Study on the Effects of Printing Process and Reinforcement Materials on the Performance of 3D-Printed Glass Bead Insulation Mortar

Abstract

:1. Introduction

2. Materials and Methods

2.1. Material Apparatus and Test Ratio

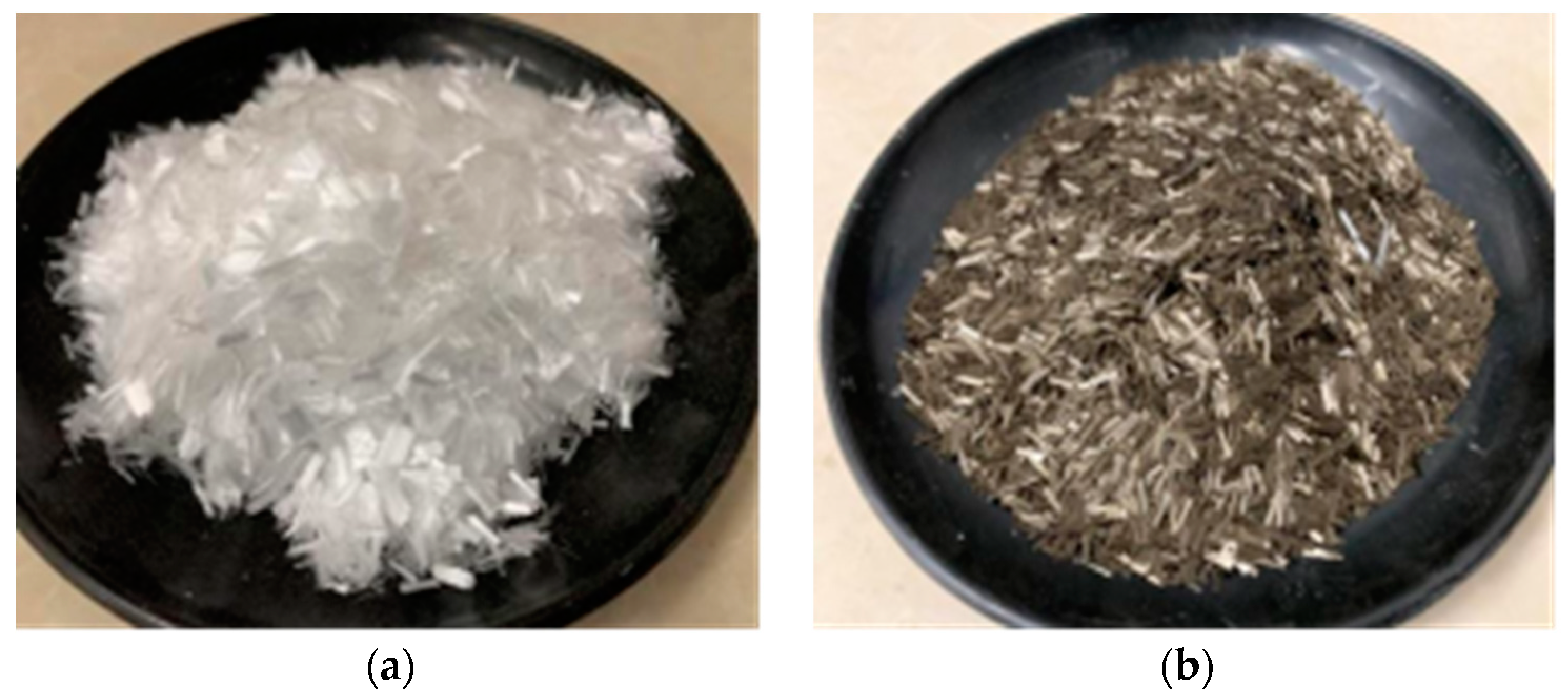

2.1.1. Material

2.1.2. Testing Equipment

2.2. Specifications

2.3. Setting of Printer Parameters

2.4. Test Block Design

2.5. Test Block Fabrication and Testing

3. Results and Discussion

3.1. Test 1 Results and Analysis

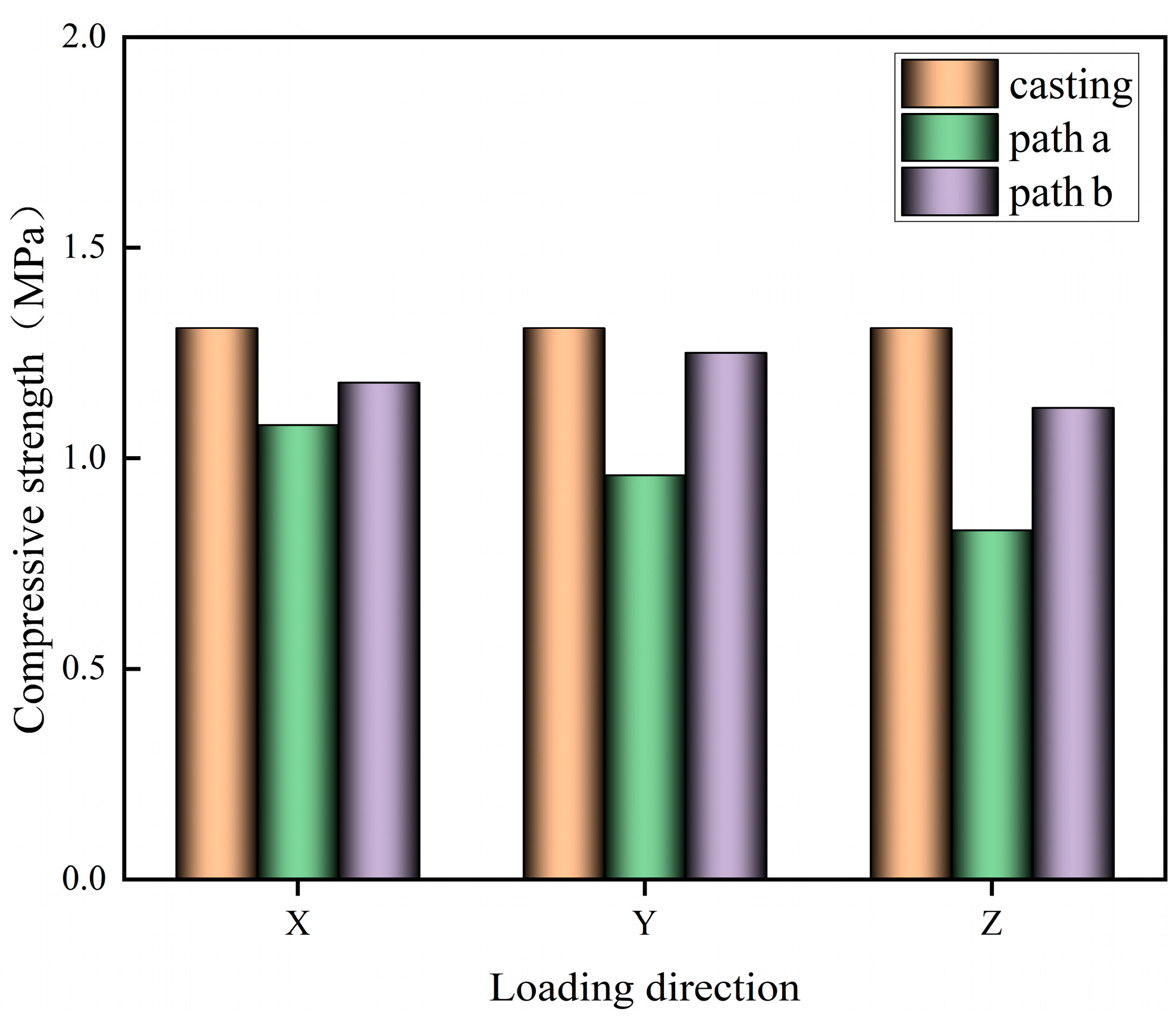

3.1.1. Compressive Strength Anisotropy Analysis

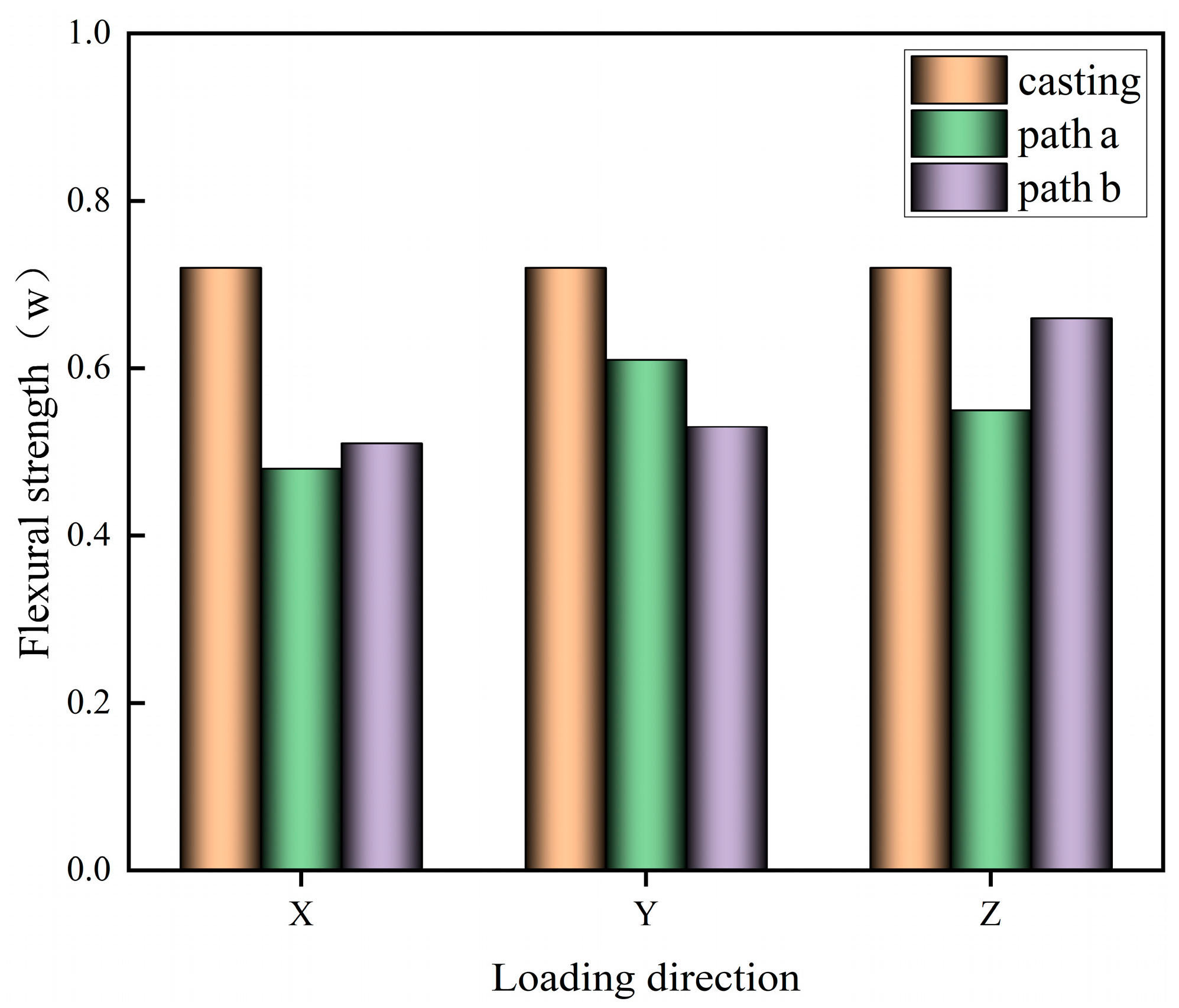

3.1.2. Flexural Strength Anisotropy Analysis

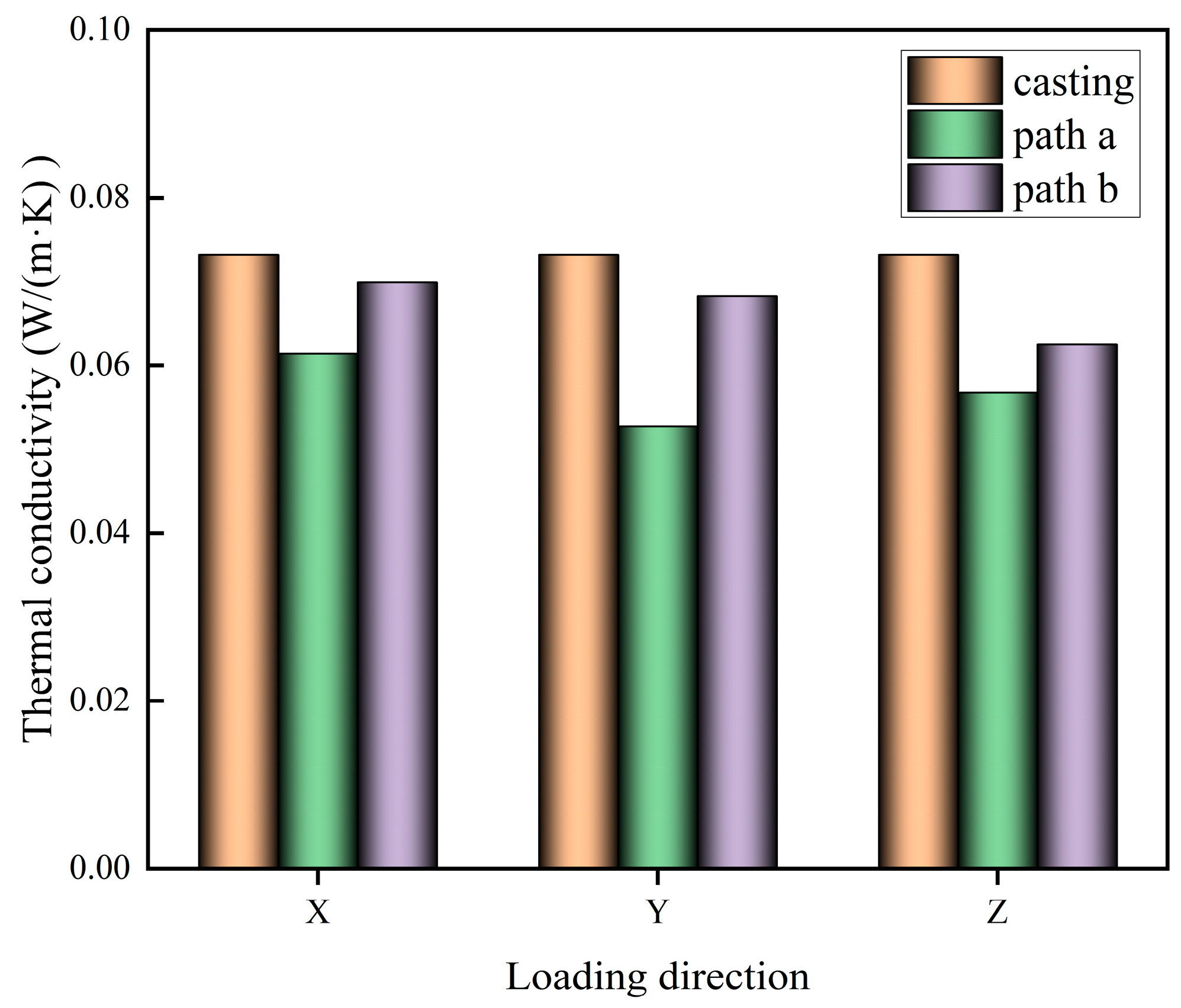

3.1.3. Thermal Conductivity Anisotropy Analysis

3.2. Test 2 Results and Analysis

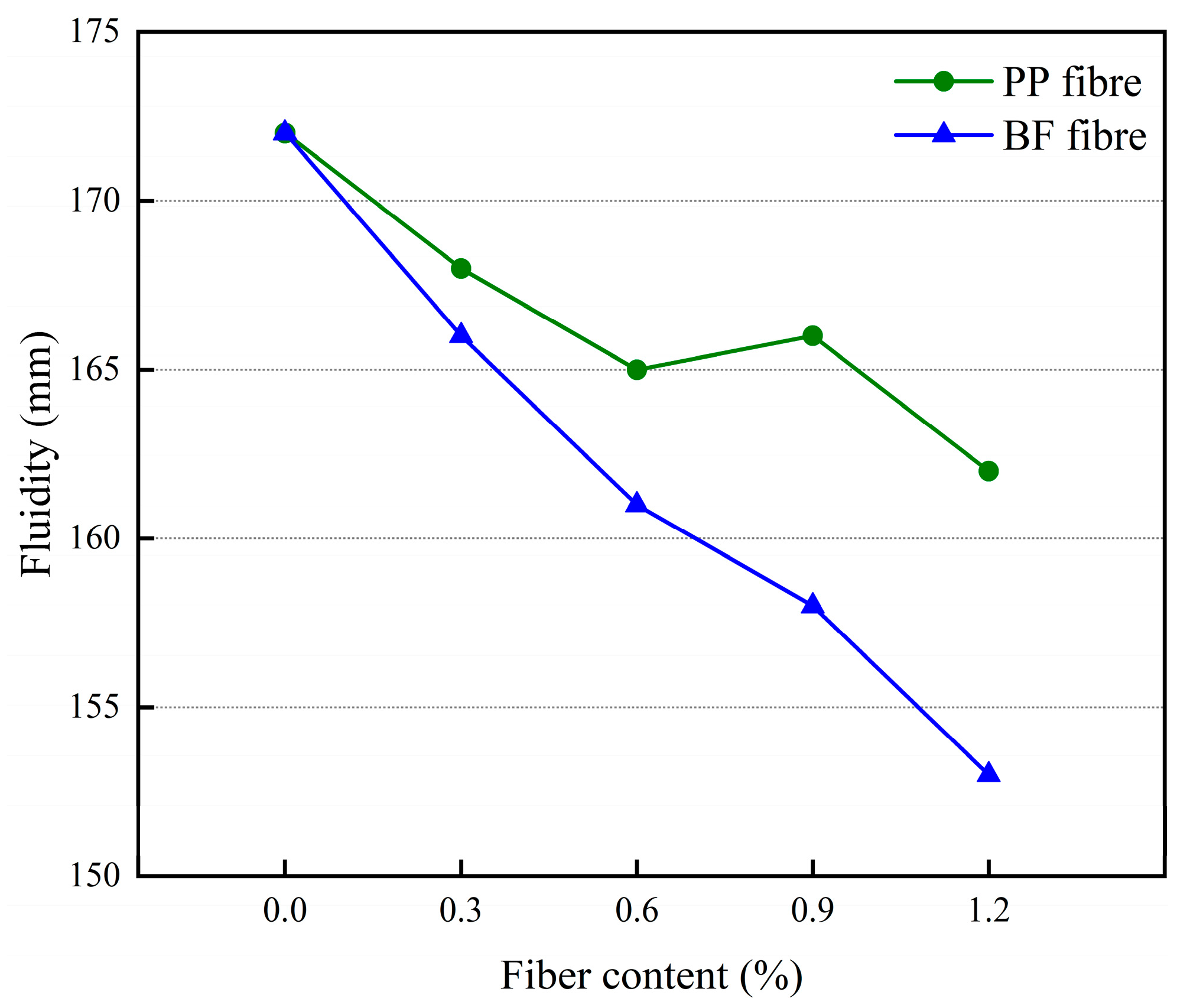

3.2.1. Mortar Flow Test Results and Analysis

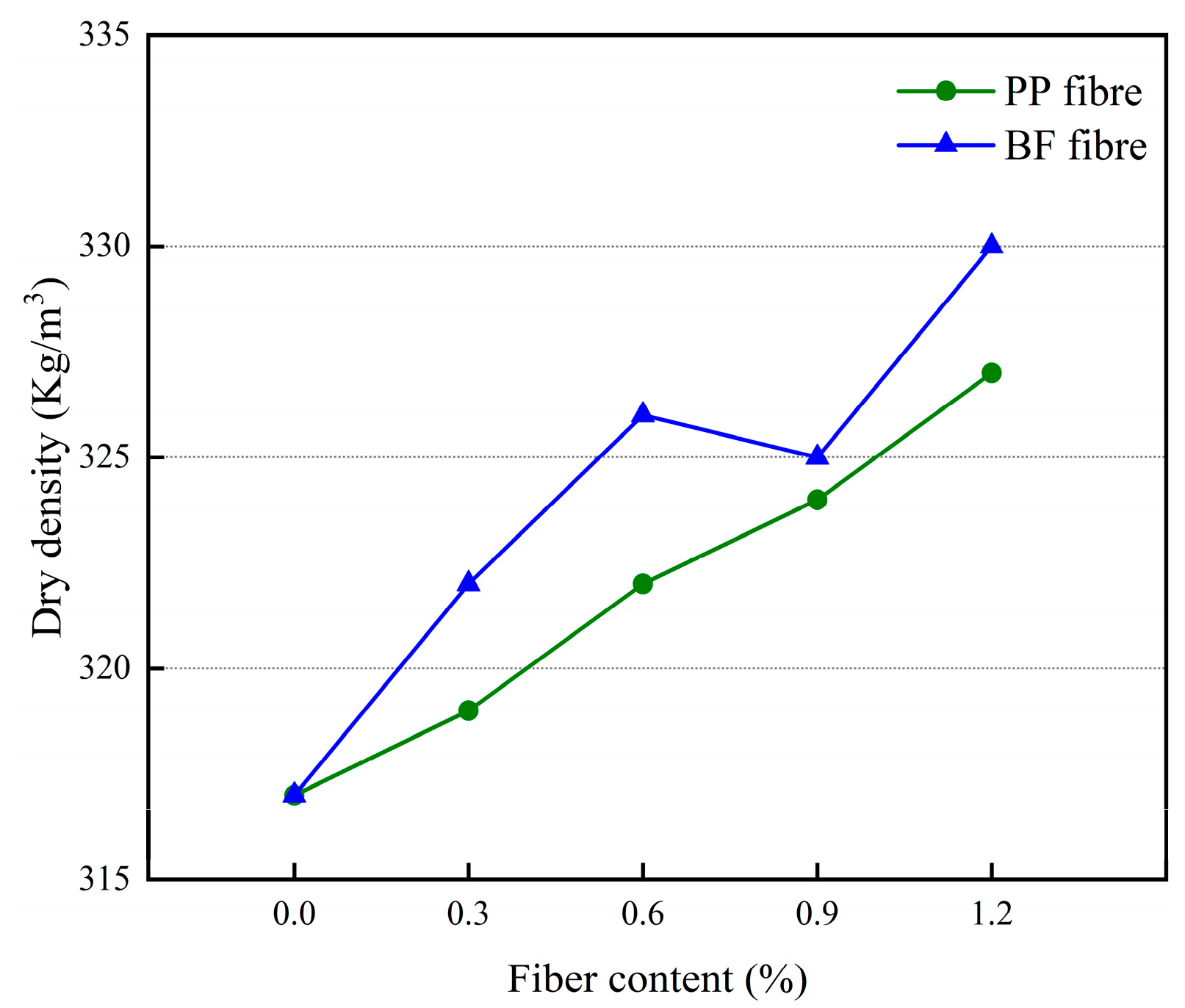

3.2.2. Dry Density Test Results and Analysis of Mortar

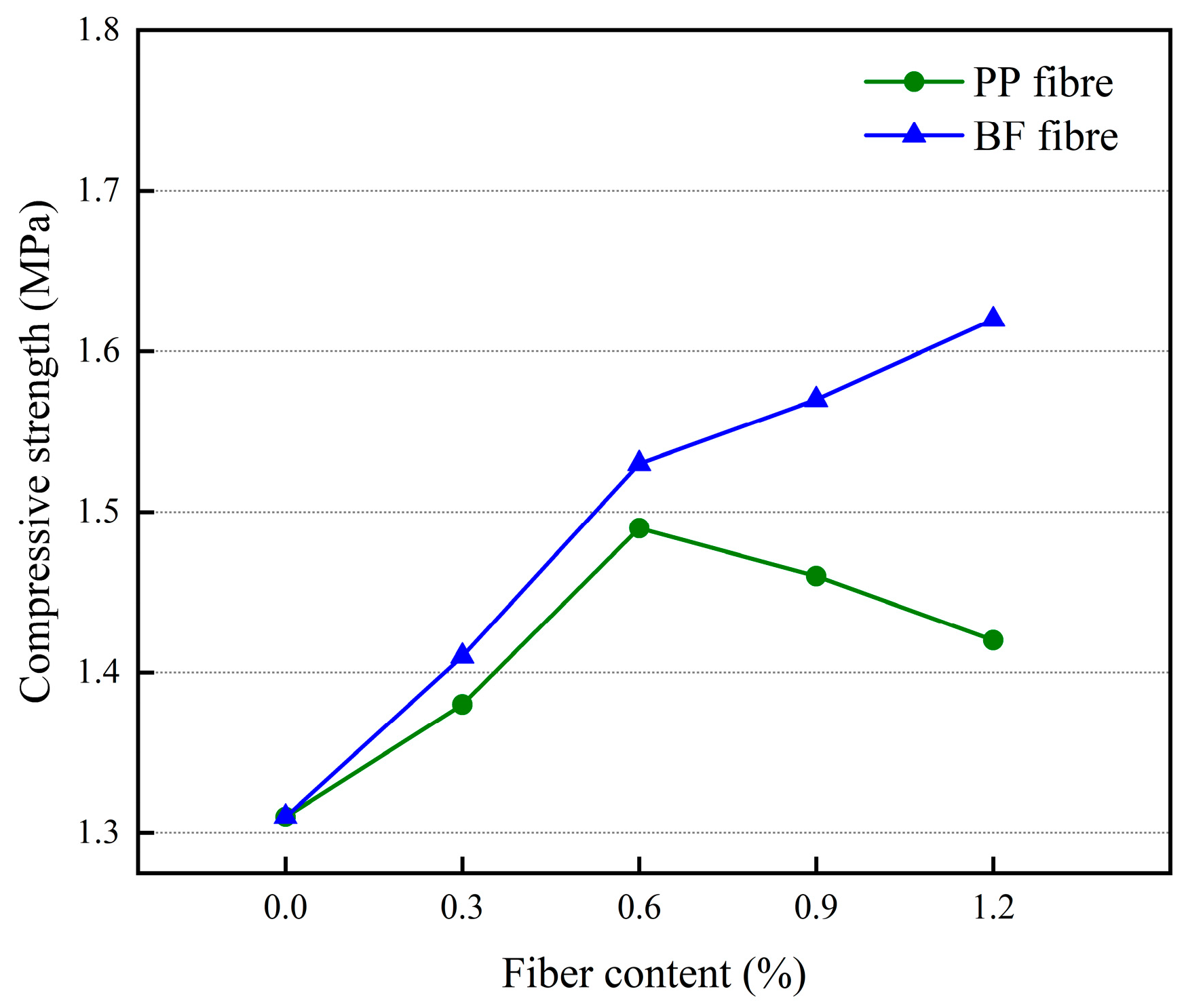

3.2.3. Mortar Compressive Strength Test Results and Analysis

3.2.4. Flexural Strength Test Results and Analysis of Mortar

3.2.5. Test Results and Analysis of Thermal Conductivity of Mortar

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Panda, B.; Paul, S.C.; Tan, M.J. Anisotropic mechanical performance of 3D printed fiber reinforced sustainable construction material. Mater. Lett. 2017, 209, 146–149. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Wang, L.; Wang, F.; Sanjayan, J. Mechanical anisotropy of aligned fiber reinforced composite for extrusion-based 3D printing. Constr. Build. Mater. 2019, 202, 770–783. [Google Scholar] [CrossRef]

- Xiao, J.; Liu, H.; Ding, T. Finite element analysis on the anisotropic behavior of 3D printed concrete under compression and flexure. Addit. Manuf. 2021, 39, 101712. [Google Scholar] [CrossRef]

- Ding, T.; Xiao, J.; Zou, S.; Yu, J. Flexural properties of 3D printed fibre-reinforced concrete with recycled sand. Constr. Build. Mater. 2021, 288, 123077. [Google Scholar] [CrossRef]

- Sun, J.; Aslani, F.; Lu, J.; Wang, L.; Huang, Y.; Ma, G. Fibre-reinforced lightweight engineered cementitious composites for 3D concrete printing. Ceram. Int. 2021, 47, 27107–27121. [Google Scholar] [CrossRef]

- Jiang, Q.; Liu, Q.; Wu, S.; Zheng, H.; Sun, W. Modification effect of nanosilica and polypropylene fiber for extrusion-based 3D printing concrete: Printability and mechanical anisotropy. Addit. Manuf. 2022, 56, 102944. [Google Scholar] [CrossRef]

- Nacht, T.; Pratter, R.; Ganglbauer, J.; Schibline, A.; Aguayo, A.; Fragkos, P.; Zisarou, E. Modeling Approaches for Residential Energy Consumption: A Literature Review. Climate 2023, 11, 184. [Google Scholar] [CrossRef]

- Yang, J.H.; Lv, L.Y.; Xiong, Z.Z. Thermal Design on Cement-Based Vitrified Microsphere Insulation Mortar Based on 65% Building Energy Efficiency Standard. Adv. Mater. Res. 2011, 347–353, 4081–4088. [Google Scholar] [CrossRef]

- Su, Z.; Guo, L.; Zhang, Z.; Duan, P. Influence of different fibers on properties of thermal insulation composites based on geopolymer blended with glazed hollow bead. Constr. Build. Mater. 2019, 203, 525–540. [Google Scholar] [CrossRef]

- Dai, J.; Li, X.; Zhao, Y.; Li, Y. Influence of Glazed Hollow Bead on the Performance of Polyvinyl Alcohol Fiber Reinforced Cement Composites. Crystals 2022, 12, 454. [Google Scholar] [CrossRef]

- Madhavi, D.T.C.; Raju, L.S.; Mathur, D. Polypropylene Fiber Reinforced Concrete—A Review. Available online: https://5.imimg.com/data5/SELLER/Doc/2021/2/KS/KB/AK/10600364/polypropylene-construction-fibres.pdf (accessed on 28 June 2014).

- Sim, J.; Park, C.; Moon, D.Y. Characteristics of basalt fiber as a strengthening material for concrete structures. Compos. Part B Eng. 2005, 36, 504–512. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, J.; Liu, Y.; Zhang, X.; Zhao, Z. Effect of processing parameters on the printing quality of 3D printed composite cement-based materials. Mater. Lett. 2022, 308, 131271. [Google Scholar] [CrossRef]

- Wei, Y.; Han, S.; Chen, Z.; Lu, J.; Li, Z.; Yu, S.; Cheng, W.; An, M.; Yan, P.J.J.o.B.E. Numerical simulation of 3D concrete printing derived from printer head and printing process. J. Build. Eng. 2024, 88, 109241. [Google Scholar] [CrossRef]

- T/CCPA 33-2022; Chinese National Standard, Test Method for Basic Mechanical Properties of 3D Printed Concrete. Standardization Administration of China: Beijing, China, 2022.

- GB/T 5486-2008; Chinese National Standard, Test Methods for Inorganic Rigid Insulation Products. Standardization Admin-istration of China: Beijing, China, 2008.

| Chemical Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | Heat Loss |

|---|---|---|---|---|---|---|---|

| Content (%) | 24.99 | 8.26 | 4.03 | 51.42 | 3.71 | 2.51 | 3.31 |

| Item | Length (mm) | Diameter (μm) | Density (g/cm3) | Tensile Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|---|

| performances | 6 | 35 | 0.91 | 630 | 6000 |

| Item | Length (mm) | Diameter (μm) | Density (g/cm3) | Tensile Strength (MPa) | Modulus of Elasticity (MPa) |

|---|---|---|---|---|---|

| performances | 6 | 17 | 2.5 | 2300 | 86,000 |

| Cementitious Material (g) | Glass Beads (g) | Gum Powder (g) | Cellulose Ether (g) | W/B | |||

|---|---|---|---|---|---|---|---|

| Cement | Coal Ash | Slaked Lime | |||||

| 1 | 750 | 200 | 50 | 1111.1 | 20 | 5 | 2.7 |

| Cementitious Material (kg) | Glass Beads (kg) | Gum Powder (kg) | Cellulose Ether (kg) | W/B | PP Fiber (%) | BF Fiber (%) | |||

|---|---|---|---|---|---|---|---|---|---|

| Cement | Coal Ash | Slaked Lime | |||||||

| K0 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0 | 0 |

| PP1 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0.3% | 0 |

| PP2 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0.6% | 0 |

| PP3 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0.9% | 0 |

| PP4 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 1.2% | 0 |

| BF1 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0 | 0.3% |

| BF2 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0 | 0.6% |

| BF3 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0 | 0.9% |

| BF4 | 0.75 | 0.2 | 0.05 | 1.1111 | 0.02 | 0.005 | 2.7 | 0 | 1.2% |

| Compression Test (P) | X-Direction Force | Y-Direction Force | Z-Direction Force |

|---|---|---|---|

| Casting | - | - | - |

| Path a | P-X-a | P-Y-a | P-Z-a |

| Path b | P-X-b | P-Y-b | P-Z-b |

| Flexural Test (K) | X-Direction Force | Y-Direction Force | Z-Direction Force |

|---|---|---|---|

| Casting | - | - | - |

| Path a | K-X-a | K-Y-a | K-Z-a |

| Path b | K-X-b | K-Y-b | K-Z-b |

| Thermal Conductivity (D) | X-Direction | Y-Direction | Z-Direction |

|---|---|---|---|

| Casting | - | - | - |

| Path a | D-X-a | D-Y-a | D-Z-a |

| Path b | D-X-b | D-Y-b | D-Z-b |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, J.; Zhang, X.; Liu, Z.; Zhao, J. Study on the Effects of Printing Process and Reinforcement Materials on the Performance of 3D-Printed Glass Bead Insulation Mortar. Materials 2024, 17, 3220. https://doi.org/10.3390/ma17133220

Wang J, Zhang X, Liu Z, Zhao J. Study on the Effects of Printing Process and Reinforcement Materials on the Performance of 3D-Printed Glass Bead Insulation Mortar. Materials. 2024; 17(13):3220. https://doi.org/10.3390/ma17133220

Chicago/Turabian StyleWang, Jun, Xuanzheng Zhang, Zhenhua Liu, and Jiasheng Zhao. 2024. "Study on the Effects of Printing Process and Reinforcement Materials on the Performance of 3D-Printed Glass Bead Insulation Mortar" Materials 17, no. 13: 3220. https://doi.org/10.3390/ma17133220