A Survey on Fused Filament Fabrication to Produce Functionally Gradient Materials

Abstract

1. Introduction

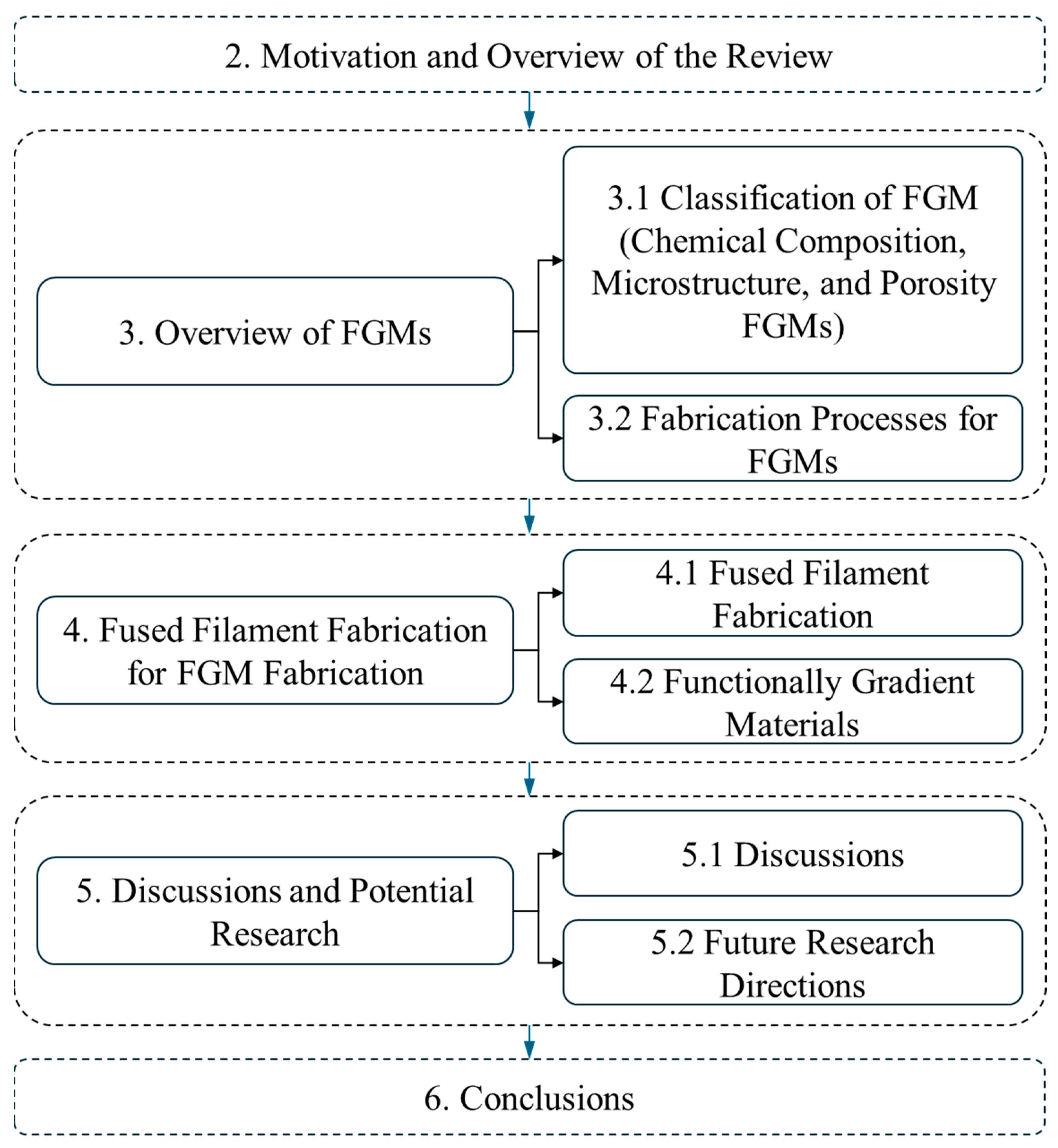

2. The Motivation and Overview of This Review

3. Functionally Gradient Materials

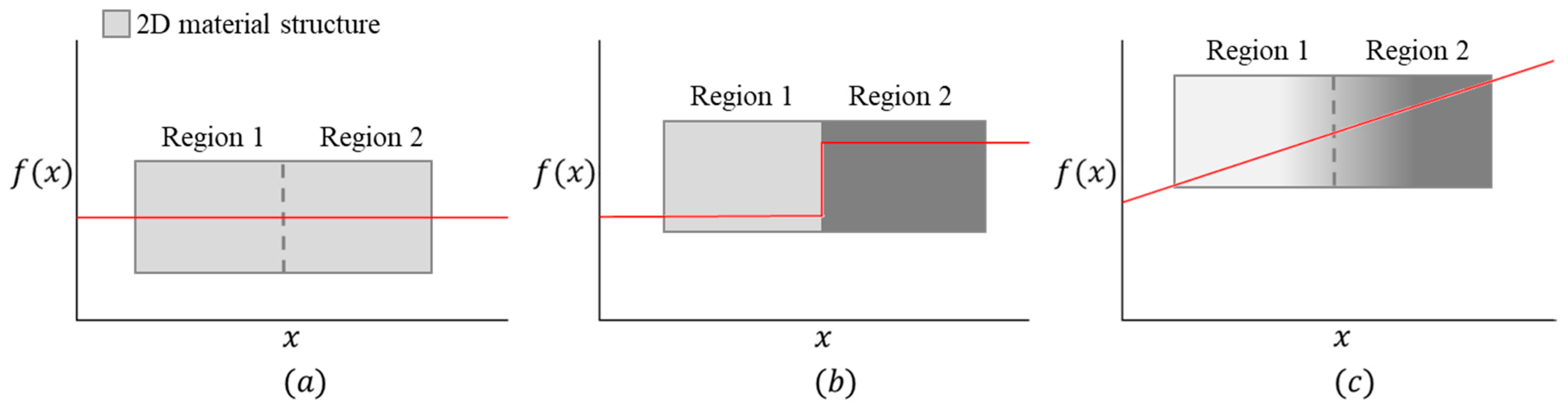

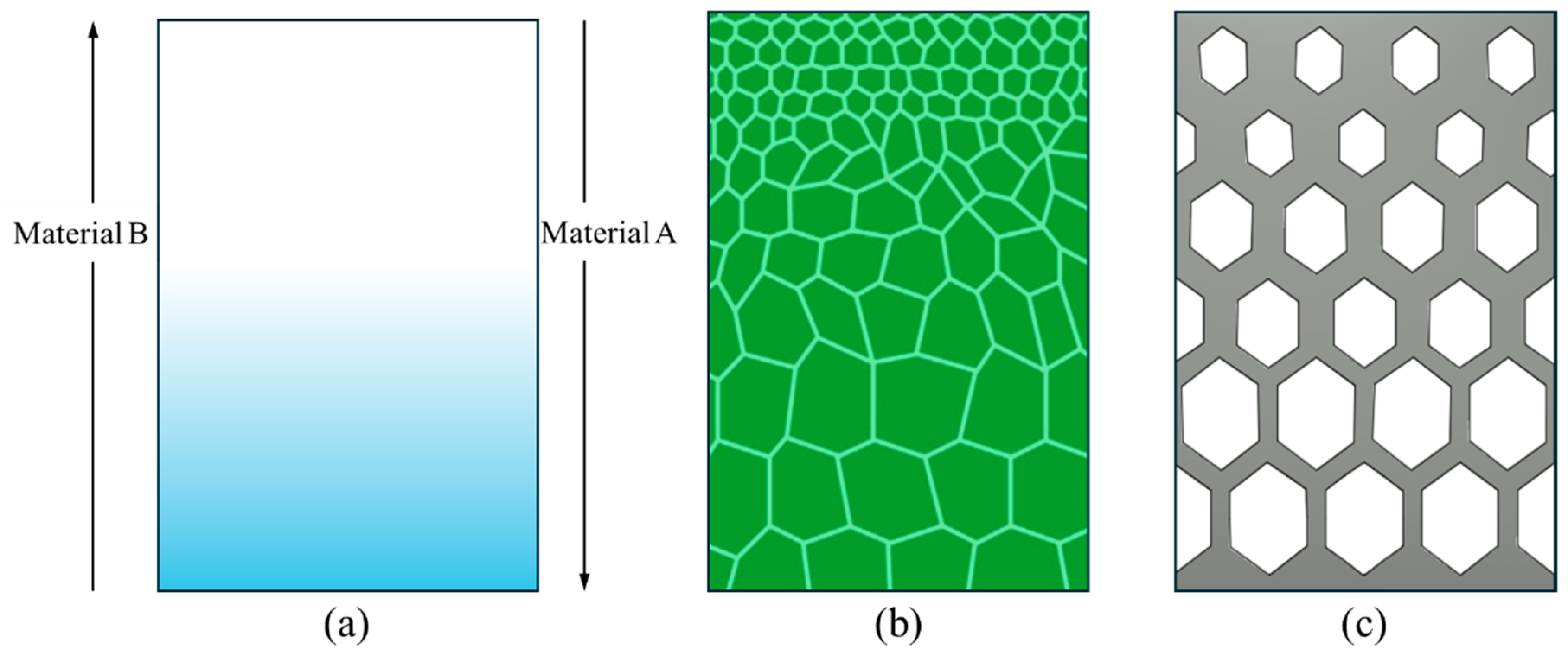

3.1. Classification of FGMs

3.1.1. Chemical Composition FGMs

3.1.2. Microstructure FGMs

3.1.3. Porosity FGMs

- Homogeneous FGMs: Homogeneous FGMs are produced using a single material. The gradient in properties is achieved by controlling factors such as microstructure and porosity. The base material can be pure metals, pure polymers, metal alloys, or composites. In homogeneous FGMs, there is no change in the chemical composition; rather, the variation in properties is due to changes in the physical structure of the material. Generally, microstructure and porosity FGMs are considered homogeneous FGMs because their gradients are achieved without varying the proportions of different materials.

- Heterogeneous FGMs: Heterogeneous FGMs involve a gradient in properties achieved through variations in chemical composition. These FGMs are produced using two or more different materials, with the proportion of each material varying at different spatial positions. This results in a gradient of properties tailored to specific application requirements. Chemical composition FGMs are always considered heterogeneous FGMs due to the inherent variation in material composition.

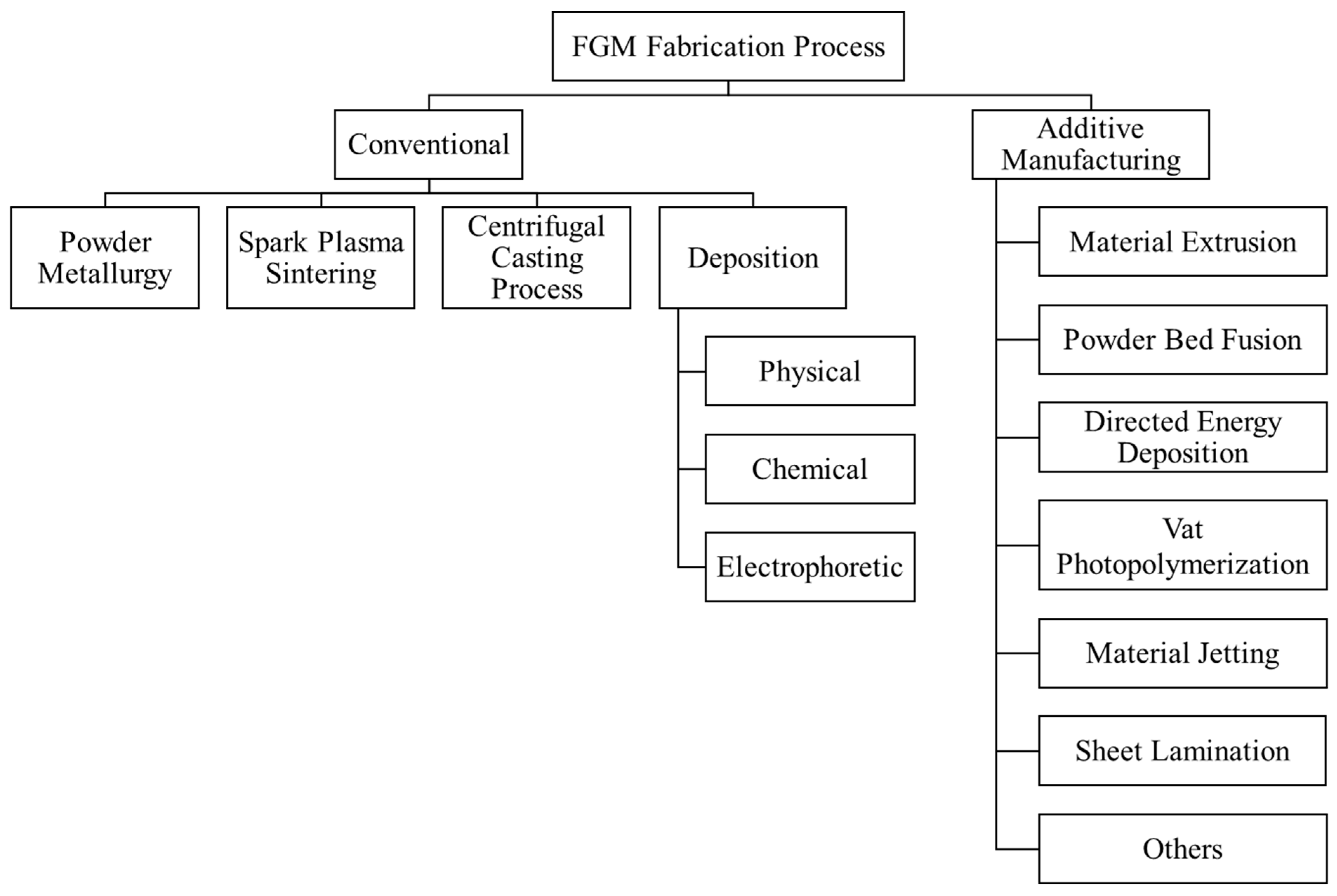

3.2. Fabrication Processes for FGMs

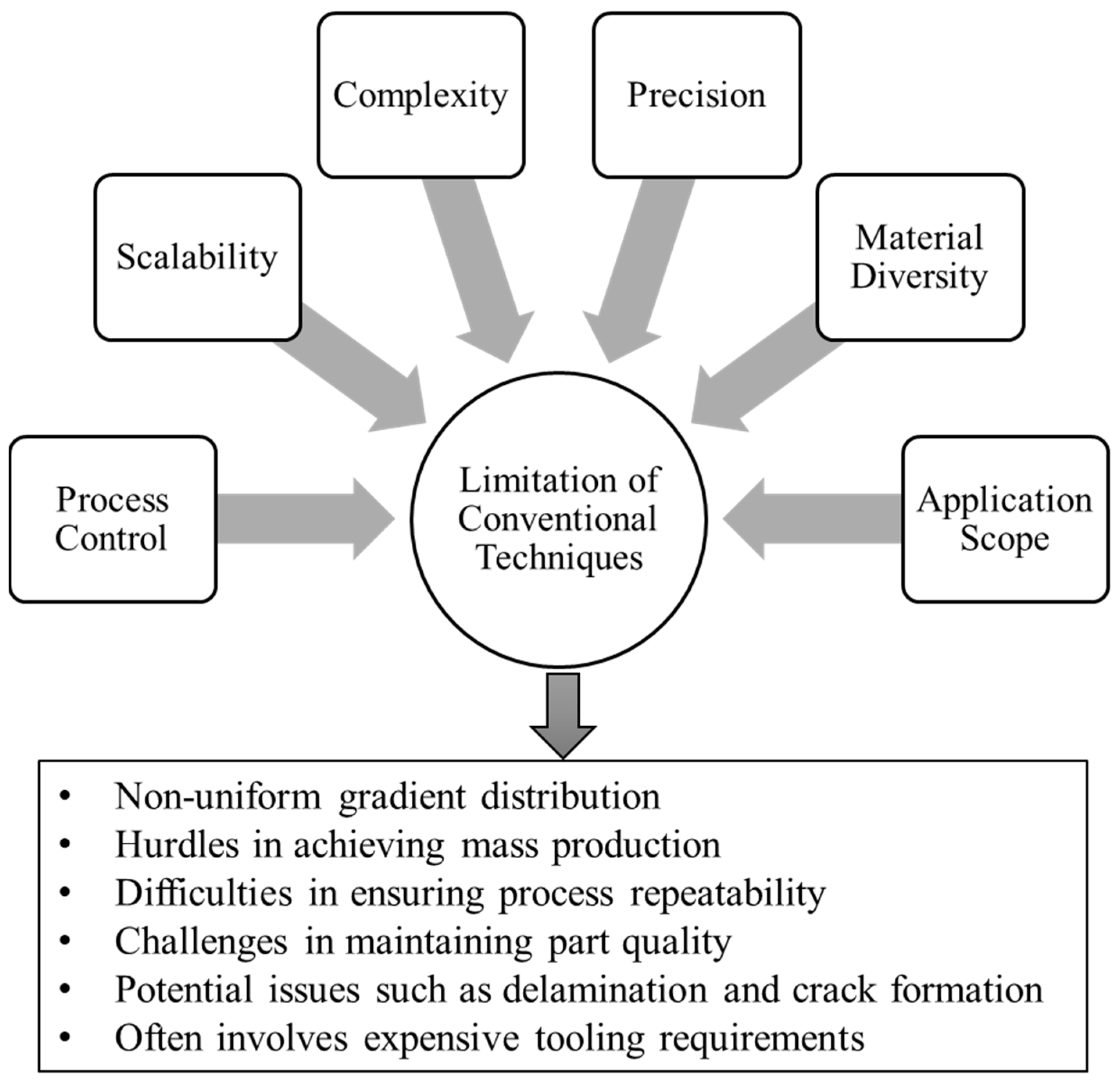

- Limited process control and scalability. Conventional techniques such as PVD, CVD, and EPD face challenges in accurately controlling the detailed thickness and continuous composition of the coating during deposition. In SPS, the short-range diffusion of atoms may affect the uniform production of FGMs during the sintering process when powders are consolidated into a solid material through rapid heating and the application of pressure. Furthermore, the CC process relies on centrifugal force, which can lead to non-uniform gradient distribution. Additionally, while FGMs can be successfully produced on a laboratory scale, there are significant hurdles in achieving mass production, ensuring process repeatability, maintaining part quality for functional applications, enhancing process capability, and addressing reliability issues for industrial-scale production.

- Limited geometrical complexity and precision. Conventional techniques for FGMs face limitations in producing geometrically complex parts, like traditional machining processes. Furthermore, these techniques often exhibit restricted gradient variations. For example, centrifugal casting (CC) is suitable primarily for cylindrically shaped parts [50]. Achieving high precision in part production is also challenging. For instance, ensuring homogeneous particle distribution and precise outcomes pose difficulties in the CC process for functional applications [19]. Although PM is widely used for FGMs, achieving greater precision through proper diffusion remains a challenge. Additionally, the presence of porosity in parts produced by PM renders their properties insufficient for specific applications.

- Limited material diversity and gradients. Conventional techniques predominantly focus on metals, metal alloys, and ceramics for developing FGMs, with limited exploration of polymers, polymer composites, and biomaterials. Additionally, most conventional techniques are primarily used for fabricating chemical composition and microstructure FGMs, while there is a need for advancements in developing porosity FGMs. Processes such as CC and SPS are not suitable for achieving a porosity gradient structure. Furthermore, in chemical composition FGMs fabricated through powder metallurgy, sharp changes from one phase to another can lead to issues such as delamination and crack formation. These limitations highlight the importance of exploring diverse materials and developing effective techniques to facilitate the development of more advanced FGMs selection.

- Limited application scope and real-world implementation. The use of conventional techniques for fabricating FGMs is often limited to surface coatings and functional parts in industries such as aerospace, automobiles, military, and energy. These methods, such as PVD, CVD, and EPD, are primarily employed for achieving gradient surface properties through varying processing parameters and material proportions. However, there are constraints when it comes to expanding FGM applications to fields like biomedicine, specifically for bone implants and prostheses, where functionally gradient properties are vital for mimicking living organs. Conventional methods focusing on surface gradients and metal/metal alloys may not be suitable for developing FGMs tailored for biomedical applications.

- Limited cost-effectiveness and sustainability. Conventional techniques for fabricating FGMs often involve expensive tooling requirements. For example, the CC process necessitates costly molds tailored to the specific part shape. It is imperative to explore more affordable fabrication methods to promote research and enable the development of FGMs with a broad spectrum of gradient properties for diverse applications. Furthermore, the sustainability aspect is often overlooked in the fabrication of FGMs. Energy efficiency, environmental considerations, and safety issues are not adequately addressed. Gas-based techniques like CVD, for instance, are energy-intensive and generate hazardous gases during FGM production.

4. Fused Filament Fabrication for FGM Fabrication

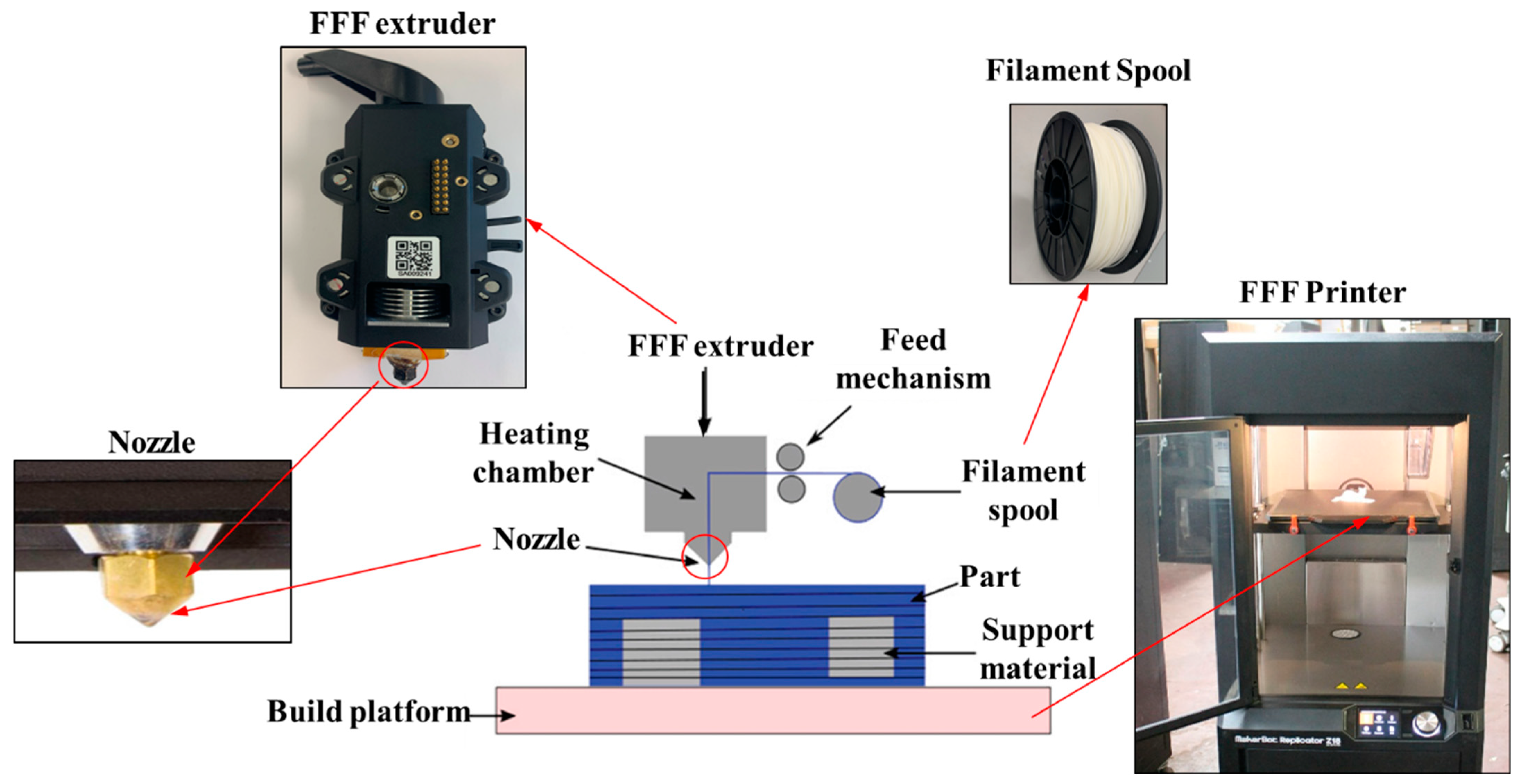

4.1. Fused Filament Fabrication

4.2. Fused Filament Fabrication-Based Functionally Gradient Materials

4.2.1. Material Proportion

4.2.2. Infill Parameters and Lattice Structures

4.2.3. Miscellaneous Gradients

5. Discussion and Potential Research

5.1. Discussion

5.2. Future Research Directions

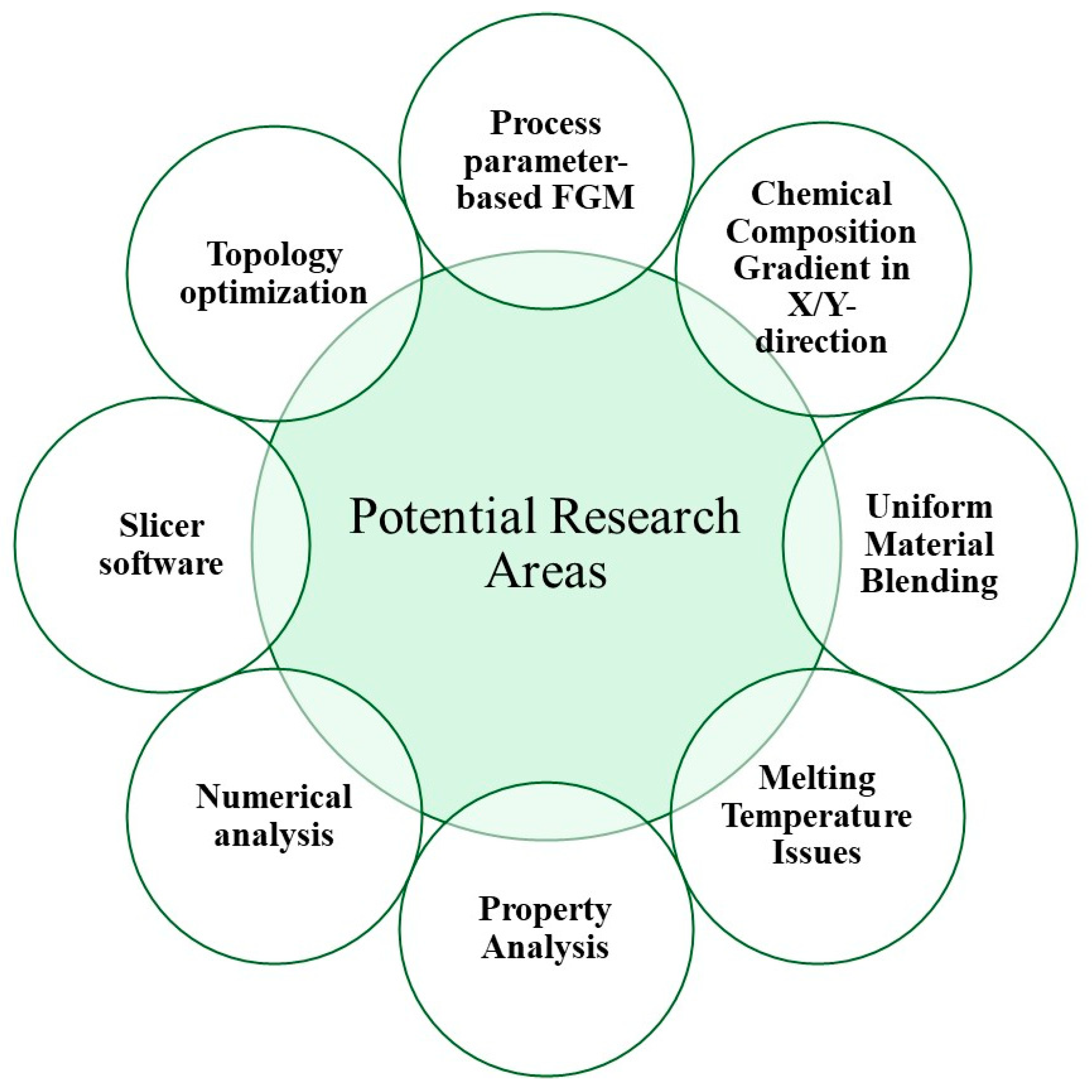

- Process parameter-based FGM: The FFF process parameters (e.g., layer thickness, infill density, build orientation, infill structures, print speed, etc.) have significant impacts on part qualities, build time, and costs. Based on requirements, different combinations of process parameters can be used at different spatial positions to optimize properties, build time, and costs. For this, optimization techniques such as multiobjective optimization and topology optimization can be used. Customized G-code is required to control print speed, deposition rate, and other parameters at different spatial position. Many open-source software options are available to customize G-code for printing parts via the FFF process.

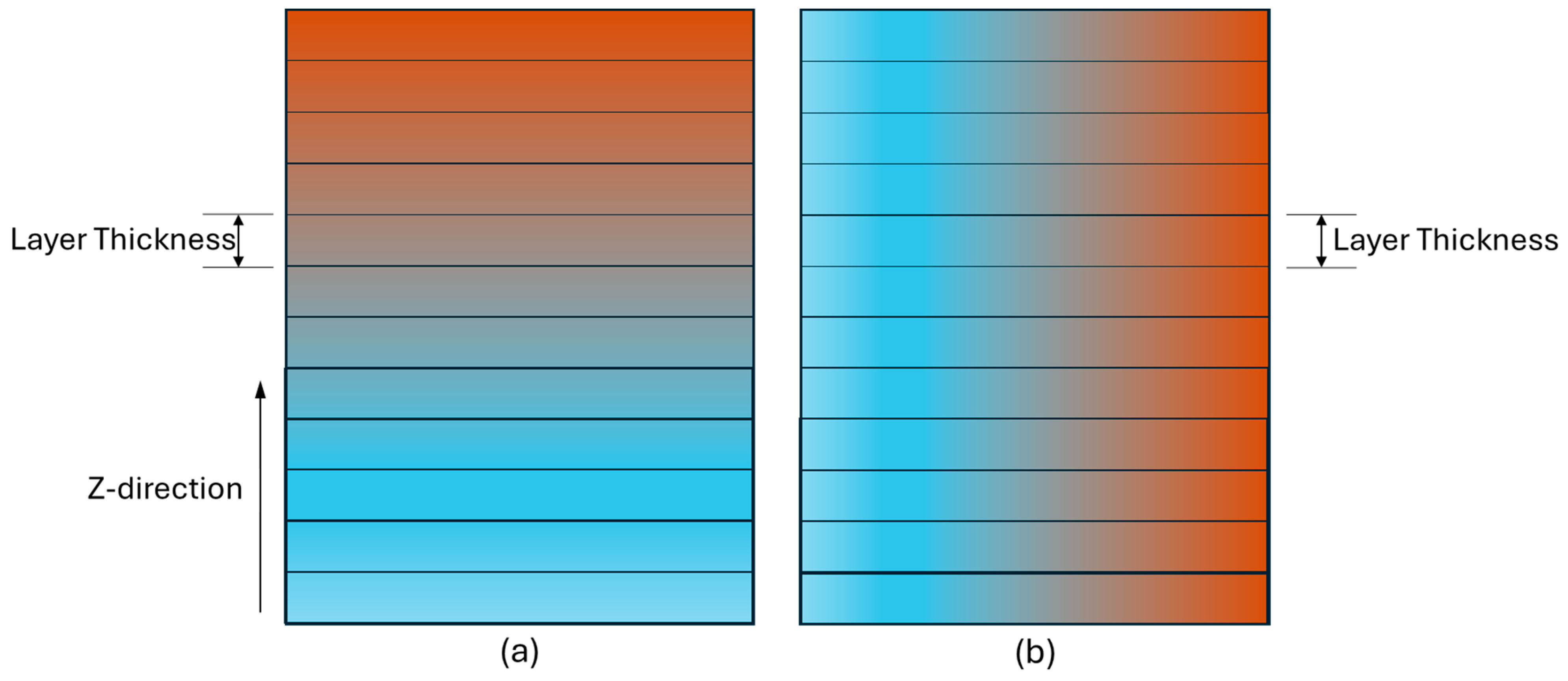

- Chemical composition gradient in X/Y-direction: In the FFF process, the chemical composition gradient can be achieved only in the Z-direction as the ratio of two or more materials is constant in a layer. Figure 8a shows the chemical composition gradient along the Z-direction of an FFF machine, while the gradient along another direction is shown in Figure 8b. Different properties (e.g., tensile properties) are low in the Z-direction compared to the X- and Y-directions due to a weak bond between two consecutive layers. Intensive research is necessary to achieve chemical composition gradients in directions other than the Z-direction. One concept involves the continuous mixing of materials at different ratios within the heating chamber of the FFF machine extruder rather than relying solely on filaments. This approach necessitates a customized FFF machine. Another concept involves the simultaneous production of filaments by connecting a twin- or single-screw extruder with an FFF machine. Some research endeavors have focused on customizing FFF machines to be compatible with an extruder for FGM components. Achieving this requires precise control and accuracy in determining the volume of materials at different locations within a layer and adjusting ratios continuously throughout the layer.

- Uniform material blending: An extruder with one nozzle for material deposition and multiple openings for input filaments is used in the FFF process where material is mixed in the heating chamber of the extruder. In many FFF machines, achieving uniform material mixing can be challenging. As a result, the actual deposited material ratio may differ from the targeted ratio, significantly impacting the quality of an FGM component. To address this challenge, focusing on refining the design of FFF machines is a highly effective approach.

- Melting temperature issues: When two materials melt within a single chamber, variations in melting point temperatures lead to differences in their molten states, viscosity, and flowability. These property variations will significantly impact factors such as dimensional accuracy and bonding strength. It is vital to consider this factor in material selection for FGM production. When the melting point temperature difference is high for two materials, an FFF machine with multiple extruders can be used. An alternative option may be a preheating system design for materials with high melting points based on the physical, chemical, and other properties of filament materials.

- Property analysis: Testing the properties of FGM parts is also challenging due to the lack of sufficient standards and gradient features. In destructive testing, determining the physical properties of a specific spatial position is not feasible. While simulation analysis is practical, most simulation software is not designed for additive manufacturing environments, where additional complexity arises due to layer-by-layer processes and the impacts of process parameters. An important research direction involves advancing computational models and simulation techniques to effectively predict and optimize the properties of FGMs produced through AM [81,92]. This entails developing improved design methodologies that leverage the distinctive features of AM processes to achieve tailored material gradients, enhanced performance, and functional integration within FGM structures.

- Numerical analysis: Most of the research efforts on the development of FGMs are experimental to study the viability of a technique for the successful fabrication of FGMs. Along with the experimental analysis, different optimization techniques [93] and machine learning algorithms can be used to predict properties and set a combination of parameters to obtain the desired properties [94]. For this, a standard data collection step is required to collect robust and high-quality data. Different types of sensors (e.g., vibration sensors, accelerometers, and thermistors) and the design of experiments can be used to collect data.

- Slicer software: Slicer software presents various limitations. A more effective solution involves modifying an existing slicer to interpret not only the geometric model but also the internal composition model, thus generating a G-code that integrates both. While such an enhanced slicer is currently unavailable, a workaround has been developed to partially address the issue.

- Topology optimization: Topology optimization optimizes material layout within a given space to achieve the maximum performance of a structure or component. Topology optimization can be utilized to generate functionally graded components by optimizing material distribution. Additionally, it allows for the incorporation of other modifications such as infill structures, adjusting infill density, varying layer thickness, and so on.

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, Z.; Shi, X.; Huang, H.; Yao, C.; Xie, W.; Huang, C.; Gu, P.; Ma, X.; Zhang, Z.; Chen, L.-Q. Magnetically actuated functional gradient nanocomposites for strong and ultra-durable biomimetic interfaces/surfaces. Mater. Horiz. 2017, 4, 869–877. [Google Scholar] [CrossRef]

- Liu, Z.; Meyers, M.A.; Zhang, Z.; Ritchie, R.O. Functional gradients and heterogeneities in biological materials: Design principles, functions, and bioinspired applications. Prog. Mater. Sci. 2017, 88, 467–498. [Google Scholar] [CrossRef]

- Shi, H.; Zhou, P.; Li, J.; Liu, C.; Wang, L. Functional gradient metallic biomaterials: Techniques, current scenery, and future prospects in the biomedical field. Front. Bioeng. Biotechnol. 2021, 8, 616845. [Google Scholar] [CrossRef] [PubMed]

- Zhang, N.; Khan, T.; Guo, H.; Shi, S.; Zhong, W.; Zhang, W. Functionally Graded Materials: An Overview of Stability, Buckling, and Free Vibration Analysis. Adv. Mater. Sci. Eng. 2019, 2019, 1354150. [Google Scholar] [CrossRef]

- Akinbade, Y.; Nettleship, I.; Papadopoulos, C.; Harries, K.A. Modelling full-culm bamboo as a naturally varying functionally graded material. Wood Sci. Technol. 2021, 55, 155–179. [Google Scholar] [CrossRef]

- Amada, S.; Munekata, T.; Nagase, Y.; Ichikawa, Y.; Kirigai, A.; Zhifei, Y. The Mechanical Structures of Bamboos in Viewpoint of Functionally Gradient and Composite Materials. J. Compos. Mater. 1996, 30, 800–819. [Google Scholar] [CrossRef]

- Articek, U.; Milfelner, M.; Anzel, I. Synthesis of functionally graded material H13/Cu by LENS technology. Adv. Prod. Eng. Manag. 2013, 8, 169–176. [Google Scholar] [CrossRef]

- Bohidar, S.K.; Sharma, R.; Mishra, P.R. Functionally graded materials: A critical review. Int. J. Res. 2014, 1, 289–301. [Google Scholar]

- Dey, A.; Eagle, I.N.R.; Yodo, N. A Review on Filament Materials for Fused Filament Fabrication. J. Manuf. Mater. Process. 2021, 5, 69. [Google Scholar] [CrossRef]

- Angelopoulos, P.M.; Samouhos, M.; Taxiarchou, M. Functional fillers in composite filaments for fused filament fabrication; a review. Mater. Today Proc. 2021, 37, 4031–4043. [Google Scholar] [CrossRef]

- Dawoud, M.M.; Saleh, H.M. Introductory chapter: Background on composite materials. In Characterizations of Some Composite Materials; IntechOpen: London, UK, 2018. [Google Scholar]

- Reiner, J.; Vaziri, R. 8.4 Structural analysis of composites with finite element codes: An overview of commonly used computational methods. In Materials Science and Materials Engineering; Elsevier: Amsterdam, The Netherlands, 2018. [Google Scholar]

- Huang, L.; Geng, L.; Peng, H. Microstructurally inhomogeneous composites: Is a homogeneous reinforcement distribution optimal? Prog. Mater. Sci. 2015, 71, 93–168. [Google Scholar] [CrossRef]

- Pavan, M.V.; Balamurugan, K.; Balamurugan, P. Compressive test Fractured Surface analysis on PLA-Cu composite filament printed at different FDM conditions. IOP Conf. Ser. Mater. Sci. Eng. 2020, 988, 012019. [Google Scholar] [CrossRef]

- Butt, J.; Oxford, P.; Sadeghi-Esfahlani, S.; Ghorabian, M.; Shirvani, H. Hybrid Manufacturing and Mechanical Characterization of Cu/PLA Composites. Arab. J. Sci. Eng. 2020, 45, 9339–9356. [Google Scholar] [CrossRef]

- Bhavar, V.; Kattire, P.; Thakare, S.; Patil, S.; Singh, R.K.P. A Review on Functionally Gradient Materials (FGMs) and Their Applications. IOP Conf. Ser. Mater. Sci. Eng. 2017, 229, 012021. [Google Scholar] [CrossRef]

- Matthews, F.L.; Rawlings, R.D. Composite Materials: Engineering and Science; CRC Press: Boca Raton, FL, USA, 1999. [Google Scholar]

- Loh, G.H.; Pei, E.; Harrison, D.; Monzón, M.D. An overview of functionally graded additive manufacturing. Addit. Manuf. 2018, 23, 34–44. [Google Scholar] [CrossRef]

- Naebe, M.; Shirvanimoghaddam, K. Functionally graded materials: A review of fabrication and properties. Appl. Mater. Today 2016, 5, 223–245. [Google Scholar] [CrossRef]

- Miyamoto, Y.; Kaysser, W.A.; Rabin, B.H.; Kawasaki, A.; Ford, R.G. Functionally Graded Materials: Design, Processing and Applications; Springer Science & Business Media: Berlin, Germany, 2013; Volume 5. [Google Scholar]

- Sarathchandra, D.; Subbu, S.K.; Venkaiah, N. Functionally graded materials and processing techniques: An art of review. Mater. Today Proc. 2018, 5, 21328–21334. [Google Scholar] [CrossRef]

- El-Galy, I.M.; Saleh, B.I.; Ahmed, M.H. Functionally graded materials classifications and development trends from industrial point of view. SN Appl. Sci. 2019, 1, 1378. [Google Scholar] [CrossRef]

- Srivastava, M.; Rathee, S.; Maheshwari, S.; Kundra, T.K. Design and processing of functionally graded material: Review and current status of research. In 3D Printing and Additive Manufacturing Technologies; Springer: Singapore, 2019; pp. 243–255. [Google Scholar]

- Koizumi, M. FGM activities in Japan. Compos. Part B Eng. 1997, 28, 1–4. [Google Scholar] [CrossRef]

- Kieback, B.; Neubrand, A.; Riedel, H. Processing techniques for functionally graded materials. Mater. Sci. Eng. A 2003, 362, 81–106. [Google Scholar] [CrossRef]

- Hazan, E.; Ben-Yehuda, O.; Madar, N.; Gelbstein, Y. Functional Graded Germanium–Lead Chalcogenide-Based Thermoelectric Module for Renewable Energy Applications. Adv. Energy Mater. 2015, 5, 1500272. [Google Scholar] [CrossRef]

- Ghanavati, R.; Naffakh-Moosavy, H. Additive manufacturing of functionally graded metallic materials: A review of experimental and numerical studies. J. Mater. Res. Technol. 2021, 13, 1628–1664. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Hao, L.; Huang, L.; Xin, C.; Wang, Y.; Bilotti, E.; Essa, K.; Zhang, H.; Li, Z.; et al. A Review on Functionally Graded Materials and Structures via Additive Manufacturing: From Multi-Scale Design to Versatile Functional Properties. Adv. Mater. Technol. 2020, 5, 1900981. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, F.; Huang, Z.; Jia, M.; Chen, G.; Ye, Y.; Lin, Y.; Liu, W.; Chen, B.; Shen, Q.; et al. Additive manufacturing of functionally graded materials: A review. Mater. Sci. Eng. A 2019, 764, 138209. [Google Scholar] [CrossRef]

- Zhang, B.; Jaiswal, P.; Rai, R.; Nelaturi, S. Additive Manufacturing of Functionally Graded Material Objects: A Review. J. Comput. Inf. Sci. Eng. 2018, 18, 041002. [Google Scholar] [CrossRef]

- Mahmoud, D.; Elbestawi, M.A. Lattice Structures and Functionally Graded Materials Applications in Additive Manufacturing of Orthopedic Implants: A Review. J. Manuf. Mater. Process. 2017, 1, 13. [Google Scholar] [CrossRef]

- Nohut, S.; Schwentenwein, M. Vat Photopolymerization Additive Manufacturing of Functionally Graded Materials: A Review. J. Manuf. Mater. Process. 2022, 6, 17. [Google Scholar] [CrossRef]

- Yan, L.; Chen, Y.; Liou, F. Additive manufacturing of functionally graded metallic materials using laser metal deposition. Addit. Manuf. 2020, 31, 100901. [Google Scholar] [CrossRef]

- Li, Y.; Feng, Z.; Huang, L.; Essa, K.; Bilotti, E.; Zhang, H.; Peijs, T.; Hao, L. Additive manufacturing high performance graphene-based composites: A review. Compos. Part A Appl. Sci. Manuf. 2019, 124, 105483. [Google Scholar] [CrossRef]

- Zhang, Y.; Moon, S.K. Data-driven design strategy in fused filament fabrication: Status and opportunities. J. Comput. Des. Eng. 2021, 8, 489–509. [Google Scholar] [CrossRef]

- Gandhi, Y.; Minak, G. A Review on Topology Optimization Strategies for Additively Manufactured Continuous Fiber-Reinforced Composite Structures. Appl. Sci. 2022, 12, 11211. [Google Scholar] [CrossRef]

- Pazhamannil, R.V.; Jishnu Namboodiri, V.N.; Govindan, P.; Edacherian, A. Property enhancement approaches of fused filament fabrication technology: A review. Polym. Eng. Sci. 2022, 62, 1356–1376. [Google Scholar] [CrossRef]

- Hench, L.L.; Jones, J.R. Biomaterials, Artificial Organs and Tissue Engineering; Elsevier: Amsterdam, The Netherlands, 2005. [Google Scholar]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S.L. Functionally graded material: An overview. In Proceedings of the World Congress on Engineering 2012 Vol III (WCE 2012), London, UK, 4–6 July 2012. [Google Scholar]

- Clyne, T.W.; Hull, D. An Introduction to Composite Materials; Cambridge University Press: Cambridge, UK, 2019. [Google Scholar]

- Campbell, F. Introduction to composite materials. In Structural Composite Materials; ASM International: Almere, The Netherlands, 2010; Volume 1, pp. 1–29. [Google Scholar]

- Ngo, T.-D. Introduction to composite materials. In Composite and Nanocomposite Materials—From Knowledge to Industrial Applications; IntechOpen: London, UK, 2020. [Google Scholar]

- Treviso, A.; Van Genechten, B.; Mundo, D.; Tournour, M. Damping in composite materials: Properties and models. Compos. Part B Eng. 2015, 78, 144–152. [Google Scholar] [CrossRef]

- Saba, N.; Jawaid, M.; Sultan, M. An overview of mechanical and physical testing of composite materials. In Mechanical and Physical Testing of Biocomposites, Fibre-Reinforced Composites and Hybrid Composites; Woodhead Publishing: Sawston, UK, 2019; pp. 1–12. [Google Scholar]

- Shanmugavel, P.G.B.B.; Bhaskar, G.B.; Chandrasekaran, M.; Mani, P.S.; Srinivasan, S.P. An overview of fracture analysis in functionally graded materials. Eur. J. Sci. Res. 2012, 68, 412–439. [Google Scholar]

- Mahamood, R.M.; Akinlabi, E.T. Types of functionally graded materials and their areas of application. In Functionally Graded Materials; Springer: Cham, Switzerland, 2017; pp. 9–21. [Google Scholar]

- Sun, J.; Jiang, Q.; Lei, L.; Zhang, J. Compositional gradient affects the residual stress distribution in Si3N4/SiC functionally graded materials. Ceram. Int. 2023, 49, 19281–19289. [Google Scholar] [CrossRef]

- Geng, Y.; Xie, W.; Tu, Y.; Deng, S.; Egan, D.; Dowling, D.P.; Song, H.; Zhang, S.; Harrison, N. Ti–6Al–4V microstructural functionally graded material by additive manufacturing: Experiment and computational modelling. Mater. Sci. Eng. A 2021, 823, 141782. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Functionally graded Inconel 718 processed by additive manufacturing: Crystallographic texture, anisotropy of microstructure and mechanical properties. Mater. Des. 2017, 114, 441–449. [Google Scholar] [CrossRef]

- Mohammadi, M.; Rajabi, M.; Ghadiri, M. Functionally graded materials (FGMs): A review of classifications, fabrication methods and their applications. Process. Appl. Ceram. 2021, 15, 319–343. [Google Scholar] [CrossRef]

- Hsu, Y.H.; Turner, I.G.; Miles, A.W. Fabrication of porous bioceramics with porosity gradients similar to the bimodal structure of cortical and cancellous bone. J. Mater. Sci. Mater. Med. 2007, 18, 2251–2256. [Google Scholar] [CrossRef]

- Zhou, S.; Li, Q. Design of graded two-phase microstructures for tailored elasticity gradients. J. Mater. Sci. 2008, 43, 5157–5167. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T. Processing methods of functionally graded materials. In Functionally Graded Materials; Springer: Cham, Switzerland, 2017; pp. 23–45. [Google Scholar]

- Hasanov, S.; Gupta, A.; Nasirov, A.; Fidan, I. Mechanical characterization of functionally graded materials produced by the fused filament fabrication process. J. Manuf. Process. 2020, 58, 923–935. [Google Scholar] [CrossRef]

- Palaniyappan, S.; Annamalai, G.; Sivakumar, N.K.; Muthu, P. Development of functional gradient multi-material composites using Poly Lactic Acid and walnut shell reinforced Poly Lactic Acid filaments by fused filament fabrication technology. J. Build. Eng. 2023, 65, 105746. [Google Scholar] [CrossRef]

- Schmidt, A.; Jensch, F.; Härtel, S. Multi-material additive manufacturing-functionally graded materials by means of laser remelting during laser powder bed fusion. Front. Mech. Eng. 2023, 18, 49. [Google Scholar] [CrossRef]

- Ghanavati, R.; Lannunziata, E.; Norouzi, E.; Bagherifard, S.; Iuliano, L.; Saboori, A. Design and development of SS316L-IN718 functionally graded materials via laser powder bed fusion. Mater. Lett. 2023, 349, 134793. [Google Scholar] [CrossRef]

- Duan, X.; Wang, S.; Yang, H.; Wang, G.; Liu, W.; Xiao, Z. Microstructure and mechanical properties of functional gradient materials of high entropy alloys prepared by direct energy deposition. J. Mater. Res. Technol. 2023, 26, 1677–1696. [Google Scholar] [CrossRef]

- Hotz, H.; Zimmermann, M.; Greco, S.; Kirsch, B.; Aurich, J.C. Additive manufacturing of functionally graded Ti-Al structures by laser-based direct energy deposition. J. Manuf. Process. 2021, 68, 1524–1534. [Google Scholar] [CrossRef]

- Kaweesa, D.V.; Spillane, D.R.; Meisel, N.A. Investigating the Impact of Functionally Graded Materials on Fatigue Life of Material Jetted Specimens; University of Texas at Austin: Austin, TX, USA, 2017. [Google Scholar]

- Ituarte, I.F.; Boddeti, N.; Hassani, V.; Dunn, M.L.; Rosen, D.W. Design and additive manufacture of functionally graded structures based on digital materials. Addit. Manuf. 2019, 30, 100839. [Google Scholar] [CrossRef]

- Zhang, Y.; Wang, J. Fabrication of Functionally Graded Porous Polymer Structures using Thermal Bonding Lamination Techniques. Procedia Manuf. 2017, 10, 866–875. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2014; Volume 17. [Google Scholar]

- Dey, A.; Yodo, N. A Systematic Survey of FDM Process Parameter Optimization and Their Influence on Part Characteristics. J. Manuf. Mater. Process. 2019, 3, 64. [Google Scholar] [CrossRef]

- Wang, J.; Mubarak, S.; Dhamodharan, D.; Divakaran, N.; Wu, L.; Zhang, X. Fabrication of thermoplastic functionally gradient composite parts with anisotropic thermal conductive properties based on multicomponent fused deposition modeling 3D printing. Compos. Commun. 2020, 19, 142–146. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, J.; Liu, T. 3D printing of polycaprolactone-based composites with diversely tunable mechanical gradients via multi-material fused deposition modeling. Compos. Commun. 2021, 23, 100600. [Google Scholar] [CrossRef]

- Zhuang, Y.; Song, W.; Ning, G.; Sun, X.; Sun, Z.; Xu, G.; Zhang, B.; Chen, Y.; Tao, S. 3D–printing of materials with anisotropic heat distribution using conductive polylactic acid composites. Mater. Des. 2017, 126, 135–140. [Google Scholar] [CrossRef]

- Tey, J.Y.; Teh, D.; Yeo, W.H.; Shak, K.P.Y.; Saw, L.H.; Lee, T.S. Development of 3D printer for functionally graded material using fused deposition modelling method. IOP Conf. Ser. Earth Environ. Sci. 2019, 268, 012019. [Google Scholar] [CrossRef]

- Alkunte, S.; Fidan, I.; Hasanov, S. Experimental Analysis of Functionally Graded Materials Produced by Fused Filament Fabrication; University of Texas at Austin: Austin, TX, USA, 2022. [Google Scholar]

- Li, W.-D.; Zhao, J.-W.; Chen, Y.; Wei, Y.-H.; Jiang, Z.-H.; Wang, C.; Lan, H.-B.; Deng, J.-B.; Zhang, G.-J. Surface Insulation Performance of 3D Printed Functionally Graded Insulator Fabricated by Active-Mixing Fused Deposition Modeling (AM-FDM). In Proceedings of the 2020 IEEE International Conference on High Voltage Engineering and Application (ICHVE), IEEE, Beijing, China, 6–10 September 2020; pp. 1–4. [Google Scholar]

- Su, Z.; Inaba, K.; Karmakar, A.; Das, A. Characterization of Mechanical Property of PLA-ABS Functionally Graded Material Fabricated by Fused Deposition Modeling. In Proceedings of the ASME 2021 Gas Turbine India Conference, Virtual, 2–3 December 2021. [Google Scholar]

- Leu, M.C.; Deuser, B.K.; Tang, L.; Landers, R.G.; Hilmas, G.E.; Watts, J.L. Freeze-form extrusion fabrication of functionally graded materials. CIRP Ann. 2012, 61, 223–226. [Google Scholar] [CrossRef]

- Li, A.; Thornton, A.S.; Deuser, B.K.; Watts, J.L.; Leu, M.C.; Hilmas, G.; Landers, R.G. Freeze-form extrusion fabrication of functionally graded material composites using zirconium carbide and tungsten. In Proceedings of the 23rd Annual International Solid Freeform Fabrication Symposium, Austin, TX, USA, 6–8 August 2012; University of Texas at Austin: Austin, TX, USA, 2012; pp. 467–479. [Google Scholar]

- Li, W.; Armani, A.; Martin, A.; Kroehler, B.; Henderson, A.; Huang, T.; Watts, J.; Hilmas, G.; Leu, M. Extrusion-based additive manufacturing of functionally graded ceramics. J. Eur. Ceram. Soc. 2021, 41, 2049–2057. [Google Scholar] [CrossRef]

- Silva, B.G.; Alves, F.; Sardinha, M.; Reis, L.; Leite, M.; Deus, A.M.; Vaz, M.F. Functionally graded cellular cores of sandwich panels fabricated by additive manufacturing. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2022, 236, 1814–1828. [Google Scholar] [CrossRef]

- Płatek, P.; Baranowski, P.; Cieplak, K.; Sarzyński, M.; Sienkiewicz, J.; Janiszewski, J.; Małachowski, J. In Investigation on deformation process of cellular structures with gradient topology manufactured additively. In AIP Conference Proceedings; AIP Publishing LLC: Melville, NY, USA, 2019; p. 020108. [Google Scholar] [CrossRef]

- Elenskaya, N.; Tashkinov, M. Modeling of Deformation Behavior of Gyroid and I-WP Polymer Lattice Structures with a Porosity Gradient. Procedia Struct. Integr. 2021, 32, 253–260. [Google Scholar] [CrossRef]

- Pais, A.; Alves, J.L.; Belinha, J. Design of functionally graded gyroid foams using optimization algorithms and the finite element method: A simple approach on prototyping from simulation to manufacturing. Int. J. Adv. Manuf. Technol. 2021, 114, 725–739. [Google Scholar] [CrossRef]

- Wen, Z.; Li, M. Compressive Properties of Functionally Graded Bionic Bamboo Lattice Structures Fabricated by FDM. Materials 2021, 14, 4410. [Google Scholar] [CrossRef]

- Duraibabu, R.; Prithvirajan, R.; Sugavaneswaran, M.; Arumaikkannu, G. Compression behavior of Functionally Graded Cellular Materials fabricated with FDM. Mater. Today Proc. 2020, 24, 1035–1041. [Google Scholar] [CrossRef]

- Srivastava, M.; Maheshwari, S.; Kundra, T.; Rathee, S.; Yashaswi, R.; Sharma, S.K. Virtual Design, Modelling and Analysis of Functionally graded materials by Fused Deposition Modeling. Mater. Today Proc. 2016, 3, 3660–3665. [Google Scholar] [CrossRef]

- Caliskan, U.; Sevim, C.; Demirbas, M.D. Tensile behavior of functionally graded sandwich PLA-ABS produced via fused filament fabrication process. Mech. Adv. Mater. Struct. 2024, 31, 261–270. [Google Scholar] [CrossRef]

- Ritter, T.; McNiffe, E.; Higgins, T.; Sam-Daliri, O.; Flanagan, T.; Walls, M.; Ghabezi, P.; Finnegan, W.; Mitchell, S.; Harrison, N.M. Design and Modification of a Material Extrusion 3D Printer to Manufacture Functional Gradient PEEK Components. Polymers 2023, 15, 3825. [Google Scholar] [CrossRef] [PubMed]

- Jaiswal, P.; Patel, J.; Rai, R. Build orientation optimization for additive manufacturing of functionally graded material objects. Int. J. Adv. Manuf. Technol. 2018, 96, 223–235. [Google Scholar] [CrossRef]

- Garland, A.; Fadel, G. Design and Manufacturing Functionally Gradient Material Objects with an Off the Shelf Three-Dimensional Printer: Challenges and Solutions. J. Mech. Des. 2015, 137, 111407. [Google Scholar] [CrossRef]

- Pompe, W.; Worch, H.; Epple, M.; Friess, W.; Gelinsky, M.; Greil, P.; Hempel, U.; Scharnweber, D.; Schulte, K. Functionally graded materials for biomedical applications. Mater. Sci. Eng. A 2003, 362, 40–60. [Google Scholar] [CrossRef]

- Watari, F.; Yokoyama, A.; Omori, M.; Hirai, T.; Kondo, H.; Uo, M.; Kawasaki, T. Biocompatibility of materials and development to functionally graded implant for bio-medical application. Compos. Sci. Technol. 2004, 64, 893–908. [Google Scholar] [CrossRef]

- Mueller, E.; Drašar, Č.; Schilz, J.; Kaysser, W.A. Functionally graded materials for sensor and energy applications. Mater. Sci. Eng. A 2003, 362, 17–39. [Google Scholar] [CrossRef]

- Niino, M.; Kisara, K.; Mori, M. Feasibility Study of FGM Technology in Space Solar Power Systems (SSPS). Mater. Sci. Forum 2005, 492–493, 163–170. [Google Scholar] [CrossRef]

- Xing, A.; Jun, Z.; Chuanzhen, H.; Jianhua, Z. Development of an advanced ceramic tool material—Functionally gradient cutting ceramics. Mater. Sci. Eng. A 1998, 248, 125–131. [Google Scholar] [CrossRef]

- Radhi, N.S. A review for functionally gradient materials processes and useful application. J. Univ. Babylon Eng. Sci. 2018, 26, 42–47. [Google Scholar]

- Gupta, A.; Talha, M. Recent development in modeling and analysis of functionally graded materials and structures. Prog. Aerosp. Sci. 2015, 79, 1–14. [Google Scholar] [CrossRef]

- Yodo, N.; Dey, A. Multi-Objective Optimization for FDM Process Parameters with Evolutionary Algorithms. In Fused Deposition Modeling Based 3D Printing; Springer: Cham, Switzerland, 2021; pp. 419–444. [Google Scholar] [CrossRef]

- Wang, C.; Tan, X.; Tor, S.; Lim, C. Machine learning in additive manufacturing: State-of-the-art and perspectives. Addit. Manuf. 2020, 36, 101538. [Google Scholar] [CrossRef]

- Saleh Alghamdi, S.; John, S.; Roy Choudhury, N.; Dutta, N.K. Additive Manufacturing of Polymer Materials: Progress, Promise and Challenges. Polymers 2021, 13, 753. [Google Scholar] [CrossRef]

| Methods | Advantages | Disadvantages |

|---|---|---|

| Powder metallurgy (PM) |

|

|

| Centrifugal casting (CC) |

|

|

| Spark plasma sintering (SPS) |

|

|

| Physical vapor deposition (PVD) |

|

|

| Chemical vapor deposition (CVD) |

|

|

| Electrophoretic deposition (EPD) |

|

|

| Ref. (Year) | Gradient Techniques | Material | FFF Machine | Technology/Equipment | Analyzed Properties |

|---|---|---|---|---|---|

| Wang et al. (2020) [65] | Material proportion | PCL, BN, AIN | - | - | Impact strength, thermal conductivity |

| Zhang et al. (2021) [66] | Material proportion | PCL, BN, AIN | m-FDM | HAAKE twin-screw (Thermo Disher Scientific Inc., Karlsruhe, Germany) Extruder, DMA Q800 (TA Instruments, New Castle, DE, USA), universal testing machine | Interlaminar shear strength, storage modulus, and tensile strength |

| Zhuang et al. (2017) [67] | Material proportion | PLA and G-PLA | iSUN3d 230C (ESUN3D Printing Co., Ltd., Shenzhen, China) | QUANTA 450 (FEI, Hillsboro, OR, USA), TGAQ600 (TA Instruments, New Castle, DE, USA), DM3068 (Rigol Technologies, Suzhou, China), APS3003S-3D (Shenzhen Atten Technology Co., Ltd., Shenzhen, China) | Electrical conductivity and heat distribution |

| Tey et al. (2019) [68] | Material proportion | PA66 | - | PLC, single screw extruder | Controllable mixer design |

| Hasanov et al. (2020) [54] | Material proportions at voxel scale | ABS and PC | ZMorph Fab Multi-Tool (Zmorph S.A., Wrocław, Poland) | Voxolizer, Instron 5582 UTM (Instron, Noorwood, MA, USA), FEA simulation | Microstructure, tensile strength, Young’s modulus |

| Alkunte et al. (2022) [69] | Material proportions at voxel scale | TPU and CF-PETG | ZMorph Fab Multi-Tool | Voxolizer (Version 2.01) | Tensile and fatigue properties |

| Li et al. (2020) [70] | Material proportion | -- | C++ (feeding and mixing mechanism), twin-screw extruder), dielectric spectroscopy analyzer | Surface insulation performance | |

| Su et al. (2021) [71] | Material proportion | PLA and ABS | GEEETECH A30M (HK Getech, Co., Ltd., Shenzhen, China) | X-ray (tomography) | Young’s modulus and natural frequency |

| Ref. (Year) | Gradient Techniques | Material | FFF Machine | Technology/Equipment | Analyzed Properties |

|---|---|---|---|---|---|

| Silva et al. (2022) [75] | Infill structure’s size and shape | PLA (experiment) PLA and Aluminum–PLA (simulation) | UltiMaker 3 (UltiMaker, Zaltbommel, The Netherlands) | SolidWorks 2018, CURA (Slicer), NX Nastran V2019.1 (simulation), Instron 3369 (Instron, Noorwood, MA, USA) | Flexural properties |

| Platek et al. (2019) [76] | Infill structure’s size and shape | TPC | Zortrax M200 (Zortrax, Olsztyn, Poland) | MTS Citerion C45 (MTS Systems GmbH, Berlin, Germany) | Stress and deformation energy |

| Elenskaya and Tashkinov (2021) [77] | Porosity size and shape of lattice structure using geometric models | PEEK (simulation) | -- | Abaqus (FEA) | Elastic behavior using FEA |

| Pais et al. (2021) [78] | Gyroid infill pattern optimization by BESO | PLA | Creality ender 3 (Shenzhen Creality 3D Technology Co. Ltd., Shenzhen, China) | FEMAs software (gyroid law) | Flexural properties |

| Wen et al. (2021) [79] | Strut diameters of lattice structures | PEEK | OmniSys H600 (Omni Tech Suzhou Co. Ltd., Suzhou, China) | LE 3504 UTM (LiShi Co., Shanghai, China), Abaqus | Compressive properties, energy absorption, and deformation behaviors |

| Duraibabu et al. (2020) [80] | Size and shape of infill structure | ABS plus | U-print SE (Stratasys, Ltd., Edina, MN, USA) | Universal testing machine | Energy absorption and compression strength |

| Ref. (Year) | Gradient Techniques | Material | FFF Machine | Technology/Equipment | Analyzed Properties |

|---|---|---|---|---|---|

| Srivastava et al. (2016) [81] | Process parameters | ABS (simulation) | -- | ANSYS 14 | Deformation under transverse load |

| Caliskan et al. (2024) [82] | Lamination sandwich structure | ABS and PLA | GEEETECH A30M (HK Getech, Co., Ltd., Shenzhen, China) | CURA V4.10.0 | Tensile properties |

| Palaniyappan et al. (2023) [55] | Lamination sandwich structure | PLA and WPLA | Pratham 3.0 | CATIA V5R20 (CAD), CURA, Universal Testing Machine | Tensile, compression, and flexural properties, contact angle, heat deflection, specific wear rate, coefficient of friction, and fracture morphology |

| Ritter et al. [83] | Microstructure via thermal control | PEEK | Velleman K8200 (Vellman, Ghent, Belgium) | Hitachi S-4700 SEM machine (Hitachi High-Tech, Tokyo, Japan), CURA V4.3, Arduino, TMP37 temperature sensor (Analog Devices Inc., Middlesex County, MA, USA) | Tensile properties |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dey, A.; Ramoni, M.; Yodo, N. A Survey on Fused Filament Fabrication to Produce Functionally Gradient Materials. Materials 2024, 17, 3675. https://doi.org/10.3390/ma17153675

Dey A, Ramoni M, Yodo N. A Survey on Fused Filament Fabrication to Produce Functionally Gradient Materials. Materials. 2024; 17(15):3675. https://doi.org/10.3390/ma17153675

Chicago/Turabian StyleDey, Arup, Monsuru Ramoni, and Nita Yodo. 2024. "A Survey on Fused Filament Fabrication to Produce Functionally Gradient Materials" Materials 17, no. 15: 3675. https://doi.org/10.3390/ma17153675

APA StyleDey, A., Ramoni, M., & Yodo, N. (2024). A Survey on Fused Filament Fabrication to Produce Functionally Gradient Materials. Materials, 17(15), 3675. https://doi.org/10.3390/ma17153675