A Study on the Pre-Hardened Shrinkage Reduction of Grout Using Carbon Materials

Abstract

1. Introduction

2. Overview of the Experiment

2.1. Experiment

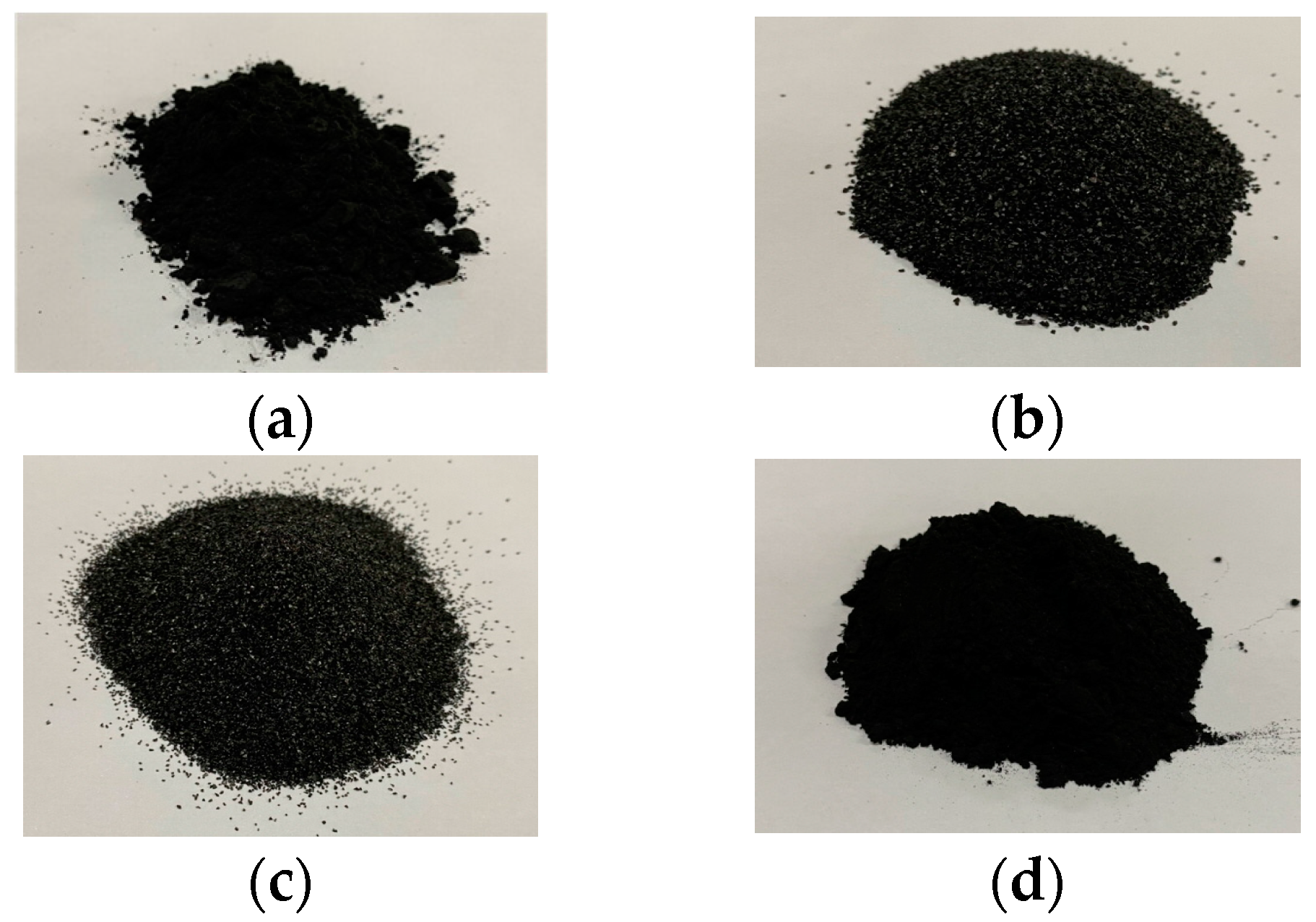

2.2. Materials Used

2.3. Experimental Method

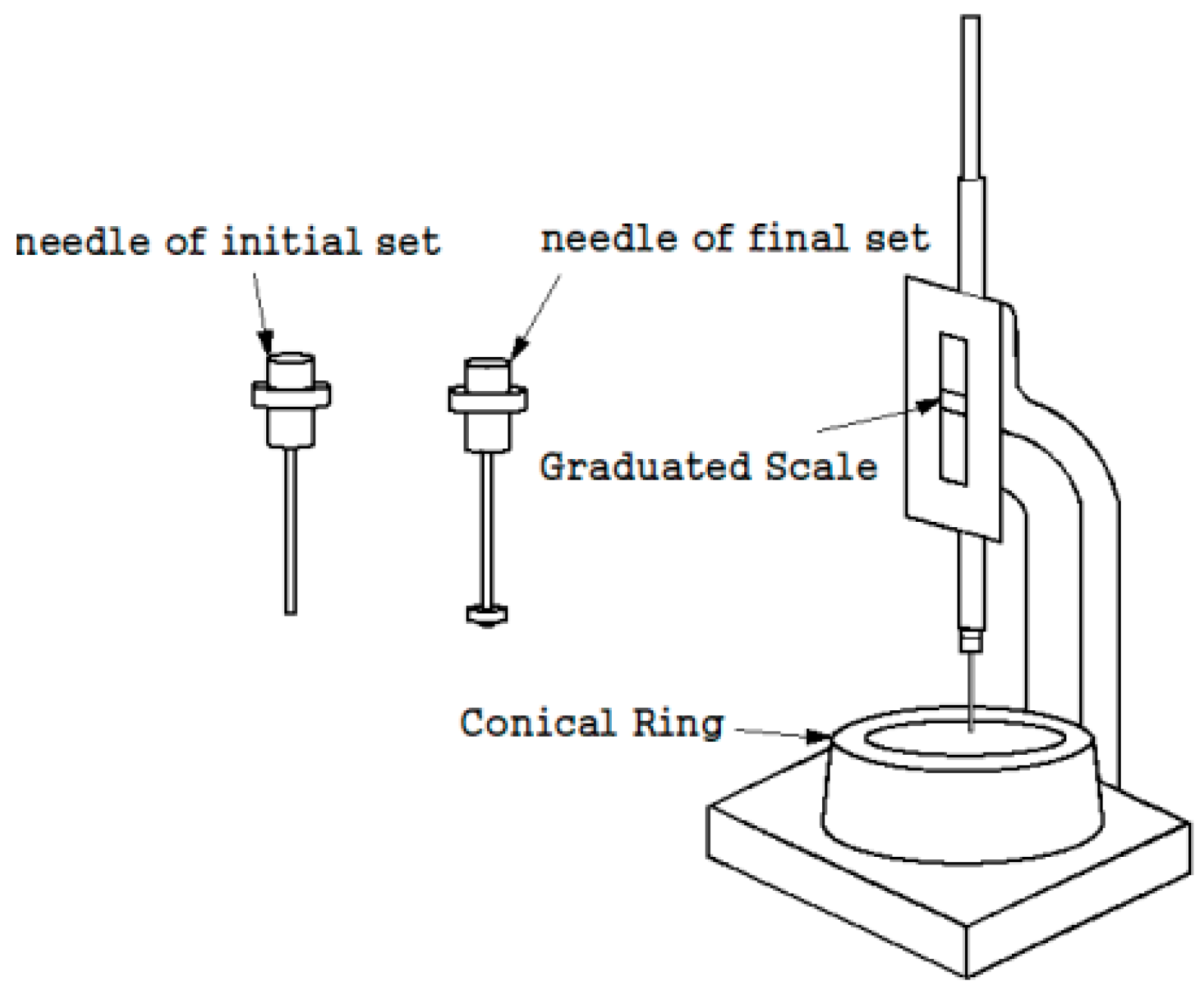

2.3.1. Setting

2.3.2. Fluidity

2.3.3. Compressive Strength

2.3.4. Shrinkage/Expansion Pre-Hardening

3. Experimental Results

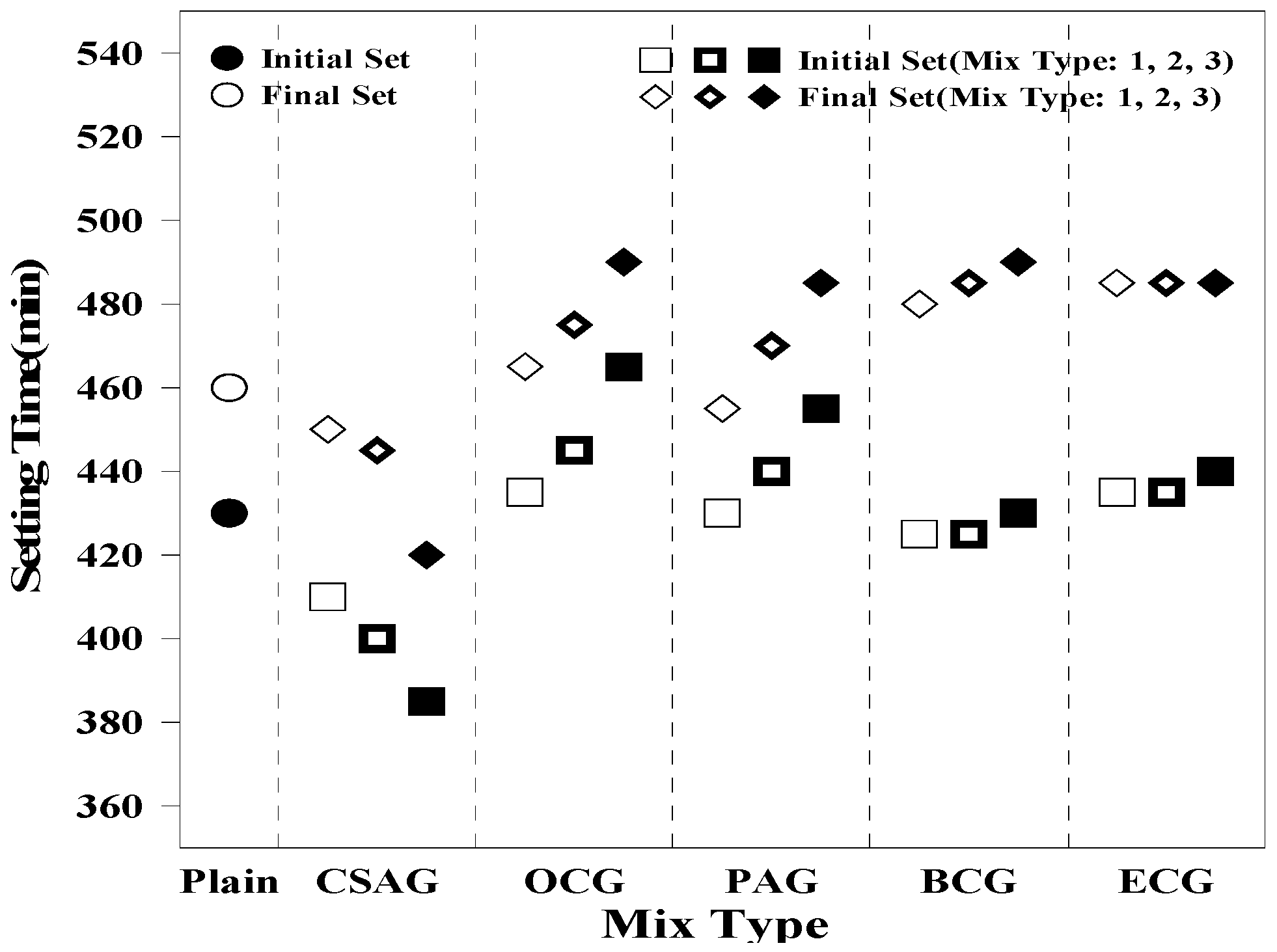

3.1. Setting Time

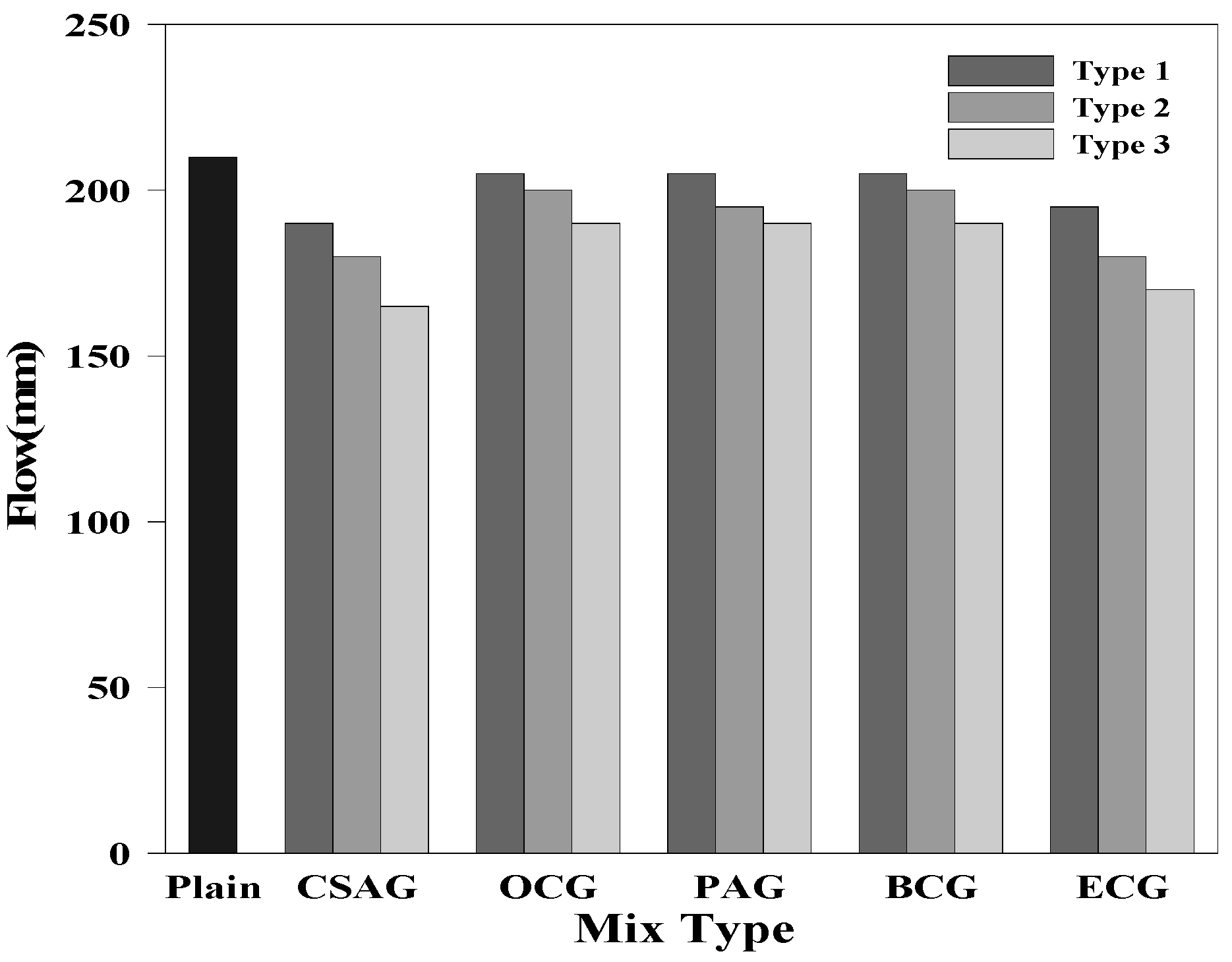

3.2. Fluidity

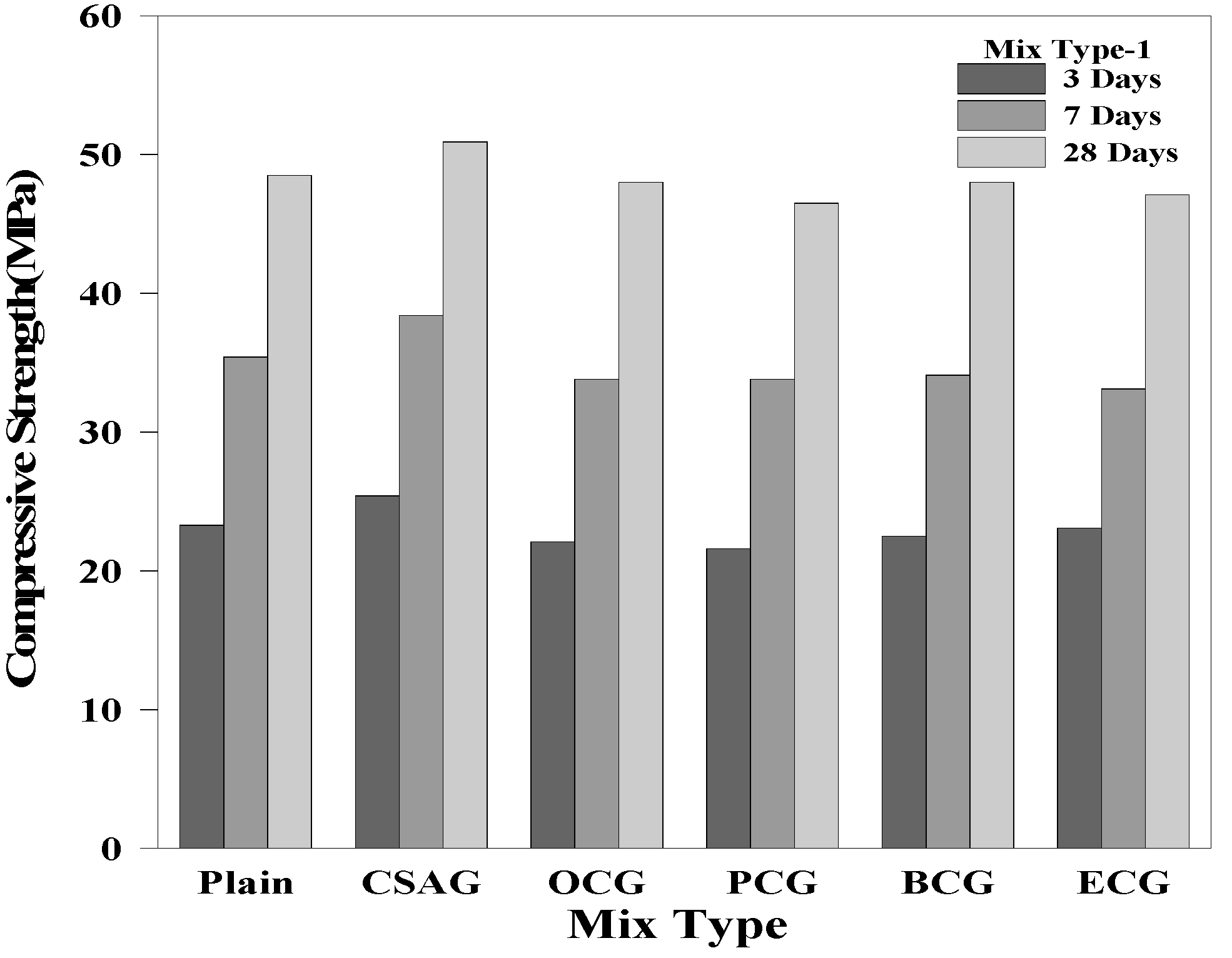

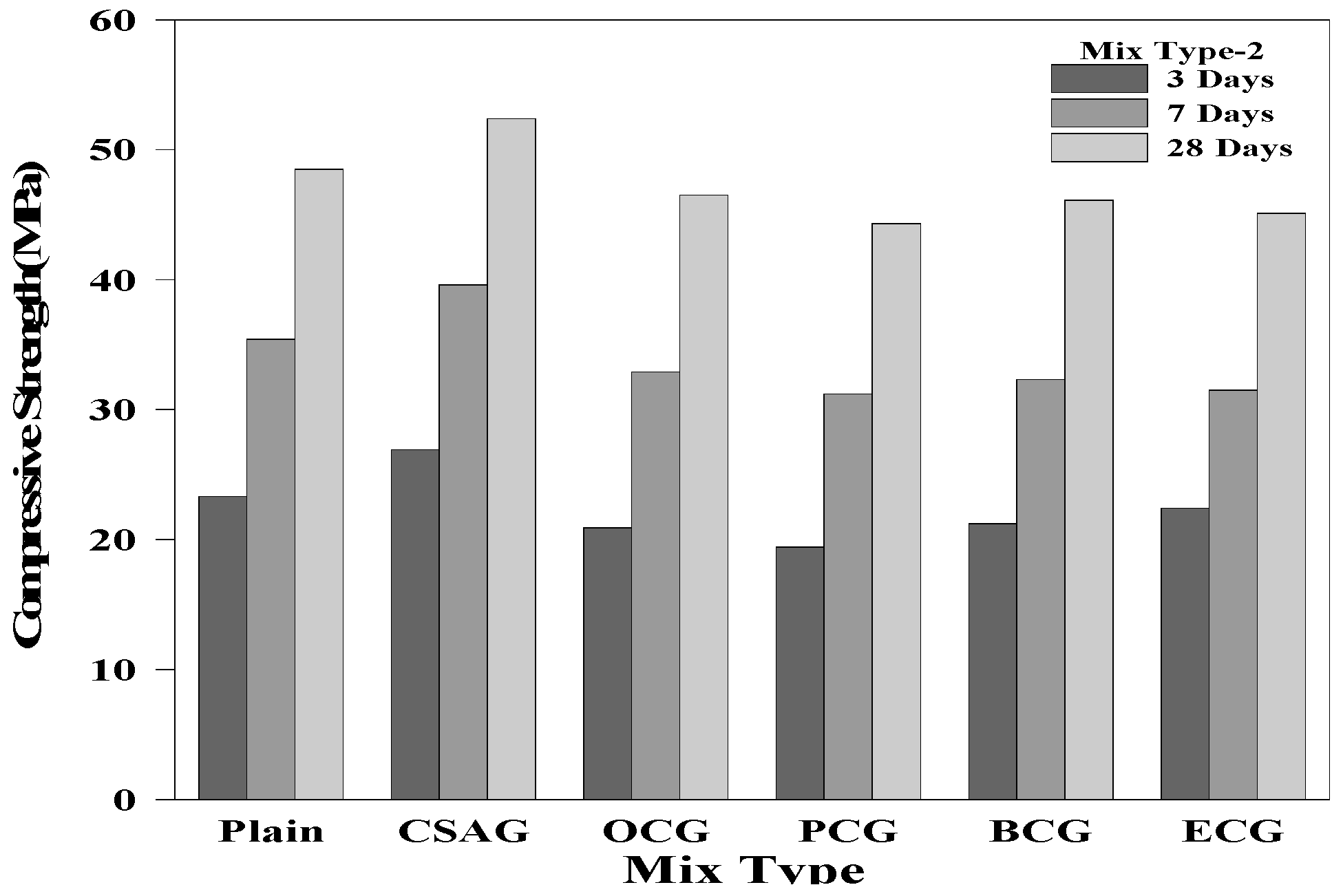

3.3. Compressive Strength

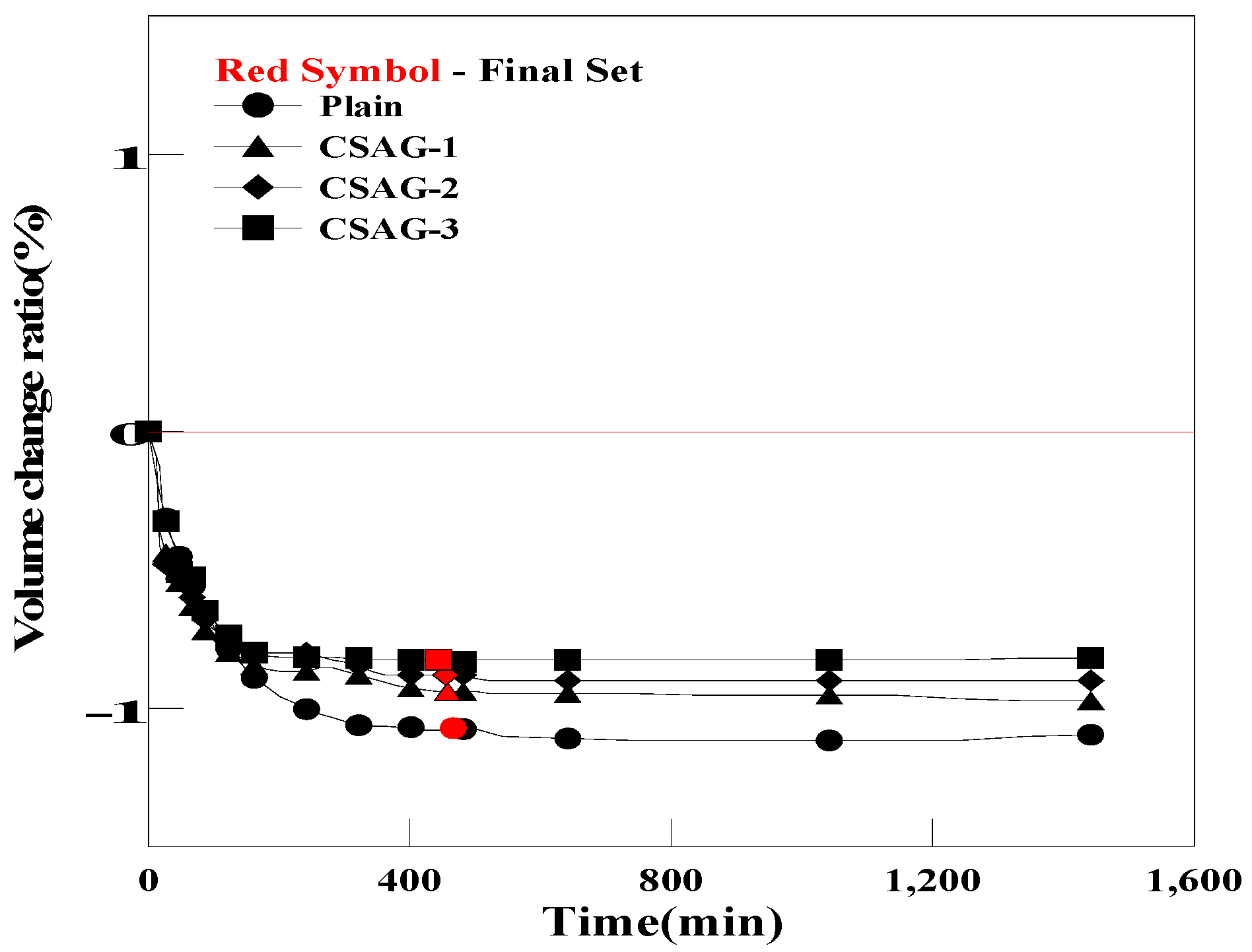

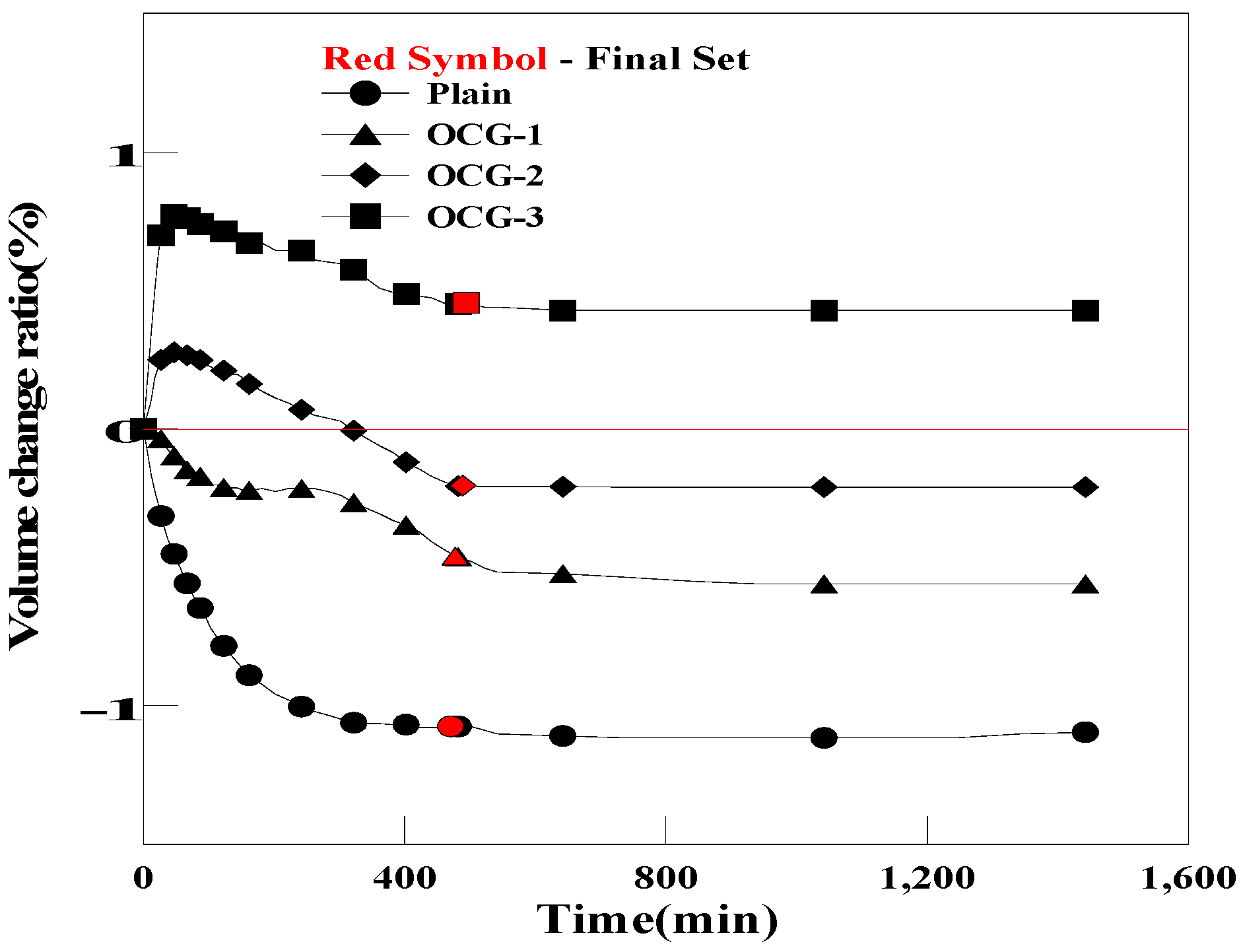

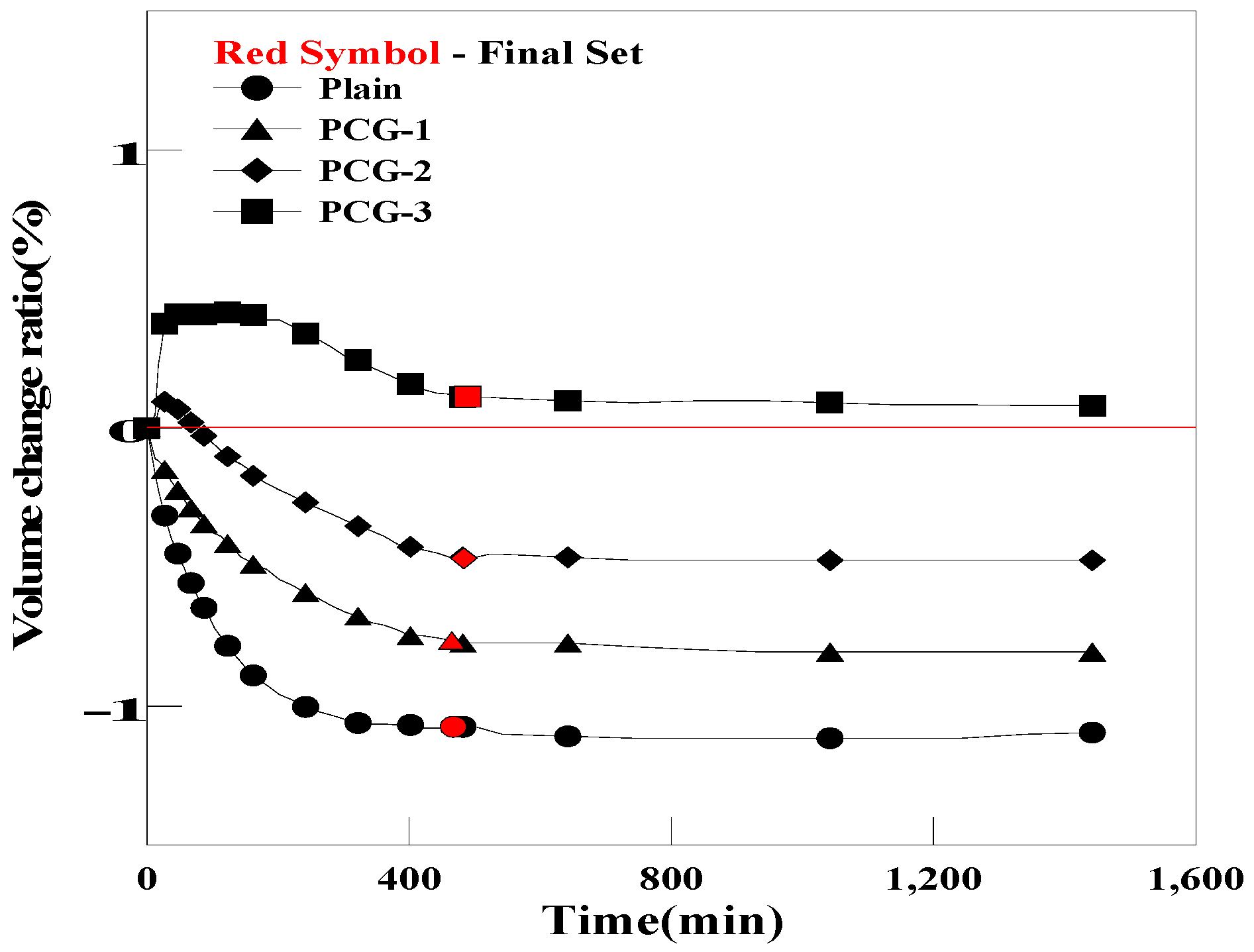

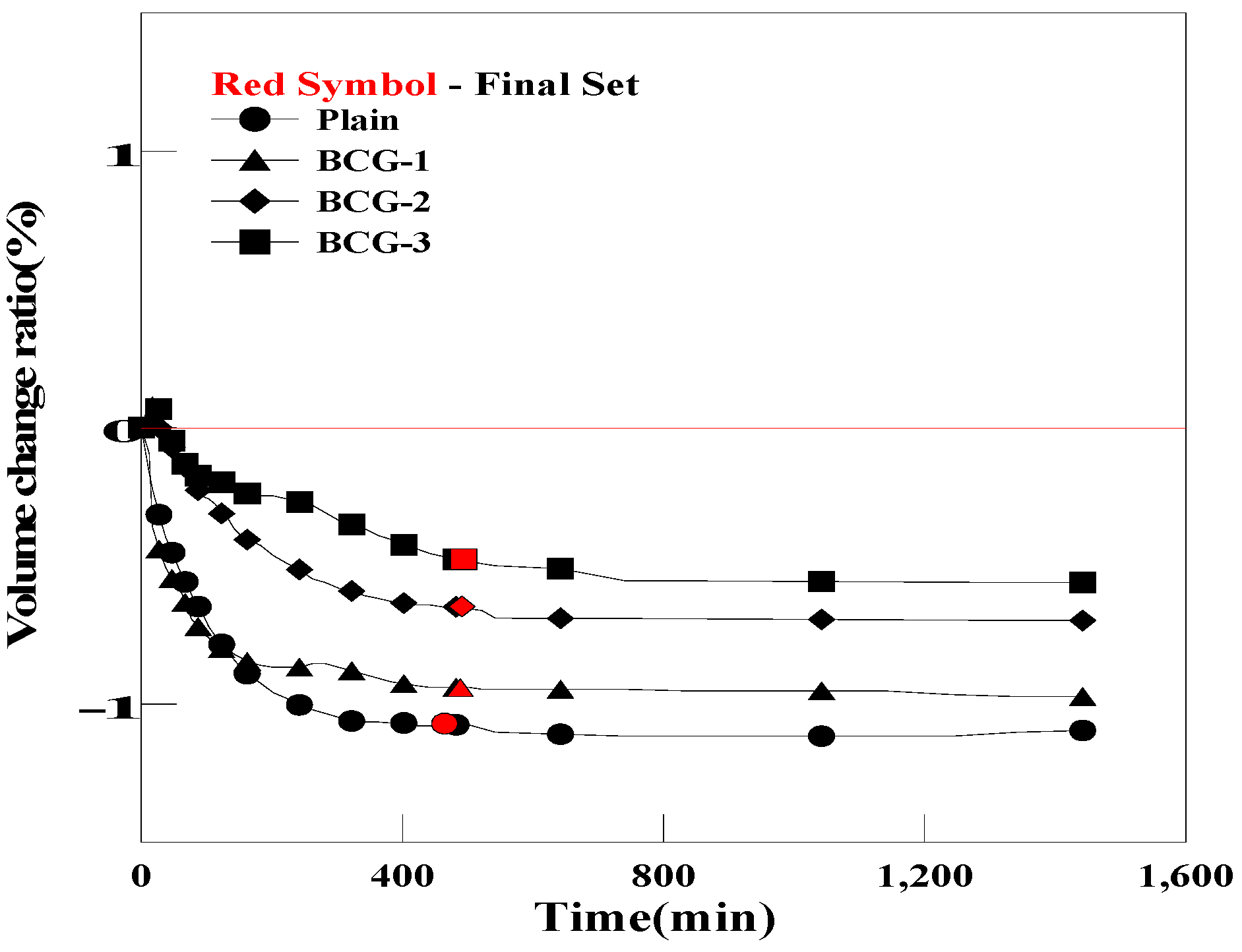

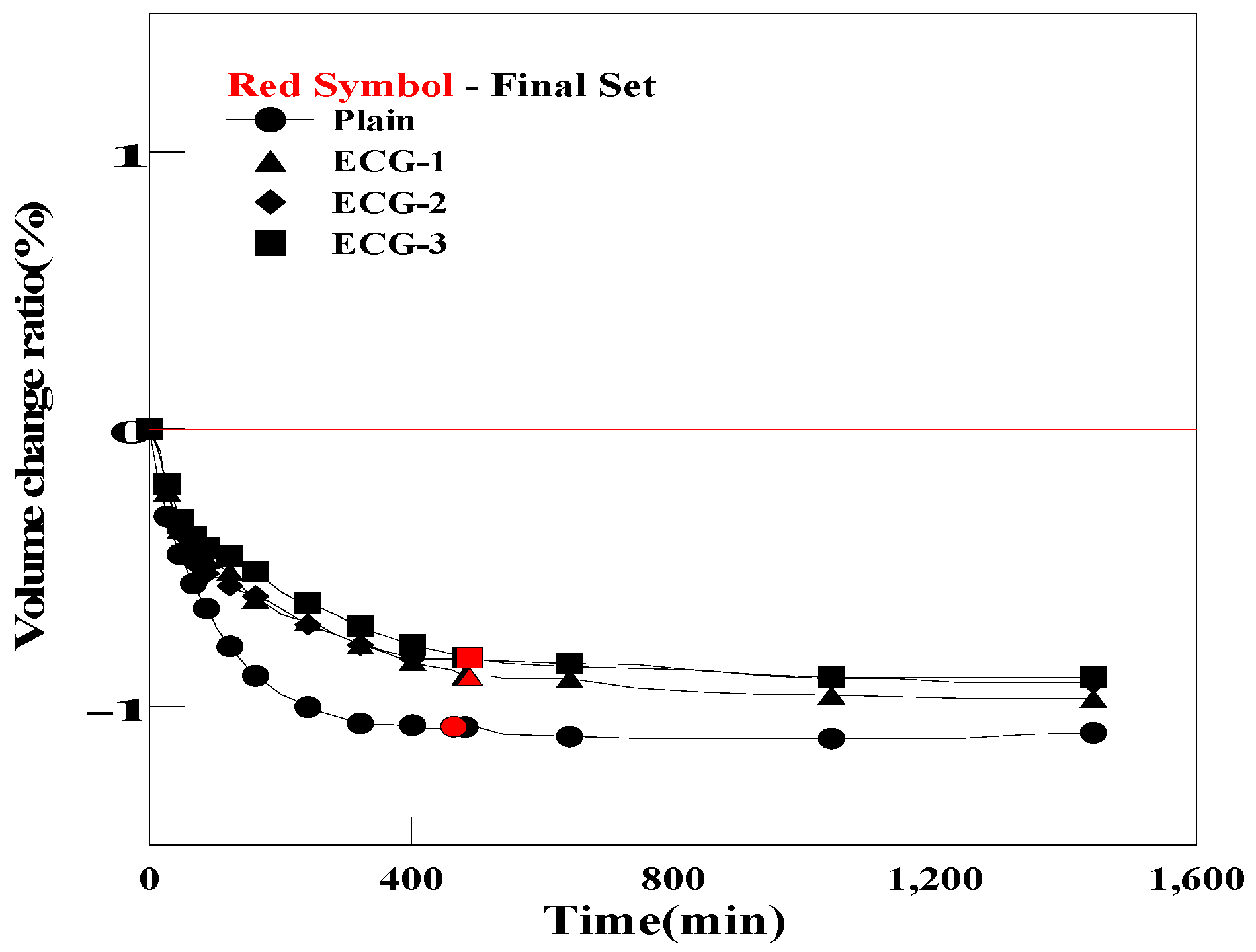

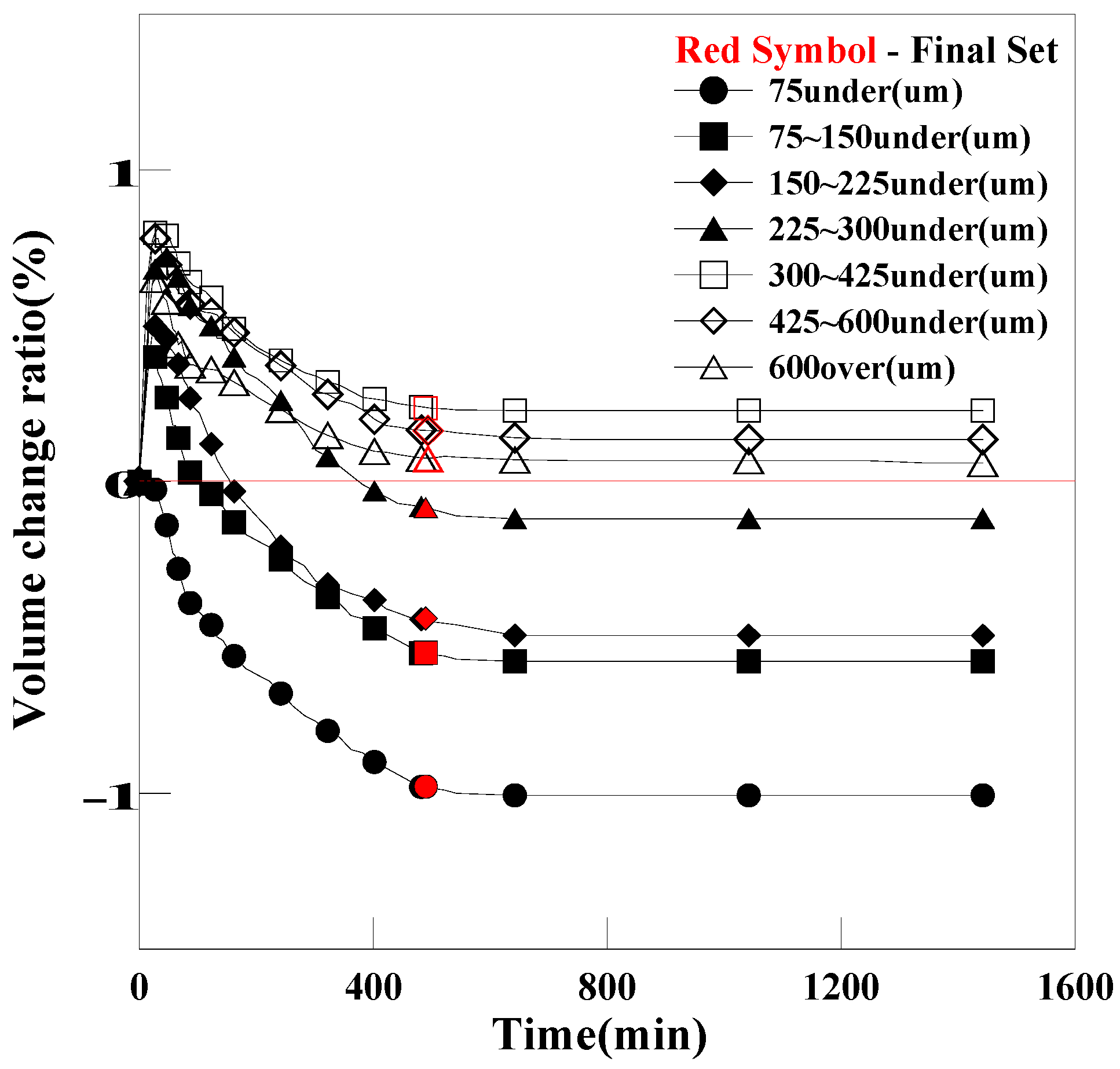

3.4. Shrinkage/Expansion before Hardening

3.5. SEM Examination of Carbon Materials

3.6. Particle Size and Pore Analysis of Carbon Materials

4. Conclusions

- The results of the setting test showed that grouts mixed with carbon materials tended to delay the setting time as compared to that of the Plain grout. This outcome can be attributed to the delayed hydration of the cement caused by the moisture adsorption process of porous carbon materials. This outcome is contrary to the outcome of utilizing CSA, which showed a tendency to shorten the setting time.

- The grouts mixed with carbon materials demonstrated decreased fluidity as compared to the Plain grout. In addition, as the amount of carbon materials that were mixed in increased, the fluidity of the grouts further decreased. The fluidity was reduced because carbon materials with porous structures absorb moisture, which affects the fluidity.

- The grouts mixed with carbon materials showed a tendency for the compressive strength to decrease as the amount of carbon materials mixed in increased. However, the compressive strength on day 28 of the curing process exceeded 45 MPa, approaching the compressive strength of the Plain grout.

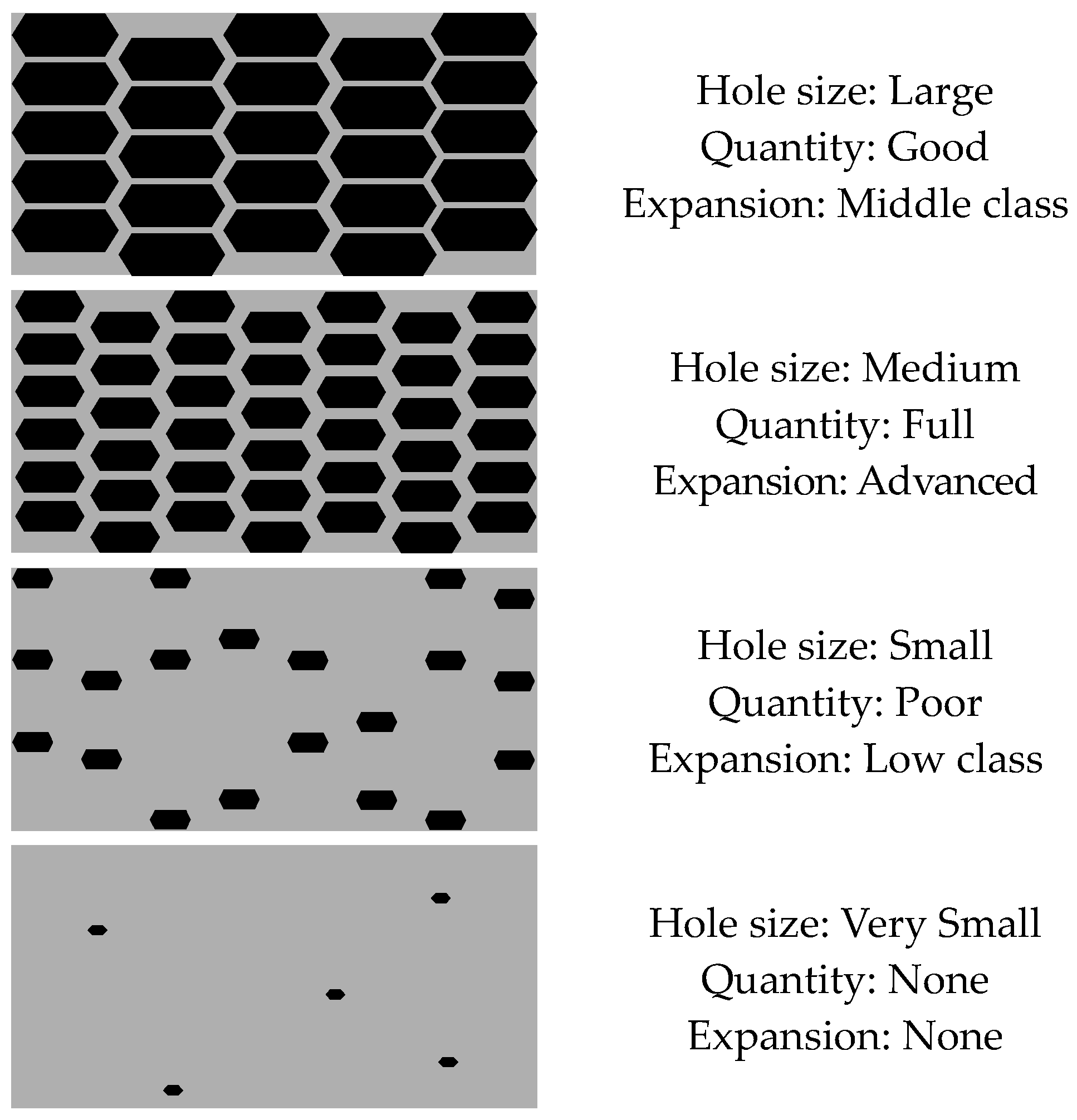

- In the test results for shrinkage/expansion before hardening, the expansion property of the grout mixed with carbon materials tended to increase as the amount of carbon material mixed in increased. The expansion effect significantly increased in the order of ECG, BCG, PCG, and OCG, according to the materials used. The expansion effect appeared to be closely related to the number and size of pores in the material. Moreover, the expansion effect varied depending on the particle size of the carbon material used. It was found that particle sizes ranging between 300 and 425 µm are most efficient for achieving an optimal expansion performance.

- The SEM results showed that carbon materials were found to have a porous structure. In addition, OC and PC had several honeycomb-shaped pores on their surfaces. However, BC had relatively fewer pores than OC and PC. In the case of EC, pores on the particle surface could not be observed.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yuan, T.F.; An, G.H.; Ryu, G.S.; Koh, K.T.; Yoon, Y.S. Evaluating shrinkage characteristic of ternary grout for PSC bridge using expansive additive and shrinkage reducing agent. J. Korea Concr. Inst. 2016, 28, 519–525. [Google Scholar] [CrossRef]

- Yuan, T.; Yoo, D.Y.; Koh, K.T.; Yoon, Y.S. Evaluating material properties of grout for PSC bridge according to admixture type. J. Korean Soc. Hazard Mitig. 2018, 18, 299–305. [Google Scholar] [CrossRef]

- Seo, J.W. Physical properties of cement mortar mixed with expansive agent. J. Ind. Technol. Res. 1998, 10, 71–84. [Google Scholar]

- Gao, P.; Lu, X.; Geng, F.; Li, X.; Hou, J.; Lin, H.; Shi, N. Production of MgO-type expansive agent in dam concrete by use of industrial by-products. Build. Environ. 2008, 43, 453–457. [Google Scholar] [CrossRef]

- Jiang, F.; Deng, M.; Mo, L.; Wu, W. Effects of MgO expansive agent and steel fiber on crack resistance of a bridge deck. Materials 2020, 13, 3074. [Google Scholar] [CrossRef] [PubMed]

- Sherir, M.A.; Hossain, K.M.; Lachemi, M. Development and recovery of mechanical properties of self-healing cementitious composites with MgO expansive agent. Constr. Build. Mater. 2017, 148, 789–810. [Google Scholar] [CrossRef]

- Olivier, G.; Combrinck, R.; Kayondo, M.; Boshoff, W.P. Combined effect of nano-silica, super absorbent polymers, and synthetic fibres on plastic shrinkage cracking in concrete. Constr. Build. Mater. 2018, 192, 85–98. [Google Scholar] [CrossRef]

- Sant, G.; Lothenbach, B.; Juilland, P.; Le Saout, G.; Weiss, J.; Scrivener, K. The origin of early age expansions induced in cementitious materials containing shrinkage reducing admixtures. Cem. Concr. Res. 2011, 41, 218–229. [Google Scholar] [CrossRef]

- Chen, Y.; Xian, R.; Wang, J.; Hu, Z.; Wang, W. Synergetic effect of superabsorbent polymer and CaO-based expansive agent on mitigating autogenous shrinkage of UHPC matrix. Materials 2023, 16, 2814. [Google Scholar] [CrossRef]

- Zhao, H.; Liu, H.; Wan, Y.; Ghantous, R.M.; Li, J.; Liu, Y.; Ni, Y.; Guan, J. Mechanical properties and autogenous deformation behavior of early-age concrete containing pre-wetted ceramsite and CaO-based expansive agent. Constr. Build. Mater. 2021, 267, 120992. [Google Scholar] [CrossRef]

- Azarhomayun, F.; Haji, M.; Kioumarsi, M.; Shekarchi, M. Effect of calcium stearate and aluminum powder on free and restrained drying shrinkage, crack characteristic and mechanical properties of concrete. Cem. Concr. Compos. 2022, 125, 104276. [Google Scholar] [CrossRef]

- Gao, S.; Wang, Z.; Wang, W.; Qiu, H. Effect of shrinkage-reducing admixture and expansive agent on mechanical properties and drying shrinkage of Engineered Cementitious Composite (ECC). Constr. Build. Mater. 2018, 179, 172–185. [Google Scholar] [CrossRef]

- Han, J.; Jia, D.; Yan, P. Understanding the shrinkage compensating ability of type K expansive agent in concrete. Constr. Build. Mater. 2016, 116, 36–44. [Google Scholar] [CrossRef]

- Hong, K.N.; Jung, J.Y.; Han, S.H. Material properties of grout using alumina cement and anhydrite. J. Korean Soc. Saf. 2011, 26, 59–64. [Google Scholar]

- Jiang, F.; Zhou, J.; Mao, Z.; Chen, B. Study on the influence of magnesite tailings on the expansion and mechanical properties of mortar. Materials 2023, 16, 7082. [Google Scholar] [CrossRef] [PubMed]

- Wang, D.; Ye, Y.; Yao, N.; Liu, Y.; Deng, X. Experimental study on strength Enhancement of Expansive Grout. Materials 2022, 15, 885. [Google Scholar] [CrossRef]

- Cao, F.; Miao, M.; Yan, P. Hydration characteristics and expansive mechanism of MgO expansive agents. Constr. Build. Mater. 2018, 183, 234–242. [Google Scholar] [CrossRef]

- Sherir, M.A.; Hossain, K.M.; Lachemi, M. The influence of MgO-type expansive agent incorporated in self-healing system of Engineered cementitious Composites. Constr. Build. Mater. 2017, 149, 164–185. [Google Scholar] [CrossRef]

- Alghamri, R.; Al-Tabbaa, A. Self-healing of cracks in mortars using novel PVA-coated pellets of different expansive agents. Constr. Build. Mater. 2020, 254, 119254. [Google Scholar] [CrossRef]

- Feng, S.; Xiao, H.; Zhang, R.; Yang, C. Bond performance between substrate concrete and repair mortar: Effect of carbon fibre and expansive agent. Constr. Build. Mater. 2020, 250, 118830. [Google Scholar] [CrossRef]

- Lingling, X.; Min, D. Dolomite used as raw material to produce MgO-based expansive agent. Cem. Concr. Res. 2005, 35, 1480–1485. [Google Scholar] [CrossRef]

- Bizzozero, J.; Gosselin, C.; Scrivener, K.L. Expansion mechanisms in calcium aluminate and sulfoaluminate systems with calcium sulfate. Cem. Concr. Res. 2014, 56, 190–202. [Google Scholar] [CrossRef]

- Hwang, I.D.; Yeom, H.N.; Jung, Y.J. Factors of expansion in cement mortar containing expansive agent. J. Korean Ceram. Soc. 2022, 37, 576–582. [Google Scholar]

- Guo, J.; Zhang, S.; Guo, T.; Zhang, P. Effects of UEA and MgO expansive agents on fracture properties of concrete. Constr. Build. Mater. 2020, 263, 120245. [Google Scholar] [CrossRef]

- Lu, A.; Xu, W.; Wang, Q.; Wang, R.; Ye, Z. Effect of different expansive agents on the deformation properties of core concrete in a steel tube with a harsh temperature history. Materials 2023, 16, 1780. [Google Scholar] [CrossRef]

- Cao, F.; Yan, P. The influence of the hydration procedure of MgO expansive agent on the expansive behavior of shrinkage-compensating mortar. Constr. Build. Mater. 2019, 202, 162–168. [Google Scholar] [CrossRef]

- Li, H.; Wang, Y.; Wang, Y.; Liu, J.; Tian, Q. Effect of CaO and MgO based expansive agent on deformation and mechanical properties of concrete-filled steel tubes. Constr. Build. Mater. 2020, 250, 118723. [Google Scholar] [CrossRef]

- Nalon, G.H.; Ribeiro, J.C.L.; de Araújo, E.N.D.; da Silva, R.M.; Pedroti, L.G. Effects of shrinkage-reducing admixtures and expansive agents on the self-sensing behavior of nanomodified cement-based materials. J. Build. Eng. 2023, 78, 107648. [Google Scholar] [CrossRef]

- Li, S.; Mo, L.; Deng, M.; Cheng, S. Mitigation on the autogenous shrinkage of ultra-high performance concrete via using MgO expansive agent. Constr. Build. Mater. 2021, 312, 125422. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M. Effects of calcination condition on expansion property of MgO-type expansive agent used in cement-based materials. Cem. Concr. Res. 2010, 40, 437–446. [Google Scholar] [CrossRef]

- Shen, P.; Lu, L.; He, Y.; Wang, F.; Lu, J.; Zheng, H.; Hu, S. Investigation on expansion effect of the expansive agents in ultra-high performance concrete. Cem. Concr. Res. 2020, 105, 103425. [Google Scholar] [CrossRef]

- Yao, N.; Chen, J.; Hu, N.; Ye, Y.; Xiao, Y.; Huang, Y. Experimental study on expansion mechanism and characteristics of expansive grout. Constr. Build. Mater. 2021, 268, 121574. [Google Scholar] [CrossRef]

- Mo, L.; Deng, M.; Tang, M. Potential approach to evaluating soundness of concrete containing MgO-based expansive agent. ACI Mater. J. 2010, 107, 99–105. [Google Scholar]

- Mo, L.; Fang, J.; Hou, W.; Ji, X.; Yang, J.; Fan, T.; Wang, H. Synergetic effects of curing temperature and hydration reactivity of MgO expansive agents on their hydration and expansion behaviours in cement pastes. Constr. Build. Mater. 2019, 207, 206–217. [Google Scholar] [CrossRef]

- Zhang, J. Recent advance of MgO expansive agent in cement and concrete. J. Build. Eng. 2022, 45, 103633. [Google Scholar] [CrossRef]

- Zhang, P.; Dai, Y.; Wang, W.; Yang, J.; Mo, L.; Guo, W.; Bao, J. Effects of magnesia expansive agents on the self-healing performance of microcracks in strain-hardening cement-based composites (SHCC). Mater. Today Commun. 2020, 25, 101421. [Google Scholar] [CrossRef]

- Zhao, H.; Xiang, Y.; Xie, D.; Xu, W.; Wang, Y.; Li, H.; Tian, Q.; Liu, J. Effects of CaO-based and MgO-based expansion agent, curing temperature and restraint degree on pore structure of early-age mortar. Constr. Build. Mater. 2020, 257, 119572. [Google Scholar] [CrossRef]

- Zhang, G.; Qiu, D.; Wang, S.; Wang, P. Effects of plastic expansive agent on the fluidity, mechanical strength, dimensional stability and hydration of high performance cementitious grouts. Constr. Build. Mater. 2020, 243, 118204. [Google Scholar] [CrossRef]

- Cao, F.; Liu, Y.; Yan, P. Properties and mechanism of the compound MgO expansive agent (CMEA) produced by calcining the mixture of dolomite and serpentine tailings. Constr. Build. Mater. 2021, 277, 122331. [Google Scholar] [CrossRef]

- Cao, F.; Miao, M.; Yan, P. Effects of reactivity of MgO expansive agent on its performance in cement-based materials and an improvement of the evaluating method of MEA reactivity. Constr. Build. Mater. 2018, 187, 257–266. [Google Scholar] [CrossRef]

- Gao, P.W.; Wu, S.X.; Lin, P.H.; Wu, Z.R.; Tang, M.S. The characteristics of air void and frost resistance of RCC with fly ash and expansive agent. Constr. Build. Mater. 2006, 20, 586–590. [Google Scholar] [CrossRef]

- Xue, C.; Li, W.; Luo, Z.; Wang, K.; Castel, A. Effect of chloride ingress on self-healing recovery of smart cementitious composite incorporating crystalline admixture and MgO expansive agent. Cem. Concr. Res. 2021, 139, 106252. [Google Scholar] [CrossRef]

- Li, X.; Peng, C.; Ao, Y.; Hao, M.; Zhong, Y.; Zhang, B. Impact of composition ratio on the expansion behavior of polyurethane grout. Materials 2024, 17, 1835. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Huang, Z.; Wu, Y. Solving shrinkage problem of ultra-high-performance concrete by a combined use of expansive agent, super absorbent polymer, and shrinkage-reducing agent. Compos. B Eng. 2022, 230, 109503. [Google Scholar] [CrossRef]

- Zhao, H.; Li, X.; Chen, X.; Qiao, C.; Xu, W.; Wang, P.; Song, H. Microstructure evolution of cement mortar containing MgO-CaO blended expansive agent and temperature rising inhibitor under multiple curing temperatures. Constr. Build. Mater. 2021, 278, 122376. [Google Scholar] [CrossRef]

- Wang, K.; Moon, J.; Du, H.; Xia, X.; Zhu, D.; Zhang, P.; Guo, J. Early-age shrinkage and hydration of concrete incorporating a mutually reinforcing systems of super absorbent polymers and MgO expansive agent under low humidity conditions. Constr. Build. Mater. 2024, 417, 135350. [Google Scholar] [CrossRef]

- KS L ISO 9597; Methods of testing cement—Determination of setting time and soundness. Korean Standards Association: Seoul, Republic of Korea, 2014.

- KS F 2476; Testing Methods for Polymer Cement Mortar. Korean Standards Association: Seoul, Republic of Korea, 2019.

- ASTM C 827; Standard Test Method for Change in Height at Early Ages of Cylindrical Specimens of Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2020.

- KS F 4044; Hydraulic Cement Non-Shrink Grout. Korean Standards Association: Seoul, Republic of Korea, 2019.

- Han, S. Carbon Sequestration Technology of Cement Composites Containing Wood-Based Biochar. Master’s Thesis, Graduate School, Gachon University, Seongnam, Republic of Korea, 2023. [Google Scholar]

- Choi, W.C.; Yun, H.D.; Lee, J.Y. Mechanical Properties of Mortar Containing Bio-Char From Pyrolysis. J. Korea Inst. Struct. Maint. Insp. 2012, 16, 67–74. [Google Scholar]

- Lee, D. Improvement of Thermal and Mechanical Properties of Carbon Material/Ultra-Rapid Hardening Cement Composites. Ph.D. Thesis, Graduate School, Chungnam National University, Daejeon, Republic of Korea, 2017. [Google Scholar]

- Ko, K.T.; Park, J.J.; Ryu, K.S.; Kang, S.T. Shrinkage characteristics of high-performance concrete using expansive agent and shrinkage-reducing agent. J. Korean Soc. Civ. Eng. A Struct. Eng. Nucl. Eng. Concr. Eng. 2006, 26, 787–794. [Google Scholar]

- Pan, Z.; Zhu, Y.; Zhang, D.; Chen, N.; Yang, Y.; Cai, X. Effect of expansive agents on the workability, crack resistance and durability of shrinkage-compensating concrete with low contents of fibers. Constr. Build. Mater. 2020, 259, 119768. [Google Scholar] [CrossRef]

- Kim, Y. A Study on the Development of Eco-Friendly Concrete Bricks Using Industrial Waste Charcoal. Master’s Thesis, Graduate School of Industry, Chungju National University, Cheongju, Republic of Korea, 2006. [Google Scholar]

- Liu, K.; Shui, Z.; Sun, T.; Ling, G.; Li, X.; Cheng, S. Effects of combined expansive agents and supplementary cementitious materials on the mechanical properties, shrinkage and chloride penetration of self-compacting concrete. Constr. Build. Mater. 2019, 211, 120–129. [Google Scholar] [CrossRef]

- Choi, H.J.; Cho, W.J.; Hwang, B.S.; Yoon, C.Y. Mechanical properties of cement grout containing conductive materials. J. Korean Geo-Environ. Soc. 2020, 21, 32–38. [Google Scholar]

- Jiang, F.; Mao, Z.; Yu, L. Hydration and expansion characteristics of MgO expansive agent in mass concrete. Materials 2022, 15, 8028. [Google Scholar] [CrossRef]

- Zhao, H.; Li, J.; Sun, G.; Jiang, J.; Xuan, W.; Chen, Y.; Tian, Q.; Liu, J. Effects of pre-soaked zeolite and CaO-based expansive agent on mechanical properties and autogenous deformation of early-age concrete. Constr. Build. Mater. 2020, 261, 120370. [Google Scholar] [CrossRef]

- Yu, Z.; Zhao, Y.; Ba, H.; Liu, M. Synergistic effects of ettringite-based expansive agent and polypropylene fiber on early-age anti-shrinkage and anti-cracking properties of mortars. J. Build. Eng. 2021, 39, 102275. [Google Scholar] [CrossRef]

| Type | Mix Ratio (Based on Grout) | ||||

|---|---|---|---|---|---|

| W/G | C | Number 5 SS | Super Plasticizer | Expansion | |

| Plain | 19 | 49.7 | 50 | 0.3 | - |

| CSAG-1 | 47 | 3 | |||

| CSAG-2 | 45.7 | 4.3 | |||

| CSAG-3 | 44 | 6 | |||

| OCG-1 | 49.8 | 0.1 | |||

| OCG-2 | 49.5 | 0.3 | |||

| OCG-3 | 49 | 0.5 | |||

| PCG-1 | 49.8 | 0.1 | |||

| PCG-2 | 49.5 | 0.3 | |||

| PCG-3 | 49 | 0.5 | |||

| BCG-1 | 49.8 | 0.1 | |||

| BCG-2 | 49.5 | 0.3 | |||

| BCG-3 | 49 | 0.5 | |||

| ECG-1 | 49.8 | 0.1 | |||

| ECG-2 | 49.5 | 0.3 | |||

| ECG-3 | 49 | 0.5 | |||

| Material | Chemical Composition (%) | ||||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | LOI | |

| Ordinary Portland cement | 15.04 | 2.48 | 2.62 | 73.13 | 2.00 | 2.68 | 2.05 |

| Material | Chemical Composition (%) | |||||

|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | SO3 | |

| CSA | 4.5 | 12 | 0.8 | 51 | 1.5 | 30 |

| Type | Average Particle Size (μm) | Absorption Rate (%) | Specific Gravity |

|---|---|---|---|

| OC | 95 | 16.5 | 0.725 |

| PC | 190 | 17.4 | 0.682 |

| BC | 155 | 15.8 | 0.600 |

| EC | 85 | 13.2 | 0.086 |

| Material | Volume Change Ratio (%) | ||||||

|---|---|---|---|---|---|---|---|

| <75 µm | 75–150 µm | 150–225 µm | 225–300 µm | 300–425 µm | 425–600 µm | >600 µm | |

| OCG | −0.98 | −0.55 | −0.44 | −0.08 | 0.24 | 0.07 | 0.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, J.-B.; Kim, S.-S.; Lee, Y.-J.; Jang, I.-S.; Kim, J.-Y. A Study on the Pre-Hardened Shrinkage Reduction of Grout Using Carbon Materials. Materials 2024, 17, 3775. https://doi.org/10.3390/ma17153775

Lee J-B, Kim S-S, Lee Y-J, Jang I-S, Kim J-Y. A Study on the Pre-Hardened Shrinkage Reduction of Grout Using Carbon Materials. Materials. 2024; 17(15):3775. https://doi.org/10.3390/ma17153775

Chicago/Turabian StyleLee, Jeong-Bae, Seong-Soo Kim, Young-Jun Lee, In-Soo Jang, and Ju-Youn Kim. 2024. "A Study on the Pre-Hardened Shrinkage Reduction of Grout Using Carbon Materials" Materials 17, no. 15: 3775. https://doi.org/10.3390/ma17153775

APA StyleLee, J.-B., Kim, S.-S., Lee, Y.-J., Jang, I.-S., & Kim, J.-Y. (2024). A Study on the Pre-Hardened Shrinkage Reduction of Grout Using Carbon Materials. Materials, 17(15), 3775. https://doi.org/10.3390/ma17153775