Modeling and Strength Calculations of Parts Made Using 3D Printing Technology and Mounted in a Custom-Made Lower Limb Exoskeleton

Abstract

1. Introduction

2. Materials and Methods

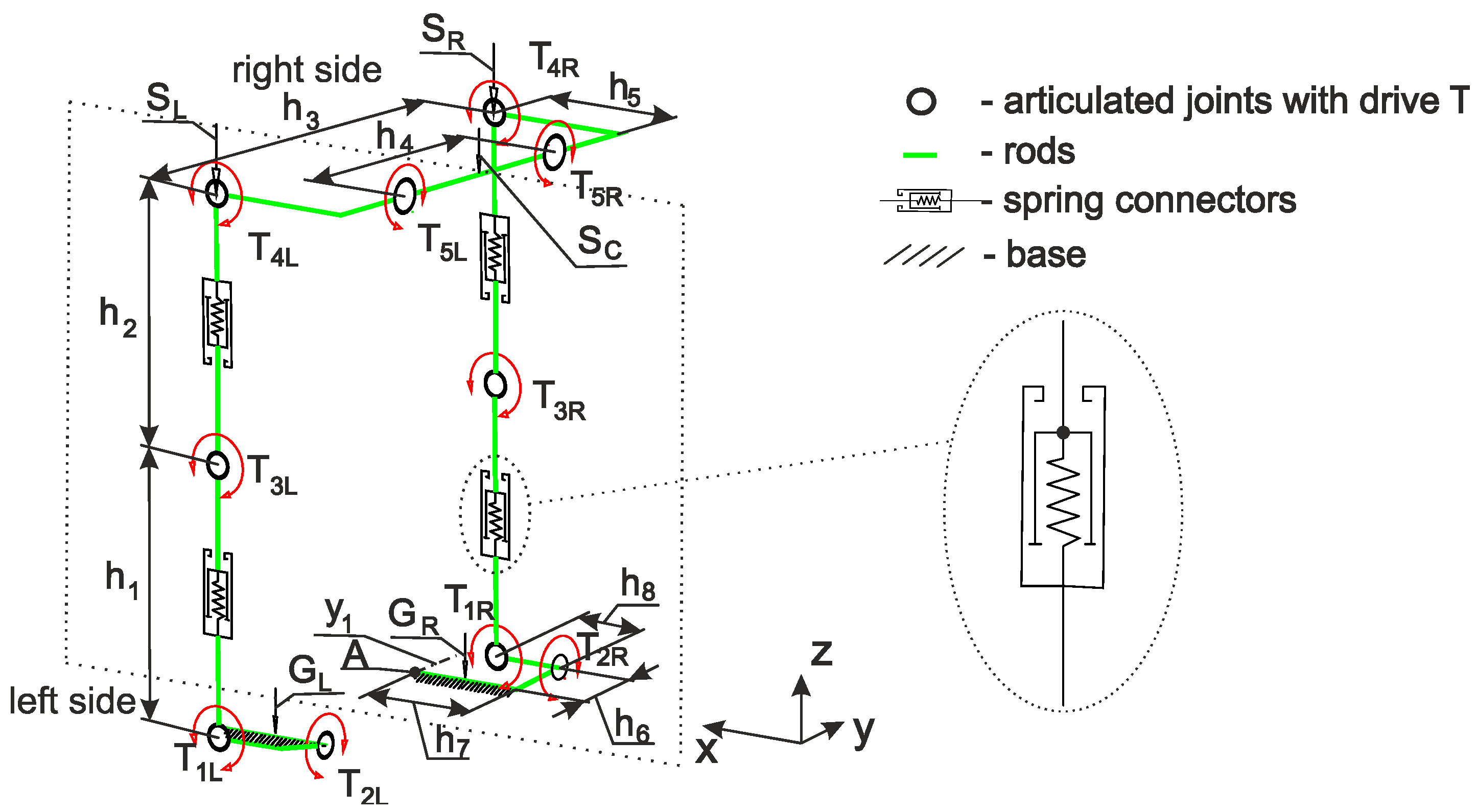

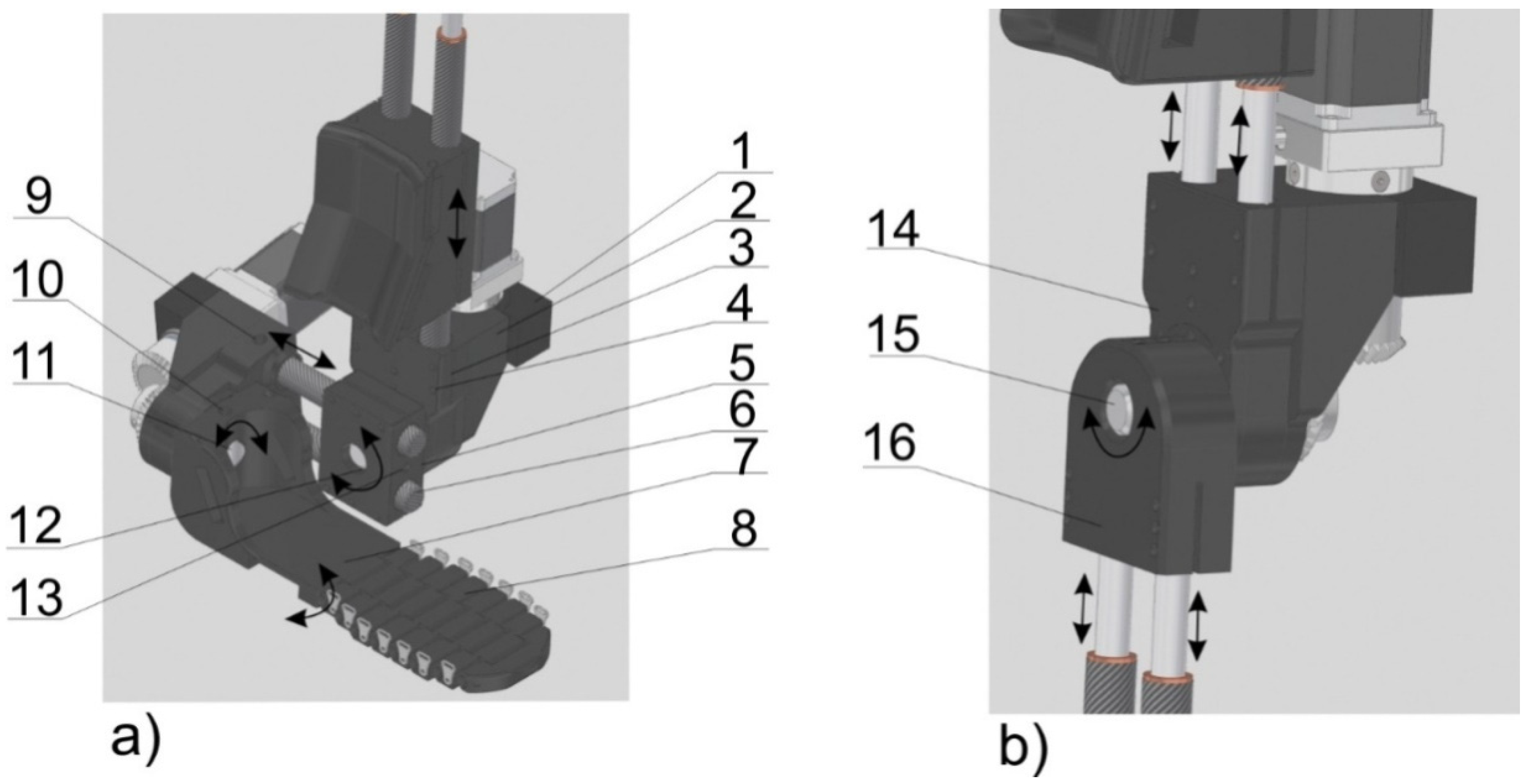

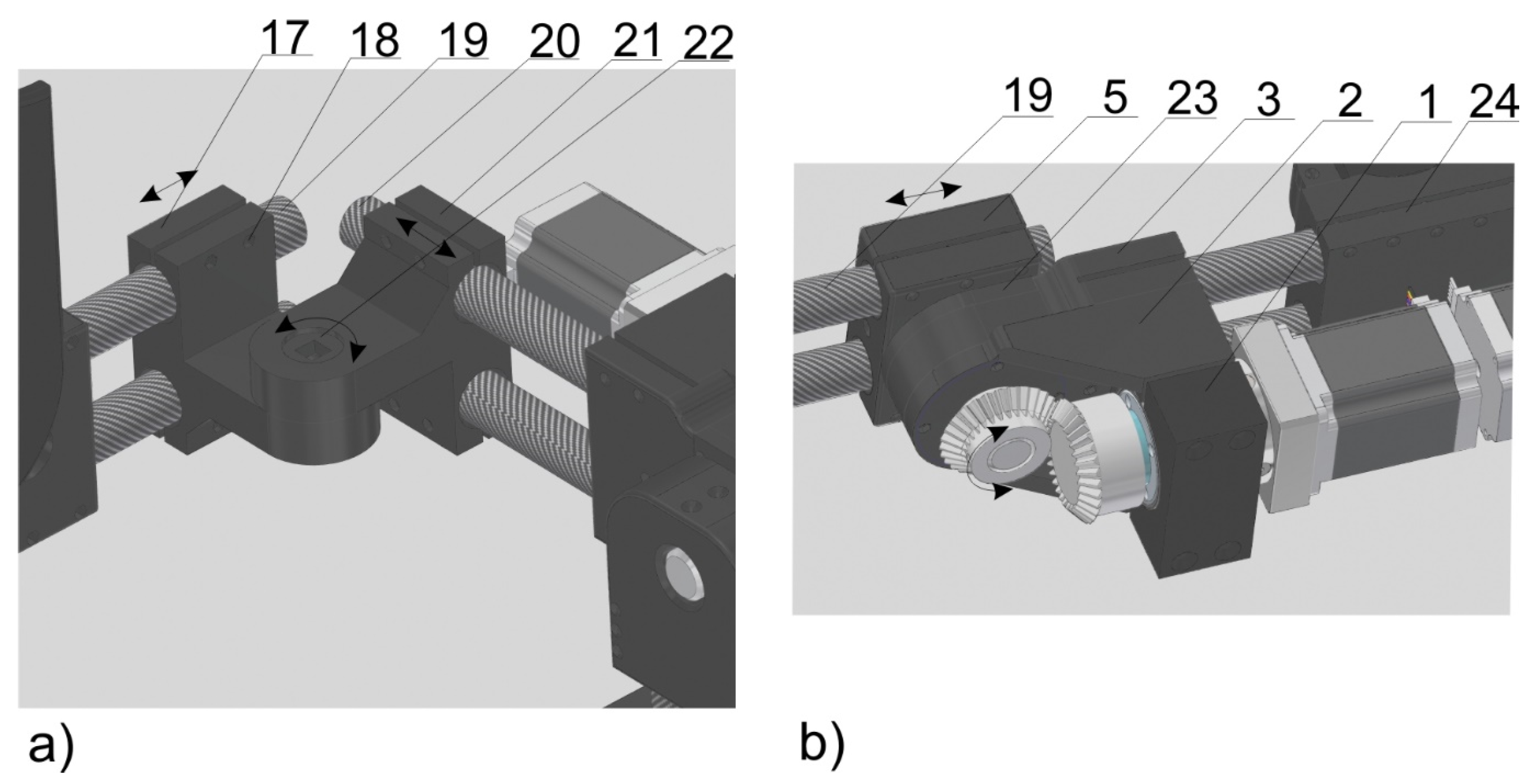

2.1. Design

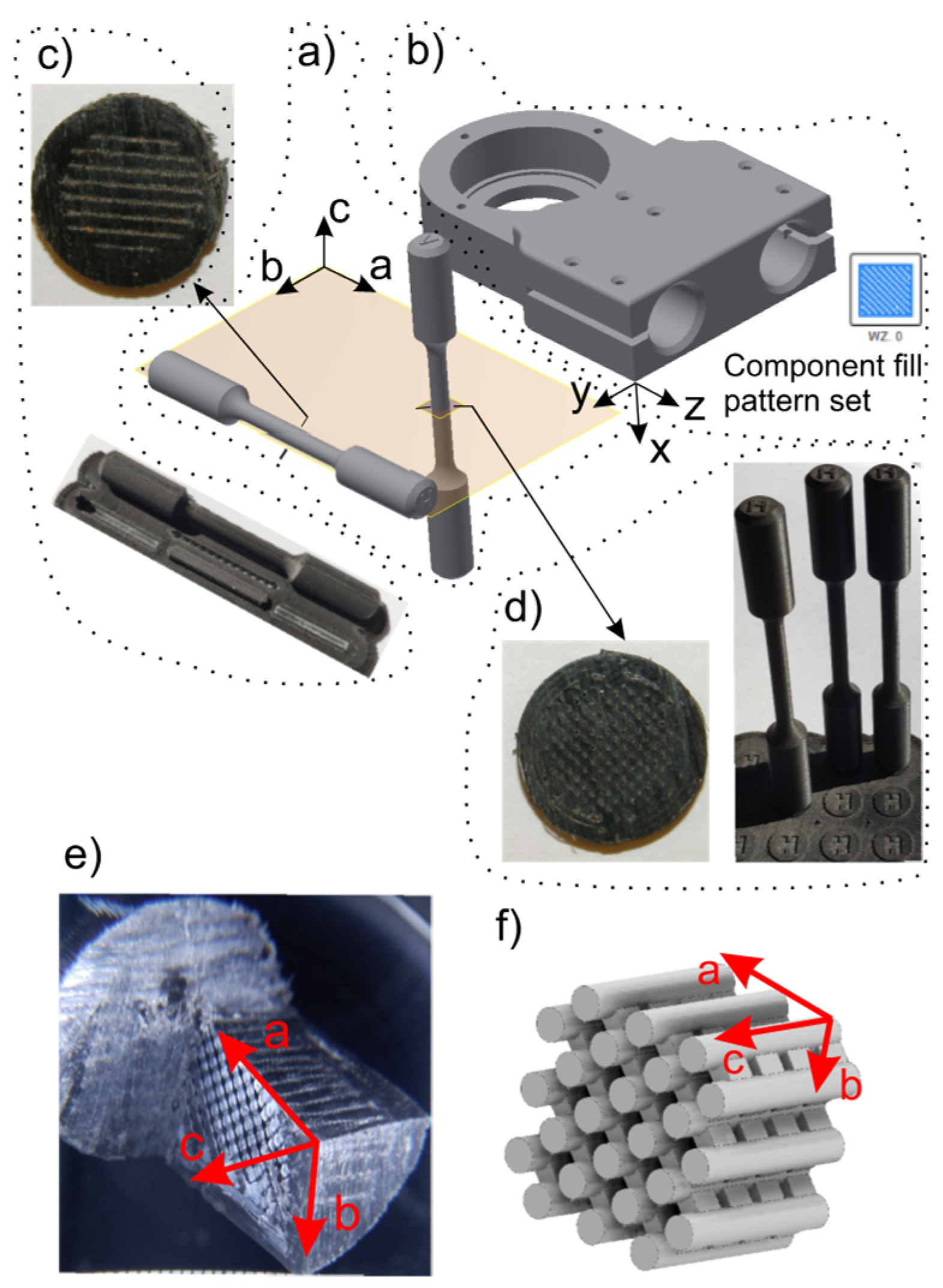

2.2. Materials

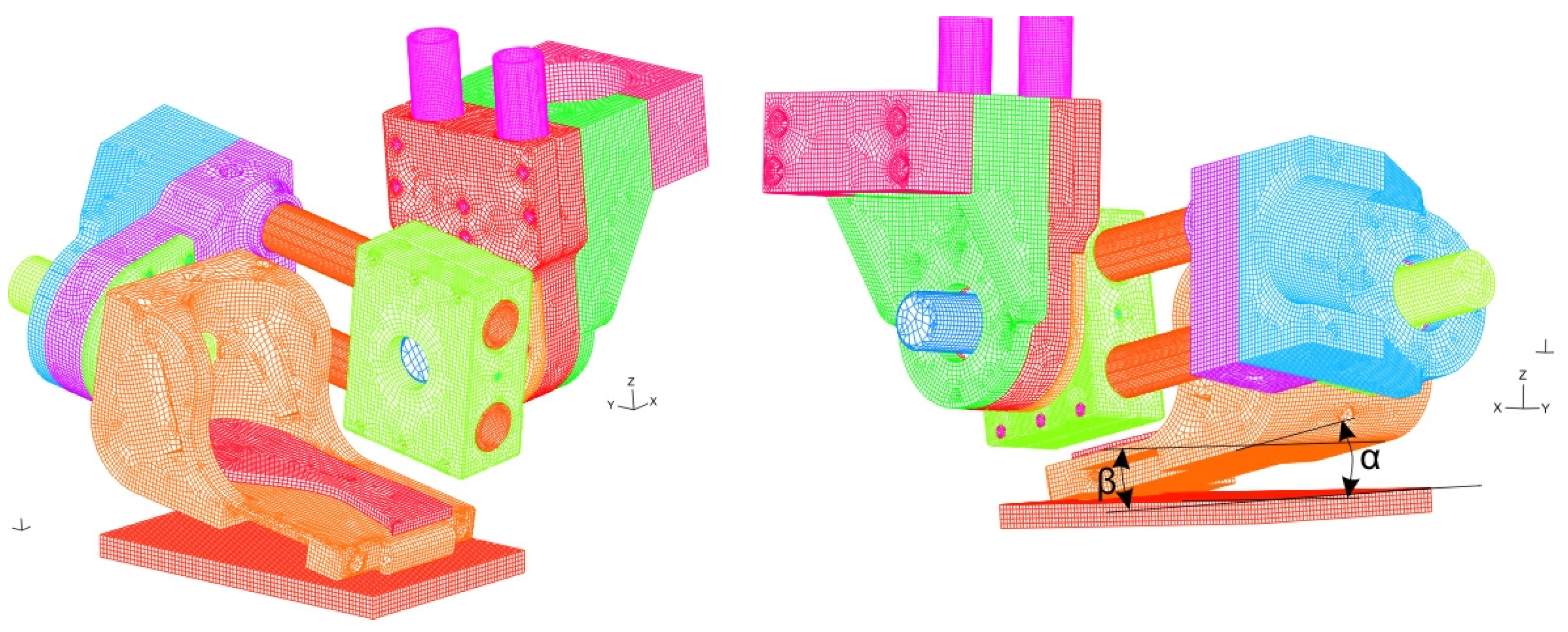

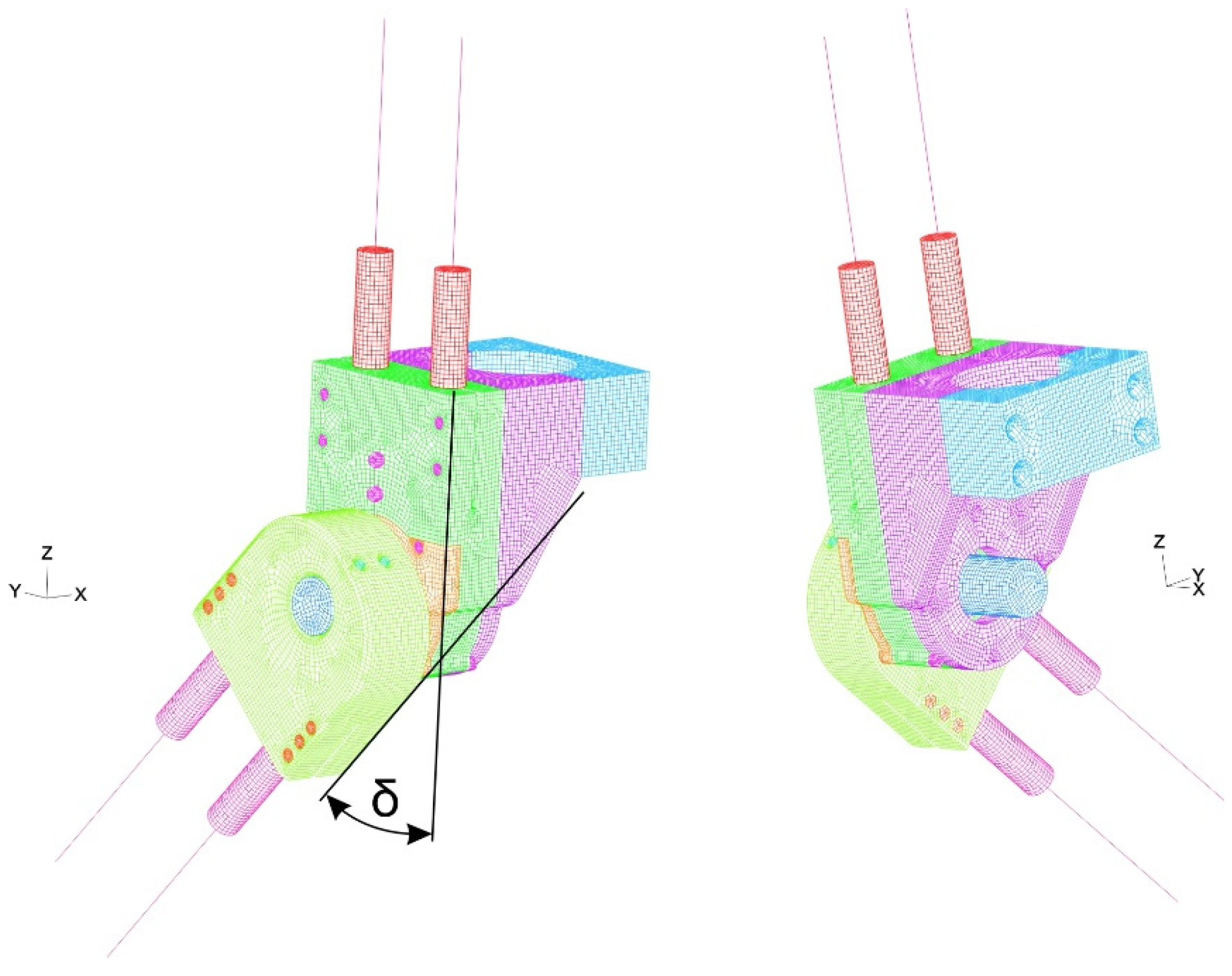

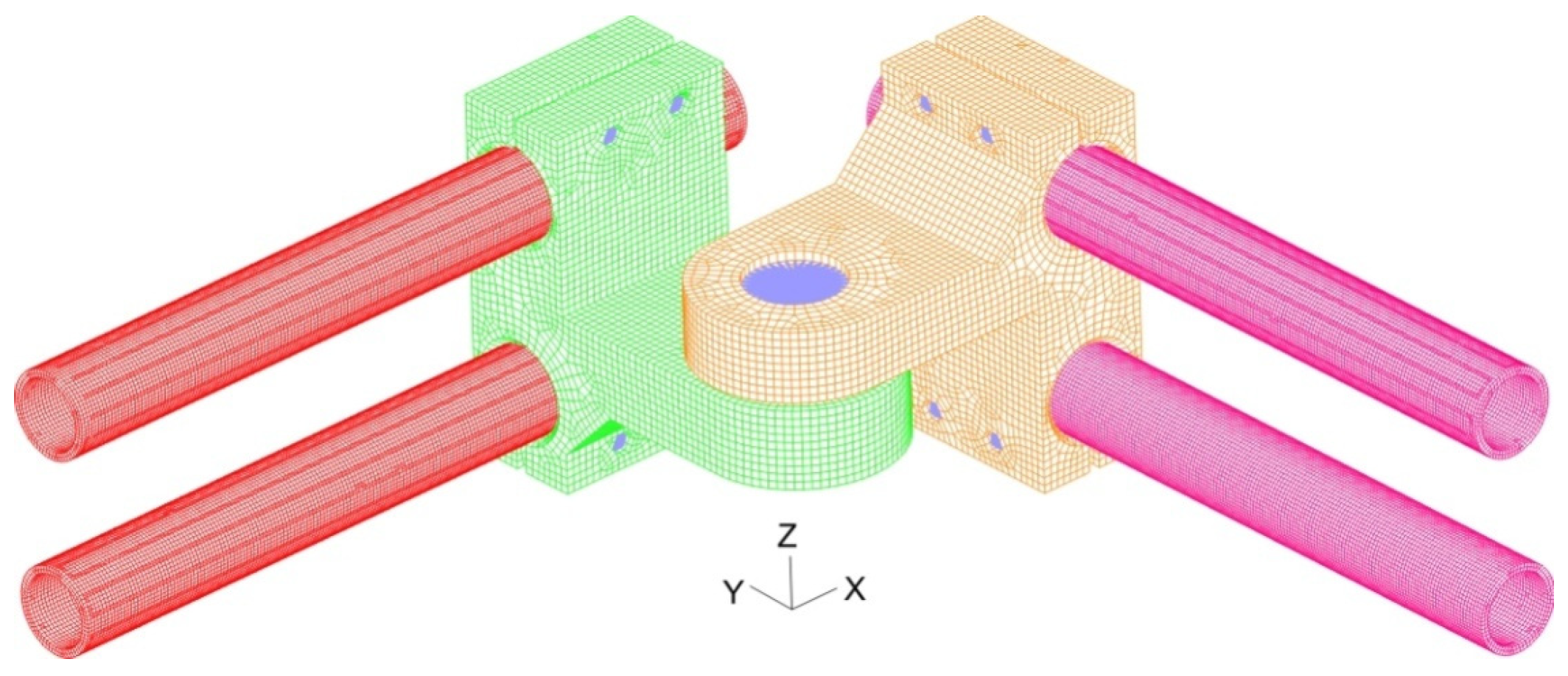

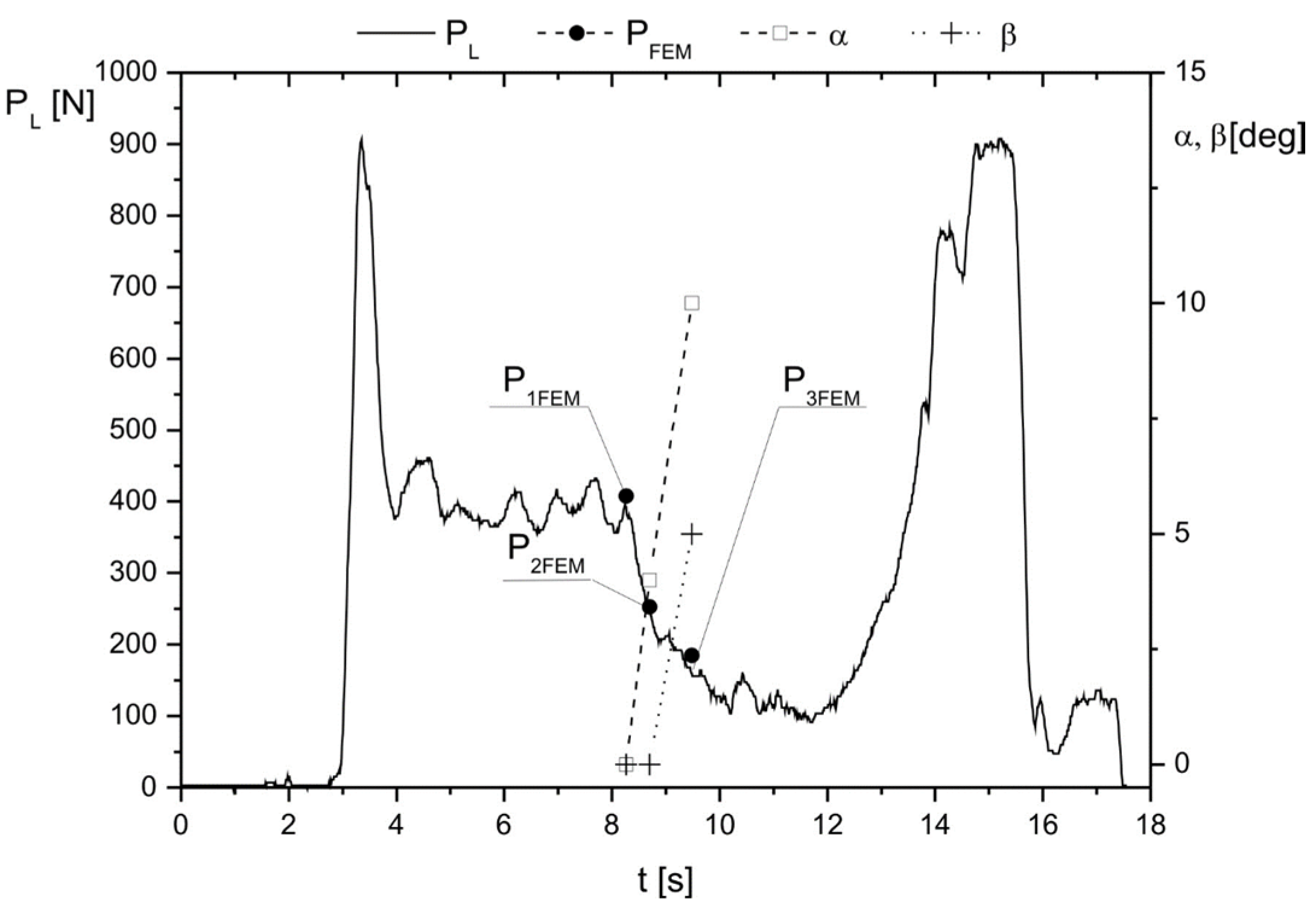

2.3. Numerical Research

3. Results

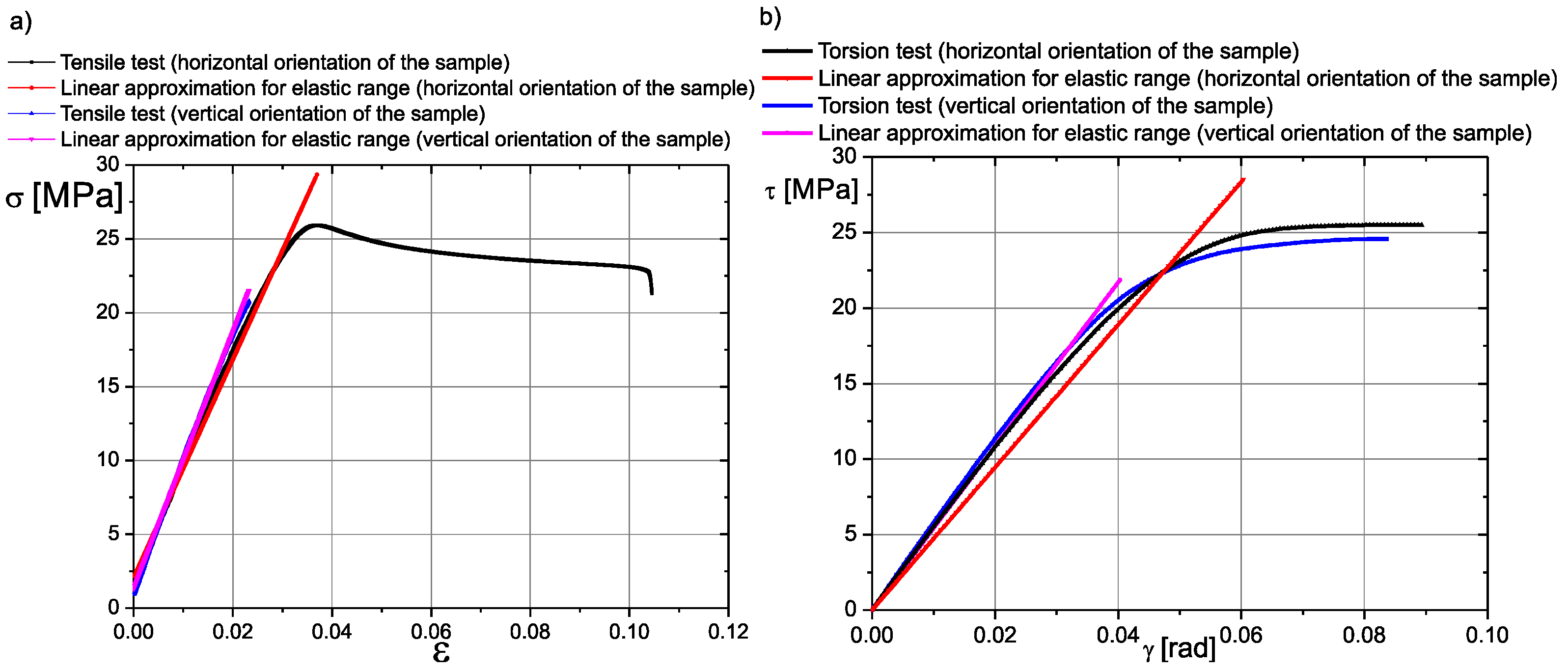

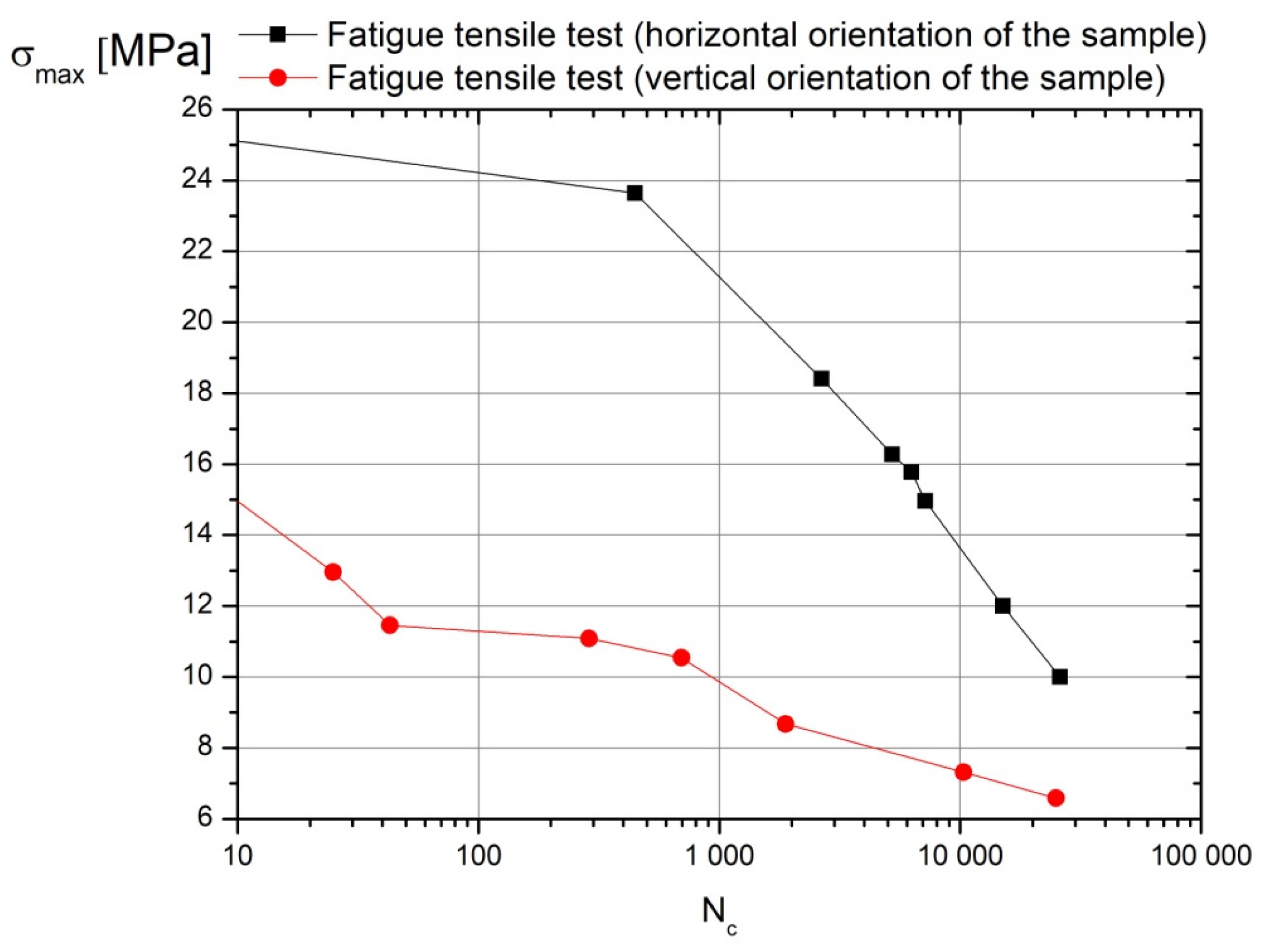

3.1. Experimental Research

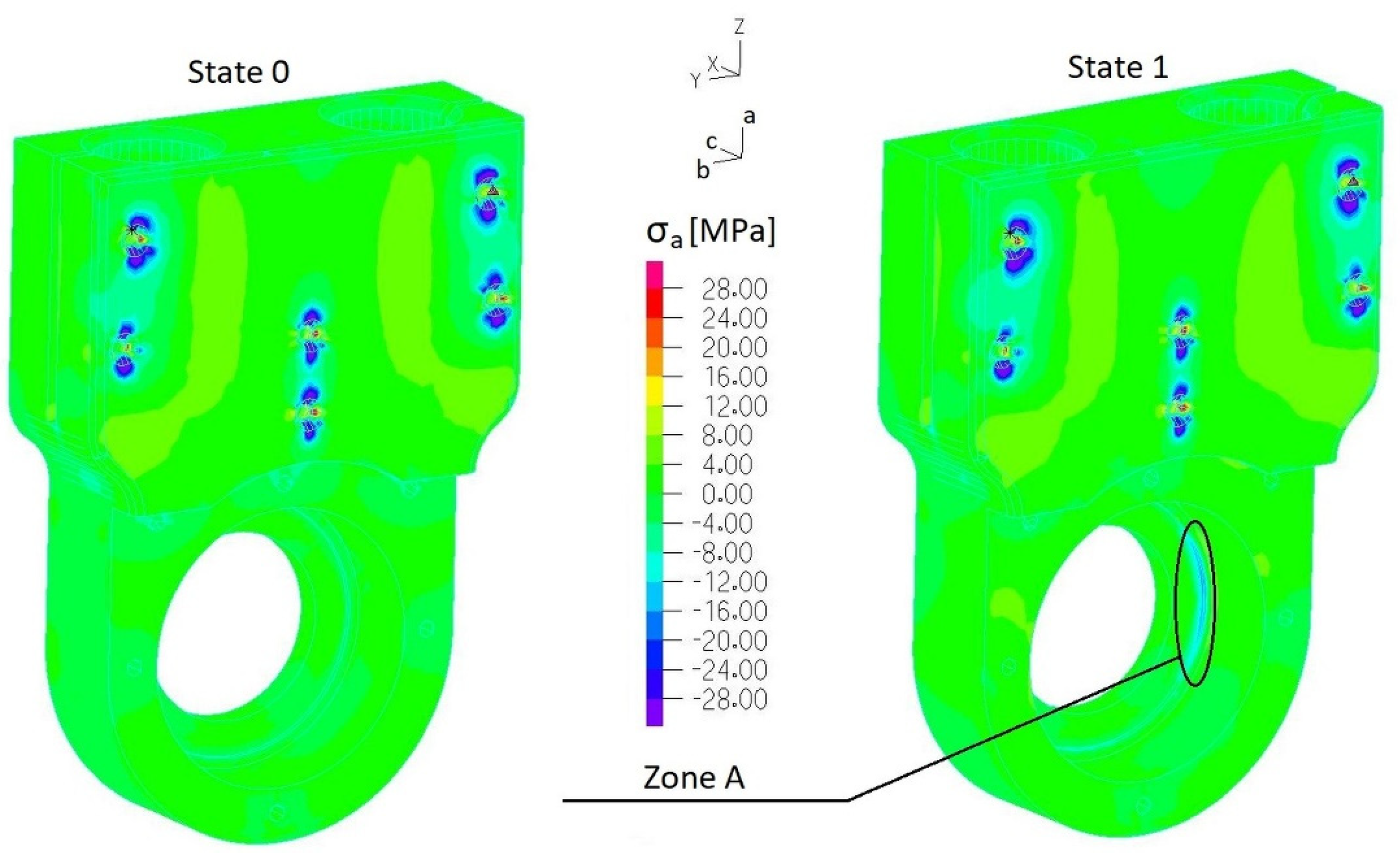

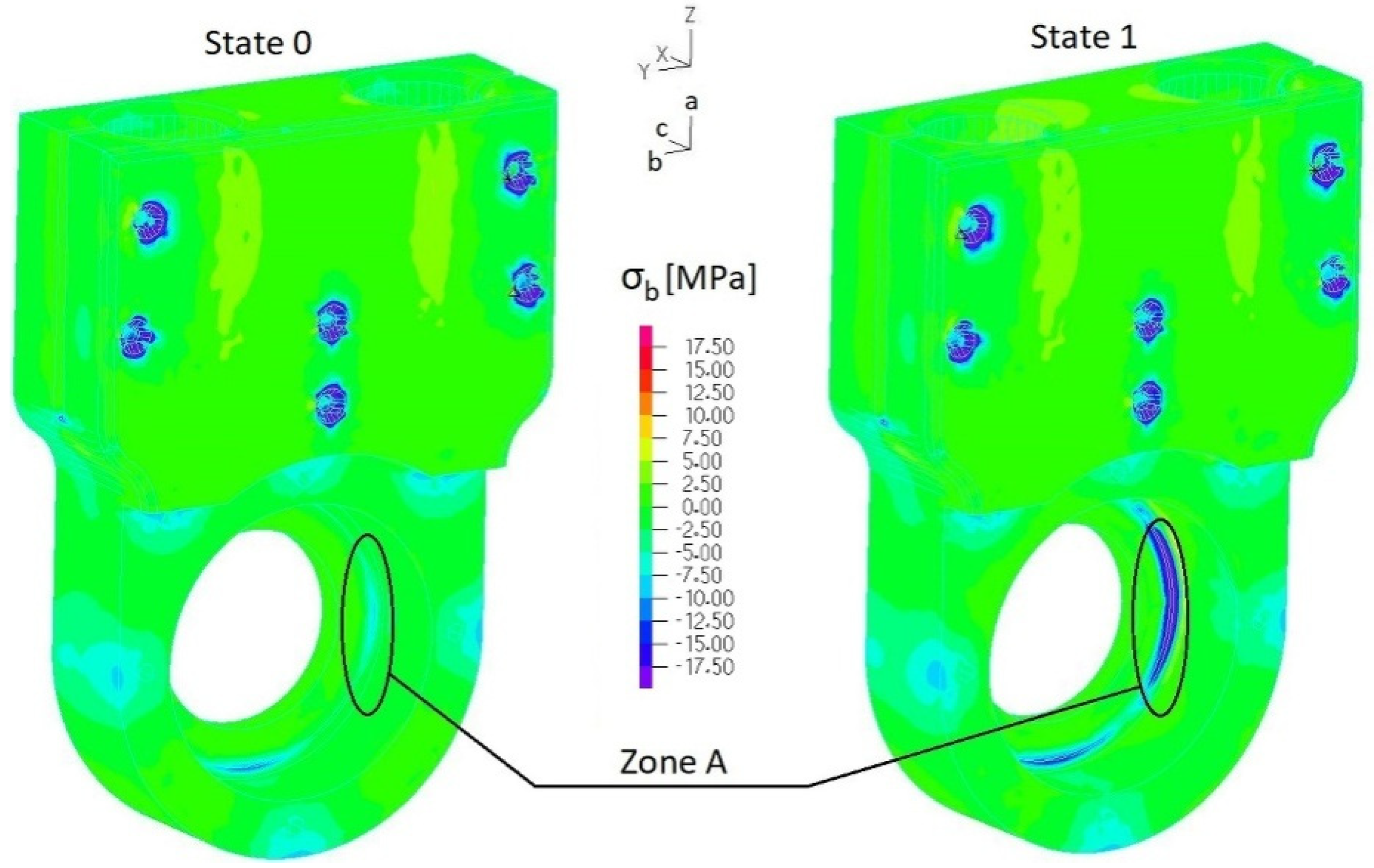

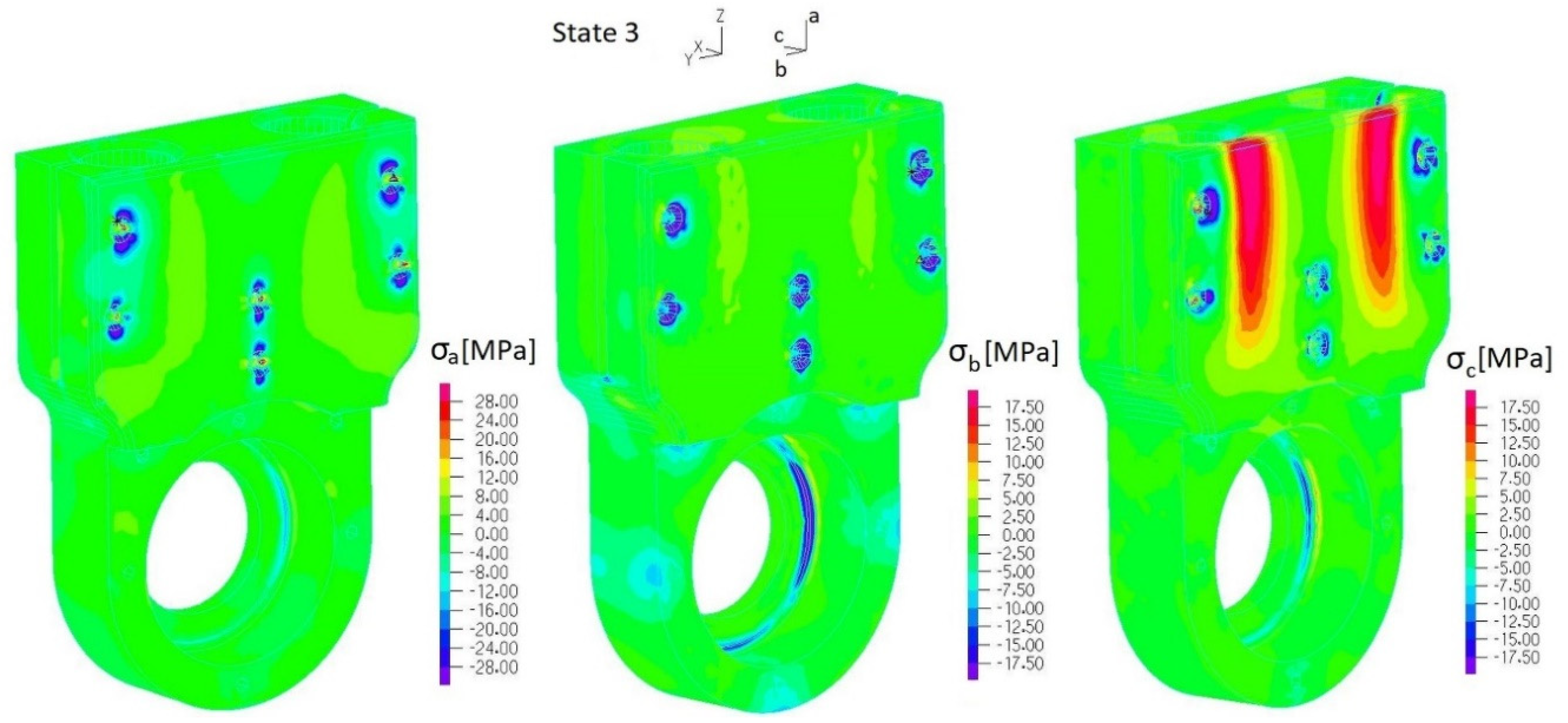

3.2. Results of Numerical Testing of Chosen 3D-Printed Elements

4. Discussion and Conclusions

5. Summary

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bassett, K.; Carriveau, R.; Ting, D.-K. 3D printed wind turbines part1: Design considerations and rapid manufacture potential. Sustain. Energy Technol. Assess. 2015, 11, 186–193. [Google Scholar] [CrossRef]

- Mitchell, A.; Lafont, U.; Hołyńska, M.; Semprimoschnig, C. Additive manufacturing—A review of 4D printing and future applications. Addit. Manuf. 2018, 24, 606–626. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Wua, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Wanga, X.; Jiang, M.; Zhoub, Z.; Goua, J.; Hui, D. 3D printing of polymer matrix composites: A review and prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Sooda, A.K.; Ohdarb, R.K.; Mahapatrac, S.S. Parametric appraisal of mechanical property of fused deposition modeling processed parts. Mater. Des. 2010, 31, 287–295. [Google Scholar] [CrossRef]

- Geng, P.; Zhao, J.; Wu, W.; Ye, W.; Wang, Y.; Wang, S.; Zhang, S. Effects of extrusion speed and printing speed on the 3D printing stability of extruded PEEK filament. J. Manuf. Process. 2019, 37, 266–273. [Google Scholar] [CrossRef]

- Chen, L.; Zhang, X. Modification the surface quality and mechanical properties by laser polishing of Al/PLA part manufactured by fused deposition modeling. Appl. Surf. Sci. 2019, 492, 765–775. [Google Scholar] [CrossRef]

- Yu, N.; Sun, X.; Wang, Z.; Zhang, D.; Li, J. Effects of auxiliary heat on warm page and mechanical properties in carbon fiber/ABS composite manufactured by fused deposition modeling. Mater. Des. 2020, 195, 108978. [Google Scholar] [CrossRef]

- Tze Ng, C.; Susmel, L. Notch static strength of additively manufactured acrylonitrile butadiene styrene (ABS). Addit. Manuf. 2020, 34, 101212. [Google Scholar] [CrossRef]

- Cicero, S.; Martinez-Mata, V.; Alonso-Estebanez, A.; Castanon-Jano, L.; Arroyo, B. Analysis of Notch Effect in 3D-Printed ABS Fracture Specimens Containing U-Notches. Materials 2020, 13, 4716. [Google Scholar] [CrossRef] [PubMed]

- Japa, N.S.F.; Pearce, G.M.; Hellier, A.K.; Russell, N.; Parrc, W.C.; Walsh, W.R. The effect of raster orientation on the static and fatigue properties of filament deposited ABS polymer International. J. Fatigue 2019, 124, 328–337. [Google Scholar] [CrossRef]

- Yadav, D.K.; Srivastava, R.; Dev, S. Design & fabrication of ABS part by FDM for automobile application. Mater. Today Proc. 2020, 26, 2089–2093. [Google Scholar] [CrossRef]

- Saraf, B.; Garg, A.; Saurav, S.; Bhattacharya, A. Joining of ABS parts built by material extrusion: Analysis of strength and fracture behavior. CIRP J. Manuf. Sci. Technol. 2020, 31, 459–466. [Google Scholar] [CrossRef]

- Wan, A.S.; Xu, Y.G.; Xue, L.H.; Xu, M.R.; Xiong, J.J. Finite element modeling and fatigue life prediction of helicopter composite tail structure under multipoint coordinated loadings pectrum. Compos. Struct. 2021, 255, 112900. [Google Scholar] [CrossRef]

- Krishnadasan, C.K.; Shanmugam, N.S.; Sivasubramonian, B.; Nageswara Rao, B.; Suresh, R. Analytical studies and numerical predictions of stresses in shear joints of layered composite panels for aerospace applications. Compos. Struct. 2021, 255, 112927. [Google Scholar] [CrossRef]

- Dhaliwal, G.S.; Dundar, M.A. Four Point Flexural Response of Acrylonitrile–Butadiene–Styrene. J. Compos. Sci. 2020, 4, 63. [Google Scholar] [CrossRef]

- Goo, B.; Kim, J.-B.; Ahn, D.-G.; Park, K. Irreversible and Repeatable Shape Transformation of Additively Manufactured Annular Composite Structures. Materials 2021, 14, 1383. [Google Scholar] [CrossRef]

- Zhang, H.; Cai, L.; Golub, M.; Zhang, Y.; Yang, X.; Schlarman, K.; Zhang, J. Tensile, Creep, and Fatigue Behaviors of 3D-Printed Acrylonitrile Butadiene Styrene. J. Mater. Eng. Perform. 2018, 27, 57–62. [Google Scholar] [CrossRef]

- Chen, B.; Zi, B.; Wang, Z.; Qin, L.; Liao, W.-H. Knee exoskeletons for gait rehabilitation and human performance augmentation: Astate-of-the-art. Mech. Mach. Theory 2019, 134, 499–511. [Google Scholar] [CrossRef]

- Beyla, P.; Knaepenb, K.; Duerinck, S.; Van Dammea, M.; Vanderborghta, B.; Meeusenb, R.; Lefebera, D. Safeand Compliant Guidance by a Powered Knee Exoskeleton for Robot-Assisted Rehabilitation of Gait. Adv. Robot. 2011, 25, 513–535. [Google Scholar] [CrossRef]

- Kong, K.; Bae, J.; Tomizuka, M. A Compact Rotary Series Elastic Actuator for Human Assistive Systems. IEEE/ASME Trans. Mechatron. 2012, 17, 288–297. [Google Scholar] [CrossRef]

- Yatsun, A.; Jatsun, S. Modeling quasi-static gait of a person wearing lower limb exoskeleton. In Proceedings of the 4th International Conference on Industrial Engineering Lecture Notes in Mechanical Engineering; Springer Nature: Cham, Switzerland, 2019; pp. 565–575. [Google Scholar] [CrossRef]

- Grimmer, M.; Quinlivan, B.T.; Lee, S.; Malcolm, P.; Rossi, D.M.; Siviy, C.; Walsh, C.J. Comparison of the human-exosuit interaction using ankle moment and ankle positive power inspired walking assistance. J. Biomech. 2019, 83, 76–84. [Google Scholar] [CrossRef] [PubMed]

- Guncan, B.; Unal, R. ANT-M: Design of passive lower-limb exoskeleton for weight-bearing assistance in industry. In Proceedings of the 4th International Symposium on Wearable Robotics, WeRob2018, Pisa, Italy, 16–20 October 2018; Springer Nature: Cham, Switzerland, 2019; Volume 22, pp. 500–504. [Google Scholar] [CrossRef]

- Gui Fang, Y.; Jigui, Z.; Fu De, W.; Rui, H.; Fei, L. Technical analysis of auxiliary exoskeleton robot based on wheeled platform. In Proceedings of the 2017 Chinese Automation Congress (CAC), Jinan, China, 20–22 October 2017. [Google Scholar] [CrossRef]

- Aycardi, L.F.; Cifuentes, C.A.; Múnera, M.; Bayón, C.; Ramírez, O.; Lerma, S.; Frizera, A.; Rocon, E. Evaluation of biomechanical gait parameters of patients with Cerebral Palsy at three different levels of gait assistance using the CP Walker. J. Neuro Eng. Rehabil. 2019, 16, 15. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.; Tian, C.; Dai, J.S. Mechanism design and analysis of a proposed wheelchair-exoskeleton hybrid robot for assistinghuman movement. Mech. Sci. 2019, 10, 11–24. [Google Scholar] [CrossRef]

- BS EN 547-3:1996+A1:2008; Safety of Machinery. Human Body Measurements. Anthropometric Data. Available online: https://standards.iteh.ai/catalog/standards/cen/877cc321-617b-48f0-89ea-67bf0f656ff1/en-547-3-1996a1-2008 (accessed on 1 September 2019).

- BS EN 349:1993+A1:2008; Safety of Machinery. Minimum Gaps to Avoid Crushing of Parts of the Human Body. Available online: https://cemarking.net/en-349_1993_a12008/ (accessed on 1 September 2019).

- EN 294; Safety of Machinery—Safety Distance to Prevent Danger Zones Being Reached by the Upper Limbs. Available online: https://standards.iteh.ai/catalog/standards/cen/3c98425d-3bc5-4cc8-bd5c-477dc451805b/en-294-1992 (accessed on 1 September 2019).

- EN/ISO 15537:2004; Principles for Selecting and Using Test Persons for Testing Anthropometric Aspects of Industrial Products and Designs. Available online: https://www.iso.org/standard/79174.html (accessed on 1 September 2019).

- ADINA. Theory and Modeling Guide; ADINAR&D, Inc.: Watertown, MA, USA, 2007; Volume 1. [Google Scholar]

- Bathe, K.J. Finite Element Procedures; Prentice-Hall, Inc.: Hoboken, NJ, USA; Simon & Schuster: New York, NY, USA; A Viacom Company: New York, NY, USA, 1996. [Google Scholar]

- Śpiewak, S.; Awrejcewicz, J. Strength Analysis of Polymer Conical Gear Wheel Made with 3D Printing Technique. J. KONES Powertrain Transp. 2019, 26, 235–242. [Google Scholar] [CrossRef]

- Śpiewak, S. Methodology for calculating the complete static carrying capacity of twin slewing bearing. Mech. Mach. Theory 2016, 101, 181–194. [Google Scholar] [CrossRef]

- Johson, K.L. Contact Mechanics; The Press Syndicate of The University of Cambridge: Cambridge, UK, 2004. [Google Scholar]

- Śpiewak, S. Peculiarity of determining a static carrying capacity for the one-row ball slewing bearing loaded the large radial force. J. KONES 2016, 23, 533–540. [Google Scholar]

- Rolling Bearings (Rolling Bearing Catalog); SKF Group: Gothenburg, Sweden, 2013.

- Jaskot, A.; Posiadała, B.; Śpiewak, S. Analysis of construction and internal load of the powertrain of the prototypical four-wheeled mobile platform. In Proceedings of the 13th International Scientific Conference, 1st Renewable Energy Sources—Research and Business (RESRB-2016), Wrocław, Poland, 22–24 June 2016; Springer: Berlin/Heidelberg, Germany, 2016; pp. 211–219. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Śpiewak, S.; Wojnicz, W.; Awrejcewicz, J.; Mazur, M.; Ludwicki, M.; Stańczyk, B.; Zagrodny, B. Modeling and Strength Calculations of Parts Made Using 3D Printing Technology and Mounted in a Custom-Made Lower Limb Exoskeleton. Materials 2024, 17, 3406. https://doi.org/10.3390/ma17143406

Śpiewak S, Wojnicz W, Awrejcewicz J, Mazur M, Ludwicki M, Stańczyk B, Zagrodny B. Modeling and Strength Calculations of Parts Made Using 3D Printing Technology and Mounted in a Custom-Made Lower Limb Exoskeleton. Materials. 2024; 17(14):3406. https://doi.org/10.3390/ma17143406

Chicago/Turabian StyleŚpiewak, Szczepan, Wiktoria Wojnicz, Jan Awrejcewicz, Magdalena Mazur, Michał Ludwicki, Bartosz Stańczyk, and Bartłomiej Zagrodny. 2024. "Modeling and Strength Calculations of Parts Made Using 3D Printing Technology and Mounted in a Custom-Made Lower Limb Exoskeleton" Materials 17, no. 14: 3406. https://doi.org/10.3390/ma17143406

APA StyleŚpiewak, S., Wojnicz, W., Awrejcewicz, J., Mazur, M., Ludwicki, M., Stańczyk, B., & Zagrodny, B. (2024). Modeling and Strength Calculations of Parts Made Using 3D Printing Technology and Mounted in a Custom-Made Lower Limb Exoskeleton. Materials, 17(14), 3406. https://doi.org/10.3390/ma17143406