Influence of Bio-Additives on Recycled Asphalt Pavements

Abstract

:1. Introduction

2. Materials

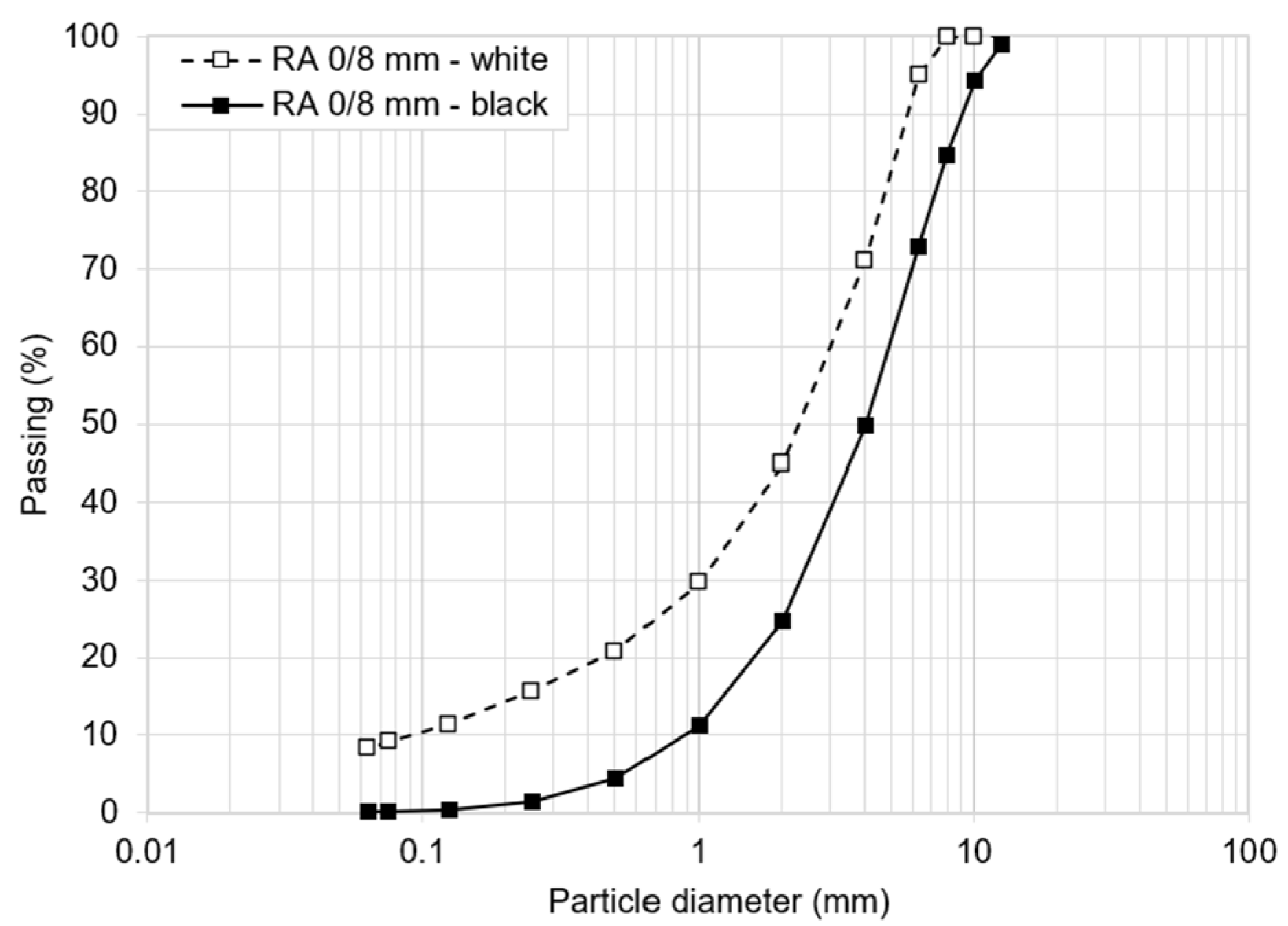

2.1. Aggregates

2.2. Reclaimed Asphalt Pavement

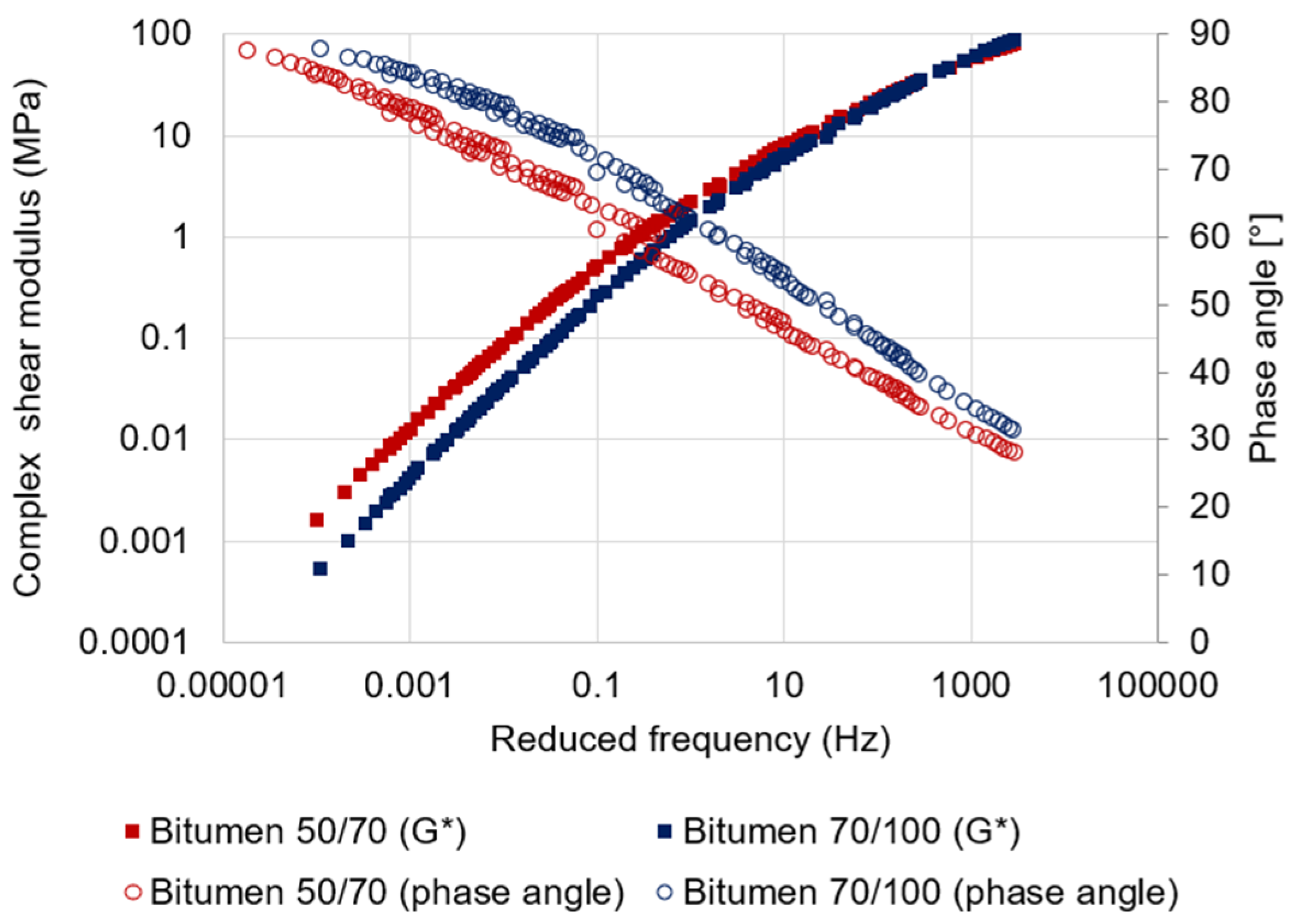

2.3. Bitumen

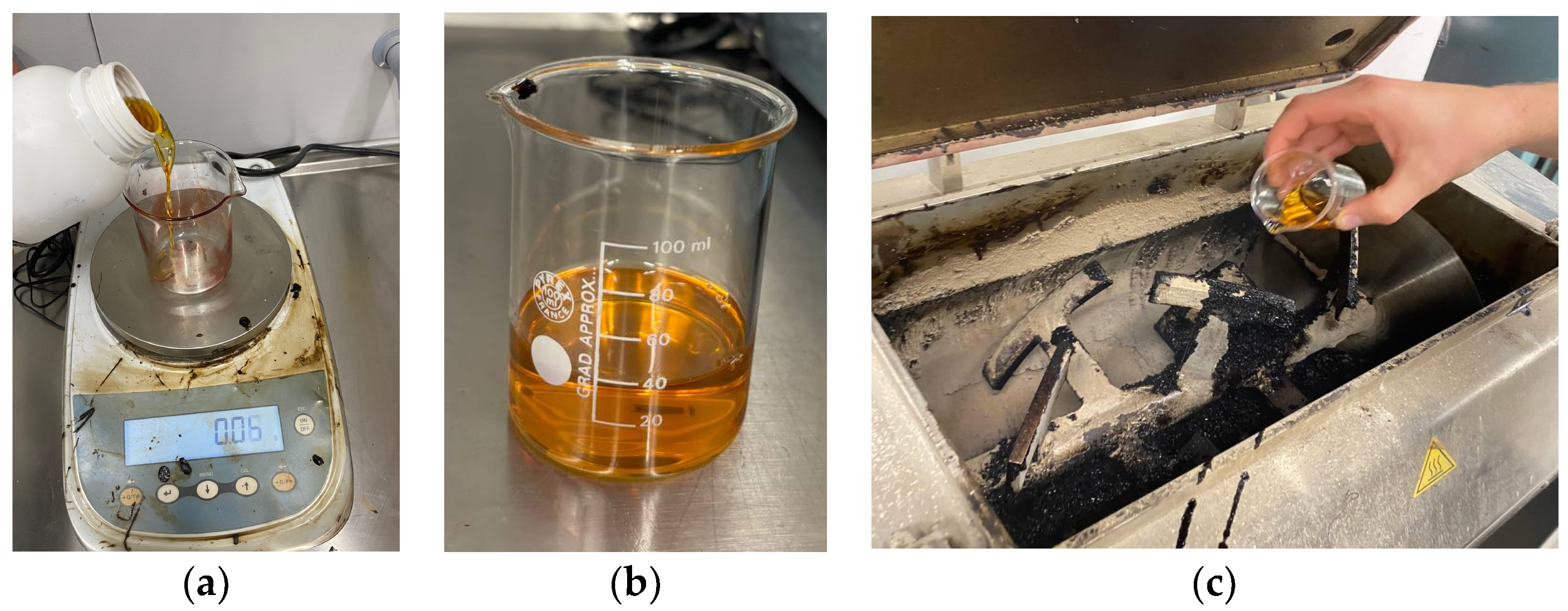

2.4. Bio-Additives

2.5. Asphalt Mixture Preparation

3. Methods

3.1. Air Voids and Workability of Asphalt Mixtures

- C is the self-densification;

- K the compactability;

- n is the gyration number.

3.2. Indirect Tensile Strength

- D is the diameter of the specimen (mm);

- ITS is the indirect tensile strength (MPa);

- Dc is the specimen deformation, measured as the distance between the load strips at failure (mm).

- is the work required to trigger the crack (J);

- is the work required to propagate the crack (J);

- is the diametral surface area where the crack propagates (mm2).

3.3. Indirect Tensile Stiffness Modulus

- F is the peak value of the applied vertical load (N);

- z is the amplitude of the horizontal deformation obtained during the load cycle (mm);

- h is the thickness of the specimen (mm);

- ν is Poisson’s ratio, equal to 0.35.

3.4. Rutting

4. Results

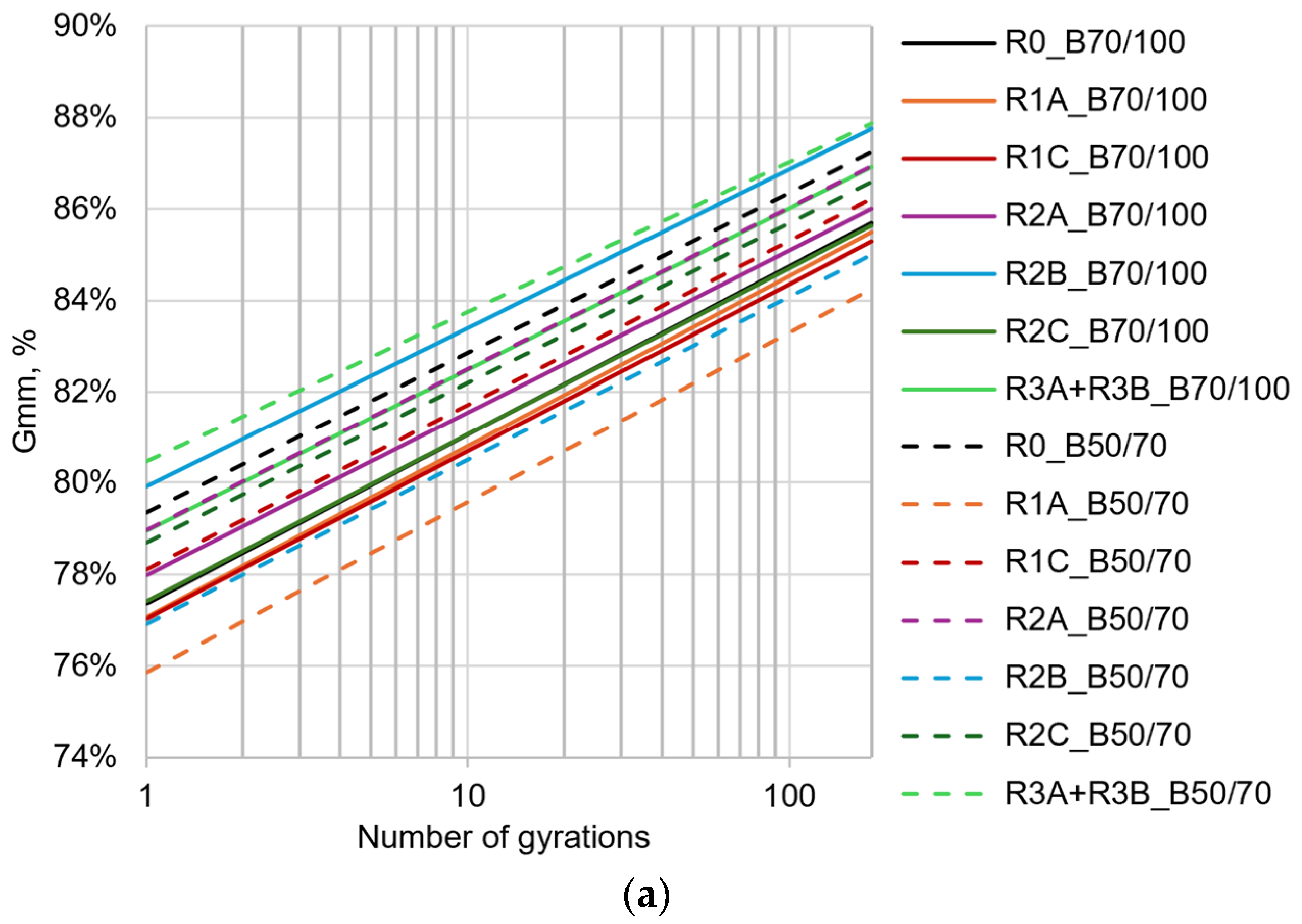

4.1. Workability

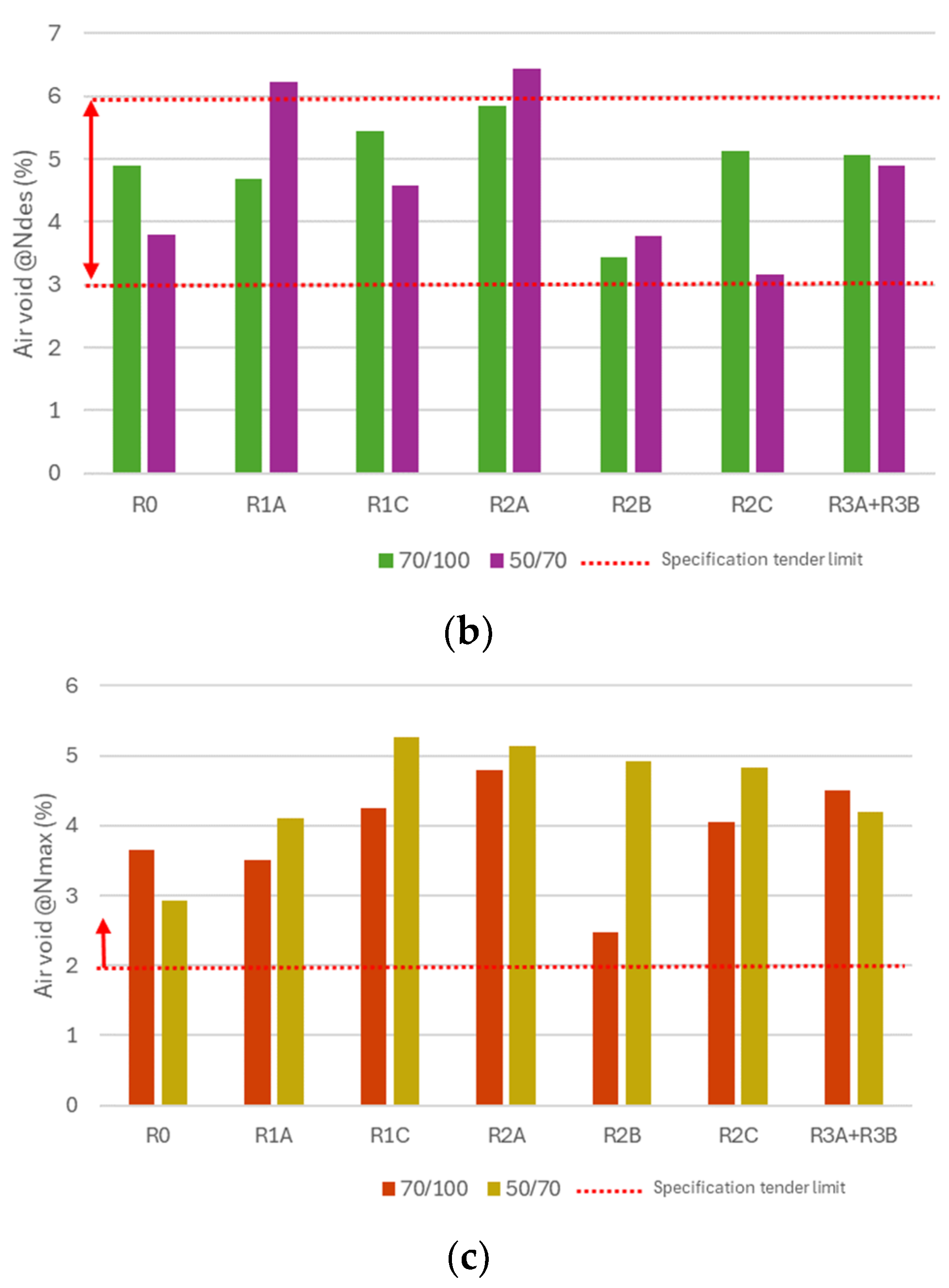

4.2. Air Voids

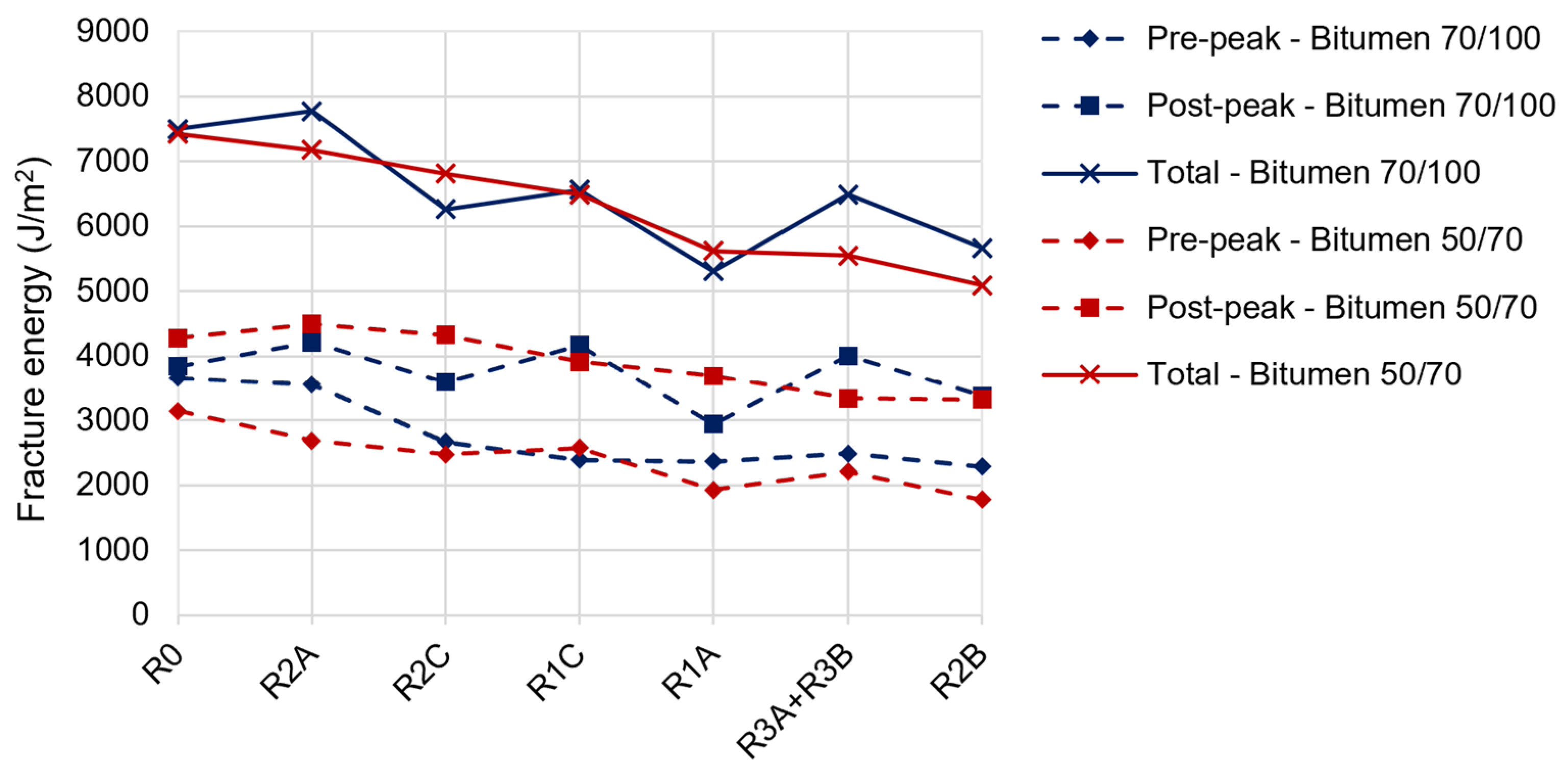

4.3. Mechanical Performance

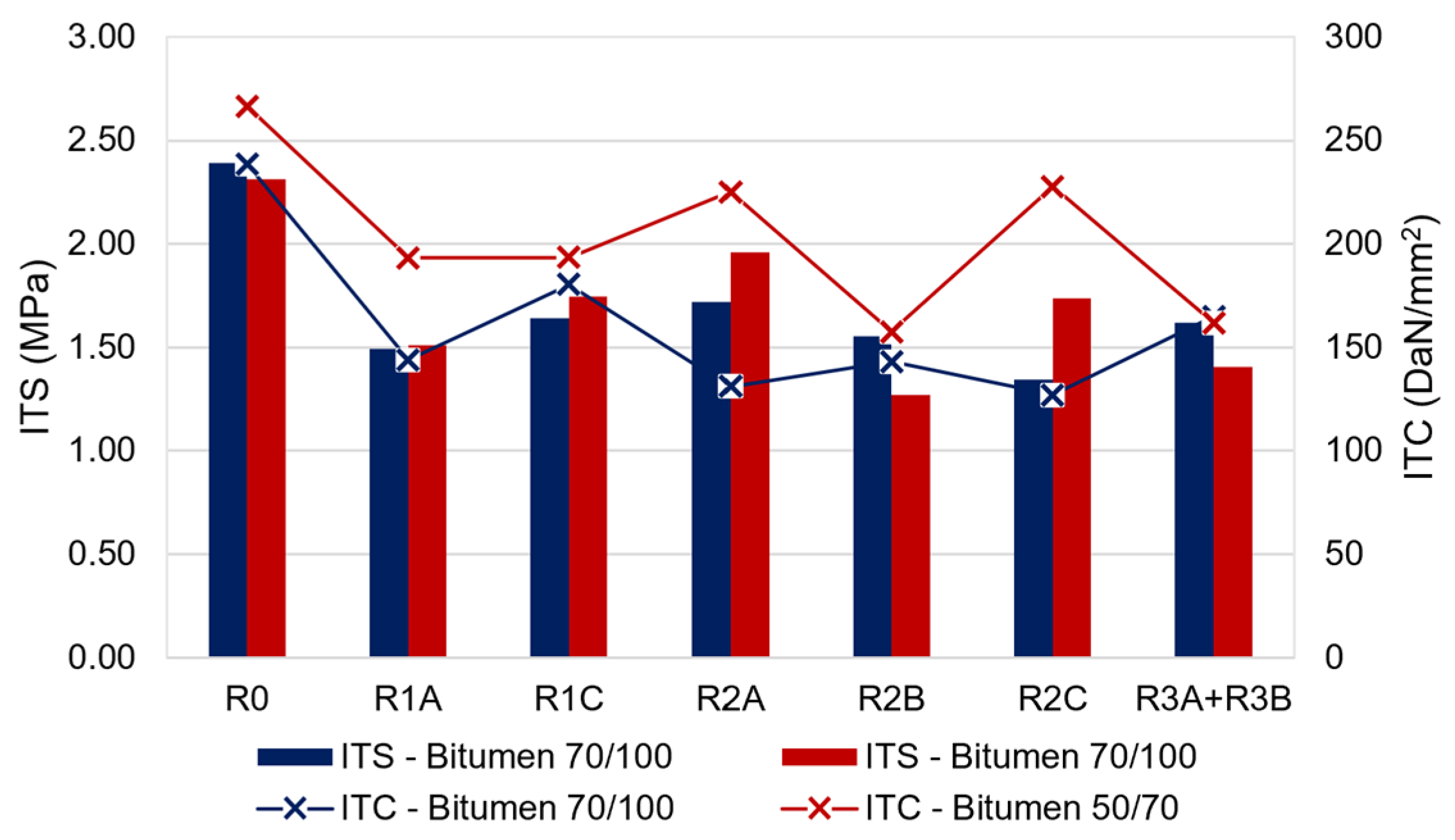

4.3.1. Indirect Tensile Strength

4.3.2. Indirect Tensile Stiffness Modulus

4.3.3. Rutting Resistance

5. Discussion

6. Conclusions

- The compactability of the asphalt mixtures containing the bio-additives varied as a function of the penetration grade of the added fresh bitumen: the greater the penetration of the fresh bitumen, the lesser the effect of the bio-additives; in addition, the R1A additive, composed of salts of ethoxylated fatty acids and waste vegetable oils, resulted as the best in terms of workability, regardless of type of added bitumen.

- It was proven that the introduction of the bio-additive, independently from the type, did not produce negative variations in relation to the desired volumetric requirements.

- All the bio-additives, both in the presence of the neat bitumen 50/70 and the neat bitumen 70/100, produced lower values of ITS at 25 °C in comparison to the reference mixture R0 without additives.

- A similar reduction trend was recorded in terms of ITSM for all the analyzed solutions containing bio-additives in comparison to the mixtures R0 at the test temperatures of 10, 20, and 40 °C; a different effect among the bio-additives was observed in correspondence of the test temperature of 60 °C, where R2A and R2B resulted in increased stiffness value compared to that of the reference mixtures. Despite the difference not being significant from a statistical point of view, a compliant result was obtained in terms of increased rutting resistance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Santos, J.; Flintsch, G.; Ferreira, A. Environmental and economic assessment of pavement construction and management practices for enhancing pavement sustainability. Resour. Conserv. Recycl. 2017, 116, 15–31. [Google Scholar] [CrossRef]

- Russo, F.; Veropalumbo, R.; Oreto, C. Climate change mitigation investigating asphalt pavement solutions made up of plastomeric compounds. Resour. Conserv. Recycl. 2023, 189, 106772. [Google Scholar] [CrossRef]

- Tuncan, M.; Tuncan, A.; Cetin, A. The use of waste materials in asphalt concrete mixtures. Waste Manag. Res. 2003, 21, 83–92. [Google Scholar] [CrossRef] [PubMed]

- Martinho, F.C.G.; Picado-Santos, L.G.; Capitão, S.D. Influence of recycled concrete and steel slag aggregates on warm-mix asphalt properties. Constr. Build. Mater. 2018, 185, 684–696. [Google Scholar] [CrossRef]

- Tarsi, G.; Tataranni, P.; Sangiorgi, C. The challenges of using reclaimed asphalt pavement for new asphalt mixtures: A review. Materials 2020, 13, 4052. [Google Scholar] [CrossRef] [PubMed]

- Oreto, C.; Russo, F.; Dell’Acqua, G.; Veropalumbo, R. A comparative environmental life cycle assessment of road asphalt pavement solutions made up of artificial aggregates. Sci. Total Environ. 2024, 927, 171716. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Wang, H. Life cycle assessment of asphalt pavement recycling for greenhouse gas emission with temporal aspect. J. Clean. Prod. 2018, 187, 148–157. [Google Scholar] [CrossRef]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid life cycle assessment for asphalt mixtures with high RAP content. Resour. Conserv. Recycl. 2014, 83, 77–86. [Google Scholar] [CrossRef]

- Monu, K.; Ransinchung, G.D.; Singh, S. Effect of long-term ageing on properties of RAP inclusive WMA mixes. Constr. Build. Mater. 2019, 206, 483–493. [Google Scholar] [CrossRef]

- Sengoz, B.; Oylumluoglu, J. Utilization of recycled asphalt concrete with different warm mix asphalt additives prepared with different penetration grades bitumen. Constr. Build. Mater. 2013, 45, 173–183. [Google Scholar] [CrossRef]

- Emtiaz, M.; Imtiyaz, M.N.; Majumder, M.; Idris, I.I.; Mazumder, R.; Rahaman, M.M. A Comprehensive Literature Review on Polymer-Modified Asphalt Binder. CivilEng 2023, 4, 901–932. [Google Scholar] [CrossRef]

- Im, S.; Karki, P.; Zhou, F. Development of new mix design method for asphalt mixtures containing RAP and rejuvenators. Constr. Build. Mater. 2016, 115, 727–734. [Google Scholar] [CrossRef]

- Pradhan, S.K. Short-term and long-term aging effect of the rejuvenation on RAP binder and mixes for sustainable pavement construction. Int. J. Transp. Sci. Technol. 2023, 12, 937–954. [Google Scholar] [CrossRef]

- Yang, S.; Lee, J.; Hwang, S.; Kwon, S.; Baek, C. Development of warm-mix asphalt additive and evaluation of performance. Transp. Res. Rec. 2012, 2294, 89–97. [Google Scholar] [CrossRef]

- Brownridge, J. The role of an asphalt rejuvenator in pavement preservation: Use and need for asphalt rejuvenation. In Proceedings of the Compendium of Papers from the First International Conference on Pavement Preservation, Newport Beach, CA, USA, 13–15 April 2010; pp. 351–364. [Google Scholar]

- Gschwendt, I. Extending the service life of pavements. Slovak J. Civ. Eng. 2018, 26, 25–32. [Google Scholar] [CrossRef]

- Mamun, A.A.; Al-Abdul Wahhab, H.I. Evaluation of Waste Engine Oil-Rejuvenated Asphalt Concrete Mixtures with High RAP Content. Adv. Mater. Sci. Eng. 2018, 2018, 7386256. [Google Scholar] [CrossRef]

- Dalmazzo, D.; Urbano, L.; Riviera, P.P.; Santagata, E. Testing of reclaimed asphalt model systems for the evaluation of the effectiveness of rejuvenators. In Proceedings of the RILEM International Symposium on Bituminous Materials: ISBM Lyon 2020; Springer International Publishing: Cham, Switzerland, 2022; pp. 1751–1757. [Google Scholar]

- Bocci, E.; Cardone, F.; Grilli, A. Mix design and volumetric analysis of hot recycled bituminous mixtures using a bio-additive. In Transport Infrastructure and Systems; CRC Press: Boca Raton, FL, USA, 2017; pp. 267–274. [Google Scholar]

- EN 1097-2; Tests for Mechanical and Physical Properties of Aggregates. Methods for the Determination of Resistance to Fragmentation. European Standard: Brussels, Belgium, 2020.

- EN 933-4; Tests for Geometrical Properties of Aggregates. Determination of Particle Shape. Shape Index. European Standard: Brussels, Belgium, 2008.

- EN 933-3; Tests for Geometrical Properties of Aggregates. Determination of Particle Shape. Flakiness Index. European Standard: Brussels, Belgium, 2012.

- EN 933-8; Tests for Geometrical Properties of Aggregates. Assessment of Fines. Sand Equivalent Test. European Standard: Brussels, Belgium, 2015.

- EN 1097-6; Tests for Mechanical and Physical Properties of Aggregates. Determination of Particle Density and Water Absorption. European Standard: Brussels, Belgium, 2022.

- EN 12697-1; Bituminous Mixtures. Test Methods. Soluble Binder Content. European Standard: Brussels, Belgium, 2020.

- EN 13108-8; Bituminous Mixtures. Material Specifications. Reclaimed Asphalt. European Standard: Brussels, Belgium, 2016.

- Russo, F.; Oreto, C.; Veropalumbo, R. Promoting Resource Conservation in Road Flexible Pavement Using Jet Grouting and Plastic Waste as Filler. Resour. Conserv. Recycl. 2022, 187, 106633. [Google Scholar] [CrossRef]

- EN 1426; Bitumen and Bituminous Binders. Determination of Needle Penetration. European Standard: Brussels, Belgium, 2015.

- EN 1427; Bitumen and Bituminous Binders. Determination of the Softening Point. Ring and Ball Method. European Standard: Brussels, Belgium, 2015.

- EN 13702; Bitumen and Bituminous Binders. Determination of Dynamic Viscosity of Bitumen and Bituminous Binders by the Cone and Plate Method. European Standard: Brussels, Belgium, 2018.

- EN 12607-1; Bitumen and Bituminous Binders. Determination of the Resistance to Hardening under Influence of Heat and Air. RTFOT Method. European Standard: Brussels, Belgium, 2014.

- EN 12697-31; Bituminous Mixtures. Test Methods. Specimen Preparation by Gyratory Compactor. European Standard: Brussels, Belgium, 2019.

- Southgate, H.F. An Analytical Investigation of AASHTO Load Equivalencies; Kentucky Transportation Center, College of Engineering, University of Kentucky: Lexington, KY, USA, 1993. [Google Scholar]

- Viscione, N.; Veropalumbo, R.; Oreto, C.; Biancardo, S.A.; Abbondati, F.; Russo, F. Additional procedures for characterizing the performance of recycled polymer modified asphalt mixtures. Measurement 2022, 187, 110238. [Google Scholar] [CrossRef]

- EN 12697-8; Bituminous Mixtures. Test Methods. Determination of Void Characteristics of Bituminous Specimens. European Standard: Brussels, Belgium, 2018.

- EN 12697-5; Bituminous Mixtures. Test Methods. Determination of the Maximum Density. European Standard: Brussels, Belgium, 2018.

- EN 12697-6; Bituminous Mixtures. Test Methods. Determination of Bulk Density of Bituminous Specimens. European Standard: Brussels, Belgium, 2020.

- Shenoy, A. Refinement of the Superpave specification parameter for performance grading of asphalt. J. Transp. Eng. 2001, 127, 357–362. [Google Scholar] [CrossRef]

- EN 12697-23; Bituminous Mixtures. Test Methods. Determination of the Indirect Tensile Strength of Bituminous Specimens. European Standard: Brussels, Belgium, 2017.

- EN 12697-26; Bituminous Mixtures. Test Methods. Stiffness. European Standard: Brussels, Belgium, 2018.

- EN 12697-22; Bituminous Mixtures. Test Methods. Wheel Tracking. European Standard: Brussels, Belgium, 2023.

- Fakhri, M.; Norouzi, M.A. Rheological And Ageing Properties of Asphalt Bio-Binders Containing Lignin and Waste Engine Oil. Constr. Build. Mater. 2022, 321, 126364. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, H.; Tighe, S.L.; Zhao, G.; You, Z. Effects of preheating conditions on performance and workability of hot in-place recycled asphalt mixtures. Constr. Build. Mater. 2019, 226, 288–298. [Google Scholar] [CrossRef]

| Properties | Unit | Standard | Limestone 10/20 mm | Limestone 8/12 mm | Limestone Sand 0/4 mm | RAP 0/8 mm |

|---|---|---|---|---|---|---|

| Los Angeles coefficient | % | EN 1097-2 [20] | 20.6 | 20.1 | - | 19.4 |

| Shape Index | % | EN 933-4 [21] | 14 | 15 | - | 9.67 |

| Flakiness Index | % | EN 933-3 [22] | 15 | 16 | - | 18.94 |

| Sand Equivalent | g/cm3 | EN 933-8 [23] | - | - | 85.3 | - |

| Bulk density | g/cm3 | EN 1097-6 [24] | 2.694 | 2.713 | 2.718 | 2.721 |

| Bitumen Content | % | EN 12697-1 [25] | - | - | - | 5.02 |

| Description | Standards | Units | Bitumen 70/100 | Bitumen 50/70 |

|---|---|---|---|---|

| Penetration | EN 1426 [28] | dmm | 72 | 68 |

| Softening point | EN 1427 [29] | °C | 43.5 | 48.0 |

| Viscosity @60 °C | EN 13702 [30] | Pa × s | 152.44 | 272.46 |

| Viscosity @100 °C | EN 13702 [30] | Pa × s | 3.42 | 4.70 |

| Viscosity @150 °C | EN 13702 [30] | Pa × s | 0.25 | 0.28 |

| Post RTFOT | ||||

| Penetration | EN 1426 [28] | dmm | 51 | 58 |

| Softening point | EN 1427 [29] | °C | 50.1 | 56.3 |

| Increase in the softening point | EN 12607-1 [31] | °C | 6.6 | 8.3 |

| Residual penetration | EN 12607-1 [31] | % | 71.0 | 85.3 |

| Additive Code | Description | Dosage | Density at 25 °C (g/cm3) | Viscosity at 25 °C (cPs) |

|---|---|---|---|---|

| R1A |

| 3.0%–5.0% by weight of the oxidized bitumen in the RAP | 0.98 | 35 |

| R1C |

| 0.10%–0.15% by RAP weight | 0.95 | 40 |

| R2A |

| 0.05%–0.30% by RAP weight | 0.92 | 50 |

| R2B |

| 0.05%–0.25% by RAP weight | 0.87 | 70 |

| R2C |

| 0.05%–0.30% by RAP weight | 0.92 | 50 |

| R3A * |

| 0.3%–0.6% by bitumen weight | 0.90 | 300 |

| R3B * |

| 0.1%–0.4% by RAP weight | 0.87 | 100 |

| Component | Percentage by Weight of the Aggregates | Percentage by Weight of the Mixture |

|---|---|---|

| Limestone 10/20 mm | 27% | 25.7% |

| RAP (white) | 50% | 47.6% |

| Limestone sand 0/4 mm | 15% | 14.3% |

| Limestone 8/12 mm | 8% | 7.6% |

| Bitumen | 5% | 4.8% |

| Mixture ID | Bitumen Type | Additive Type | Additive Dosage (% by Mass of the Mix) |

|---|---|---|---|

| R0_B50/70 | Bitumen 50/70 | - | - |

| R1A_B50/70 | R1A | 0.095% | |

| R1C_B50/70 | R1C | 0.071% | |

| R2A_B50/70 | R2A | 0.071% | |

| R2B_B50/70 | R2B | 0.071% | |

| R2C_B50/70 | R2C | 0.071% | |

| R3A + R3B_B50/70 | R3A R3B | 0.005% 0.021% | |

| R0_B70/100 | Bitumen 70/100 | - | - |

| R1A_B70/100 | R1A | 0.095% | |

| R1C_B70/100 | R1C | 0.071% | |

| R2A_B70/100 | R2A | 0.071% | |

| R2B_B70/100 | R2B | 0.071% | |

| R2C_B70/100 | R2C | 0.071% | |

| R3A + R3B_B70/100 | R3A R3B | 0.005% 0.021% |

| Mixture ID | Parameter | Unit | 10 °C | 20 °C | 40 °C | 60 °C |

|---|---|---|---|---|---|---|

| R0_B70/100 | ITSM (±σ) | MPa (MPa) | 15,465 (±190) | 9123 (±370) | 2013 (±194) | 421 (±128) |

| R1A_B70/100 | ITSM (±σ) p-value | MPa (MPa) - | 12,773 (±249) 0.00012 | 7010 (±431) 0.00299 | 1382 (±106) 0.00787 | 372 (±50) 0.57728 |

| R1C_B70/100 | ITSM (±σ) p-value | MPa (MPa) - | 11,837 (±227) 0.00029 | 6871 (±477) 0.00720 | 1446 (±92) 0.010301 | 339 (±51) 0.36336 |

| R2A_B70/100 | ITSM (±σ) p-value | MPa (MPa) - | 13,370 (±403) 0.00124 | 8241 (±350) 0.04016 | 1610 (±236) 0.04968 | 447 (±56) 0.75674 |

| R2B_B70/100 | ITSM (±σ) p-value | MPa (MPa) - | 12,426 (±352) 0.00067 | 7421 (±421) 0.00128 | 1452 (±155) 0.0456 | 380 (±38) 0.27891 |

| R2C_B70/100 | ITSM (±σ) p-value | MPa (MPa) - | 11,262 (±514) 0.00093 | 6726 (±322) 0.00672 | 1316 (±127) 0.02669 | 344 (±62) 0.52383 |

| R3A+R3B_B70/100 | ITSM (±σ) p-value | MPa (MPa) - | 11,739 (±164) 0.00037 | 7639 (±186) 0.00359 | 1183 (±166) 0.03881 | 313 (±44) 0.39112 |

| R0_B50/70 | ITSM (±σ) | MPa (MPa) | 16,236 (±289) | 9577 (±265) | 2113 (±214) | 441 (±39) |

| R1A_B50/70 | ITSM (±σ) p-value | MPa (MPa) - | 13,863 (±311) 0.00122 | 8788 (±320) 0.00952 | 1611 (±181) 0.0461 | 376 (±42) 0.67392 |

| R1C_B50/70 | ITSM (±σ) p-value | MPa (MPa) - | 12,619 (±184) 0.000744 | 7999 (±199) 0.00341 | 1466 (±87) 0.02294 | 342 (±54) 0.61395 |

| R2A_B50/70 | ITSM (±σ) p-value | MPa (MPa) - | 12,651 (±612) 0.00832 | 8628 (±294) 0.00799 | 1522 (±89) 0.03863 | 317 (±52) 0.58911 |

| R2B_B50/70 | ITSM (±σ) p-value | MPa (MPa) - | 13,524 (±295) 0.00017 | 7825 (±286) 0.00612 | 1666 (±188) 0.02774 | 459 (±37) 0.49922 |

| R2C_B50/70 | ITSM (±σ) p-value | MPa (MPa) - | 12,597 (±312) 0.00118 | 7980 (±139) 0.00103 | 1549 (±149) 0.0482 | 290 (±45) 0.78324 |

| R3A+R3B_B50/70 | ITSM (±σ) p-value | MPa (MPa) - | 12,478 (±188) 0.00076 | 8119 (±283) 0.00741 | 1288 (±127) 0.00952 | 384 (±49) 0.64387 |

| Mixture ID | RD after 10,000 Cycles [mm] | WTSwater [mm/1000 Cycles] |

|---|---|---|

| R0_B70/100 | 4.57 | 0.12 |

| R1A_B70/100 | 7.58 | 0.49 |

| R1C_B70/100 | 13.12 | 0.30 |

| R2A_B70/100 | 4.23 | 0.19 |

| R2B_B70/100 | 6.93 | 0.61 |

| R2C_B70/100 | 12.11 | 0.27 |

| R3A+R3B_B70/100 | 18.12 | 0.86 |

| R0_B50/70 | 4.16 | 0.15 |

| R1A_B50/70 | 6.29 | 0.58 |

| R1C_B50/70 | 10.83 | 0.42 |

| R2A_B50/70 | 16.96 | 0.92 |

| R2B_B50/70 | 3.12 | 0.18 |

| R2C_B50/70 | 17.46 | 0.83 |

| R3A+R3B_B50/70 | 8.74 | 0.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

D’Addio, G.; Oreto, C.; Viscione, N.; Veropalumbo, R. Influence of Bio-Additives on Recycled Asphalt Pavements. Materials 2024, 17, 3526. https://doi.org/10.3390/ma17143526

D’Addio G, Oreto C, Viscione N, Veropalumbo R. Influence of Bio-Additives on Recycled Asphalt Pavements. Materials. 2024; 17(14):3526. https://doi.org/10.3390/ma17143526

Chicago/Turabian StyleD’Addio, Giuseppe, Cristina Oreto, Nunzio Viscione, and Rosa Veropalumbo. 2024. "Influence of Bio-Additives on Recycled Asphalt Pavements" Materials 17, no. 14: 3526. https://doi.org/10.3390/ma17143526