New Technique to Repair Keyhole of 2195 Al-Li Alloy Friction Stir Welding Joints

Abstract

:1. Introduction

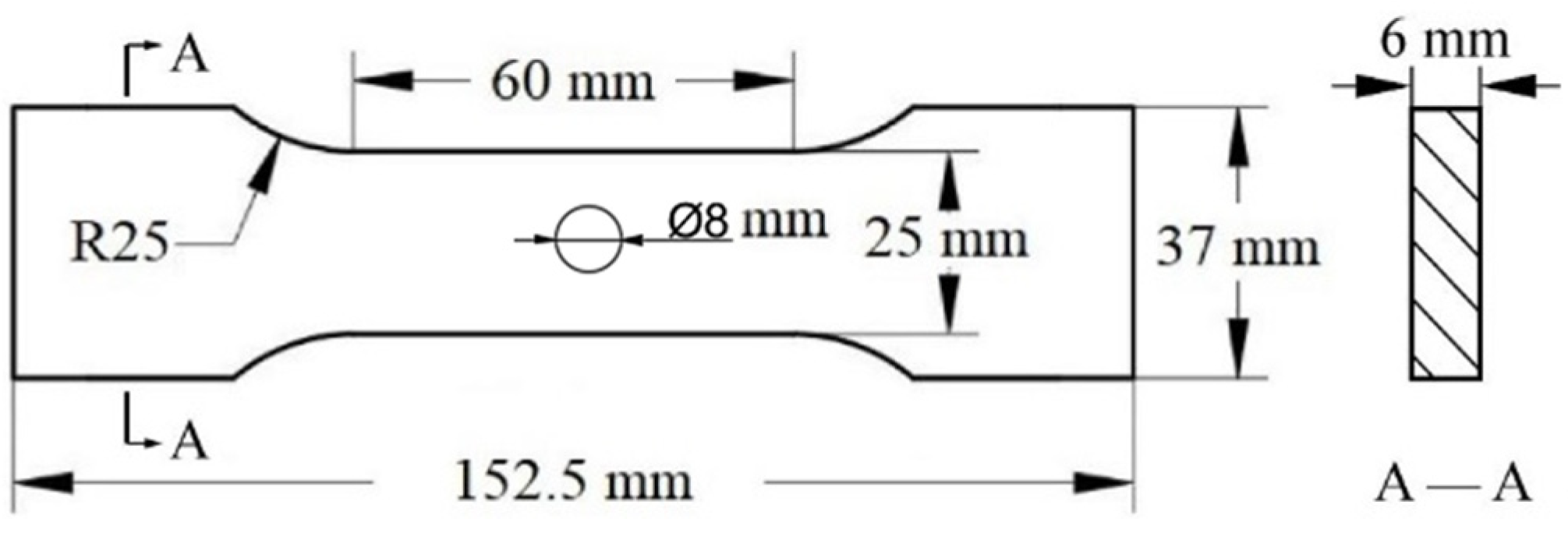

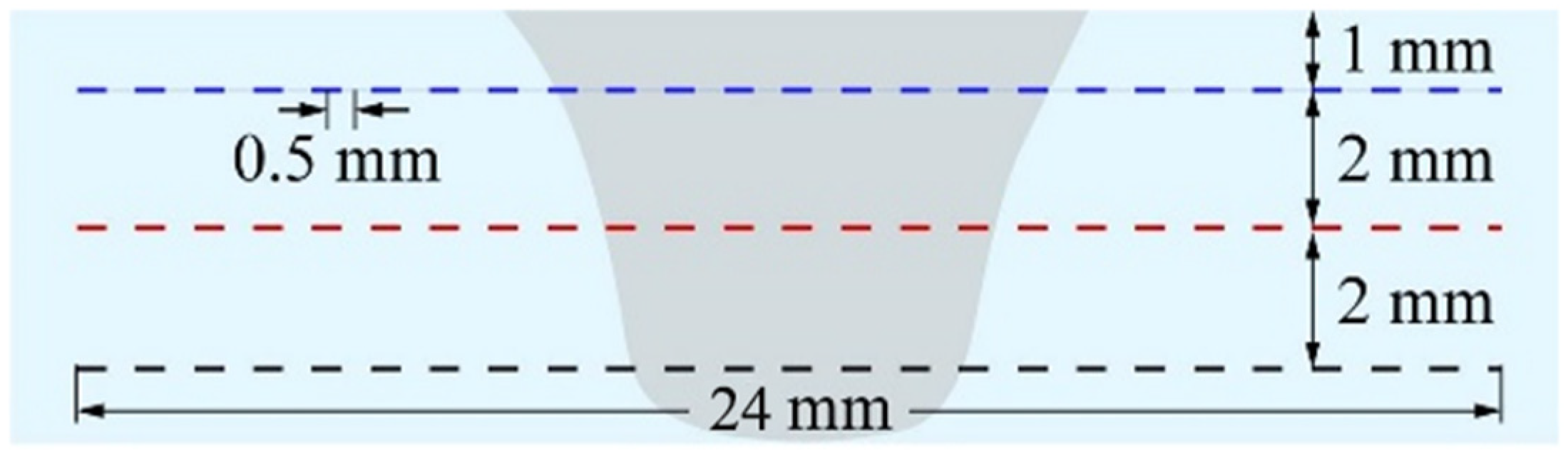

2. Experimental Procedures

3. Results

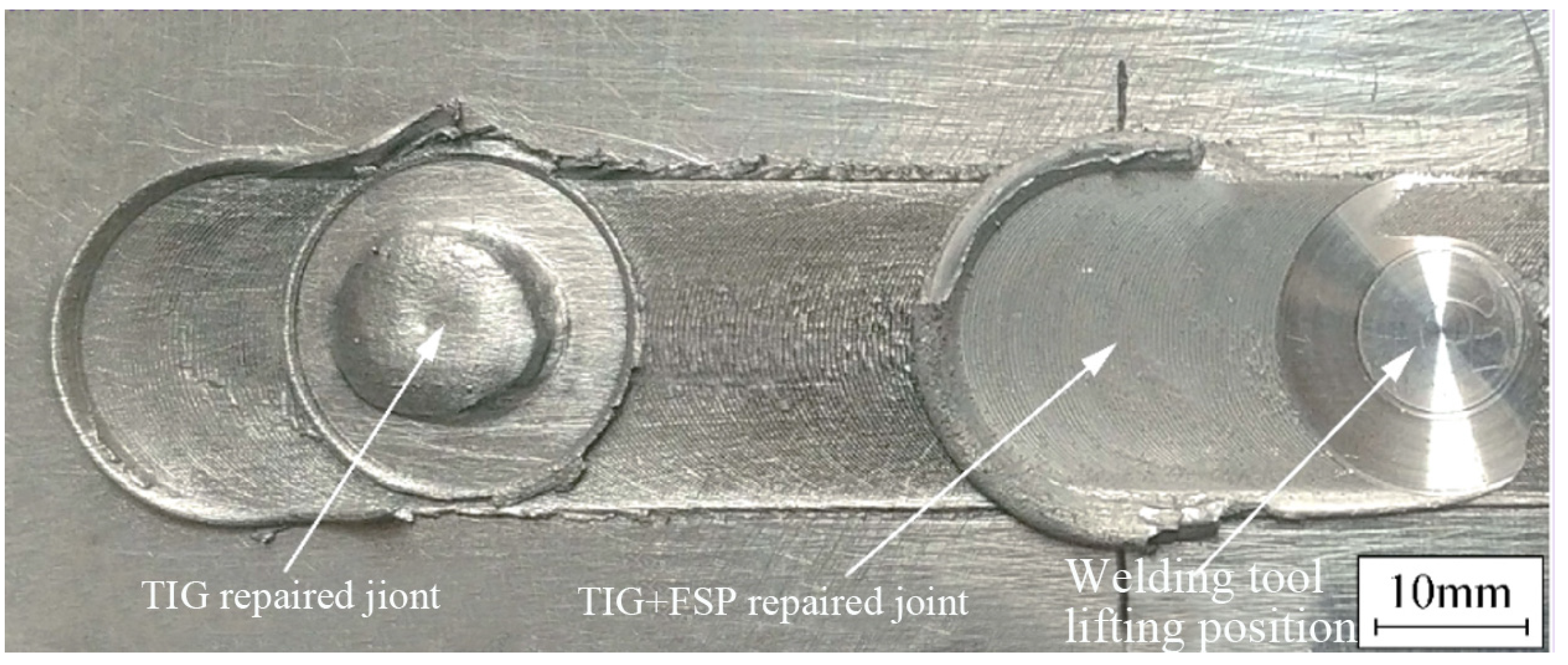

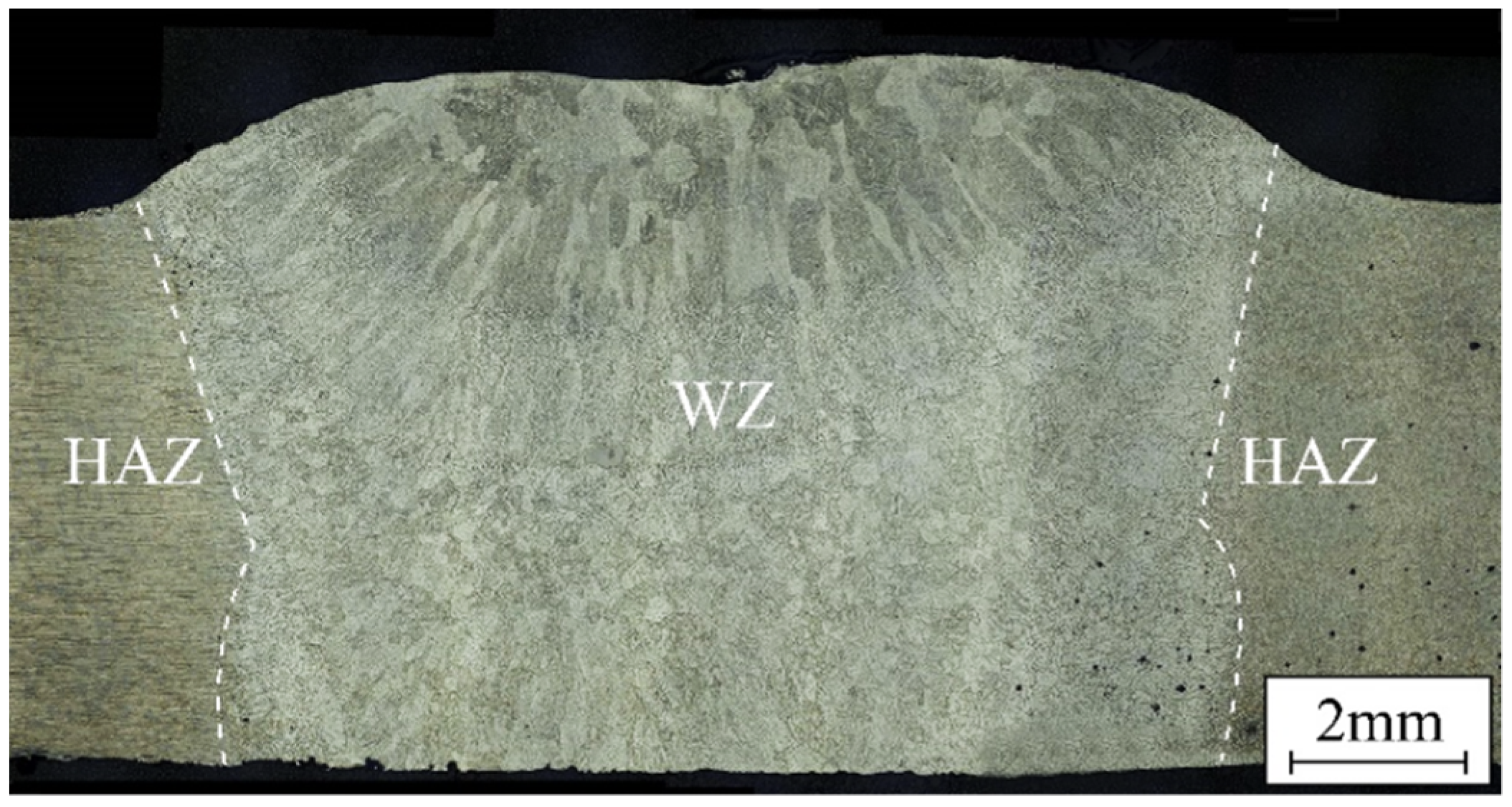

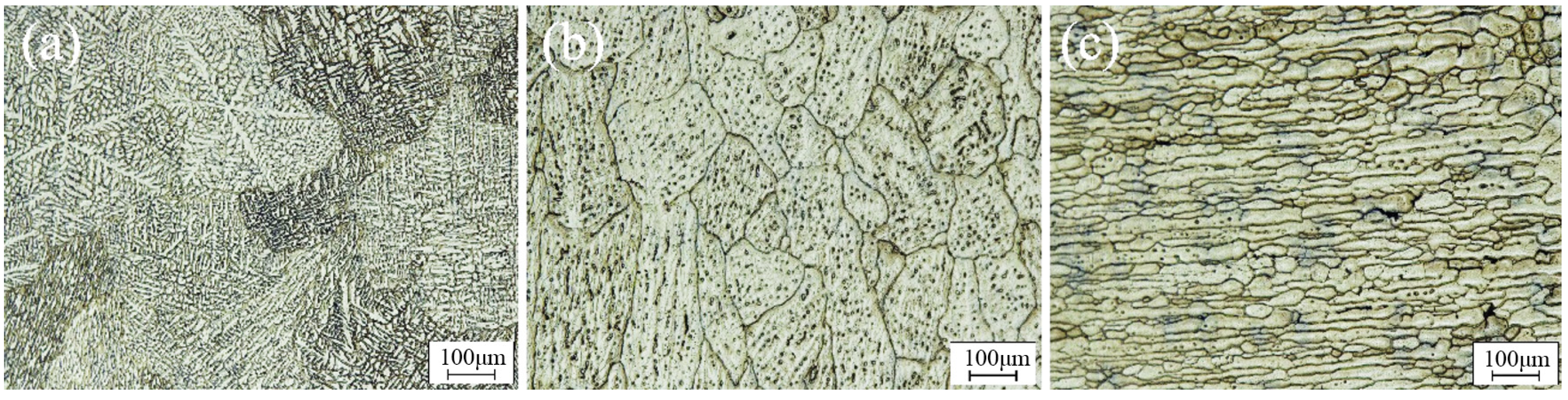

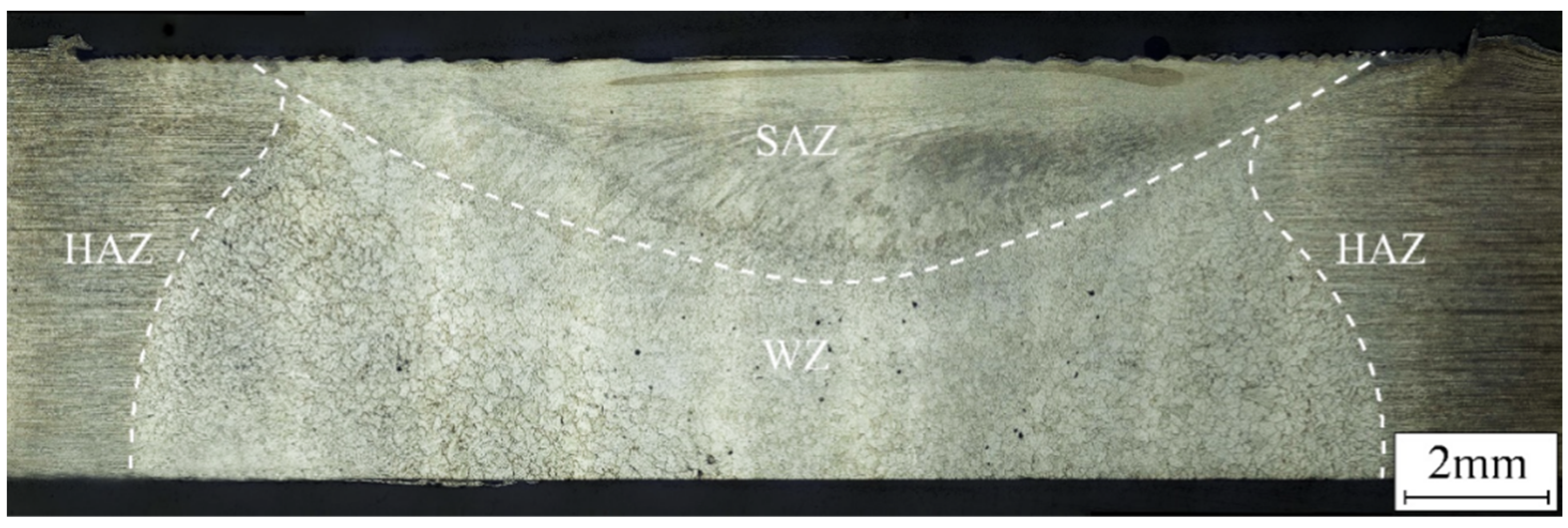

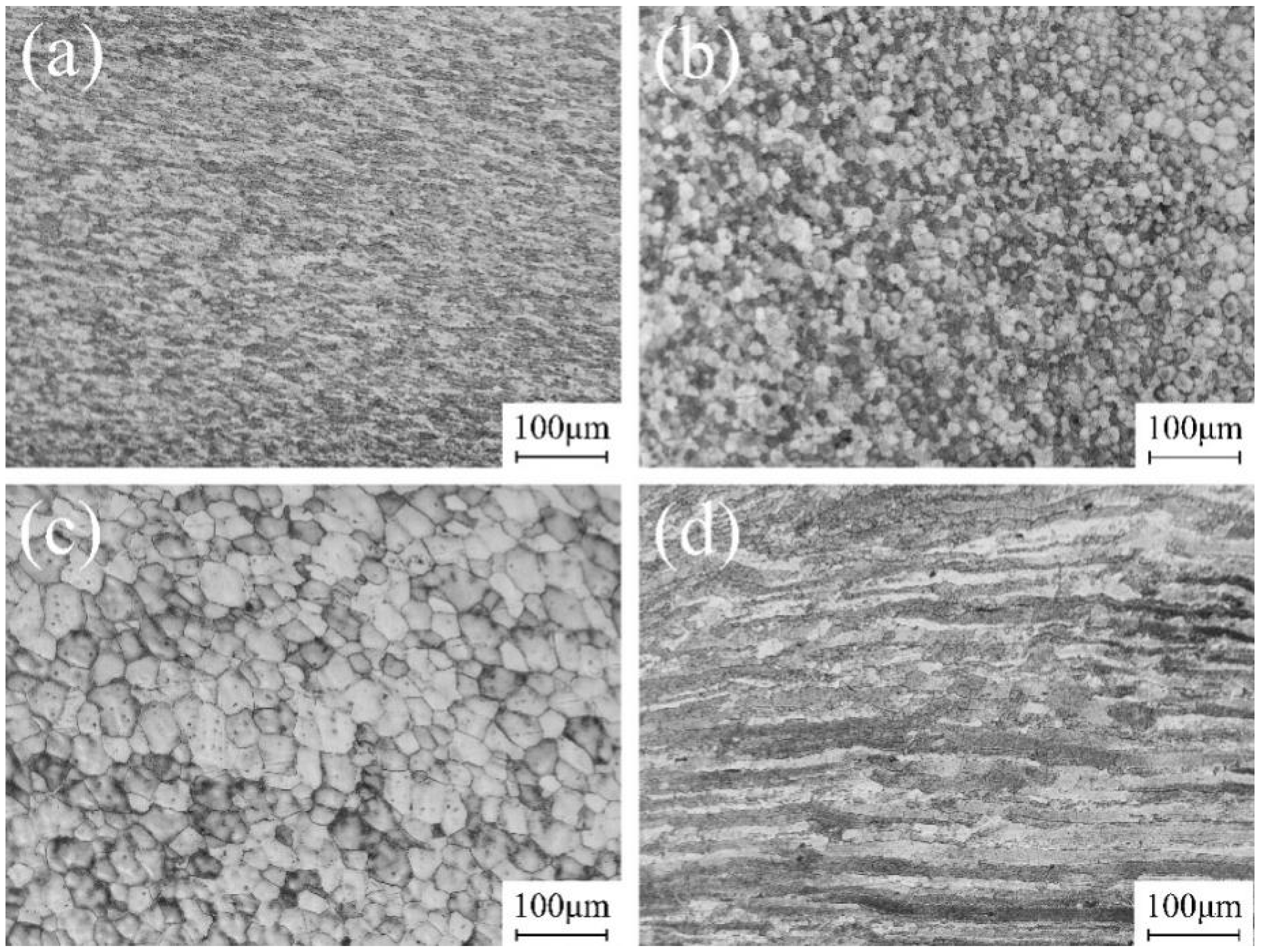

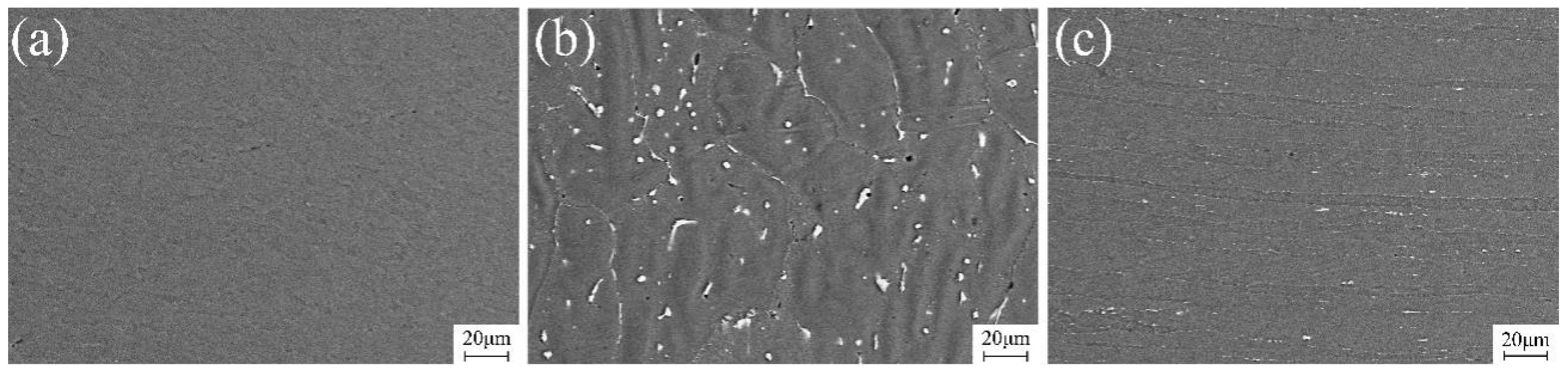

3.1. Repairing Formation and Microstructure Characterization

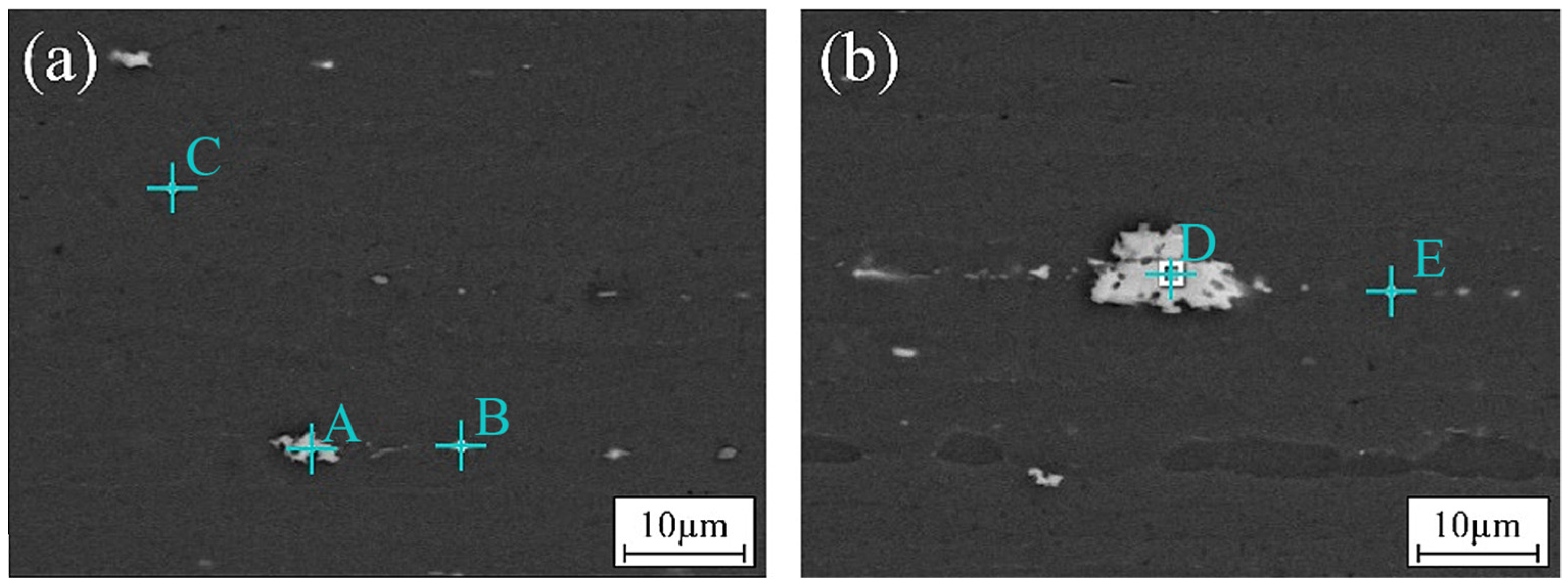

3.2. Precipitate Characterization

3.3. Mechanical Properties

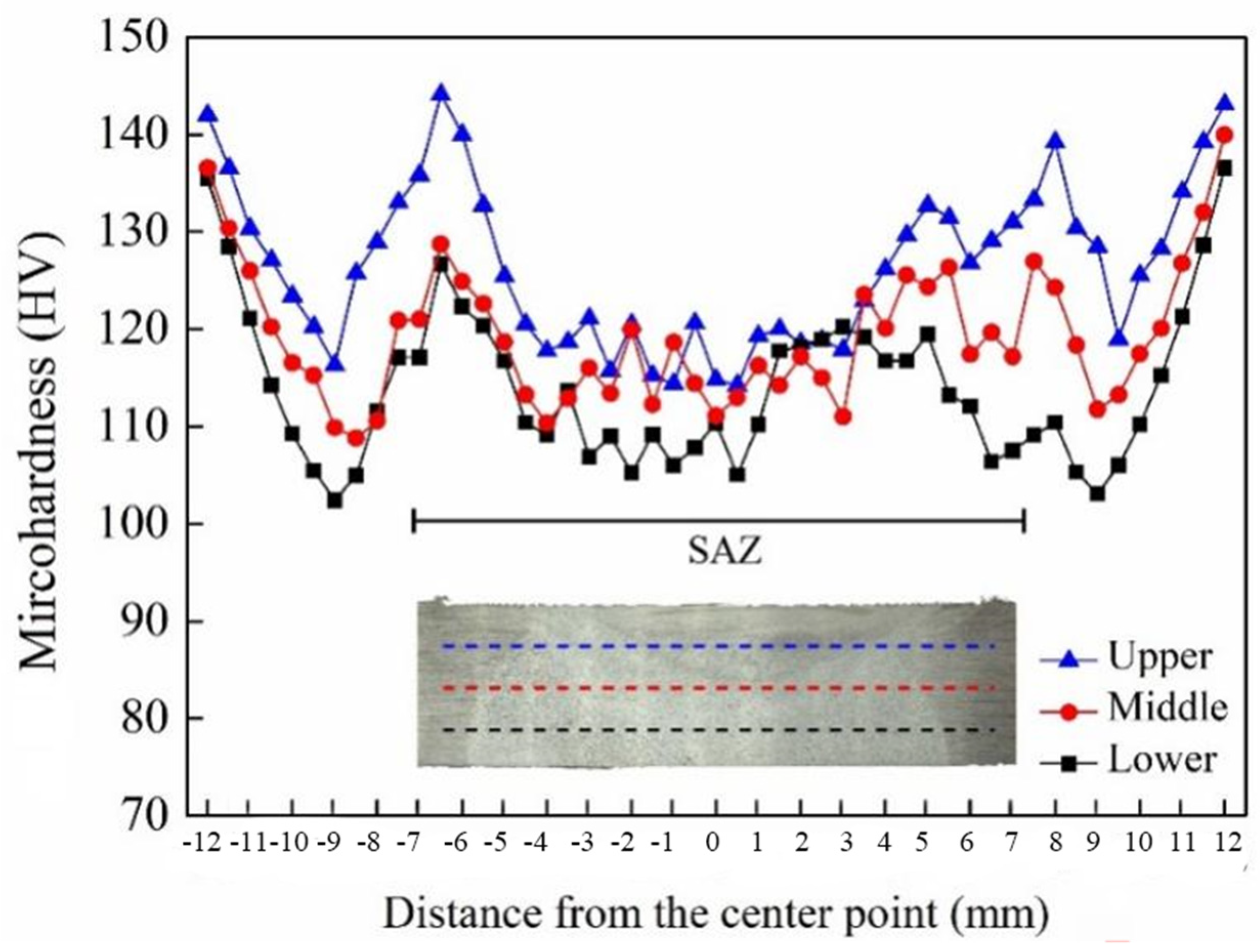

3.3.1. Hardness Distribution

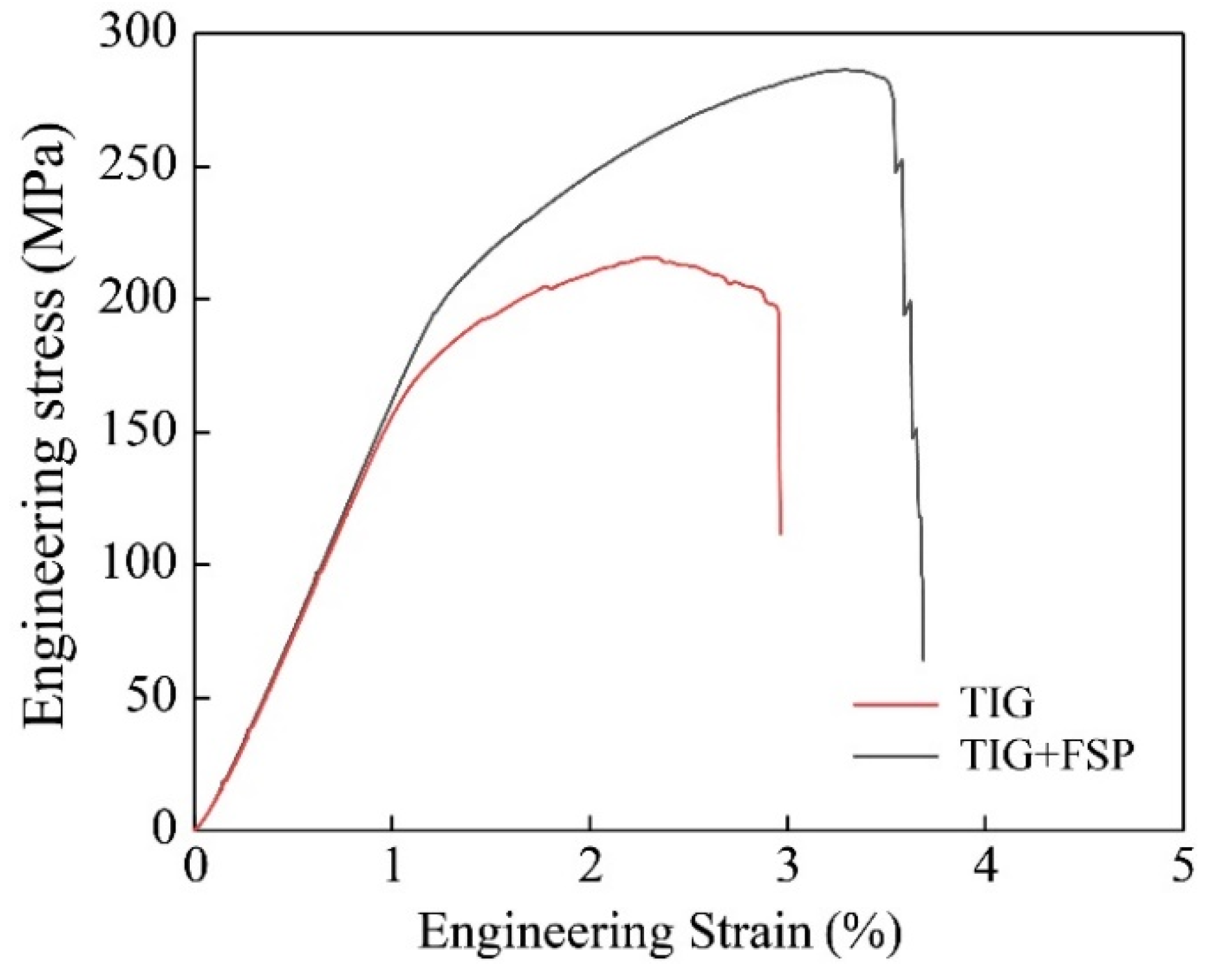

3.3.2. Tensile Properties

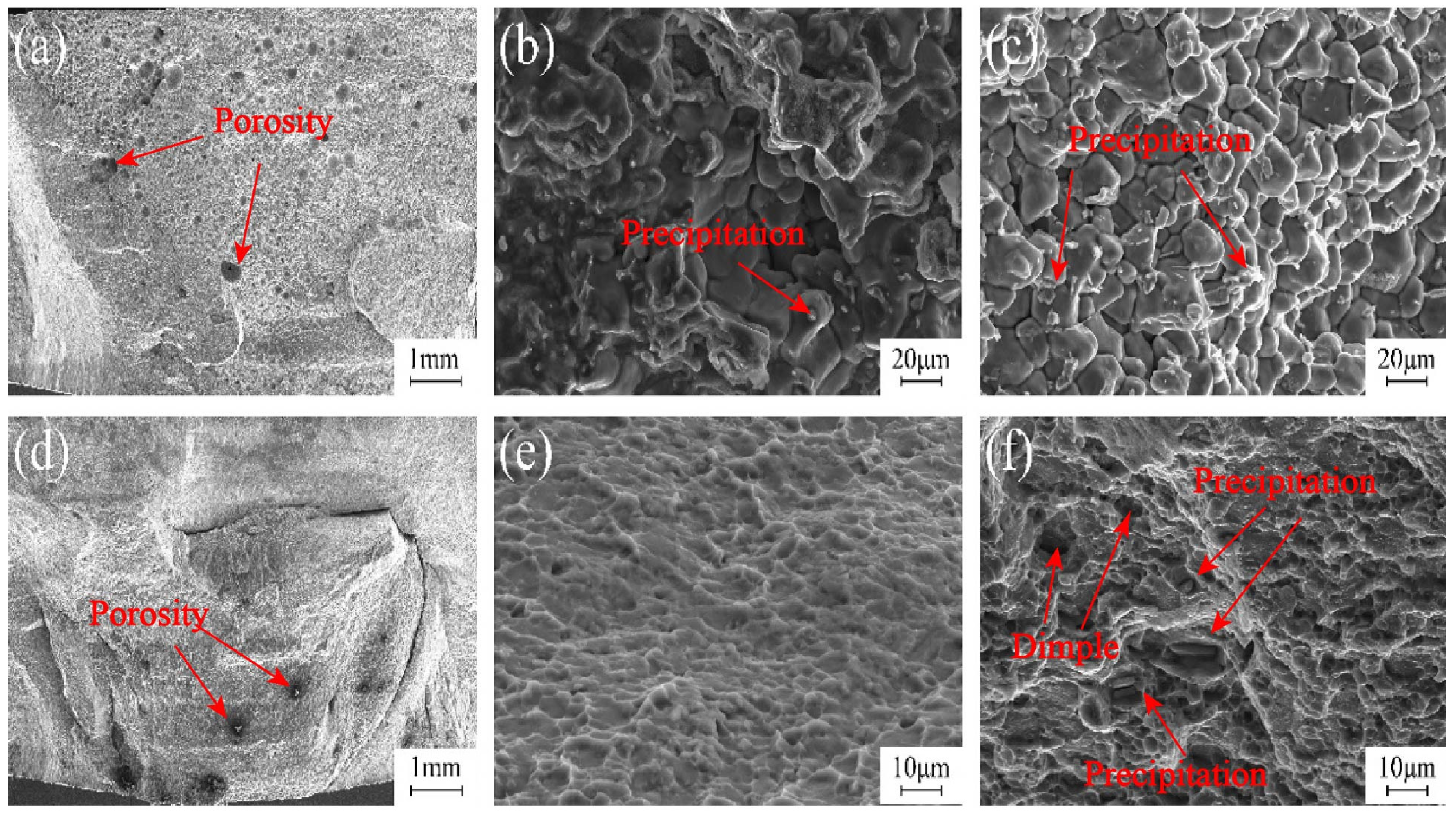

3.3.3. Fracture Surface Morphologies

4. Conclusions

- (1)

- FSP, after filling via TIG welding, was proposed to repair the keyhole defects in an FFSW joint of 2195 Al-Li alloy. The joint with good surface formation was obtained via low heat input and pressure.

- (2)

- TIG effectively achieved complete filling of the keyhole and realized the interfacial bonding of the repairing zone. FSP transformed the coarse casting microstructures in the TIG filling zone into fine and equiaxed forging microstructures and broke the precipitates at the grain boundary, which was attributed to the uniform microstructures.

- (3)

- The tensile strength of FSP after filling via TIG reached 283 MPa, equivalent to 74.7% of the high-quality joints. Compared with the single TIG repairing, the tensile strength was improved by 31.7%. The fracture mode was changed from cleavage in TIG repairing to a mixed-fracture mode of cleavage and ductile characteristics in TIG + FSP.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Lei, C.; Wang, Q.; Ebrahimi, M.; Li, D.; Tang, H.; Zhang, N.; Cai, H. Hot Deformation Behavior and Processing Maps of an As-Cast Al-5Mg-3Zn-1Cu (wt%) Alloy. Materials 2023, 16, 4093. [Google Scholar] [CrossRef] [PubMed]

- Dursun, T.; Soutis, C. Recent developments in advanced aircraft aluminium alloys. Mater. Des. 2014, 56, 862–871. [Google Scholar] [CrossRef]

- Wanhill, R.J.H.; Bray, G.H. Aerostructural design and its application to aluminum–lithium alloys. In Aluminum-Lithium Alloys; Prasad, N.E., Gokhale, A.A., Wanhill, R.J.H., Eds.; Elsevier: Amsterdam, The Netherlands, 2014; pp. 27–58. [Google Scholar] [CrossRef]

- Kurpiel, S.; Zagórski, K.; Cieślik, J.; Skrzypkowski, K. Investigation of Selected Surface Topography Parameters and Deformation during Milling of Vertical Thin-Walled Structures from Titanium Alloy Ti6Al4V. Materials 2023, 16, 3182. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y. Auxetic Composite Laminates with Through-Thickness Negative Poisson’s Ratio for Mitigating Low Velocity Impact Damage: A Numerical Study. Materials 2022, 15, 6963. [Google Scholar] [CrossRef] [PubMed]

- Hu, Y.; Jiang, R.; Li, X.; Hu, R. Effect of Ultrasonic-Assisted Casting on the Hydrogen and Lithium Content of Al-Li Alloy. Materials 2022, 15, 1081. [Google Scholar] [CrossRef] [PubMed]

- Nayan, N.; Murty, S.N.; Jha, A.K.; Pant, B.; Sharma, S.C.; George, K.M.; Sastry, G.V.S. Mechanical properties of aluminium–copper–lithium alloy AA2195 at cryogenic temperatures. Mater. Des. 2014, 58, 445–450. [Google Scholar] [CrossRef]

- Walsh, D.W.; Gibbs, D.B. Weldability Study of Aluminum Alloys Using Weld Simulation and Complimentary Variable Restraint Testing. Mater. Sci. Forum 2010, 638–642, 3799–3804. [Google Scholar] [CrossRef]

- Çam, G.; Mistikoglu, S. Recent developments in friction stir welding of al-Alloys. J. Mater. Eng. Perform. 2014, 23, 1936–1953. [Google Scholar] [CrossRef]

- He, X.; Gu, F.; Ball, A. A review of numerical analysis of friction stir welding. Prog. Mater. Sci. 2014, 65, 1–66. [Google Scholar] [CrossRef]

- Wen, Q.; Guo, R.; Song, Q.; Dong, Z.; Liu, G.; Huang, R.; Yang, K. Active-passive filling friction stir repairing of casting defects in ZL210 aluminum alloys. Int. J. Adv. Manuf. Technol. 2020, 106, 5307–5315. [Google Scholar] [CrossRef]

- Ma, Z.Y.; Feng, A.H.; Chen, D.L.; Shen, J. Recent Advances in Friction Stir Welding/Processing of Aluminum Alloys: Microstructural Evolution and Mechanical Properties. Crit. Rev. Solid State Mater. Sci. 2018, 43, 269–333. [Google Scholar] [CrossRef]

- Peng, C.; Jing, C.; Siyi, Q.; Siqi, Z.; Shoubo, S.; Ting, J.; Zhiqing, Z.; Zhihong, J.; Qing, L. Friction stir welding joints of 2195-T8 Al–Li alloys: Correlation of temperature evolution, microstructure and mechanical properties. Mater. Sci. Eng. A 2021, 823, 141501. [Google Scholar] [CrossRef]

- Suresh, M.; Kalsar, R.; More, A.M.; Bisht, A.; Nayan, N.; Suwas, S. Evolution of microstructure and texture in the third generation Al–Li alloy AA2195 during warm hybrid processing. J. Alloys Compd. 2021, 855, 156750. [Google Scholar] [CrossRef]

- Meng, X.C.; Huang, Y.X.; Cao, J.; Shen, J.J.; dos Santos, J.F. Recent progress on control strategies for inherent issues in friction stir welding. Prog. Mater. Sci. 2021, 115, 100706. [Google Scholar] [CrossRef]

- Du, B.; Sun, Z.; Yang, X.; Cui, L.; Song, J.; Zhang, Z. Characteristics of friction plug welding to 10 mm thick AA2219-T87 sheet: Weld formation, microstructure and mechanical property. Mater. Sci. Eng. A 2016, 654, 21–29. [Google Scholar] [CrossRef]

- Du, B.; Yang, X.; Tang, W.; Sun, Z. Numerical analyses of material flows and thermal processes during friction plug welding for AA2219 aluminum alloy. J. Mater. Process. Technol. 2020, 278, 116466. [Google Scholar] [CrossRef]

- Metz, D.F.; Weishaupt, E.R.; Barkey, M.E.; Fairbee, B.S. A Microstructure and Microhardness Characterization of a Friction Plug Weld in Friction Stir Welded 2195 Al-Li. J. Eng. Mater. Technol. 2012, 134, 021005. [Google Scholar] [CrossRef]

- Metz, D.F.; Barkey, M.E. Fatigue behavior of friction plug welds in 2195 Al–Li alloy. Int. J. Fatigue 2012, 43, 178–187. [Google Scholar] [CrossRef]

- Liu, H.; Liu, Z.; Ji, S.; Yue, Y.; Dong, Z.; Chen, C. Active-passive radial-additive friction stir repairing of mechanical hole out of dimension tolerance of AZ31 magnesium alloy. J. Magnes. Alloys 2023, 11, 3186–3199. [Google Scholar] [CrossRef]

- Ji, S.; Meng, X.; Zeng, Y.; Ma, L.; Gao, S. New technique for eliminating keyhole by active-passive filling friction stir repairing. Mater. Des. 2016, 97, 175–182. [Google Scholar] [CrossRef]

- Han, B.; Huang, Y.; Lv, S.; Wan, L.; Feng, J.; Fu, G. AA7075 bit for repairing AA2219 keyhole by filling friction stir welding. Mater. Des. 2013, 51, 25–33. [Google Scholar] [CrossRef]

- Zhang, P.; Chen, C.; Zhang, C.; Cao, Y.; Li, S.; Li, F.; Jiang, H.; Zhao, S. Novel technique of friction extrusion self-refilling for repairing keyhole of flat clinched joint. Int. J. Mech. Sci. 2022, 233, 107658. [Google Scholar] [CrossRef]

- GB/T2651-2008; Destructive Tests on Welds in Materials-Transverse Tensile Test. National Standards of People’s Republic of China: Beijing, China, 2023.

- Kang, S.J.; Kim, T.H.; Yang, C.W.; Lee, J.I.; Park, E.S.; Noh, T.W.; Kim, M. Atomic structure and growth mechanism of T1 precipitate in Al-Cu-Li-Mg-Ag alloy. Scr. Mater. 2015, 109, 68–71. [Google Scholar] [CrossRef]

- Rodríguez-Veiga, A.; Bellón, B.; Papadimitriou, I.; Esteban-Manzanares, G.; Sabirov, I.; LLorca, J. A multidisciplinary approach to study precipitation kinetics and hardening in an Al-4Cu (wt. %) alloy. J. Alloys Compd. 2018, 757, 504–519. [Google Scholar] [CrossRef]

- Naing, T.H.; Muangjunburee, P. Effect of Conventional and Pulsed TIG Welding on Microstructural and Mechanical Characteristics of AA 6082-T6 Repair Welds. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2023, 38, 865–876. [Google Scholar] [CrossRef]

| Cu | Li | Ag | Mg | Zr | Al |

|---|---|---|---|---|---|

| 4.00 | 1.00 | 0.27 | 0.25 | 0.11 | Bal. |

| Location | Al | Cu | Zr |

|---|---|---|---|

| A | 60.46 | 38.41 | 1.13 |

| B | 75.69 | 23.92 | 0.39 |

| C | 87.24 | 12.77 | -- |

| D | 59.54 | 39.61 | 0.85 |

| E | 87.61 | 11.89 | 0.50 |

| State | Tensile Strength/MPa | Elongation/% |

|---|---|---|

| Sound FSW joints | 395 ± 3.1 | 3.5 ± 0.2 |

| TIG | 215 ± 4.5 | 3.0 ± 0.1 |

| TIG + FSP | 283 ± 5.5 | 3.7 ± 0.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, X.; Chen, X.; Han, Z.; Yuan, J.; Xie, Y.; Dong, J.; Xia, P.; Huang, Y. New Technique to Repair Keyhole of 2195 Al-Li Alloy Friction Stir Welding Joints. Materials 2024, 17, 3418. https://doi.org/10.3390/ma17143418

Meng X, Chen X, Han Z, Yuan J, Xie Y, Dong J, Xia P, Huang Y. New Technique to Repair Keyhole of 2195 Al-Li Alloy Friction Stir Welding Joints. Materials. 2024; 17(14):3418. https://doi.org/10.3390/ma17143418

Chicago/Turabian StyleMeng, Xiangchen, Xi Chen, Zhulin Han, Jingyu Yuan, Yuming Xie, Jihong Dong, Peiyun Xia, and Yongxian Huang. 2024. "New Technique to Repair Keyhole of 2195 Al-Li Alloy Friction Stir Welding Joints" Materials 17, no. 14: 3418. https://doi.org/10.3390/ma17143418