Microwave De-Icing Efficiency Improvement of Asphalt Mixture with Structural Layer Optimization and Heat-Resistance Design

Abstract

:1. Introduction

2. Experimental Programs

2.1. Raw Materials

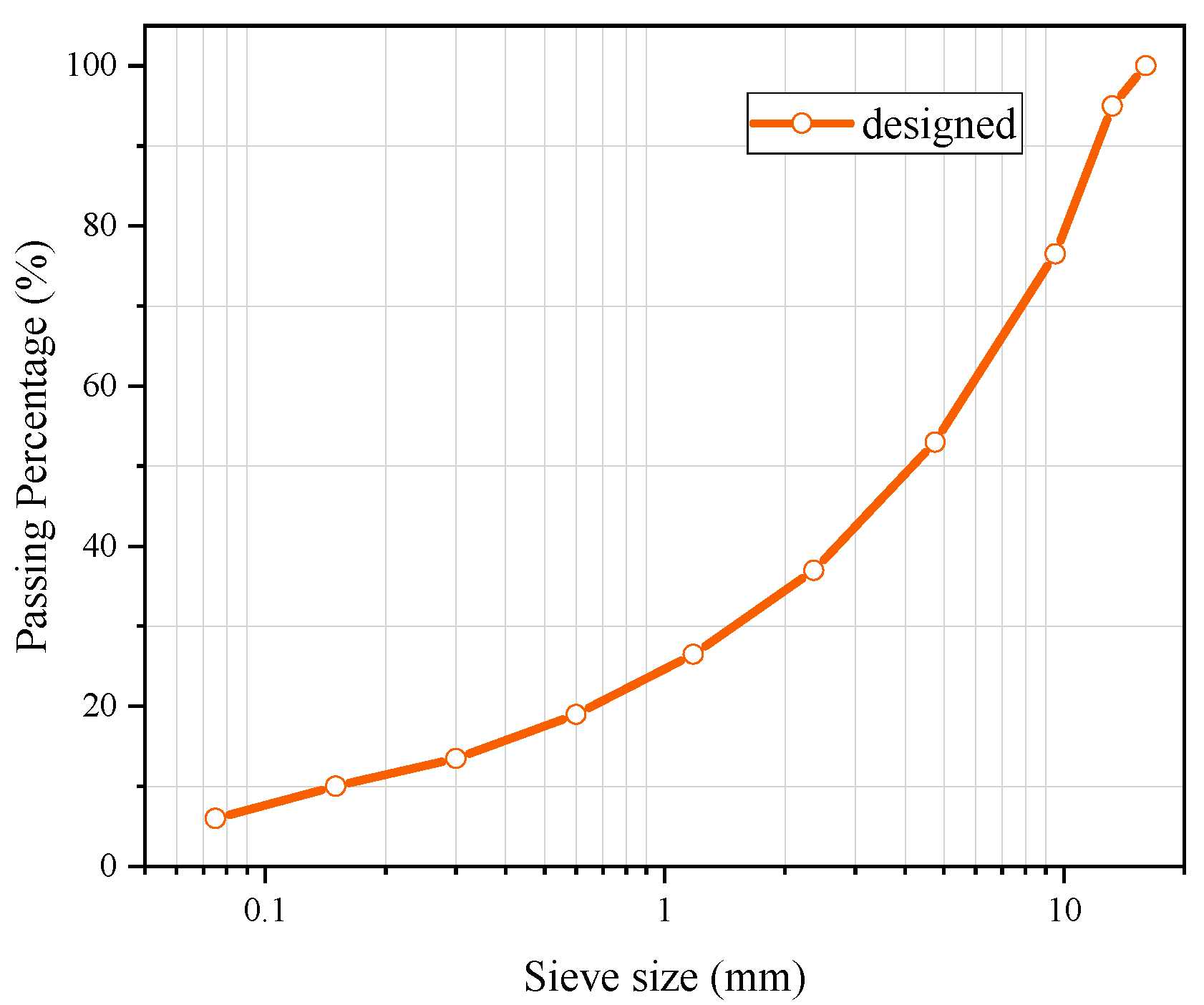

2.2. Sample Preparation

2.3. Methods

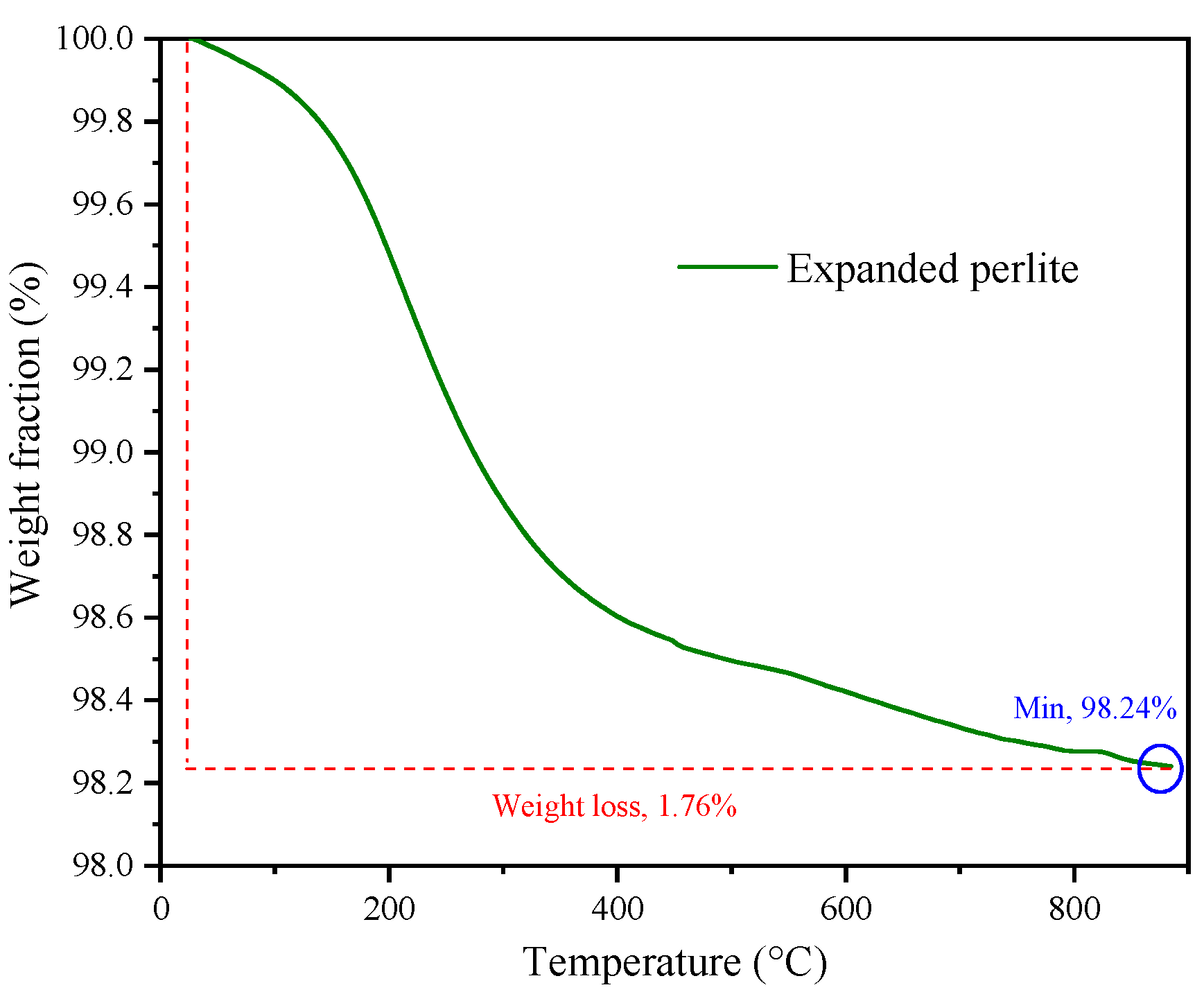

2.3.1. Thermal-Resistance Potentiality Tests of EP

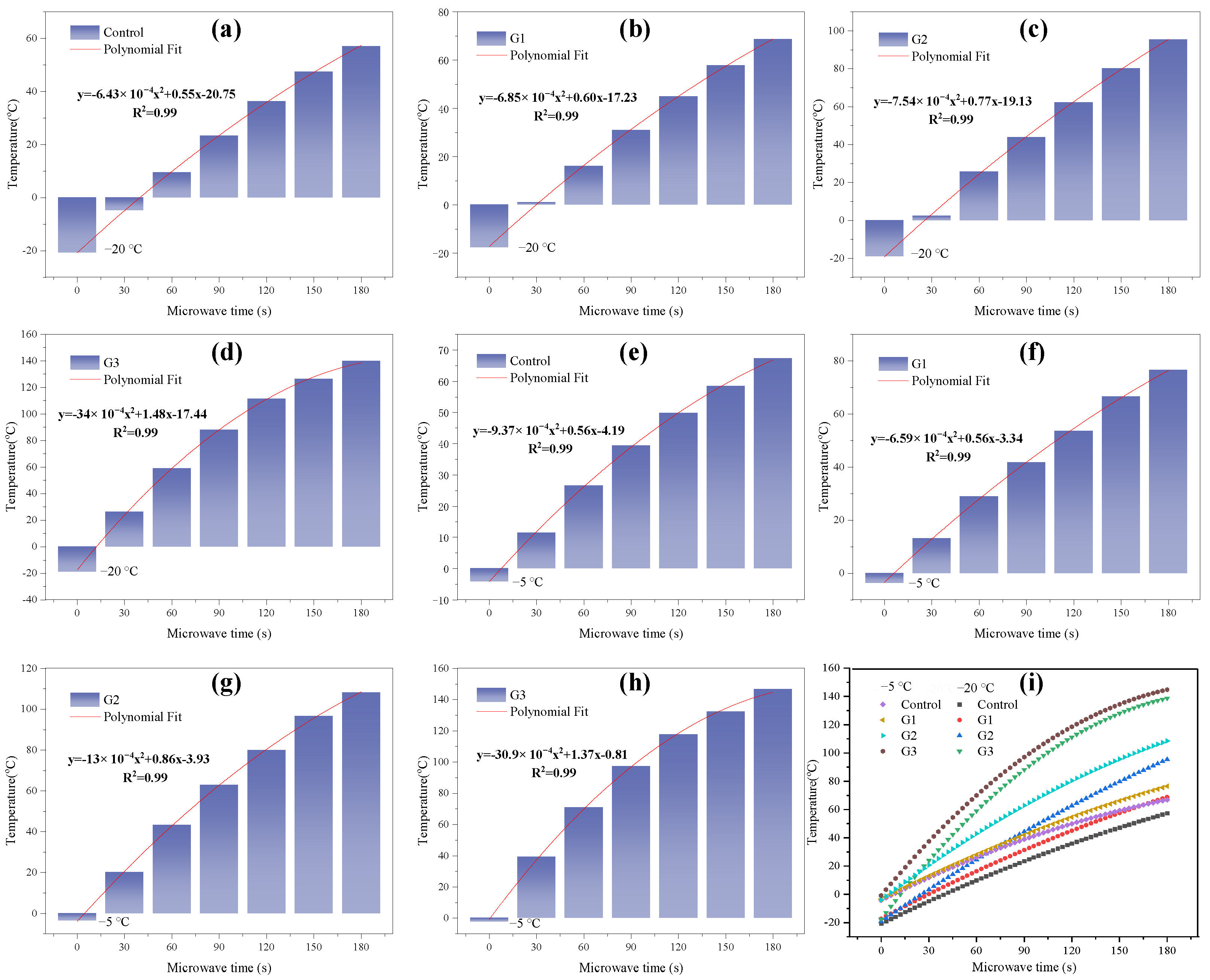

2.3.2. Heat Generation and Conduction Test on Specimen Surface

2.3.3. Heat Conduction Test of Specimens In-Depth Direction

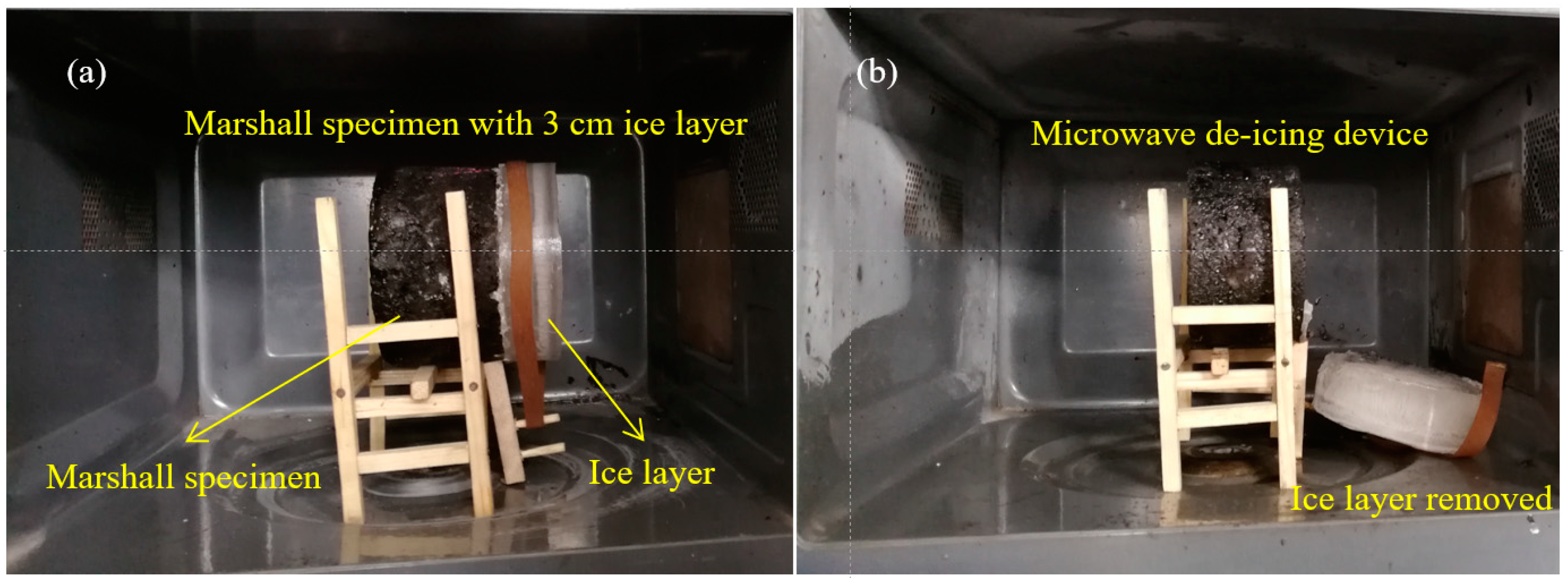

2.3.4. Microwave De-Icing Time Test

3. Results

3.1. Feasibility Verification of Thermal-Resistance Materials

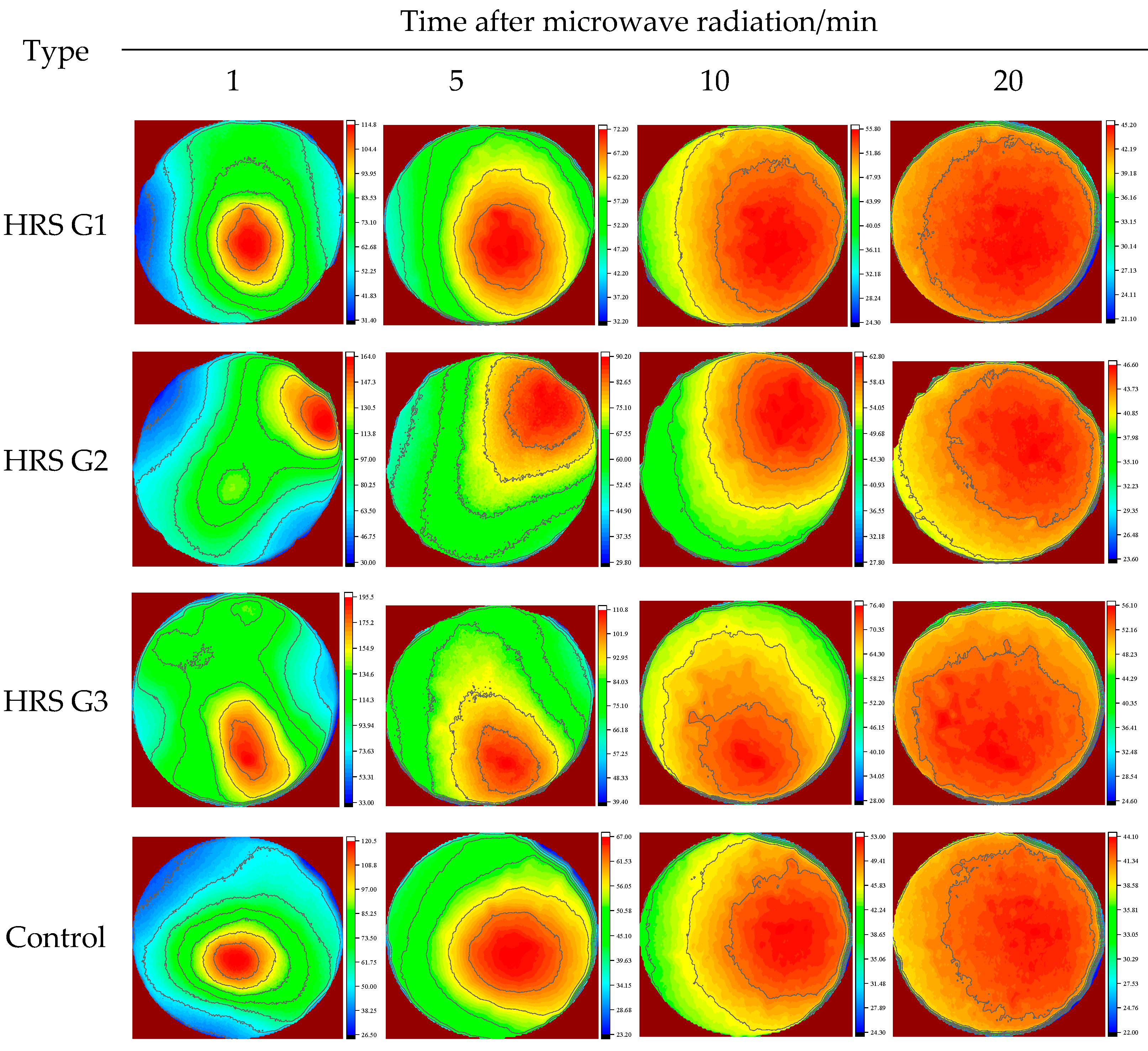

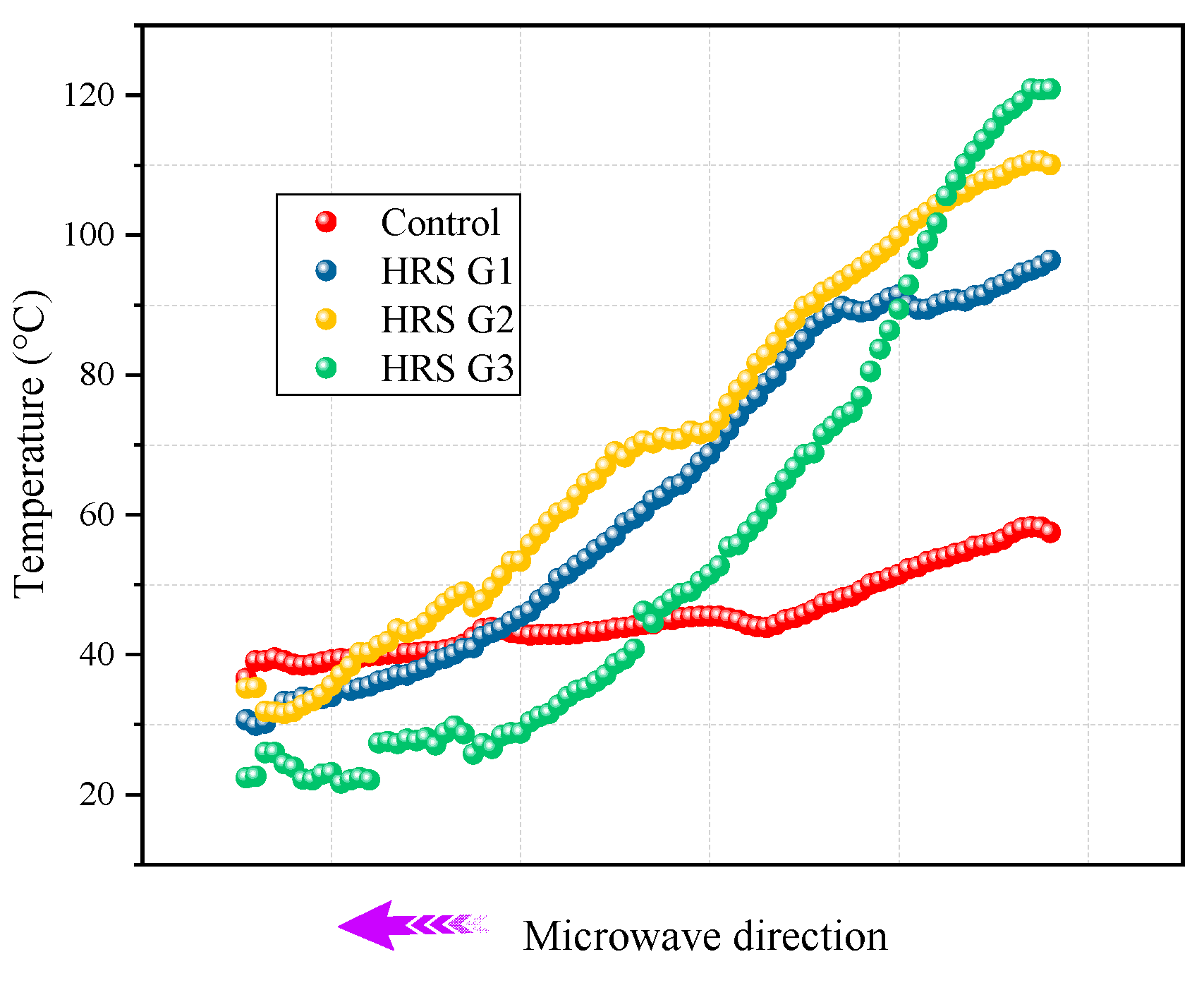

3.2. Surface Heating Rates of Specimens

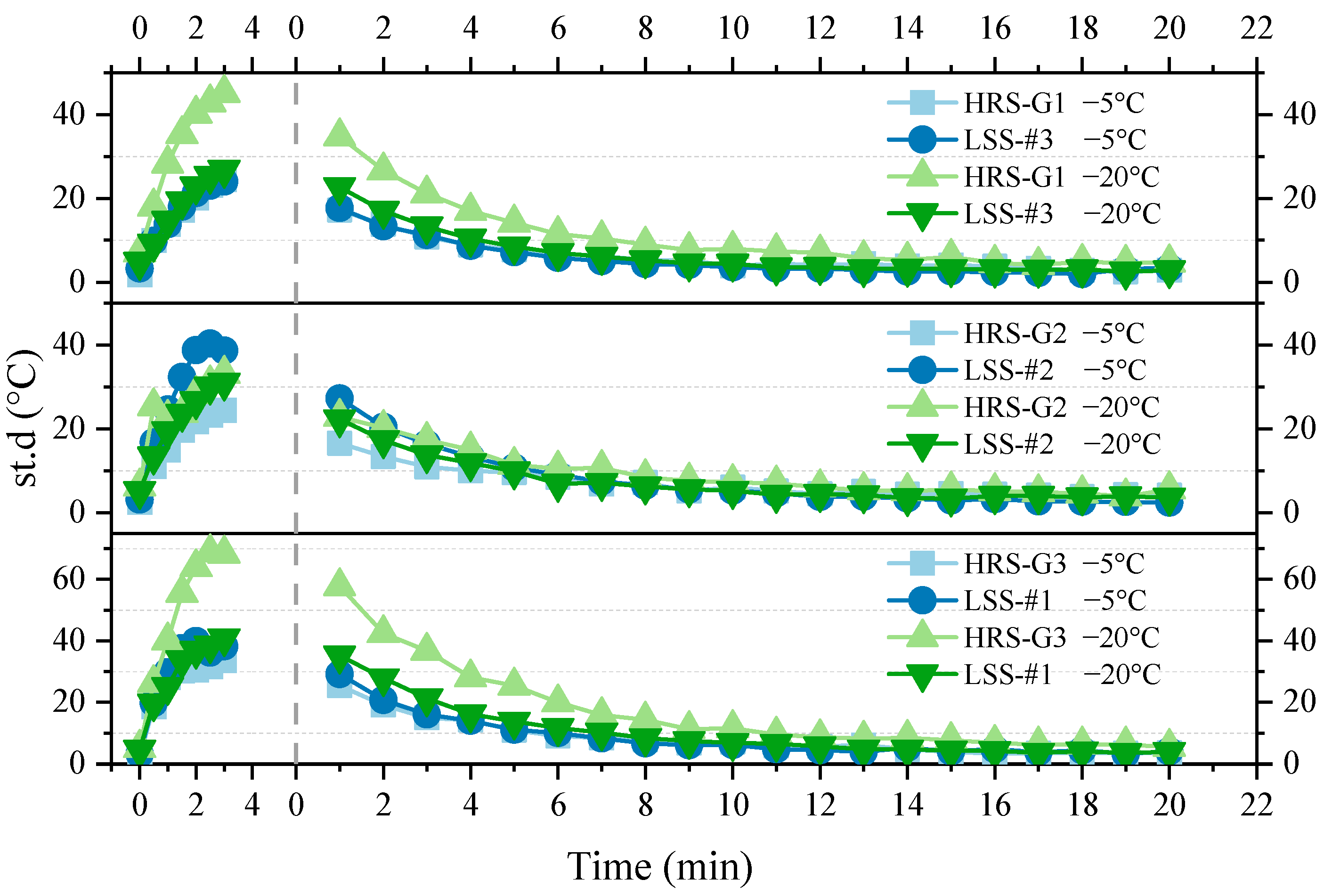

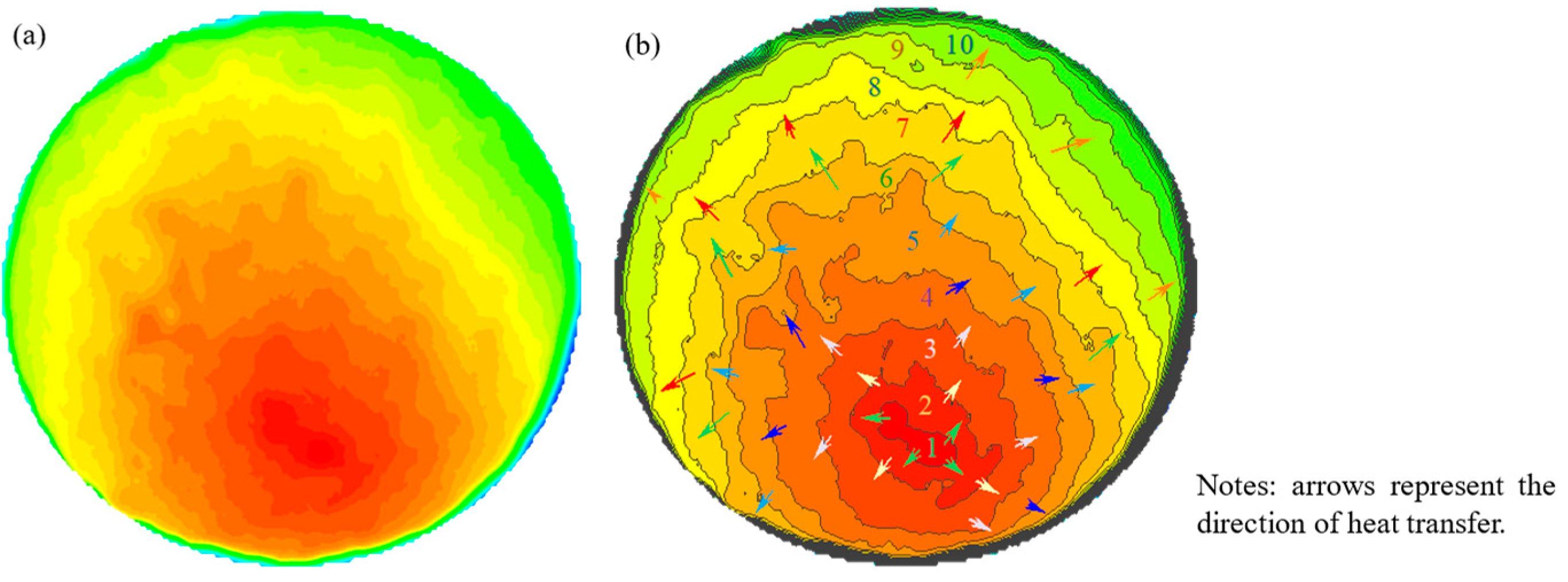

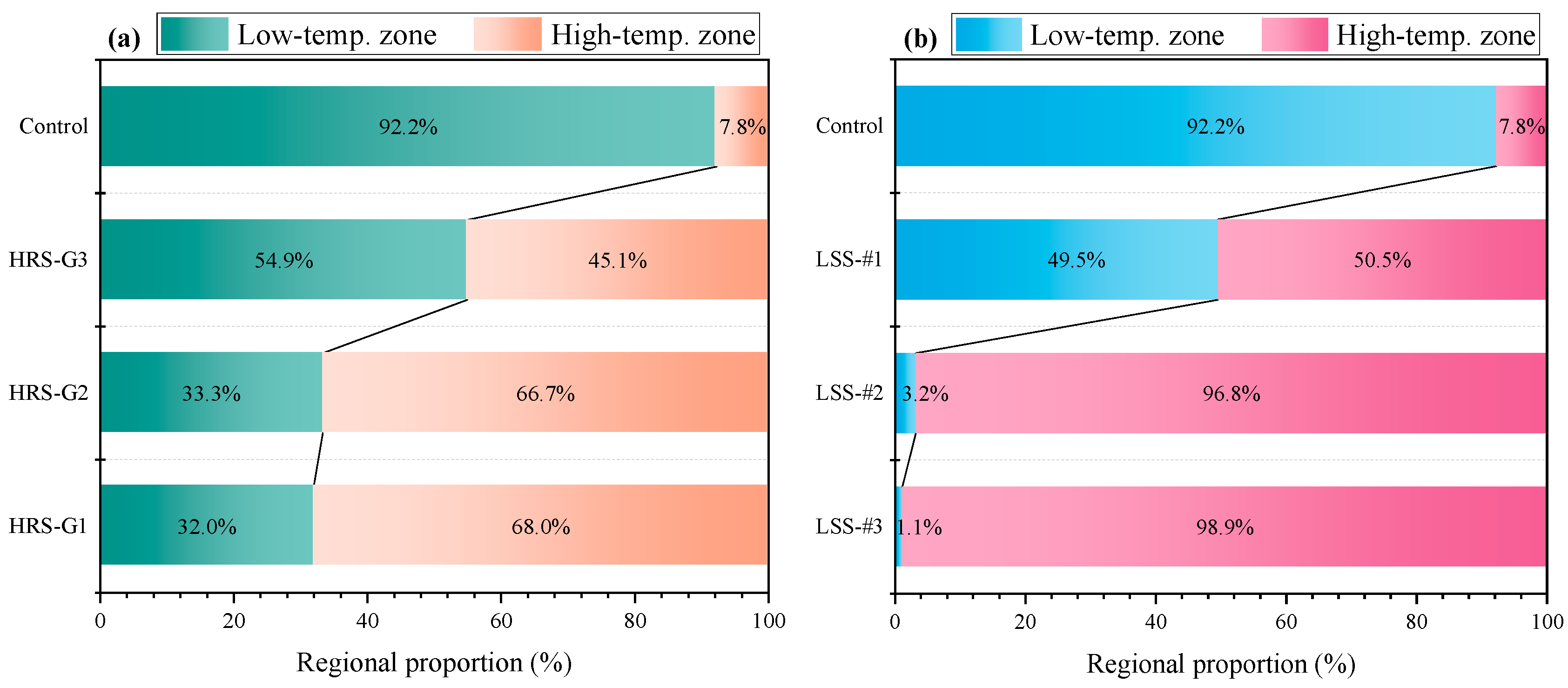

3.3. Surface Thermal Analyses of Specimens

3.4. Heat Conduction In-Depth Direction

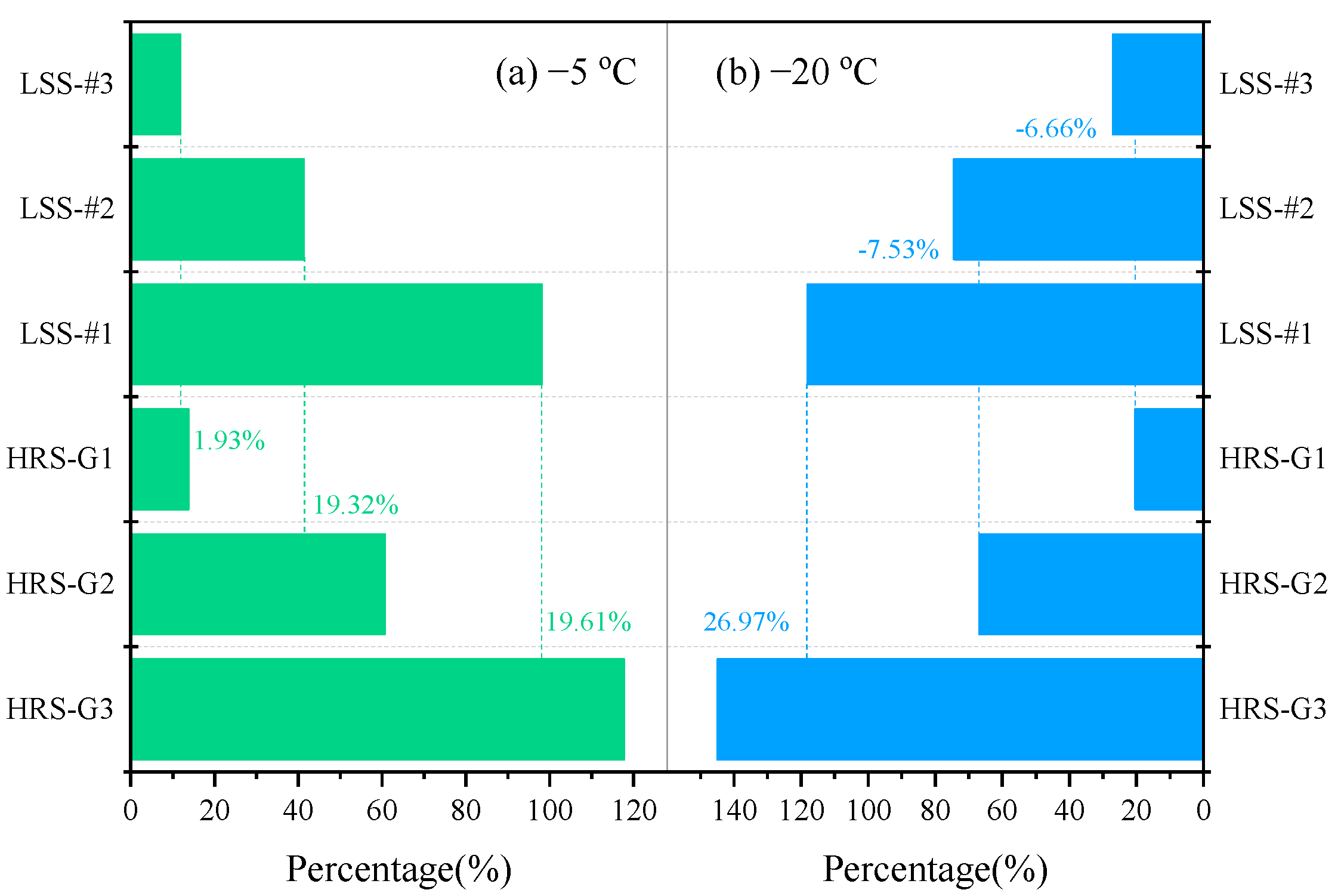

3.5. De-Icing Time

4. Discussions

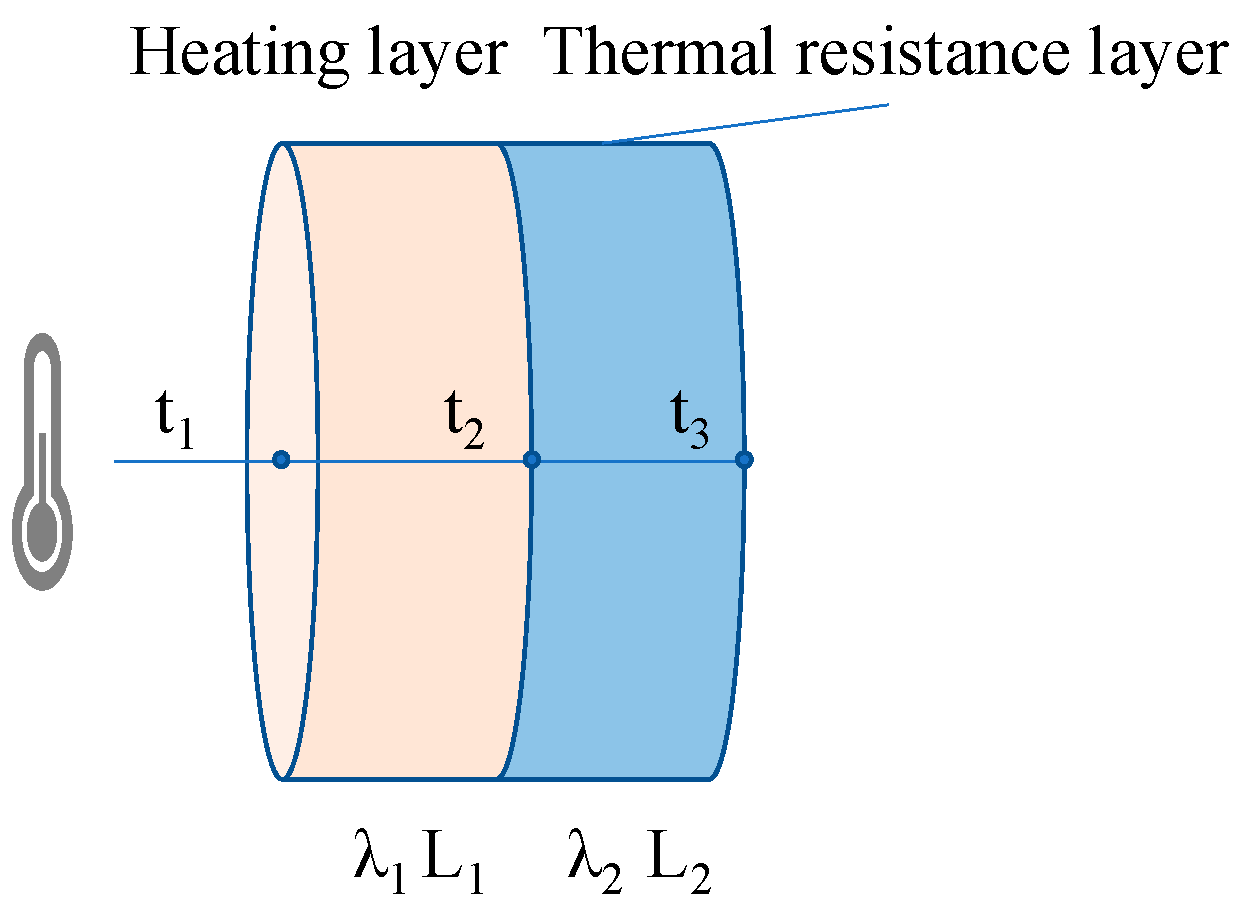

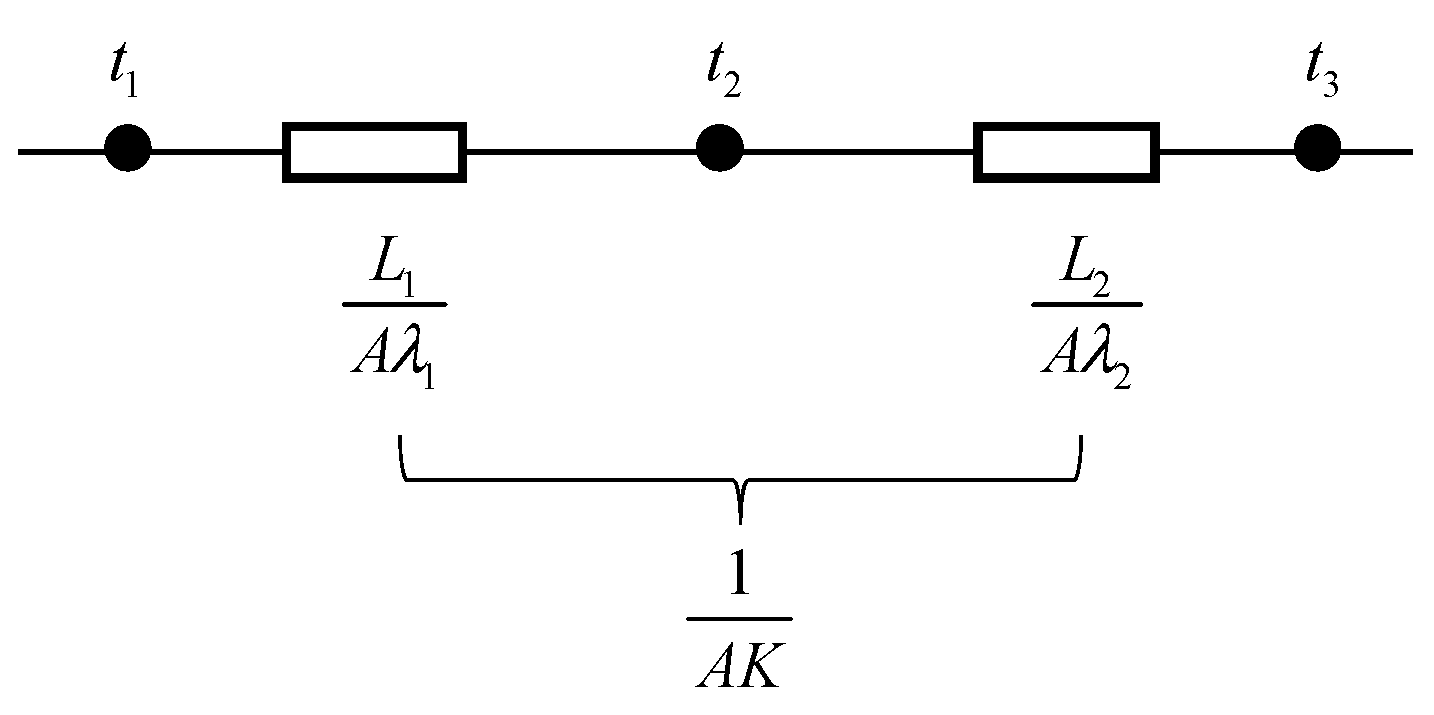

4.1. Heat-Resistance Layer Function in Heat Transfer

4.2. Cost-Effectiveness Analyses

5. Conclusions

6. Further Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Sha, A.; Wang, Z.; Liu, Z. Laboratory Measurement of the Adhesion Strength between Asphalt Concrete and Ice Layer. Constr. Build. Mater. 2024, 416, 135102. [Google Scholar] [CrossRef]

- Zhu, T.; Yuan, Y.; Song, L.; Wei, X.; Xiang, H.; Dai, X.; Hua, X.; Liao, R. A PDMS Coating with Excellent Durability for Large-Scale Deicing. J. Mater. Res. Technol. 2024, 29, 4526–4536. [Google Scholar] [CrossRef]

- Zou, G.; Chen, Q.; Zhang, Y.; Zhang, D.; Yu, J. Research on Deicing Performance and Environmental Impact of Anti-Freezing Asphalt Mixtures. Constr. Build. Mater. 2024, 428, 136355. [Google Scholar] [CrossRef]

- Sun, Z.; Chen, J.; Liu, S.; Qian, J.; Huang, R. Evaluation of the Performance of SBS/CR Composite-Modified Deicing Asphalt Mixture Prepared for Ultra-Thin Wearing Course. Constr. Build. Mater. 2024, 416, 135085. [Google Scholar] [CrossRef]

- Yamamoto, M.; Nakarai, K.; Yoshizumi, Y.; Torrent, R. Relationship between Chloride Ingress and Concrete Cover Quality of Inland Structures Exposed to Deicing Salts. Case Stud. Constr. Mater. 2024, 20, e03075. [Google Scholar] [CrossRef]

- Wang, Z. Research on Freezing Adhesive Characteristics of Asphalt Pavement and Evaluation Effect of Deicing Measures; Chang’an University: Xi’an, China, 2018. [Google Scholar]

- Dan, H.; He, L.; Zou, J.; Zhao, L.; Bai, S. Laboratory Study on the Adhesive Properties of Ice to the Asphalt Pavement of Highway. Cold Reg. Sci. Technol. 2014, 104, 7–13. [Google Scholar] [CrossRef]

- Qiu, H.; Wu, Y.; Chen, H.; Wang, R.; Han, Z.; Wan, Z. Effect of Silicon Carbide Powder on Temperature Field Distribution Characteristics and Microwave Deicing Efficiency of Cement Concrete Containing Magnetite (Fe3O4) Powder. Constr. Build. Mater. 2023, 392, 132005. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Liu, W.; Yan, D. Microwave Heating and Deicing Efficiency for Asphalt Concrete with SiC–Fe3O4 Microwave Enhanced Functional Layer. J. Clean. Prod. 2022, 332, 130111. [Google Scholar] [CrossRef]

- Lu, S.; Bai, E.; Xu, J.; Chen, J. Research on Electromagnetic Properties and Microwave Deicing Performance of Carbon Fiber Modified Concrete. Constr. Build. Mater. 2021, 286, 122868. [Google Scholar] [CrossRef]

- Wei, W.; Shao, Z.; Zhang, Y.; Qiao, R.; Gao, J. Fundamentals and Applications of Microwave Energy in Rock and Concrete Processing—A Review. Appl. Therm. Eng. 2019, 157, 113751. [Google Scholar] [CrossRef]

- Wang, Z.; Zhang, T.; Zhou, L. Investigation on Electromagnetic and Microwave Absorption Properties of Copper Slag-Filled Cement Mortar. Cem. Concr. Compos. 2016, 74, 174–181. [Google Scholar] [CrossRef]

- Al-Kheetan, M.J.; Azim, T.; Byzyka, J.; Ghaffar, S.H.; Rahman, M.M. Performance of Magnetite-Based Stone Mastic Asphalt (SMA) as a Superior Surface Course Material. Constr. Build. Mater. 2022, 322, 126463. [Google Scholar] [CrossRef]

- Jahanbakhsh, H.; Nejad, F.M.; Khodaii, A.; Karimi, M.M. Induction Heating and Induced Healing Evaluation of the Asphalt Concretes Incorporating Conductive Aggregates Exposed to Microwave Radiation. Constr. Build. Mater. 2024, 416, 135126. [Google Scholar] [CrossRef]

- Ren, X.; Sha, A.; Li, J.; Jiang, W.; Jiao, W.; Wu, W.; Ling, X. Carbon Fiber Powder in Sustainable Asphalt Pavements: Improving Microwave Self-Healing Capacity and Low-Temperature Performance. J. Clean. Prod. 2024, 440, 140828. [Google Scholar] [CrossRef]

- Qiu, H.; Wu, Y.; Yu, J.; Wan, Z.; Zheng, L.; Chen, H. Effect of Calcium-Silicate-Hydrate (C-S-H) Nano-Crystals on the Hydration Rate and Early Strength of Microwave-Absorbing Cement Mortar Containing Magnetite (Fe3O4) Powder. Ceram. Int. 2023, 49, 39039–39048. [Google Scholar] [CrossRef]

- Guan, X.; Luo, W.; Liu, S.; Hernandez, A.G.; Do, H.; Li, B. Ultra-High Early Strength Fly Ash-Based Geopolymer Paste Cured by Microwave Radiation. Dev. Built Environ. 2023, 14, 100139. [Google Scholar] [CrossRef]

- Yang, Y.; Tian, D.; Gao, P.; Zhan, B.; Yu, Q.; Wang, J.; Wang, A.; Ni, M.; Zhao, P.; Zhang, Y.; et al. Study on the Effect and Mechanism of Microwave Excitation on the Activity of Recycled Powder of Waste Concrete. Constr. Build. Mater. 2024, 429, 136410. [Google Scholar] [CrossRef]

- Liu, X.; Zhao, Y.; Yan, D.; Feng, Y. An Environmentally Friendly Asphalt Concrete Containing SiC Aggregate for Microwave Heating Deicing. J. Mater. Civ. Eng. 2023, 35, 04023369. [Google Scholar] [CrossRef]

- Li, J.; Zhao, P.; Jing, M.; Luo, X.; Guo, J.; Zhang, F. Enhanced Microwave Deicing Capacity of Cement Pavement with Carbon Fiber Screens. Materials 2024, 17, 1488. [Google Scholar] [CrossRef]

- Wang, Z.; Bai, E.; Huang, H.; Wang, T.; Sun, H. Study on the Electromagnetic Property and Microwave Heating Efficiency of Concrete with Magnetite Aggregate. Constr. Build. Mater. 2022, 342, 128080. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Z.; Huo, J.; Wang, X.; Liu, Z.; Li, G. Microwave Heating Improvement of Asphalt Mixtures through Optimizing Layer Thickness of Magnetite and Limestone Aggregates. J. Clean. Prod. 2020, 273, 123090. [Google Scholar] [CrossRef]

- Yan, X.; Chen, L.; You, Q.; Fu, Q. Experimental Analysis of Thermal Conductivity of Semi-Rigid Base Asphalt Pavement. Road Mater. Pavement Des. 2019, 20, 1215–1227. [Google Scholar] [CrossRef]

- Karimi, M.M.; Jahanbakhsh, H.; Jahangiri, B.; Nejad, F.M. Induced Heating-Healing Characterization of Activated Carbon Modified Asphalt Concrete under Microwave Radiation. Constr. Build. Mater. 2018, 178, 254–271. [Google Scholar] [CrossRef]

- Jia, G.; Guo, J.; Li, Z. Controllable Preparation of Aerogel/Expanded Perlite Composite and Its Application in Thermal Insulation Mortar. Constr. Build. Mater. 2023, 394, 132257. [Google Scholar] [CrossRef]

- Guo, H.; Wang, Z.; An, D.; Huo, J. Collaborative Design of Cement-Based Composites Incorporated with Cooper Slag in Considerations of Engineering Properties and Microwave-Absorbing Characters. J. Clean. Prod. 2021, 283, 124614. [Google Scholar] [CrossRef]

- JTG E42-2005; Test Methods of Aggregate for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2005.

- Majeed, S.S.; Othuman Mydin, M.A.; Bahrami, A.; Dulaimi, A.; Özkılıç, Y.O.; Omar, R.; Jagadesh, P. Development of Ultra-Lightweight Foamed Concrete Modified with Silicon Dioxide (SiO2) Nanoparticles: Appraisal of Transport, Mechanical, Thermal, and Microstructural Properties. J. Mater. Res. Technol. 2024, 30, 3308–3327. [Google Scholar] [CrossRef]

| Aggregates | Bulk Density (g/cm3) | Water Absorption (%) | Needle Flake Content (%) | Crushing Value (%) | Los Angeles Abrasion (%) |

|---|---|---|---|---|---|

| Magnetite slag | 3.418 | 0.67 | 10.3 | 13.5 | 21.2 |

| Limestone | 2.836 | 0.30 | 11.2 | 15.6 | 23.5 |

| Properties | Results |

|---|---|

| Penetration (25 °C, 5 s, 100 g; 0.1 mm) | 93.5 |

| Softening Point (°C) | 48.3 |

| Ductility (15 °C, 5 cm/min; cm) | 63 |

| Solubility (%) | 99.5 |

| Density (15 °C, g/cm3) | 1.03 |

| Wax content (distillation method, %) | 1.6 |

| Flash Point (°C) | 264 |

| Structural Design of Marshall Specimens | Sieve Size (mm) | Asphalt/Aggregate Ratio (%) | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | Filler | |||||

| LS | MS | MP | EP | ||||||||||||

| HRS G1 | Heating layer | 0 | 41.8 | 154.6 | 0 | 236.6 | 133.7 | 87.8 | 62.7 | 46.0 | 29.3 | 33.4 | 50.1 | 0 | 4.5 |

| Heat-resistance layer | 0 | 17.9 | 66.3 | 84.2 | 0 | 57.3 | 37.6 | 26.9 | 19.7 | 12.5 | 14.3 | 0 | 18.3 | 4.7 | |

| HRS G2 | Heating layer | 0 | 29.8 | 110.4 | 0 | 169.0 | 95.5 | 62.7 | 44.8 | 32.8 | 20.9 | 23.9 | 35.8 | 0 | 4.5 |

| Heat-resistance layer | 0 | 29.8 | 110.4 | 140.3 | 0 | 95.5 | 62.7 | 44.8 | 32.8 | 20.9 | 23.9 | 0 | 30.4 | 4.7 | |

| HRS G3 | Heating layer | 0 | 17.9 | 66.3 | 0 | 101.4 | 57.3 | 37.6 | 26.9 | 19.7 | 12.5 | 14.3 | 21.5 | 0 | 4.5 |

| Heat-resistance layer | 0 | 41.8 | 154.6 | 196.4 | 0 | 133.7 | 87.8 | 62.7 | 46.0 | 29.3 | 33.4 | 0 | 42.6 | 4.7 | |

| Control | One layer | 0 | 59.7 | 220.9 | 0 | 338.1 | 191.0 | 125.4 | 89.5 | 65.7 | 41.8 | 47.8 | 71.6 | 0 | 4.5 |

| Pavement Type | Normalized Cost | Pavement Type | Normalized Cost |

|---|---|---|---|

| Plain asphalt mixture | 1.000 | Plain asphalt mixture | 1.000 |

| Control | 1.334 | Control | 1.334 |

| LSS #3 | 1.234 | HRS G1 | 1.419 |

| LSS #2 | 1.167 | HRS G2 | 1.323 |

| LSS #1 | 1.100 | HRS G3 | 1.230 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, H.; Zhou, X.; Guo, H.; Zhang, T.; Zhao, X.; Wang, Z. Microwave De-Icing Efficiency Improvement of Asphalt Mixture with Structural Layer Optimization and Heat-Resistance Design. Materials 2024, 17, 3112. https://doi.org/10.3390/ma17133112

Zhang H, Zhou X, Guo H, Zhang T, Zhao X, Wang Z. Microwave De-Icing Efficiency Improvement of Asphalt Mixture with Structural Layer Optimization and Heat-Resistance Design. Materials. 2024; 17(13):3112. https://doi.org/10.3390/ma17133112

Chicago/Turabian StyleZhang, Haibao, Xiaowei Zhou, Haoyan Guo, Ting Zhang, Xin Zhao, and Zhenjun Wang. 2024. "Microwave De-Icing Efficiency Improvement of Asphalt Mixture with Structural Layer Optimization and Heat-Resistance Design" Materials 17, no. 13: 3112. https://doi.org/10.3390/ma17133112