Experimental and Meshless Numerical Simulations on the Crack Propagation of Semi-Circular Bending Specimens Containing X-Shaped Fissures Under Three-Point Bending

Abstract

:1. Introduction

2. Experiment Preparation

3. Numerical Treatments of Material Failure in SPH

3.1. SPH Theories

3.2. Establishment of Numerical Models

4. Experimental and Numerical Results

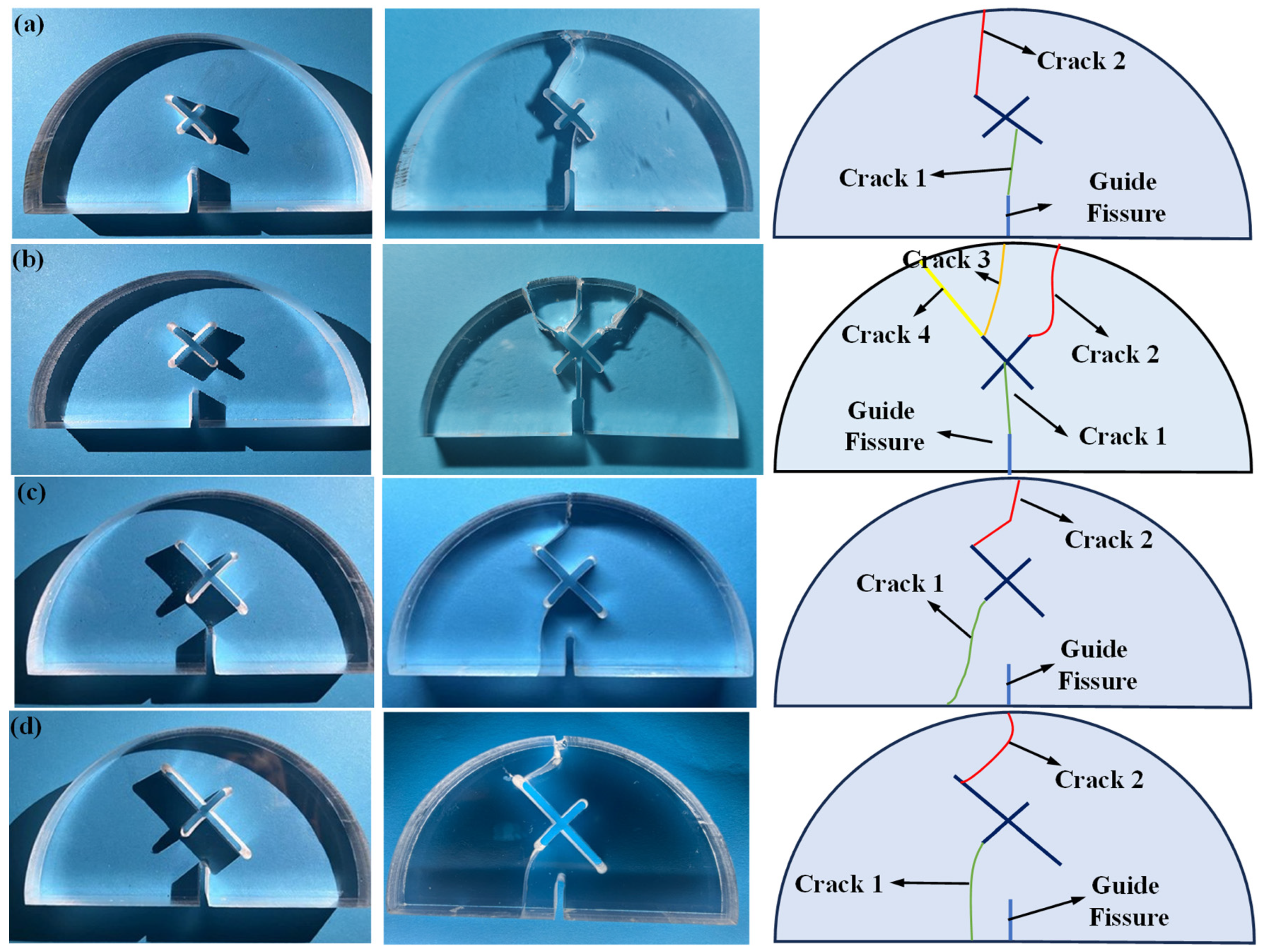

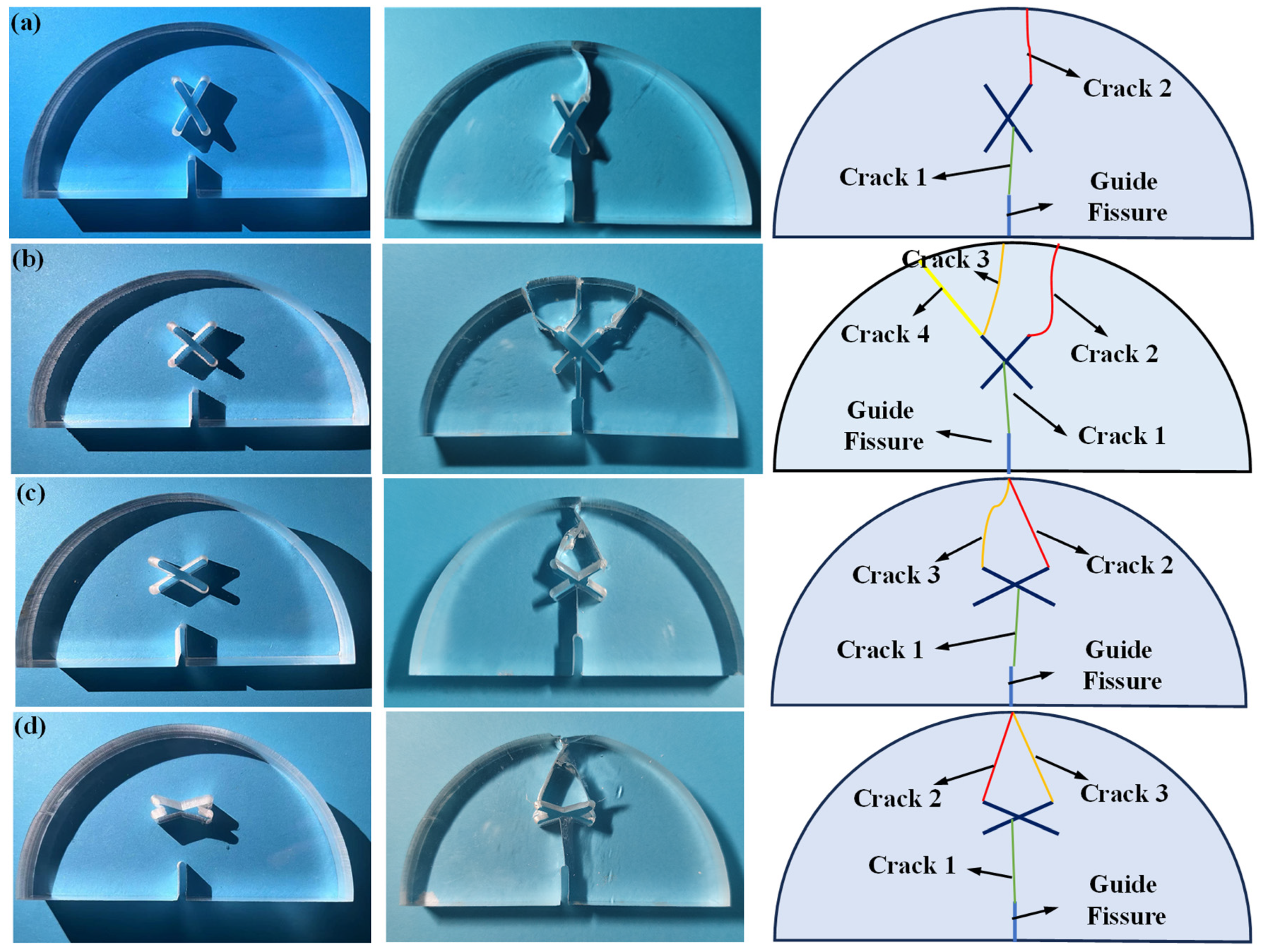

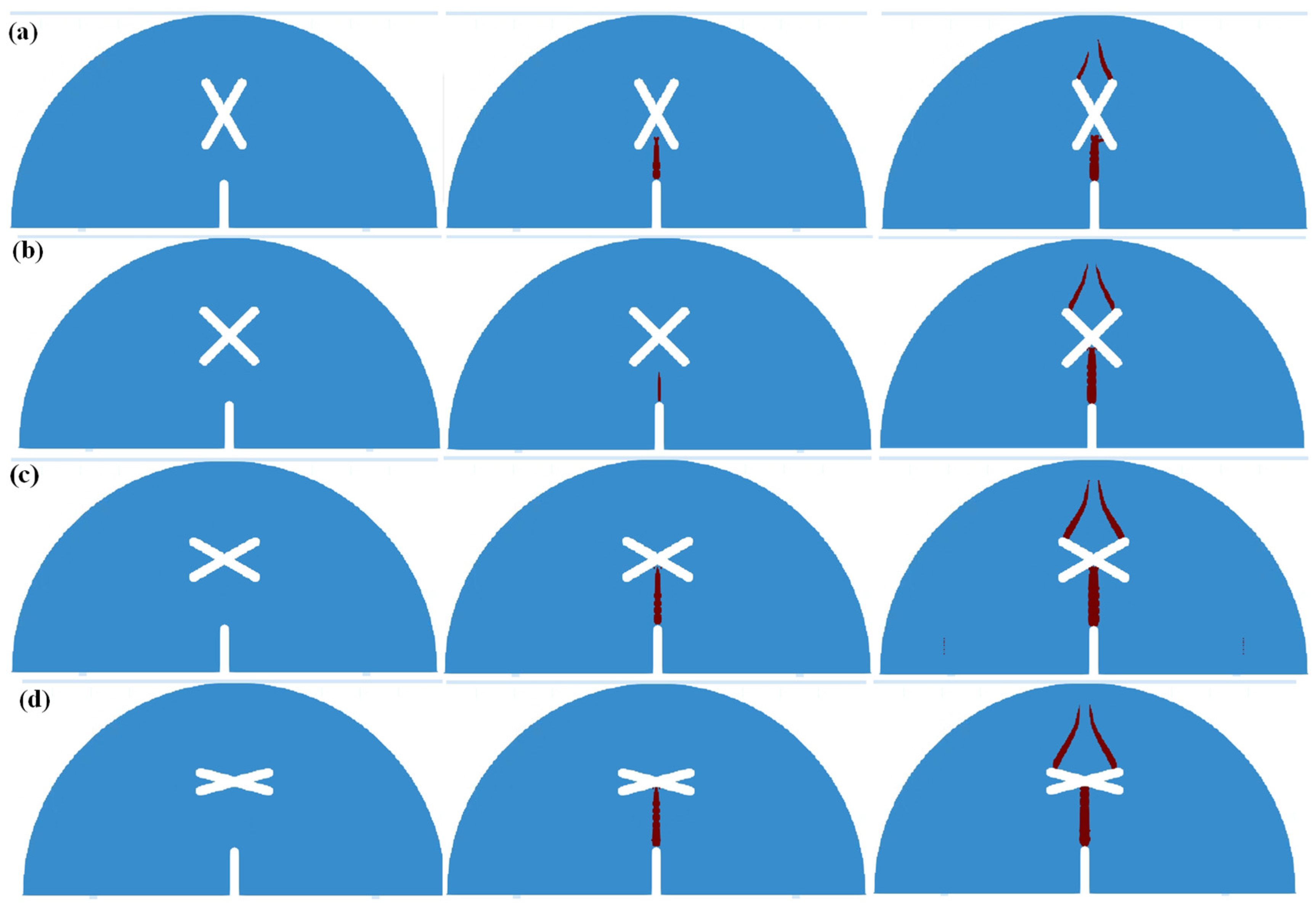

4.1. Fracture Morphology of SCB Samples Containing X-Shaped Fissures

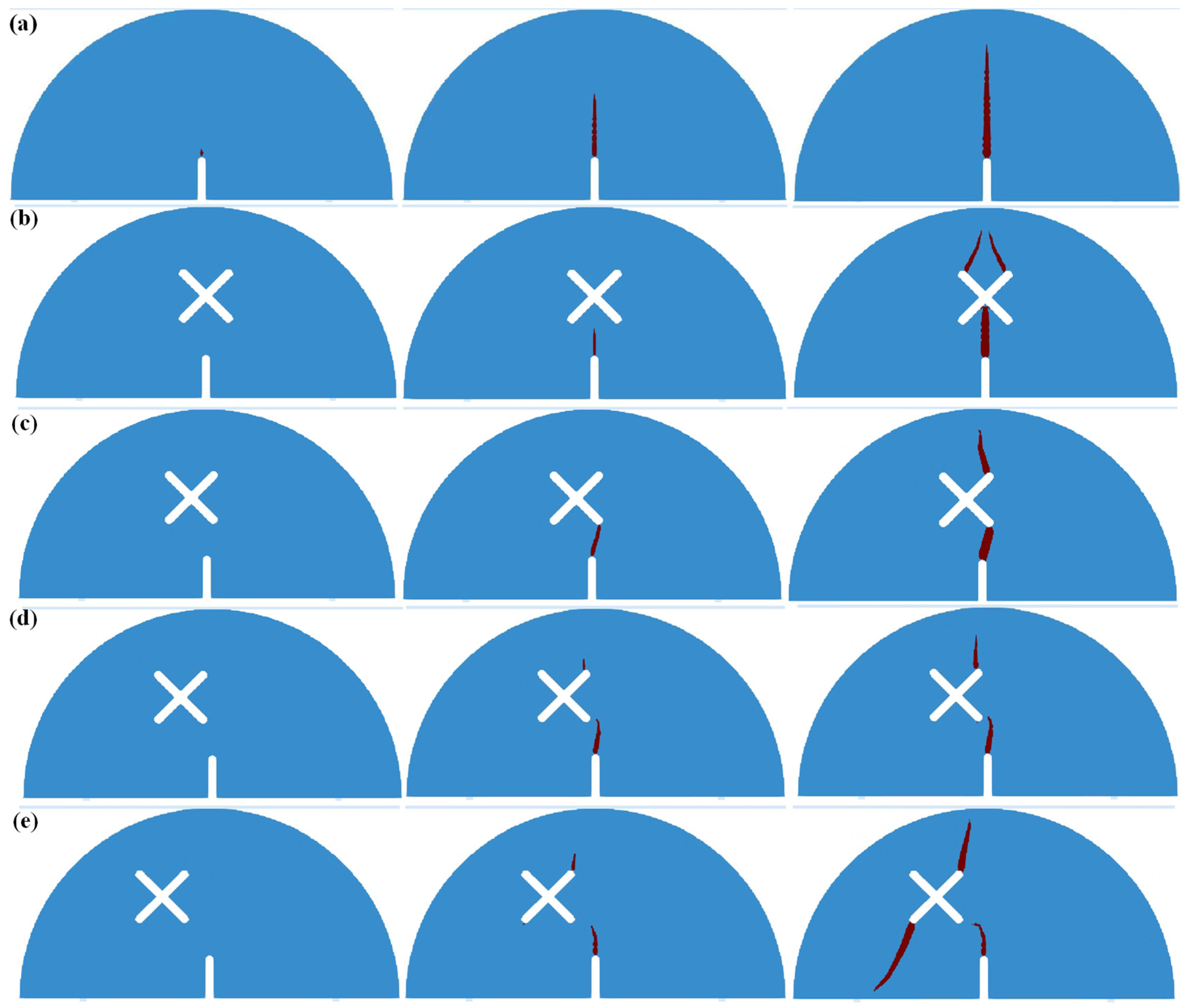

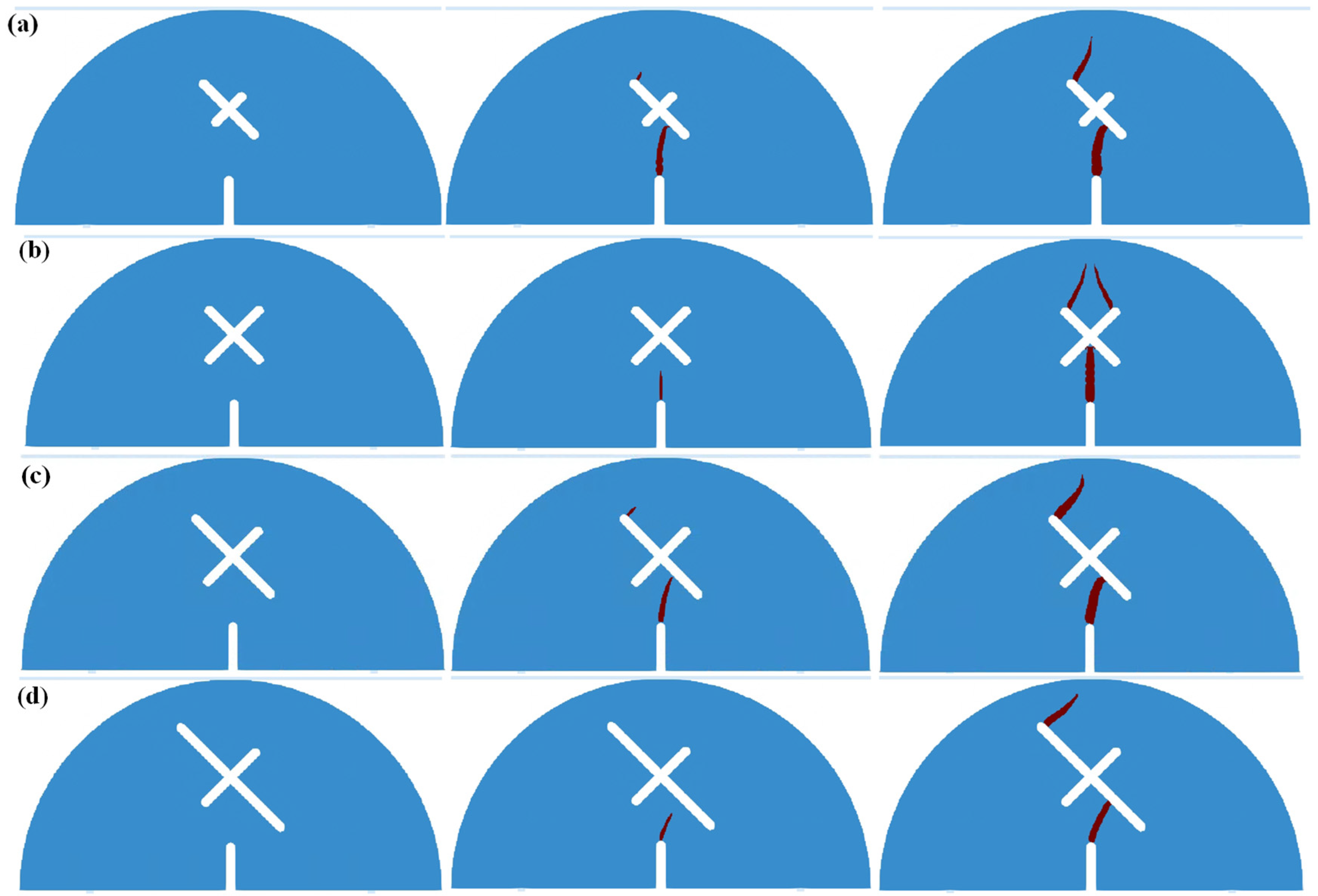

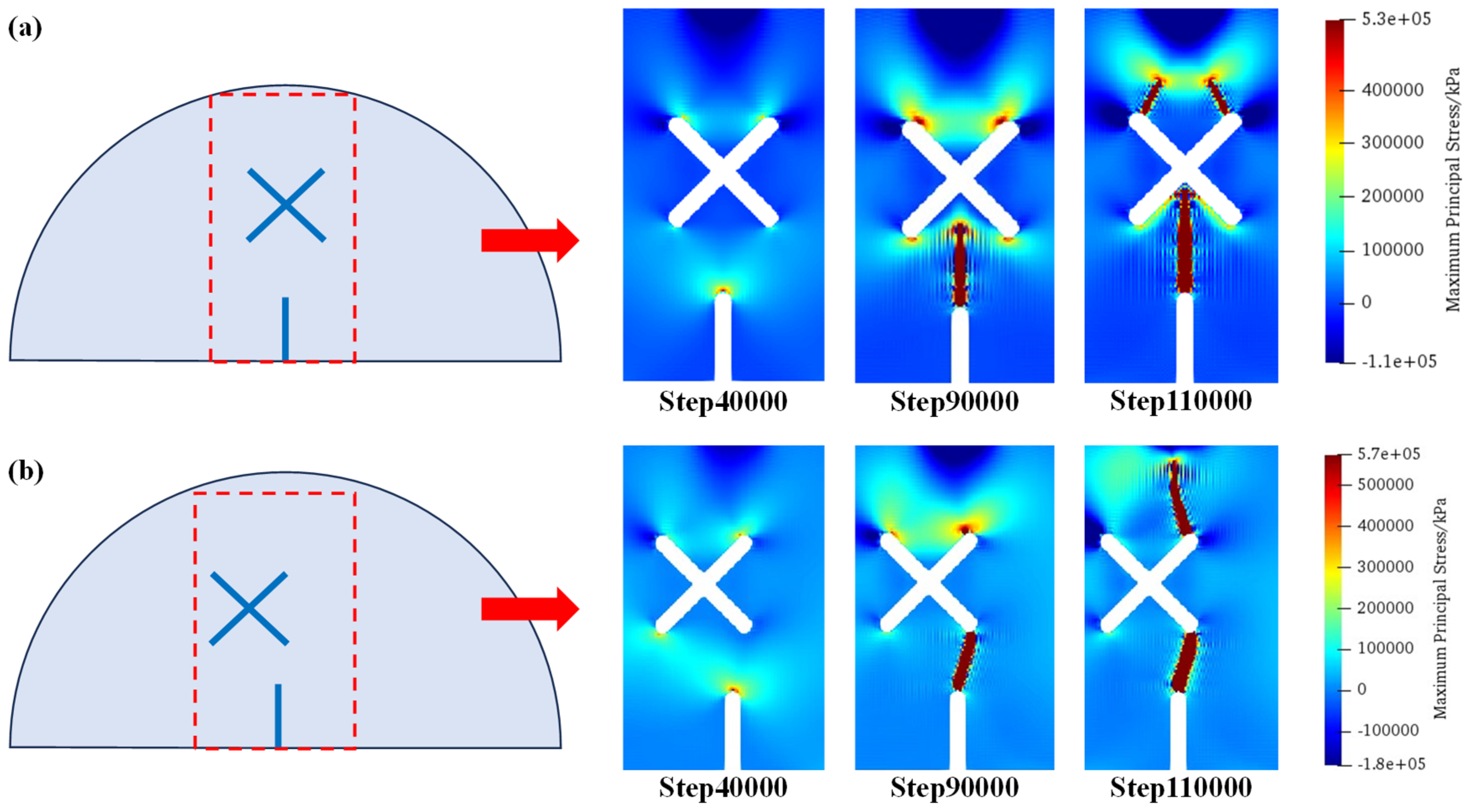

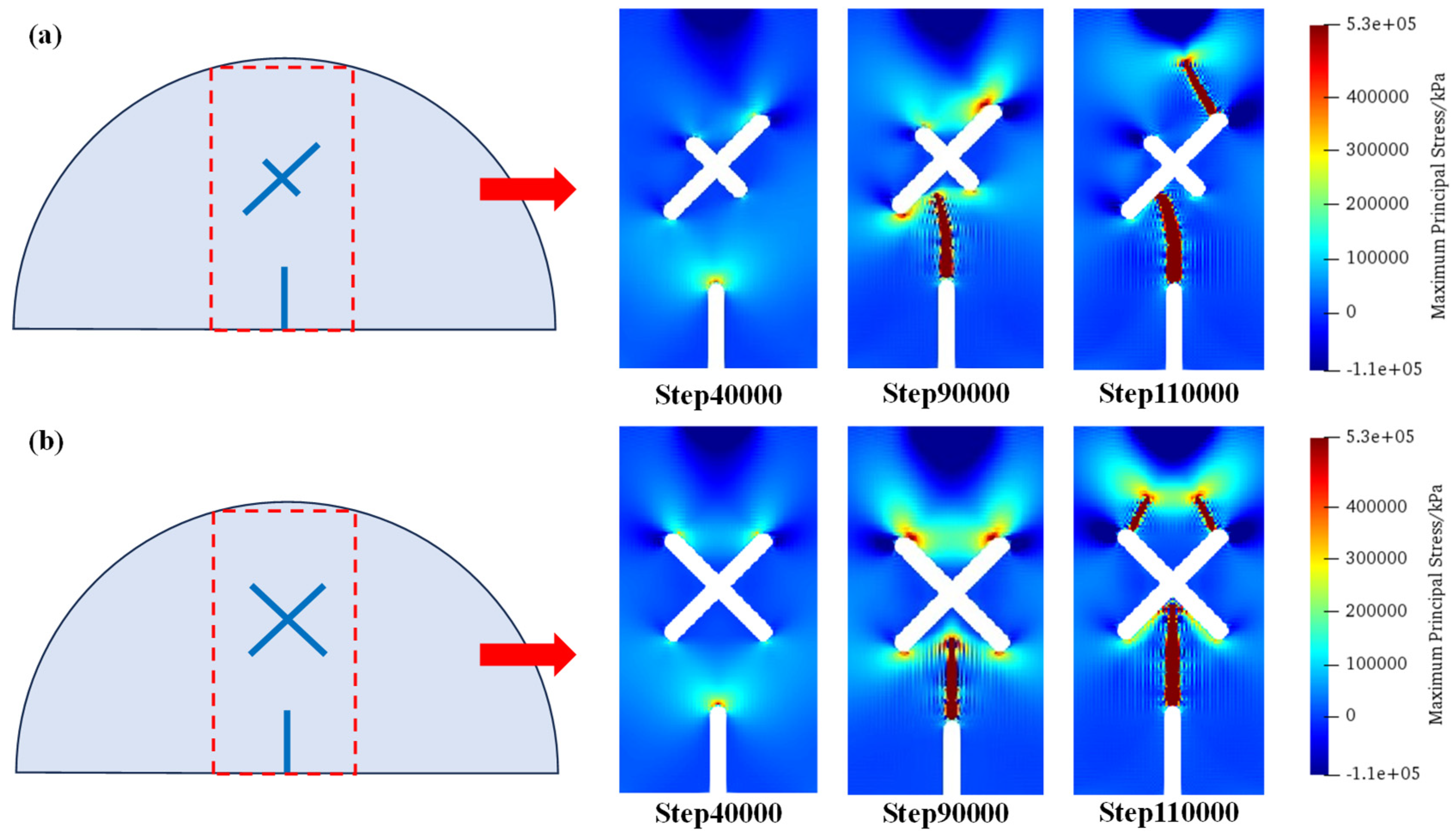

4.2. Simulation Results of SCB Specimens Containing X-Shaped Fissures

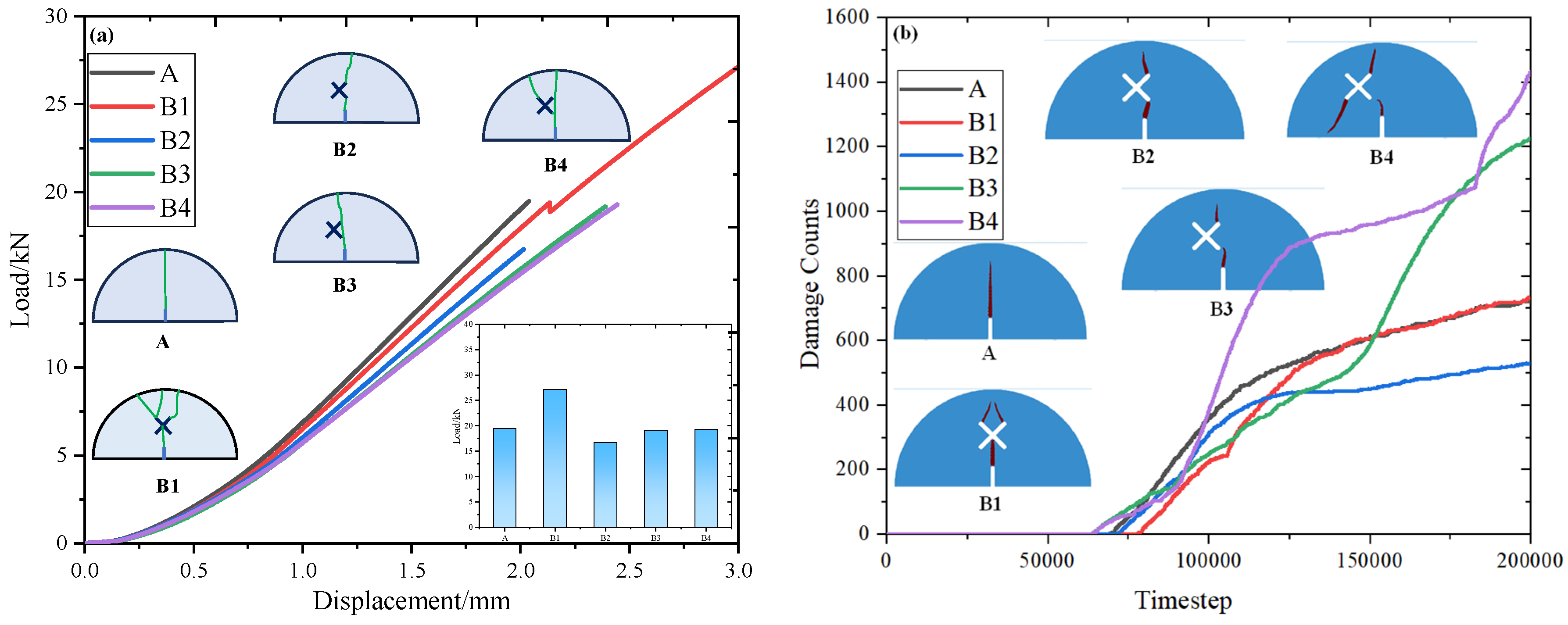

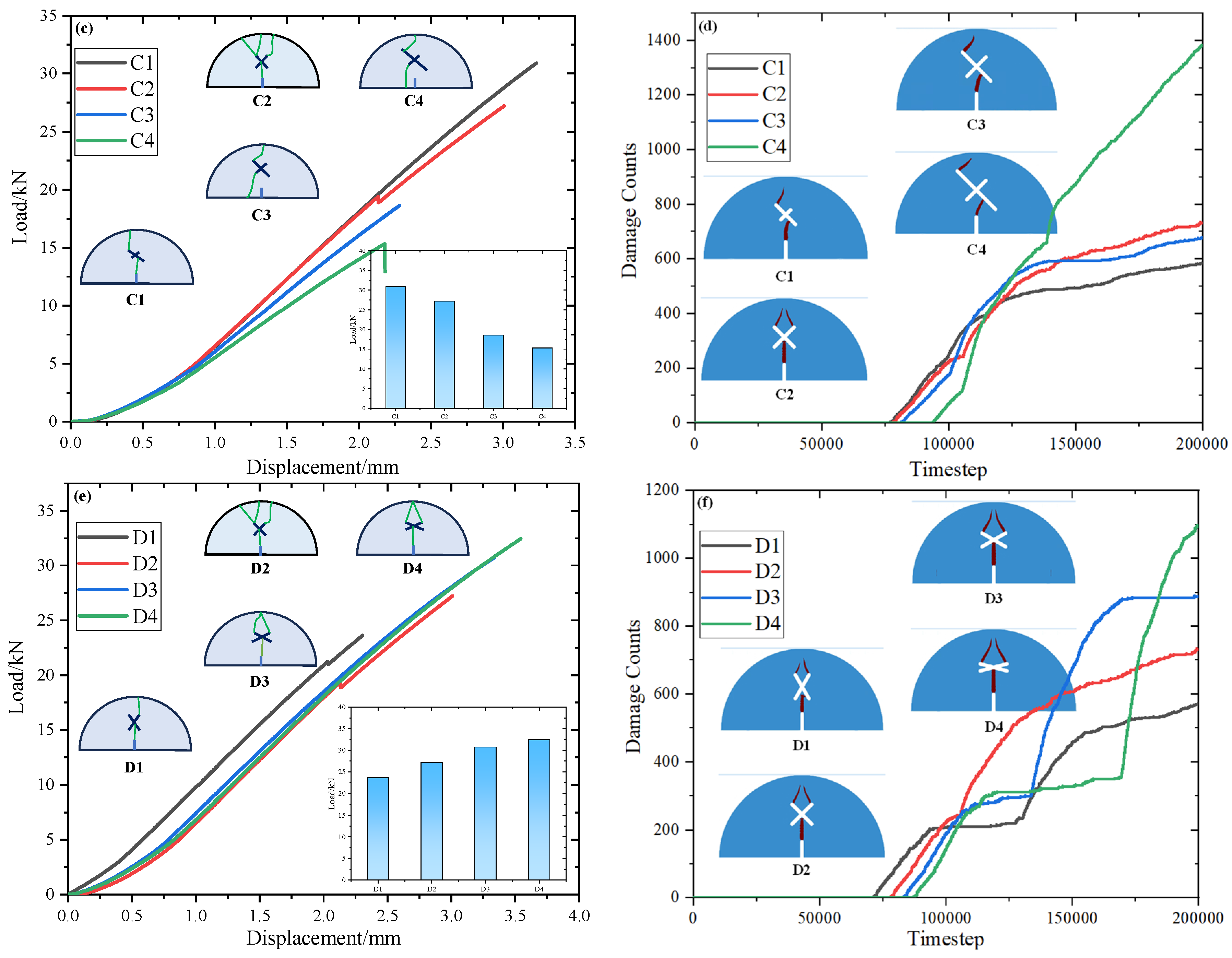

4.3. Effects of X-Shaped Fissure Properties on SCB Specimen Strength and Damage Counts

5. Discussions

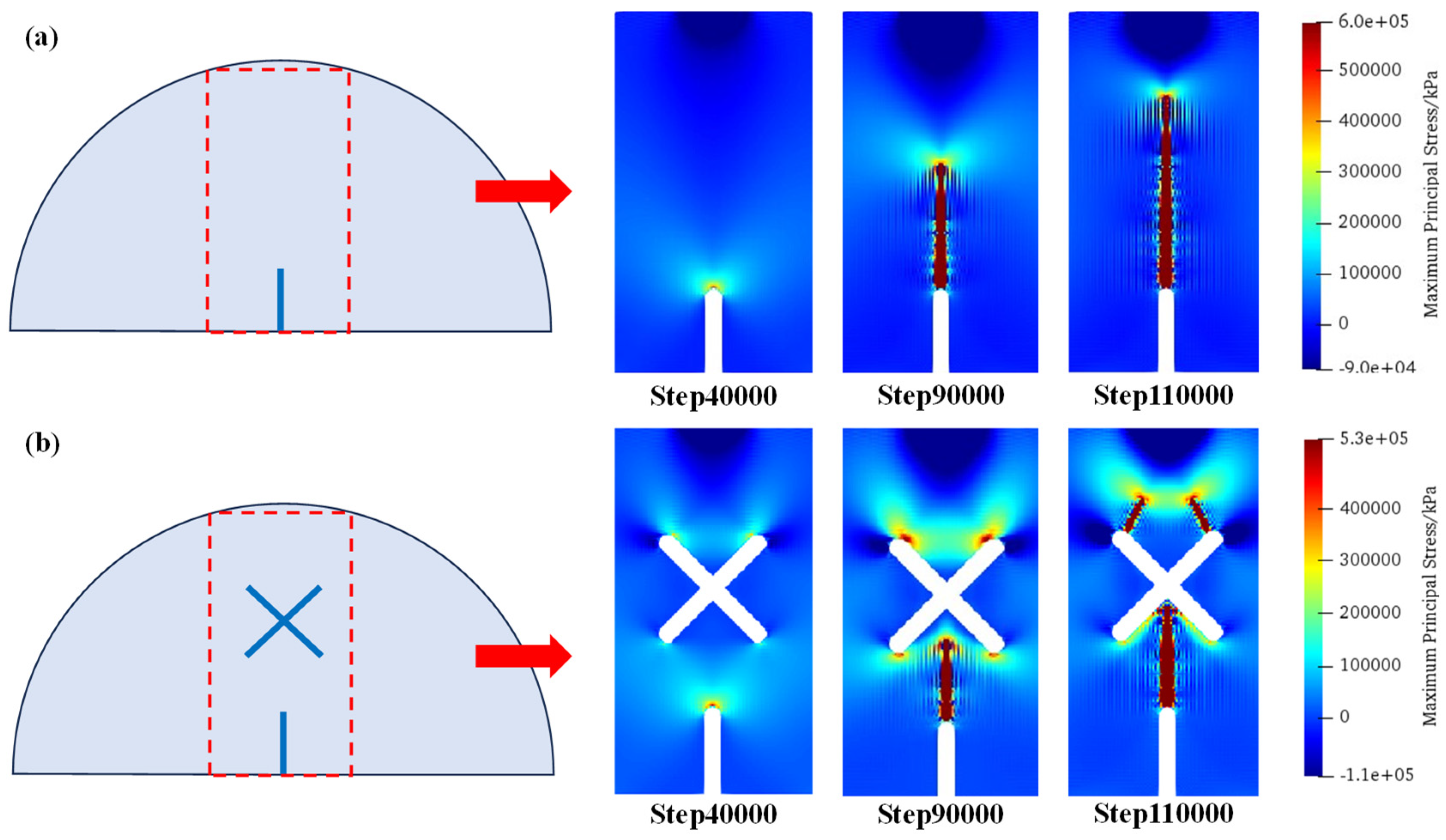

5.1. Effects of X-Shaped Fissures on Crack Propagation Paths

5.2. Asymmetric Crack Propagation Mechanisms under the Case of Eccentric X-Shaped Fissures

5.3. Crack Propagation Mechanisms of X-Shaped Fissure with Unequal Length

5.4. Research Prospects in Experiments and Simulations

6. Conclusions

- (1)

- SCB (semi-circular bending) specimens containing X-shaped fissures were prepared, and three-point bending tests were carried out. The crack growth paths of specimens with no X-shaped fissures are relatively simple; the cracks extend vertically from the guide fissure. The existence of X-shaped fissures greatly alters the crack growth path and the final fracture morphology.

- (2)

- The momentum equation in SPH (Smoothed Particle Hydrodynamics) was improved and the “activation state” coefficient η was defined to simulate the brittle fracture characteristics of solids. The crack propagation processes of SCB samples containing X-shaped fissures were simulated. The simulation results were consistent with the experimental results, which verify the rationality of the improved method; the improved SPH method can be well applied to simulations of rock fractures.

- (3)

- The load–displacement curves of the SCB (semi-circular bending) specimens present three stages: an initial compaction stage, linear elastic deformation stage, and failure stage. The peak strength of SCB (semi-circular bending) specimens decrease first then increase with an increase in eccentricity d, and decrease with an increase in X-shaped fissure length as well as a decrease in X-shaped fissure angle. The damage counts remain 0 at the initial loading stage, corresponding to the initial compaction stage and the linear elastic deformation stage, but increase sharply at the later loading stage, corresponding to the failure stage, which is consistent with the experimental results.

- (4)

- The influence mechanisms of X-shaped fissures on the fracture modes of the SCB (semi-circular bending) specimens are discussed. The existence of an X-shaped fissure intensifies the concentrations of tensile stress on its upper sides, and thus alters the vertical propagation modes existing in the circumstance with no X-shaped fissures. The eccentricity and different length of X-shaped fissures aggravate the tensile stress concentration at the unilateral tip, thus forming an asymmetric crack propagation pattern.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rong, G.; Tan, J.; Zhan, H.; He, R.; Zhang, Z. Quantitative evaluation of fracture geometry influence on nonlinear flow in a single rock fracture. J. Hydrol. 2020, 589, 125162. [Google Scholar] [CrossRef]

- Zhen, G.; Xu, Q.; Liu, X.; Li, Y.; Dong, X.; Ju, N.; Guo, C. The Jichang landslide on 23 July 2019 in Shuicheng, Guizhou: Characteristics and failure mechanism. J. Eng. Geol. 2020, 28, 541–556. [Google Scholar]

- Yu, H. Macro and Micro Mechanical Properties and Engineering Applications of Deep-Buried Marble. Ph.D. Thesis, Hohai University, Nanjing, China, 2013. [Google Scholar]

- Song, E. The Destruction and Repair of Fengman Concrete Dam from Freeze-thaw and dilatation. J. Hydroelectr. Eng. 2000, 1, 70–80. [Google Scholar]

- Zhai, M.; Jiang, F.; Qi, Q. Research and practice of rock burst classified control system. J. China Coal Soc. 2017, 42, 3116–3124. [Google Scholar]

- Brace, W.; Byerlee, J. Recent experimental studies of brittle fracture rocks. In Proceedings of the Eighth Symposium on Rock Mechanics, Mankato, MN, USA; American Rock Mechanics Association: New York, NY, USA, 1967; pp. 57–81. [Google Scholar]

- Bobet, A.; Einstin, H. Fracture coalescence in rock-type material under unaxial and biaxial compression. Int. J. Rock Mech. Min. Sci. 1998, 35, 863–888. [Google Scholar] [CrossRef]

- Zhang, X.; Li, X.; Liu, Y.; Liu, W.; Li, Q.; Li, L. Experimental study on crack propagation and failure mode of fissured shale under uniaxial compression. Theor. Appl. Fract. Mech. 2022, 121, 103512. [Google Scholar] [CrossRef]

- Zhou, Z.; Zhao, Y.; Bi, J.; Cheng, H.; Wang, C. Shear mechanical properties and failure modes of rock with V-shaped intersecting double-cracks. Theor. Appl. Fract. Mech. 2023, 124, 103755. [Google Scholar] [CrossRef]

- Wu, Y.; Xue, J.; Yu, Y.; Shi, C.; Fan, Y.; Wang, H.; Yang, J.; Gong, M.; Huang, W. Research of reflective crack in asphalt pavement using SCB specimen and XFEM: From laboratory test to numerical simulation. Constr. Build. Mater. 2023, 406, 133419. [Google Scholar] [CrossRef]

- Xu, Y.; Zhao, G.; Li, X.; Wu, B.; Xia, K. Influences of notch width and notch-tip angle on the fracture toughness measurement using the semi-circular bend (SCB) specimen. Eng. Fract. Mech. 2023, 281, 109098. [Google Scholar] [CrossRef]

- Zhou, H.; Guo, W.; Zhou, Y. Investigation on stress intensity factor and fracture characteristics of SCB sandstone containing prefabricated cracks. Theor. Appl. Fract. Mech. 2023, 124, 103754. [Google Scholar] [CrossRef]

- Wang, C.; Wang, S.; Chen, G.; Yu, P.; Peng, X. Implementation of a J-integral based Maximum Circumferential Tensile Stress theory in DDA for simulating crack propagation. Eng. Fract. Mech. 2021, 246, 107621. [Google Scholar] [CrossRef]

- Chen, Z.; Luo, Q.; Jin, D.; Wang, Z. Numerical study of fractal analysis of crack propagation in concrete under different strain rates by meso-scale particle element modeling. Int. J. Impact Eng. 2023, 173, 104440. [Google Scholar] [CrossRef]

- Han, W.; Jiang, Y.; Luan, H.; Du, Y.; Zhu, Y.; Liu, J. Numerical investigation on the shear behavior of rock-like materials containing fissure-holes with FEM-CZM method. Comput. Geotech. 2020, 125, 103670. [Google Scholar] [CrossRef]

- Yang, D.; Zhou, Y.; Xia, X.; Gu, S.; Xiong, Q.; Chen, W. Extended finite element modeling nonlinear hydro-mechanical process in saturated porous media containing crossing fractures. Comput. Geotech. 2019, 111, 209–221. [Google Scholar] [CrossRef]

- Jia, Z.; Zhou, X. Fracture parameters analysis of stationary cracks under dynamic loads based on the field-enriched finite element method. Eng. Fract. Mech. 2023, 289, 109402. [Google Scholar] [CrossRef]

- Yang, D.; Zhou, Y.; Xia, X.; Gu, S.; Xiong, Q.; Chen, W. Experimental and discrete element modeling on cracking behavior of sandstone containing a single oval flaw under uniaxial compression. Eng. Fract. Mech. 2018, 194, 154–174. [Google Scholar] [CrossRef]

- Li, X.F.; Li, H.B.; Liu, L.W.; Liu, Y.Q.; Ju, M.H.; Zhao, J. Investigating the crack initiation and propagation mechanism in brittle rocks using grain-based finite-discrete element method. Int. J. Rock Mech. Min. Sci. 2020, 127, 104219. [Google Scholar] [CrossRef]

- Deng, P.; Liu, Q.; Huang, X.; Pan, Y.; Wu, J. FDEM numerical modeling of failure mechanisms of anisotropic rock masses around deep tunnels. Comput. Geotech. 2022, 142, 104535. [Google Scholar] [CrossRef]

- Nikolić, M.; Karavelić, E.; Ibrahimbegovic, A.; Miščević, P. Lattice Element Models and Their Peculiarities. Arch Comput. Methods Eng 2018, 25, 753–784. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, Y.; Qian, Q. Smooth particle hydrodynamic numerical simulation of rock failure under uniaxial compression. Chin. J. Rock Mech. Eng. 2015, 34, 2647–2658. [Google Scholar]

- Zhao, Y.; Zhou, X.; Qian, Q. Progressive failure processes of reinforced slopes based on general particle dynamic method. J. Cent. South Univ. 2015, 22, 4049–4055. [Google Scholar] [CrossRef]

- Zhou, X.; Zhao, Y.; Qian, Q. A novel meshless numerical method for modeling progressive failure processes of slopes. Eng. Geol. 2015, 192, 139–153. [Google Scholar] [CrossRef]

- Bi, J. The Fracture Mechanisms of Rock Mass under Stress, Seepage, Temperature and Damage Coupling Condition and Numerical Simulations by Using the General Particle Dynamics (GPD) Algorithm. Ph.D. Thesis, Chongqing University, Chongqing, China, 2016. [Google Scholar]

- Bi, J.; Zhou, X. A Novel Numerical Algorithm for Simulation of Initiation, Propagation and Coalescence of Flaws Subject to Internal Fluid Pressure and Vertical Stress in the Framework of General Particle Dynamics. Rock Mech. Rock Eng. 2017, 50, 1833–1849. [Google Scholar] [CrossRef]

- Bi, J.; Zhou, X.; Qian, Q. The 3D Numerical Simulation for the Propagation Process of Multiple Pre-existing Flaws in Rock-Like Materials Subjected to Biaxial Compressive Loads. Rock Mech. Rock Eng. 2016, 49, 1611–1627. [Google Scholar] [CrossRef]

- Bi, J.; Zhou, X. Numerical Simulation of Zonal Disintegration of the Surrounding Rock Masses around a Deep Circular Tunnel Under Dynamic Unloading. Int. J. Comput. Methods 2015, 12, 1550020. [Google Scholar] [CrossRef]

- Zhou, X.; Bi, J.; Qian, Q. Numerical Simulation of Crack Growth and Coalescence in Rock-Like Materials Containing Multiple Pre-existing Flaws. Rock Mech. Rock Eng. 2015, 48, 1097–1114. [Google Scholar] [CrossRef]

- Zhou, X.; Bi, J. 3D Numerical Study on the Growth and Coalescence of Pre-existing Flaws in Rocklike Materials Subjected to Uniaxial Compression. Int. J. Geomech. 2016, 16, 04015096. [Google Scholar] [CrossRef]

- Greco, D.; Ferrero, A.; Oggeri, C. Experimental and analytical interpretation of the behaviour of laboratory tests on composite specimens. Int. J. Rock Mech. Min. Sci. 1993, 30, 1539–1543. [Google Scholar] [CrossRef]

- Haeri, H.; Khaloo, A.; Shahriar, K. A boundary element analysis of crack-propagation mechanism of micro-cracks in rock-like specimens under a uniform normal tension. J. Min. Environ. 2015, 6, 73–93. [Google Scholar]

- Bessa, M.; Foster, J.; Belytschko, T. A meshfree unification: Reproducing kernel peridynamics. Comput. Mech. 2014, 53, 1251–1264. [Google Scholar] [CrossRef]

- Shahbazi, K.; Abdideh, M.; Hadipoor, M. Modelling hydraulic fracturing process in one of the Iranian southwest oil reservoirs. Appl. Earth Sci. 2017, 126, 108–117. [Google Scholar] [CrossRef]

| Number | Test Scheme | Number | Test Scheme |

|---|---|---|---|

| A | No X-shaped fissures | C3 | l = 30 mm |

| B1 | d = 0 mm | C4 | l = 40 mm |

| B2 | d = 5 mm | D1 | θ = 60° |

| B3 | d = 10 mm | D2 | θ = 90° |

| B4 | d = 15 mm | D3 | θ = 120° |

| C1 | l = 10 mm | D4 | θ = 150° |

| C2 | l = 20 mm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mao, H.; Hu, C.; Xue, J.; Li, T.; Chang, H.; Fu, Z.; Sun, W.; Lu, J.; Wang, J.; Yu, S. Experimental and Meshless Numerical Simulations on the Crack Propagation of Semi-Circular Bending Specimens Containing X-Shaped Fissures Under Three-Point Bending. Materials 2024, 17, 3547. https://doi.org/10.3390/ma17143547

Mao H, Hu C, Xue J, Li T, Chang H, Fu Z, Sun W, Lu J, Wang J, Yu S. Experimental and Meshless Numerical Simulations on the Crack Propagation of Semi-Circular Bending Specimens Containing X-Shaped Fissures Under Three-Point Bending. Materials. 2024; 17(14):3547. https://doi.org/10.3390/ma17143547

Chicago/Turabian StyleMao, Haiying, Cong Hu, Jianfeng Xue, Taicheng Li, Haotian Chang, Zhaoqing Fu, Wenhui Sun, Jieyu Lu, Jing Wang, and Shuyang Yu. 2024. "Experimental and Meshless Numerical Simulations on the Crack Propagation of Semi-Circular Bending Specimens Containing X-Shaped Fissures Under Three-Point Bending" Materials 17, no. 14: 3547. https://doi.org/10.3390/ma17143547

APA StyleMao, H., Hu, C., Xue, J., Li, T., Chang, H., Fu, Z., Sun, W., Lu, J., Wang, J., & Yu, S. (2024). Experimental and Meshless Numerical Simulations on the Crack Propagation of Semi-Circular Bending Specimens Containing X-Shaped Fissures Under Three-Point Bending. Materials, 17(14), 3547. https://doi.org/10.3390/ma17143547