Numerical Investigation on Thermal Conductivity of Graphene Foam Composite for Thermal Management Applications

Abstract

1. Introduction

2. Methodology

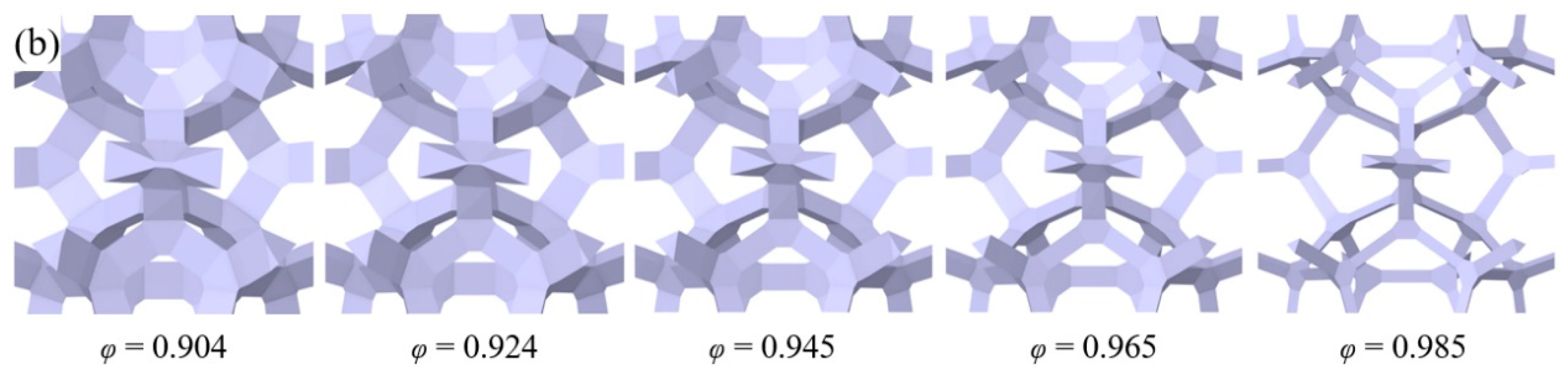

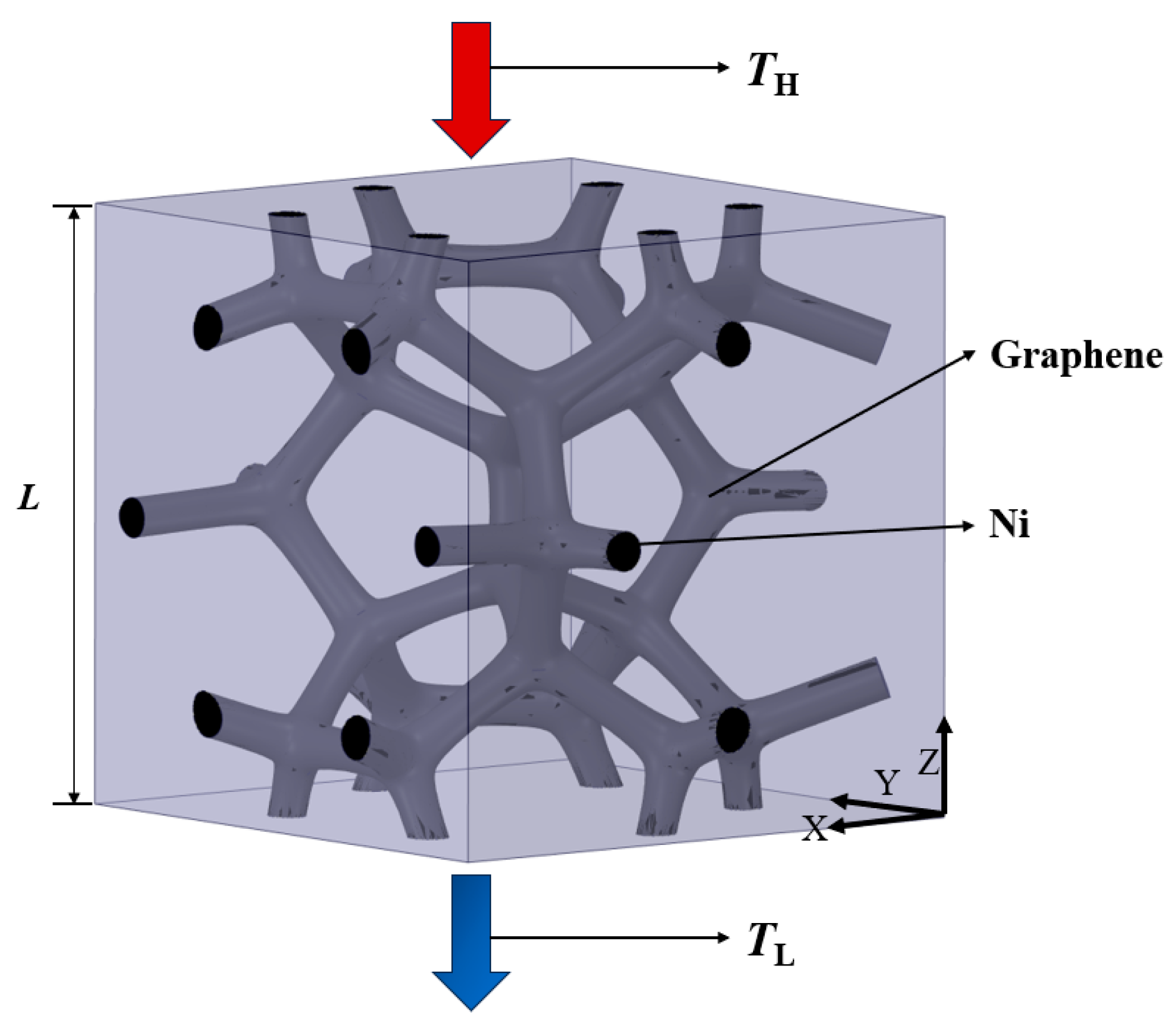

2.1. Design of Physical Structure

2.2. Heat Transfer of GF Composite

2.3. Boundary Conditions and Governing Equations

- (1)

- Because the CVD-based GF is mostly used as a thermal interface material, the heat transfer along the direction of thickness is much more important. As the thickness of the GF composite is much smaller, the heat flow of the GF composite is set as a one-dimensional transfer in the Z-axial direction;

- (2)

- The thermal conduction of the solid skeleton is isotropic;

- (3)

- The thermal conductivity of solids is constant.

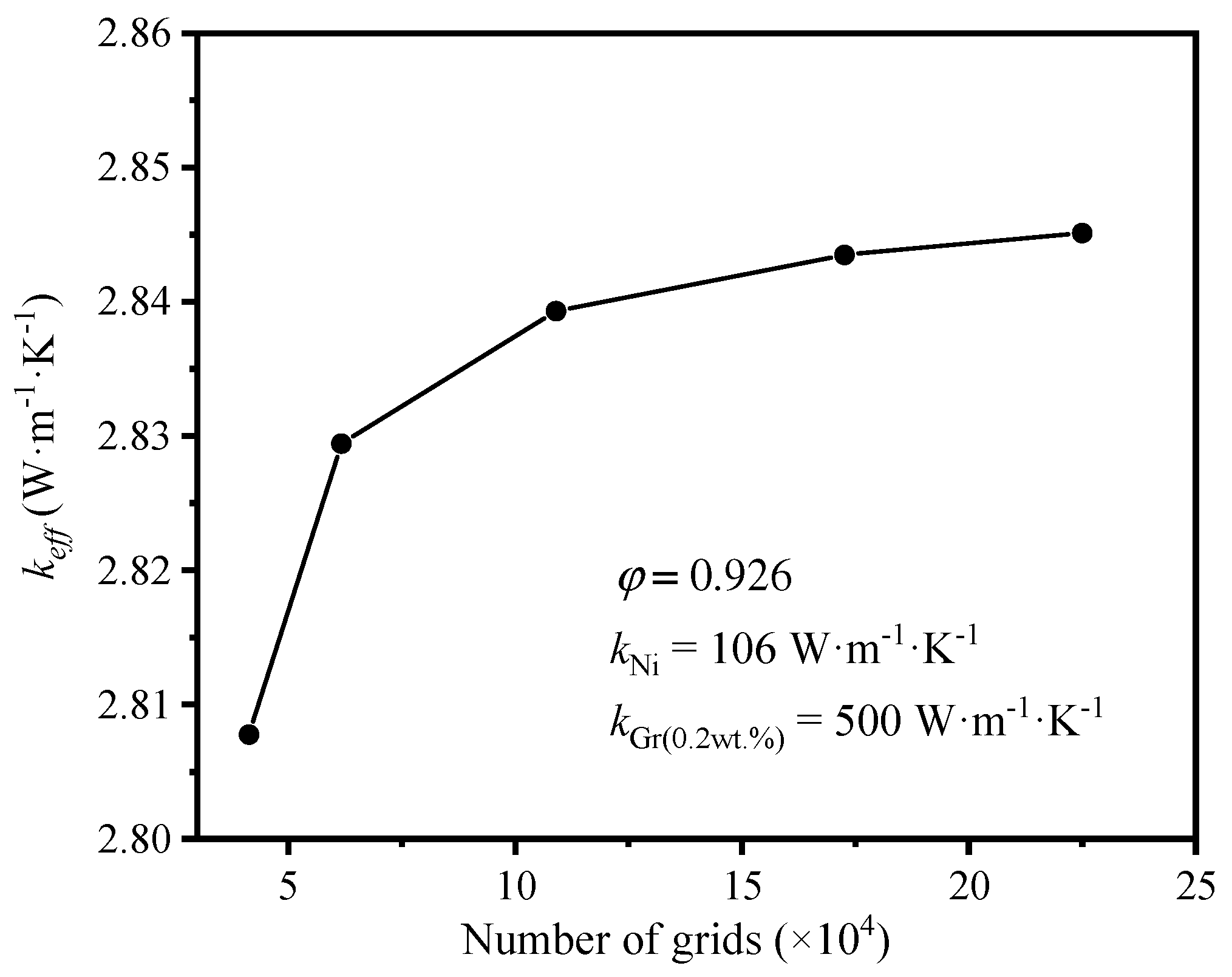

2.4. Verification of Grid Independence

2.5. Numerical Method Validation

3. Results and Discussion

3.1. The Thermal Properties and the Influencing Factors at Room Temperature

3.1.1. The Impact of the Growth Template on Thermal Properties

3.1.2. The Impact of the Growth Template on Thermal Properties

3.2. The Thermal Properties and the Influence Factors at a High Temperature

3.2.1. The Impact of Mean Temperature on Thermal Properties

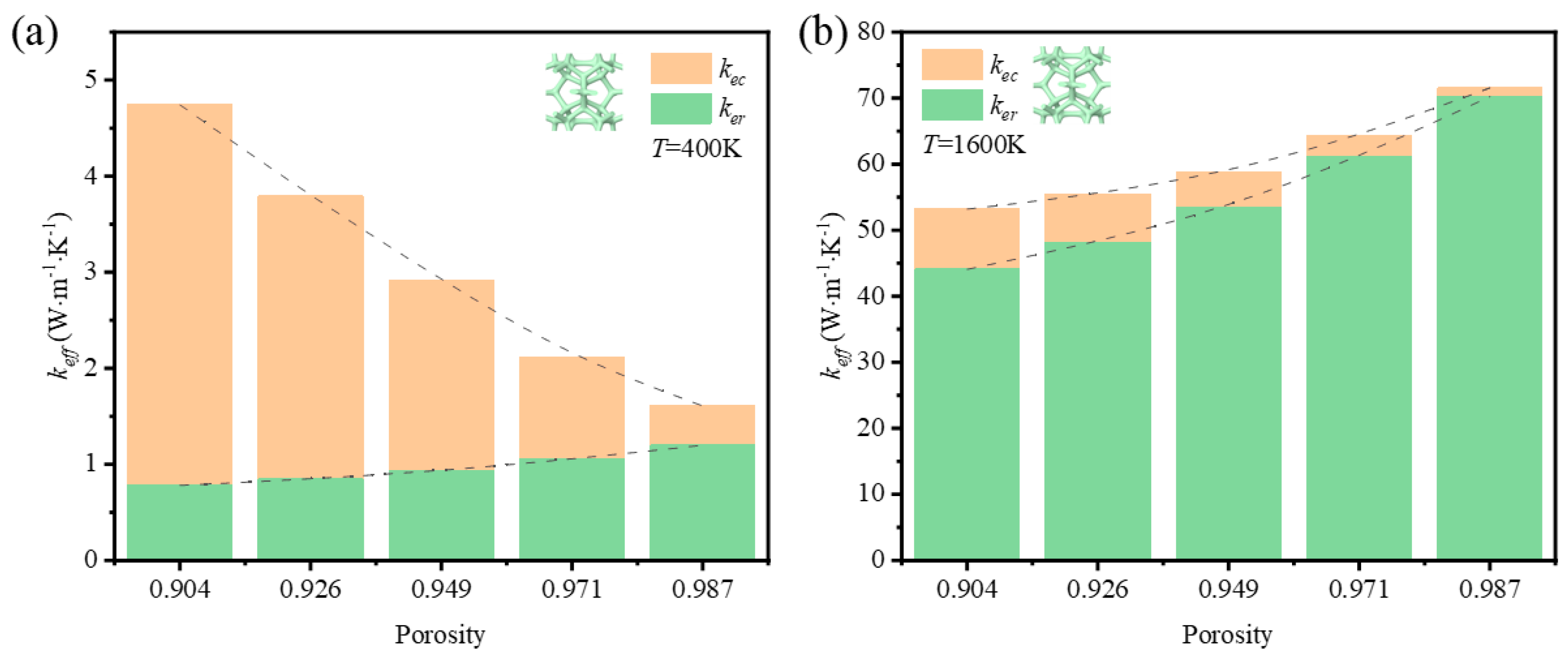

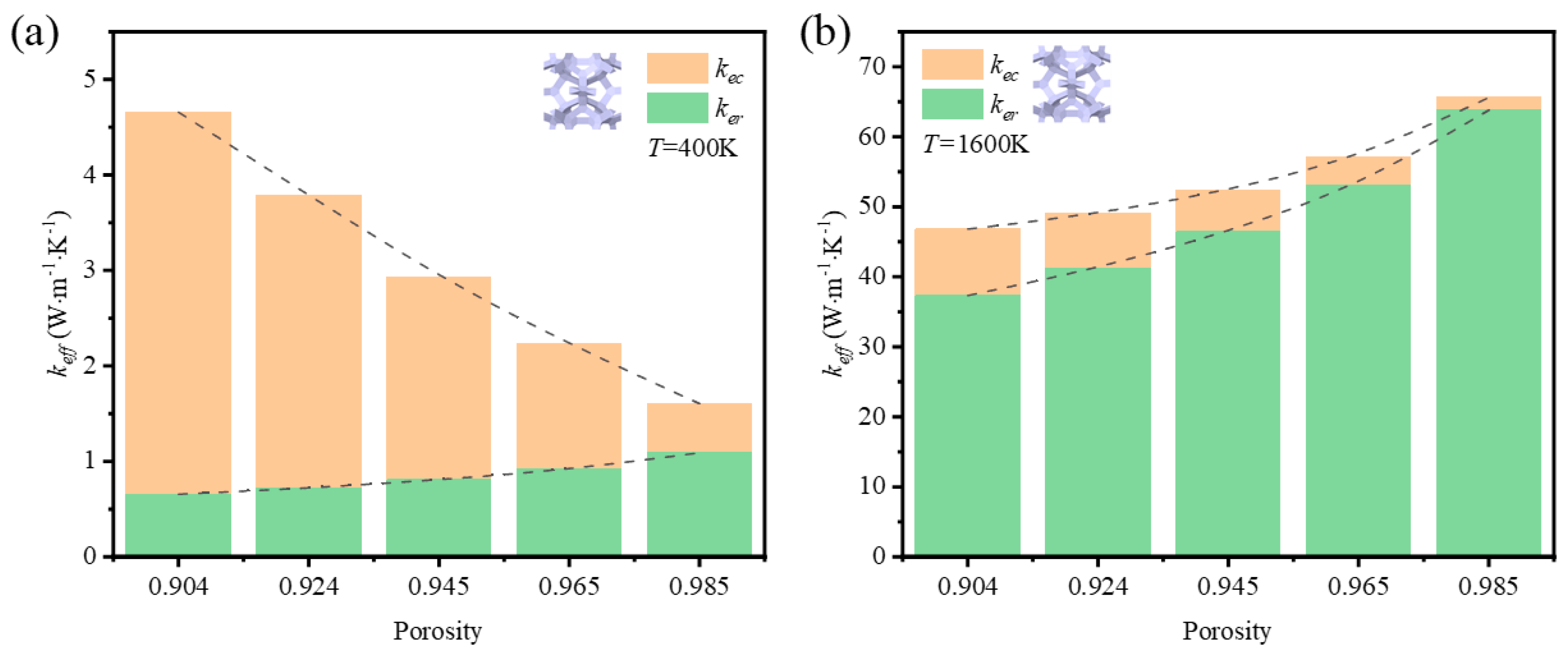

3.2.2. The Impact of Porosity on Thermal Properties

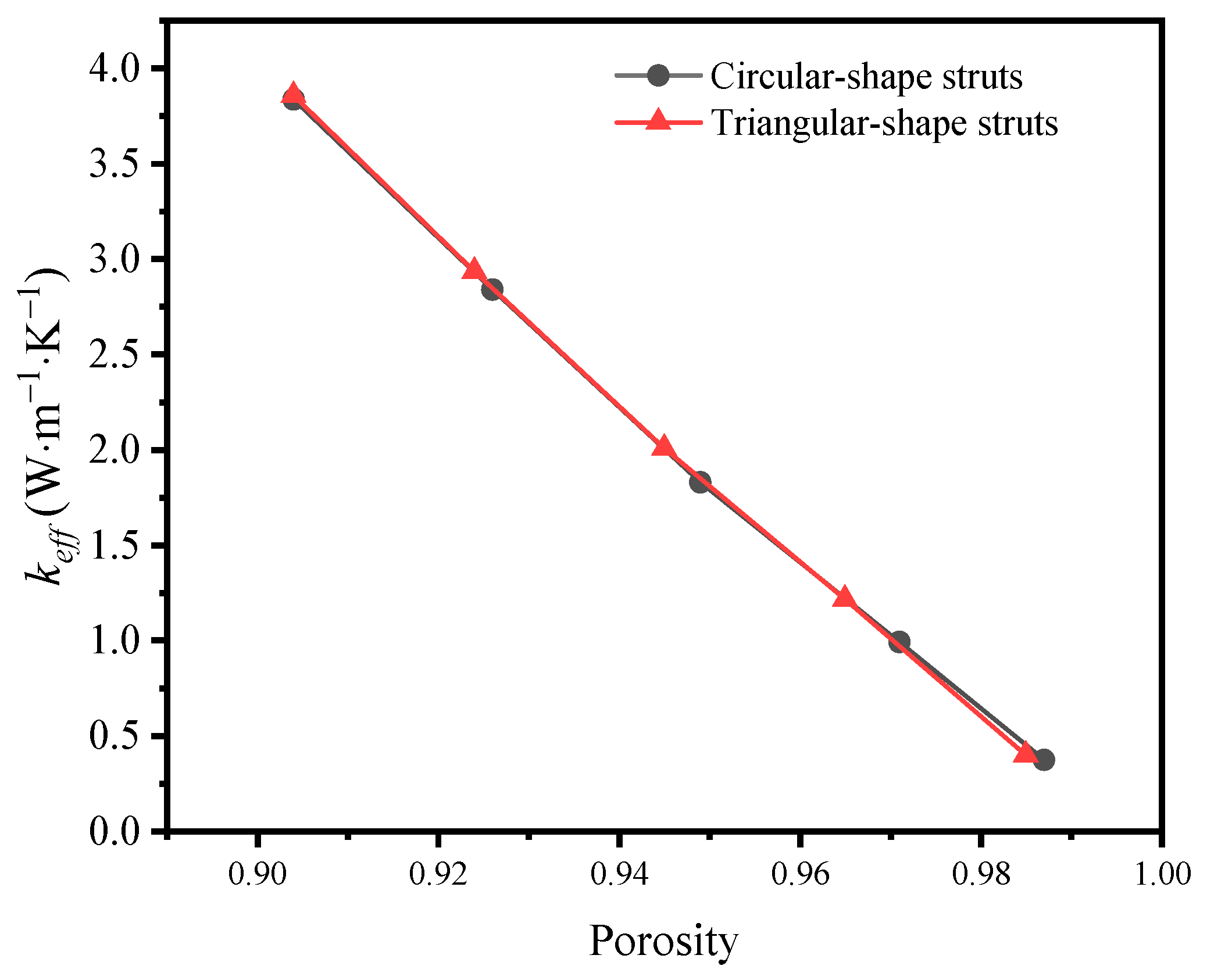

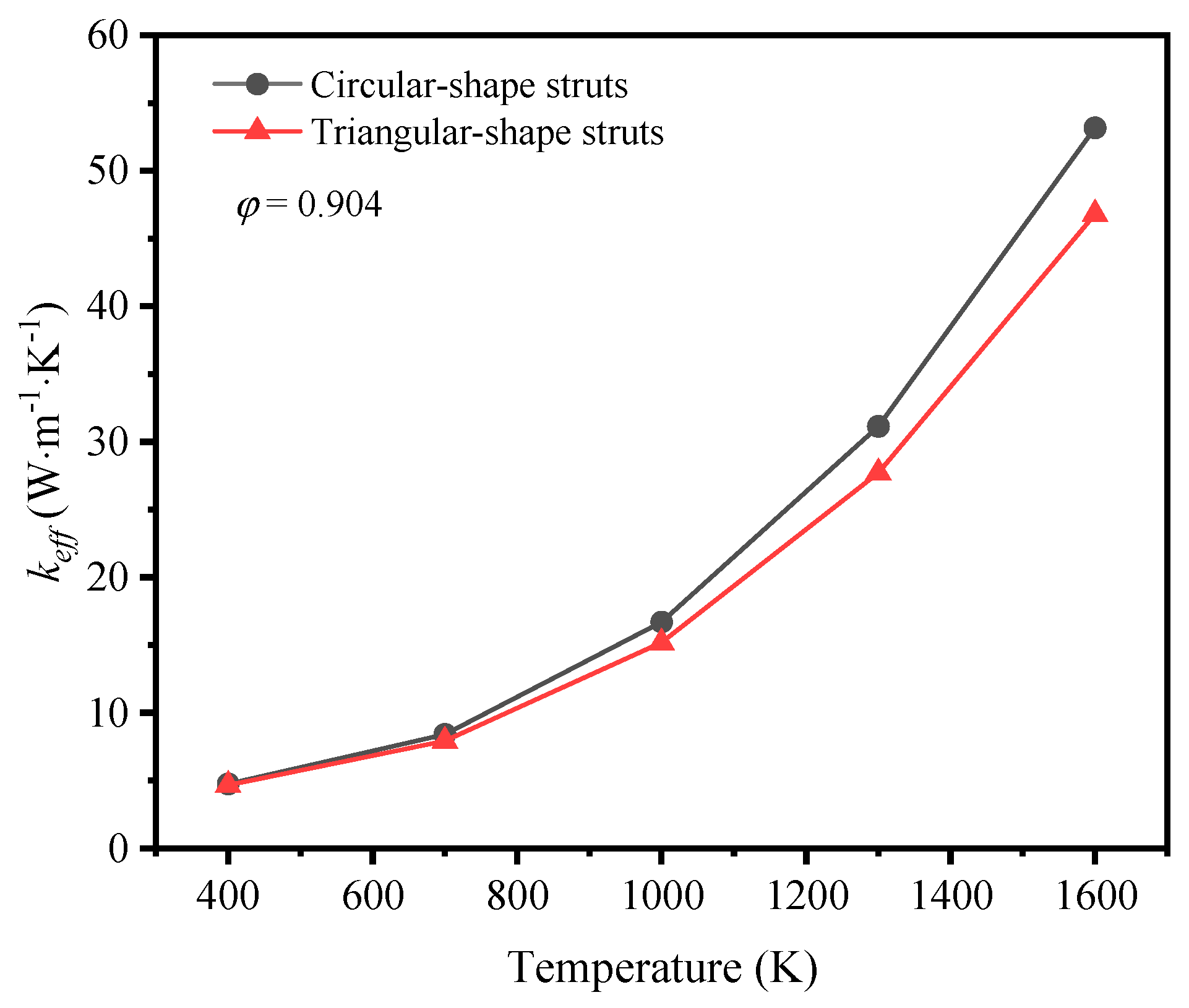

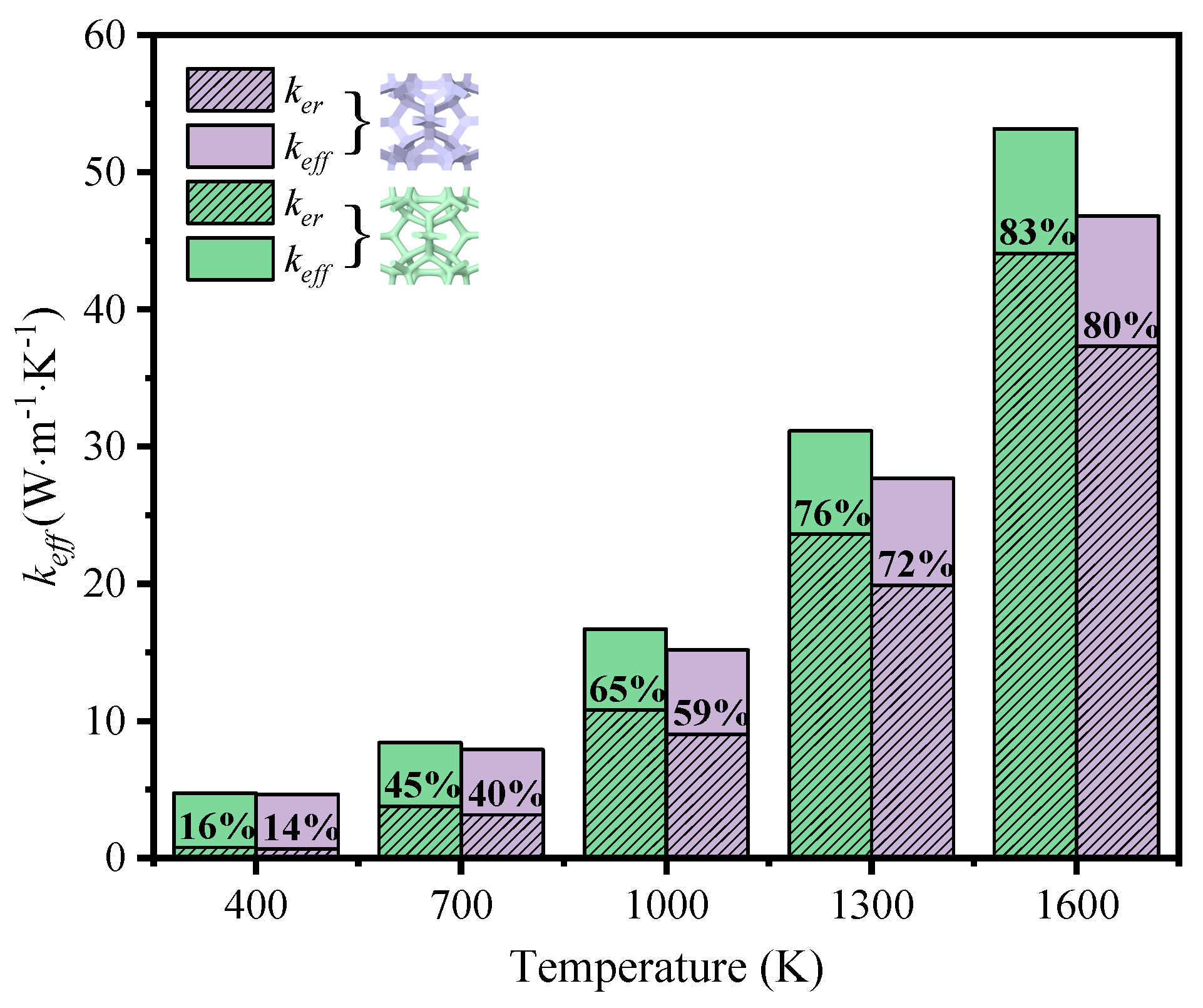

3.3. The Impact of Cross-Section Shape of Struts on Thermal Properties

3.4. The Impact of Cross-Section Shape of Struts on Thermal Properties

3.5. The Impact of Temperature Difference on Thermal Properties

3.6. Curve Fitting

4. Conclusions

- (1)

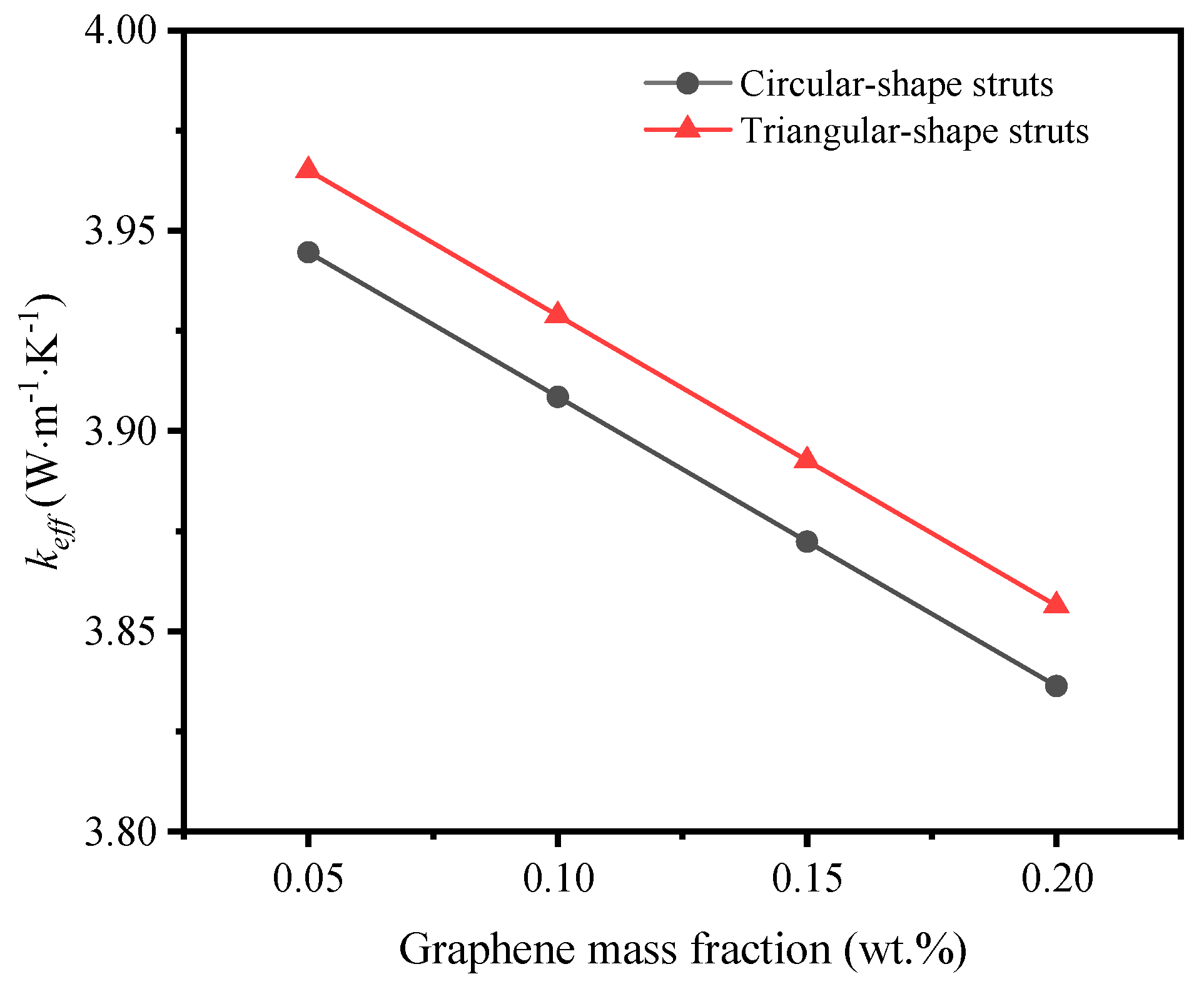

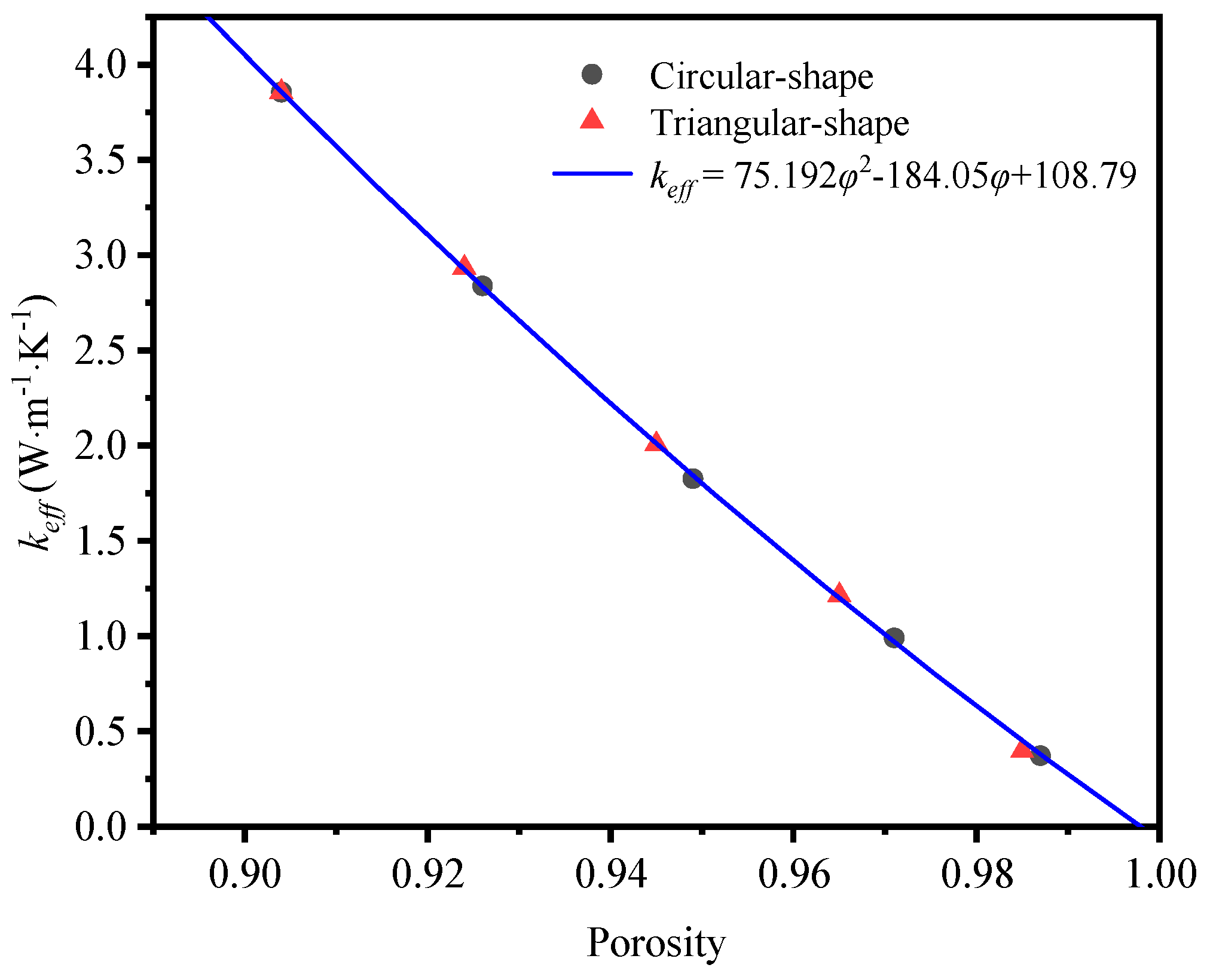

- The effective thermal conductivity of GF composite can be enhanced with the decrease of porosity, which can be attributed to the higher solid volume fraction at lower porosity. In addition, the effective thermal conductivity of GF composite is decreased with the increase of deposition time. When the volume fraction of graphene increased from 0.05% to 0.2%, the effective thermal conductivity of the GF composite decreased from 3.96 W·m−1·K−1 to 3.86 W·m−1·K−1.

- (2)

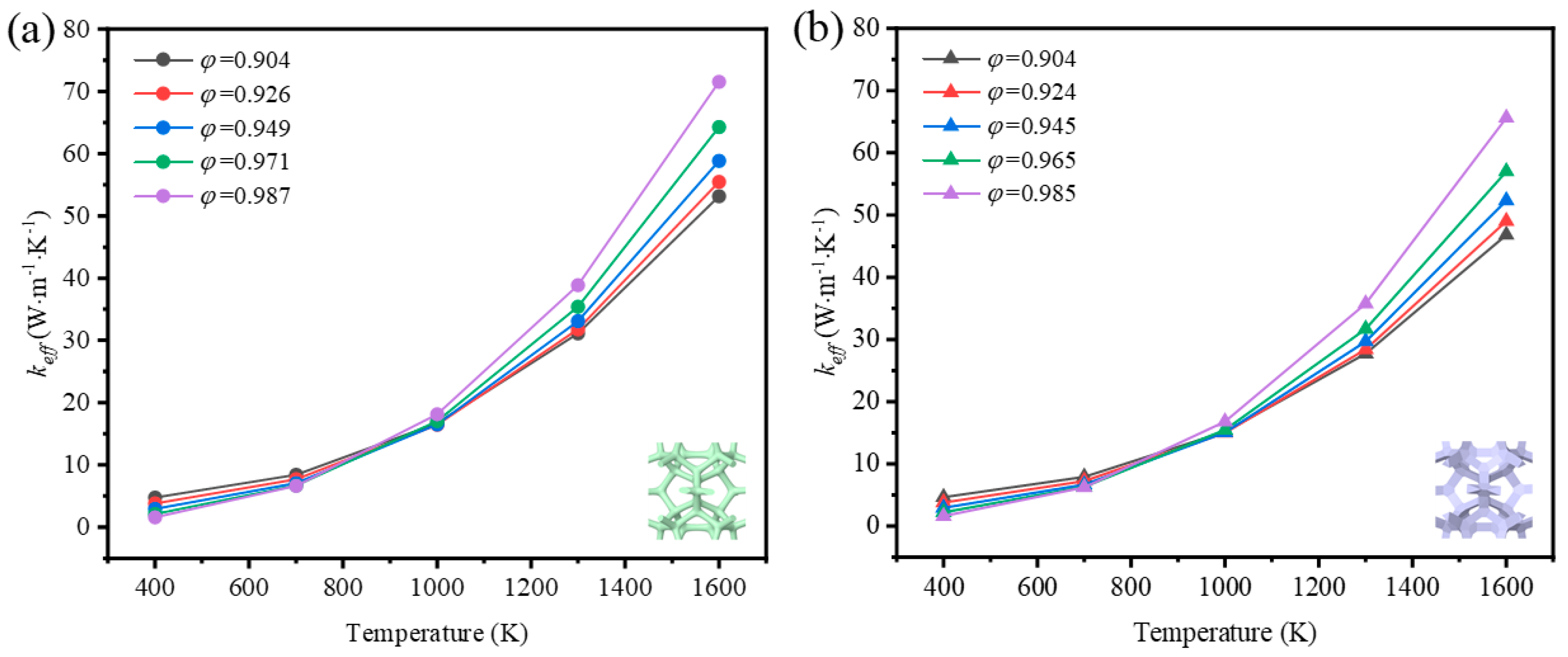

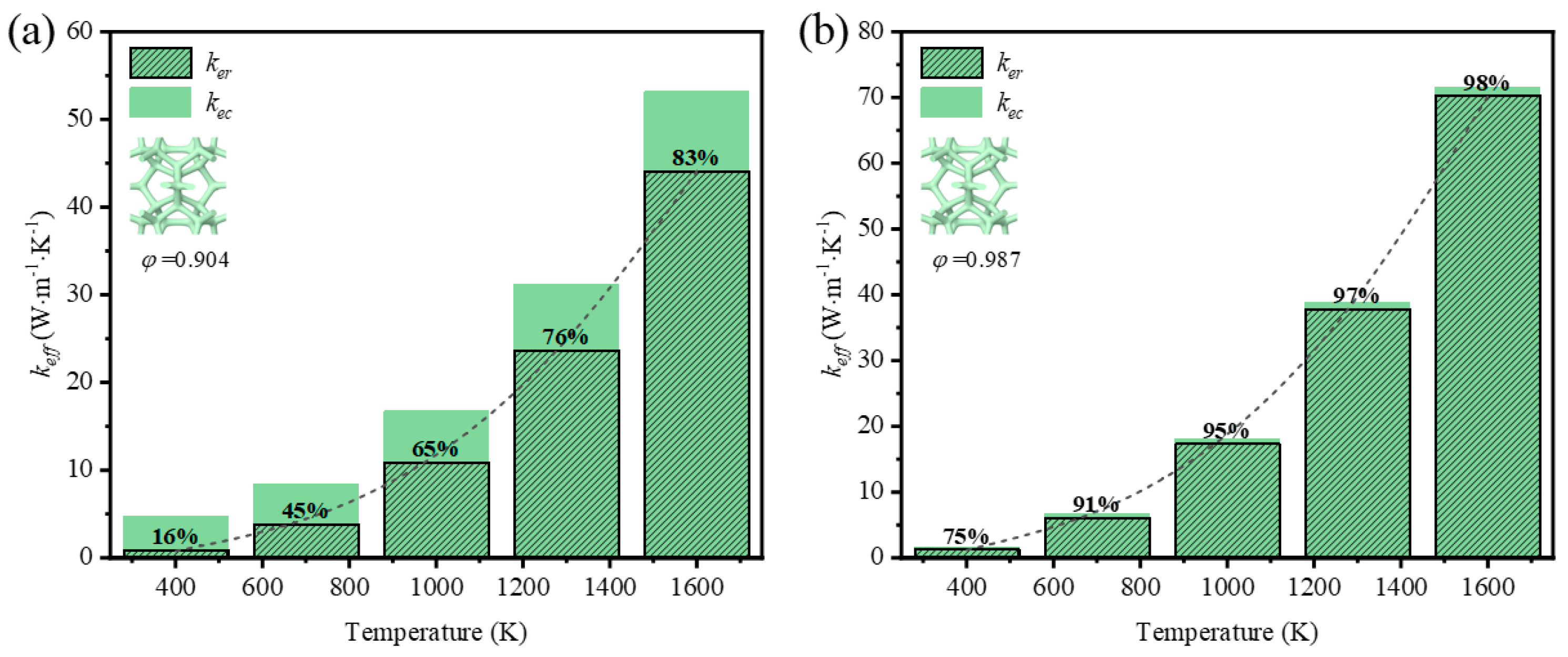

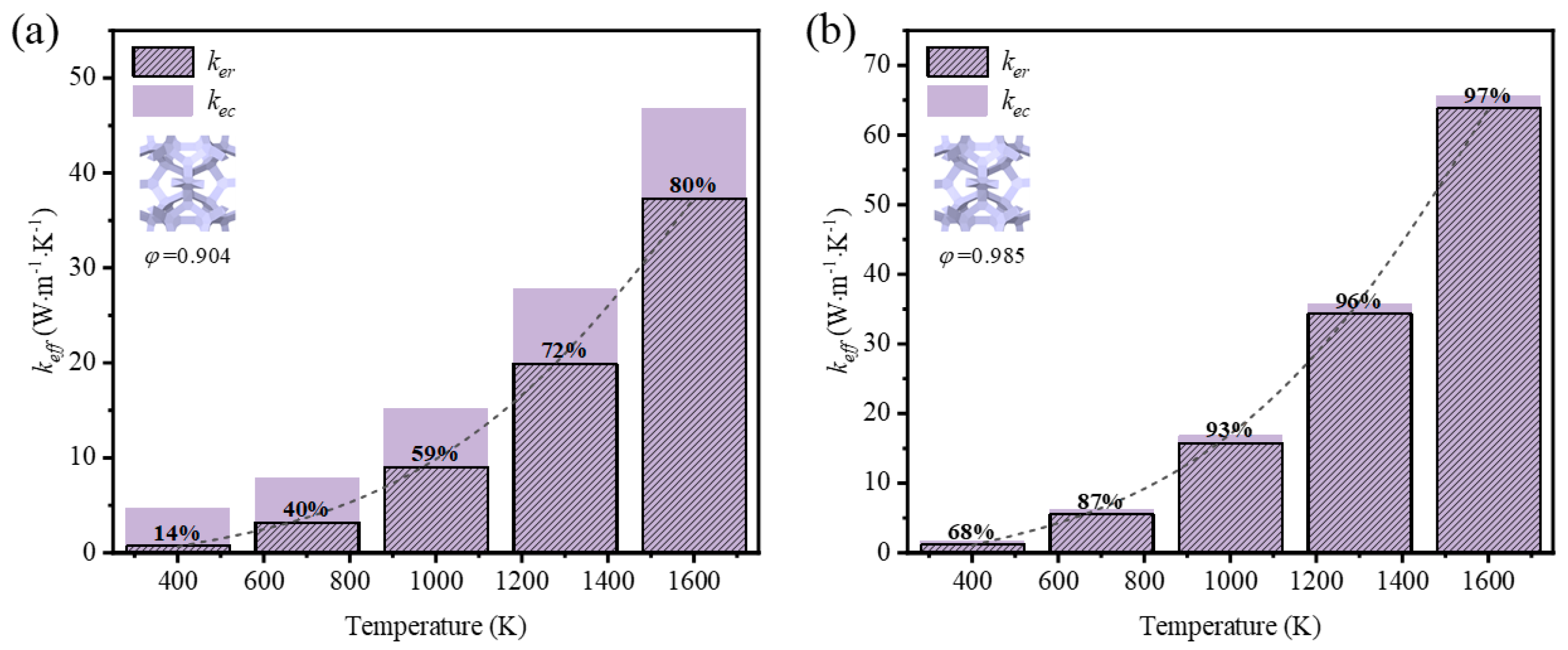

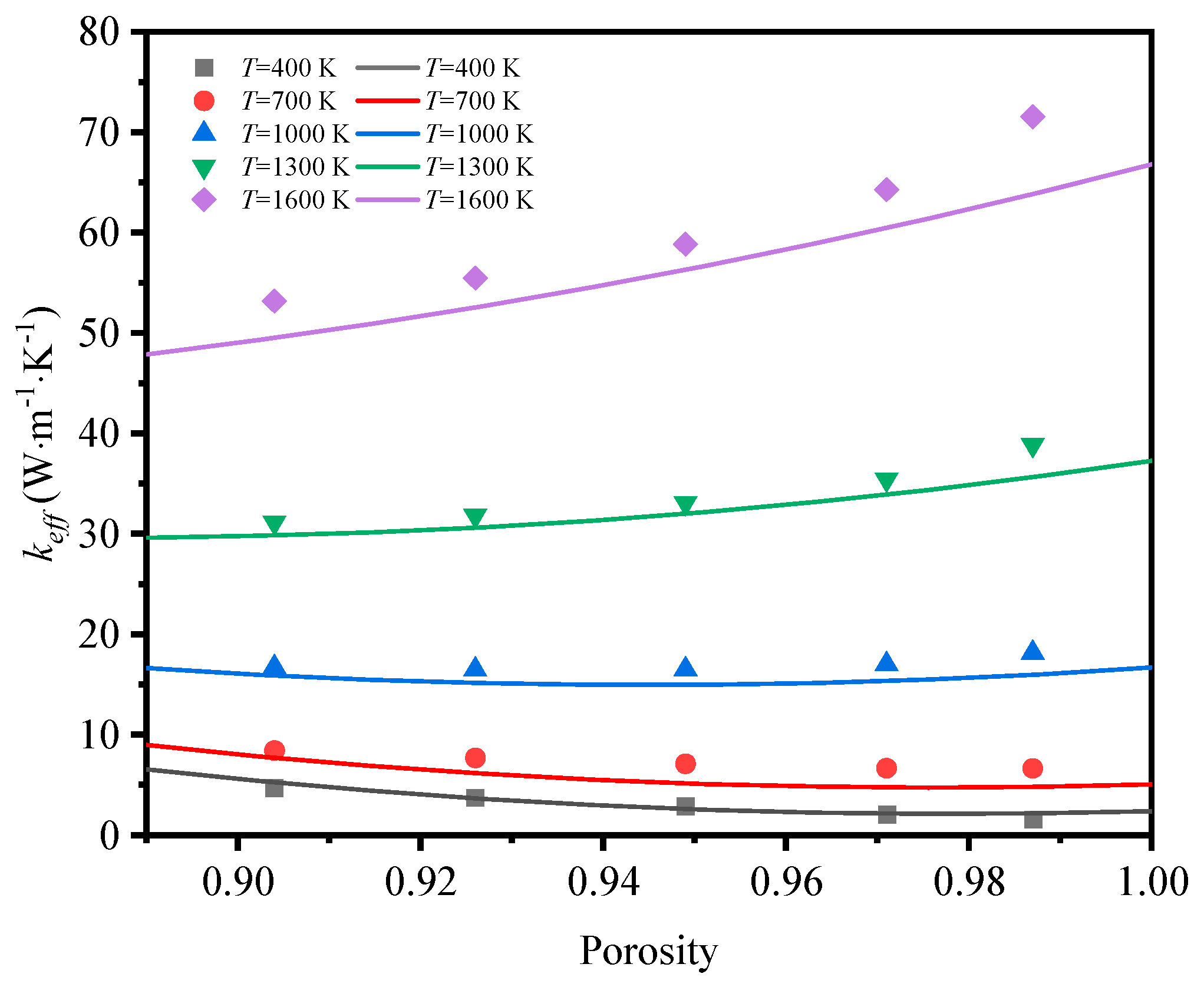

- Under the condition of temperature higher than 400 K, the thermal radiation effect cannot be neglected. At a given porosity of 0.904, when the average temperature increases from 400 K to 1600 K, the effective thermal conductivity of GF composite with circular sections and triangle sections increased by 1021.94% and 906.45%, respectively. In addition, GF composite with higher porosity was more easily affected by temperature compared to that with lower porosity. For GF composite with circular cross-sections at 1600 K, the contribution of thermal radiation to effective thermal conductivity increased from 83% to 98% when the porosity increased from 0.904 to 0.987.

- (3)

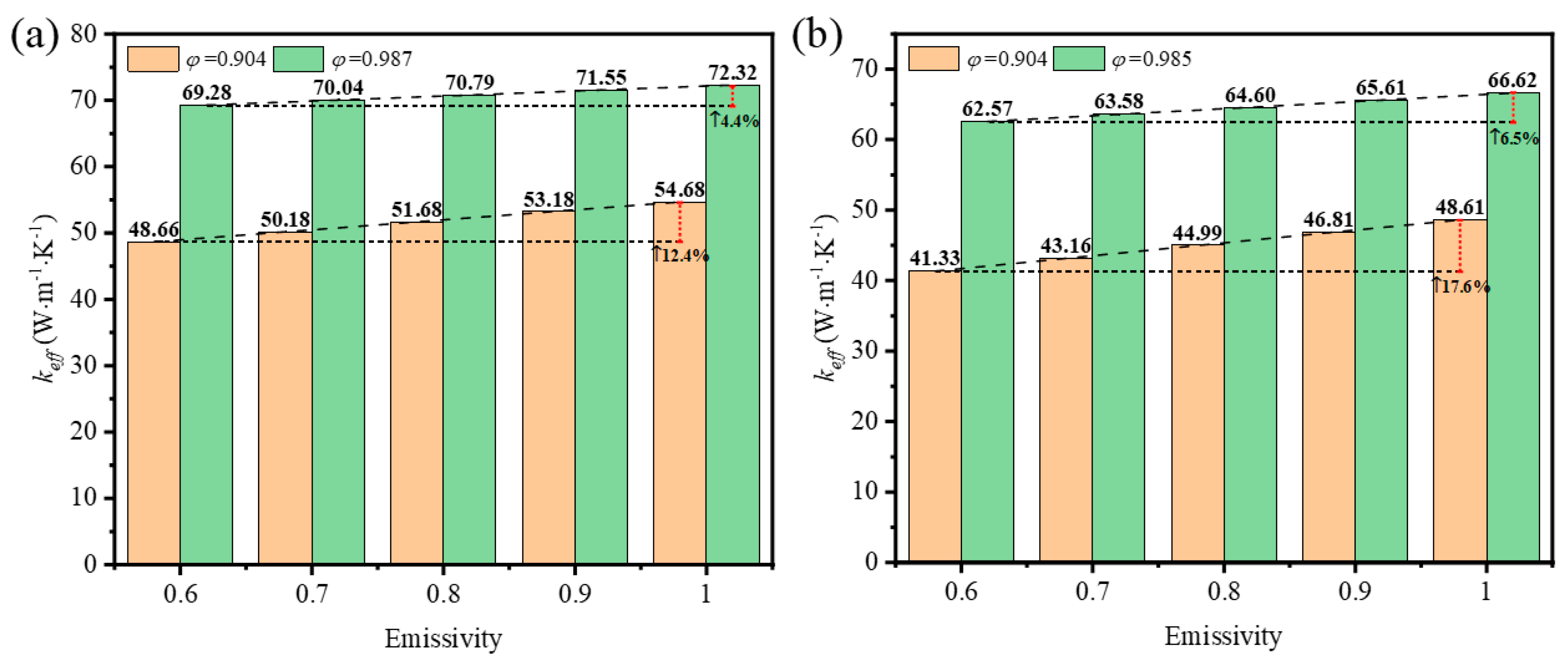

- The thermal properties of GF composite with lower porosity and larger pore surface area are more sensitive to changes of surface emissivity. When the surface emissivity of GF composite increased from 0.6 to 1, the effective thermal conductivity of GF composite with circular cross-section struts increased by 12.4% and 4.4% at porosity values of 0.904 and 0.987, respectively. The effective thermal conductivity of GF composite with triangular cross-section struts increased by 17.6% and 6.5% at porosity values of 0.904 and 0.985, respectively.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bagatella, S.; Cereti, A.; Manarini, F.; Cavallaro, M.; Suriano, R.; Levi, M. Thermally Conductive and Electrically Insulating Polymer-Based Composites Heat Sinks Fabricated by Fusion Deposition Modeling. Polymers 2024, 16, 432. [Google Scholar] [CrossRef] [PubMed]

- Alghamdi, A.A. Computational Optimization of Sandwich Silicone Rubber Composite for Improved Thermal Conductivity and Electrical Insulation. Polymers 2024, 16, 616. [Google Scholar] [CrossRef] [PubMed]

- Torres-Alba, A.; Mercado-Colmenero, J.M.; Caballero-Garcia, J.D.D.; Martin-Doñate, C. A hybrid cooling model based on the use of newly designed fluted conformal cooling channels and fastcool inserts for green molds. Polymers 2021, 13, 3115. [Google Scholar] [CrossRef] [PubMed]

- Tian, J.; Wang, C.; Wang, K.; Xue, R.; Liu, X.; Yang, Q. Flexible Polyolefin Elastomer/Paraffin Wax/Alumina/Graphene Nanoplatelets Phase Change Materials with Enhanced Thermal Conductivity and Mechanical Performance for Solar Conversion and Thermal Energy Storage Applications. Polymers 2024, 16, 362. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Qiu, L.; Liu, J.; Feng, Y. Enhancing thermal transport across diamond/graphene heterostructure interface. Int. J. Heat Mass Transf. 2023, 209, 124123. [Google Scholar] [CrossRef]

- Ho, K.S.; Paek, H.K.; Im, S.J.; Kim, J.W.; Kim, S.C.; Kim, U.S.; Kim, K.D.; Song, K.S. Robust and high-performance plasmonic refractive index sensor based on graphene waveguide ring resonator. Phys. Rev. B Condens. 2023, 663, 414980. [Google Scholar] [CrossRef]

- Lee, M.S.; Choi, H.J.; Baek, J.B.; Chang, D.W. Simple solution-based synthesis of pyridinic-rich nitrogen-doped graphene nanoplatelets for supercapacitors. Appl. Energy 2017, 195, 1071–1078. [Google Scholar] [CrossRef]

- Banda, H.; Rupam, T.H.; Rezk, A.; Visak, Z.; Hammerton, J.; Yuan, Q.; Saha, B.B. Preparation and assessment of ionic liquid and few-layered graphene composites to enhance heat and mass transfer in adsorption cooling and desalination systems. Int. J. Heat Mass Transf. 2024, 221, 125095. [Google Scholar] [CrossRef]

- Yan, Q.; Chen, B.; Ye, W.; Zhang, T.; Wan, J.; Zhou, Q.; Shen, J.; Li, J.; Lu, W.F.; Wang, H. Simultaneously improving mechanical, thermal, and anti-wear properties of Ti alloys using 3D-networked graphene as reinforcement. Carbon 2023, 213, 118152. [Google Scholar] [CrossRef]

- Rajeswari, K.; Suganthi, K.S.; Thiruvenkatam, S.; Devaraj, S.; Rajan, K.S. Graphene oxide–adipic acid nanocomposites for thermal energy storage: Assessment of thermophysical properties and energy storage performance. J. Energy Storage 2024, 77, 109949. [Google Scholar]

- Chen, H.; He, H.; Wang, B.; Han, L.; Ma, J.; Sui, D.; Wang, C.; Hua, Y. Investigating the physical-chemical effects of reduced graphene oxide-covered manganese oxide on ammonium-ion batteries. Appl. Energy 2024, 353, 122067. [Google Scholar] [CrossRef]

- Kumar, S.; Goswami, M.; Singh, N.; Deshpande, U.; Kumar, S.; Sathish, N. Flexible and lightweight graphene grown by rapid thermal processing chemical vapor deposition for thermal management in consumer electronics. New Carbon Mater. 2023, 38, 534–540. [Google Scholar] [CrossRef]

- Huang, P.; Feng, R.; Tang, Z.; He, Y.; Peng, D.; Li, E.; Wei, M.; He, Z.; Bai, Z. Exploring the use of 3D graphene sponge composited phase change material for improved thermal performance in battery thermal management systems. Appl. Therm. Eng. 2023, 235, 121389. [Google Scholar] [CrossRef]

- Romo-Rico, J.; Bright, R.; Krishna, S.M.; Vasilev, K.; Golledge, J.; Jacob, M.V. Antimicrobial graphene-based coatings for biomedical implant applications. Carbon Trends 2023, 12, 100282. [Google Scholar] [CrossRef]

- Fu, Q.; Feng, S.; Xiao, Z.; Gong, K.; Pang, X.; Yang, Y.; Zhou, C.; Liu, H.; Wang, J.; Zhou, J. An integrated sample-to-answer graphene microchip for ultrafast detection of multiple microorganisms. Sens. Actuat B-Chem. 2024, 409, 135584. [Google Scholar] [CrossRef]

- Baig, Z.; Mamat, O.; Mustapha, M. Recent progress on the dispersion and the strengthening effect of carbon nanotubes and graphene-reinforced metal nanocomposites: A review. Crit. Rev. Solid State 2018, 43, 1–46. [Google Scholar] [CrossRef]

- Chen, K.; Shi, L.; Zhang, Y.; Liu, Z. Scalable chemical-vapour-deposition growth of three-dimensional graphene materials towards energy-related applications. Chem. Soc. Rev. 2018, 47, 3018–3036. [Google Scholar] [CrossRef]

- Banciu, C.A.; Nastase, F.; Istrate, A.I.; Veca, L.M. 3D graphene foam by chemical vapor deposition: Synthesis, properties, and energy-related applications. Molecules 2022, 27, 3634. [Google Scholar] [CrossRef]

- Yu, Z.; Feng, Y.; Feng, D.; Zhang, X. Thermal properties of three-dimensional hierarchical porous graphene foam-carbon nanotube hybrid structure composites with phase change materials. Micropor. Mesopor. Mat. 2021, 312, 110781. [Google Scholar] [CrossRef]

- Zhao, Y.H.; Wu, Z.K.; Bai, S.L. Thermal resistance measurement of 3D graphene foam/polymer composite by laser flash analysis. Int. J. Heat Mass Transf. 2016, 101, 470–475. [Google Scholar] [CrossRef]

- Yuan, Y.; Liu, L.; Yang, M.; Zhang, T.; Xu, F.; Lin, Z.; Ding, Y.; Wang, C.; Li, J.; Yin, W. Lightweight, thermally insulating and stiff carbon honeycomb-induced graphene composite foams with a horizontal laminated structure for electromagnetic interference shielding. Carbon 2017, 123, 223–232. [Google Scholar] [CrossRef]

- Cheng, G.; Wang, X.; He, Y. 3D graphene paraffin composites based on sponge skeleton for photo thermal conversion and energy storage. Appl. Therm. Eng. 2020, 178, 115560. [Google Scholar] [CrossRef]

- Zhang, X.; Yeung, K.K.; Gao, Z.; Li, J.; Sun, H.; Xu, H.; Zhang, K.; Zhang, M.; Chen, Z.; Yuen, M.M.; et al. Exceptional thermal interface properties of a three-dimensional graphene foam. Carbon 2014, 66, 201–209. [Google Scholar] [CrossRef]

- Lin, H.; Xu, S.; Wang, X.; Mei, N. Significantly reduced thermal diffusivity of free-standing two-layer graphene in graphene foam. Nat. Nanotechnol. 2013, 24, 415706. [Google Scholar] [CrossRef] [PubMed]

- Zhou, M.; Lin, T.; Huang, F.; Zhong, Y.; Wang, Z.; Tang, Y.; Bi, H.; Wan, D.; Lin, J. Highly conductive porous graphene/ceramic composites for heat transfer and thermal energy storage. Adv. Funct. 2013, 23, 2263–2269. [Google Scholar] [CrossRef]

- Zhou, M.; Bi, H.; Lin, T.; Lü, X.; Huang, F.; Lin, J. Directional architecture of graphene/ceramic composites with improved thermal conduction for thermal applications. J. Mater. Chem. A 2014, 2, 2187–2193. [Google Scholar] [CrossRef]

- Chen, Z.; Ren, W.; Gao, L.; Liu, B.; Pei, S.; Cheng, H.M. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition. Nat. Mater. 2011, 10, 424–428. [Google Scholar] [CrossRef]

- Pettes, M.T.; Ji, H.; Ruoff, R.S.; Shi, L. Thermal transport in three-dimensional foam architectures of few-layer graphene and ultrathin graphite. Nano Lett. 2012, 12, 2959–2964. [Google Scholar] [CrossRef] [PubMed]

- Qi, G.; Yang, J.; Bao, R.; Xia, D.; Cao, M.; Yang, W.; Yang, M.; Wei, D. Hierarchical graphene foam-based phase change materials with enhanced thermal conductivity and shape stability for efficient solar-to-thermal energy conversion and storage. Nano Res. 2017, 10, 802–813. [Google Scholar] [CrossRef]

- Gao, J.; Xie, D.; Wang, X.; Zhang, X.; Yue, Y. High thermal conductivity of free-standing skeleton in graphene foam. Appl. Phys. Lett. 2020, 117, 251901. [Google Scholar] [CrossRef]

- Li, M.; Sun, Y.; Xiao, H.; Hu, X.; Yue, Y. High temperature dependence of thermal transport in graphene foam. Nat. Nanotechnol. 2015, 26, 105703. [Google Scholar] [CrossRef] [PubMed]

- Khosravani, S.; Sadr, M.H.; Carrera, E.; Pagani, A.; Masia, R. Multi-scale analysis of thermal conductivity of graphene foam/PDMS composites. Mech. Adv. Mater. Struc. 2023, 1–13. [Google Scholar] [CrossRef]

- Chen, X.K.; Hu, X.Y.; Jia, P.; Xie, Z.X.; Liu, J. Tunable anisotropic thermal transport in porous carbon foams: The role of phonon coupling. Int. J. Mech. Sci. 2021, 206, 106576. [Google Scholar] [CrossRef]

- Xiong, Z.; Marconnet, A.; Ruan, X. Unconventional and Dynamically Anisotropic Thermal Conductivity in Compressed Flexible Graphene Foams. ACS Appl. Mater. 2022, 14, 48960–48966. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.F.; Zhao, Y.H.; Bai, S.L.; Yuan, X. Numerical simulation of thermal conductivity of graphene filled polymer composites. Compos. Part B-Eng. 2016, 106, 324–331. [Google Scholar] [CrossRef]

- Xia, D.; Yi, K.; Zheng, B.; Li, M.; Qi, G.; Cai, Z.; Cao, M.; Liu, D.; Peng, L.; Wei, D. Solvent-free process to produce three dimensional graphene network with high electrochemical stability. J. Phys. Chem. C. 2017, 121, 3062–3069. [Google Scholar] [CrossRef]

- Ma, W.; Miao, T.; Zhang, X.; Kohno, M.; Takata, Y. Comprehensive study of thermal transport and coherent acoustic-phonon wave propagation in thin metal film–substrate by applying picosecond laser pump–probe method. J. Phys. Chem. C. 2015, 119, 5152–5159. [Google Scholar] [CrossRef]

- Zhao, C.Y.; Lu, T.J.; Hodson, H.P.; Jackson, J.D. The temperature dependence of effective thermal conductivity of open-celled steel alloy foams. Mat. Sci. Eng. A-Struct. 2004, 367, 123–131. [Google Scholar] [CrossRef]

- Liu, Y.; Lu, J.; Cui, Y. Improved thermal conductivity of epoxy resin by graphene–nickel three-dimensional filler. Carbon Resour. Convers. 2020, 3, 29–35. [Google Scholar] [CrossRef]

- Chan, K.C.; Tso, C.Y.; Hussain, A.; Chao, C.Y. A theoretical model for the effective thermal conductivity of graphene coated metal foams. Appl. Therm. Eng. 2023, 161, 114112. [Google Scholar] [CrossRef]

- AL-Saleem, N.K.; Ghrib, T.; Aishah, A.N.; Elshekhipy, A.A.; Almalki, N.; Gmati, N.; Turki, N.K. Effect of porosity on structural, optical, thermal, and electrical properties of nickel-foam coated graphene sheets. J. Mater. Res. Technol. 2022, 19, 300–313. [Google Scholar] [CrossRef]

- Shahrzadi, M.; Emami, M.D.; Akbarzadeh, A.H. Heat transfer in BCC lattice materials: Conduction, convection, and radiation. Compos. Struct. 2022, 284, 115159. [Google Scholar] [CrossRef]

- Wang, M.; Pan, N. Modeling and prediction of the effective thermal conductivity of random open-cell porous foams. Int. J. Heat Mass Transf. 2008, 51, 1325–1331. [Google Scholar] [CrossRef]

- Kovács, R.; Rogolino, P. Numerical treatment of nonlinear Fourier and Maxwell-Cattaneo-Vernotte heat transport equations. Int. J. Heat Mass Transf. 2020, 150, 119281. [Google Scholar] [CrossRef]

| Material | Thermal Conductivity (W·m−1·K−1) | Specific Heat (J·kg−1·K−1) | Density (kg·m−3) |

|---|---|---|---|

| Air | 0.026 | 1006.43 | 1.225 |

| Graphene | 500 | 709 | 2250 |

| Nickel | 106 | 460.6 | 8900 |

| Epoxy resin | 0.2617 | 1110 | 1450 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, R.; Lv, Y.; Du, T.; Bi, J. Numerical Investigation on Thermal Conductivity of Graphene Foam Composite for Thermal Management Applications. Materials 2024, 17, 3300. https://doi.org/10.3390/ma17133300

Zhou R, Lv Y, Du T, Bi J. Numerical Investigation on Thermal Conductivity of Graphene Foam Composite for Thermal Management Applications. Materials. 2024; 17(13):3300. https://doi.org/10.3390/ma17133300

Chicago/Turabian StyleZhou, Rongyao, Yuexia Lv, Tingting Du, and Jinpeng Bi. 2024. "Numerical Investigation on Thermal Conductivity of Graphene Foam Composite for Thermal Management Applications" Materials 17, no. 13: 3300. https://doi.org/10.3390/ma17133300

APA StyleZhou, R., Lv, Y., Du, T., & Bi, J. (2024). Numerical Investigation on Thermal Conductivity of Graphene Foam Composite for Thermal Management Applications. Materials, 17(13), 3300. https://doi.org/10.3390/ma17133300