Progress on Material Design and Device Fabrication via Coupling Photothermal Effect with Thermoelectric Effect

Abstract

1. Introduction

2. Photothermal Conversion Materials

2.1. Metallic Nanomaterials

2.2. Metal Oxide Nanoparticles

2.3. Carbon-Based Nanomaterials

3. Thermoelectric Materials

3.1. Electronic Thermoelectric Materials

3.2. Ionic Thermoelectric Materials

3.3. Thermo-Electrochemical Cells

4. Applications of Photothermoelectric Devices

4.1. Sensors

4.2. Thermoelctric Cells

4.3. Generators

4.4. Wearable Fabric

4.5. Multi-Effect Devices

| Photothermal Layer | Thermoelectric Layer | Simulated Sunlight Intensity (mW cm−2) | Output Voltage and Current |

|---|---|---|---|

| PC sponge/copper foil (CNTs/PDMS) | +TC PVA (Fe2+/Fe3+/Na/Cl) | 100 | 21.8 mV [96] |

| Mxene | GG-Ca2+/PHEAA/Mxene | 2000 | —— [97] |

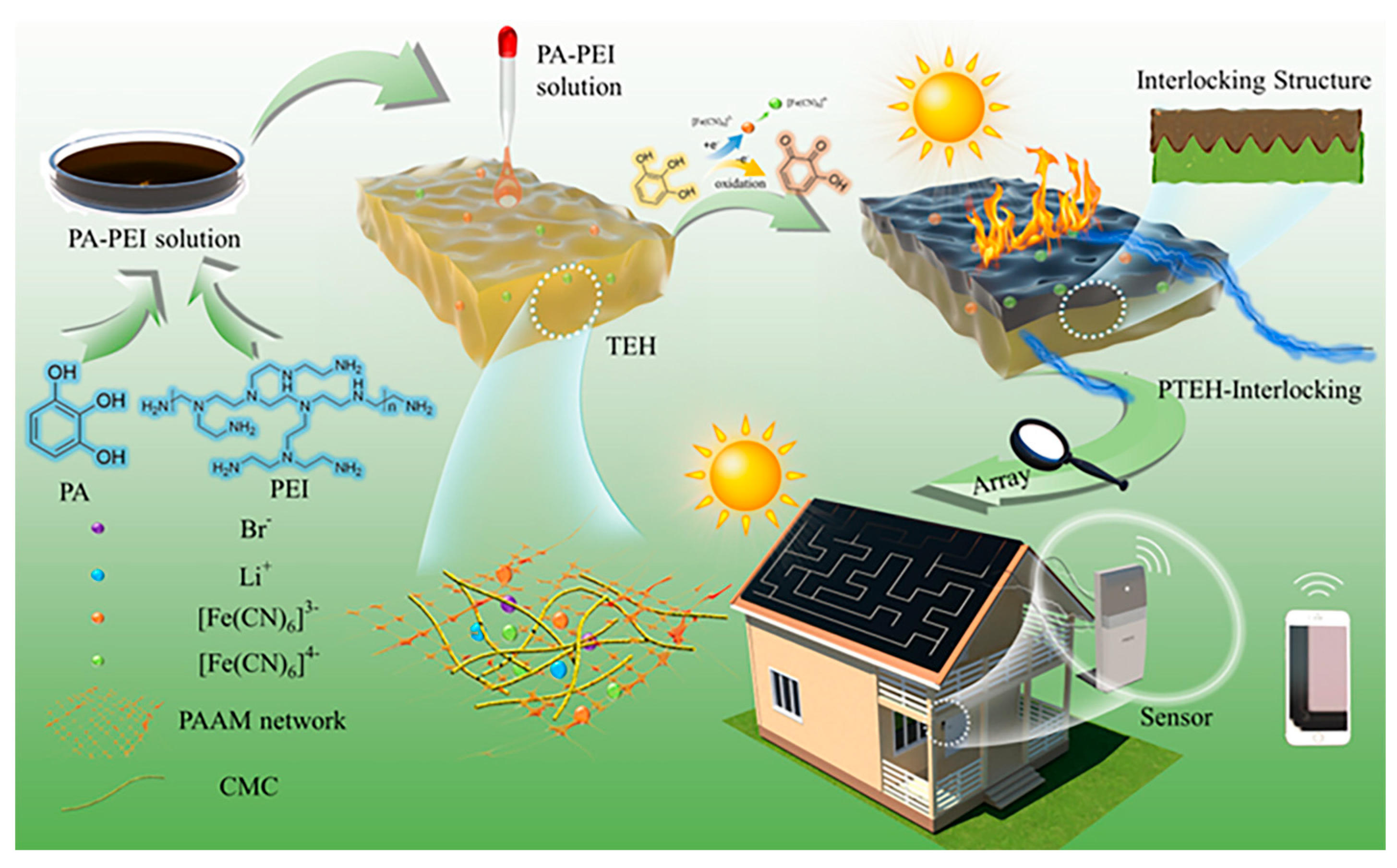

| PA-PEI-Fe | TEH (PAAm/CMC/Fe(CN)63−/4−) | 100 | >20 mV [102] |

| PBI_AAO/CdS | Ag electrodes/CdS | Human Finger (a LWIR under low-power radiation) | 60.2 pA [103] |

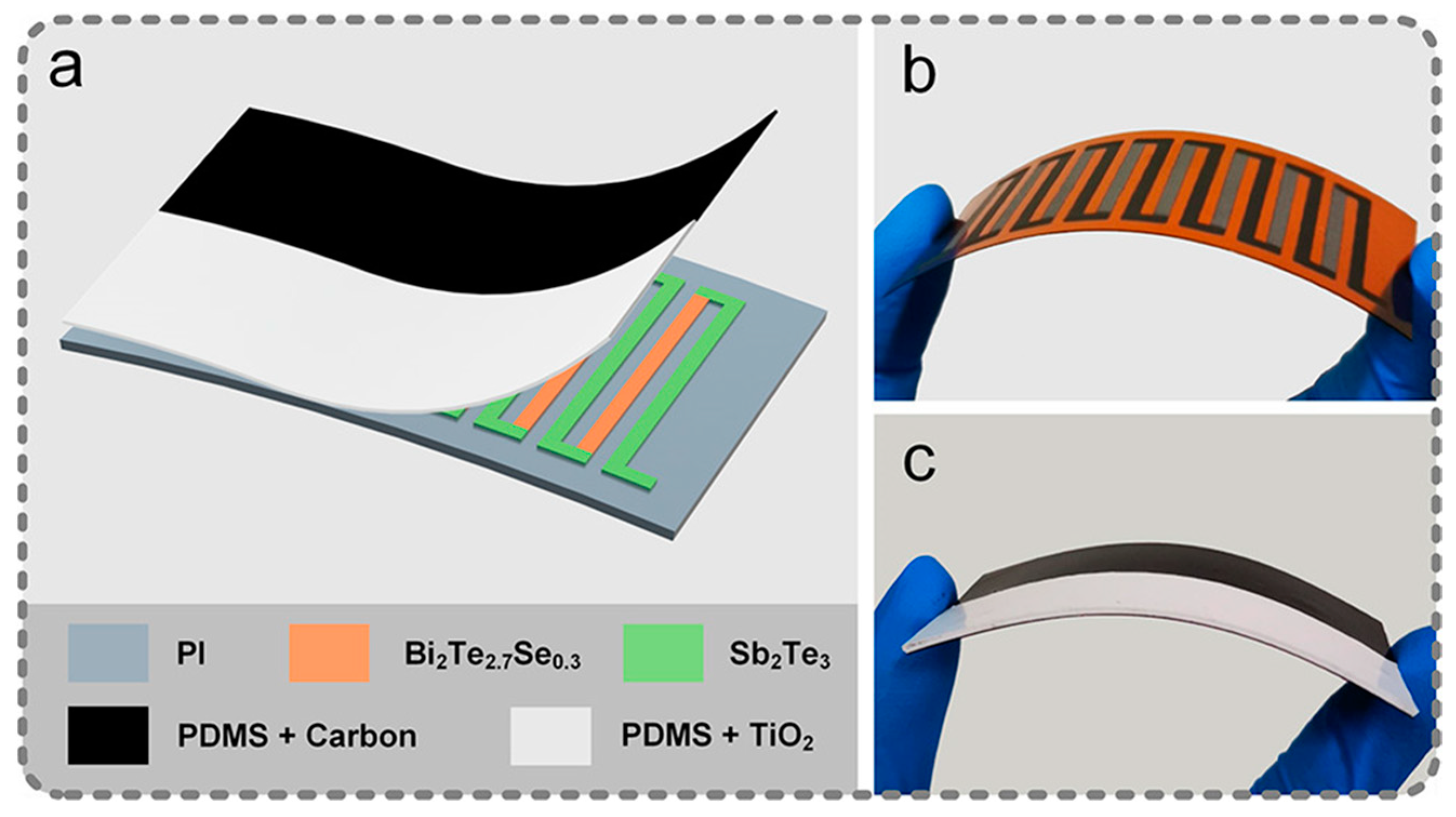

| Carbon power/PDMS, TiO2/PDMS | Bi2Te2.7Se0.3/Sb2Te3 | 40 | 116.2 mV [104] |

| PEDOT:PSS | P_IL_SiO2+ (PEDOT: PSS/IL/SiO2+) | 186.8 | ~0.8 mV, 50 μA [23] |

| PPy | PEDOT: Tos | Body Heat and Solar | 0.667 mV [27] |

| PAN@SiO2 nanofiber film | PEDOT: Tos | Sunlight | 0.56 mV [105] |

| PPy | PEDOT/CuI | Body Heat and Solar | 0.51 V [106] |

5. Summary and Outlook

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Yun, J.-S.; Choi, S.; Im, S.H. Advances in carbon-based thermoelectric materials for high-performance, flexible thermoelectric devices. Carbon Energy 2021, 3, 667–708. [Google Scholar] [CrossRef]

- Dincer, I. Renewable energy and sustainable development: A crucial review. Renew. Sustain. Energy Rev. 2000, 4, 157–175. [Google Scholar] [CrossRef]

- Zhang, X.; Ma, C.; Song, X.; Zhou, Y.; Chen, W. The impacts of wind technology advancement on future global energy. Appl. Energy 2016, 184, 1033–1037. [Google Scholar] [CrossRef]

- Terrapon-Pfaff, J.C.; Ortiz, W.; Viebahn, P.; Kynast, E.; Flörke, M. Water Demand Scenarios for Electricity Generation at the Global and Regional Levels. Water 2020, 12, 2482. [Google Scholar] [CrossRef]

- Zheng, Q.; Tang, Q.; Wang, Z.L.; Li, Z. Self-powered cardiovascular electronic devices and systems. Nat. Rev. Cardiol. 2021, 18, 7–21. [Google Scholar] [CrossRef] [PubMed]

- Zeng, X.; Peng, R.; Fan, Z.; Lin, Y. Self-powered and wearable biosensors for healthcare. Mater. Today Energy 2022, 23, 100900. [Google Scholar] [CrossRef]

- Davis, S.J.; Lewis, N.S.; Shaner, M.; Aggarwal, S.; Arent, D.; Azevedo, I.L.; Benson, S.M.; Bradley, T.; Brouwer, J.; Chiang, Y.-M.; et al. Net-zero emissions energy systems. Science 2018, 360, 1419–1429. [Google Scholar] [CrossRef] [PubMed]

- Basko, D. A Photothermoelectric Effect in Graphene. Science 2011, 334, 610–611. [Google Scholar] [CrossRef] [PubMed]

- Guo, Q.; Yuan, F.; Zhang, B.; Zhou, S.; Zhang, J.; Bai, Y.; Fan, L.; Hayat, T.; Alsaedi, A.; Tan, Z.A. Passivation of the grain boundaries of CH3NH3PbI3 using carbon quantum dots for highly efficient perovskite solar cells with excellent environmental stability. Nanoscale 2019, 11, 115–124. [Google Scholar] [CrossRef]

- Su, P.; Liu, Y.; Zhang, J.; Chen, C.; Yang, B.; Zhang, C.; Zhao, X. Pb-Based Perovskite Solar Cells and the Underlying Pollution behind Clean Energy: Dynamic Leaching of Toxic Substances from Discarded Perovskite Solar Cells. J. Phys. Chem. Lett. 2020, 11, 2812–2817. [Google Scholar] [CrossRef]

- Zhou, W.; Fan, Q.; Zhang, Q.; Cai, L.; Li, K.; Gu, X.; Yang, F.; Zhang, N.; Wang, Y.; Liu, H.; et al. High-performance and compact-designed flexible thermoelectric modules enabled by a reticulate carbon nanotube architecture. Nat. Commun. 2017, 8, 14886. [Google Scholar] [CrossRef] [PubMed]

- Lan, X.; Liu, Y.; Xu, J.; Liu, C.; Liu, P.; Liu, C.; Zhou, W.; Jiang, F. p–n hybrid bulk heterojunction enables enhanced photothermoelectric performance with UV-Vis-NIR light. Nanoscale 2022, 14, 18003–18009. [Google Scholar] [CrossRef] [PubMed]

- Tsai, C.-H.; Tung, S.-H.; Lin, J.-M.; Liu, C.-L. A PEDOT:PSS nanocomposite film doped with black phosphorus modified with silver nanoparticles for wearable photothermoelectric generators. J. Mater. Chem. A 2023, 11, 24890–24901. [Google Scholar] [CrossRef]

- Zheng, Y.; Hatzell, K.B. Technoeconomic analysis of solar thermal desalination. Desalination 2020, 474, 114168. [Google Scholar] [CrossRef]

- Abdelghani-Idrissi, M.A.; Khalfallaoui, S.; Seguin, D.; Vernières-Hassimi, L.; Leveneur, S. Solar tracker for enhancement of the thermal efficiency of solar water heating system. Renew. Energy 2018, 119, 79–94. [Google Scholar] [CrossRef]

- Lei, C.; Guo, Y.; Guan, W.; Yu, G. Polymeric materials for solar water purification. J. Polym. Sci. 2021, 59, 3084–3099. [Google Scholar] [CrossRef]

- Aqachmar, Z.; Ben Sassi, H.; Lahrech, K.; Barhdadi, A. Solar technologies for electricity production: An updated review. Int. J. Hydrogen Energy 2021, 46, 30790–30817. [Google Scholar] [CrossRef]

- Nardekar, S.S.; Krishnamoorthy, K.; Pazhamalai, P.; Sahoo, S.; Jae Kim, S. MoS2 quantum sheets-PVDF nanocomposite film based self-poled piezoelectric nanogenerators and photovoltaically self-charging power cell. Nano Energy 2022, 93, 106869. [Google Scholar] [CrossRef]

- Ding, T.; Zhou, Y.; Wang, X.-Q.; Zhang, C.; Li, T.; Cheng, Y.; Lu, W.; He, J.; Ho, G.W. All-Soft and Stretchable Thermogalvanic Gel Fabric for Antideformity Body Heat Harvesting Wearable. Adv. Energy Mater. 2021, 11, 2102219. [Google Scholar] [CrossRef]

- Dresselhaus, M.S.; Chen, G.; Tang, M.Y.; Yang, R.G.; Lee, H.; Wang, D.Z.; Ren, Z.F.; Fleurial, J.P.; Gogna, P. New Directions for Low-Dimensional Thermoelectric Materials. Adv. Mater. 2007, 19, 1043–1053. [Google Scholar] [CrossRef]

- Bonetti, M.; Nakamae, S.; Roger, M.; Guenoun, P. Huge Seebeck coefficients in nonaqueous electrolytes. J. Chem. Phys. 2011, 134, 114513. [Google Scholar] [CrossRef]

- Abol-Fotouh, D.; Dörling, B.; Zapata-Arteaga, O.; Rodríguez-Martínez, X.; Gómez, A.; Reparaz, J.S.; Laromaine, A.; Roig, A.; Campoy-Quiles, M. Farming thermoelectric paper. Energy Environ. Sci. 2019, 12, 716–726. [Google Scholar] [CrossRef]

- Tang, X.-H.; Jin, X.-Z.; Zhang, Q.; Zhao, Q.; Yang, Z.-Y.; Fu, Q. Achieving Free-Standing PEDOT:PSS Solar Generators with Efficient All-in-One Photothermoelectric Conversion. ACS Appl. Mater. Interfaces 2023, 15, 23286–23298. [Google Scholar] [CrossRef]

- Chen, G.; Xu, W.; Zhu, D. Recent advances in organic polymer thermoelectric composites. J. Mater. Chem. C 2017, 5, 4350–4360. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, W.; Pradel, K.C.; Zhu, G.; Zhou, Y.; Zhang, Y.; Hu, Y.; Lin, L.; Wang, Z.L. Pyroelectric Nanogenerators for Harvesting Thermoelectric Energy. Nano Lett. 2012, 12, 2833–2838. [Google Scholar] [CrossRef] [PubMed]

- Kraemer, D.; Poudel, B.; Feng, H.-P.; Caylor, J.C.; Yu, B.; Yan, X.; Ma, Y.; Wang, X.; Wang, D.; Muto, A.; et al. High-performance flat-panel solar thermoelectric generators with high thermal concentration. Nat. Mater. 2011, 10, 532–538. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Li, T.-T.; Ren, H.-T.; Peng, H.-K.; Shiu, B.-C.; Wang, Y.; Lou, C.-W.; Lin, J.-H. Dual-Shell Photothermoelectric Textile Based on a PPy Photothermal Layer for Solar Thermal Energy Harvesting. ACS Appl. Mater. Interfaces 2020, 12, 55072–55082. [Google Scholar] [CrossRef] [PubMed]

- Kim, B.; Han, M.; Kim, E. Photothermally powered conductive films for absorber-free solar thermoelectric harvesting. J. Mater. Chem. A 2019, 7, 2066–2074. [Google Scholar] [CrossRef]

- Oh, J.Y.; Lee, J.H.; Han, S.W.; Chae, S.S.; Bae, E.J.; Kang, Y.H.; Choi, W.J.; Cho, S.Y.; Lee, J.-O.; Baik, H.K.; et al. Chemically exfoliated transition metal dichalcogenide nanosheet-based wearable thermoelectric generators. Energy Environ. Sci. 2016, 9, 1696–1705. [Google Scholar] [CrossRef]

- Jin, X.-Z.; Li, H.; Wang, Y.; Yang, Z.-Y.; Qi, X.-D.; Yang, J.-H.; Wang, Y. Ultraflexible PEDOT:PSS/Helical Carbon Nanotubes Film for All-in-One Photothermoelectric Conversion. ACS Appl. Mater. Interfaces 2022, 14, 27083–27095. [Google Scholar] [CrossRef]

- Tyagi, V.V.; Kaushik, S.C.; Tyagi, S.K. Advancement in solar photovoltaic/thermal (PV/T) hybrid collector technology. Renew. Sustain. Energy Rev. 2012, 16, 1383–1398. [Google Scholar] [CrossRef]

- Buker, M.S.; Riffat, S.B. Building integrated solar thermal collectors—A review. Renew. Sustain. Energy Rev. 2015, 51, 327–346. [Google Scholar] [CrossRef]

- Kumar, A.; Baredar, P.; Qureshi, U. Historical and recent development of photovoltaic thermal (PVT) technologies. Renew. Sustain. Energy Rev. 2015, 42, 1428–1436. [Google Scholar] [CrossRef]

- Ullah, I.; Rasul, M.G. Recent Developments in Solar Thermal Desalination Technologies: A Review. Energies 2019, 12, 119. [Google Scholar] [CrossRef]

- Geng, S.; Zhao, H.; Zhan, G.; Zhao, Y.; Yang, X. Injectable in Situ Forming Hydrogels of Thermosensitive Polypyrrole Nanoplatforms for Precisely Synergistic Photothermo-Chemotherapy. ACS Appl. Mater. Interfaces 2020, 12, 7995–8005. [Google Scholar] [CrossRef] [PubMed]

- Yu, W.; Li, X.; Huang, Y.; Chen, Y.; Gao, Q.; Wang, Y.; Ji, J. Build an implanted “arsenal”: Detachable microneedles for NIR-triggered cancer photothermo-chemotherapy. Biomater. Sci. 2021, 9, 4737–4745. [Google Scholar] [CrossRef] [PubMed]

- Hasnain, S.M. Review on sustainable thermal energy storage technologies, Part I: Heat storage materials and techniques. Energy Convers. Manag. 1998, 39, 1127–1138. [Google Scholar] [CrossRef]

- Sarı, A.; Ouikhalfan, M.; Chehouani, H.; Hekimoğlu, G.; Bicer, A.; Al-Ahmed, A.; Al-Sulaiman, F.A.; Tyagi, V.V. Form-Stabilized Polyethylene Glycol/Palygorskite Composite Phase Change Material: Thermal Energy Storage Properties, Cycling Stability, and Thermal Durability. Polym. Eng. Sci. 2020, 60, 909–916. [Google Scholar] [CrossRef]

- Tao, Y.B.; He, Y.-L. A review of phase change material and performance enhancement method for latent heat storage system. Renew. Sustain. Energy Rev. 2018, 93, 245–259. [Google Scholar] [CrossRef]

- Rycenga, M.; Cobley, C.M.; Zeng, J.; Li, W.; Moran, C.H.; Zhang, Q.; Qin, D.; Xia, Y. Controlling the Synthesis and Assembly of Silver Nanostructures for Plasmonic Applications. Chem. Rev. 2011, 111, 3669–3712. [Google Scholar] [CrossRef]

- Haes, A.J.; Van Duyne, R.P. A unified view of propagating and localized surface plasmon resonance biosensors. Anal. Bioanal. Chem. 2004, 379, 920–930. [Google Scholar] [CrossRef] [PubMed]

- Mallah, A.R.; Zubir, M.N.M.; Alawi, O.A.; Kazi, S.N.; Ahmed, W.; Sadri, R.; Kasaeian, A. Experimental study on the effects of multi-resonance plasmonic nanoparticles for improving the solar collector efficiency. Renew. Energy 2022, 187, 1204–1223. [Google Scholar] [CrossRef]

- Gong, H.; Shao, W.; Ma, X.; Cui, Z. Absorption properties of a multilayer composite nanoparticle for solar thermal utilization. Opt. Laser Technol. 2022, 150, 107914. [Google Scholar] [CrossRef]

- Gupta, V.K.; Kumar, S.; Kukreja, R.; Chander, N.; Ravi, R.K. Real-time thermal performance investigation of a thermal energy storage integrated direct absorption solar collector under tropical climate. Energy Storage 2024, 6, e567. [Google Scholar] [CrossRef]

- Toroker, M.C.; Carter, E.A. Transition metal oxide alloys as potential solar energy conversion materials. J. Mater. Chem. A 2013, 1, 2474–2484. [Google Scholar] [CrossRef]

- Moghaieb, H.S.; Amendola, V.; Khalil, S.; Chakrabarti, S.; Maguire, P.; Mariotti, D. Nanofluids for Direct-Absorption Solar Collectors—DASCs: A Review on Recent Progress and Future Perspectives. Nanomaterials 2023, 13, 1232. [Google Scholar] [CrossRef]

- Gupta, H.K.; Agrawal, G.D.; Mathur, J. An experimental investigation of a low temperature Al2O3-H2O nanofluid based direct absorption solar collector. Sol. Energy 2015, 118, 390–396. [Google Scholar] [CrossRef]

- Karami, M.; Akhavan-Bahabadi, M.A.; Delfani, S.; Raisee, M. Experimental investigation of CuO nanofluid-based Direct Absorption Solar Collector for residential applications. Renew. Sustain. Energy Rev. 2015, 52, 793–801. [Google Scholar] [CrossRef]

- Balakin, B.V.; Stava, M.; Kosinska, A. Photothermal convection of a magnetic nanofluid in a direct absorption solar collector. Sol. Energy 2022, 239, 33–39. [Google Scholar] [CrossRef]

- Sreekumar, S.; Joseph, A.; Sujith Kumar, C.S.; Thomas, S. Investigation on influence of antimony tin oxide/silver nanofluid on direct absorption parabolic solar collector. J. Clean. Prod. 2020, 249, 119378. [Google Scholar] [CrossRef]

- Balandin, A.A. Thermal properties of graphene and nanostructured carbon materials. Nat. Mater. 2011, 10, 569–581. [Google Scholar] [CrossRef]

- Murshed, S.M.S.; Nieto de Castro, C.A. Superior thermal features of carbon nanotubes-based nanofluids—A review. Renew. Sustain. Energy Rev. 2014, 37, 155–167. [Google Scholar] [CrossRef]

- Sadeghinezhad, E.; Mehrali, M.; Saidur, R.; Mehrali, M.; Tahan Latibari, S.; Akhiani, A.R.; Metselaar, H.S.C. A comprehensive review on graphene nanofluids: Recent research, development and applications. Energy Convers. Manag. 2016, 111, 466–487. [Google Scholar] [CrossRef]

- Ahmadi, A.; Ganji, D.D.; Jafarkazemi, F. Analysis of utilizing Graphene nanoplatelets to enhance thermal performance of flat plate solar collectors. Energy Convers. Manag. 2016, 126, 1–11. [Google Scholar] [CrossRef]

- Zeng, J.; Xuan, Y. Enhanced solar thermal conversion and thermal conduction of MWCNT-SiO2/Ag binary nanofluids. Appl. Energy 2018, 212, 809–819. [Google Scholar] [CrossRef]

- Said, Z.; Saidur, R.; Rahim, N.A.; Alim, M.A. Analyses of exergy efficiency and pumping power for a conventional flat plate solar collector using SWCNTs based nanofluid. Energy Build. 2014, 78, 1–9. [Google Scholar] [CrossRef]

- Zhang, Q.; Sun, Y.; Xu, W.; Zhu, D. Organic Thermoelectric Materials: Emerging Green Energy Materials Converting Heat to Electricity Directly and Efficiently. Adv. Mater. 2014, 26, 6829–6851. [Google Scholar] [CrossRef]

- Huo, B.; Kuang, F.; Guo, C.-Y. Design and Optimization Strategies for Flexible Quasi-Solid-State Thermo-Electrochemical Cells. Materials 2023, 16, 6574. [Google Scholar] [CrossRef]

- Tian, Y.; Yang, X.; Li, K.; Zhang, Q.; Li, Y.; Wang, H.; Hou, C. High-performance ionic thermoelectric materials and emerging applications of ionic thermoelectric devices. Mater. Today Energy 2023, 36, 101342. [Google Scholar] [CrossRef]

- Ao, D.; Liu, W.-D.; Ma, F.; Bao, W.; Chen, Y. Post-Electric Current Treatment Approaching High-Performance Flexible n-Type Bi2Te3 Thin Films. Micromachines 2022, 13, 1544. [Google Scholar] [CrossRef] [PubMed]

- Liu, G.; Guo, A.; Cao, F.; Ju, W.; Wang, Z.; Wang, H.; Li, G.-L.; Gao, Z. Ultrahigh thermoelectric performance of Janus α-STe2 and α-SeTe2 monolayers. Phys. Chem. Chem. Phys. 2022, 24, 28295–28305. [Google Scholar] [CrossRef] [PubMed]

- Ryu, B.; Kim, B.; Lee, J.E.; Joo, S.-J.; Min, B.-K.; Lee, H.; Park, S.; Oh, M.-W. Prediction of the band structures of Bi2Te3-related binary and Sb/Se-doped ternary thermoelectric materials. J. Korean Phys. Soc. 2016, 68, 115–120. [Google Scholar] [CrossRef][Green Version]

- Guélou, G.; Lemoine, P.; Raveau, B.; Guilmeau, E. Recent developments in high-performance thermoelectric sulphides: An overview of the promising synthetic colusites. J. Mater. Chem. C 2021, 9, 773–795. [Google Scholar] [CrossRef]

- Baghdadi, N.; Salah, N.; Alshahrie, A.; Ansari, A.R.; Koumoto, K. The effect of morphological modification on the thermoelectric properties of ZnO nanomaterials. Ceram. Int. 2021, 47, 6169–6178. [Google Scholar] [CrossRef]

- Liu, W.-D.; Yang, L.; Chen, Z.-G.; Zou, J. Promising and Eco-Friendly Cu2X-Based Thermoelectric Materials: Progress and Applications. Adv. Mater. 2020, 32, 1905703. [Google Scholar] [CrossRef]

- Zong, P.-A.; Liang, J.; Zhang, P.; Wan, C.; Wang, Y.; Koumoto, K. Graphene-Based Thermoelectrics. ACS Appl. Energy Mater. 2020, 3, 2224–2239. [Google Scholar] [CrossRef]

- Ziouche, K.; Bel-Hadj, I.; Bougrioua, Z. Thermoelectric properties of nanostructured porous-polysilicon thin films. Nano Energy 2021, 80, 105553. [Google Scholar] [CrossRef]

- Nandihalli, N.; Liu, C.-J.; Mori, T. Polymer based thermoelectric nanocomposite materials and devices: Fabrication and characteristics. Nano Energy 2020, 78, 105186. [Google Scholar] [CrossRef]

- Jaldurgam, F.F.; Ahmad, Z.; Touati, F. Low-Toxic, Earth-Abundant Nanostructured Materials for Thermoelectric Applications. Nanomaterials 2021, 11, 895. [Google Scholar] [CrossRef]

- Samanta, M.; Ghosh, T.; Chandra, S.; Biswas, K. Layered materials with 2D connectivity for thermoelectric energy conversion. J. Mater. Chem. A 2020, 8, 12226–12261. [Google Scholar] [CrossRef]

- Chodankar, N.R.; Ji, S.-H.; Han, Y.-K.; Kim, D.-H. Dendritic Nanostructured Waste Copper Wires for High-Energy Alkaline Battery. Nano-Micro Lett. 2019, 12, 1. [Google Scholar] [CrossRef] [PubMed]

- Dolyniuk, J.-A.; Owens-Baird, B.; Wang, J.; Zaikina, J.V.; Kovnir, K. Clathrate thermoelectrics. Mater. Sci. Eng. R Rep. 2016, 108, 1–46. [Google Scholar] [CrossRef]

- Liang, L.; Gao, C.; Chen, G.; Guo, C.-Y. Large-area, stretchable, super flexible and mechanically stable thermoelectric films of polymer/carbon nanotube composites. J. Mater. Chem. C 2016, 4, 526–532. [Google Scholar] [CrossRef]

- Fan, W.; Guo, C.-Y.; Chen, G. Flexible films of poly(3,4-ethylenedioxythiophene)/carbon nanotube thermoelectric composites prepared by dynamic 3-phase interfacial electropolymerization and subsequent physical mixing. J. Mater. Chem. A 2018, 6, 12275–12280. [Google Scholar] [CrossRef]

- Nonoguchi, Y.; Nakano, M.; Murayama, T.; Hagino, H.; Hama, S.; Miyazaki, K.; Matsubara, R.; Nakamura, M.; Kawai, T. Simple Salt-Coordinated n-Type Nanocarbon Materials Stable in Air. Adv. Funct. Mater. 2016, 26, 3021–3028. [Google Scholar] [CrossRef]

- Ding, Z.; Du, C.; Long, W.; Cao, C.-F.; Liang, L.; Tang, L.-C.; Chen, G. Thermoelectrics and thermocells for fire warning applications. Sci. Bull. 2023, 68, 3261–3277. [Google Scholar] [CrossRef] [PubMed]

- Han, S.; Jiao, F.; Khan, Z.U.; Edberg, J.; Fabiano, S.; Crispin, X. Thermoelectric Polymer Aerogels for Pressure–Temperature Sensing Applications. Adv. Funct. Mater. 2017, 27, 1703549. [Google Scholar] [CrossRef]

- Wu, X.; Yin, S.; Guo, C.-Y. Self-Healable and Robust PE/PEDOT/SWCNT Thermoelectric Composites. ACS Appl. Mater. Interfaces 2022, 14, 32056–32065. [Google Scholar] [CrossRef] [PubMed]

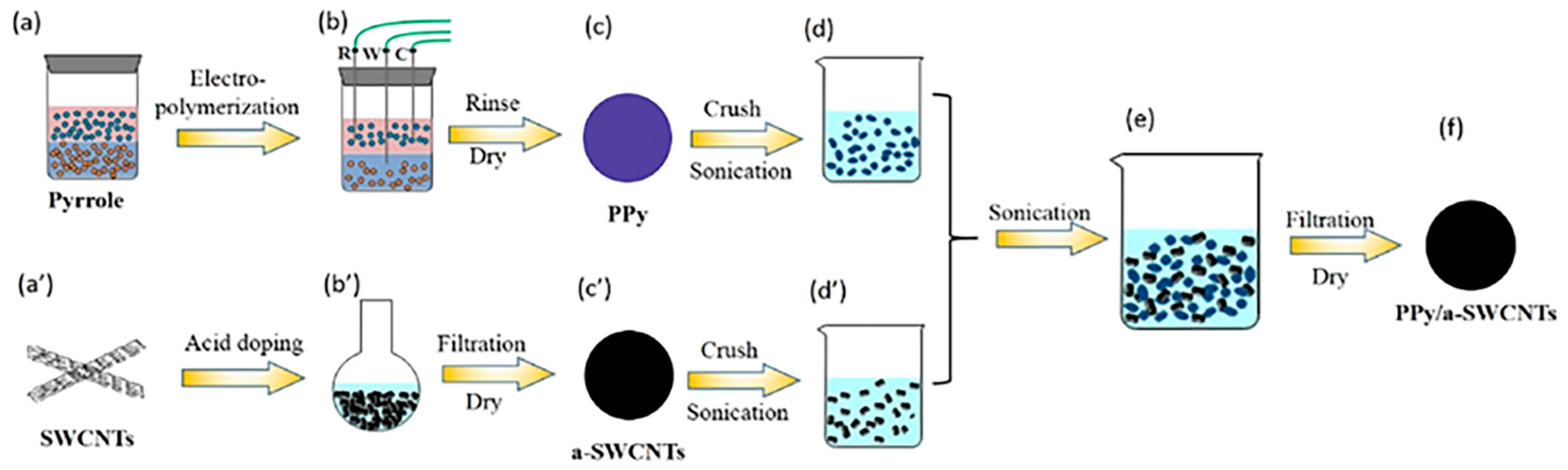

- Fan, W.; Zhang, Y.; Guo, C.-Y.; Chen, G. Toward high thermoelectric performance for polypyrrole composites by dynamic 3-phase interfacial electropolymerization and chemical doping of carbon nanotubes. Compos. Sci. Technol. 2019, 183, 107794. [Google Scholar] [CrossRef]

- Li, Y.; Ai, L.; Luo, Q.; Wu, X.; Li, B.; Guo, C.-Y. Compositing Benzothieno[3,2-b]Benzofuran Derivatives with Single-Walled Carbon Nanotubes for Enhanced Thermoelectric Performance. Molecules 2023, 28, 6519. [Google Scholar] [CrossRef]

- Akbar, Z.A.; Jeon, J.-W.; Jang, S.-Y. Intrinsically self-healable, stretchable thermoelectric materials with a large ionic Seebeck effect. Energy Environ. Sci. 2020, 13, 2915–2923. [Google Scholar] [CrossRef]

- Kim, B.; Na, J.; Lim, H.; Kim, Y.; Kim, J.; Kim, E. Robust High Thermoelectric Harvesting Under a Self-Humidifying Bilayer of Metal Organic Framework and Hydrogel Layer. Adv. Funct. Mater. 2019, 29, 1807549. [Google Scholar] [CrossRef]

- Cheng, H.; He, X.; Fan, Z.; Ouyang, J. Flexible Quasi-Solid State Ionogels with Remarkable Seebeck Coefficient and High Thermoelectric Properties. Adv. Energy Mater. 2019, 9, 1901085. [Google Scholar] [CrossRef]

- Zhao, D.; Wang, H.; Khan, Z.U.; Chen, J.C.; Gabrielsson, R.; Jonsson, M.P.; Berggren, M.; Crispin, X. Ionic thermoelectric supercapacitors. Energy Environ. Sci. 2016, 9, 1450–1457. [Google Scholar] [CrossRef]

- He, X.; Cheng, H.; Yue, S.; Ouyang, J. Quasi-solid state nanoparticle/(ionic liquid) gels with significantly high ionic thermoelectric properties. J. Mater. Chem. A 2020, 8, 10813–10821. [Google Scholar] [CrossRef]

- Kim, T.; Lee, J.S.; Lee, G.; Yoon, H.; Yoon, J.; Kang, T.J.; Kim, Y.H. High thermopower of ferri/ferrocyanide redox couple in organic-water solutions. Nano Energy 2017, 31, 160–167. [Google Scholar] [CrossRef]

- Kim, S.L.; Lin, H.T.; Yu, C. Thermally Chargeable Solid-State Supercapacitor. Adv. Energy Mater. 2016, 6, 1600546. [Google Scholar] [CrossRef]

- Lu, X.; Xie, D.; Zhu, K.; Wei, S.; Mo, Z.; Du, C.; Liang, L.; Chen, G.; Liu, Z. Swift Assembly of Adaptive Thermocell Arrays for Device-Level Healable and Energy-Autonomous Motion Sensors. Nano-Micro Lett. 2023, 15, 196. [Google Scholar] [CrossRef]

- Burmistrov, I.; Gorshkov, N.; Kovyneva, N.; Kolesnikov, E.; Khaidarov, B.; Karunakaran, G.; Cho, E.-B.; Kiselev, N.; Artyukhov, D.; Kuznetsov, D.; et al. High seebeck coefficient thermo-electrochemical cell using nickel hollow microspheres electrodes. Renew. Energy 2020, 157, 1–8. [Google Scholar] [CrossRef]

- Peng, P.; Li, Z.; Xie, D.; Zhu, K.; Du, C.; Liang, L.; Liu, Z.; Chen, G. Aqueous eutectic hydrogel electrolytes enable flexible thermocells with a wide operating temperature range. J. Mater. Chem. A 2023, 11, 6986–6996. [Google Scholar] [CrossRef]

- Lee, K.-T.; Lee, D.-S.; Chen, W.-H.; Lin, Y.-L.; Luo, D.; Park, Y.-K.; Bandala, A. An overview of commercialization and marketization of thermoelectric generators for low-temperature waste heat recovery. iScience 2023, 26, 107874. [Google Scholar] [CrossRef] [PubMed]

- Guo, R.; Zhang, H.; Cao, S.; Cui, X.; Yan, Z.; Sang, S. A self-powered stretchable sensor fabricated by serpentine PVDF film for multiple dynamic monitoring. Mater. Des. 2019, 182, 108025. [Google Scholar] [CrossRef]

- Liu, G.; Chen, J.; Tang, Q.; Feng, L.; Yang, H.; Li, J.; Xi, Y.; Wang, X.; Hu, C. Wireless Electric Energy Transmission through Various Isolated Solid Media Based on Triboelectric Nanogenerator. Adv. Energy Mater. 2018, 8, 1703086. [Google Scholar] [CrossRef]

- Zhao, X.J.; Kuang, S.Y.; Wang, Z.L.; Zhu, G. Highly Adaptive Solid–Liquid Interfacing Triboelectric Nanogenerator for Harvesting Diverse Water Wave Energy. ACS Nano 2018, 12, 4280–4285. [Google Scholar] [CrossRef] [PubMed]

- Mondal, R.; Hasan, M.A.M.; Zhang, R.; Olin, H.; Yang, Y. Nanogenerators-Based Self-Powered Sensors. Adv. Mater. Technol. 2022, 7, 2200282. [Google Scholar] [CrossRef]

- Bai, C.; Zhang, J.; Yang, K.; Zhang, Z.; Zhang, H. A vertical stretchable self-powered light sensor based on thermogalvanic gel electrolyte via photo-thermal-electric conversion. Sens. Actuators A Phys. 2023, 354, 114305. [Google Scholar] [CrossRef]

- Hou, M.; Yu, M.; Liu, W.; Zhang, H.; Wang, Z.; Du, J.; Xu, L.; Li, N.; Xu, J. Mxene hybrid conductive hydrogels with mechanical flexibility, frost-resistance, photothermoelectric conversion characteristics and their multiple applications in sensing. Chem. Eng. J. 2024, 483, 149299. [Google Scholar] [CrossRef]

- Sun, S.; Li, M.; Shi, X.-L.; Chen, Z.-G. Advances in Ionic Thermoelectrics: From Materials to Devices. Adv. Energy Mater. 2023, 13, 2203692. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, L.; Shi, X.-L.; Shi, X.; Chen, L.; Dargusch, M.S.; Zou, J.; Chen, Z.-G. Flexible Thermoelectric Materials and Generators: Challenges and Innovations. Adv. Mater. 2019, 31, 1807916. [Google Scholar] [CrossRef]

- Tian, C.; Bai, C.; Wang, T.; Yan, Z.; Zhang, Z.; Zhuo, K.; Zhang, H. Thermogalvanic hydrogel electrolyte for harvesting biothermal energy enabled by a novel redox couple of SO4/32− ions. Nano Energy 2023, 106, 108077. [Google Scholar] [CrossRef]

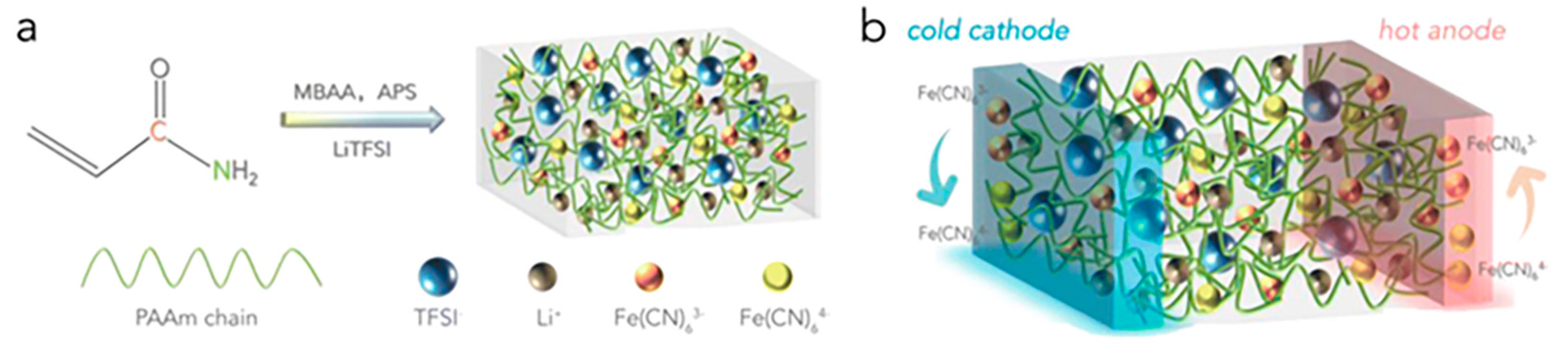

- Shen, J.; Ma, Y.; Yang, C.; Liu, S.; Li, J.; Chen, Z.; Tian, B.; Li, S. Boosting solar-thermal-electric conversion of thermoelectrochemical cells by construction of a carboxymethylcellulose-interpenetrated polyacrylamide network. J. Mater. Chem. A 2022, 10, 7785–7791. [Google Scholar] [CrossRef]

- Shen, J.; Yang, C.; Ma, Y.; Cao, M.; Gao, Z.; Wang, S.; Li, J.; Liu, S.; Chen, Z.; Li, S. Photo-thermo-electric hydrogel with interlocking photothermal layer and hydrogel for enhancement of thermopower generation. EcoMat 2024, 6, e12428. [Google Scholar] [CrossRef]

- Liu, S.; Tian, J.; Wu, S.; Zhang, W.; Luo, M. A bioinspired broadband self-powered photodetector based on photo-pyroelectric-thermoelectric effect able to detect human radiation. Nano Energy 2022, 93, 106812. [Google Scholar] [CrossRef]

- Wen, D.-L.; Liu, X.; Bao, J.-F.; Li, G.-K.; Feng, T.; Zhang, F.; Liu, D.; Zhang, X.-S. Flexible Hybrid Photo-Thermoelectric Generator Based on Single Thermoelectric Effect for Simultaneously Harvesting Thermal and Radiation Energies. ACS Appl. Mater. Interfaces 2021, 13, 21401–21410. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Shiu, B.C.; Li, T.-T.; Liu, X.; Ren, H.-T.; Wang, Y.; Lou, C.-W.; Lin, J.-H. Photo-thermoelectric nanofiber film based on the synergy of conjugated polymer and light traps for the solar-energy harvesting of textile solar panel. Sol. Energy Mater. Sol. Cells 2021, 232, 111353. [Google Scholar] [CrossRef]

- Li, T.-T.; Fan, X.-X.; Zhang, X.; Zhang, X.; Lou, C.-W.; Lin, J.-H. Photothermoelectric Synergistic Hydrovoltaic Effect: A Flexible Photothermoelectric Yarn Panel for Multiple Renewable-Energy Harvesting. ACS Appl. Mater. Interfaces 2023, 15, 57219–57229. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, S.; Huo, B.; Guo, C.-Y. Progress on Material Design and Device Fabrication via Coupling Photothermal Effect with Thermoelectric Effect. Materials 2024, 17, 3524. https://doi.org/10.3390/ma17143524

Liu S, Huo B, Guo C-Y. Progress on Material Design and Device Fabrication via Coupling Photothermal Effect with Thermoelectric Effect. Materials. 2024; 17(14):3524. https://doi.org/10.3390/ma17143524

Chicago/Turabian StyleLiu, Shuang, Bingchen Huo, and Cun-Yue Guo. 2024. "Progress on Material Design and Device Fabrication via Coupling Photothermal Effect with Thermoelectric Effect" Materials 17, no. 14: 3524. https://doi.org/10.3390/ma17143524

APA StyleLiu, S., Huo, B., & Guo, C.-Y. (2024). Progress on Material Design and Device Fabrication via Coupling Photothermal Effect with Thermoelectric Effect. Materials, 17(14), 3524. https://doi.org/10.3390/ma17143524