Numerical Simulation of Friction Stir Welding of Dissimilar Al/Mg Alloys Using Coupled Level Set and Volume of Fluid Method

Abstract

1. Introduction

2. Model Formulation

2.1. Governing Equations

2.2. VOF Method

2.3. CLSVOF Method

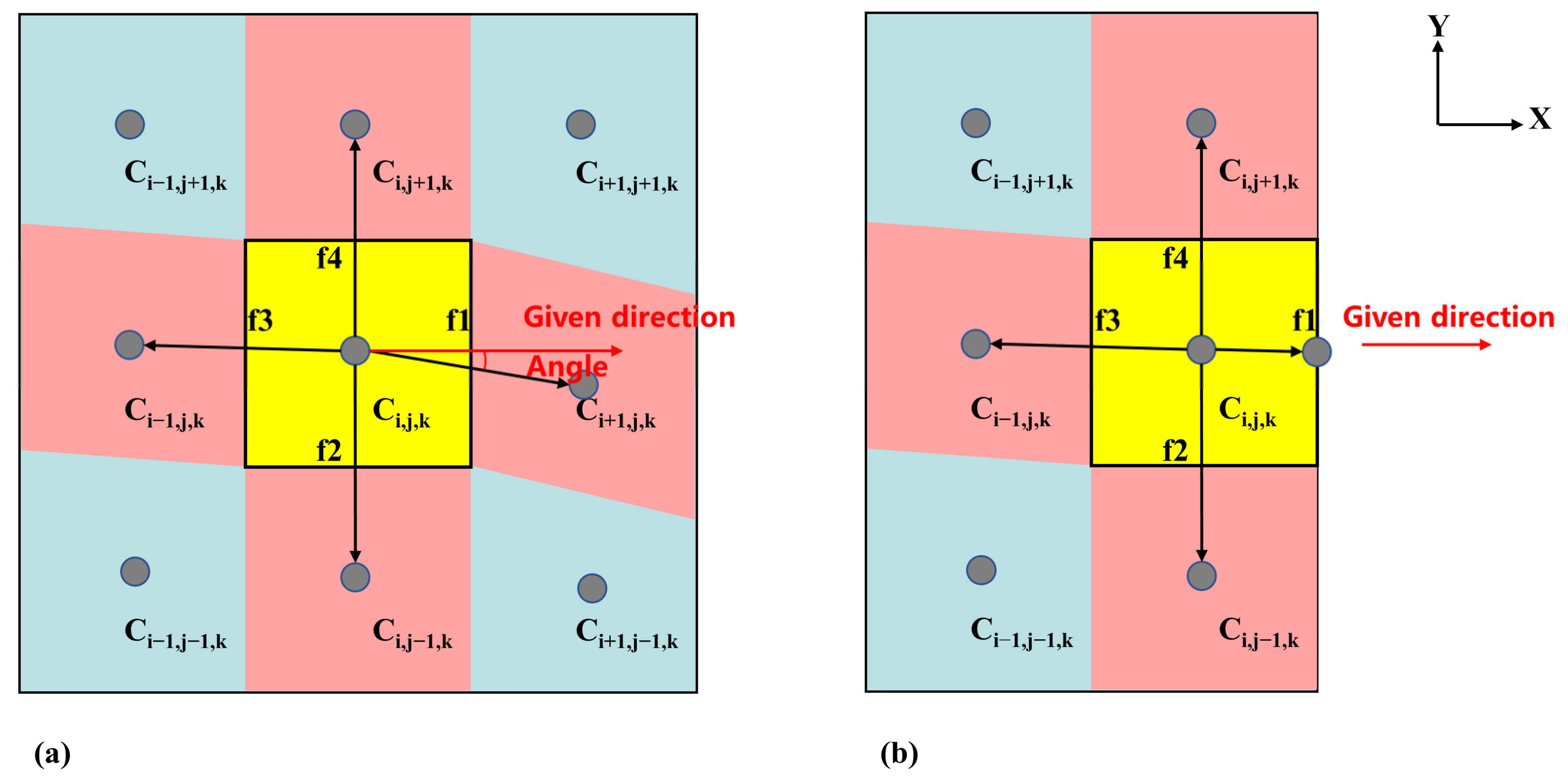

2.4. Implementation of CLSVOF

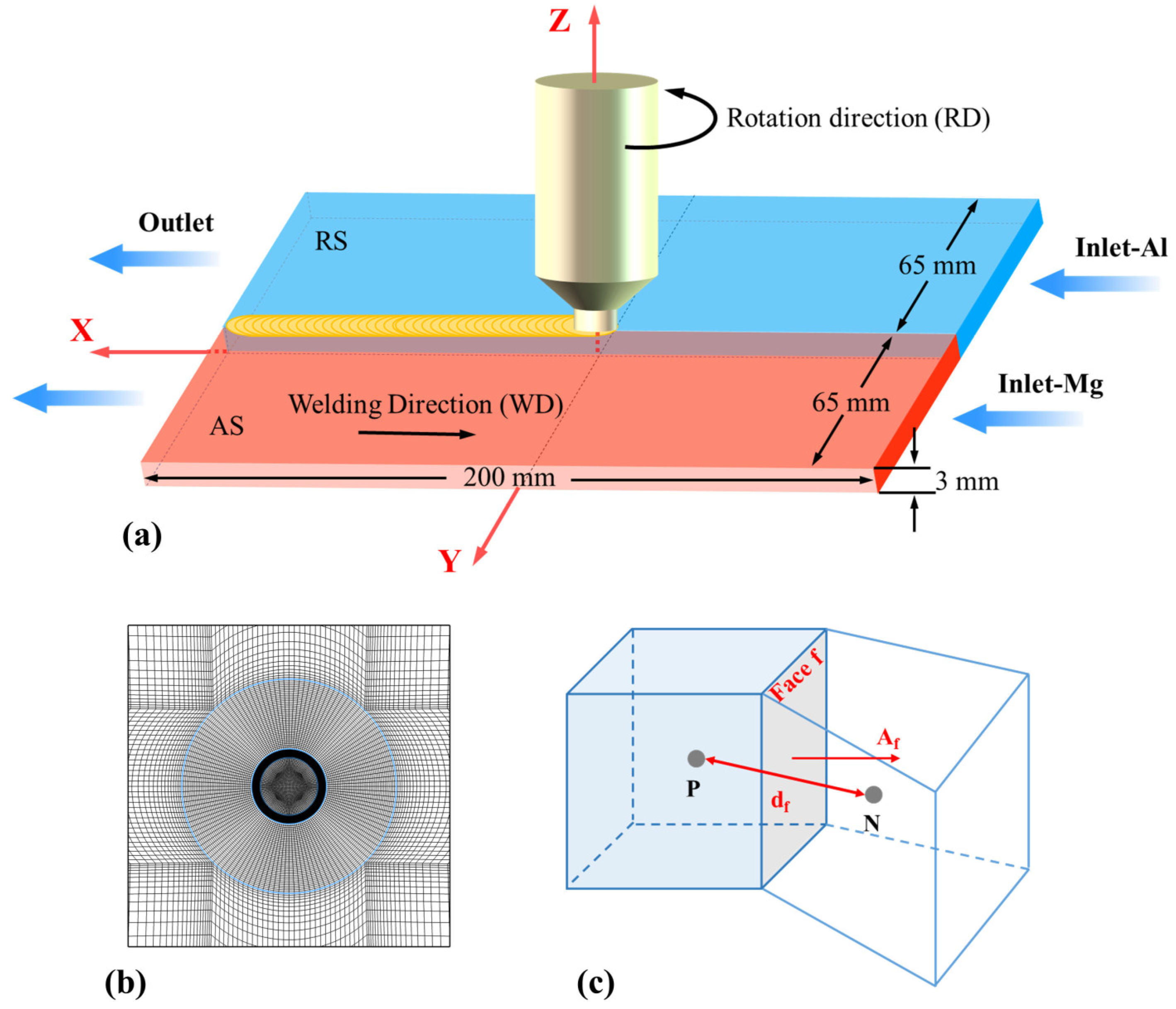

2.5. Geometric Model

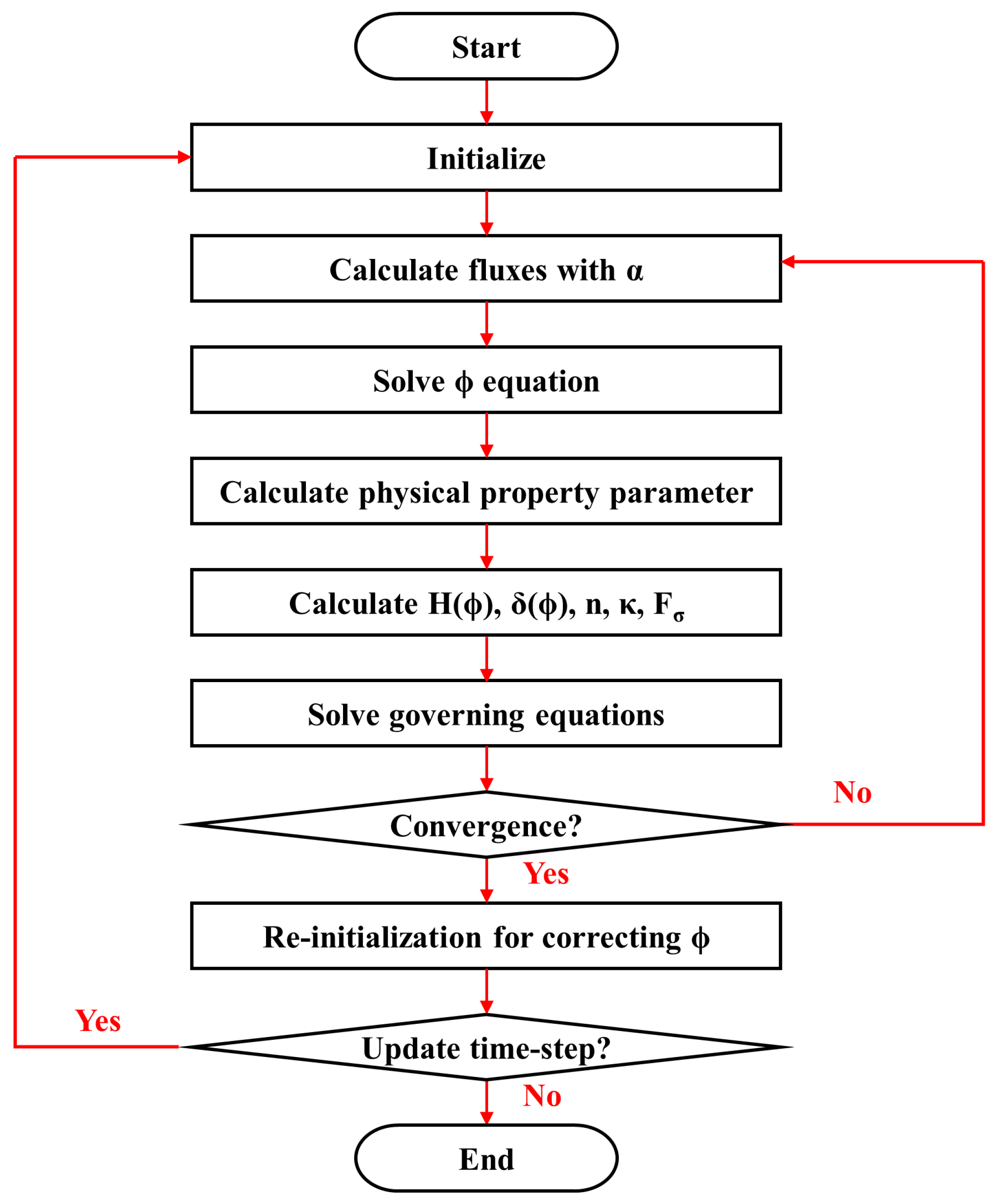

2.6. Solution Algorithm

- Open and initialize the UDS equation to solve the level set function;

- On the basis of the initial conditions or the value of the previous time step, initialize the physical quantities required to be solved, such as velocity, density, and level set function;

- Solve the VOF equation, Equation (6);

- Solve the level set equation, Equation (10);

- Calculate relevant physical properties and store normal vector components, interface curvature, and other intermediate values;

- Add the interacting force between two phases in the form of the source term to the momentum equation, solve the governing equations, Equations (14)–(16), and obtain an updated velocity field;

- Assign the initial value to the level set function according to the VOF function, and use Equation (11) to reinitialize the level set function;

- Go to the next time and repeat step 2–7.

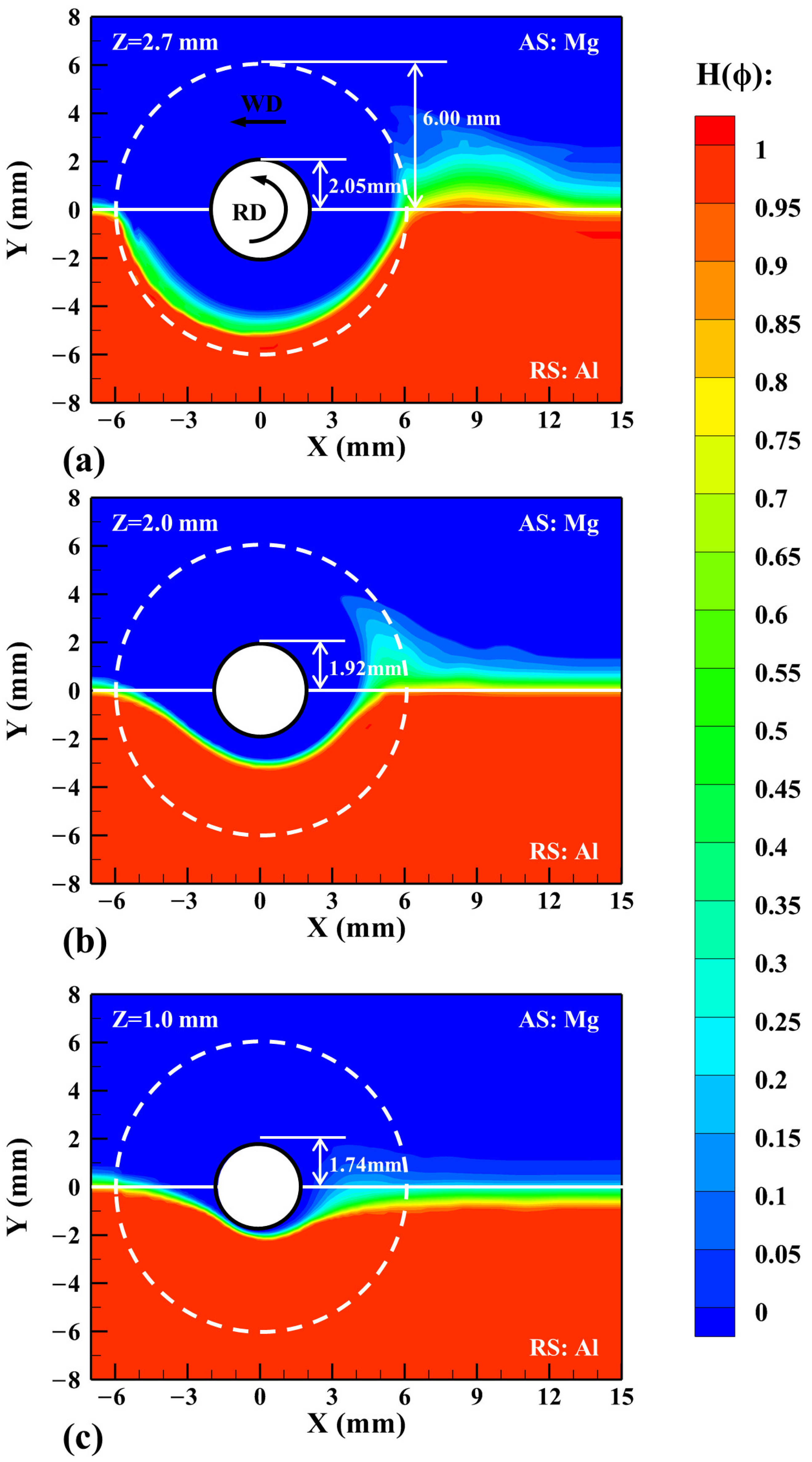

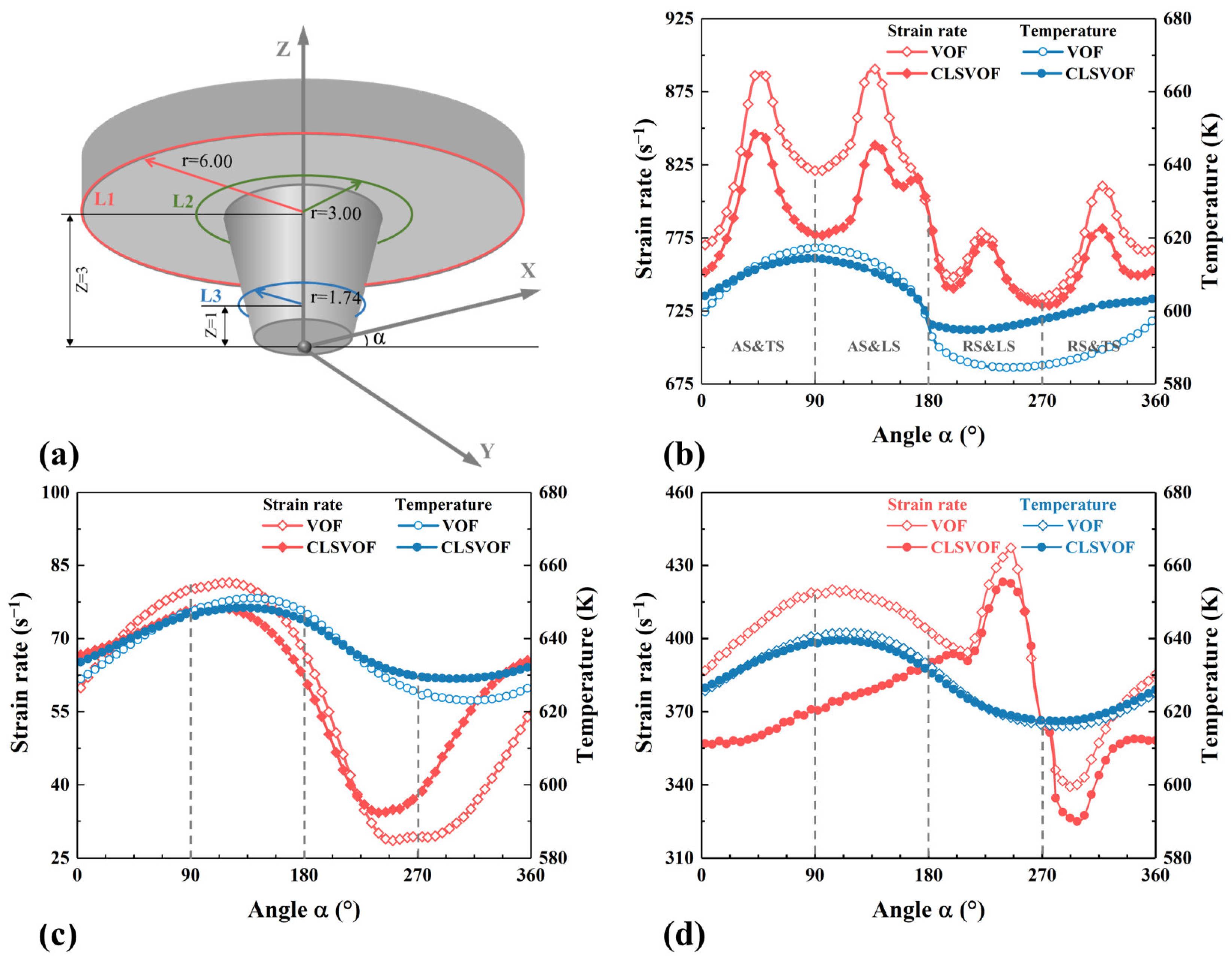

3. Results and Discussion

4. Conclusions

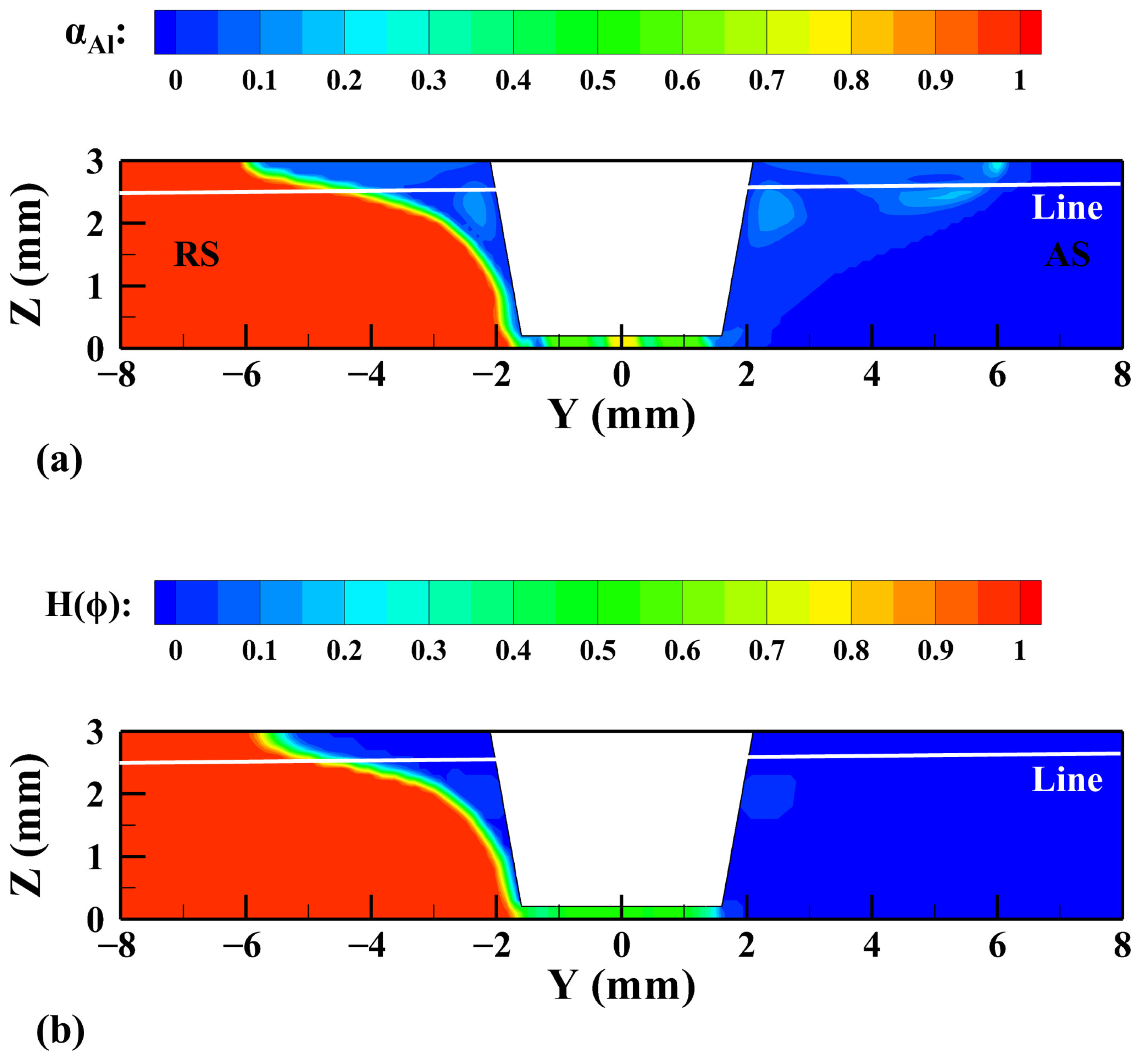

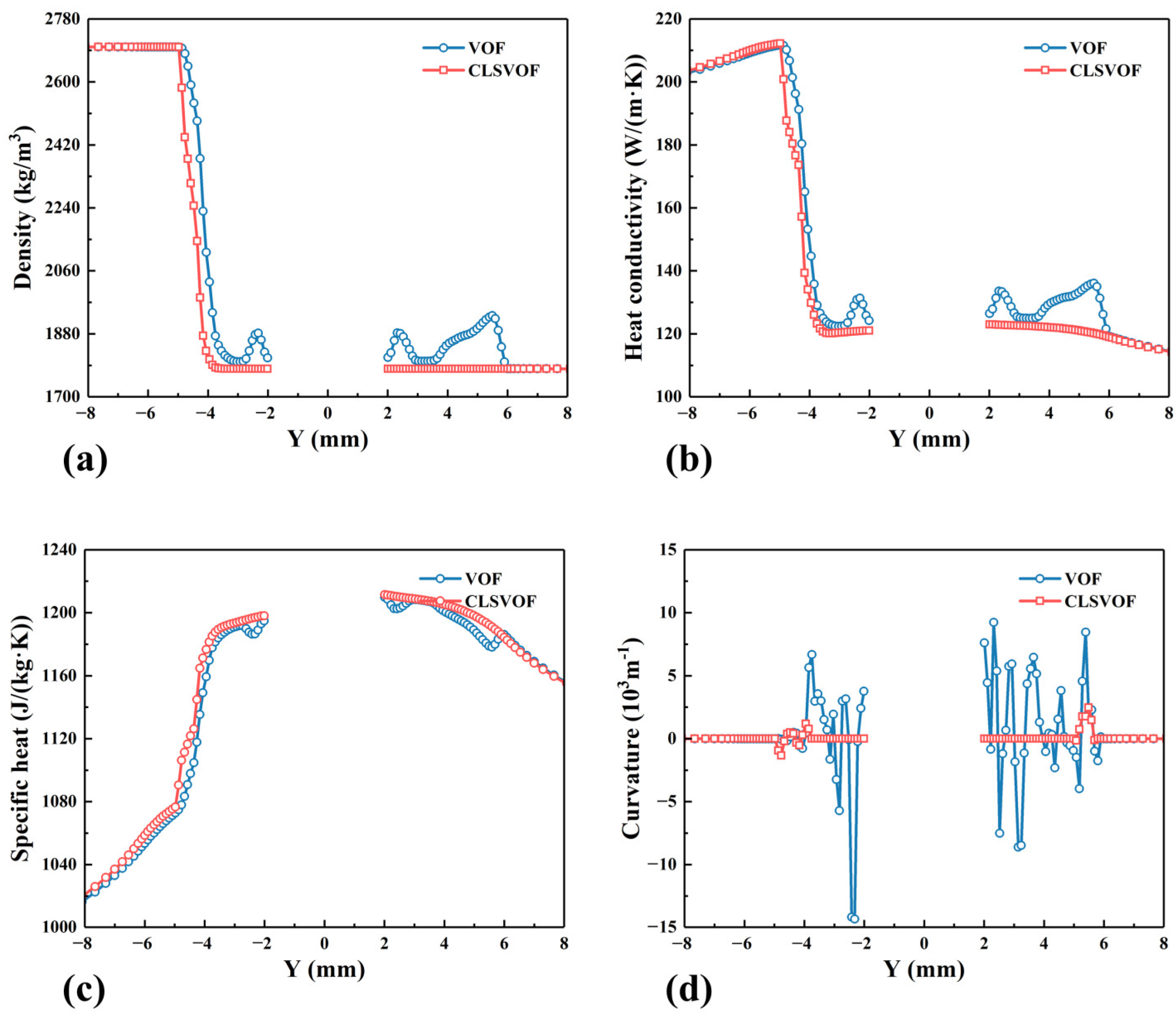

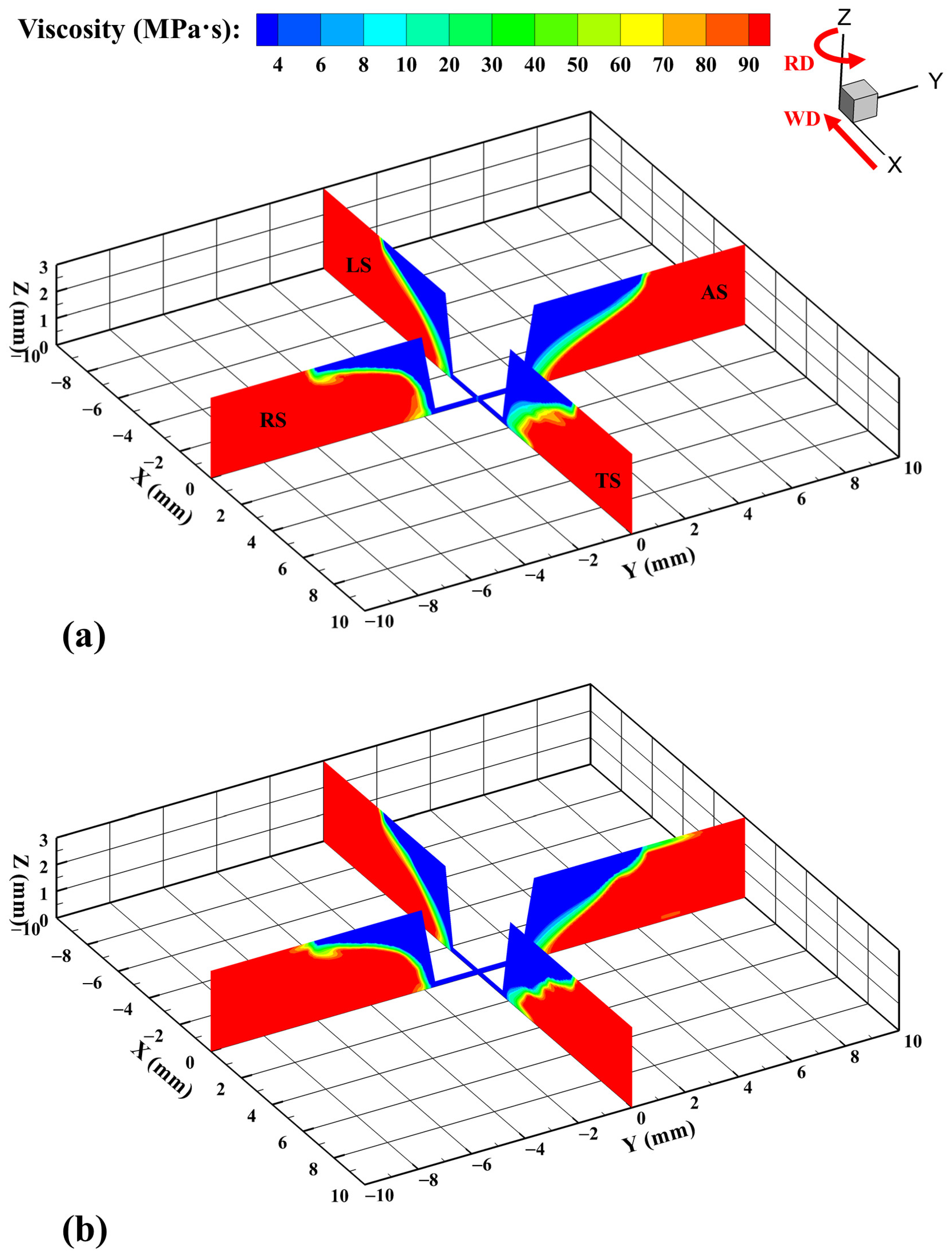

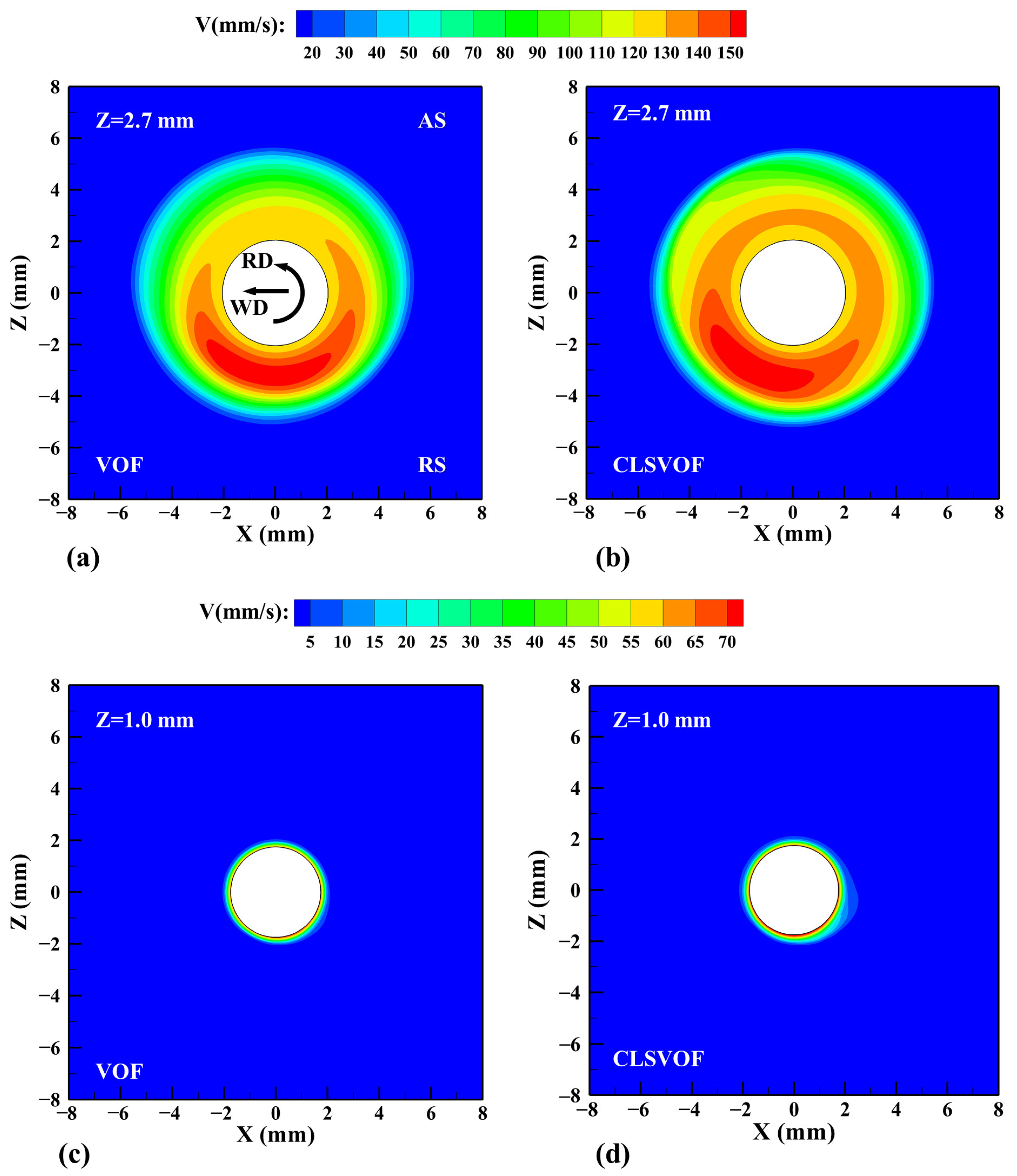

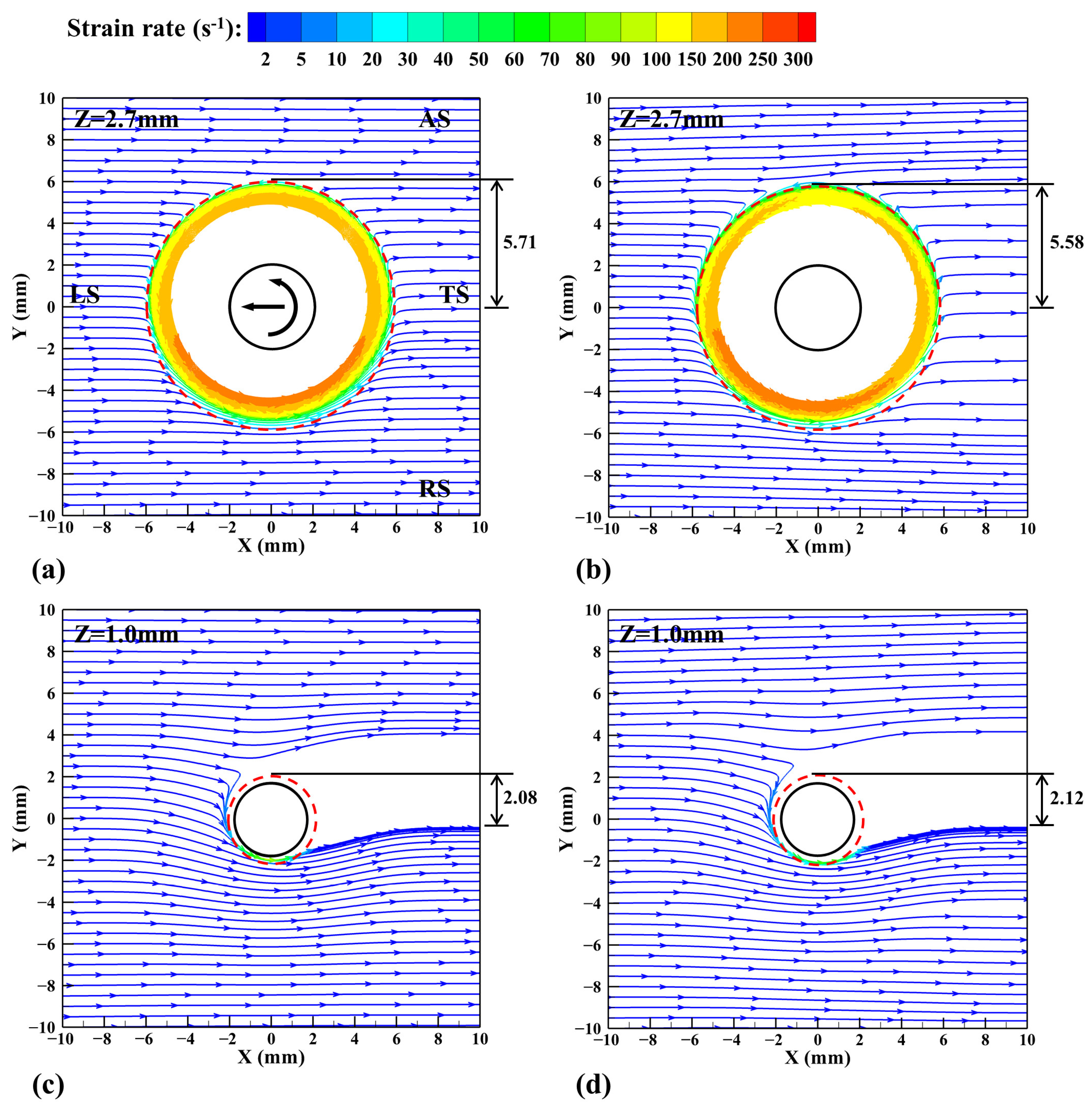

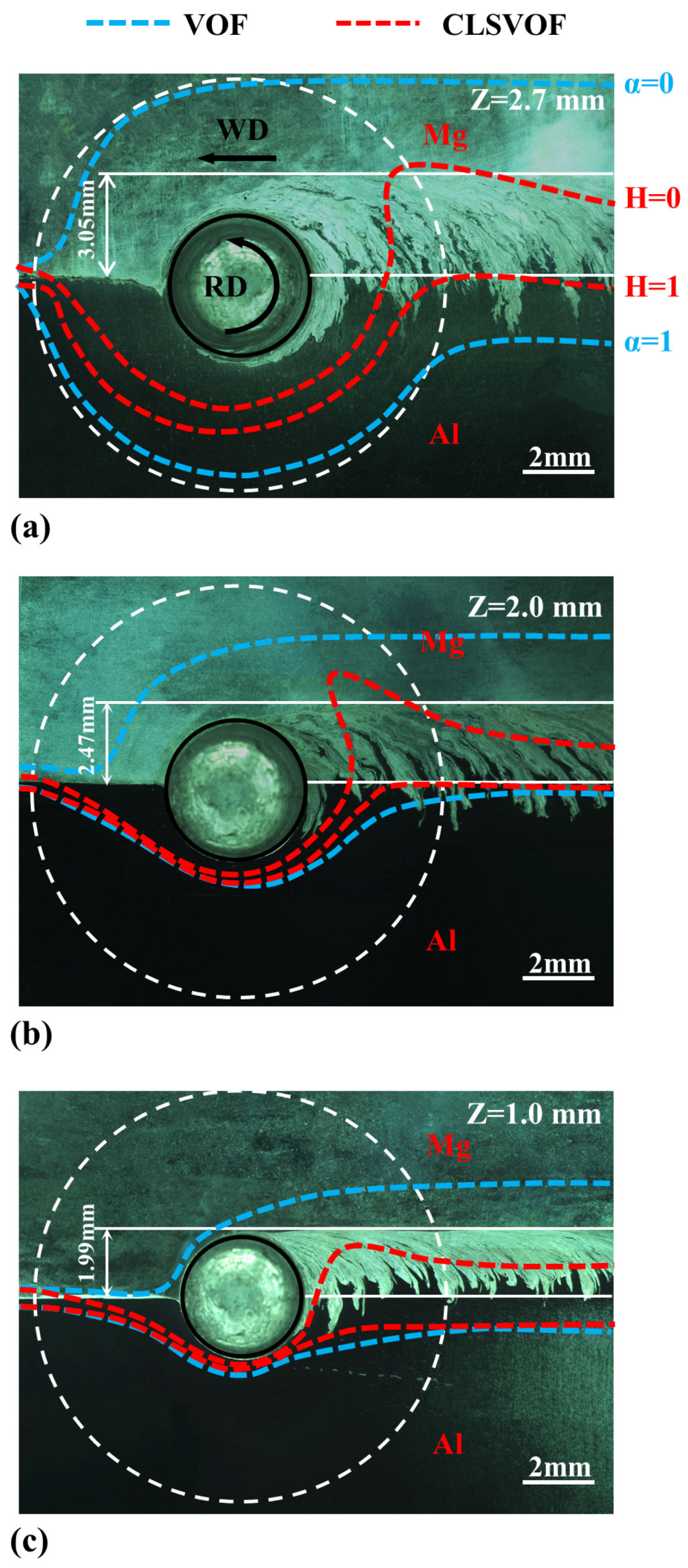

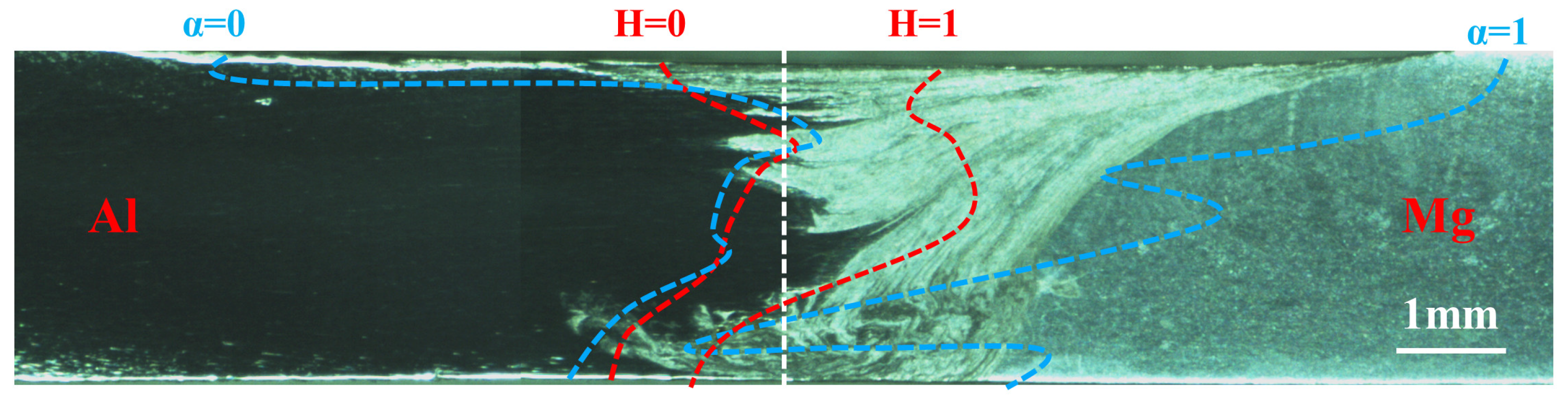

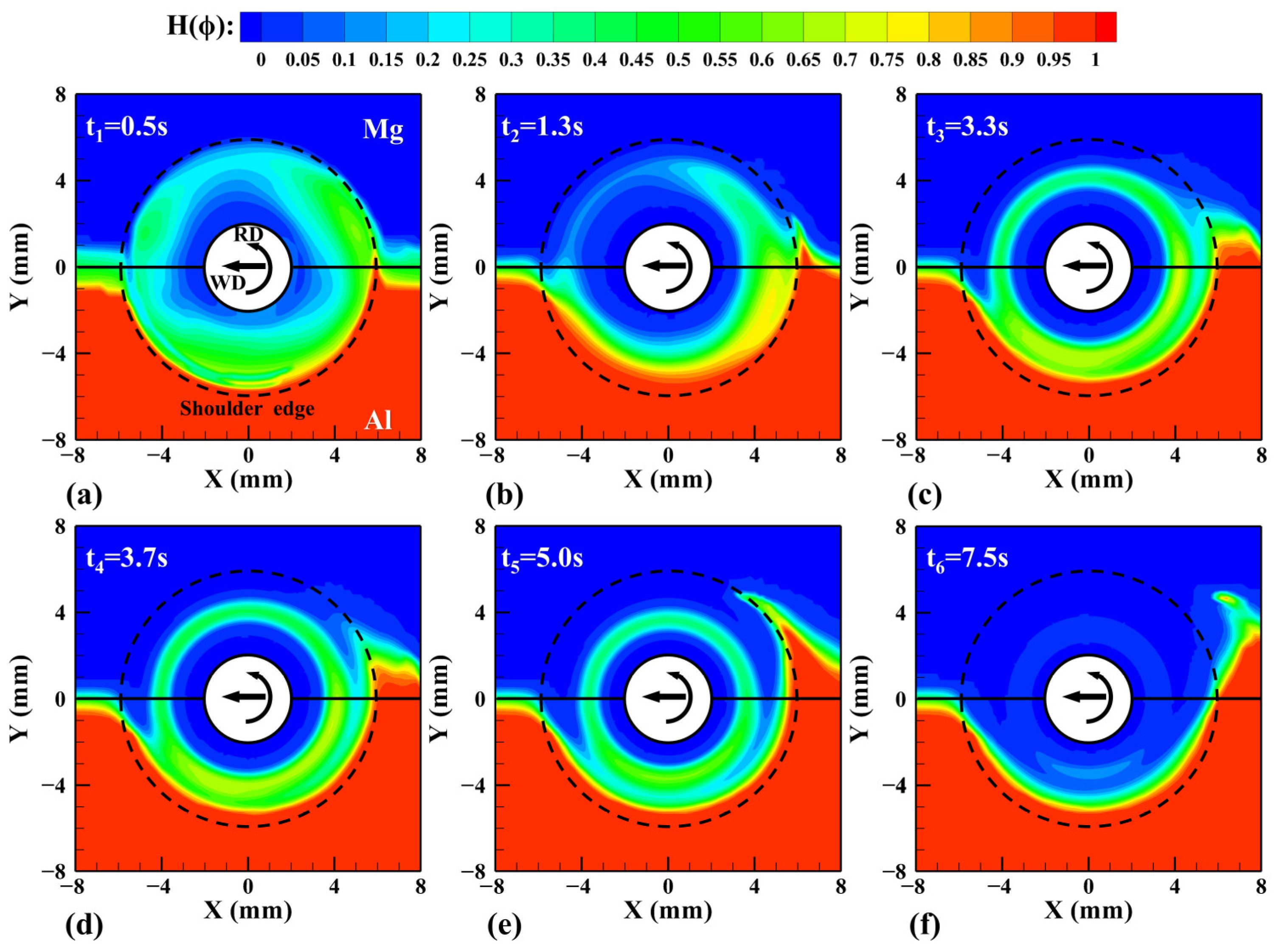

- The coupled level set and volume of fluid (CLSVOF) method is proposed and the method can not only maintain the conservation of mass but also accurately calculate the material physical properties near the interface. The material mixing and distribution in the Al/Mg dissimilar FSW are studied by using the CLSVOF method. In the upper part of the workpiece, the distance of the Al alloy moving across the original abutting surface is larger than that in the middle and lower part of the workpiece, and the degree of Al/Mg bonding is better.

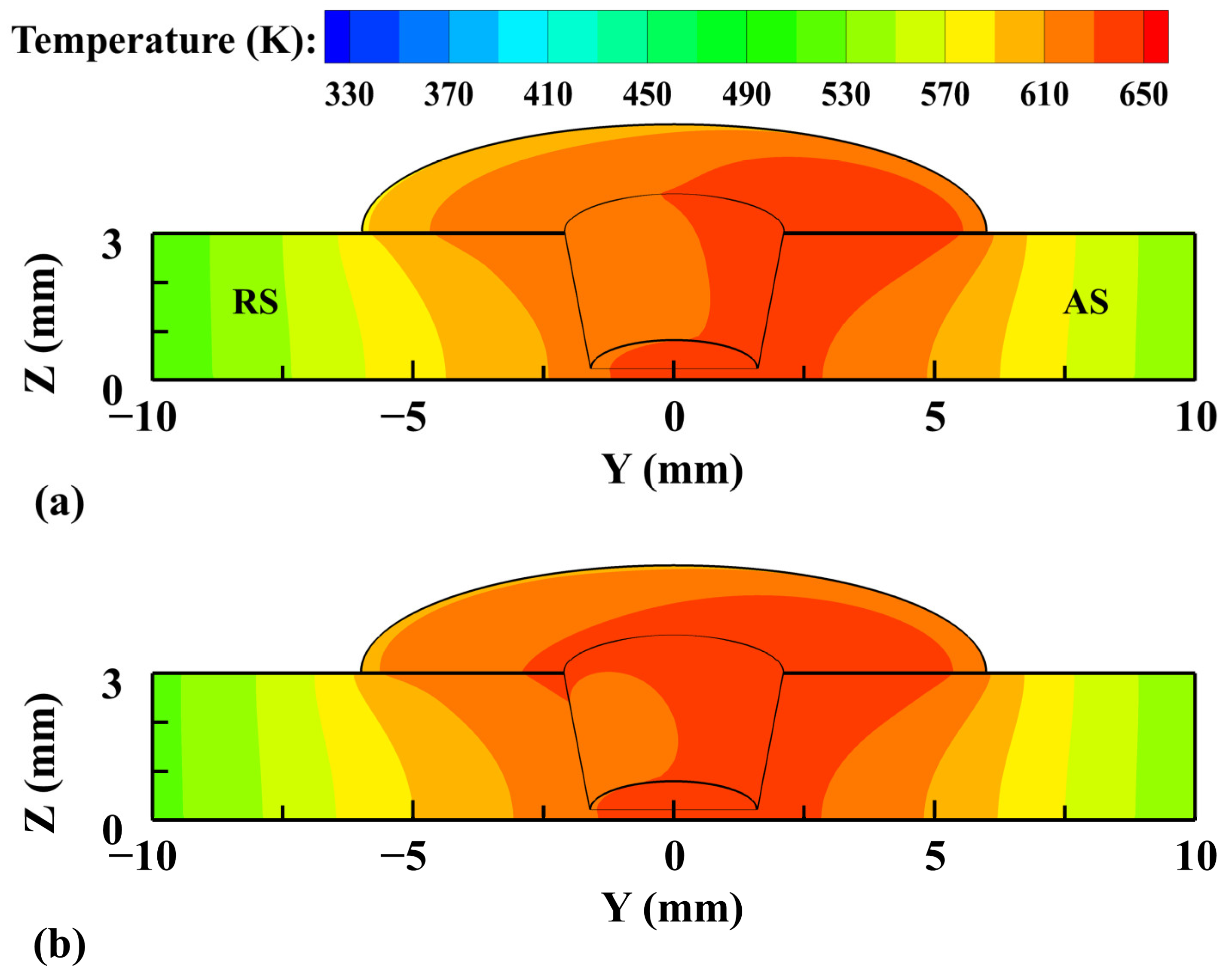

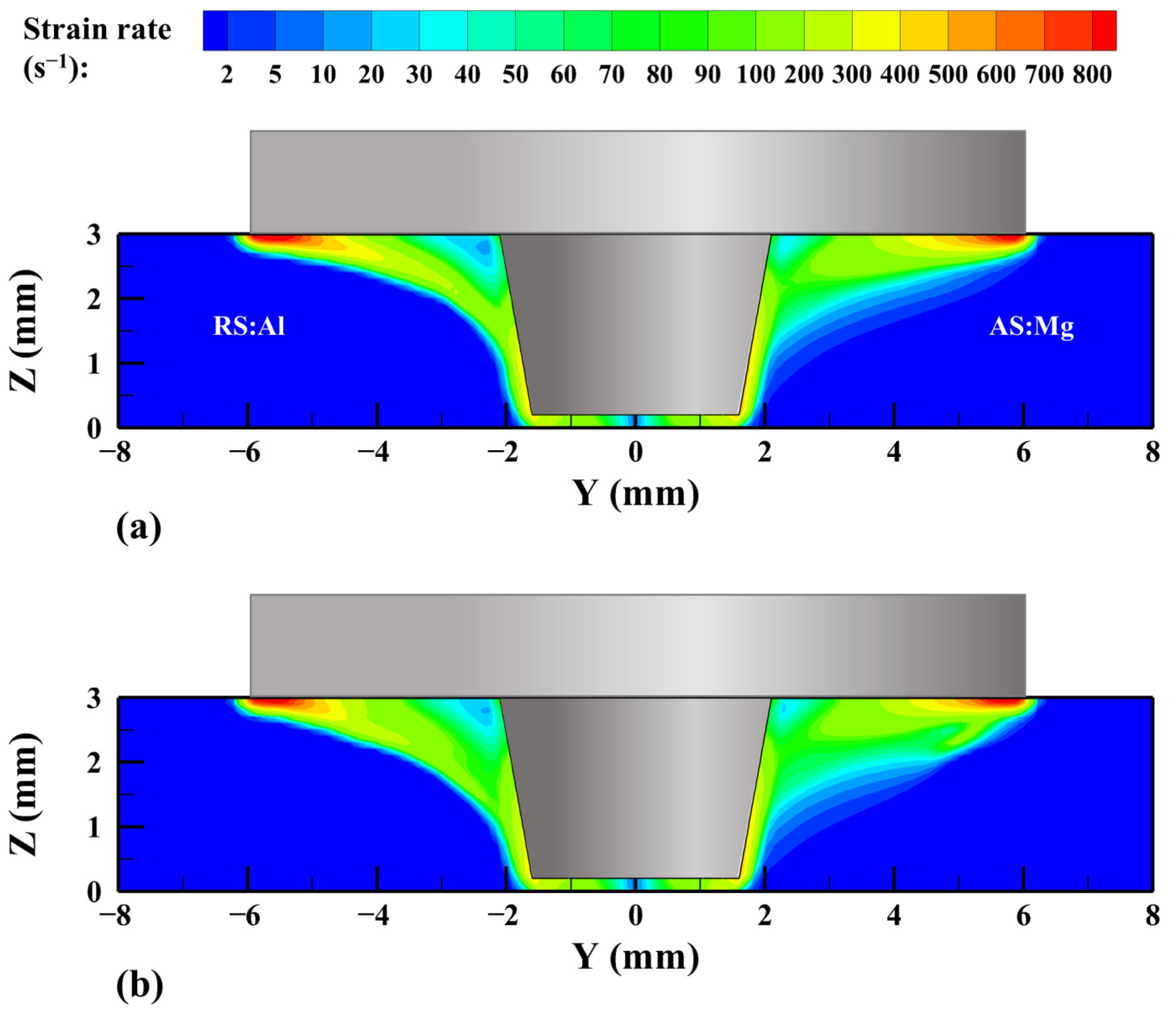

- A comparative analysis is conducted on the heat transfer and material flow in the Al/Mg dissimilar FSW process by using the VOF model and CLSVOF model. The heat transfer and material flow play important roles on the mechanical locking between Al and Mg alloys. At the lower part of the workpiece, low heat and poor material fluidity result in weak bonding, making it easy for defects to occur there.

- In order to verify the accuracy of the model, the predicted weld morphologies are compared with the experimental results. The CLSVOF model calculates a more concentrated interface zone and could better describe the Al/Mg bonding interface in the stable region.

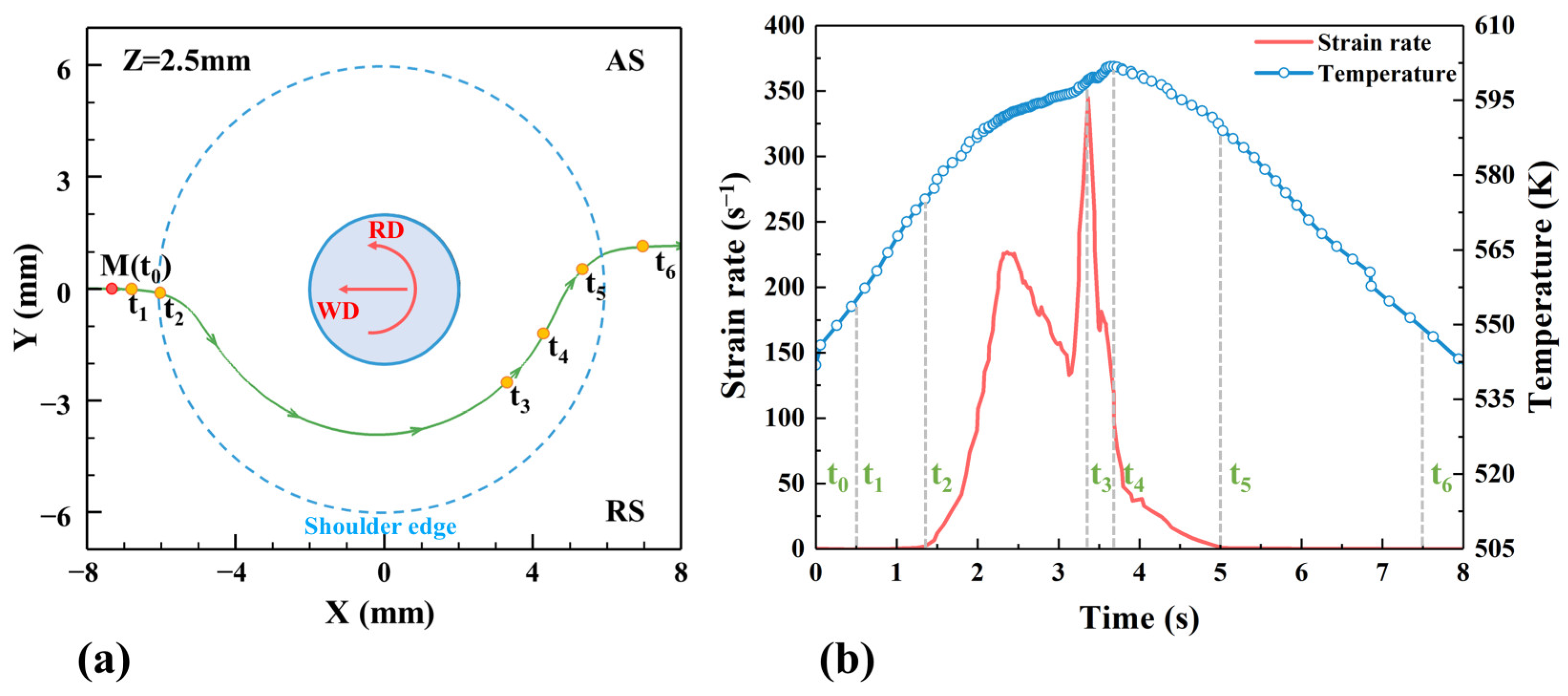

- The transient change process of the material near the tool is predicted. Under the severe action of the tool, the Al alloy easily loses continuity. A part of the material is deposited behind the tool and the other part is migrated near the pin and makes a downward spiral movement until the tool bottom under the shear and extrusion of the pin. Finally, a stable continuous two-phase interface is formed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baghdadi, A.H.; Sajuri, Z.; Selamat, N.F.M.; Omar, M.Z.; Miyashita, Y.; Kokabi, A.H. Effect of intermetallic compounds on the fracture behavior of dissimilar friction stir welding joints of Mg and Al alloys. Int. J. Min. Met. Mater. 2019, 26, 1285–1298. [Google Scholar] [CrossRef]

- Sen, M.; Puri, A.B. Formation of intermetallic compounds (IMCs) in FSW of aluminum and magnesium alloys (Al/Mg alloys)—A review. Mater. Today Commun. 2022, 33, 105017. [Google Scholar] [CrossRef]

- Ahmed, M.M.Z.; Seleman, M.M.E.; Fydrych, D.; Cam, G. Review on friction stir welding of dissimilar magnesium and aluminum alloys: Scientometric analysis and strategies for achieving high-quality joints. J. Magnes. Alloy 2023, 11, 4082–4127. [Google Scholar] [CrossRef]

- Chen, K.; Liu, X.; Ni, J. A review of friction stir–based processes for joining dissimilar materials. Int. J. Adv. Manuf. Tech. 2019, 104, 1709–1731. [Google Scholar] [CrossRef]

- Isa, M.S.M.; Moghadasi, K.; Ariffin, M.A.; Raja, S.; bin Muhamad, M.R.; Yusof, F.; Jamaludin, M.F.; bin Yusoff, N.; bin Ab Karim, M.S. Recent research progress in friction stir welding of aluminium and copper dissimilar joint: A review. J. Mater. Res. Tech. 2021, 15, 2735–2780. [Google Scholar] [CrossRef]

- Ke, W.C.; Oliveira, J.P.; Ao, S.S.; Teshome, F.B.; Chen, L.; Peng, B.; Zeng, Z. Thermal process and material flow during dissimilar double-sided friction stir spot welding of AZ31/ZK60 magnesium alloys. J. Mater. Res. Tech. 2022, 17, 1942–1954. [Google Scholar] [CrossRef]

- Pankaj, P.; Tiwari, A.; Dhara, L.N.; Biswas, P. Multiphase CFD simulation and experimental investigation of friction stir welded high strength shipbuilding steel and aluminum alloy. CIRP J. Manuf. Sci. Tech. 2022, 39, 37–69. [Google Scholar] [CrossRef]

- Liu, Q.M.; Palm, B. Numerical study of bubbles rising and merging during convective boiling in micro-channels. Appl. Therm. Eng. 2016, 99, 1141–1151. [Google Scholar] [CrossRef]

- Osher, S.; Sethian, J.A. Fronts propagating with curvature-dependent speed: Algorithms based on Hamilton-Jacobi formulations. J. Comput. Phys. 1988, 79, 12–49. [Google Scholar] [CrossRef]

- Tomashchuk, I.; Sallamand, P.; Jouvard, J.M.; Grevey, D. The simulation of morphology of dissimilar copper–steel electron beam welds using level set method. Comp. Mater. Sci. 2010, 48, 827–836. [Google Scholar] [CrossRef]

- Kesharwani, R.; Jha, K.K.; Imam, M.; Sarkar, C. The optimization of gap width size during friction stir welding of AA 6061-T6 with Al2O3 particle reinforcement. J. Mater. Eng. Perform. 2022, 32, 6008–6027. [Google Scholar] [CrossRef]

- Sadeghian, B.; Taherizadeh, A.; Atapour, M. Simulation of weld morphology during friction stir welding of aluminum-stainless steel joint. J. Mater. Process. Tech. 2018, 259, 96–108. [Google Scholar] [CrossRef]

- Olsson, E.; Kreiss, G.; Zahedi, S. A conservative level set method for two phase flow II. J. Comput. Phys. 2007, 225, 785–807. [Google Scholar] [CrossRef]

- Sussman, M.; Puckett, E.G. A coupled level set and volume-of-fluid method for computing 3D and axisymmetric incompressible two-phase flows. J. Comput. Phys. 2000, 162, 301–337. [Google Scholar] [CrossRef]

- Tomar, G.; Biswas, G.; Sharma, A.; Agrawal, A. Numerical simulation of bubble growth in film boiling using a coupled level-set and volume-of-fluid method. Phys. Fluids 2005, 17, 112103. [Google Scholar] [CrossRef]

- Liu, Q.M.; Wang, W.J.; Palm, B. Numerical study of the interactions and merge of multiple bubbles during convective boiling in micro channels. Int. Commun. Heat. Mass. 2017, 80, 10–17. [Google Scholar] [CrossRef]

- Zhang, G.L.; Gao, J.Q.; Wu, C.S. Revealing the acoustic effects on heat transfer and material flow in ultrasonic assisted friction stir welding of dissimilar Al/Mg alloys. J. Mater. Res. Tech. 2023, 26, 1882–1902. [Google Scholar] [CrossRef]

- Zhang, A.; Wang, Y.; Sun, D.; Yu, S.; Yu, B.; Li, Y. Development of a VOF+LS+SPP method based on FLUENT for simulating bubble behaviors in the electric field. Numer. Heat. Tr. B-Fund. 2017, 71, 186–201. [Google Scholar] [CrossRef]

- Yang, C.L.; Wu, C.S.; Lv, X.Q. Numerical analysis of mass transfer and material mixing in friction stir welding of aluminum/magnesium alloys. J. Manuf. Process. 2018, 32, 380–394. [Google Scholar] [CrossRef]

- Ferrari, A.; Magnini, M.; Thome, J.R. A flexible coupled level set and volume of fluid (flexCLV) method to simulate microscale two-phase flow in non-uniform and unstructured meshes. Int. J. Multiphas. Flow 2017, 91, 276–295. [Google Scholar] [CrossRef]

- Malvandi, A.; Ghasemi, A.; Nikbakhti, R.; Ghasemi, A.; Hedayati, F. Modeling and parallel computation of the non-linear interaction of rigid bodies with incompressible multi-phase flow. Comput. Math. Appl. 2016, 72, 1055–1065. [Google Scholar] [CrossRef]

- Sussman, M.; Fatemi, E.; Smereka, P.; Osher, S. An improved level set method for incompressible two-phase flows. Comput. Fluids 1998, 27, 663–680. [Google Scholar] [CrossRef]

- An, R.D.; Yu, C.H.; Lin, Y.T.; Chiu, P.H. Numerical study of incompressible interfacial flows by an one-step level set method. Numer. Heat. Tr. A-Appl. 2020, 78, 636–655. [Google Scholar] [CrossRef]

- Tsui, Y.Y.; Liu, C.Y.; Lin, S.W. Coupled level-set and volume-of-fluid method for two-phase flow calculations. Numer. Heat. Tr. B-Fund. 2017, 71, 173–185. [Google Scholar] [CrossRef]

- Yang, B.X.; Ouyang, J.; Wang, F. Simulation of stress distribution near weld line in the viscoelastic melt mold filling process. J. Appl. Math. 2013, 2013, 856171. [Google Scholar] [CrossRef]

- Lyras, P.; Hubert, A.; Lyras, K.G. A conservative level set method for liquid-gas flows with application in liquid jet atomisation. Exp. Comput. Multi. Flow 2023, 5, 67–83. [Google Scholar] [CrossRef]

- Gu, Z.H.; Wen, H.L.; Yao, Y.; Yu, C.H. A volume of fluid method algorithm for simulation of surface tension dominant two-phase flows. Numer. Heat. Tr. B-Fund. 2019, 76, 1–17. [Google Scholar] [CrossRef]

- Nichita, B.A.; Zun, I.; Thome, J.R. A level set method coupled with a volume of fluid method for modeling of gas-liquid interface in bubbly flow. J. Fluid. Eng. 2010, 132, 081302. [Google Scholar] [CrossRef]

- Zhang, M.Q.; Shu, C.W.; Wong, G.C.K.; Wong, S.C. A weighted essentially non-oscillatory numerical scheme for a multi-class Lighthill–Whitham–Richards traffic flow model. J. Comput. Phys. 2003, 191, 639–659. [Google Scholar] [CrossRef]

- Zhao, J.J.; Wu, C.S.; Su, H. Ultrasonic effect on thickness variations of intermetallic compound layers in friction stir welding of aluminium/magnesium alloys. J. Manuf. Process. 2021, 62, 388–402. [Google Scholar] [CrossRef]

| Component | Al | Mg | Cu | Si | Mn | Fe | Zn | Ti | Cr |

|---|---|---|---|---|---|---|---|---|---|

| 6061-T6 | Bal. | 1.09 | 0.3 | 0.51 | 0.009 | 0.200 | 0.050 | - | 0.13 |

| AZ31B-H24 | 3.91 | Bal. | 0.004 | 0.034 | 0.322 | 0.005 | 0.936 | - | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, G.; Gao, J.; Wu, C. Numerical Simulation of Friction Stir Welding of Dissimilar Al/Mg Alloys Using Coupled Level Set and Volume of Fluid Method. Materials 2024, 17, 3014. https://doi.org/10.3390/ma17123014

Zhang G, Gao J, Wu C. Numerical Simulation of Friction Stir Welding of Dissimilar Al/Mg Alloys Using Coupled Level Set and Volume of Fluid Method. Materials. 2024; 17(12):3014. https://doi.org/10.3390/ma17123014

Chicago/Turabian StyleZhang, Guanlan, Jinqiang Gao, and Chuansong Wu. 2024. "Numerical Simulation of Friction Stir Welding of Dissimilar Al/Mg Alloys Using Coupled Level Set and Volume of Fluid Method" Materials 17, no. 12: 3014. https://doi.org/10.3390/ma17123014

APA StyleZhang, G., Gao, J., & Wu, C. (2024). Numerical Simulation of Friction Stir Welding of Dissimilar Al/Mg Alloys Using Coupled Level Set and Volume of Fluid Method. Materials, 17(12), 3014. https://doi.org/10.3390/ma17123014