Phase Transformations and Mechanical Properties in In–Bi–Sn Alloys as a Result of Low-Temperature Storage

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

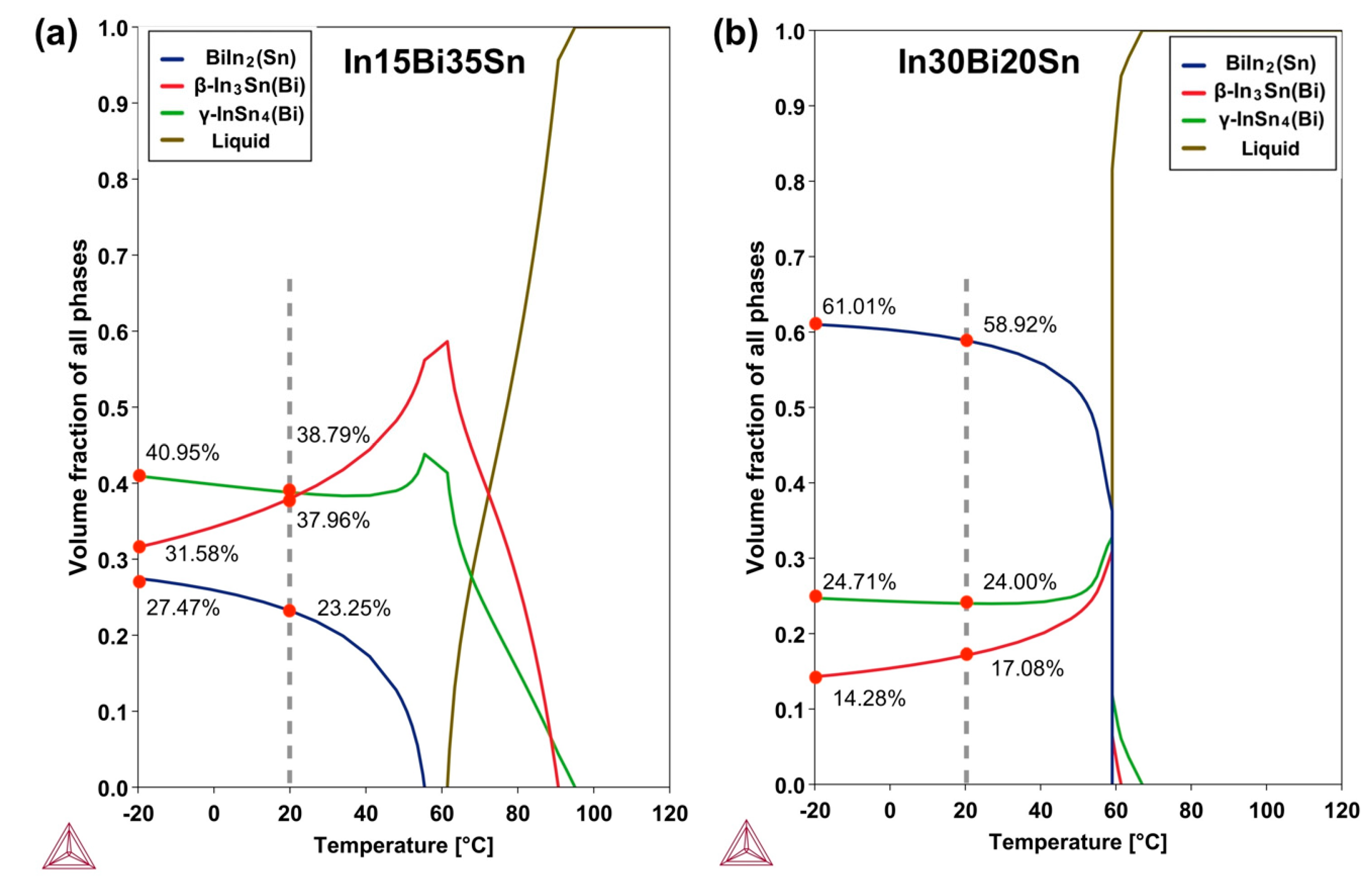

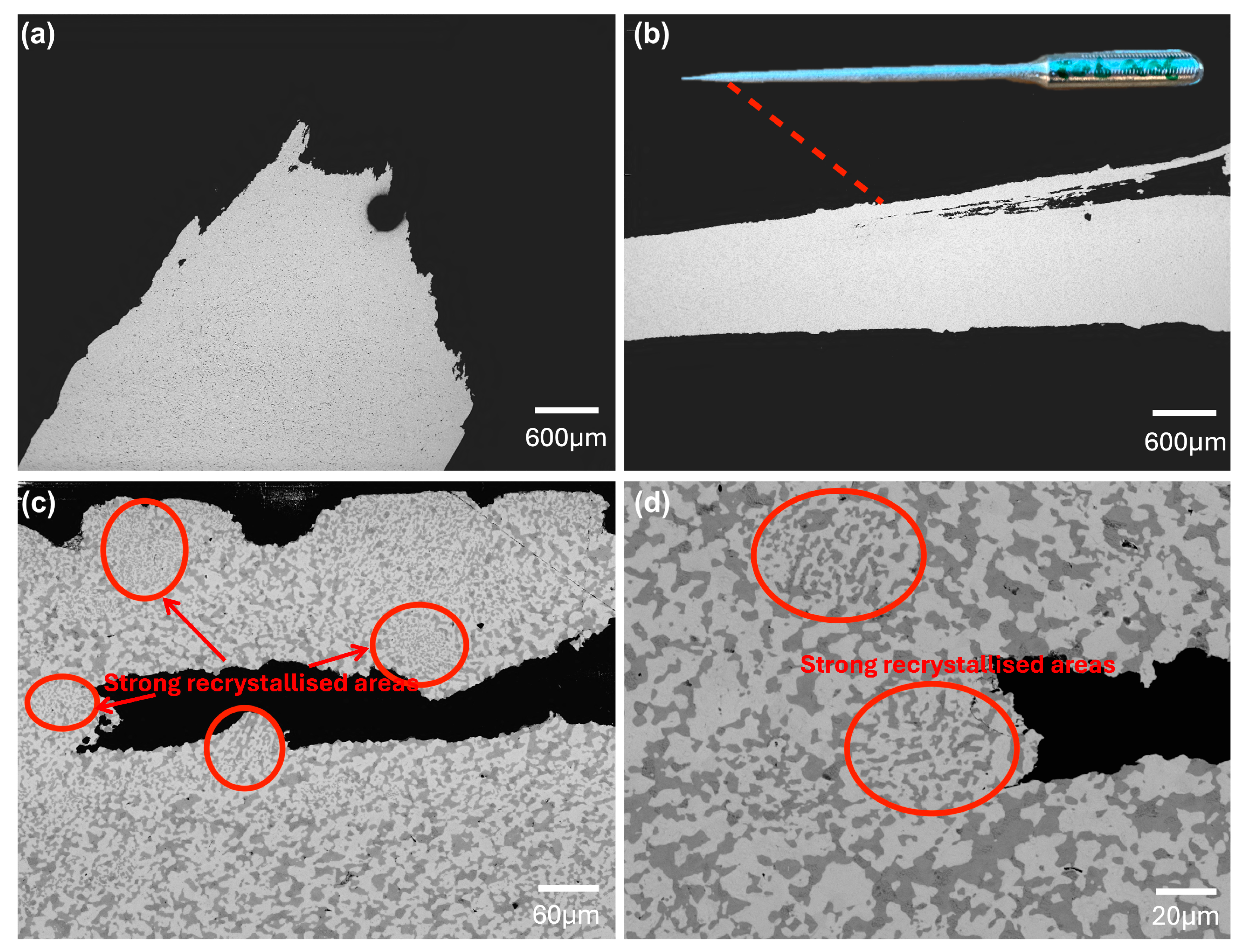

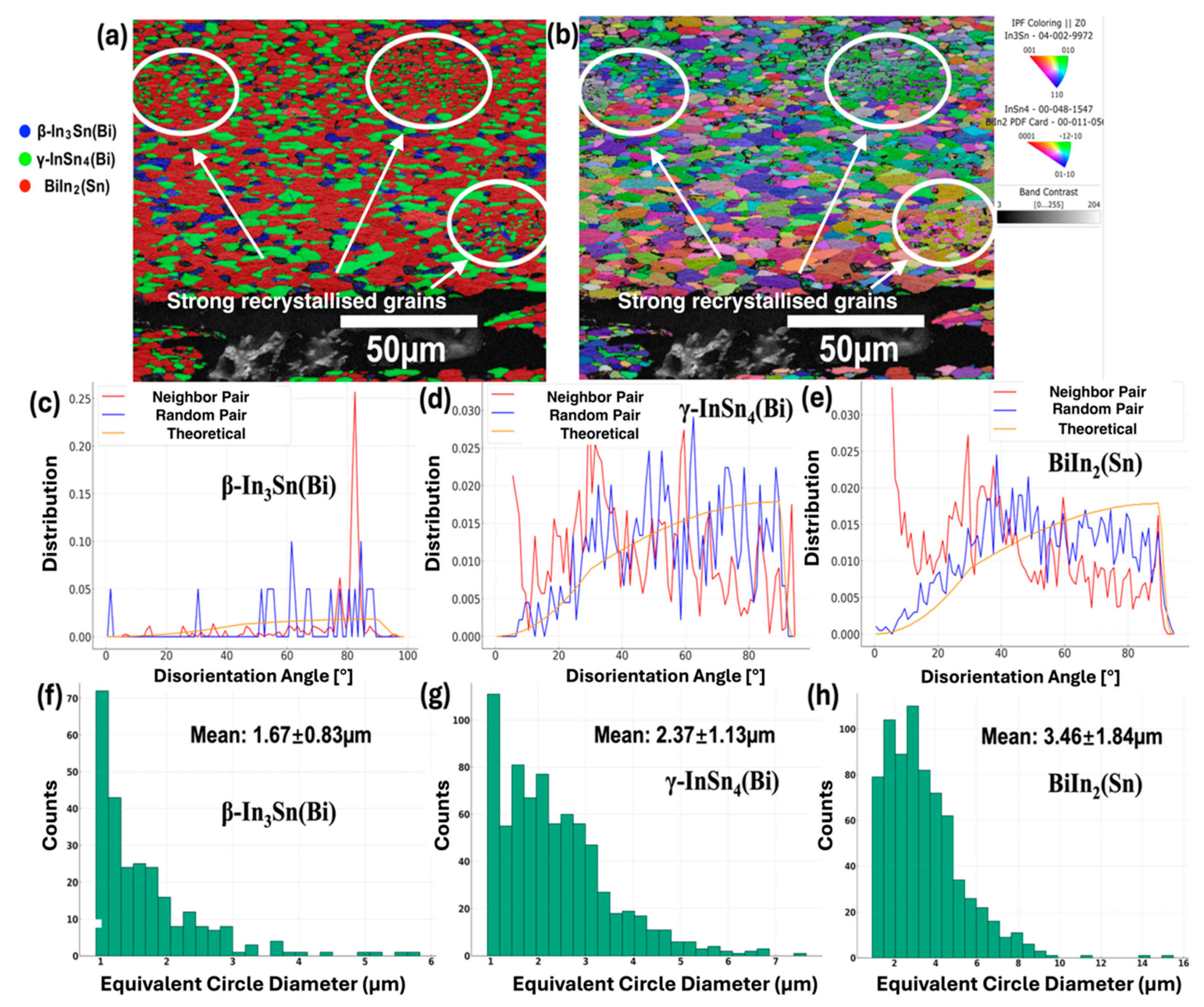

3.1. Microstructural Analysis

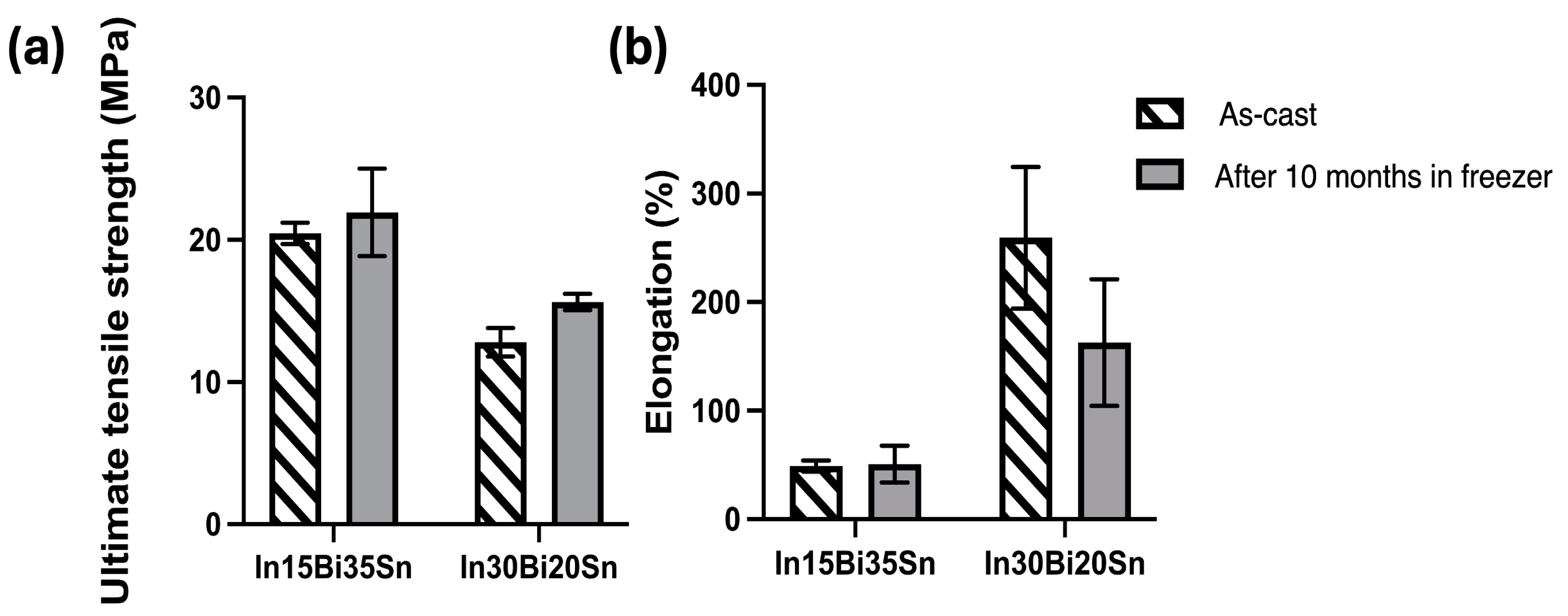

3.2. Mechanical Properties

4. Conclusions

- The ultimate tensile strength (UTS) of In–Bi–Sn solder alloys increased after storing at −20 °C for extended periods for both compositions. In30Bi20Sn showed a decrease in elongation, whereas In15Bi35Sn, which contains a larger proportion of the ductile β phase, exhibited minimal change in elongation. The precipitation of the more brittle hexagonal BiIn2(Sn) and γ phases is the primary reason for the decreased elongation, as these phases strengthen the alloy while reducing ductility by acting as barriers to dislocation movement, thereby increasing the creep resistance of the alloy.

- Notable changes in the proportion of phases in the microstructure, as predicted by Thermo-Calc, were verified by SEM results. Compared to the as-cast samples, phase transformations from β to γ + BiIn2(Sn) were observed in the original β phase for both samples after freezing at −20 °C for extended periods.

- Phase transformations and hardening due to the reprecipitation of phases have a more significant impact on the mechanical properties of alloys with a high amount of γ or BiIn2(Sn) phases after solidification while having less impact on alloys with a high amount of the ductile β phase. Despite the phase transformations, the ductile fracture mode of the tested alloys remained consistent with that of the as-cast samples, and strong recrystallization was observed.

- For operating environments ranging from room temperature to below −100 °C, future research should explore other indium-based solder alloy compositions, particularly those with a high amount of the ductile β phase, which are shown to have more stable mechanical properties under temperature variations. Additionally, conducting long-term testing under thermal cycling at different temperature ranges on In–Bi–Sn/Cu solder joints could provide more insights into the reliability and performance of these alloys in real-world applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Test Sample | Strain Rate | UTS (MPa) | Elongation (%) | SD (%) |

|---|---|---|---|---|

| In–15wt%Bi–35wt%Sn (S1) | 1.8 mm/min | 24.11 | 38.8 | 16.9 |

| 19.77 | 62.75 | |||

| In–30wt%Bi–20wt%Sn (S2) | 16.04 | 204.1 | 58.2 | |

| 15.23 | 121.6 |

References

- Tudryn, C.D. Solder Joint Fatigue Study Under Low Temperature Martian Conditions. In Proceedings of the 2006 IEEE Aerospace Conference, Big Sky, MT, USA, 4–11 March 2006; p. 9. [Google Scholar]

- Chang, R.W.; Patrick McCluskey, F. Reliability assessment of indium solder for low temperature electronic packaging. Cryogenics 2009, 49, 630–634. [Google Scholar] [CrossRef]

- Deshpande, M.; Chaudhari, R.; Narayanan, P.R.; Kale, H. Evaluation of Shear Properties of Indium Solder Alloys for Cryogenic Applications. J. Mater. Eng. Perform. 2021, 30, 7958–7966. [Google Scholar] [CrossRef]

- Plötner, M.; Donat, B.; Benke, A. Deformation properties of indium-based solders at 294 and 77 K. Cryogenics 1991, 31, 159–162. [Google Scholar] [CrossRef]

- Subramaniam, K.N. Lead-Free Solders Materials Reliability for Electronics, 1st ed.; Wiley: Chichester, UK, 2012. [Google Scholar]

- Zhou, J.; Tan, X.F.; McDonald, S.D.; Nogita, K. Mechanical Properties and Microstructure of Binary In-Sn Alloys for Flexible Low Temperature Electronic Joints. Materials 2022, 15, 8321. [Google Scholar] [CrossRef] [PubMed]

- Reed, R.P.; McCowan, C.N.; Walsh, R.P.; Delgado, L.A.; McColskey, J.D. Tensile strength and ductility of indium. Mater. Sci. Eng. A 1988, 102, 227–236. [Google Scholar] [CrossRef]

- Jin, S.; Kim, M.-S.; Kanayama, S.; Nishikawa, H. Microstructure and mechanical properties of indium–bismuth alloys for low melting-temperature solder. J. Mater. Sci. Mater. Electron. 2018, 29, 16460–16468. [Google Scholar] [CrossRef]

- Huang, M.L.; Zhou, Q.; Zhao, N.; Chen, L.D. Interfacial microstructure and mechanical properties of In–Bi–Sn lead-free solder. J. Mater. Sci. Mater. Electron. 2013, 24, 2624–2629. [Google Scholar] [CrossRef]

- Zhou, J.; Tan, X.F.; McDonald, S.D.; Gu, Q.; Nogita, K. Controlling Mechanical Properties in In-Sn-Bi Alloys Through Microstructure Design. Acta Materialia, 2024; under review. [Google Scholar]

- Lupinacci, A.; Shapiro, A.A.; Suh, J.O.; Minor, A.M. A Study of Solder Alloy Ductility for Cryogenic Applications. In Proceedings of the 2013 IEEE International Symposium on Advanced Packaging Materials (APM), Irvine, CA, USA, 27 February–1 March 2013; pp. 82–88. [Google Scholar]

- Deshpande, M.C.; Chaudhari, R.; Narayanan, R.; Kale, H. Study of mechanical properties of indium-based solder alloys for cryogenic applications. Solder. Surf. Mt. Technol. 2022, 34, 212–221. [Google Scholar] [CrossRef]

- Witusiewicz, V.T.; Hecht, U.; Böttger, B.; Rex, S. Thermodynamic re-optimisation of the Bi–In–Sn system based on new experimental data. J. Alloys Compd. 2007, 428, 115–124. [Google Scholar] [CrossRef]

- Manasijević, I.; Balanović, L.; Grgurić, T.H.; Minić, D.; Gorgievski, M. Study of microstructure and thermal properties of the low melting Bi-In-Sn eutectic alloys. Mat. Res. 2018, 21, e20180501. [Google Scholar] [CrossRef]

- ASTM Standard E8/E8M; Standard Test Methods for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2016.

- Sigworth, G.; Cáceres, C. Quality Issues in Aluminum Net-Shape Castings. In Proceedings of the AFS Transactions: 108th Metalcasting Congress, Rosemont, IL, USA, 12–15 June 2004. [Google Scholar]

- Andersson, J.O.; Helander, T.; Höglund, L.; Shi, P.; Sundman, B. Thermo-Calc & DICTRA, computational tools for materials science. Calphad 2002, 26, 273–312. [Google Scholar] [CrossRef]

- Silva, B.L.; Reinhart, G.; Nguyen-Thi, H.; Mangelinck-Noël, N.; Garcia, A.; Spinelli, J.E. Microstructural development and mechanical properties of a near-eutectic directionally solidified Sn–Bi solder alloy. Mater. Charact. 2015, 107, 43–53. [Google Scholar] [CrossRef]

- Wang, F.; Huang, Y.; Zhang, Z.; Yan, C. Interfacial Reaction and Mechanical Properties of Sn-Bi Solder joints. Materials 2017, 10, 920. [Google Scholar] [CrossRef]

- Hao, Q.; Tan, X.F.; McDonald, S.D.; Sweatman, K.; Nishimura, T.; Nishimura, T.; Nogita, K. Comparison of the Mechanical Properties of Conventional Pb-free Solders and Eutectic Sn-Bi Solder. In Proceedings of the 2022 International Conference on Electronics Packaging (ICEP), Sapporo, Japan, 11–14 May 2022; Institute of Electrical and Electronics Engineers: Piscataway, NJ, USA, 2022; pp. 173–174. [Google Scholar]

- Kossakowski, P. Influence of initial porosity on strength properties of S235JR steel at low stress triaxiality. Arch. Civ. Eng. 2012, 58, 293–308. [Google Scholar] [CrossRef]

- Noell, P.J.; Sills, R.B.; Boyce, B.L. Suppression of Void Nucleation in High-Purity Aluminum via Dynamic Recrystallization. Metall. Mater. Trans. A 2020, 51, 154–166. [Google Scholar] [CrossRef]

- Dutkiewicz, J.; Kalita, D.; Maziarz, W.; Faryna, M. Superplastic deformation of Mg–9Li–2Al–0.5Sc alloy after grain refinement by KoBo extrusion and cyclic forging. Arch. Civ. Mech. Eng. 2020, 20, 121. [Google Scholar] [CrossRef]

- Clemens, H.; Mayer, S.; Scheu, C. Neutrons and Synchrotron Radiation in Engineering Materials Science: From Fundamentals to Applications, 2nd ed.; Wiley: Hoboken, NJ, USA, 2017; pp. 3–20. [Google Scholar]

- Wang, C.; He, Y.; Langdon, T. The significance of strain weakening and self-annealing in a superplastic Bi-Sn eutectic alloy processed by high-pressure torsion. Acta Mater. 2019, 185, 245–256. [Google Scholar] [CrossRef]

- Malik, A.; Masood Chaudry, U.; Hamad, K.; Jun, T.-S. Microstructure Features and Superplasticity of Extruded, Rolled and SPD-Processed Magnesium Alloys: A Short Review. Metals 2021, 11, 1766. [Google Scholar] [CrossRef]

- Yoshida, H.; Liebmann, B.; Lücke, K. Orientation of recrystallized grains in strained aluminum single crystals. Acta Metall. 1959, 7, 51–56. [Google Scholar] [CrossRef]

| Test Sample | S1 | S2 |

|---|---|---|

| Composition | In–15wt%Bi–35wt%Sn | In–30wt%Bi–20wt%Sn |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhou, J.; Tan, X.F.; McDonald, S.D.; Nogita, K. Phase Transformations and Mechanical Properties in In–Bi–Sn Alloys as a Result of Low-Temperature Storage. Materials 2024, 17, 3669. https://doi.org/10.3390/ma17153669

Zhou J, Tan XF, McDonald SD, Nogita K. Phase Transformations and Mechanical Properties in In–Bi–Sn Alloys as a Result of Low-Temperature Storage. Materials. 2024; 17(15):3669. https://doi.org/10.3390/ma17153669

Chicago/Turabian StyleZhou, Jiye, Xin Fu Tan, Stuart D. McDonald, and Kazuhiro Nogita. 2024. "Phase Transformations and Mechanical Properties in In–Bi–Sn Alloys as a Result of Low-Temperature Storage" Materials 17, no. 15: 3669. https://doi.org/10.3390/ma17153669

APA StyleZhou, J., Tan, X. F., McDonald, S. D., & Nogita, K. (2024). Phase Transformations and Mechanical Properties in In–Bi–Sn Alloys as a Result of Low-Temperature Storage. Materials, 17(15), 3669. https://doi.org/10.3390/ma17153669