Influence of Immersion Time on the Frequency Domain Characteristics of Acoustic Emission Signals in Clayey Mineral Rocks

Abstract

:1. Introduction

2. Rock Sample Preparation and Test Method

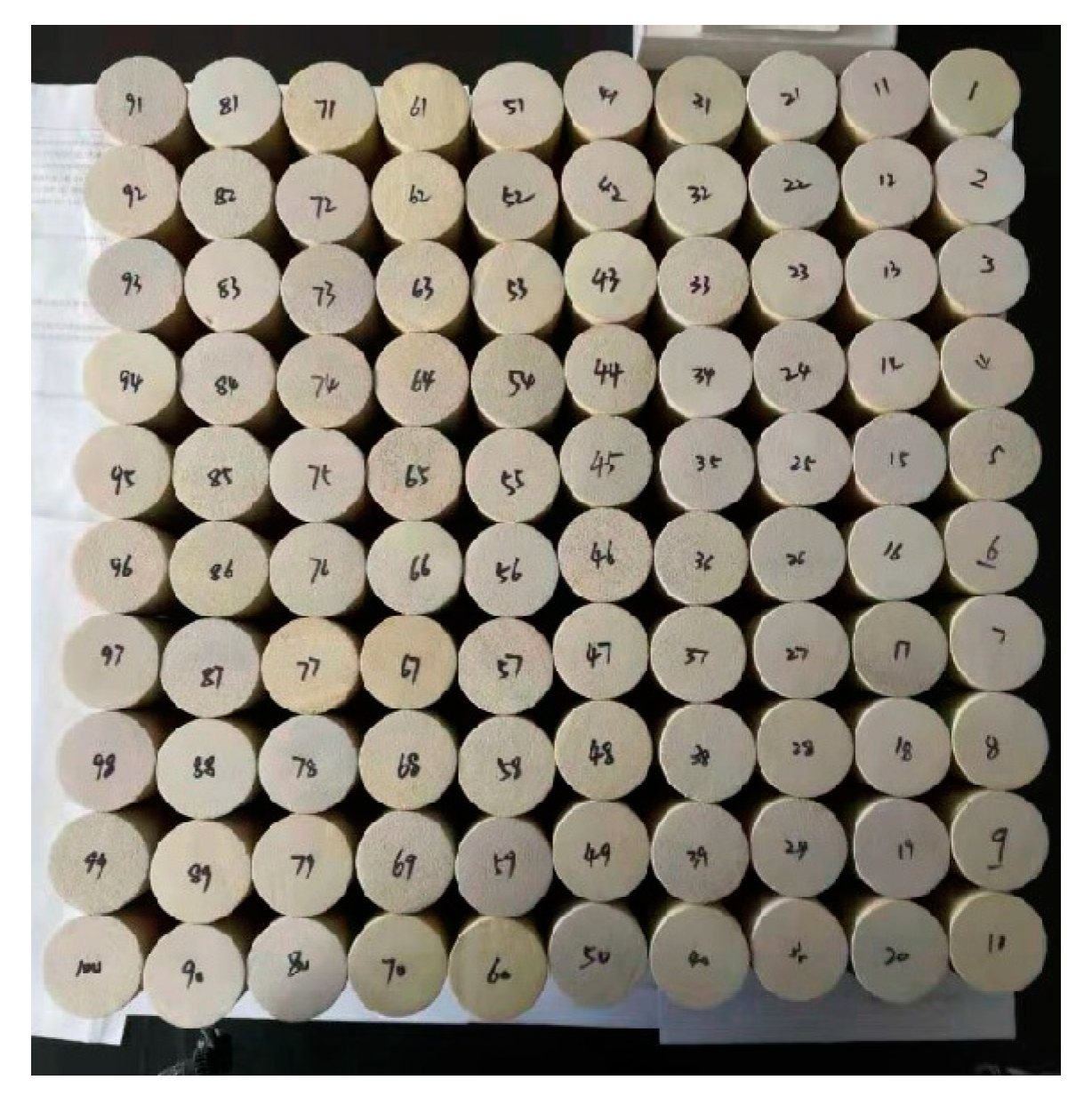

2.1. Rock Sample Preparation

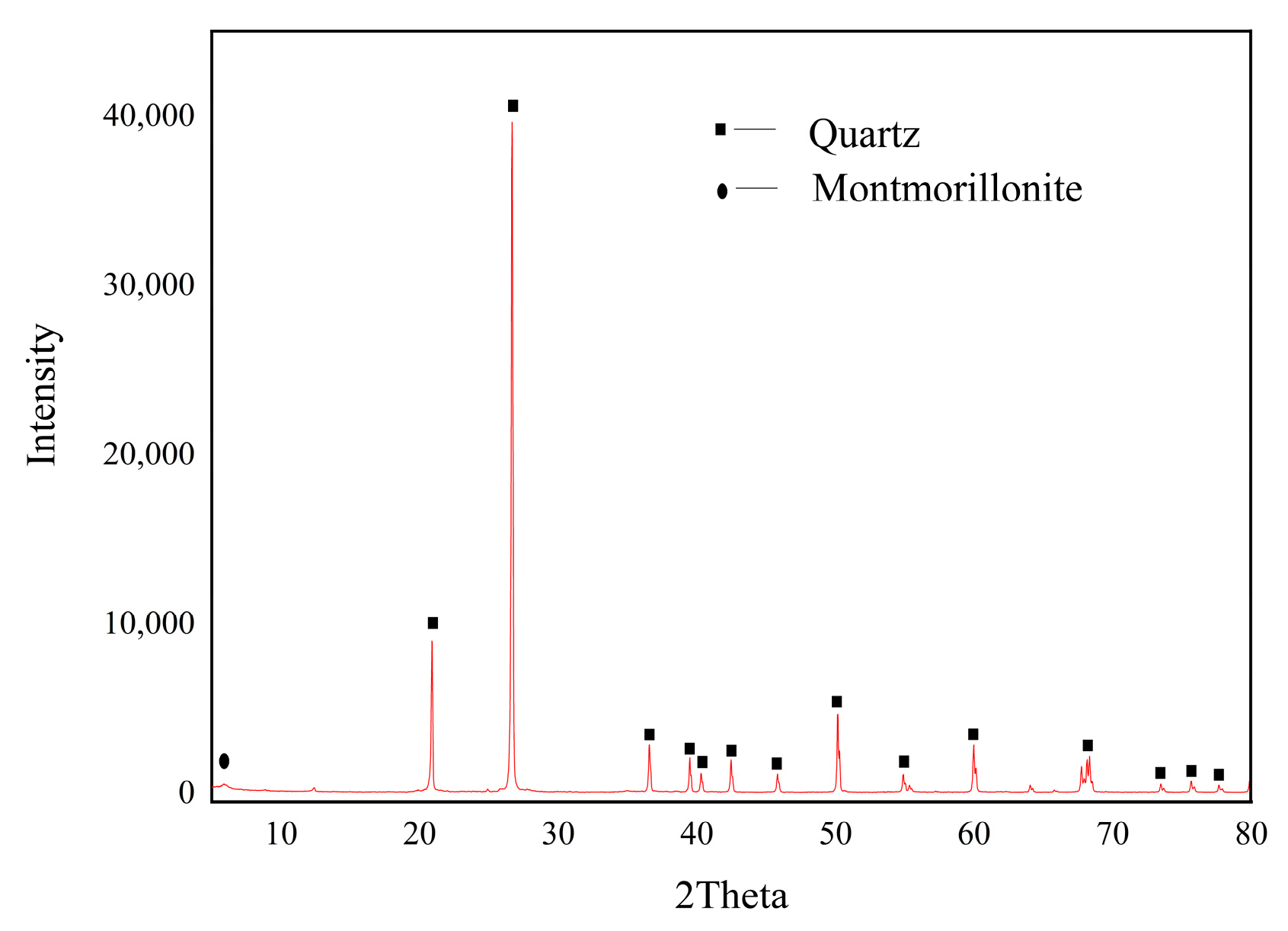

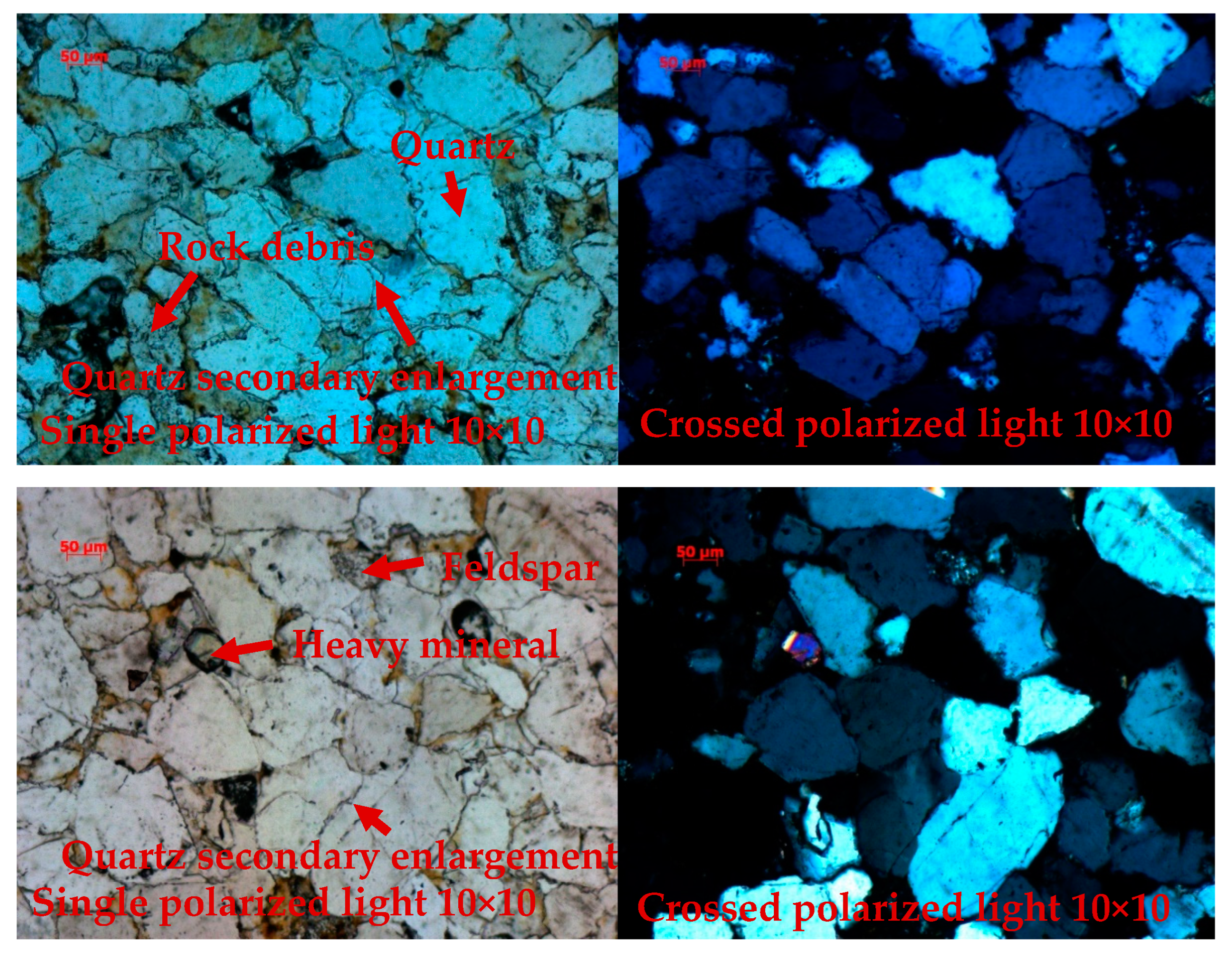

2.2. Composition and Structure Analysis of Rock Samples

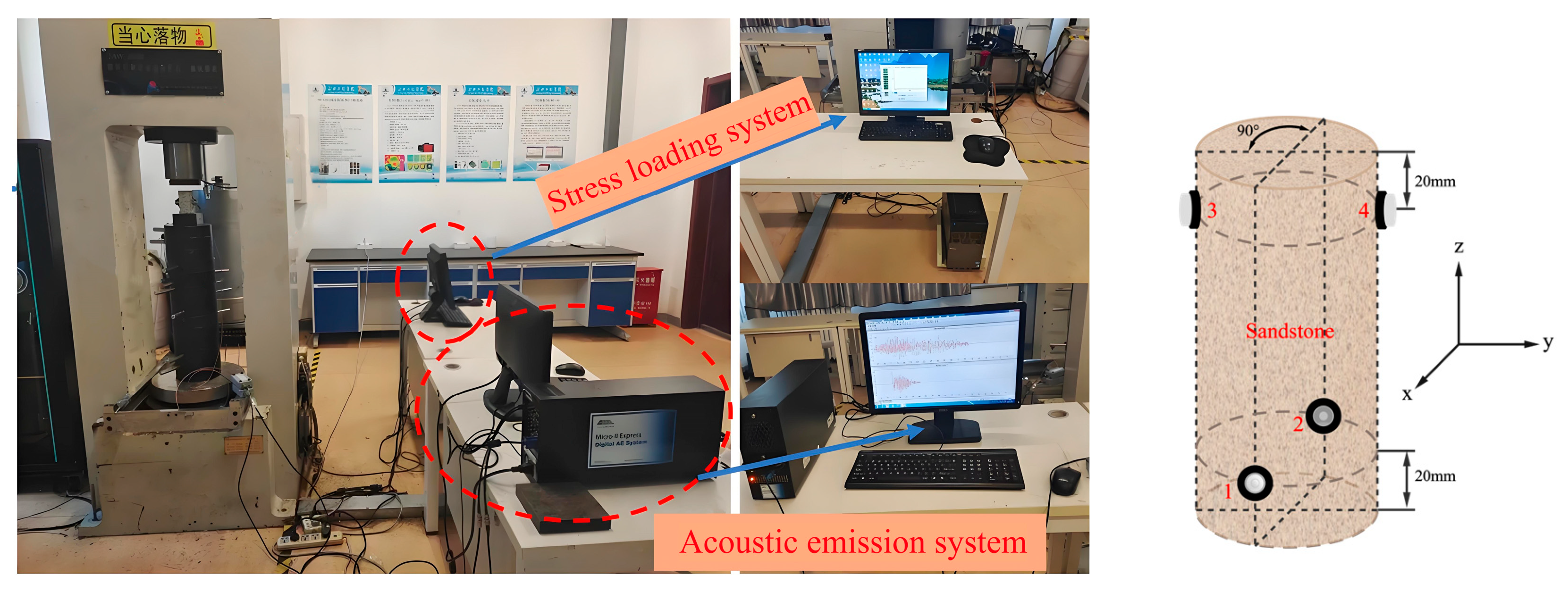

2.3. Test Methods

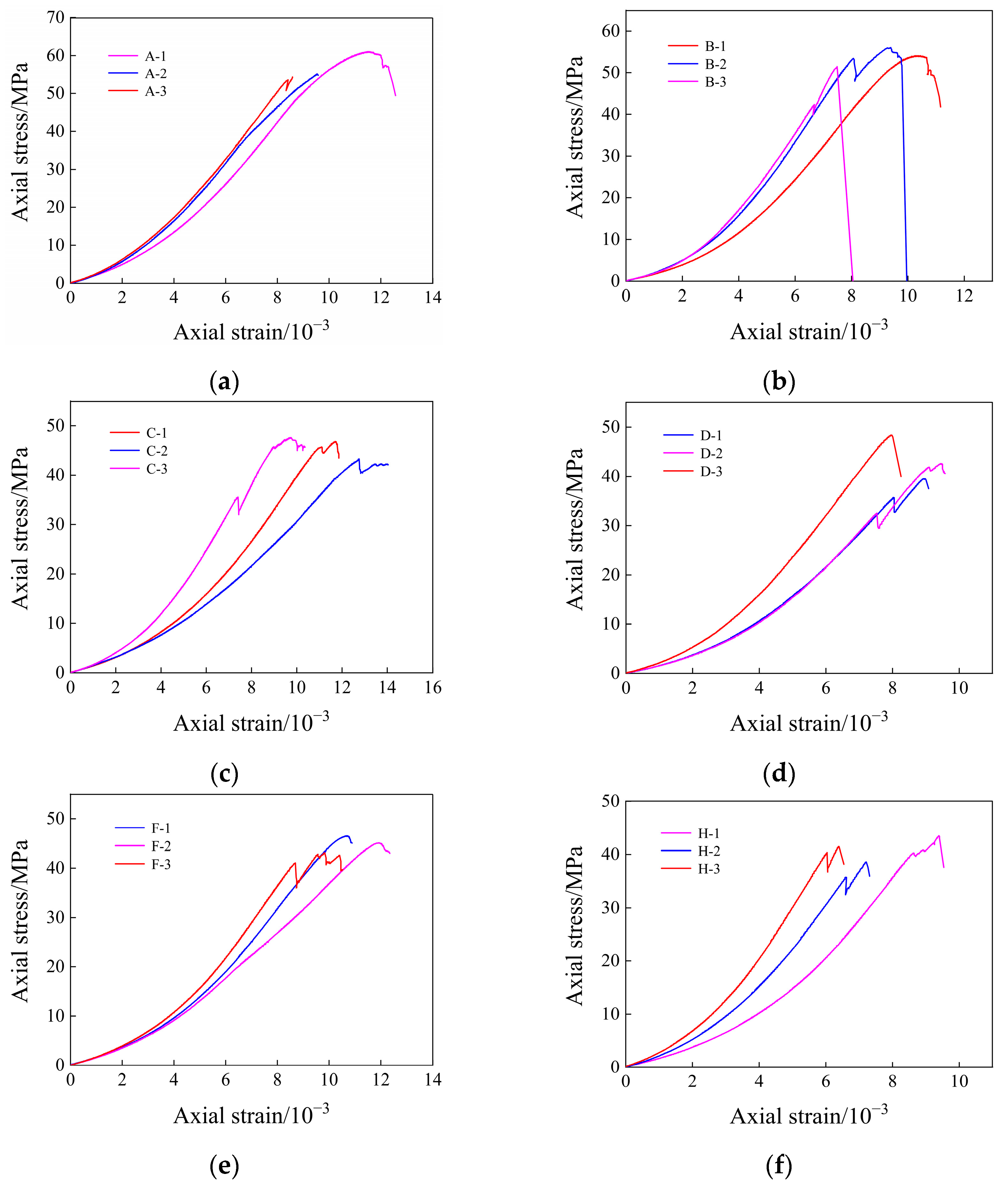

3. Effect of Immersion Time on the Mechanical Behavior of Rock Samples

4. Analysis of the Main Frequency Characteristics of Acoustic Emission Signals

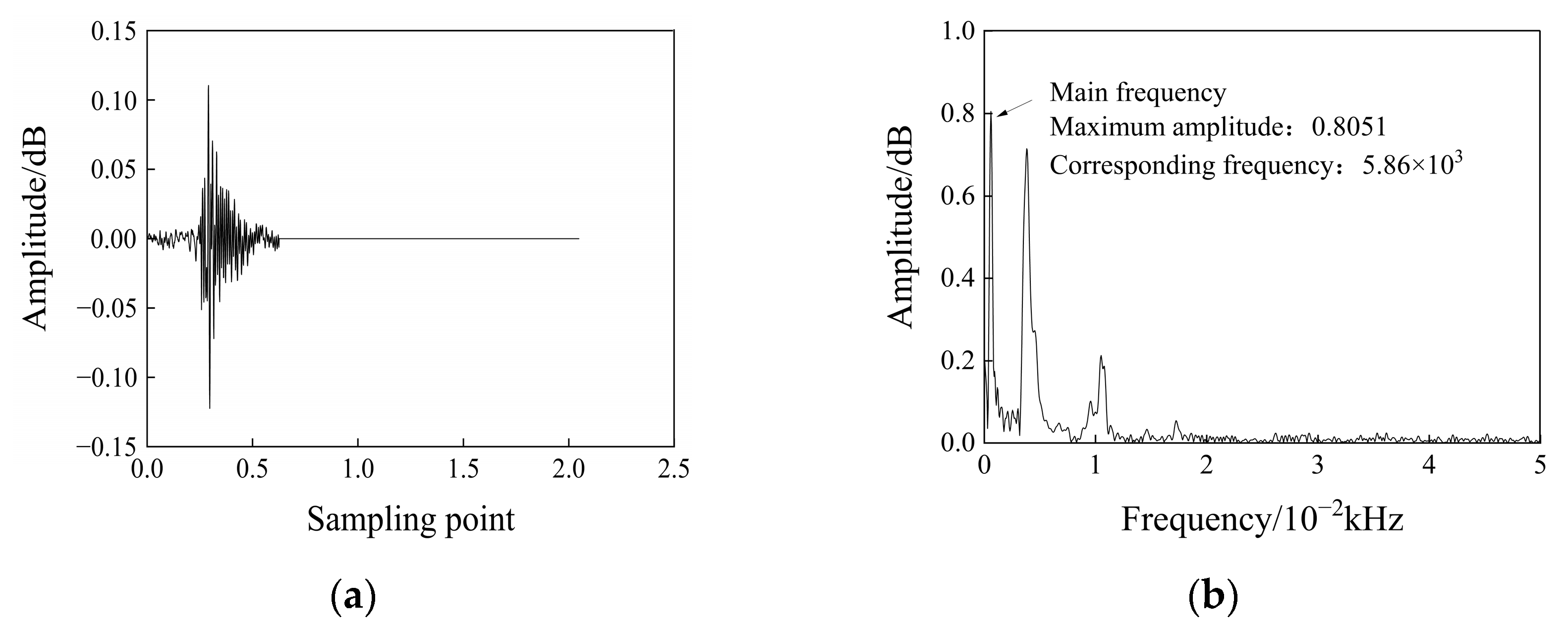

4.1. Extraction of the Main Frequency Information of the Acoustic Emission Signal

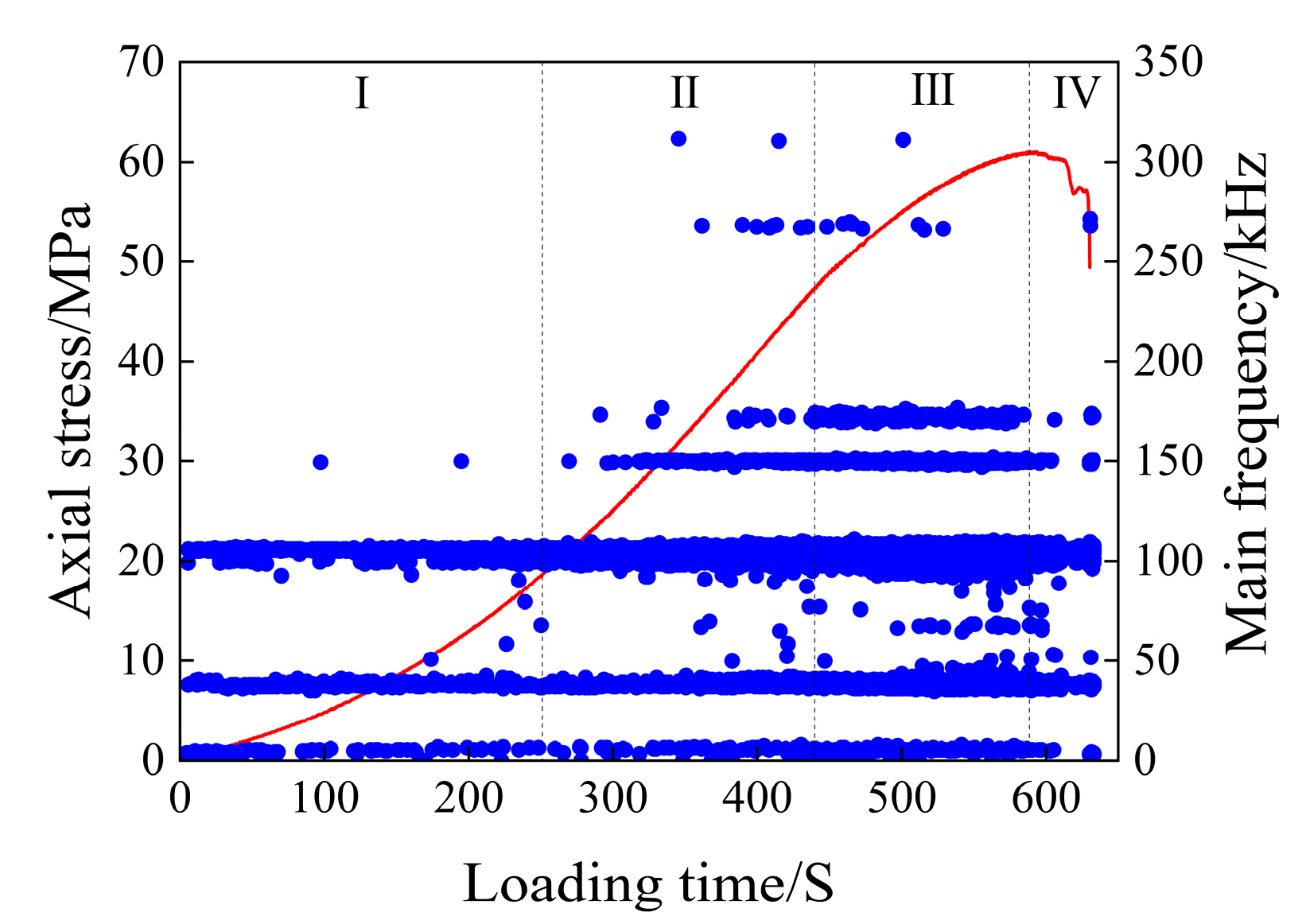

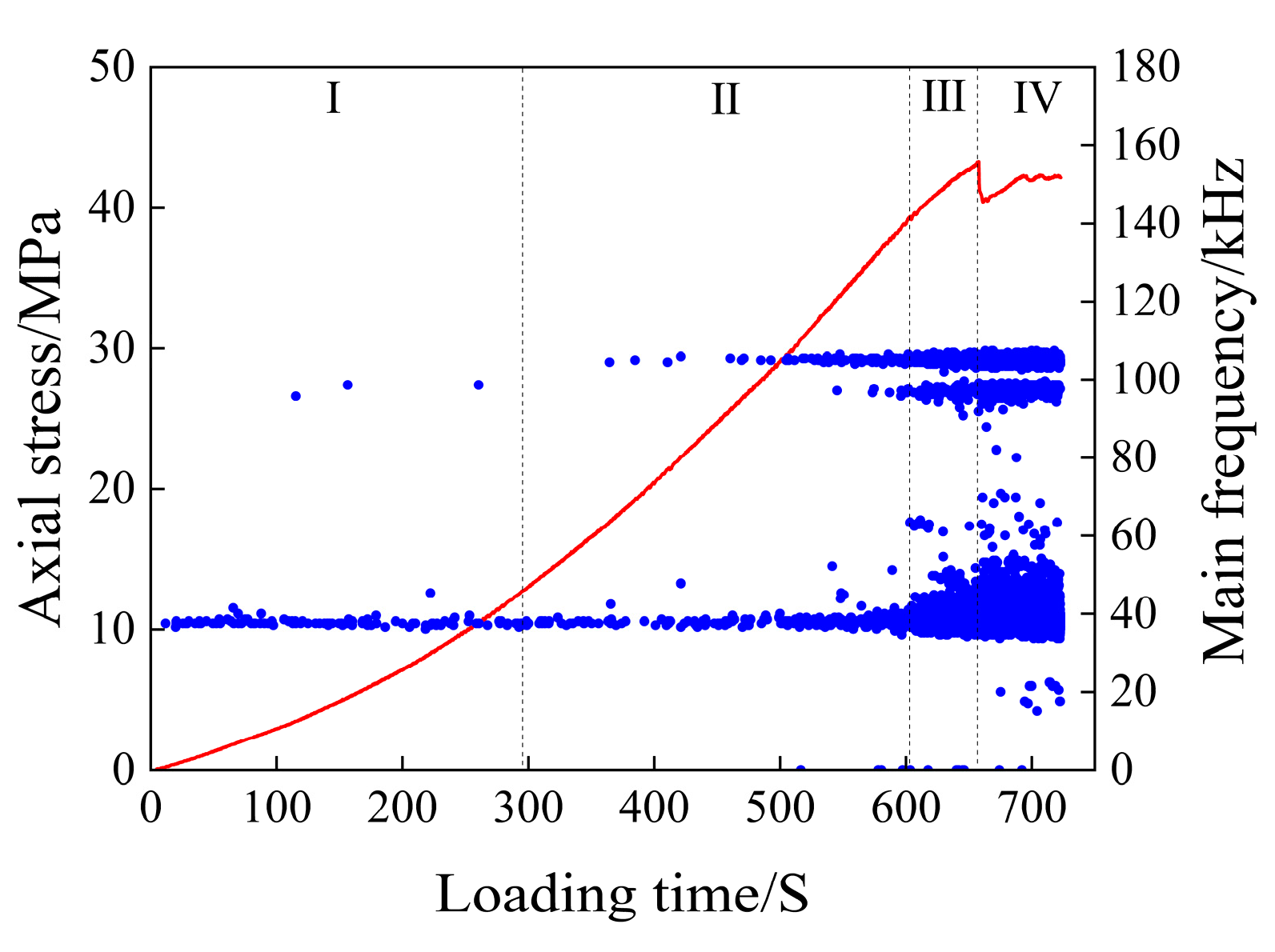

4.2. Characteristics of the Main Frequency of Acoustic Emission of Dry Rock Samples

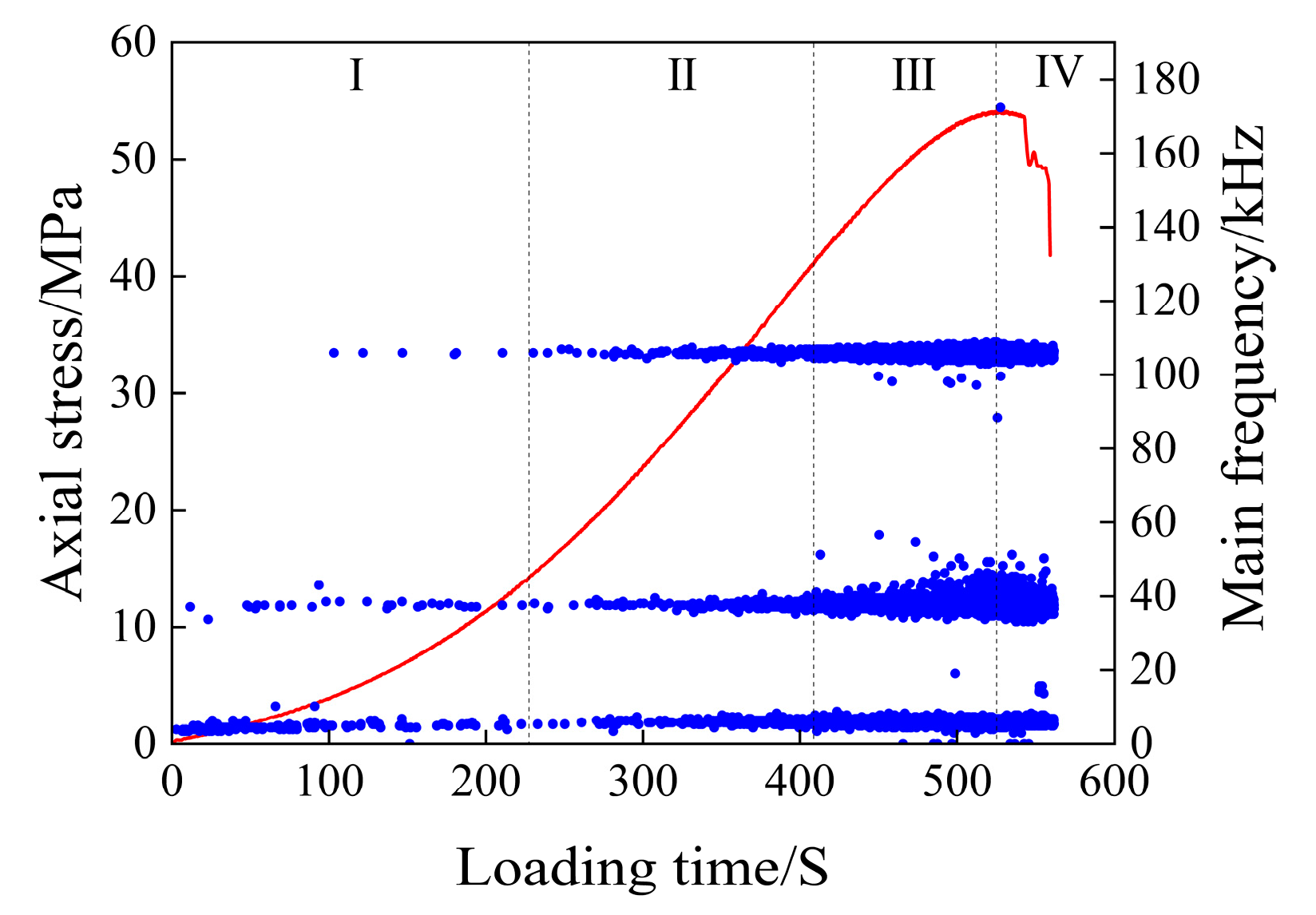

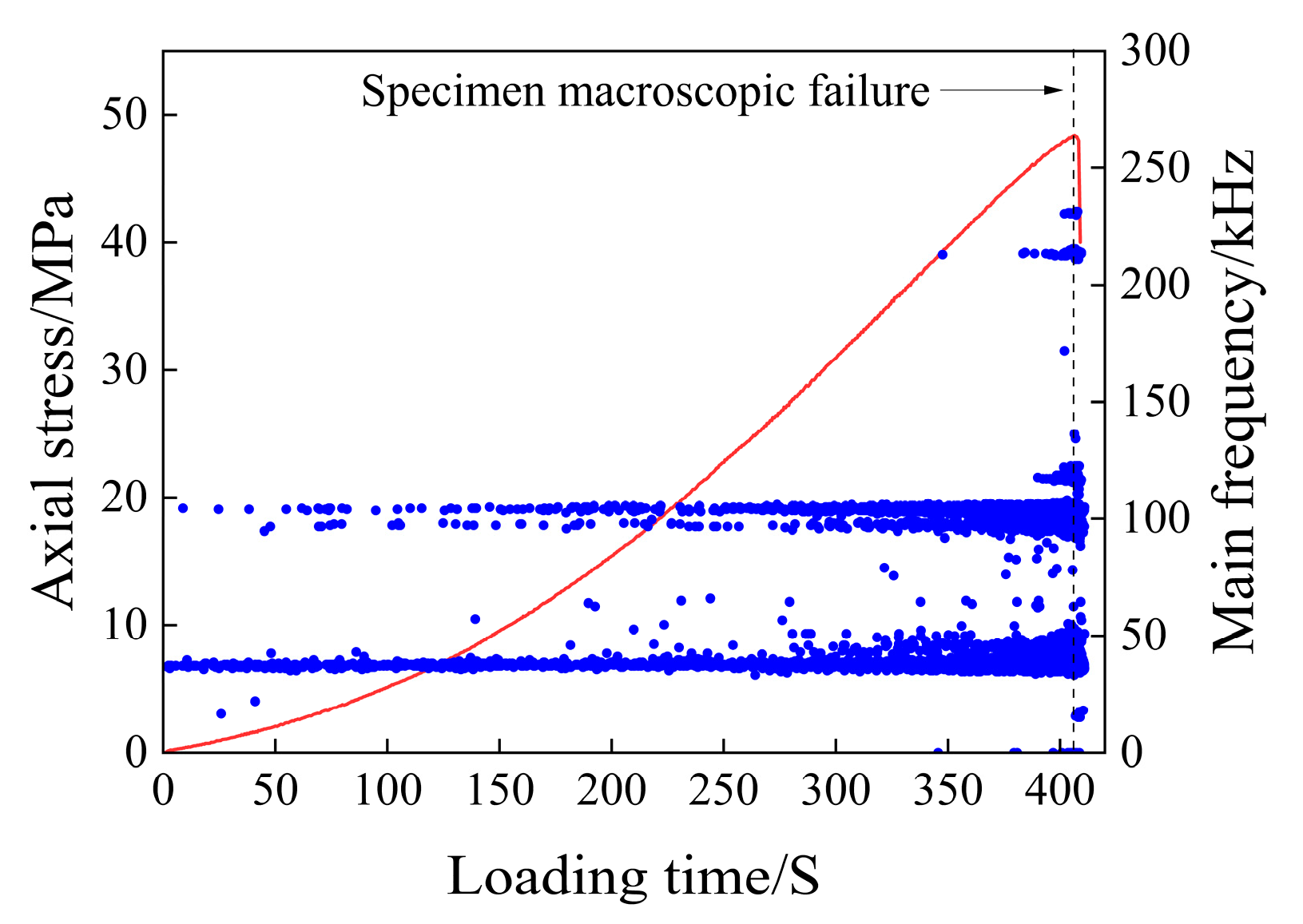

4.3. Characteristics of the Main Frequency of Acoustic Emission of Saturated Rock Samples

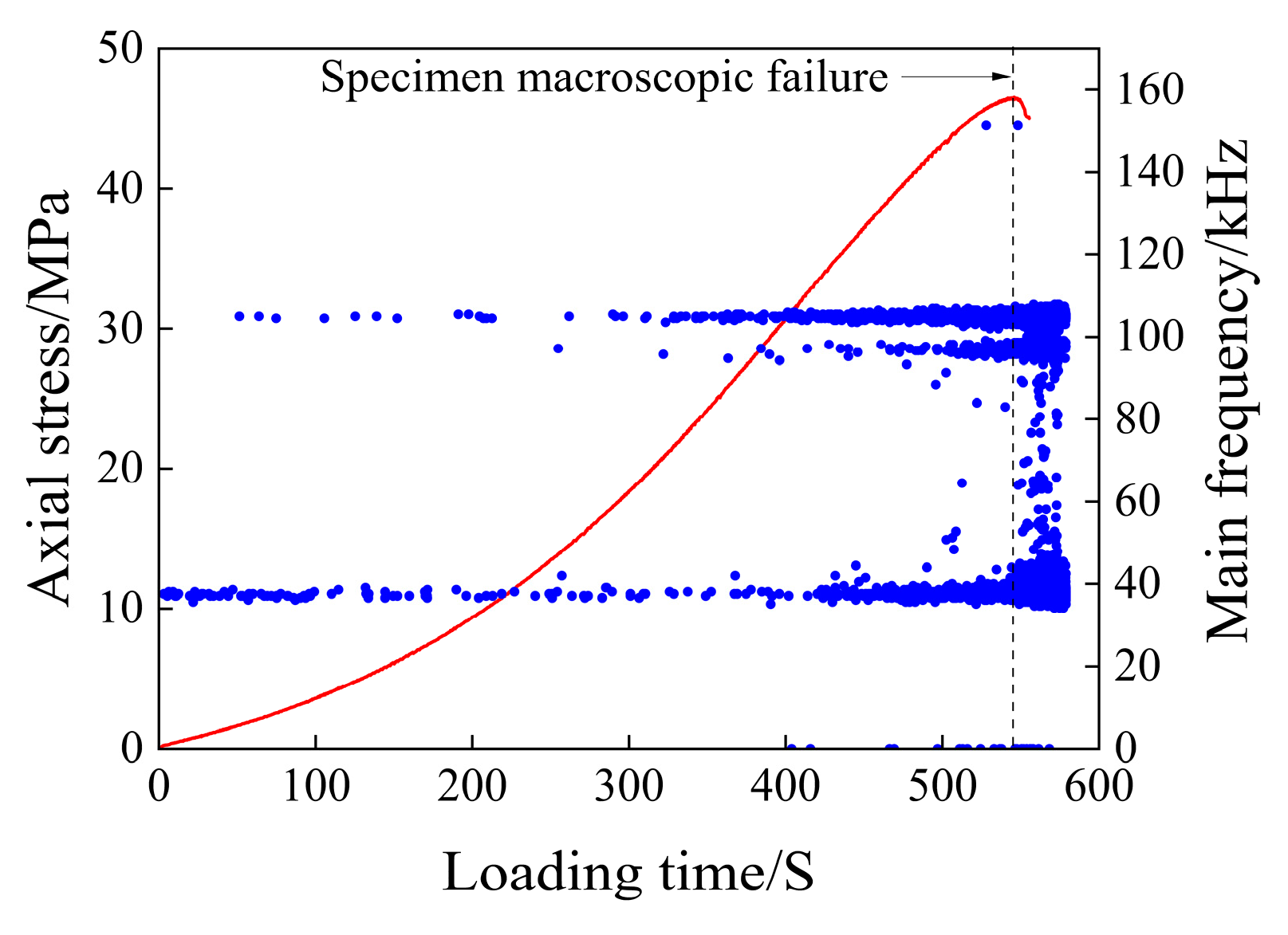

4.4. Characteristics of the Main Frequency of Acoustic Emission of 5-Day Rock Samples Immersed in Water

4.5. Characteristics of the Main Frequency of Acoustic Emission of 10-Day Rock Samples Immersed in Water

4.6. Characteristics of the Main Frequency of Acoustic Emission of Long-Term Flooded Rock Samples

4.7. A Comprehensive Analysis of the Influence of Immersion Time on the Main Frequency Characteristics of Acoustic Emission Signals

5. Analysis of the Characteristics of the Main Frequency Signal of Acoustic Transmission

- (1)

- After water enters the rock through the original micro-fractures of the rock, it can lead to the dissolution of quartz debris, feldspar debris, and other materials with dissolution characteristics in the rock, resulting in the destruction of the internal structure of the rock and then the weakening of the rock’s strength and the further development of fractures.

- (2)

- The presence of water will reduce the cohesion between the particles inside the rock, so that the initial defects of the rock will be magnified. During the rock loading process, the development of fractures tends to concentrate on the defect parts, and the development and expansion rate of the cracks in the defects are slow, which changes the development law of the fractures during drying.

- (3)

- Water will also fill the original micro-fractures in the rock, and some of the micro-fractures will heal and close when the rock sample is pressurized, and the water will produce additional stress in the closed fractures. The stress will act on the periphery of the rock pores, which will change the stress state of the rock when it is dry, causing the damage of the larger defective parts first and thus changing the development and expansion of the fractures.

- (4)

- The water content of the rock leads to the softening and mudding of the argillaceous mineral components, which, together with the water, play a shock-absorbing role, resulting in the acceleration of the weakening speed of the acoustic signal inside the rock. With an increase in immersion time, this effect becomes more obvious, so that the small signal cannot be transmitted to the surface of the rock sample to be received by the instrument.

6. Conclusions

- (1)

- The uniaxial compressive strength of dried yellow sandstone is 53.52 MPa, while it decreases to 49.51 MPa after saturation. This is an indication of the softening effect of water. The strengths corresponding to immersion durations of 5, 10, 15, 30, 45, 60, 75, 90, 105, and 120 days were 44.93 MPa, 43.08 MPa, 41.20 MPa, 42.11 MPa, 41.82 MPa, 41.19 MPa, 41.44 MPa, 39.21 MPa, 39.58 MPa, and 39.73 MPa, respectively. This indicates that water significantly weakens the strength of rock samples in the early stages of immersion. After 30 days of immersion, the coupling effect between water and rock gradually decreases, and the strength of the samples stabilizes.

- (2)

- Immersion time has a significant impact on the distribution characteristics of the dominant frequencies of acoustic emission signals in mudstone. Dry and initially saturated rock samples exhibited three dominant frequency bands. However, different immersion durations resulted in a dominant frequency band appearing between 95 kHz and 110 kHz. After 5 days of immersion, the dominant frequency band near 0 kHz gradually disappeared, making it difficult for low-frequency signals near 0 kHz to occur. After 60 days of immersion, the dominant frequency band between 35 kHz and 40 kHz gradually disappeared. With increasing immersion time, low-frequency dominant bands gradually disappeared, and the dominant frequencies of acoustic emission signals showed an increasing trend.

- (3)

- Immersion time also affects the frequency range of dominant frequencies in rock acoustic emission signals. During the loading process of dry rock samples, the dominant frequency of acoustic emission signals is mainly concentrated between 0 kHz and 310 kHz, with few signals near 310 kHz. After saturation, the high-frequency signals near 310 kHz disappeared, and high-frequency signals appeared near 230 kHz, with only a small amount occurring after 10 days of immersion, while the dominant frequencies for the remaining immersion durations were all below 180 kHz. The long-term immersion affects the frequency range of dominant frequencies in rock acoustic emission signals by significantly reducing the number of low-frequency dominant frequencies and lowering the frequencies of high-frequency signals.

- (4)

- The frequency-domain characteristics of acoustic emission signals can be used to predict the instability and rupture of rock samples under different immersion durations. For dry rock samples, the most significant features before rupture are the frequent occurrences of high-frequency signals and numerous sudden changes in the dominant frequencies. For initially saturated samples and those immersed for 5, 10, and 30 days, the precursor characteristics include the frequent appearance and rapid increase in these sudden changes in dominant frequencies, as well as an expansion in the frequency range of these dominant frequencies. However, after 60 days of immersion, these precursor characteristics gradually disappear. Additionally, sudden changes in dominant frequencies frequently occur at various stages of sample loading, making it difficult to accurately predict the rupture of specimens based on such changes at this stage.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Xia, D.; Wu, Z.; Yang, T.; Jia, Y.; Chang, H. Numerical investigation on the influence by the weakening of surrounding rock strength to the stability of grouting curtain. J. China Coal Soc. 2019, 44, 220–230. [Google Scholar]

- Ding, S.; Tang, S.; Jia, H.; Li, Y. The influence of water on the failure characteristics of sandstone under uniaxial compression conditions by acoustic emission and NMR observation. Eng. Geol. 2023, 322, 107173. [Google Scholar] [CrossRef]

- Han, P.; Zhang, C.; Wang, X.; Wang, L. Study of mechanical characteristics and damage mechanism of sandstone under long-term immersion. Eng. Geol. 2023, 315, 107020. [Google Scholar] [CrossRef]

- Erguler, Z.A.; Ulusay, R. Water-induced variations in mechanical properties of clay-bearing rocks. Int. J. Rock Mech. Min. Sci. 2009, 46, 355–370. [Google Scholar] [CrossRef]

- Liu, D.; Wang, Z.; Zhang, X.; Wang, Y.; Zhang, X.; Li, D. Experimental investigation on the mechanical and acoustic emission characteristics of shale softened by water absorption. J. Nat. Gas Sci. Eng. 2018, 50, 301–308. [Google Scholar] [CrossRef]

- Xie, X.; Chen, H.; Xiao, X.; Wang, J.; Zhou, J. Micro-structural characteristics and softening mechanism of red-bed soft rock under water-rock interaction condition. J. Eng. Geol. 2019, 27, 966–972. [Google Scholar]

- Jia, H.; Wang, T.; Xiang, W.; Tan, L.; Shen, Y.; Yang, G. Influence of water content on the physical and mechanical behaviour of argillaceous siltstone and some microscopic explanations. Chin. J. Rock Mech. Eng. 2018, 37, 1618–1628. [Google Scholar]

- Roy, D.G.; Singh, T.N.; KKodikara, J.; Das, R. Effect of water saturation on the fracture and mechanical properties of sedimentary rocks. Rock Mech. Rock Eng. 2017, 50, 2585–2600. [Google Scholar]

- Zhao, K.; Ma, H.; Yang, C.; Daemen, J.J.K. The role of prior creep duration on the acoustic emission characteristics of rock salt under cyclic loading. Int. J. Rock Mech. Min. Sci. 2022, 157, 105166. [Google Scholar] [CrossRef]

- Li, H.; Ma, H.; Yang, C.; Zhao, K.; Hu, Z.; Daemen, J.J.K. Acoustic emission characteristics of rock slat under multi-stage cyclic loading. Int. J. Fatigue 2023, 176, 107911. [Google Scholar] [CrossRef]

- Ding, Z.W.; Li, X.F.; Huang, X.; Wang, M.B.; Tang, Q.B.; Jia, J.D. Feature extraction, recognition, and classification of acoustic emission waveform signal of coal rock sample under uniaxial compression. Int. J. Rock Mech. Min. Sci. 2022, 160, 105262. [Google Scholar] [CrossRef]

- Deng, J.; Li, L.; Chen, F.; Liu, J.; Yu, J. Twin-peak frequencies of acoustic emission due to the fracture of marble and their possible mechanism. Adv. Eng. Sci. 2018, 50, 12–17. [Google Scholar]

- Cai, M.; Kaiser, P.K.; Morioka, H.; Minami, M.; Maejima, T.; Tasaka, Y.; Kurose, H. FLAC/PFC coupled numerical simulation of AE in large-scale underground excavations. Int. J. Rock Mech. Min. Sci. 2007, 44, 550–564. [Google Scholar] [CrossRef]

- Zhang, Z.H.; Deng, J.H.; Zhu, J.B.; Li, L.R. An experimental investigation of the failure mechanisms of jointed and intact marble under compression based on quantitative analysis of acoustic emission waveforms. Rock Mech. Rock Eng. 2018, 51, 2209–2307. [Google Scholar] [CrossRef]

- Wong, L.N.Y.; Guo, T.Y. Microcracking behavior of two semi-circular bend specimens in model I fracture toughness test of granite. Eng. Fract. Mech. 2019, 211, 106565. [Google Scholar] [CrossRef]

- Kim, J.S.; Lee, K.S.; Cho, W.J.; Choi, H.J.; Cho, G.C. A comparative evaluation of stress-strain and acoustic emission methods for quantitative damage assessments of brittle rock. Rock Mech. Rock Eng. 2015, 48, 495–508. [Google Scholar] [CrossRef]

- Petruzalek, M.; Lokajicek, T.; Svitek, T.; Jechumtalova, Z.; Kolar, P.; Sileny, J. Fracturing of migmatite monitored by acoustic emission and ultrasonic sounding. Rock Mech. Rock Eng. 2019, 52, 47–59. [Google Scholar] [CrossRef]

- Florian, A.; Yves, L.G.; Montse, S.; Sophie, G.; Jerome, W.; Christophe, N.; Joel, S. Analysis of acoustic emissions recorded during a mine by experiment in an underground research laboratory in clay shales. Int. J. Rock Mech. Min. Sci. 2018, 106, 51–59. [Google Scholar]

- Geng, J.; Cao, L. Failure analysis of water-bearing sandstone using acoustic emission and energy dissipation. Eng. Fract. Mech. 2020, 231, 107021. [Google Scholar] [CrossRef]

- Li, H.; Qiao, Y.; Shen, R.; He, M.; Cheng, T.; Xiao, Y.; Tang, J. Effect of water on mechanical behavior and acoustic emission response of sandstone during loading process: Phenomenon and mechanism. Eng. Geol. 2021, 294, 106386. [Google Scholar] [CrossRef]

- Zhang, H.; Lu, K.; Zhang, W.; Zhou, Y.; Yang, G.; Li, J.; Huang, C. A comprehensive study of damage characteristics and acoustic emission response mechanism of sandstone with different water contents. Eng. Fract. Mech. 2023, 288, 109392. [Google Scholar] [CrossRef]

- Zhang, Y.; Liang, P.; Liu, X.; Liu, S.; Tian, B. Experimental study on precursor of rock burst based on acoustic emission signal dominant-frequency and entropy. Chin. J. Rock Mech. Eng. 2015, 34, 2959–2967. [Google Scholar]

- Zhang, Y.; Liang, P.; Sun, L.; Tian, B.; Yao, X.; Liu, X. Spectral characteristics of AE in the process of saturated granite fracture under uniaxial compression. Rock Soil Mech. 2019, 40, 2497–2506. [Google Scholar]

- Zhao, K.; Wang, X.; Wang, L.; Zeng, P.; Yang, D.; Jin, J. Investigation of the crack and acoustic emission behavior evolution of red sandstone subjected to water. Theor. Appl. Fract. Mech. 2022, 120, 103419. [Google Scholar] [CrossRef]

- Xu, R.; Hu, Y.; Yan, Z.; Zhao, Y.; Li, Z. Experimental investigation on the effect of water saturation on the failure mechanism and acoustic emission characteristics of sandstone. Int. J. Geomech. 2024, 24, 04024102. [Google Scholar] [CrossRef]

- Wang, H.; Cui, Z.; Xu, C.; Yong, R.; Zhao, F.; Chen, S. Study on the damage mechanism of sandstone under different water content states. Remote Sens. 2023, 15, 3127. [Google Scholar] [CrossRef]

- Duan, H.; Gao, M.; Yan, H. Time-frequency characteristics of acoustic emission signals on water-bearing sandstone specimen subjected to conventional uniaxial compression. Geofluids 2022, 2022, 8101861. [Google Scholar] [CrossRef]

- Song, H.; Li, S.; Xu, J.; Zhang, Q.; Zhi, Y. Fractal characteristics and acoustic emission during the failure process of argillaceous siltstone with different moisture contents. Geofluids 2023, 2023, 4558171. [Google Scholar] [CrossRef]

- Shan, T.; Li, Z.; Zhang, X.; Niu, Y.; Tian, H.; Zhang, Q.; Zang, Z.; Gu, Z.; Cai, C.; Liu, C. Infrared radiation and acoustic emission of damage evolution and failure precursory for water-bearing coal. Rock Mech. Rock Eng. 2022, 55, 7657–7674. [Google Scholar] [CrossRef]

- Huang, Z.; Zuo, Q.; Wu, L.; Chen, F.; Hu, S.; Zhu, S. Nonlinear softening mechanism of argillaceous slate under water-rock interaction. Rock Soil Mech. 2020, 41, 2931–2942. [Google Scholar]

- Deng, H.; Yuan, X.; Li, J.; Luo, Q.; He, M. Fracture mechanics characteristics and deterioration mechanism of sandstone under reservoir immersion interaction. J. China Univ. Geosci. 2014, 39, 108–114. [Google Scholar]

- Yao, Q.; Chen, T.; Ju, M.; Liang, S.; Liu, Y.; Li, X. Effects of water intrusion on mechanical properties of and crack propagation in coal. Rock Mech. Rock Eng. 2016, 49, 4699–4709. [Google Scholar] [CrossRef]

- Li, T.; Zhao, J.; Xie, M.; Tan, S.; Wang, G. Experimental study on the effect of slate rock mechanics properties degradation by the saturation-time. Sci. Technol. Eng. 2018, 18, 217–222. [Google Scholar]

- Han, P.; Zhao, Y.; Gao, S.; Gao, Y.; Zhang, C.; Hu, Y. Progressive damage characteristics and damage constitutive model of coal samples under long-term immersion. Chin. J. Rock Mech. Eng. 2024, 43, 918–933. [Google Scholar]

- Xia, D.; Yang, T.; Xu, T.; Wang, P.; Zhao, Y. Experimental study on AE properties during the damage process of water-saturated rock specimens on time effect. J. China Coal Soc. 2015, 40, 337–345. [Google Scholar]

- Wu, B.; Wang, W.; Guo, D. Strength damage and AE characteristics of fractured sandstone under the influence of water intrusion times. J. Min. Saf. Eng. 2020, 37, 1054–1060. [Google Scholar]

- Fang, J.; Yao, Q.; Wang, W.; Tang, C.; Wang, G. Experimental study on damage characteristics of siltstone under water action. J. China Coal Soc. 2018, 43, 412–419. [Google Scholar]

- Zhang, T.; Chen, J. Fractal characteristics of particle size distribution of broken coal samples with different immersion time. J. Min. Saf. Eng. 2018, 35, 598–604. [Google Scholar]

- Lu, C.; Zeng, Q.; Liu, J.; Ma, Z.; Shao, X.; Tang, L.; Huang, Y.; Zhou, G.; Meng, X.; Wang, J.; et al. Proppant embedment in rough fractures considering shale hudration. Energy Rep. 2023, 9, 5146–5154. [Google Scholar] [CrossRef]

- Song, C.; Feng, G.; Bai, J.; Cui, J.; Wang, K.; Shi, X.; Qian, R. Progressive failure characteristics and water-induced deterioration mechanism of fissured sandstone under water-rock interaction. Theor. Appl. Fract. Mech. 2023, 128, 104151. [Google Scholar] [CrossRef]

- Bayesteh, H.; Mirghasemi, A.A. Numerical simulation of pore fluid characteristic effect on the volume change behavior of montmorillonite clays. Comput. Geotech. 2013, 48, 146–155. [Google Scholar] [CrossRef]

- He, M.; Zhao, F.; Du, S.; Zheng, M.-J. Rockburst characteristics based on experimental tests under different unloading rates. Rock Soil Mech. 2014, 35, 2737–2747. [Google Scholar]

| No. | V (m/s) | No. | V (m/s) | No. | V (m/s) | No. | V (m/s) | No. | V (m/s) | No. | V (m/s) |

|---|---|---|---|---|---|---|---|---|---|---|---|

| A-1 | 2023 | C-1 | 2030 | E-1 | 2087 | G-1 | 2000 | I-1 | 2013 | K-1 | 2107 |

| A-2 | 2140 | C-2 | 2153 | E-2 | 2203 | G-2 | 2130 | I-2 | 2137 | K-2 | 2210 |

| A-3 | 2250 | C-3 | 2253 | E-3 | 2277 | G-3 | 2223 | I-3 | 2240 | K-3 | 2307 |

| A-4 | 2343 | C-4 | 2350 | E-4 | 2383 | G-4 | 2323 | I-4 | 2330 | K-4 | 2397 |

| A-5 | 2443 | C-5 | 2453 | E-5 | 2483 | G-5 | 2430 | I-5 | 2437 | K-5 | 2490 |

| B-1 | 2030 | D-1 | 2133 | F-1 | 2107 | H-1 | 2010 | J-1 | 2017 | L-1 | 2130 |

| B-2 | 2147 | D-2 | 2210 | F-2 | 2207 | H-2 | 2137 | J-2 | 2140 | L-2 | 2220 |

| B-3 | 2250 | D-3 | 2317 | F-3 | 2290 | H-3 | 2230 | J-3 | 2247 | L-3 | 2320 |

| B-4 | 2343 | D-4 | 2400 | F-4 | 2390 | H-4 | 2327 | J-4 | 2330 | L-4 | 2427 |

| B-5 | 2447 | D-5 | 2503 | F-5 | 2483 | H-5 | 2437 | J-5 | 2443 | L-5 | 2523 |

| Soaking Time/d | Number of Main Frequencies | Main Frequency Band/kHz | Frequency Range/kHz |

|---|---|---|---|

| Dry | 81,697 | 0, 45, 105 | 0~310 |

| Saturated | 42,951 | 5, 40, 105 | 0~180 |

| 5 | 40,109 | 35, 95, 105 | 0~110 |

| 10 | 17,133 | 40, 95, 105 | 0~230 |

| 30 | 16,171 | 40, 95, 105 | 0~110 |

| 60 | 17,516 | 35, 95, 105 | 0~170 |

| 90 | 13,876 | 70, 100, 110, 160, 180 | 0~180 |

| 120 | 2286 | 110 | 0~180 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, J.; Li, Z.; Xia, D.; Bai, Y.; Shao, G. Influence of Immersion Time on the Frequency Domain Characteristics of Acoustic Emission Signals in Clayey Mineral Rocks. Materials 2024, 17, 3147. https://doi.org/10.3390/ma17133147

Yan J, Li Z, Xia D, Bai Y, Shao G. Influence of Immersion Time on the Frequency Domain Characteristics of Acoustic Emission Signals in Clayey Mineral Rocks. Materials. 2024; 17(13):3147. https://doi.org/10.3390/ma17133147

Chicago/Turabian StyleYan, Jiaju, Zhuxi Li, Dong Xia, Yuxin Bai, and Guoliang Shao. 2024. "Influence of Immersion Time on the Frequency Domain Characteristics of Acoustic Emission Signals in Clayey Mineral Rocks" Materials 17, no. 13: 3147. https://doi.org/10.3390/ma17133147

APA StyleYan, J., Li, Z., Xia, D., Bai, Y., & Shao, G. (2024). Influence of Immersion Time on the Frequency Domain Characteristics of Acoustic Emission Signals in Clayey Mineral Rocks. Materials, 17(13), 3147. https://doi.org/10.3390/ma17133147