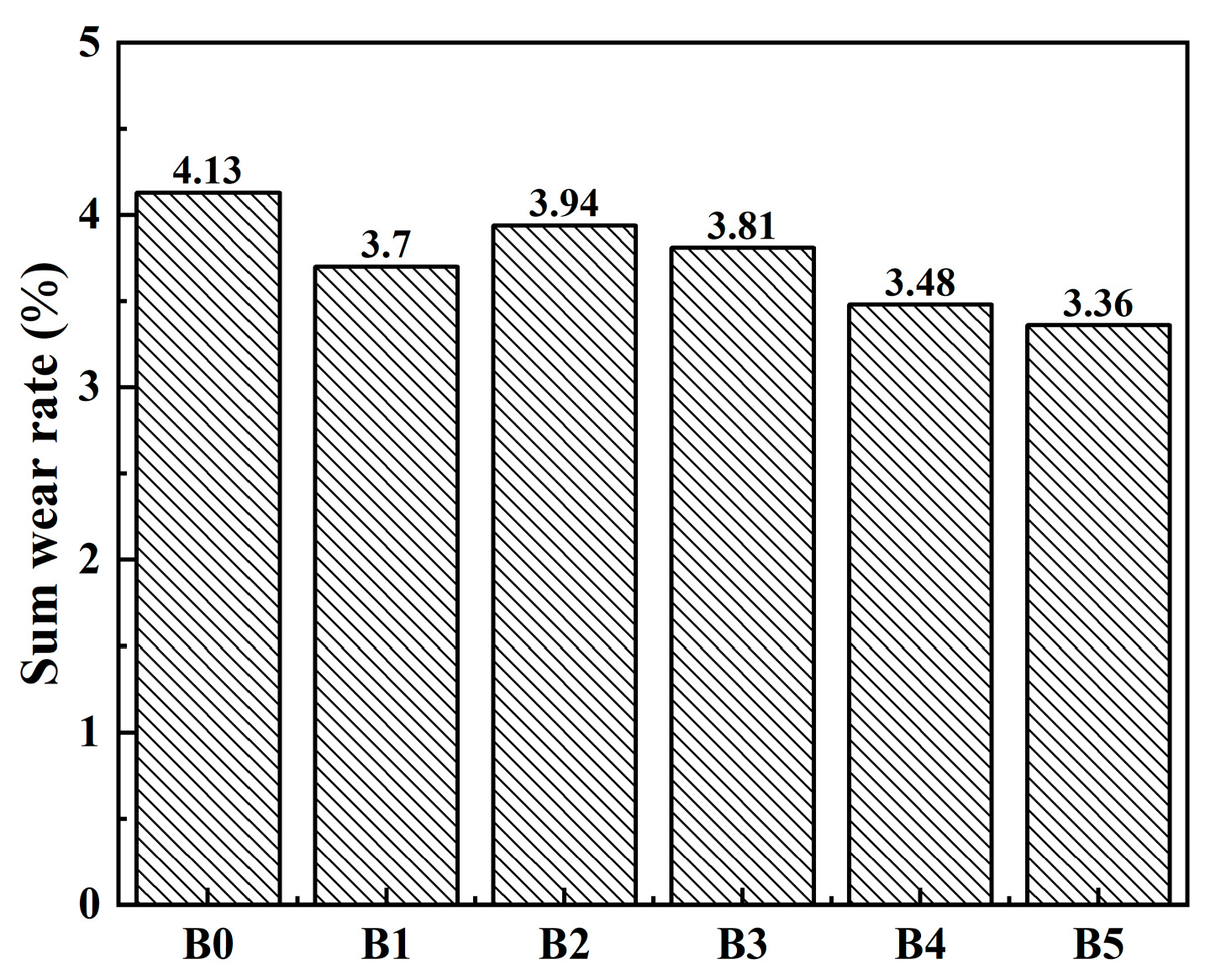

3.2.2. Wear Performance

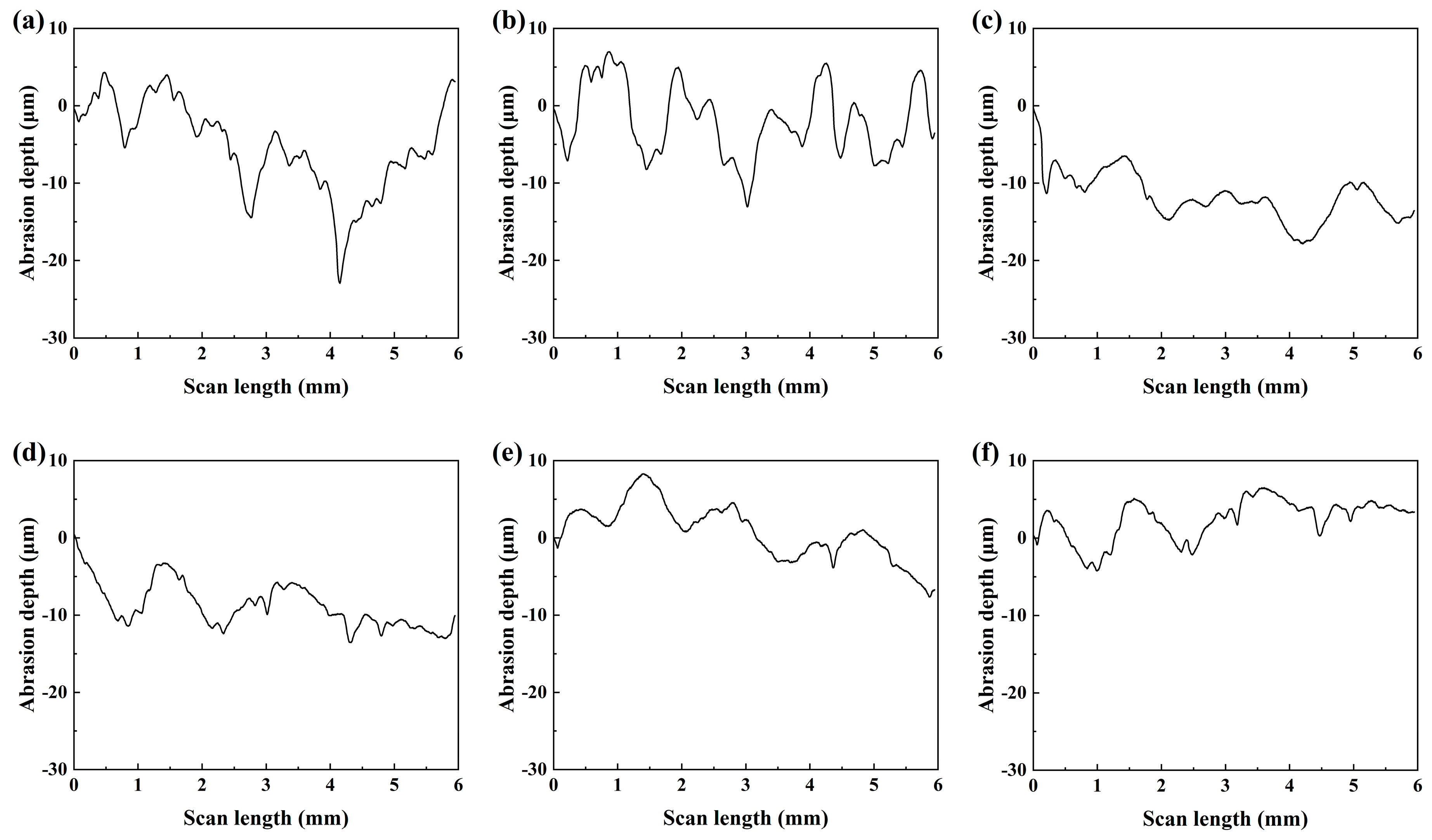

3.2.3. Two-Dimensional Profile

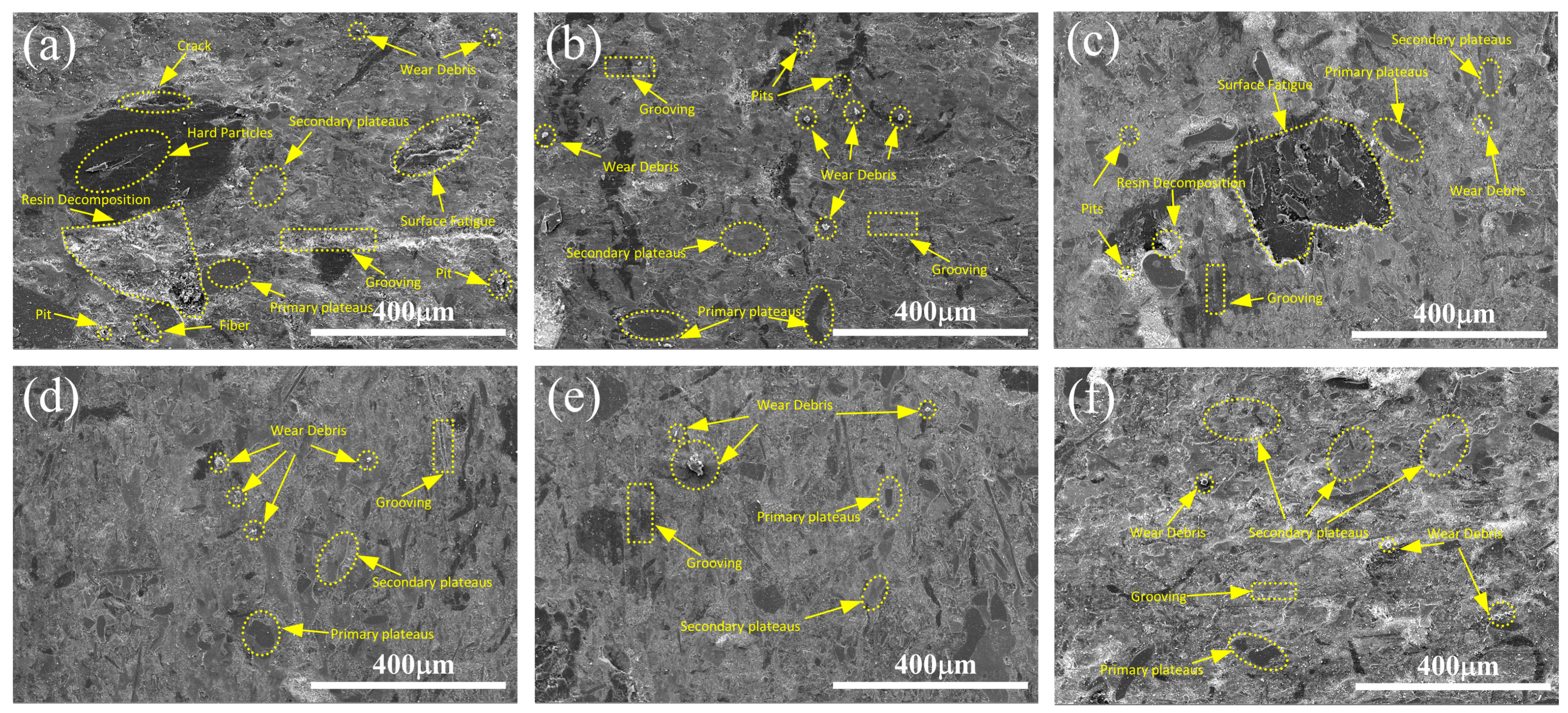

3.3. Worn Surface Analyses

3.4. Energy-Dispersive Spectroscopy Elemental and X-ray Diffractometer Phase Analysis

4. Discussion

5. Conclusions

- (1)

- The addition of rare earth lanthanum oxide and cerium oxide to the material can effectively improve the friction coefficient and reduce the wear rate, as well as improve the Rockwell hardness and compression resistance of the material. Among these, when the content of lanthanum oxide and cerium oxide is 5% and 1%, respectively, the specimens have the highest high-temperature friction coefficient, the wear is low and stable, and the total wear rate is reduced by 18.6%. Compared with that of the specimen without rare earth oxides, the surface wears uniformly, with the shallowest wear marks and optimal comprehensive tribological performance;

- (2)

- The results show that the wear surface of the specimens without rare earth oxide shows flaking pits, obvious abrasion marks, and many abrasive debris, and the wear mode is mainly adhesive wear. However, the wear surface of most of the specimens with lanthanum/cerium oxides is relatively flat. When the content of lanthanum oxide and cerium oxide is 5% and 1%, respectively, many continuous secondary platforms and abrasive debris are formed on the surface of the specimen. The wear mode is dominated by abrasive wear and supplemented by adhesive wear. It indicates that lanthanum oxide/cerium oxide can increase the bonding strength of the resin and promote formation of a friction film on the surface of the material;

- (3)

- At high temperatures, lanthanum oxide and cerium oxide can coordinate with the oxygen atoms in the phenolic hydroxyl groups in the resin. This coordination inhibits grain growth at grain boundaries and increases the area of grain boundaries. Therefore, the modified materials show better antidegradation performance and friction and wear properties under high-temperature conditions. This improves the service life of resin-based friction materials at high temperatures and also broadens their field of use.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wiser, R.H.; Rand, J.; Seel, J.; Beiter, P.; Baker, E.D.; Lantz, E.; Gilman, P. Expert elicitation survey predicts 37% to 49% declines in wind energy costs by 2050. Nat. Energy 2021, 6, 555–565. [Google Scholar] [CrossRef]

- Sun, C.Y.; Peng, Y.B.; Dong, Q.; Zheng, Y.H.; Mao, L.M.; Jing, J.B.; Wu, Y. An analysis of typical wind energy characteristics in northern shaanxi. Power Syst. Clean Energy 2021, 37, 110–115, 122. [Google Scholar]

- Tavangar, R.; Moghadam, H.A.; Khavandi, A. Comparison of dry sliding behavior and wear mechanism of low metallic and copper-free brake pads. Tribol. Int. 2020, 151, 106416. [Google Scholar] [CrossRef]

- Zheng, K.K.; Gao, C.H.; He, F.S.; Jiang, W. Development of a high-quality rare earth oxide modified resin-based brake material. Tribol. Mater. Surf. Interfaces 2019, 13, 50–57. [Google Scholar] [CrossRef]

- Seong Jin Kim, H.J. Friction and wear of friction materials containing two different phenolic resins reinforced with aramid pulp. Tribol. Int. 2000, 33, 477–484. [Google Scholar]

- Bijwe, J. Composites as friction materials: Recent developments in non-asbestos fiber reinforced friction materials—A review. Polym. Compos. 1997, 18, 378–396. [Google Scholar] [CrossRef]

- Lee, P.W.; Filip, P. Friction and wear of Cu-free and Sb-free environmental friendly automotive brake materials. Wear 2013, 302, 1404–1413. [Google Scholar] [CrossRef]

- Martinez, A.M.; Echeberria, J. Towards a better understanding of the reaction between metal powders and the solid lubricant Sb2S3 in a low-metallic brake pad at high temperature. Wear 2016, 348–349, 27–42. [Google Scholar] [CrossRef]

- Jiang, P.C.; Wang, Z.F.; Liu, H.; Ma, Y.; Wang, Y.L.; Niu, J.W.; Pang, H.X.; Wang, X.T.; Deng, C.J. Improving the strength and oxidation resistance of phenolic resin derived pyrolytic carbons via Cu-catalyzed in-situ formation of SiC@SiO2. Solid State Sci. 2021, 118, 106645. [Google Scholar] [CrossRef]

- Mahale, V.; Bijwe, J. Role of thermal conductivity in controlling the tribo-performance of non-asbestos organic brake-pads. J. Compos. Mater. 2020, 54, 4145–4155. [Google Scholar] [CrossRef]

- Meliksetyan, N.G.; Myshkin, N.K.; Agbalyan, S.G.; Meliksetyan, G.N. Friction and Wear of Asbestos-Free Brake Friction Materials. J. Frict. Wear 2022, 43, 416–422. [Google Scholar] [CrossRef]

- Zhang, B.; Ning, Y.K.; Cao, F.; Yang, H.P. Current situation of worldwide rare earth resources. Multipurp. Util. Miner. Resour. 2018, 4, 7–12. [Google Scholar]

- Ge, R.X.; Cao, H.Z.; Yu, X.L.; Chen, M.G.; Zhang, Y.X.; Zhao, F. Application of micro/nano rare earth compounds in polymer materials. Chin. Rare Earths 2019, 40, 139–146. [Google Scholar]

- Wu, Y.C.; Liu, M.; Li, Y.L.; Liu, J.Q. Advances in the application of rare earth compounds for high-energy-density lithium sulfur batteries. Trans. Mater. Heat Treat. 2021, 42, 1–14. [Google Scholar]

- Duan, H.J.; Guan, W.H.; Ma, S.F.; Liu, X.Y.; Gao, K.; Ming, J.L. New hematite method: Efficient and enhanced separation of rare earth and iron by alkaline regulation of pH in rare earth chloride solutions. Sep. Purif. Technol. 2024, 344, 127209. [Google Scholar] [CrossRef]

- Jing, W.; He, F.S.; Zheng, K.K.; Zhou, Z.H.; Jiang, L.X.; Lin, Y.X.; Gao, C.H. Effect of lanthanum oxide on tribological performance of brake friction materials. Lubr. Eng. 2019, 44, 58–63. [Google Scholar]

- He, F.S.; Zhou, Z.H.; Zheng, K.K.; Gao, C.H.; Lin, Y.X.; Jiang, W. Tribological performance of RE compound modified composites under oil lubrication. Lubr. Eng. 2020, 45, 38–43. [Google Scholar]

- Zheng, K.K.; Gao, C.H.; He, F.S.; Lin, Y.X.; Lin, J. Effect of rare earth solution modification on mechanical and tribological properties of bamboo fiber reinforced brake materials. Trans. Mater. Heat Treat. 2018, 39, 147–154. [Google Scholar]

- Sun, J.C.; Chen, S.; Zhao, Y.C.; Nie, J.P.; Huang, Q.H.; Sang, H.D. Tribological properties of resin-based brake sheets modified by rare earth composite nanomaterials. Lubr. Eng. 2024, 49, 137–142. [Google Scholar]

- Manroo, S.A.; Khan, N.Z.; Ahmad, B. Development of Nano-Composites on Rare-Earth Mg-ZE41 Alloy Via Friction Stir Processing (FSP): Microstructure, Mechanical, and Tribological Properties. JOM 2022, 74, 2047–2062. [Google Scholar] [CrossRef]

- GB/T 22309-2008; Road Vehicles-Brake Linings-Shear Test Procedure for Disc Brake Pad and Drum Brake Shoe Assemblies. Standardization Administration of China: Xianyang, China, 2008.

- GB/T 10424-2002; Sintered Metal Friction Materials-Determination of Compressive Strength. China National Standardization Administration Committee: Beijing, China, 2002.

- GB/T 5766-2007; Test Method of Rockwell Hardness for Friction Materials. China National Standardization Administration Committee: Beijing, China, 2007.

- GB 5763-2008; Brake Linings for Automobiles. China National Standardization Administration Committee: Beijing, China, 2008.

- JB/T 7498-2018; Coated Abrasives−Abrasive Paper. China National Standardization Administration Committee: Beijing, China, 2018.

- Shangguan, Q.Q.; Cheng, X.H. Friction and wear of rare earths modified carbon fibers filled PTFE composite under dry sliding condition. Appl. Surf. Sci. 2007, 253, 9000–9006. [Google Scholar]

- Bian, C.; Wang, S.J.; Liu, Y.H.; Jing, X.L. Thermal stability of phenolic resin: New insights based on bond dissociation energy and reactivity of functional groups. RSC Adv. 2016, 6, 55007–55016. [Google Scholar] [CrossRef]

- Wang, K.Y.; Gu, H.Z.; Huang, A.; Ke, C.M.; Zhang, M.J.; Luo, Z.A.; Fu, L.P. Modified phenolic resin with aluminium and rectorite: Structure, characterization, and performance. Polym. Compos. 2020, 41, 4431–4441. [Google Scholar] [CrossRef]

- Chen, Y. Study on the Friction and Worn Properites of Rare Earth Lanthanum Oxide Reinforced Resin-Based Automotive Friction Plates. Master’s Thesis, Anhui Ploytechnic University, Wuhu, China, 2020. [Google Scholar]

- Jara, D.C.; Jang, H. Synergistic effects of the ingredients of brake friction materials on friction and wear: A case study on phenolic resin and potassium titanate. Wear 2019, 430, 222–232. [Google Scholar] [CrossRef]

| Raw Materials (by wt%) | B0 | B1 | B2 | B3 | B4 | B5 |

|---|---|---|---|---|---|---|

| phenolic resin | 17 | 11 | 11 | 11 | 11 | 11 |

| aramid fiber | 4 | 4 | 4 | 4 | 4 | 4 |

| ceramic fiber | 15 | 15 | 15 | 15 | 15 | 15 |

| potassium titanate whiskers | 12 | 12 | 12 | 12 | 12 | 12 |

| calcium sulfate whisker | 5 | 5 | 5 | 5 | 5 | 5 |

| lanthanum oxide | 1 | 2 | 3 | 4 | 5 | |

| cerium oxide | 5 | 4 | 3 | 2 | 1 | |

| other | 47 | 47 | 47 | 47 | 47 | 47 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, L.; Huang, M.; Du, J.; Liu, Z.; Li, W.; Zhu, J. Study on the Friction and Wear Properties of Multiple Rare-Earth-Oxide-Reinforced Resin-Based Friction Materials. Materials 2024, 17, 2990. https://doi.org/10.3390/ma17122990

Huang L, Huang M, Du J, Liu Z, Li W, Zhu J. Study on the Friction and Wear Properties of Multiple Rare-Earth-Oxide-Reinforced Resin-Based Friction Materials. Materials. 2024; 17(12):2990. https://doi.org/10.3390/ma17122990

Chicago/Turabian StyleHuang, Lirong, Minjie Huang, Junhua Du, Zhigang Liu, Wei Li, and Jiangbo Zhu. 2024. "Study on the Friction and Wear Properties of Multiple Rare-Earth-Oxide-Reinforced Resin-Based Friction Materials" Materials 17, no. 12: 2990. https://doi.org/10.3390/ma17122990

APA StyleHuang, L., Huang, M., Du, J., Liu, Z., Li, W., & Zhu, J. (2024). Study on the Friction and Wear Properties of Multiple Rare-Earth-Oxide-Reinforced Resin-Based Friction Materials. Materials, 17(12), 2990. https://doi.org/10.3390/ma17122990