The Influence of Heat Treatment on the Microstructure and Properties of a Cu-Bearing Ultra-Low Carbon Steel

Abstract

1. Introduction

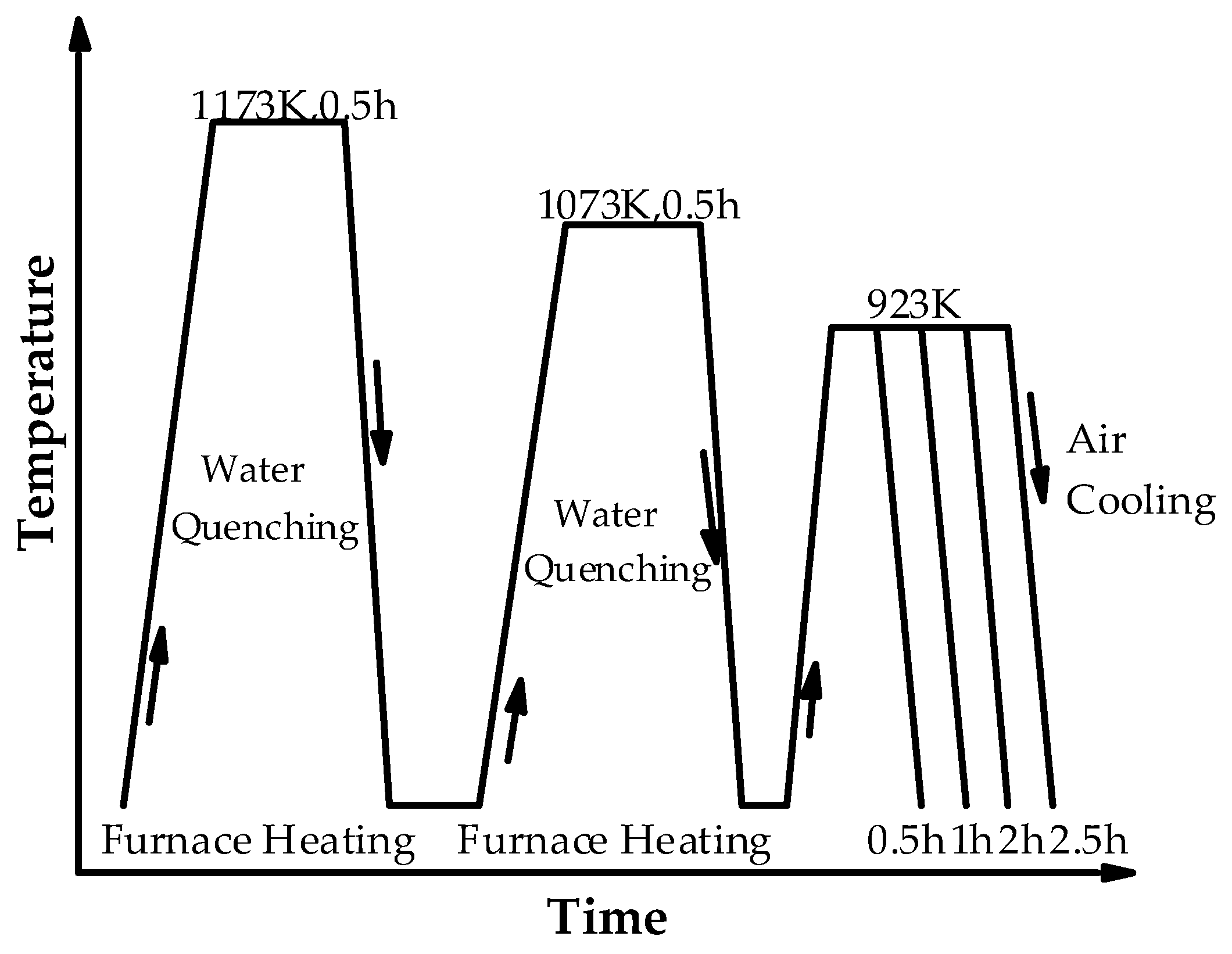

2. Materials and Method

3. Results

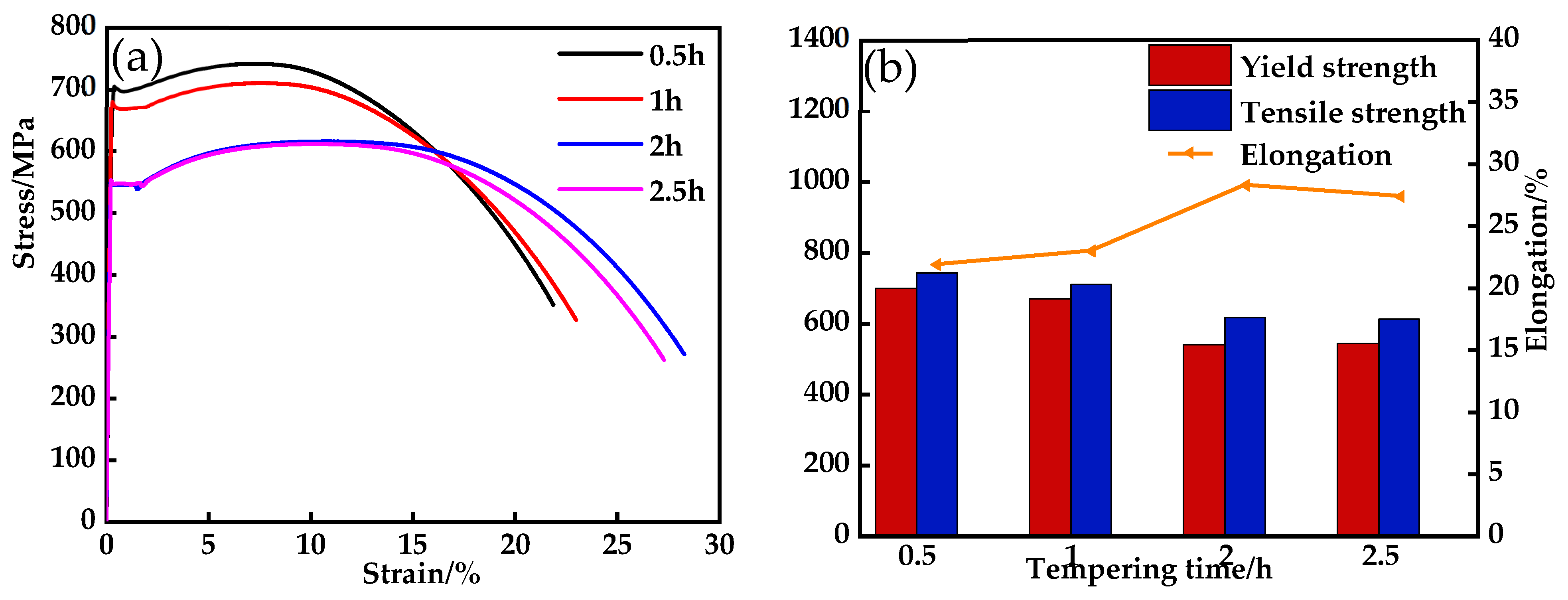

3.1. Tensile Properties

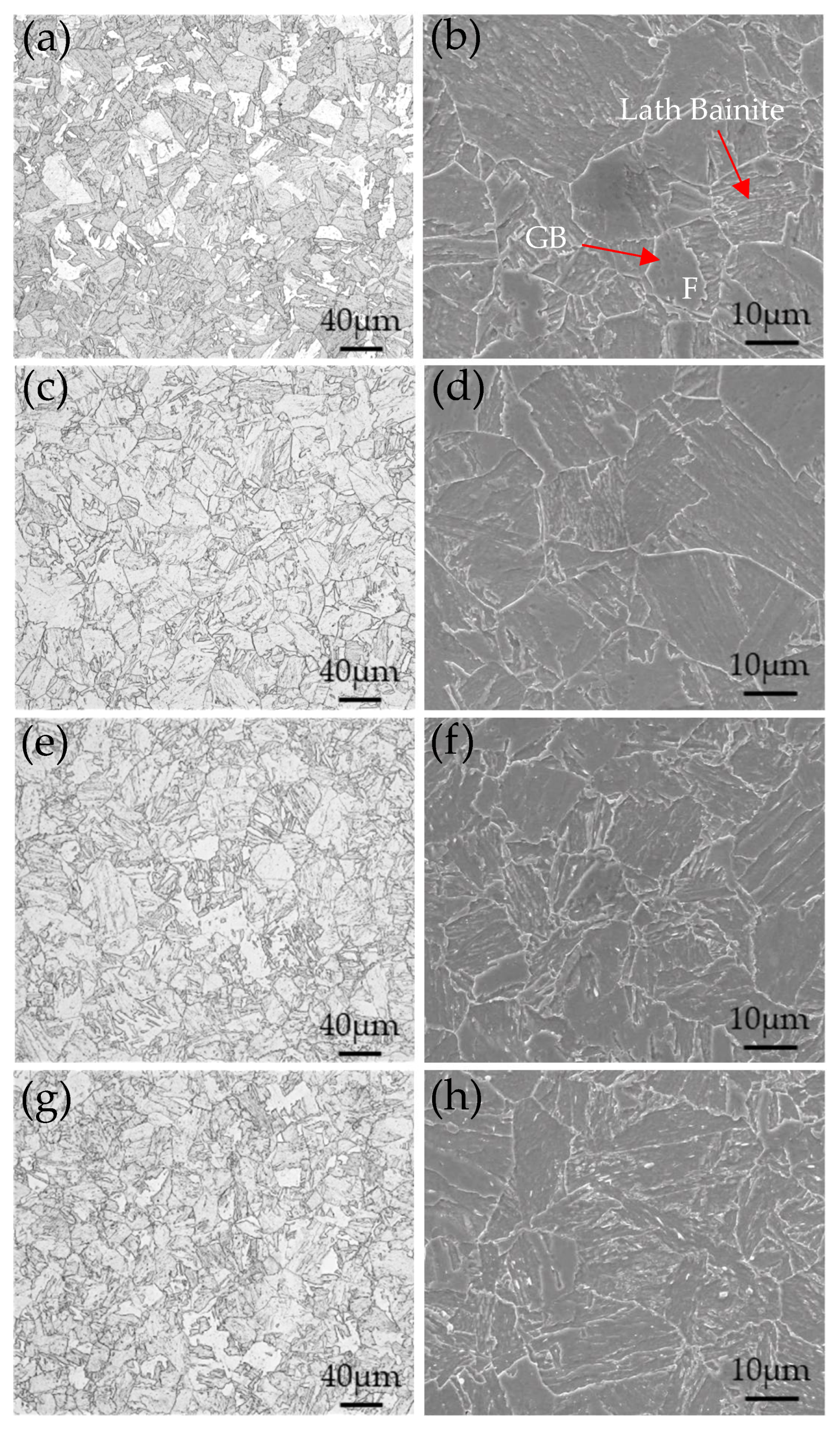

3.2. Microstructural Characterization by SEM

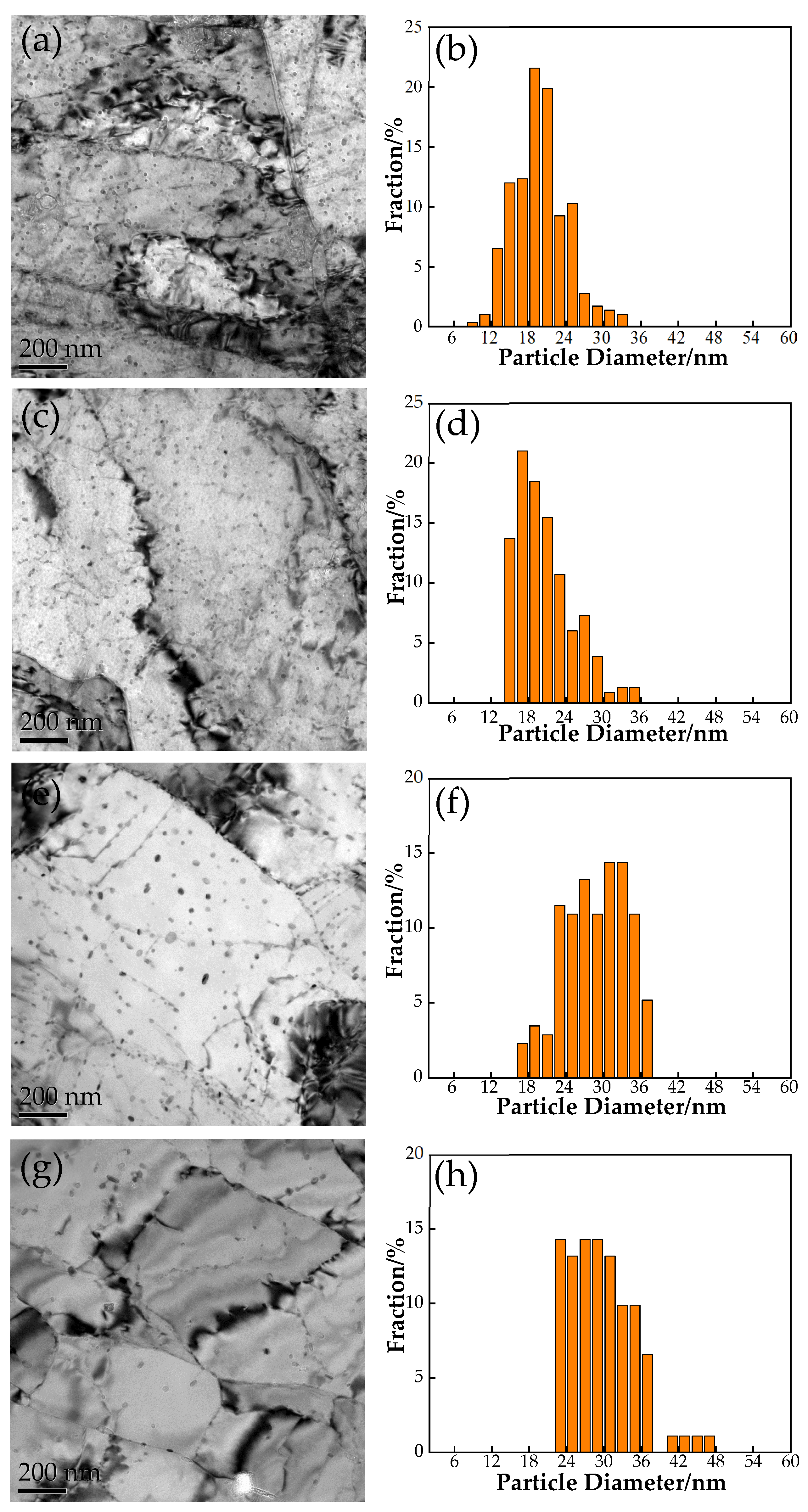

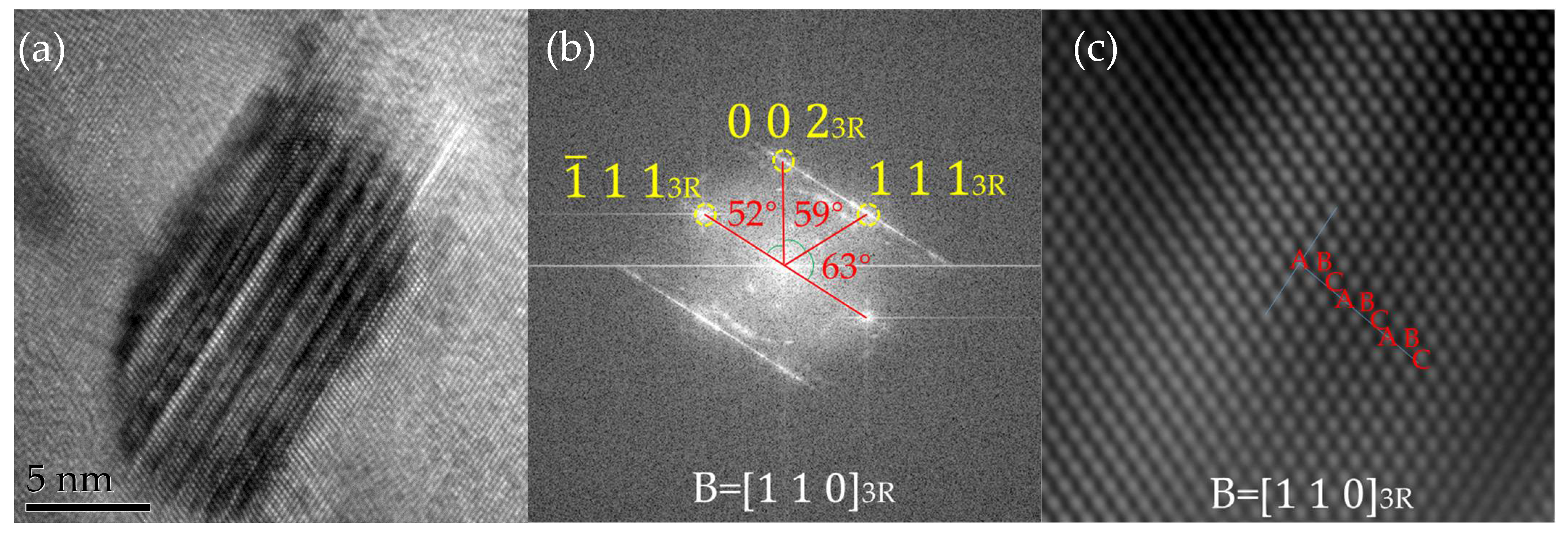

3.3. Microstructural Characterization by TEM

4. Discussion

4.1. Influence of Heat Treatment on Precipitation Strengthening

4.2. Influence of Heat Treatment on Cu Precipitation

5. Conclusions

- As the heat treatment time increased, the strength gradually decreased and then remained stable, and the elongation gradually increased and then remained stable. In the tempering time between 2 and 2.5 h, the precipitation-strengthening effect and the tempering-softening effect reached an equilibrium state.

- The microstructure of experimental steel treated at different times was mainly composed of tempered bainite. As the tempering time increased, the size of precipitates increased, and the density decreased. By increasing the heat treatment time, the size and density of the precipitates could be controlled, thereby improving the mechanical properties.

- This study used the Russell–Brown model to calculate the precipitation-strengthening effect and assessed the contributions of each strengthening mechanism to the yield strength under different cooling processes, which were 117, 107, 102, and 89 MPa, respectively.

- During the tempering process, nano-Cu precipitates formed in the experimental steel. As the annealing time increased, the precipitates grew and formed a stable 3R-Cu structure.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, Z.W.; Liu, C.T.; Wen, Y.R.; Hirata, A.; Guo, S.; Chen, G.; Chen, M.W.; Chin, B.A. Influence of aging and thermomechanical treatments on the mechanical properties of a nanocluster-strengthened ferritic steel. Metall. Mater. Trans. A 2012, 43, 351–358. [Google Scholar] [CrossRef]

- Ray, P.K.; Ganguly, R.I.; Panda, A.K. Optimization of mechanical properties of an HSLA-100 steel through control of heat treatment variables. Mater. Sci. Eng. A 2003, 346, 122–131. [Google Scholar] [CrossRef]

- Misra, R.D.K.; Jia, Z.; O’Malley, R.; Jansto, S.J. Precipitation behavior during thin slab thermomechanical processing and isothermal aging of copper-bearing niobium-microalloyed high strength structural steels: The effect on mechanical properties. Mater. Sci. Eng. A 2011, 528, 8772–8780. [Google Scholar] [CrossRef]

- Jablokov, V.; Goto, D.M.; Koss, D.A. Damage accumulation and failure of HY-100 steel. Metall. Mater. Trans. A 2001, 32, 2985–2994. [Google Scholar] [CrossRef]

- Yayla, P.; Kaluc, E.; Ural, K. Effects of welding processes on the mechanical properties of HY 80 steel weldments. Mater. Des. 2007, 28, 1898–1906. [Google Scholar] [CrossRef]

- Chen, C.; Thompson, A.W.; Bernstein, I.M. The correlation of microstructure and stress corrosion fracture of HY-130 steel weldments. Metall. Trans. A 1980, 11, 1723–1730. [Google Scholar] [CrossRef]

- Sun, M.; Xu, Y.; Xu, T. Cu Precipitation Behaviors and Microscopic Mechanical Characteristics of a Novel Ultra-Low Carbon Steel. Materials 2020, 13, 3571. [Google Scholar] [CrossRef] [PubMed]

- Nizinkovskyi, R.; Halle, T.; Krüger, M. Investigation of the equilibrium morphology of fcc ϵ− Cu in Fe–Cu alloys using a non-local Allen–Cahn model. Mater. Today Commun. 2024, 38, 107635. [Google Scholar] [CrossRef]

- Konstrukcijska, V.M.H. High-strength low-alloy (HSLA) steels. Mater. Technol. 2011, 45, 295–301. [Google Scholar]

- Shi, L.; Yan, Z.; Liu, Y.; Zhang, C.; Qiao, Z.; Ning, B.; Li, H. Improved toughness and ductility in ferrite/acicular ferrite dual-phase steel through intercritical heat treatment. Mater. Sci. Eng. A 2014, 590, 7–15. [Google Scholar] [CrossRef]

- Jiang, J.; Wu, H.; Liang, J.; Tang, D. Microstructural characterization and impact toughness of a jack up rig rack steel treated by intercritical heat treatment. Mater. Sci. Eng. A 2013, 587, 359–364. [Google Scholar] [CrossRef]

- Wen, Y.R.; Li, Y.P.; Hirata, A.; Zhang, Y.; Fujita, T.; Liu, C.T.; Chiba, A.; Chen, M.W. Synergistic alloying effect on microstructural evolution and mechanical properties of Cu precipitation-strengthened ferritic alloys. Acta Mater. 2013, 61, 7726–7740. [Google Scholar] [CrossRef]

- Liu, G.; Li, Y.; Liao, T.; Wang, S.Z.; Lv, B.; Guo, H.B.; Huang, Y.H.; Yong, Q.L.; Mao, X.P. Revealing the precipitation kinetics and strengthening mechanisms of a 450 MPa grade Nb-bearing HSLA steel. Mater. Sci. Eng. A 2023, 884, 145506. [Google Scholar] [CrossRef]

- Zhang, Y.; Yun, X.; Zhao, R.; Fu, H.W. Preparing large-scale, uniform, and high-performance Cu–Cr–Zr strips by a novel continuous expanding extrusion process. J. Mater. Res. Technol. 2023, 27, 3860–3869. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, X.; He, Z.; Zu, G.Q.; Ji, G.F.; Duan, J.Y.; Misra, R.D.K. Effect of copper precipitates on mechanical and magnetic properties of Cu-bearing non-oriented electrical steel processed by twin-roll strip casting. Mater. Sci. Eng. A 2017, 703, 340–347. [Google Scholar] [CrossRef]

- Phaniraj, M.P.; Shin, Y.M.; Jung, W.S.; Kim, M.H.; Choi, I.S. Understanding dual precipitation strengthening in ultra-high strength low carbon steel containing nano-sized copper precipitates and carbides. Nano Converg. 2017, 4, 16. [Google Scholar] [CrossRef] [PubMed]

- Goodman, S.R.; Brenner, S.S.; Low, J.R. An FIM-atom probe study of the precipitation of copper from lron-1.4 at. pct copper. Part II: Atom probe analyses. Metall. Trans. 1973, 4, 2371–2378. [Google Scholar] [CrossRef]

- Goodman, S.R.; Brenner, S.S.; Low, J.R. An FIM-atom probe study of the precipitation of copper from lron-1.4 at. pct copper. Part I: Field-ion microscopy. Metall. Trans. 1973, 4, 2363–2369. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.L.; Smith, G.D.W.; Phythian, W.J. Transmission electron microscope investigations of the structure of copper precipitates in thermally-aged Fe—Cu and Fe—Cu—Ni. Philos. Mag. Lett. 1991, 64, 383–391. [Google Scholar] [CrossRef]

- Monzen, R.; Iguchi, M.; Jenkins, M.L. Structural changes of 9R copper precipitates in an aged Fe-Cu alloy. Philos. Mag. Lett. 2000, 80, 137–148. [Google Scholar] [CrossRef]

- Lee, T.H.; Kim, Y.O.; Kim, S.J. Crystallographic model for bcc-to-9R martensitic transformation of Cu precipitates in ferritic steel. Philos. Mag. 2007, 87, 209–224. [Google Scholar] [CrossRef]

- Othen, P.J.; Jenkins, M.L.; Smith, G.D.W. High-resolution electron microscopy studies of the structure of Cu precipitates in α-Fe. Philos. Mag. A 1994, 70, 1–24. [Google Scholar] [CrossRef]

- Monzen, R.; Jenkins, M.L.; Sutton, A.P. The bcc-to-9R martensitic transformation of Cu precipitates and the relaxation process of elastic strains in an Fe-Cu alloy. Philos. Mag. A 2000, 80, 711–723. [Google Scholar] [CrossRef]

- Xu, C.; Dai, W.J.; Chen, Y.; Qi, Z.X.; Zheng, G.; Cao, Y.D.; Zhang, J.P.; Bu, C.C.; Chen, G. Control of dislocation density maximizing precipitation strengthening effect. J. Mater. Sci. Technol. 2022, 127, 133–143. [Google Scholar] [CrossRef]

- Heo, Y.U.; Kim, Y.K.; Kim, J.S.; Kim, J.K. Phase transformation of Cu precipitates from bcc to fcc in Fe–3Si–2Cu alloy. Acta Mater. 2013, 61, 519–528. [Google Scholar] [CrossRef]

- GB/T 228.1—2010; Metallic Materials-Tensle Testing, Part 1: Method of Test at Room Temperature. ISO: Beijing, China, 2010.

- Russel, K.C.; Brown, L.M. A dispersion strengthening model based on differing elastic moduli applied to the iron-copper system. Acta Met. 1972, 20, 969–974. [Google Scholar] [CrossRef]

- Kong, H.J.; Xu, C.; Bu, C.C.; Da, C.; Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Hardening mechanisms and impact toughening of a high-strength steel containing low Ni and Cu additions. Acta Mater. 2019, 172, 150–160. [Google Scholar] [CrossRef]

| Fe | C | Cu | Ni | Mn | Cr | Si | Mo | V | Al |

|---|---|---|---|---|---|---|---|---|---|

| Bal. | 0.02 | 1.52 | 1.54 | 1.0 | 0.58 | 0.33 | 0.29 | 0.03 | 0.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Gao, Z.; Zhang, H.; Wei, H.; Chen, Z.; Xue, W.; Liu, Z. The Influence of Heat Treatment on the Microstructure and Properties of a Cu-Bearing Ultra-Low Carbon Steel. Materials 2024, 17, 3031. https://doi.org/10.3390/ma17123031

Zhang W, Gao Z, Zhang H, Wei H, Chen Z, Xue W, Liu Z. The Influence of Heat Treatment on the Microstructure and Properties of a Cu-Bearing Ultra-Low Carbon Steel. Materials. 2024; 17(12):3031. https://doi.org/10.3390/ma17123031

Chicago/Turabian StyleZhang, Weina, Zhanjie Gao, Huimin Zhang, Hao Wei, Zejin Chen, Wenying Xue, and Zhenyu Liu. 2024. "The Influence of Heat Treatment on the Microstructure and Properties of a Cu-Bearing Ultra-Low Carbon Steel" Materials 17, no. 12: 3031. https://doi.org/10.3390/ma17123031

APA StyleZhang, W., Gao, Z., Zhang, H., Wei, H., Chen, Z., Xue, W., & Liu, Z. (2024). The Influence of Heat Treatment on the Microstructure and Properties of a Cu-Bearing Ultra-Low Carbon Steel. Materials, 17(12), 3031. https://doi.org/10.3390/ma17123031