Study on the Tribological Properties of DIN 16MnCr5 Steel after Duplex Gas-Nitriding and Pack Boriding

Abstract

1. Introduction

2. Materials and Methods

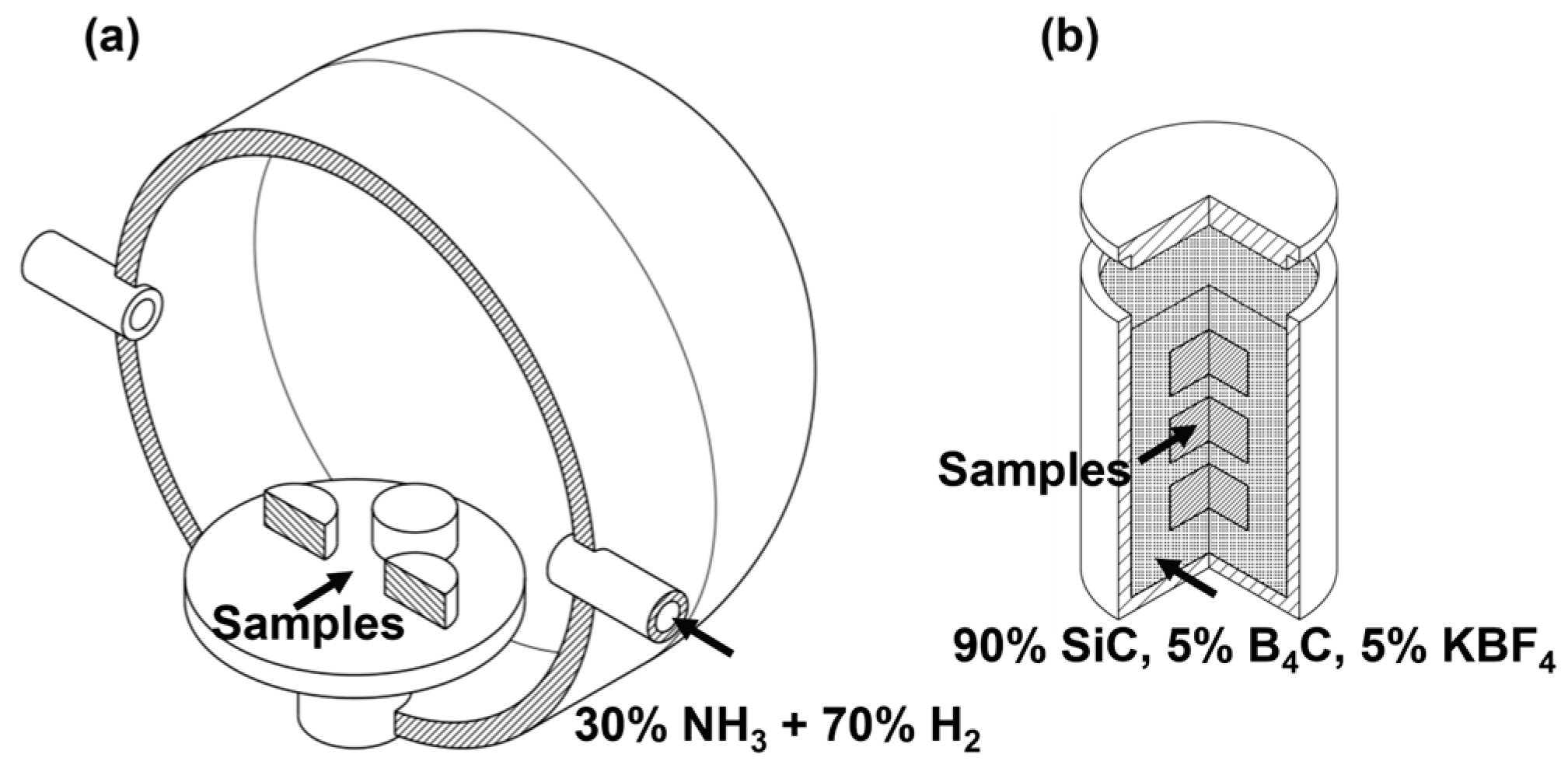

2.1. Gas-Nitriding and Pack Boriding Processes

2.2. Characterization

2.3. Mechanical and Tribological Properties

3. Results and Discussion

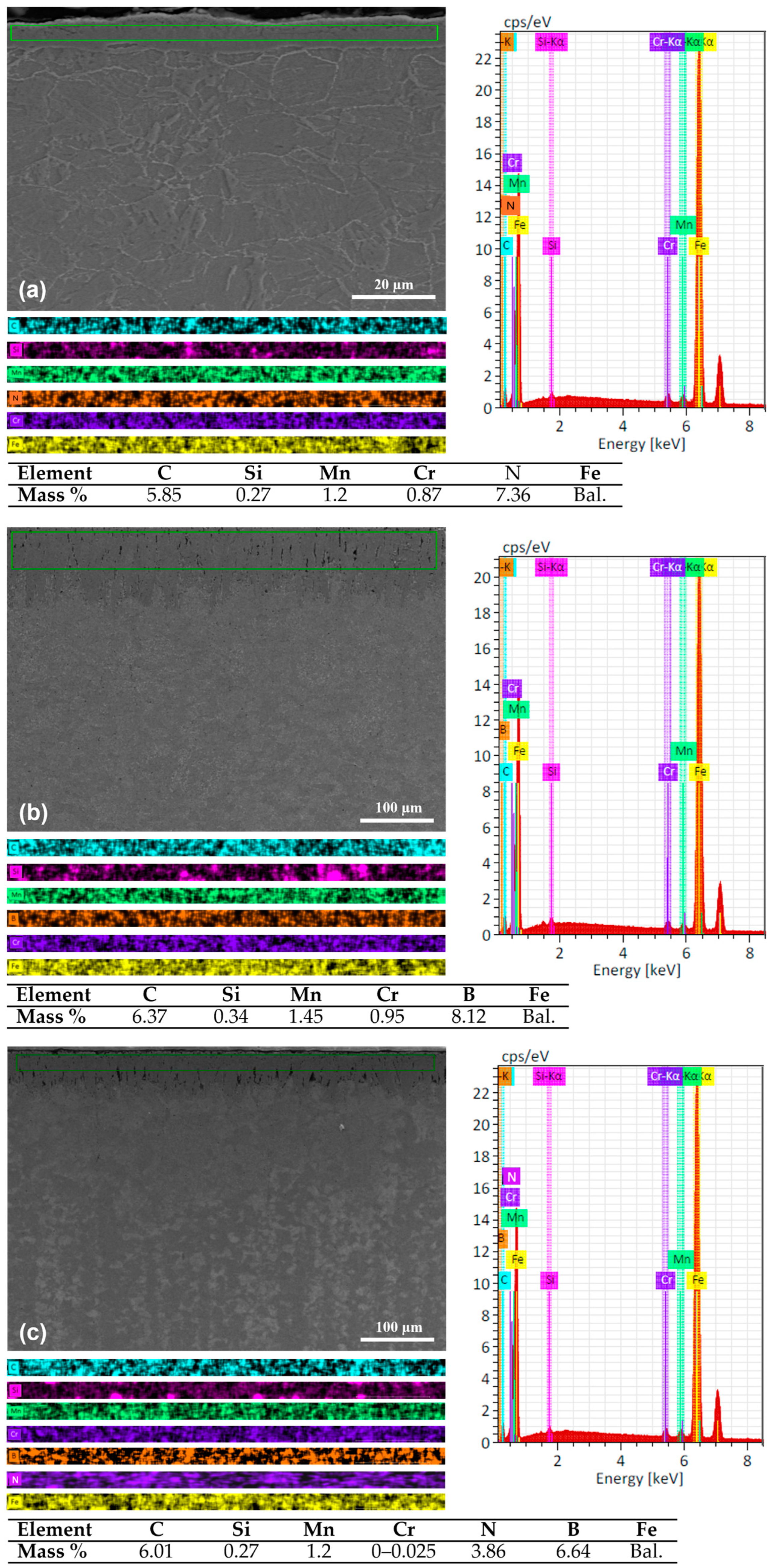

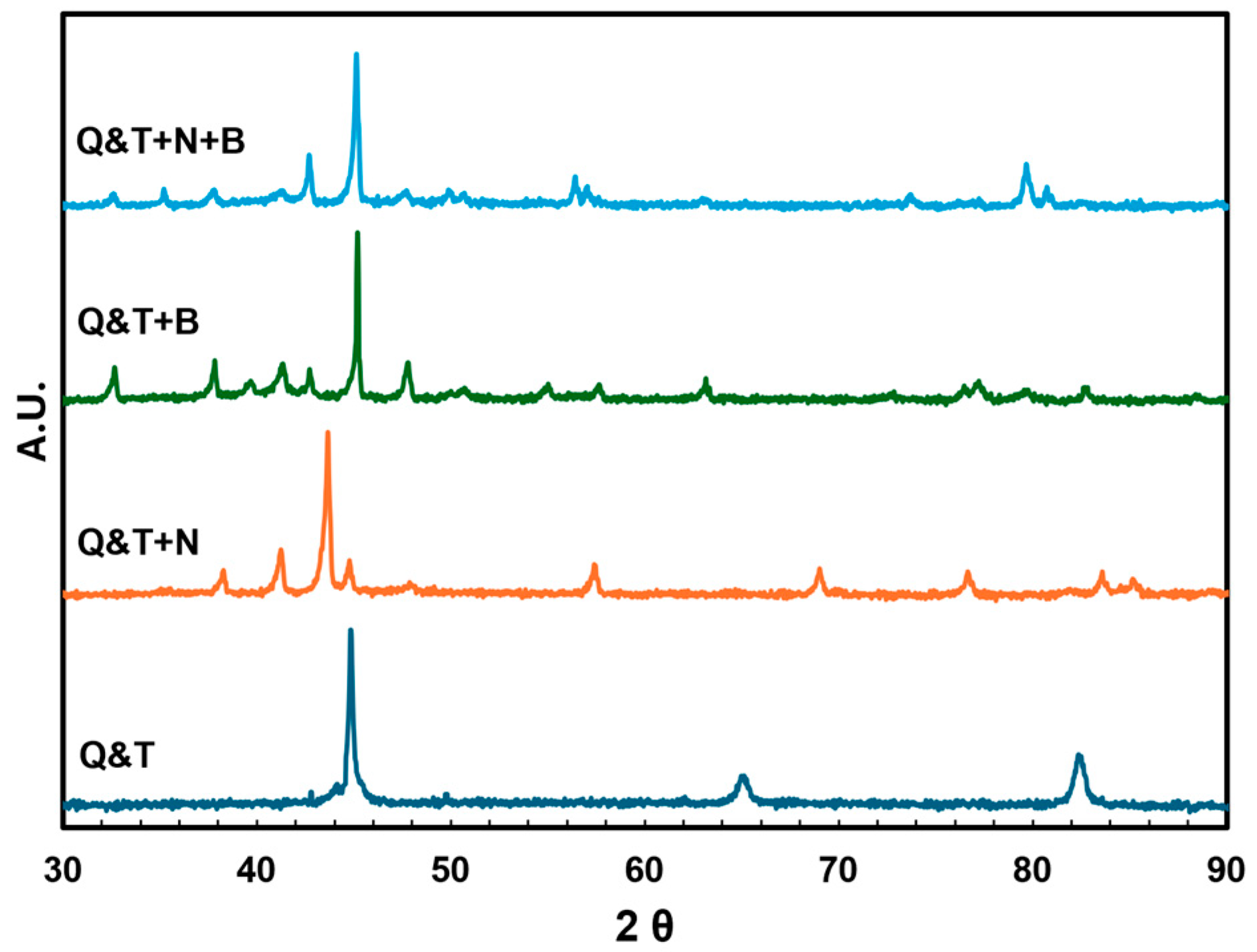

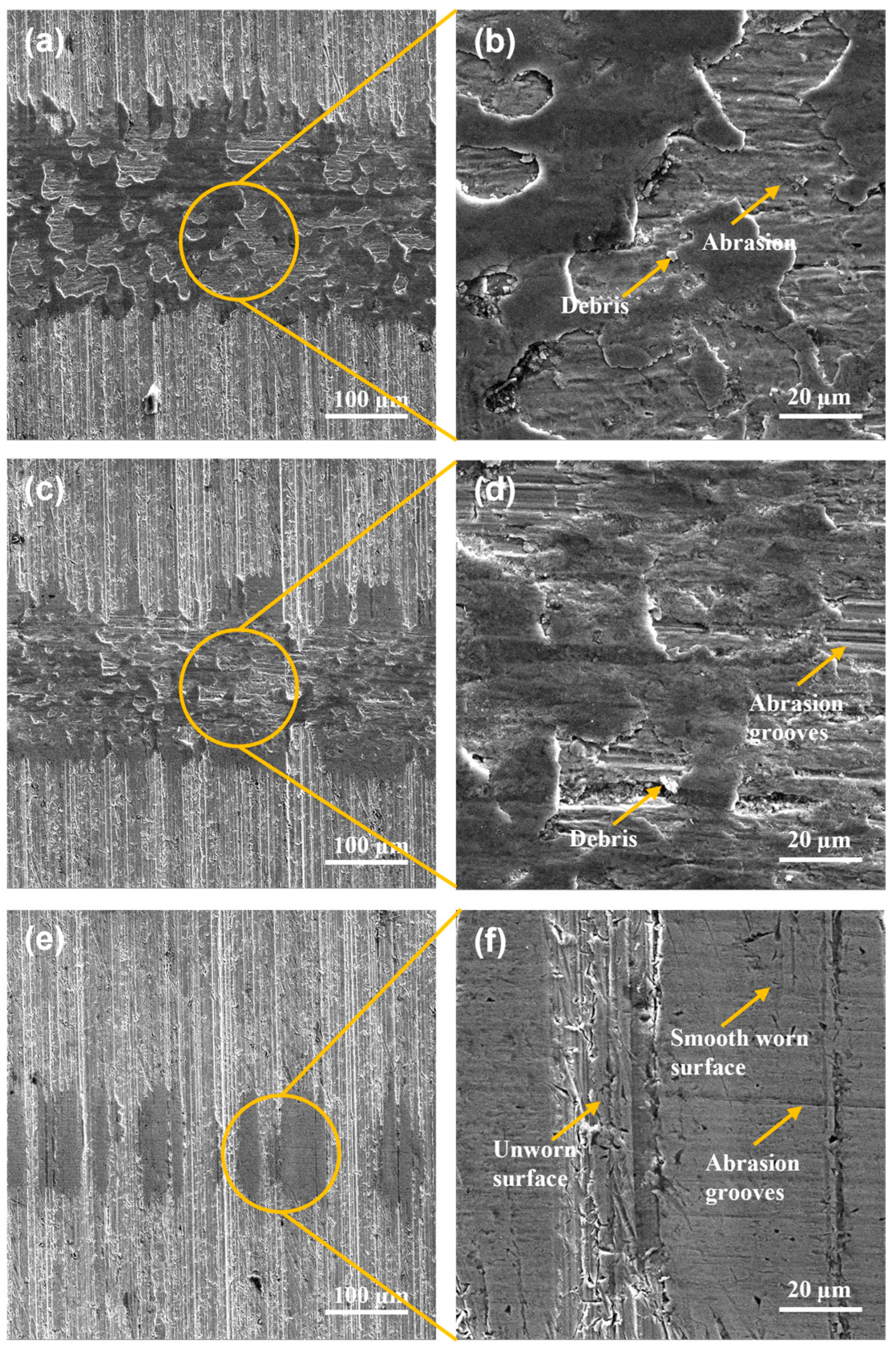

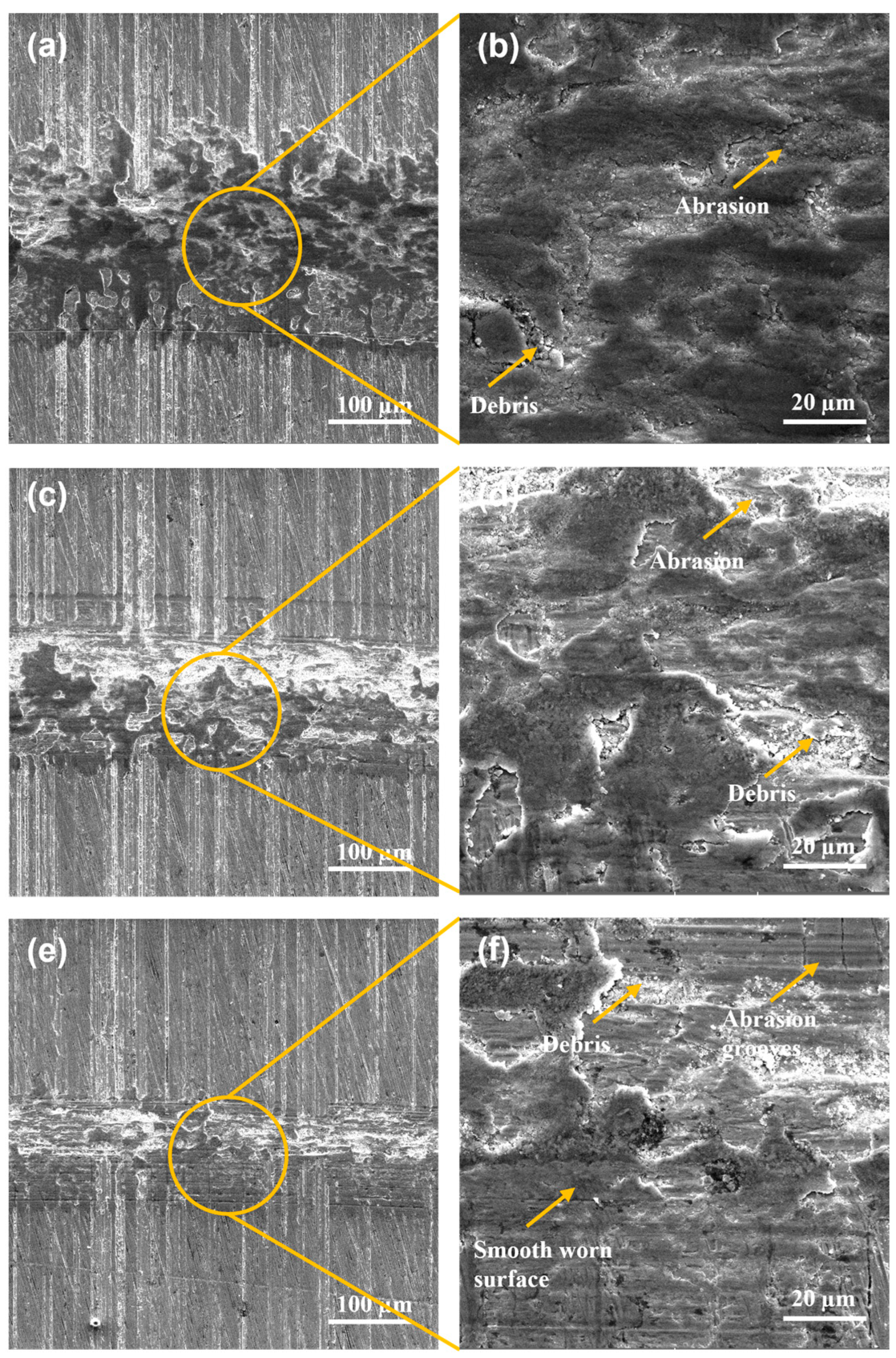

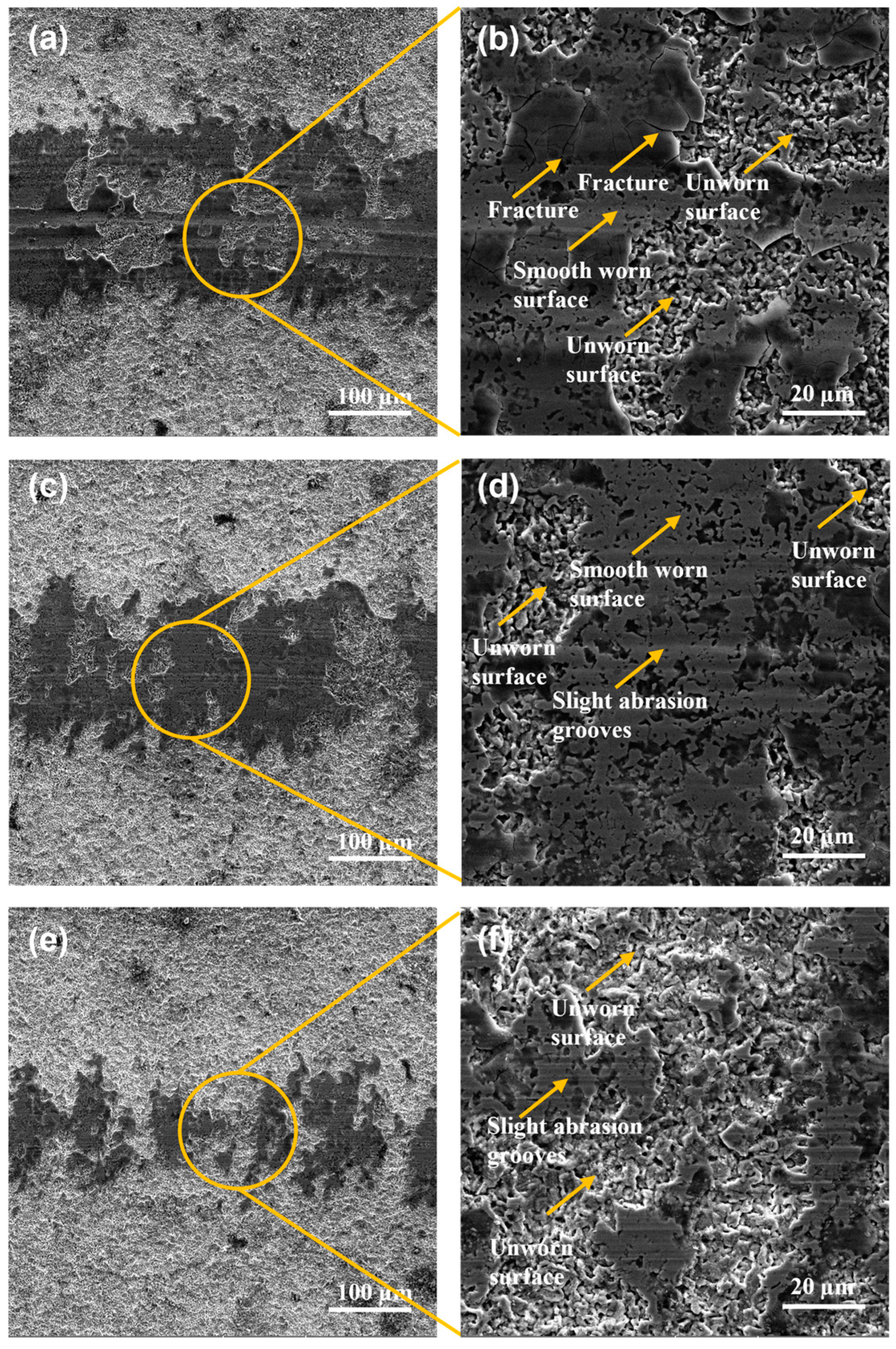

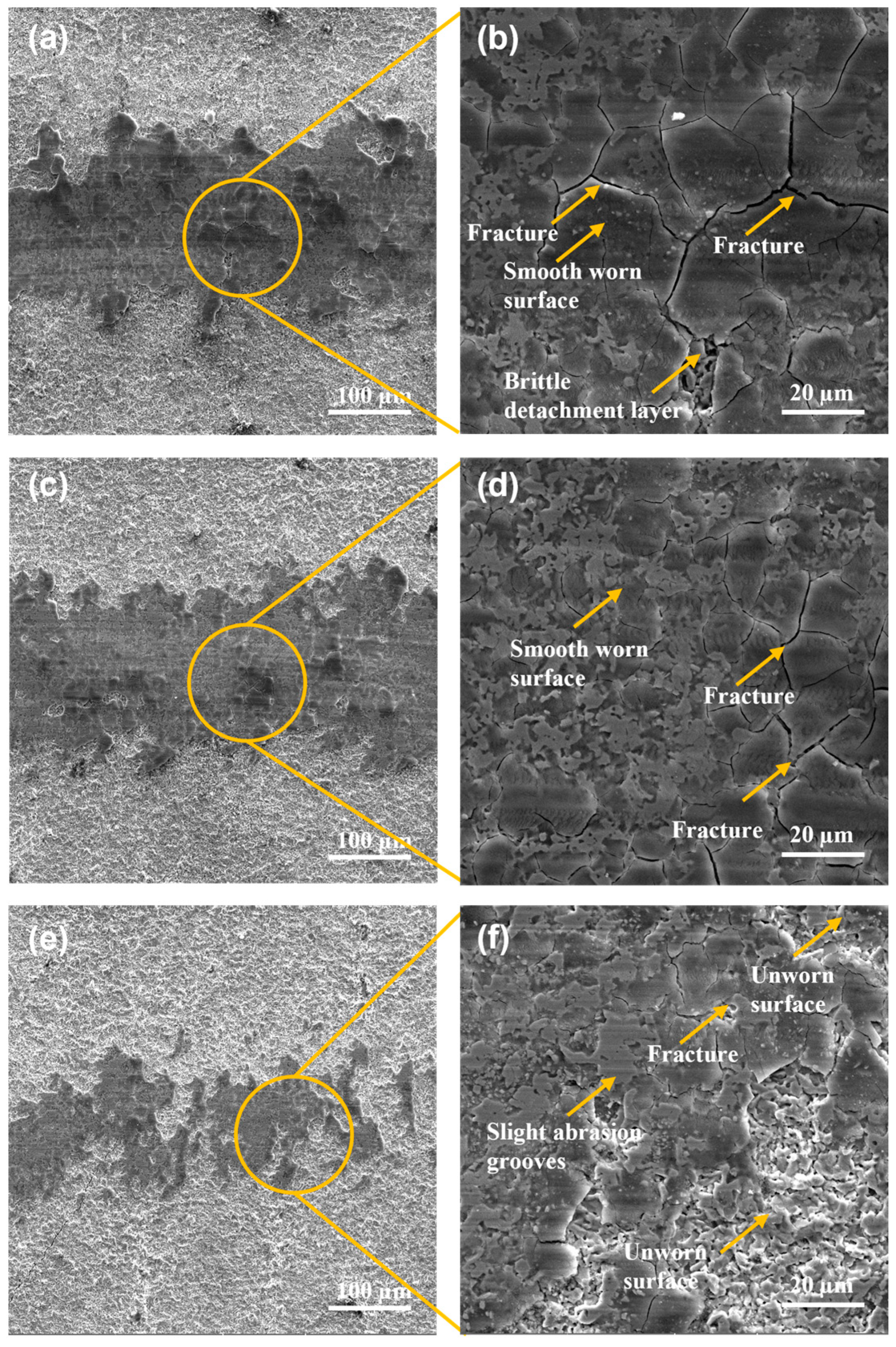

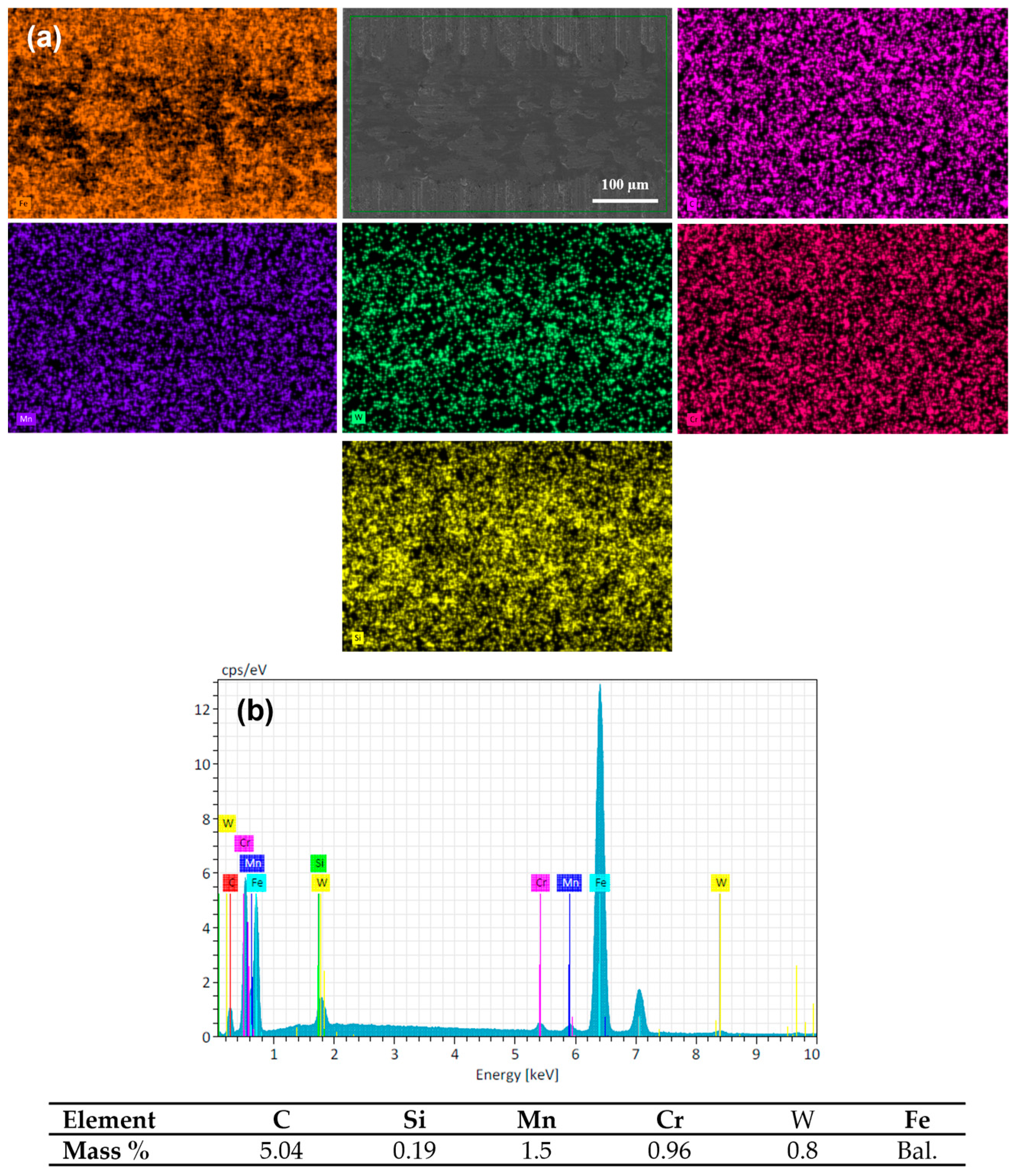

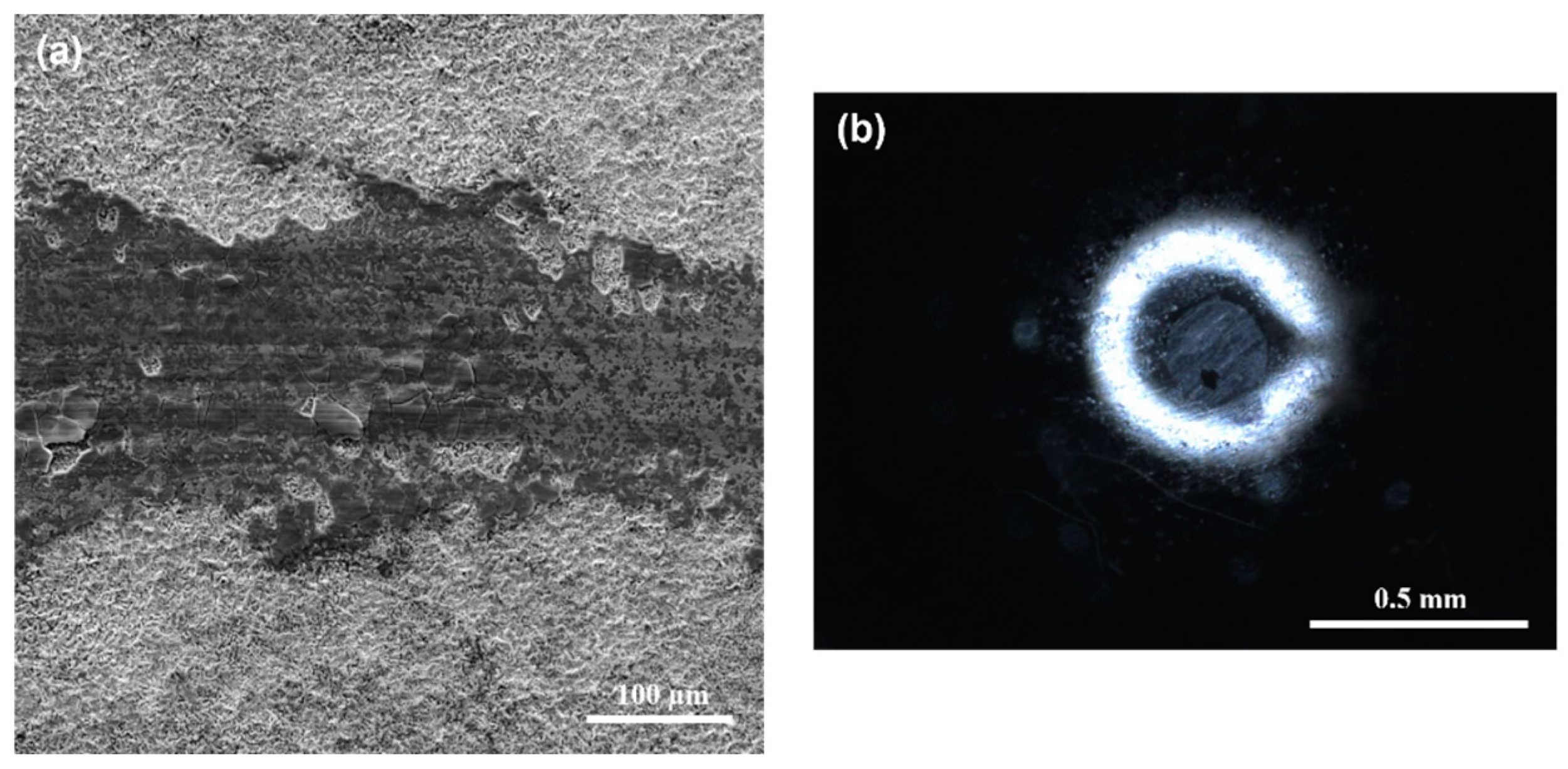

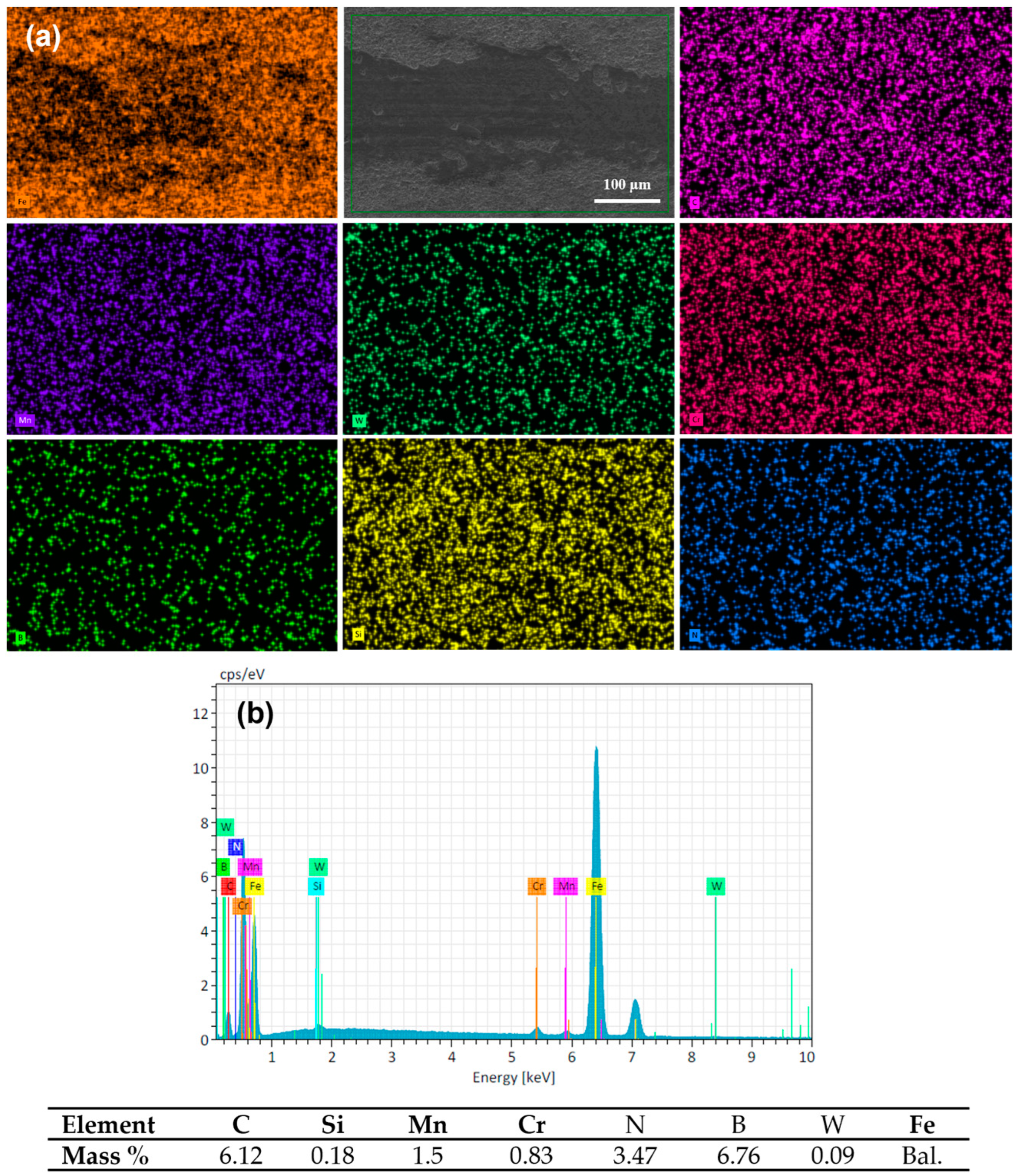

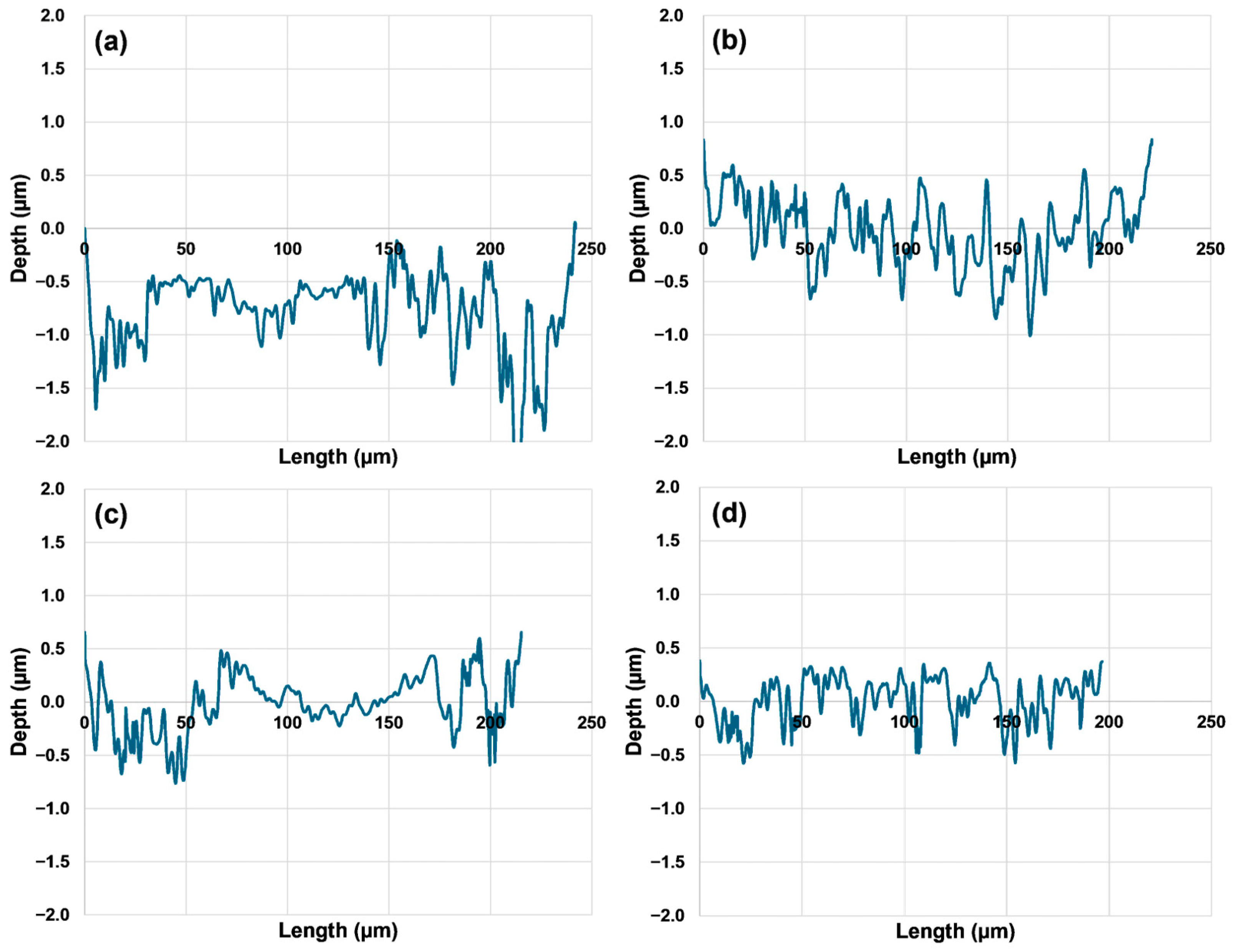

Microstructure Analyses

4. Conclusions

- The nitriding layers of ~8 μm and ~10 μm were formed by γ’-Fe4N, and ε-Fe3N, showing the layer in N-rich phases and the microstructure of DIN 16MnCr5 steel in the diffusion zone. A boriding layer of ~70 μm and ~80 μm was formed by FeB and Fe2B iron borides on DIN 16MnCr5 steel. The duplex gas-nitriding and pack boriding layers of ~80 μm and ~100 μm showed the presence of N-rich and B-rich content in layers with γ’-Fe4N, ε-Fe3N, FeB, and Fe2B phases.

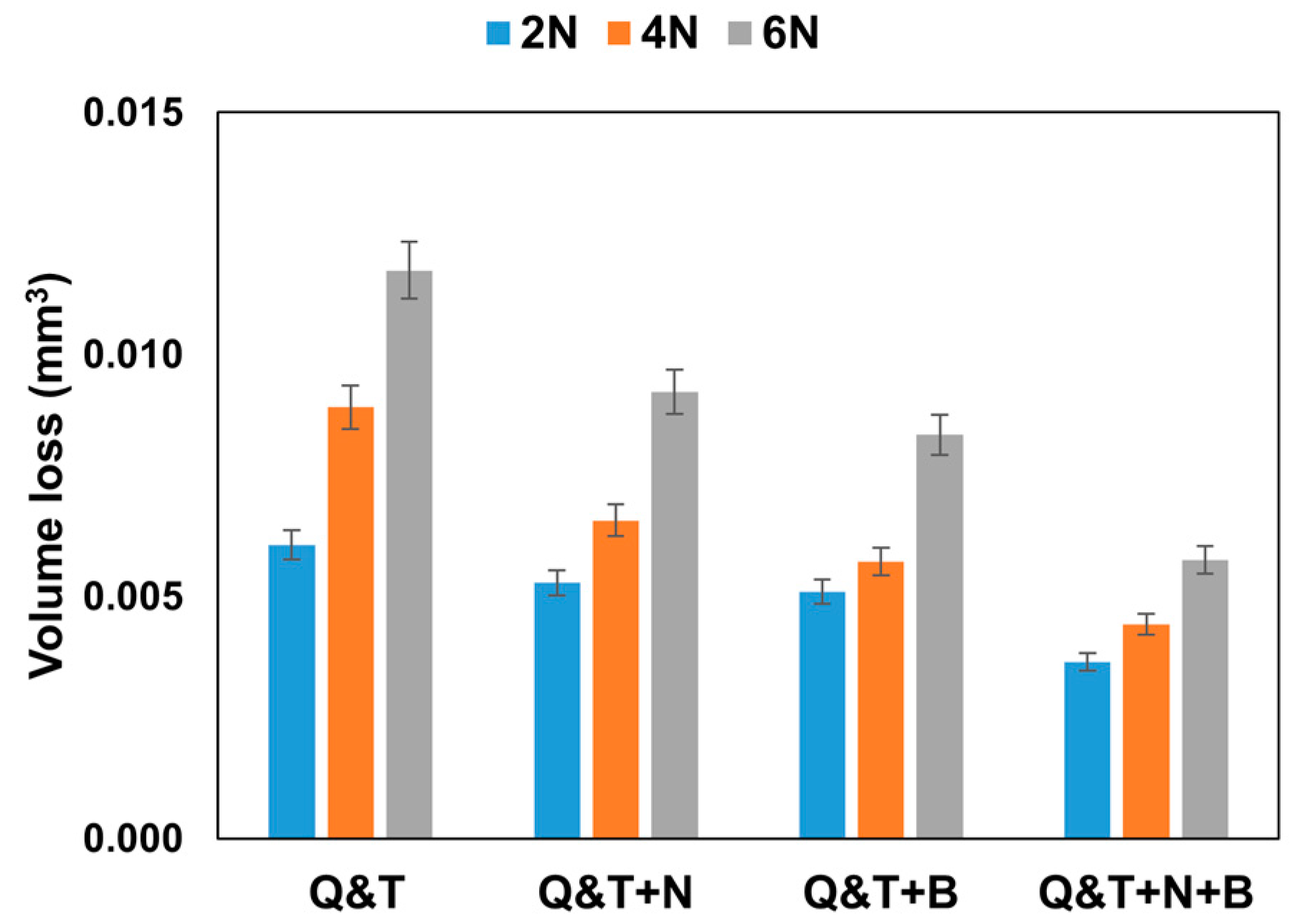

- The samples treated with gas-nitriding, pack boriding and duplex gas-nitriding, and pack boriding showed increased microhardness, elastic modulus, and nanohardness, resulting in higher wear resistance.

- The quenched and tempered DIN 16MnCr5 steel showed higher volumetric wear compared to the gas-nitriding and pack boriding processes, which exhibited 49% lower volumetric wear.

- Compared to quenched and tempered DIN 16MnCr5 steel, the coefficient of friction decreased by 9.18% for gas-nitriding, 17.27% for pack boriding, and 19.77% for duplex gas-nitriding and pack boriding.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cortabitarte, G.; Llavori, I.; Esnaola, J.A.; Blasón, S.; Larrañaga, M.; Larranaga, J.; Arana, A.; Ulacia, I. Application of the theory of critical distances for fatigue life assessment of spur gears. Theor. Appl. Fract. Mech. 2023, 128, 104086. [Google Scholar] [CrossRef]

- Li, X.; Olofsson, U.; Bergseth, E. Pin-on-disc study of tribological performance of standard and sintered gear materials treated with triboconditioning process: Pretreatment by pressure-induced tribofilm formation. Tribol. Trans. 2017, 60, 47–57. [Google Scholar] [CrossRef]

- Knyazeva, M.; Rozo Vasquez, J.; Gondecki, L.; Weibring, M.; Pöhl, F.; Kipp, M.; Tenberge, P.; Theisen, W.; Walther, F.; Biermann, D. Micro-Magnetic and Microstructural Characterization of Wear Progress on Case-Hardened 16MnCr5 Gear Wheels. Materials 2018, 11, 2290. [Google Scholar] [CrossRef]

- Tenkamp, J.; Haack, M.; Walther, F.; Weibring, M.; Tenberge, P. Application of micro-magnetic testing systemsfor non-destructive analysis of wear progress in case hardened 16MnCr5 gear wheels. Mater. Test. 2016, 58, 709–716. [Google Scholar] [CrossRef]

- Arunkumar, S.; Chandrasekaran, M.; Muthuraman, V.; Kumar, T.V. Study properties and mechanical behavior of the shaft material 16MnCr5. Mater. Today Proc. 2021, 37, 2458–2461. [Google Scholar] [CrossRef]

- Cai, S.; Sun, J.; He, Q.; Shi, T.; Wang, D.; Si, J.; Yang, J.; Li, F.; Xie, K.; Li, M. 16MnCr5 gear shaft fracture caused by inclusions and heat treatment process. Eng. Fail. Anal. 2021, 126, 105458. [Google Scholar] [CrossRef]

- Dobrenizki, L.; Tremmel, S.; Wartzack, S.; Hoffmann, D.C.; Brögelmann, T.; Bobzin, K.; Bagcivan, N.; Musayev, Y.; Hosenfeldt, T. Efficiency improvement in automobile bucket tappet/camshaft contacts by DLC coatings—Influence of engine oil, temperature and camshaft speed. Surf. Coat. Technol. 2016, 308, 360–373. [Google Scholar] [CrossRef]

- Mohan, N.; Arul, S. Effect of cryogenic treatment on the mechanical properties of alloy steel 16MnCr5. Mater. Today Proc. 2018, 5, 25265–25275. [Google Scholar] [CrossRef]

- Trauth, D.; Basturk, S.; Hild, R.; Mattfeld, P.; Brogelmann, T.; Bobzin, K.; Klocke, F. Evaluation of the shear stresses on surface structured workpieces in dry forming using a novel pin-on-cylinder tribometer with axial feed. Int. J. Mater. Form. 2017, 10, 557–565. [Google Scholar] [CrossRef]

- Agarwal, S.; Suman, R.; Bahl, S.; Haleem, A.; Javaid, M.; Sharma, M.K.; Prakash, C.; Sehgal, S.; Singhal, P. Optimisation of cutting parameters during turning of 16MnCr5 steel using Taguchi technique. Int. J. Interact. Des. Manuf. 2022, 18, 2055–2066. [Google Scholar] [CrossRef]

- Dizisaz, M.; Parast, M.S.A.; Azadi, M.; Dadashi, A. Plain and fretting fatigue characteristics of 16MnCr5 steel under cyclic bending loading with the application of engine piston pin. Mater. Chem. Phys. 2024, 316, 129110. [Google Scholar] [CrossRef]

- Buhl, S.; Schmidt, K.; Sappok, D.; Merz, R.; Godard, C.; Kerscher, E.; Kopnarski, M.; Sauer, B.; Antonyuk, S.; Ripperger, S. Surface Structuring of Case Hardened Chain Pins by Cold-Sprayed Microparticles to Modify Friction and Wear Properties. Particuology 2015, 21, 32–40. [Google Scholar] [CrossRef]

- Schlegel, J. The World of Steel; Springer Nature: Berlin/Heidelberg, Germany, 2023. [Google Scholar]

- Cieslik, J.; Jacquet, P.; Tlili, B.; Mulin, H. Decrease of Compound Layer Thickness Obtained in Plasma Nitriding of Alloyed Steels by Diffusion Stage. J. Mater. Sci. Eng. A 2011, 1, 974–980. [Google Scholar]

- Esfahani, A.; Sohi, H.M.; Rassizadehghani, J.; Mahboubi, F. Effect of treating atmosphere in plasma post-oxidation of nitrocarburized AISI 5115 steel. Vacuum 2007, 82, 346–351. [Google Scholar] [CrossRef]

- Wong-Ángel, W.D.; Martinez-Trinidad, J.; Campos-Silva, I.; Hernandez-Hernandez, V.; Silva-Rivera, U.S.; Garcia-Leon, R.A. Wear-corrosion synergy on Din-16MnCr5 steel under nitriding and post-oxidizing treatments. J. Bio-Tribo-Corros. 2021, 7, 83. [Google Scholar] [CrossRef]

- Vivek, C. Influence of carburizing and carbonitriding in 16MnCr5 to enhance mechanical properties. Int. J. Innov. Eng. Technol. 2016, 7, 261–266. [Google Scholar]

- Arumparithy, G.L.; Adalarasan, R.; Santhanakumar, M.; Mulugeta, L. Parameter Design in Carbonitriding of EN36, 16MnCr5, and AISI 4140 Steels Using Principal Component-Based Grey Incidence (PGI). Adv. Mater. Sci. Eng. 2022, 2022, 12. [Google Scholar] [CrossRef]

- Caliari, D.; Vanzo, F.; Timelli, G. Microstructural and mechanical investigation of nitrocarburized 16MnCr5 steel in annealed and workhardened conditions. In Proceedings of the International Conference on Surface Modification Technologies (SMT30), Milan, Italy, 29 June–1 July 2016; p. 8. [Google Scholar]

- Caliari, D.; Timelli, G.; Vanzo, F. Nitrocarburising of annealed and severe plastically deformed 16MnCr5 steel. Surf. Eng. 2018, 34, 536–546. [Google Scholar] [CrossRef]

- Khusainov, Y.G.; Esipov, R.S.; Ramazanov, K.N.; Vardanyan, E.L.; Tarasov, P.V.; Shekhtman, S.R. Influence of hydrogen content in working gas on growth kinetics of hardened layer at ion nitriding of 16MnCr5 and A290C1M steels/IOP Conference Series: Materials Science and Engineering. In 25th International Conference on Vacuum Technique and Technology; IOP Publishing: Bristol, UK, 2018; Volume 387, p. 012034. [Google Scholar]

- Davis, J.R. Surface Hardening of Steels: Understanding the Basics, 2nd ed.; ASM International: Novelty, OH, USA, 2002; p. 217. [Google Scholar]

- Calik, A.; Ucar, N.; Yeniay, N. A Study of Boronizing Kinetics and Its Effect on the Structure and Mechanical Properties of Steel 16MnCr5. Met. Sci. Heat Treat. 2022, 64, 63–68. [Google Scholar] [CrossRef]

- Calik, A.; Ucar, N.; Kosaaslan, A.; Karakas, S. Effect of interrupted boriding on microstructure and mechanical properties of 16MnCr5 steel. Surf. Rev. Lett. 2018, 25, 1950022. [Google Scholar] [CrossRef]

- Sahin, A.Y.; Turan, M.E. Effect of boronizing process on wear properties of 16MnCr5 steels. J. Steel Res. Dev. 2002, 3, 8–15. [Google Scholar]

- Drajewicz, M.; Przybyło, A.; Jopek, J.; Góral, M.; Kościelniak, B.; Ochał, K.; Kubaszek, T.; Gurak, A.; Dychtoń, K.; Woźniak, M.; et al. The Diffusion Coatings for Industrial Tool Application. Manuf. Technol. 2022, 22, 530–541. [Google Scholar] [CrossRef]

- Calik, A.; Yeniay, N.; Ucar, N. Nanoindentation Study of Borided Low-Carbon 16MnCr5 Steel. Met. Sci. Heat Treat. 2024, 65, 758–761. [Google Scholar] [CrossRef]

- ASTM G99-17; Standard Test Method for Wear Testing with a Pin-on-Disk Apparatus. ASTM International: Philadelphia, PA, USA, 2017.

- Mittemeijer, E.J. Fundamentals of nitriding and nitrocarburizing. In ASM Handbook; Dosse, J., Totten, G.E., Eds.; ASM International: Kinsman, OH, USA, 2013; Volume 4, pp. 619–646. [Google Scholar]

- Boca, N.T.; Mišković, Ž.Z.; Mitrović, R.M.; Obradović, B.M.; Kuraica, M.M. Effects of high thermal loads produced by interaction of accelerated plasma with steel surfaces (100Cr6, 16MnCr5, 42CrMo4). Surf. Coat. Technol. 2021, 416, 127157. [Google Scholar] [CrossRef]

- Ulutan, M.; Celik, O.N.; Gasan, H.; Er, U. Effect of different surface treatment methods on the friction and wear behavior of AISI 4140 steel. J. Mater. Sci. Technol. 2010, 26, 251–257. [Google Scholar] [CrossRef]

| Sample | Quenched and Tempered | Gas-Nitriding | Pack Boriding |

|---|---|---|---|

| Q&T | 15 min/870 °C | - | - |

| Q&T+N | 15 min/870 °C | 6 h/560 °C (30% NH3 + 70% H2) | - |

| Q&T+B | 15 min/870 °C | - | 4 h/950 °C powder wt.% (90% SiC, 5% B4C, 5% KBF4) |

| Q&T+N+B | 15 min/870 °C | 6 h/560 °C (30% NH3 + 70% H2) | 4 h/950 °C powder wt.% (90% SiC, 5% B4C, 5% KBF4) |

| Element | C | Si | Mn | P | S | Cr | Fe |

|---|---|---|---|---|---|---|---|

| 0.14–0.19 | 0–0.4 | 1.0–1.3 | 0–0.025 | 0–0.035 | 0.8–1.1 | Bal. |

| Parameters | Dry Condition |

|---|---|

| Normal force (N) | 2, 4, 6 |

| Sliding speed (m/s) | 0.1675, 0.1256, 0.0837 |

| Sliding distance (m) | 100 |

| Environment | Air |

| Track diameter (mm) | 16, 12, 8 |

| Temperature (°C) | 21 |

| Humidity (RH) | 40–60 |

| Sample | Nanohardness H (GPa)–HV | Elastic Modulus E (GPa) |

|---|---|---|

| Q&T | 1.8–187.1 | 101.9 |

| Q&T+N | 3.2–332.4 | 141.7 |

| Q&T+B | 3.8–390.5 | 161.2 |

| Q&T+N+B | 8.7–887.1 | 194.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Carrera Espinoza, R.; Alvarez Vera, M.; Wettlaufer, M.; Kerl, M.; Barth, S.; Moreno Garibaldi, P.; Díaz Guillen, J.C.; Hernández García, H.M.; Muñoz Arroyo, R.; Ortega, J.A. Study on the Tribological Properties of DIN 16MnCr5 Steel after Duplex Gas-Nitriding and Pack Boriding. Materials 2024, 17, 3057. https://doi.org/10.3390/ma17133057

Carrera Espinoza R, Alvarez Vera M, Wettlaufer M, Kerl M, Barth S, Moreno Garibaldi P, Díaz Guillen JC, Hernández García HM, Muñoz Arroyo R, Ortega JA. Study on the Tribological Properties of DIN 16MnCr5 Steel after Duplex Gas-Nitriding and Pack Boriding. Materials. 2024; 17(13):3057. https://doi.org/10.3390/ma17133057

Chicago/Turabian StyleCarrera Espinoza, Rafael, Melvyn Alvarez Vera, Marc Wettlaufer, Manuel Kerl, Stefan Barth, Pablo Moreno Garibaldi, Juan Carlos Díaz Guillen, Héctor Manuel Hernández García, Rita Muñoz Arroyo, and Javier A. Ortega. 2024. "Study on the Tribological Properties of DIN 16MnCr5 Steel after Duplex Gas-Nitriding and Pack Boriding" Materials 17, no. 13: 3057. https://doi.org/10.3390/ma17133057

APA StyleCarrera Espinoza, R., Alvarez Vera, M., Wettlaufer, M., Kerl, M., Barth, S., Moreno Garibaldi, P., Díaz Guillen, J. C., Hernández García, H. M., Muñoz Arroyo, R., & Ortega, J. A. (2024). Study on the Tribological Properties of DIN 16MnCr5 Steel after Duplex Gas-Nitriding and Pack Boriding. Materials, 17(13), 3057. https://doi.org/10.3390/ma17133057