Preparation, Magnetic and Mechanical Properties of Fe/Ni-Based Amorphous Fibers

Abstract

1. Introduction

2. Experimental Methods

2.1. Samples Preparation

2.2. Structural Characterizations

2.3. Magnetic Performance Tests

2.4. Mechanical Property Tests

3. Results and Discussions

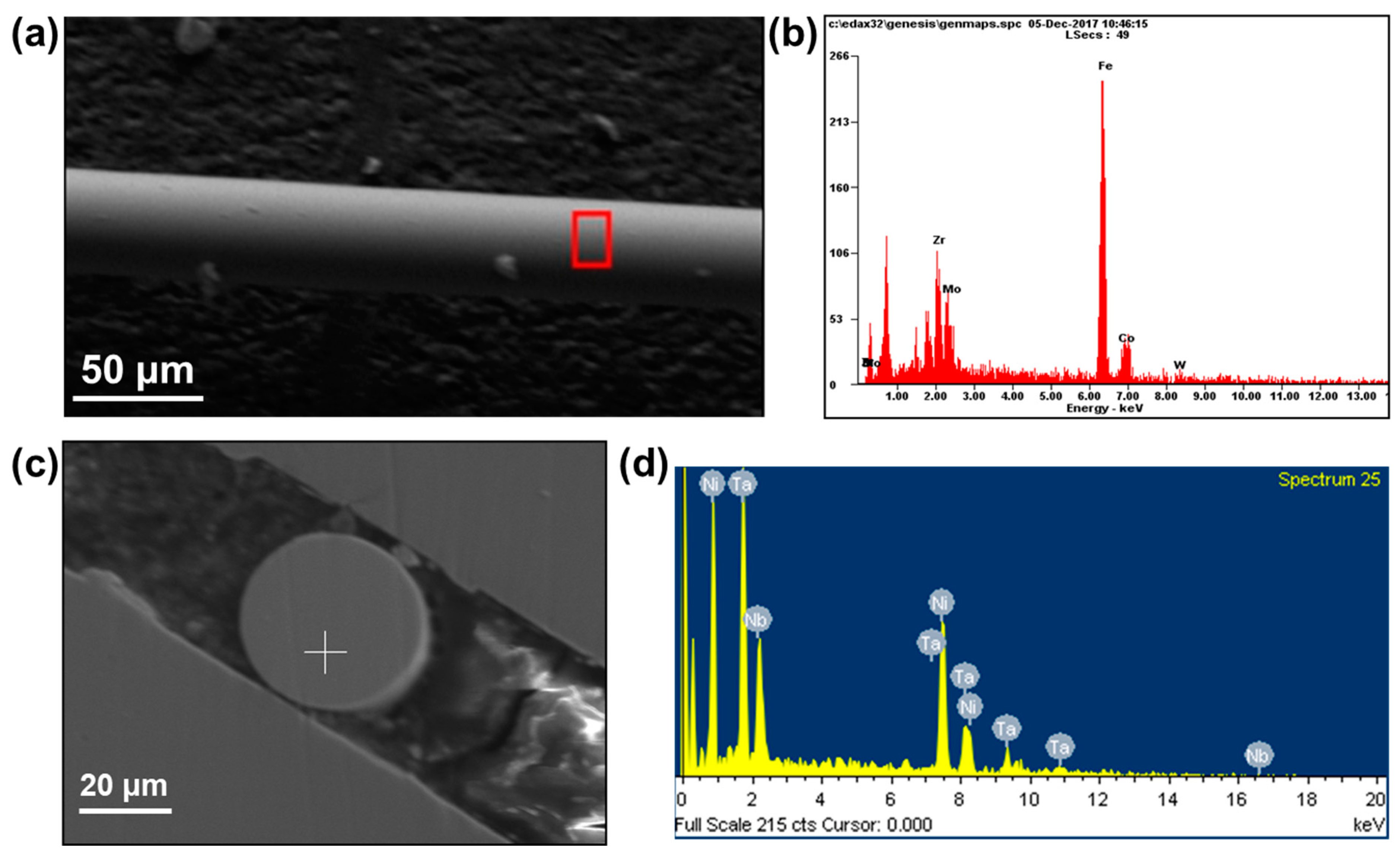

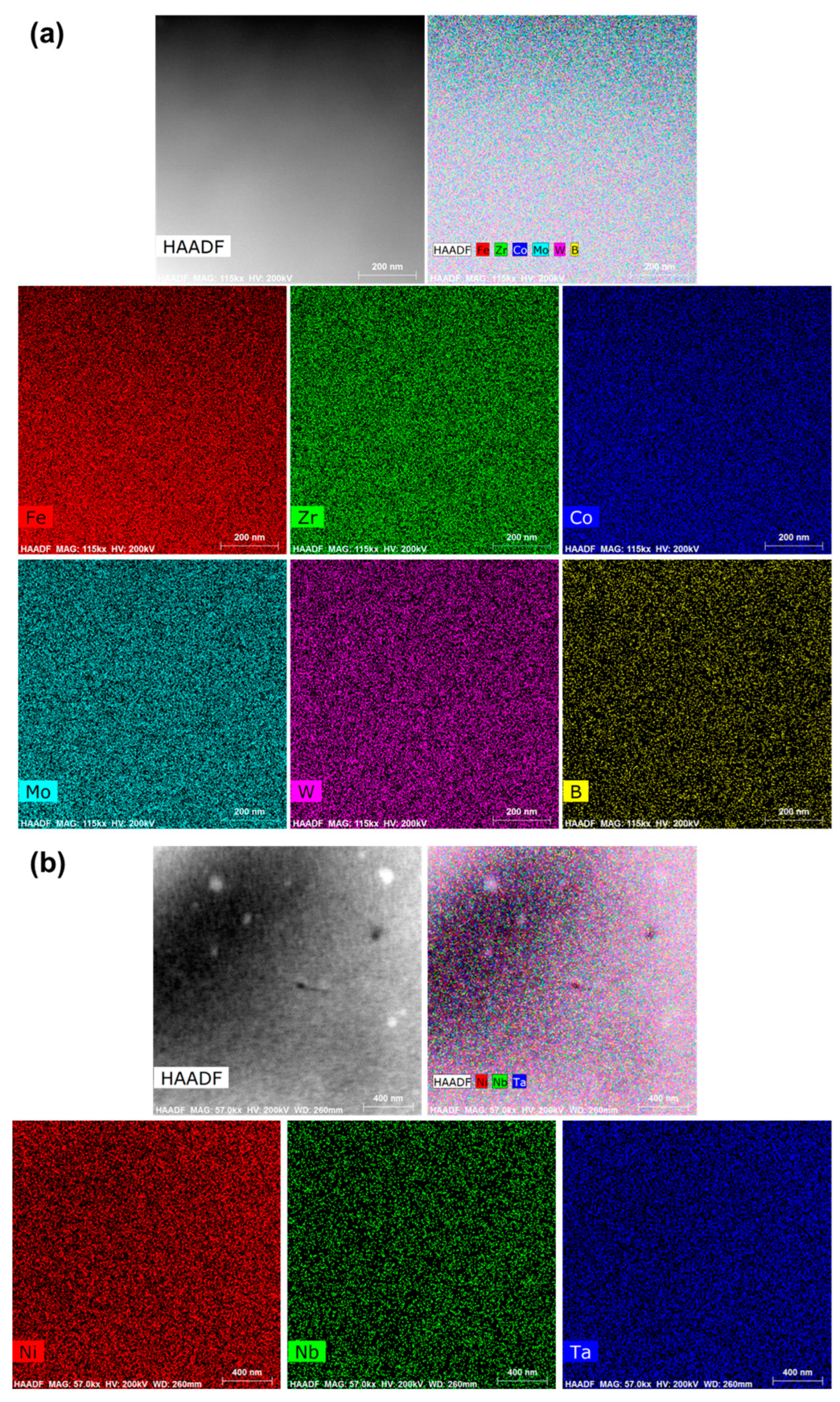

3.1. Structural Characterizations

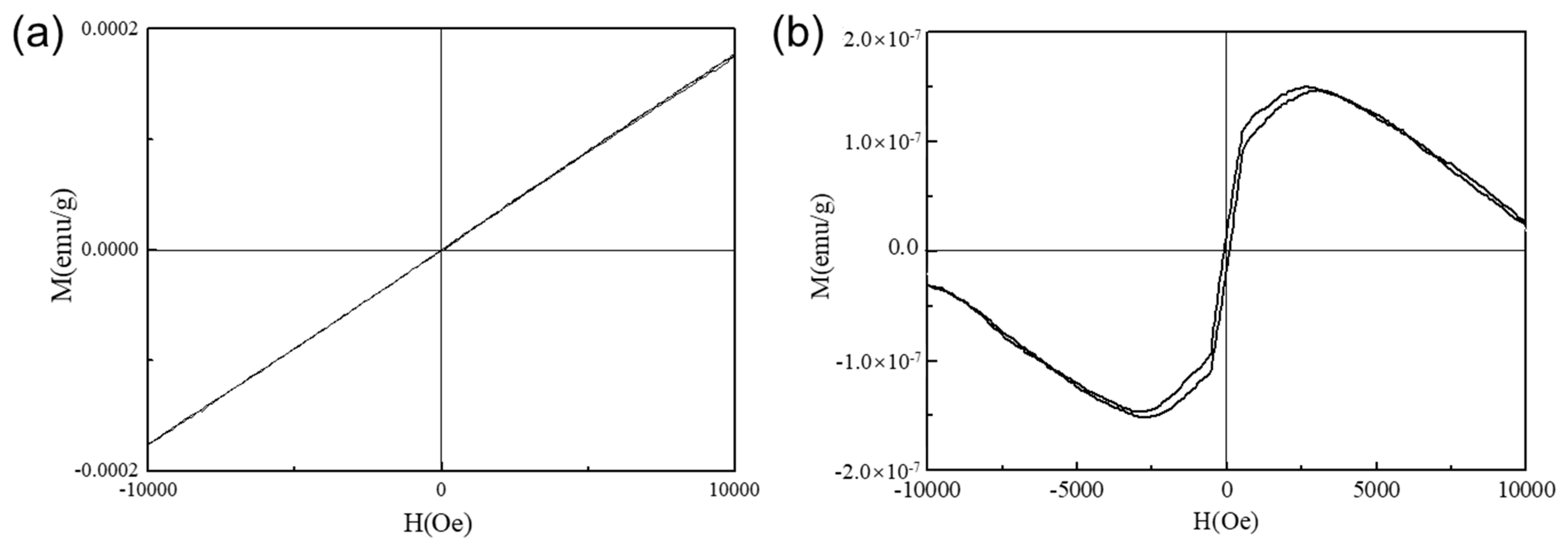

3.2. Magnetic Properties

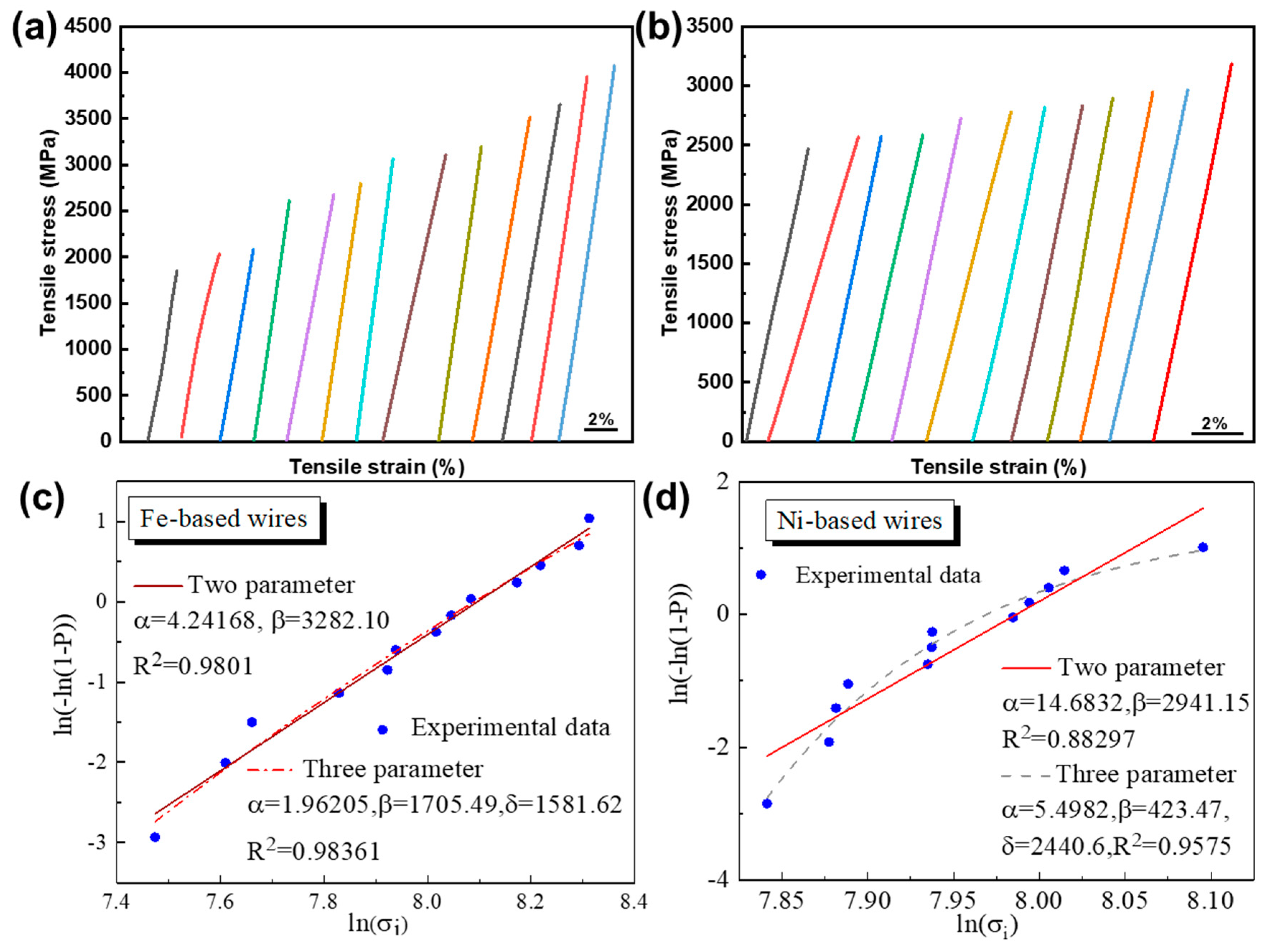

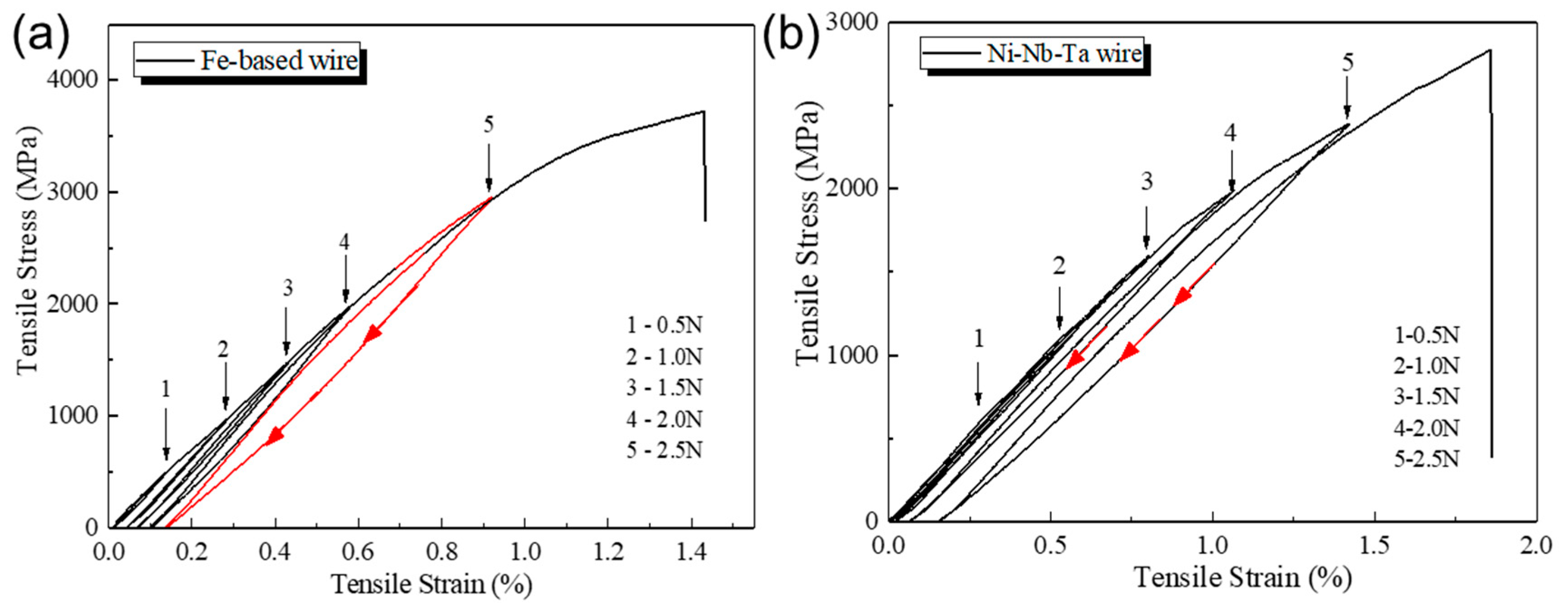

3.3. Mechanical Properties

4. Summary

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Michalik, S.; Molcanova, Z.; Sulikova, M.; Kusnirova, K.; Jovari, P.; Darpentigny, J.; Saksl, K. Structure and Physical Properties of Mg93-xZnxCa7 Metallic Glasses. Materials 2023, 16, 2313. [Google Scholar] [CrossRef] [PubMed]

- Pierwola, A.; Lelito, J.; Krawiec, H.; Szucki, M.; Gondek, L.; Koziel, T.; Babilas, R. Non-Isothermal Analysis of the Crystallization Kinetics of Amorphous Mg72Zn27Pt1 and Mg72Zn27Ag1 Alloys. Materials 2024, 17, 408. [Google Scholar] [CrossRef]

- Atzmon, M.; Ju, J.D.; Lei, T. Structural Relaxation, Rejuvenation and Plasticity of Metallic Glasses: Microscopic Details from Anelastic Relaxation Spectra. Materials 2023, 16, 7444. [Google Scholar] [CrossRef] [PubMed]

- Chen, M.; Zhu, L.; Chen, Y.; Dai, S.; Liu, Q.; Xue, N.; Li, W.; Wang, J.; Huang, Y.; Yang, K. Effect of Chemical Composition on the Thermoplastic Formability and Nanoindentation of Ti-Based Bulk Metallic Glasses. Materials 2024, 17, 1699. [Google Scholar] [CrossRef] [PubMed]

- Hong, Y.; Wang, H.; Li, X.; Zhong, L.; Chen, H.; Zhang, Z.; Cao, P.; Ritchie, R.O.; Wang, J. Structural heterogeneity governing deformability of metallic glass. Matter 2023, 6, 1160–1172. [Google Scholar] [CrossRef]

- Ouyang, D.; Zhao, L.; Li, N.; Pan, J.; Liu, L.; Chan, K.C. Atomistic investigation of modulating structural heterogeneities to achieve strength-ductility synergy in metallic glasses. Comput. Mater. Sci. 2023, 217, 111918. [Google Scholar] [CrossRef]

- Wang, H.; Qin, F.X.; Xing, D.W.; Cao, F.Y.; Wang, X.D.; Peng, H.X.; Sun, J.F. Relating residual stress and microstructure to mechanical and giant magneto-impedance properties in cold-drawn Co-based amorphous microwires. Acta Mater. 2012, 60, 5425–5436. [Google Scholar] [CrossRef]

- Yi, J.; Wang, W.H.; Lewandowski, J.J. Sample size and preparation effects on the tensile ductility of Pd-based metallic glass nanowires. Acta Mater. 2015, 87, 1–7. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, Q.K.; Li, M. Internal stress and its effect on mechanical strength of metallic glass nanowires. Acta Mater. 2015, 91, 174–182. [Google Scholar] [CrossRef]

- Xie, J.; Pei, C.; Zhou, J.; Ding, D.; Feng, T.; Li, H.; Sun, B. Tensile plasticity with enhanced β-relaxation in high-energy metallic glass wires. Sci. China Mater. 2023, 66, 4233–4238. [Google Scholar] [CrossRef]

- Yi, J. Fabrication and Properties of Micro- and Nanoscale Metallic Glassy Wires: A Review. Adv. Eng. Mater. 2018, 20, 1700875. [Google Scholar] [CrossRef]

- Su, S.; Huang, Y.; Zhang, J.; Zhang, L.; Wang, H.; Ning, Z.; Sun, J. Tensile Properties of Melt-Extracted and Annealed NiFe-Based Amorphous Metallic Fibers. Metals 2022, 12, 918. [Google Scholar] [CrossRef]

- Zhang, X.; Sun, Y.; Yan, B.; Zhuang, X. Correlation of Magnetomechanical Coupling and Damping in Fe80Si9B11 Metallic Glass Ribbons. Materials 2023, 16, 4990. [Google Scholar] [CrossRef]

- Zheng, S.-H.; Wang, Q.; Zhu, L.-Z.; Wang, P.-J.; Ding, D.; Tang, B.-Z.; Yu, P.; Yao, J.-L.; Xia, L. Excellent Magnetocaloric Performance of the Fe87Ce13− xBx (x= 5, 6, 7) Metallic Glasses and Their Composite. Materials 2023, 16, 4393. [Google Scholar] [CrossRef]

- Wang, H.; Xing, D.; Peng, H.; Qin, F.; Cao, F.; Wang, G.; Sun, J. Nanocrystallization enabled tensile ductility of Co-based amorphous microwires. Scr. Mater. 2012, 66, 1041–1044. [Google Scholar] [CrossRef]

- Lee, M.; Kim, J.-H.; Park, J.; Kim, J.; Kim, W.; Kim, D. Fabrication of Ni–Nb–Ta metallic glass reinforced Al-based alloy matrix composites by infiltration casting process. Scr. Mater. 2004, 50, 1367–1371. [Google Scholar] [CrossRef]

- Ding, H.; Zhang, Q.; Yao, K. Composition Design Strategy for High Entropy Amorphous Alloys. Materials 2024, 17, 453. [Google Scholar] [CrossRef]

- Lu, Z.; Liu, C.; Porter, W. Role of yttrium in glass formation of Fe-based bulk metallic glasses. Appl. Phys. Lett. 2003, 83, 2581–2583. [Google Scholar] [CrossRef]

- Su, S.; Ning, Z.; Huang, Y.; Yang, T.; Wang, K.; Jiang, M.; Sun, J.; Jiang, S. Effect of strain rate on fracture reliability of Cu45Zr45Co10 amorphous alloy microwires by statistical analyses. J. Alloys Compd. 2022, 898, 162951. [Google Scholar] [CrossRef]

- Beck, F.; Rigue, J.; Carara, M. The profile of the domain walls in amorphous glass-covered microwires. J. Magn. Magn. Mater. 2017, 435, 21–25. [Google Scholar] [CrossRef]

- Zhukov, A.; Ipatov, M.; Del Val, J.; Churyukanova, M.; Zhukova, V. Tailoring of magnetic properties of Heusler-type glass-coated microwires by annealing. J. Alloys Compd. 2018, 732, 561–566. [Google Scholar] [CrossRef]

- Nematov, M.; Baraban, I.; Yudanov, N.; Rodionova, V.; Qin, F.; Peng, H.-X.; Panina, L. Evolution of the magnetic anisotropy and magnetostriction in Co-based amorphous alloys microwires due to current annealing and stress-sensory applications. J. Alloys Compd. 2020, 837, 155584. [Google Scholar] [CrossRef]

- Franczak, A.; Levesque, A.; Coïsson, M.; Li, D.; Barrera, G.; Celegato, F.; Wang, Q.; Tiberto, P.; Chopart, J.P. Magnetic properties dependence on the coupled effects of magnetic fields on the microstructure of as-deposited and post-annealed Co/Ni bilayer thin films. J. Magn. Magn. Mater. 2014, 372, 159–166. [Google Scholar] [CrossRef]

- Gupta, P.; Akhila, K.; Srihari, V.; Svec, P.; Kane, S.; Rai, S.; Ganguli, T. On the origin of magnetic anisotropy of FeCo (Nb) B alloy thin films: A thermal annealing study. J. Magn. Magn. Mater. 2019, 480, 64–72. [Google Scholar] [CrossRef]

- Chen, W. Asymmetric Hysteresis Loops in Amorphous Alloys. Met. Funct. Mater. 1997, 4, 155–158. [Google Scholar]

- Liu, J.; Woodcock, T.G.; Scheerbaum, N.; Gutfleisch, O. Influence of annealing on magnetic field-induced structural transformation and magnetocaloric effect in Ni–Mn–In–Co ribbons. Acta Mater. 2009, 57, 4911–4920. [Google Scholar] [CrossRef]

- Li, Z.; Zhang, G. Displaced Hysteresis Loops of Fe-based Nanocrystalline Alloy. Met. Funct. Mater. 1994, 2, 14–18. [Google Scholar]

- Wang, Y.; Wang, Q.; Zhao, J.; Dong, C. Ni–Ta binary bulk metallic glasses. Scr. Mater. 2010, 63, 178–180. [Google Scholar] [CrossRef]

- Miracle, D.; Senkov, O. Topological criterion for metallic glass formation. Mater. Sci. Eng. A 2003, 347, 50–58. [Google Scholar] [CrossRef]

- Chen, S.; Tu, J.; Wu, J.; Hu, Q.; Xie, S.; Zou, J.; Zeng, X. Phase separation and significant plastic strain in a Zr–Cu–Ni–Al–Fe bulk metallic glass. Mater. Sci. Eng. A 2016, 656, 84–89. [Google Scholar] [CrossRef]

- Aich, P.; Meneghini, C.; Tortora, L. Advances in Structural and Morphological Characterization of Thin Magnetic Films: A Review. Materials 2023, 16, 7331. [Google Scholar] [CrossRef] [PubMed]

- Whittle, G.; Stewart, A.; Kaiser, A. Magnetic and electrical properties of (FeTM) 85B15 (TM= Cr, Ni) metallic glasses. Phys. Status Solidi (A) 1986, 97, 199–211. [Google Scholar] [CrossRef]

- Sagasti, A.; Palomares, V.; Porro, J.M.; Orúe, I.; Sánchez-Ilárduya, M.B.; Lopes, A.C.; Gutiérrez, J. Magnetic, magnetoelastic and corrosion resistant properties of (Fe–Ni)-based metallic glasses for structural health monitoring applications. Materials 2019, 13, 57. [Google Scholar] [CrossRef] [PubMed]

- Zhukova, V.; Ipatov, M.; Talaat, A.; Blanco, J.; Churyukanova, M.; Taskaev, S.; Zhukov, A. Effect of stress-induced anisotropy on high frequency magnetoimpedance effect of Fe and Co-rich glass-coated microwires. J. Alloys Compd. 2018, 735, 1818–1825. [Google Scholar] [CrossRef]

- Jacquelin, J. A reliable algorithm for the exact median rank function. IEEE Trans. Electr. Insul. 1993, 28, 168–171. [Google Scholar] [CrossRef]

- Elgueta, M.; Kittl, P. Probabilistic control of materials by a simulation method. Mater. Des. 2007, 28, 1919–1922. [Google Scholar] [CrossRef]

- Abrosimova, G.; Chirkova, V.; Pershina, E.; Volkov, N.; Sholin, I.; Aronin, A. The Effect of Free Volume on the Crystallization of Al87Ni8Gd5 Amorphous Alloy. Metals 2022, 12, 332. [Google Scholar] [CrossRef]

- Jiménez-Marín, E.; Villalpando, I.; Trejo-Valdez, M.; Cervantes-Sodi, F.; Vargas-García, J.R.; Torres-Torres, C. Coexistence of positive and negative photoconductivity in nickel oxide decorated multiwall carbon nanotubes. Mater. Sci. Eng. B 2017, 220, 22–29. [Google Scholar] [CrossRef]

- Zhang, M.; Qu, G.; Liu, J.; Pang, M.; Wang, X.; Liu, R.; Cao, G.; Ma, G. Enhancement of Magnetic and Tensile Mechanical Performances in Fe-Based Metallic Microwires Induced by Trace Ni-Doping. Materials 2021, 14, 3589. [Google Scholar] [CrossRef]

| Element | Weight % | Atomic % |

|---|---|---|

| Fe | 58.08 ± 0.46 | 61.02 ± 0.05 |

| Zr | 15.02 ± 0.53 | 9.66 ± 0.26 |

| Co | 5.65 ± 0.47 | 5.63 ± 0.51 |

| Mo | 11.51 ± 0.18 | 7.04 ± 0.05 |

| W | 7.08 ± 0.88 | 2.26 ± 0.30 |

| B | 2.65 ± 0.11 | 14.39 ± 0.51 |

| Element | Weight % | Atomic % |

|---|---|---|

| Ni | 40.02 ± 0.21 | 60.96 ± 0.21 |

| Nb | 20.08 ± 0.10 | 19.32 ± 0.12 |

| Ta | 39.90 ± 0.14 | 19.72 ± 0.11 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Su, S.; Zhao, W.; Shadangi, Y.; Zhang, J.; Ning, Z.; Sun, J.; Huang, Y. Preparation, Magnetic and Mechanical Properties of Fe/Ni-Based Amorphous Fibers. Materials 2024, 17, 3733. https://doi.org/10.3390/ma17153733

Su S, Zhao W, Shadangi Y, Zhang J, Ning Z, Sun J, Huang Y. Preparation, Magnetic and Mechanical Properties of Fe/Ni-Based Amorphous Fibers. Materials. 2024; 17(15):3733. https://doi.org/10.3390/ma17153733

Chicago/Turabian StyleSu, Shuang, Wenjie Zhao, Yagnesh Shadangi, Jiapeng Zhang, Zhiliang Ning, Jianfei Sun, and Yongjiang Huang. 2024. "Preparation, Magnetic and Mechanical Properties of Fe/Ni-Based Amorphous Fibers" Materials 17, no. 15: 3733. https://doi.org/10.3390/ma17153733

APA StyleSu, S., Zhao, W., Shadangi, Y., Zhang, J., Ning, Z., Sun, J., & Huang, Y. (2024). Preparation, Magnetic and Mechanical Properties of Fe/Ni-Based Amorphous Fibers. Materials, 17(15), 3733. https://doi.org/10.3390/ma17153733