Technology for Automated Production of High-Performance Building Compounds for 3D Printing

Abstract

:1. Introduction

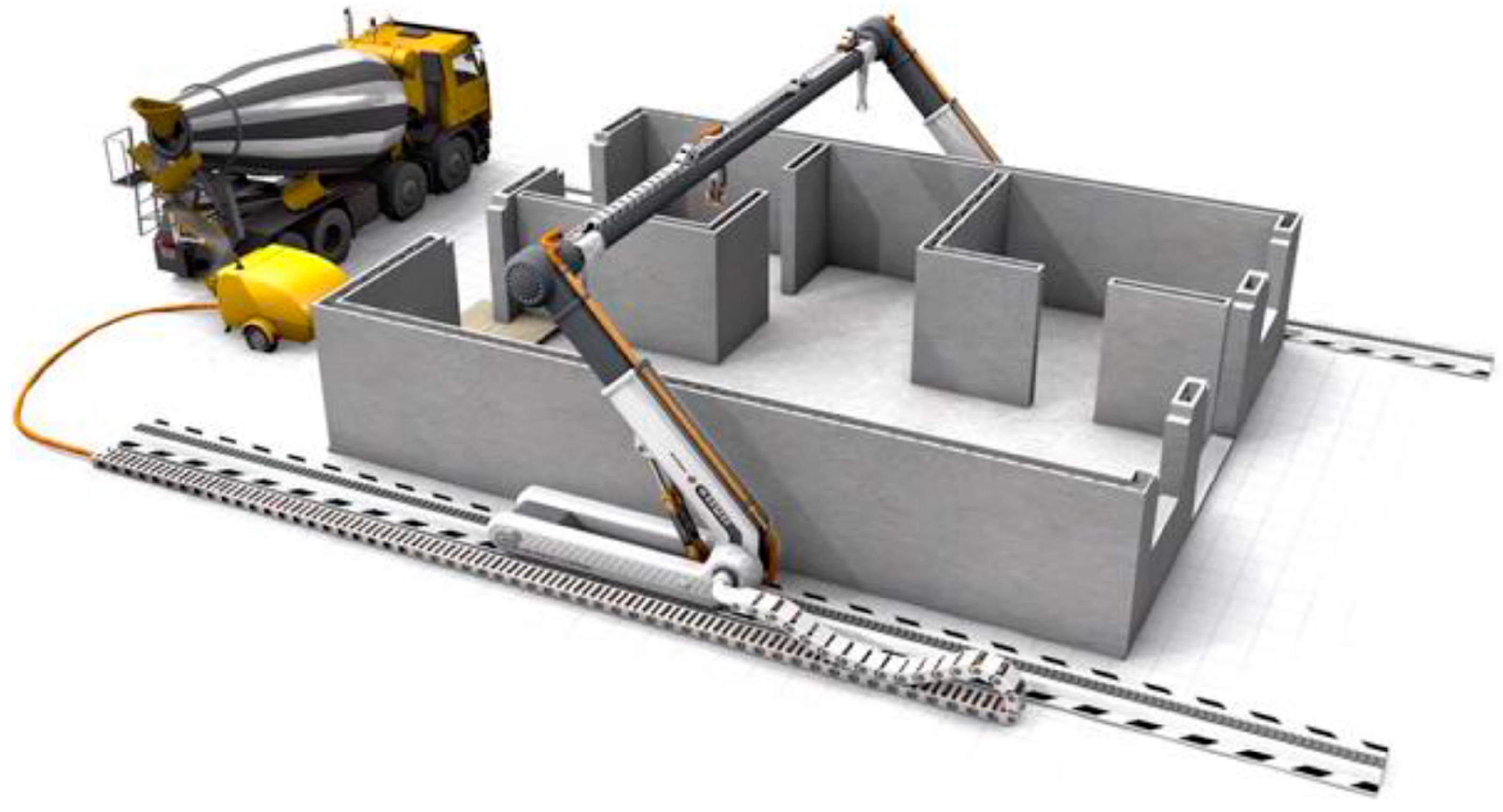

2. Basics of 3D Printing Technology in Construction

2.1. Description of the 3D Printing Process and Its Applications in Construction

2.2. Review of Various 3D Printing Technologies Used in Construction and Their Applications

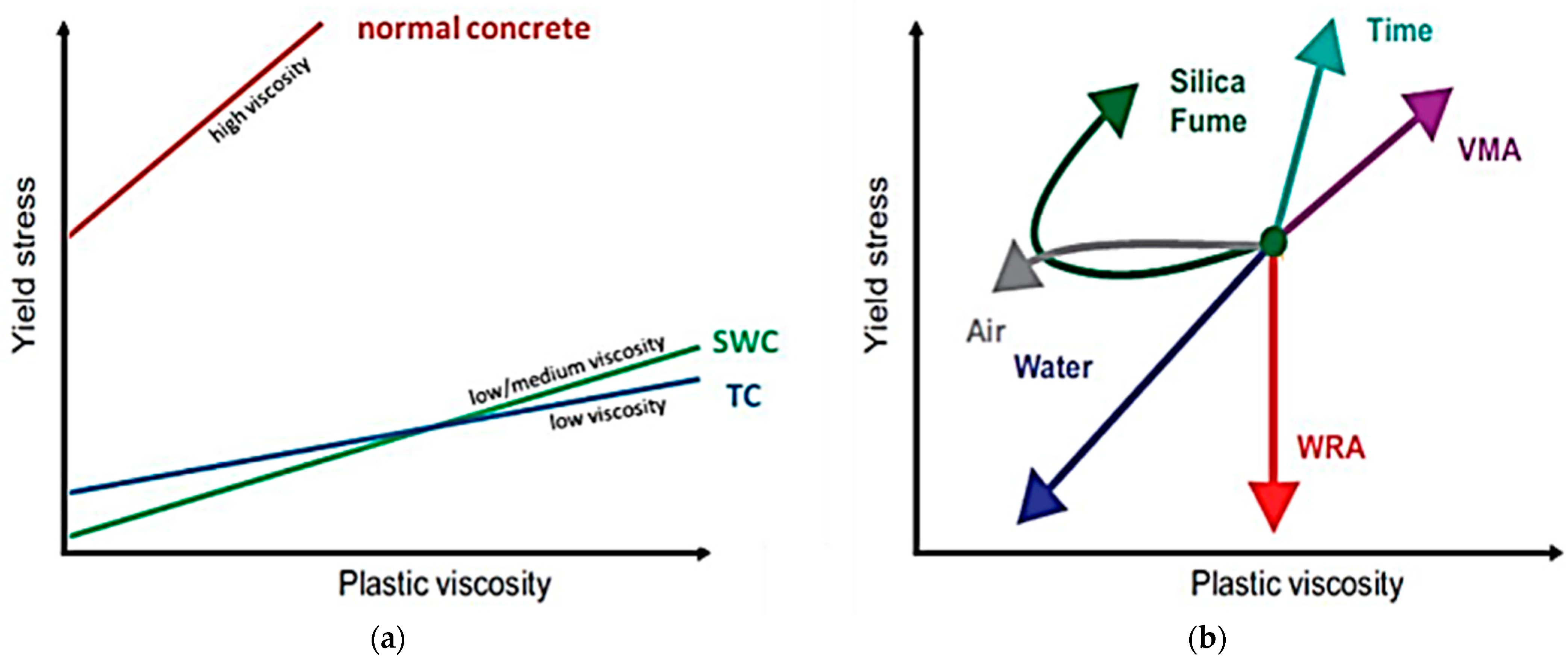

3. Properties and Requirements of High-Performance Building Mixtures

4. Automated Dosing and Mixing Systems

5. Types of Mixtures for 3D Printing in Construction Applications

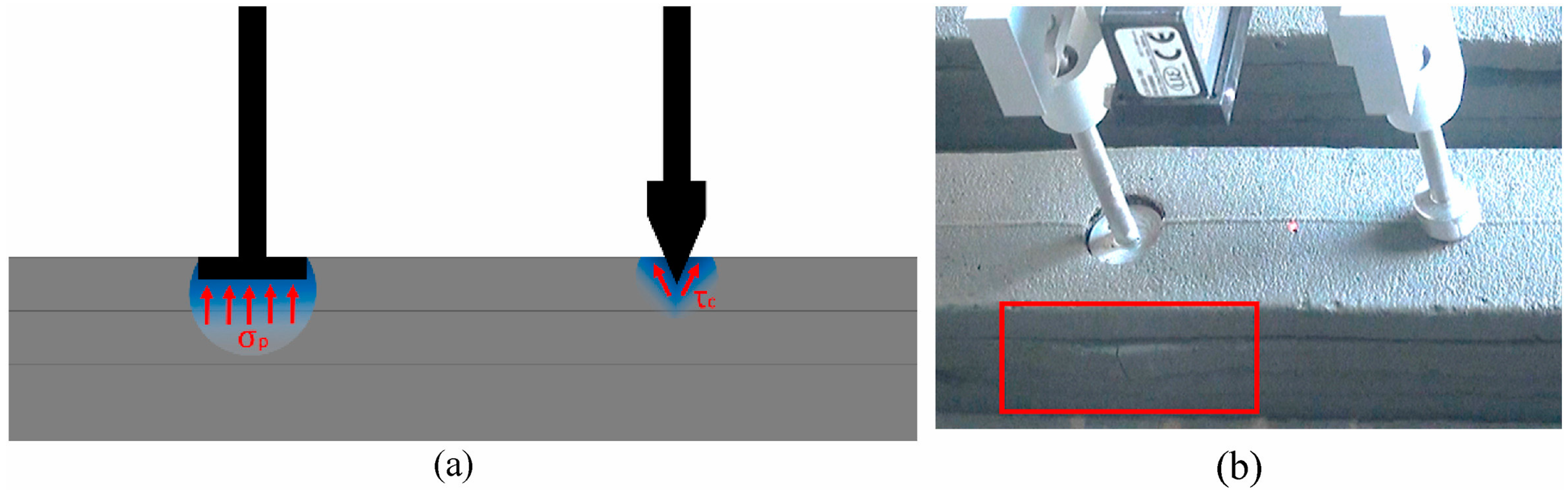

5.1. Concrete Mixtures

5.2. Gypsum-Based Mixtures

5.3. Geopolymers

5.4. Composites

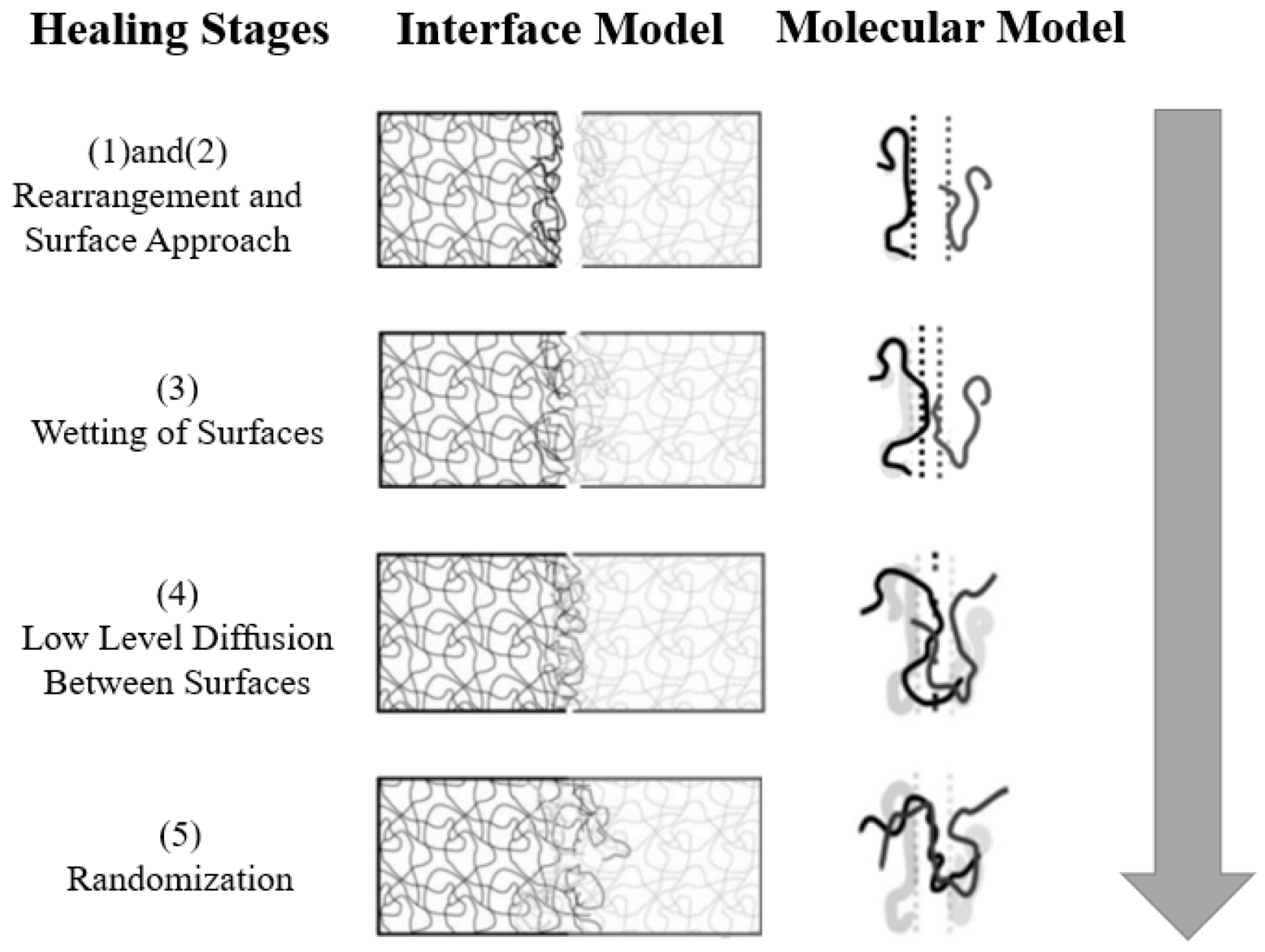

5.5. Self-Healing Materials

6. Challenges and Directions of Development

7. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ali, M.; Issayev, G.; Shehab, E.; Sarfraz, S. A Critical Review of 3D Printing and Digital Manufacturing in Construction Engineering. Rapid Prototyp. J. 2022, 28, 1312–1324. [Google Scholar] [CrossRef]

- Guamán-Rivera, R.; Martínez-Rocamora, A.; García-Alvarado, R.; Muñoz-Sanguinetti, C.; González-Böhme, L.F.; Auat-Cheein, F. Recent Developments and Challenges of 3D-Printed Construction: A Review of Research Fronts. Buildings 2022, 12, 229. [Google Scholar] [CrossRef]

- Makul, N. Advanced Smart Concrete—A Review of Current Progress, Benefits and Challenges. J. Clean. Prod. 2020, 274, 122899. [Google Scholar] [CrossRef]

- Dixit, M. 3-D Printing in Building Construction: A Literature Review of Opportunities and Challenges of Reducing Life Cycle Energy and Carbon of Buildings. IOP Conf. Ser. Earth Environ. Sci. 2019, 290, 12012. [Google Scholar] [CrossRef]

- Ning, X.; Liu, T.; Wu, C.; Wang, C. 3D Printing in Construction: Current Status, Implementation Hindrances, and Development Agenda. Adv. Civ. Eng. 2021, 2021, 6665333. [Google Scholar] [CrossRef]

- Huang, S.; Liu, P.; Mokasdar, A.; Liang, H. Additive Manufacturing and Its Societal Impact: A Literature Review. Int. J. Adv. Manuf. Technol. 2013, 67, 1191–1203. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive Construction: State-of-the-Art, Challenges and Opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Hossain, M.A.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and Its Impact on the Labor Market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Mallakpour, S.; Tabesh, F.; Hussain, C.M. 3D and 4D Printing: From Innovation to Evolution. Adv. Colloid Interface Sci. 2021, 294, 102482. [Google Scholar] [CrossRef] [PubMed]

- Chang, R.; Antwi-Afari, M.F. Critical Success Factors for Implementing 3D Printing Technology in Construction Projects: Academics and Construction Practitioners’ Perspectives. Constr. Innov. Advance online publication. [CrossRef]

- Puzatova, A.; Shakor, P.; Laghi, V.; Dmitrieva, M. Large-Scale 3D Printing for Construction Application by Means of Robotic Arm and Gantry 3D Printer: A Review. Buildings 2022, 12, 2023. [Google Scholar] [CrossRef]

- Siddika, A.; Mamun, M.; Ferdous, W.; Saha, A.; Alyousef, R. 3D-Printed Concrete: Applications, Performance, and Challenges. J. Sustain. Cem.-Based Mater. 2019, 9, 127–164. [Google Scholar] [CrossRef]

- Žujović, M.; Obradović, R.; Rakonjac, I.; Milošević, J. 3D Printing Technologies in Architectural Design and Construction: A Systematic Literature Review. Buildings 2022, 12, 1319. [Google Scholar] [CrossRef]

- Nebrida, J.A.; Oliveros, O. Artificial Intelligence Utilized in 3D Printing Construction Technology. Asian J. Adv. Res. Reports 2023, 17, 20–25. [Google Scholar] [CrossRef]

- Sandeep, B.; Kannan, T.T.M.; Chandradass, J.; Ganesan, M.; John Rajan, A. Scope of 3D Printing in Manufacturing Industries-A Review. Mater. Today Proc. 2021, 45, 6941–6945. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Hrib, V.-F.; Chifan, F.; Ciorap, M.; Dumitraş, C.G. An Study Regarding a New Concept of 3D Printing Using a 6 Axis Industrial Robotic ARM. Bull. Polytech. Inst. Iași. Mach. Constr. Sect. 2023, 69, 85–98. [Google Scholar] [CrossRef]

- Dai, Y.; Sang, S.; Zhou, Y.; Mao, J.; Yu, Z.; Zhou, K.; Wang, C. Working Principle, Application and Development Trend of 3D Printing. In Proceedings of the Ninth International Conference on Mechanical Engineering, Materials, and Automation Technology (MMEAT 2023), Dalian, China, 25 October 2023; Volume 12801, pp. 1363–1367. [Google Scholar]

- Abed Ali, S.; Rahmatabadi, D.; Baghani, M.; Baniassadi, M. Design, Processing, 3D/4D Printing, and Characterization of the Novel PETG–PBAT Blends. J. Mater. Sci. 2024, 59, 9150–9164. [Google Scholar] [CrossRef]

- Rahmatabadi, D.; Khajepour, M.; Bayati, A.; Mirasadi, K.; Amin Yousefi, M.; Shegeft, A.; Ghasemi, I.; Baniassadi, M.; Abrinia, K.; Bodaghi, M.; et al. Advancing Sustainable Shape Memory Polymers through 4D Printing of Polylactic Acid-Polybutylene Adipate Terephthalate Blends. Eur. Polym. J. 2024, 216, 113289. [Google Scholar] [CrossRef]

- Karimi, A.; Rahmatabadi, D.; Baghani, M. Various FDM Mechanisms Used in the Fabrication of Continuous-Fiber Reinforced Composites: A Review. Polymers 2024, 16, 831. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Pumera, M. 3D Printing of Functional Microrobots. Chem. Soc. Rev. 2021, 50, 2794–2838. [Google Scholar] [CrossRef] [PubMed]

- Dhangar, M.; Chaturvedi, K.; Mili, M.; Patel, S.S.; Khan, M.A.; Bhargaw, H.N.; Srivastava, A.K.; Verma, S. Emerging 3D Printed Thermal Insulating Materials for Sustainable Approach: A Review and a Way Forward. Polym. Adv. Technol. 2023, 34, 1425–1434. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef] [PubMed]

- Shakor, P.; Nejadi, S.; Paul, G.; Malek, S. Review of Emerging Additive Manufacturing Technologies in 3D Printing of Cementitious Materials in the Construction Industry. Front. Built Environ. 2019, 4, 85. [Google Scholar] [CrossRef]

- Ali, M.; Abilgaziyev, A.; Adair, D. 4D Printing: A Critical Review of Current Developments, and Future Prospects. Int. J. Adv. Manuf. Technol. 2019, 105, 701–717. [Google Scholar] [CrossRef]

- Yerramala, A.; Desai, B. Influence of Fly Ash Replacement on Strength Properties of Cement Mortar. Int. J. Eng. Sci. Technol. 2012, 4, 3657–3665. [Google Scholar]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agustí-Juan, I. Vision of 3D Printing with Concrete—Technical, Economic and Environmental Potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Zhao, Y.; Yang, G.; Zhu, L.; Ding, Y.; Guan, X.; Wu, X.; Yang, Z. Effects of Rheological Properties and Printing Speed on Molding Accuracy of 3D Printing Basalt Fiber Cementitious Materials. J. Mater. Res. Technol. 2022, 21, 3462–3475. [Google Scholar] [CrossRef]

- Larisch, M. Concrete Defects in Bored Piles as a Result of Insufficient Applications of Chemical Admixtures. In Proceedings of the NZ Concrete Industry Conference, Dunedin, New Zealand, 10–12 October 2019. [Google Scholar]

- Anwar, C.; Benamara, A.; Kaci, A. Flax Fibers Composite Made up by 3D Printing. In Proceedings of the 4th International Conference on Bio-Based Building Materials, Barcelona, Spain, 16–18 June 2021. [Google Scholar]

- Li, L.; Hao, L.; Li, X.; Xiao, J.; Zhang, S.; Poon, C.S. Development of CO2-Integrated 3D Printing Concrete. Constr. Build. Mater. 2023, 409, 134233. [Google Scholar] [CrossRef]

- Rubio, M.; Sonebi, M.; Amziane, S. Fresh and Rheological Properties of 3D Printing Bio-Cementbased Materials. Acad. J. Civ. Eng. 2017, 35, 283–290. [Google Scholar] [CrossRef]

- Li, H.; Addai-Nimoh, A.; Khayat, K. Design and Performance of 3D Printable UHPC Using Locally Available Materials. In Proceedings of the Third International Interactive Symposium on Ultra-High Performance Concrete, Wilmington, DE, USA, 6 July 2023. [Google Scholar]

- Gibson, I.; Rosen, D.; Stucker, B.; Khorasani, M. Development of Additive Manufacturing Technology. In Additive Manufacturing Technologies; Gibson, I., Rosen, D., Stucker, B., Khorasani, M., Eds.; Springer International Publishing: Cham, Switzerland, 2021; pp. 23–51. ISBN 978-3-030-56127-7. [Google Scholar]

- Chua, C.K.; Leong, K.F. 3D Printing and Additive Manufacturing; World Scientific: Singapore, 2016; ISBN 978-981-314-675-4. [Google Scholar]

- Akbari, A.; Modarres, A. Evaluating the Effect of Nano-Clay and Nano-Alumina on the Fatigue Response of Bitumen Using Strain and Time Sweep Tests. Int. J. Fatigue 2018, 114, 311–322. [Google Scholar] [CrossRef]

- Khan, S.A.; Koç, M.; Al-Ghamdi, S.G. Sustainability Assessment, Potentials and Challenges of 3D Printed Concrete Structures: A Systematic Review for Built Environmental Applications. J. Clean. Prod. 2021, 303, 127027. [Google Scholar] [CrossRef]

- Rehman, A.U.; Kim, I.-G.; Kim, J.-H. Towards Full Automation in 3D Concrete Printing Construction: Development of an Automated and Inline Sensor-Printer Integrated Instrument for in-Situ Assessment of Structural Build-up and Quality of Concrete. Dev. Built Environ. 2024, 17, 100344. [Google Scholar] [CrossRef]

- Khan, S.A.; Ghazi, S.M.U.; Amjad, H.; Imran, M.; Khushnood, R.A. Emerging Horizons in 3D Printed Cement-Based Materials with Nanomaterial Integration: A Review. Constr. Build. Mater. 2024, 411, 134815. [Google Scholar] [CrossRef]

- Praveen Kumar, V.V.; Dey, S. Study on Strength and Durability Characteristics of Nano-Silica Based Blended Concrete. Hybrid Adv. 2023, 2, 100011. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; Martínez-García, R.; Alsharari, F.; Ahmed, M.; Arbili, M.M. Impact of Nano-Silica on the Hydration, Strength, Durability, and Microstructural Properties of Concrete: A State-of-the-Art Review. Case Stud. Constr. Mater. 2023, 18, e01997. [Google Scholar] [CrossRef]

- Kashyap, V.S.; Sancheti, G.; Yadav, J.S.; Agrawal, U. Smart Sustainable Concrete: Enhancing the Strength and Durability with Nano Silica. Smart Constr. Sustain. Cities 2023, 1, 20. [Google Scholar] [CrossRef]

- Antolín-Rodríguez, A.; Merino-Maldonado, D.; González-Domínguez, J.M.; Fernández-Raga, M.; Morán-del Pozo, J.M.; García-González, J.; Juan-Valdés, A. Performance of Graphene Oxide as a Water-Repellent Coating Nanomaterial to Extend the Service Life of Concrete Structures. Heliyon 2024, 10, e23969. [Google Scholar] [CrossRef] [PubMed]

- Abdalla, J.A.; Hawileh, R.A.; Bahurudeen, A.; Jittin; Syed Ahmed Kabeer, K.I.; Thomas, B.S. Influence of Synthesized Nanomaterials in the Strength and Durability of Cementitious Composites. Case Stud. Constr. Mater. 2023, 18, e02197. [Google Scholar] [CrossRef]

- Sun, J.; Shi, C.; Li, P.; Li, A. Influence of Nanomodified Waterproofing Agent on the Performance of Rigid Waterproof Concrete in Underground Engineering. J. Nanomater. 2022, 2022, 2966551. [Google Scholar] [CrossRef]

- Bautista-Gutierrez, K.P.; Herrera-May, A.L.; Santamaría-López, J.M.; Honorato-Moreno, A.; Zamora-Castro, S.A. Recent Progress in Nanomaterials for Modern Concrete Infrastructure: Advantages and Challenges. Materials 2019, 12, 3548. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, H.; Moura, B.; Soares, N. Advancements in Nano-Enabled Cement and Concrete: Innovative Properties and Environmental Implications. J. Build. Eng. 2022, 56, 104736. [Google Scholar] [CrossRef]

- Goel, G.; Sachdeva, P.; Chaudhary, A.K.; Singh, Y. The Use of Nanomaterials in Concrete: A Review. Mater. Today Proc. 2022, 69, 365–371. [Google Scholar] [CrossRef]

- Saleem, H.; Zaidi, S.J.; Alnuaimi, N.A. Recent Advancements in the Nanomaterial Application in Concrete and Its Ecological Impact. Materials 2021, 14, 6387. [Google Scholar] [CrossRef] [PubMed]

- Jandyal, A.; Chaturvedi, I.; Wazir, I.; Raina, A.; Ul Haq, M.I. 3D Printing—A Review of Processes, Materials and Applications in Industry 4.0. Sustain. Oper. Comput. 2022, 3, 33–42. [Google Scholar] [CrossRef]

- Senthilnathan, S.; Raphael, B. Using Computer Vision for Monitoring the Quality of 3D-Printed Concrete Structures. Sustainability 2022, 14, 15682. [Google Scholar] [CrossRef]

- Jhun, J.; Lee, D.-H.; Rehman, A.U.; Kang, S.; Kim, J.-H. Development of a Real-Time Geometric Quality Monitoring System for Extruded Filaments of 3D Concrete Printing Construction. IEEE Access 2024, 12, 69981–69999. [Google Scholar] [CrossRef]

- Teizer, J.; Blickle, A.; King, T.; Leitzbach, O.; Guenther, D. Large Scale 3D Printing of Complex Geometric Shapes in Construction. In Proceedings of the 33th International Symposium on Automation and Robotics in Construction, Auburn, AL, USA, 18–21 July 2016. [Google Scholar]

- Sustarevas, J.; Kanoulas, D.; Julier, S. Autonomous Mobile 3D Printing of Large-Scale Trajectories. In Proceedings of the 2022 IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022. [Google Scholar]

- Fonseca, M.; Matos, A.M. 3D Construction Printing Standing for Sustainability and Circularity: Material-Level Opportunities. Materials 2023, 16, 2458. [Google Scholar] [CrossRef]

- Javed, A.; Mantawy, I.; Azizinamini, A. 3D-Printing of Ultra-High-Performance Concrete for Robotic Bridge Construction. Transp. Res. Rec. J. Transp. Res. Board 2021, 2675, 307–319. [Google Scholar] [CrossRef]

- Brooks, J.; Rahman, M.M.T.; Joyee, E. Design and Construction of a Belt-Assisted Vertical Extrusion Based Fused Deposition Modeling 3D Printer for Automated Part Removal. In Proceedings of the ASME 2023 18th International Manufacturing Science and Engineering Conference, New Brunswick, NJ, USA, 12–16 June 2023. [Google Scholar]

- Abdulloh, M.K.; Sulistijono, I.A.; Tamara, M.N. Design of Miniature 3D Concrete Printer (3DCP) for One-Story House Building. AIP Conf. Proc. 2024, 2710, 20022. [Google Scholar] [CrossRef]

- Tay, Y.W.D.; Panda, B.; Paul, S.; Noor Mohamed, N.A.; Tan, M.J.; Leong, K.F. 3D Printing Trends in Building and Construction Industry: A Review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Gamage, K.; Fawzia, S.; Zahra, T.; Teixeira, M.B.F.; Ramli Sulong, N.H. Advancement in Sustainable 3D Concrete Printing: A Review on Materials, Challenges, and Current Progress in Australia. Buildings 2024, 14, 494. [Google Scholar] [CrossRef]

- Lesovik, V.; Tolstoy, A.; Fediuk, R.; Amran, M.; Ali, M.; de Azevedo, A.R.G. Improving the Performances of a Mortar for 3D Printing by Mineral Modifiers. Buildings 2022, 12, 1181. [Google Scholar] [CrossRef]

- Isaac, G.; Nicholas, P.; Paul, G.; Pietroni, N.; Calleja, T.; Xie, Y.; Schork, T. Automated Shotcrete: A More Sustainable Construction Technology. In Sustainable Engineering: Concepts and Practices; Springer International Publishing: Cham, Switzerland, 2024; pp. 331–345. ISBN 978-3-031-47214-5. [Google Scholar]

- Natanzi, A.S.; Mcnally, C. Characterising Concrete Mixes for 3D Printing. In Second RILEM International Conference on Concrete and Digital Fabrication: Digital Concrete 2020; Springer International Publishing: Cham, Switzerland, 2020; pp. 83–92. ISBN 978-3-030-49915-0. [Google Scholar]

- Khan, M.A. Mix Suitable for Concrete 3D Printing: A Review. Mater. Today Proc. 2020, 32, 831–837. [Google Scholar] [CrossRef]

- Zhang, C.; Nerella, V.N.; Krishna, A.; Wang, S.; Zhang, Y.; Mechtcherine, V.; Banthia, N. Mix Design Concepts for 3D Printable Concrete: A Review. Cem. Concr. Compos. 2021, 122, 104155. [Google Scholar] [CrossRef]

- Pan, Z.; Si, D.; Tao, J.; Xiao, J. Compressive Behavior of 3D Printed Concrete with Different Printing Paths and Concrete Ages. Case Stud. Constr. Mater. 2023, 18, e01949. [Google Scholar] [CrossRef]

- Sanjayan, J.G.; Nematollahi, B.; Xia, M.; Marchment, T. Effect of Surface Moisture on Inter-Layer Strength of 3D Printed Concrete. Constr. Build. Mater. 2018, 172, 468–475. [Google Scholar] [CrossRef]

- Joergensen, H.; Douglas, P.; Naboni, R. Experimental Study on the Anisotropic Behaviour and Strength of 3D Printed Concrete; International Federation for Structural Concrete: Lausanne, Switzerland, 2021. [Google Scholar]

- Kazemian, A.; Yuan, X.; Cochran, E.; Khoshnevis, B. Cementitious Materials for Construction-Scale 3D Printing: Laboratory Testing of Fresh Printing Mixture. Constr. Build. Mater. 2017, 145, 639–647. [Google Scholar] [CrossRef]

- Kaszynska, M.; Hoffmann, M.; Skibicki, S.; Zielinski, A.; Techman, M.; Olczyk, N.; Wroblewski, T. Evaluation of Suitability for 3D Printing of High Performance Concretes. MATEC Web Conf. 2018, 163, 1002. [Google Scholar] [CrossRef]

- Chen, Y.; He, S.; Gan, Y.; Çopuroğlu, O.; Veer, F.; Schlangen, E. A Review of Printing Strategies, Sustainable Cementitious Materials and Characterization Methods in the Context of Extrusion-Based 3D Concrete Printing. J. Build. Eng. 2022, 45, 103599. [Google Scholar] [CrossRef]

- Moelich, G.M.; Kruger, J.; Combrinck, R. Plastic Shrinkage Cracking in 3D Printed Concrete. Compos. Part B Eng. 2020, 200, 108313. [Google Scholar] [CrossRef]

- Moelich, G.M.; Kruger, P.J.; Combrinck, R. Mitigating Early Age Cracking in 3D Printed Concrete Using Fibres, Superabsorbent Polymers, Shrinkage Reducing Admixtures, B-CSA Cement and Curing Measures. Cem. Concr. Res. 2022, 159, 106862. [Google Scholar] [CrossRef]

- Markin, S.; Combrinck, R.; Mechtcherine, V. Specifics of Plastic Shrinkage in 3D-Printed Concrete Elements. Cem. Concr. Res. 2024, 184, 107512. [Google Scholar] [CrossRef]

- Zhou, L.; Gou, M.; Ji, J.; Hou, X.; Zhang, H. Durability and Hardened Properties of 3D Printed Concrete Containing Bauxite Tailings. Mater. Today Sustain. 2024, 25, 100704. [Google Scholar] [CrossRef]

- Narjabadifam, P.; Mollaei, S.; Farsangi, E.; Talebi, S. Numerical Analysis of Seismic Behavior of an Arched-Roof 3D-Printed Building. Gradjevinski Mater. i Konstr. 2024, 67, 12. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef]

- Ge, Q.; Sakhaei, A.H.; Lee, H.; Dunn, C.; Fang, N.; Dunn, M. Multimaterial 4D Printing with Tailorable Shape Memory Polymers. Sci. Rep. 2016, 6, 31110. [Google Scholar] [CrossRef]

- Chen, K.; Qu, F.; Huang, Y.; Cai, J.; Wu, F.; Li, W. Advancing Photocatalytic Concrete Technologies in Design, Performance and Application for a Sustainable Future. Adv. Nanocomposites 2024, 1, 180–200. [Google Scholar] [CrossRef]

- Leng, J.; Lan, X.; Liu, Y.; Du, S. Shape-Memory Polymers and Their Composites: Stimulus Methods and Applications. Prog. Mater. Sci. 2011, 56, 1077–1135. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 5th ed.; Institut Géopolymère: Saint-Quentin, France, 2008; Volume 171, ISBN 9782954453118. [Google Scholar]

- Ahi, O.; Ertunç, Ö.; Bundur, Z.; Bebek, O. Automated Flow Rate Control of Extrusion for 3D Concrete Printing Incorporating Rheological Parameters. Autom. Constr. 2024, 160, 105319. [Google Scholar] [CrossRef]

- Skripkiunas, G.; Daukšys, M.; Štuopys, A.; Levinskas, R. The Influence of Cement Particles Shape and Concentration on the Rheological Properties of Cement Slurry. Mater. Sci. 2005, 11, 150–158. [Google Scholar]

- Chernysheva, N.; Shatalova, S.; Lesovik, V.; Kozlov, P. Deformation Characteristics of Dense and Foamed Mortars Based on Cement and Gypsum-to-Cement Binders for 3D Printing. Constr. Build. Mater. 2023, 409, 133986. [Google Scholar] [CrossRef]

- Bumanis, G.; Sapata, A.; Sinka, M.; Spurina, E.; Bajare, D. Additive Manufacturing of Lightweight Gypsum and Expanded Polystyrene Granulate Composite. J. Compos. Sci. 2023, 7, 425. [Google Scholar] [CrossRef]

- Charai, M.; Mghazli, M.O.; Channouf, S.; El hammouti, A.; Jagadesh, P.; Moga, L.; Mezrhab, A. Lightweight Waste-Based Gypsum Composites for Building Temperature and Moisture Control Using Coal Fly Ash and Plant Fibers. Constr. Build. Mater. 2023, 393, 132092. [Google Scholar] [CrossRef]

- Ikotun, J.O.; Aderinto, G.E.; Madirisha, M.M.; Katte, V.Y. Geopolymer Cement in Pavement Applications: Bridging Sustainability and Performance. Sustainability 2024, 16, 5417. [Google Scholar] [CrossRef]

- Perales-Santillan, M.; Díaz Aguilera, J.H.; Mendoza-Rangel, J. Evaluation of the Rheological Behavior for Alkaline-Activated Cements of Metakaolin and Limestone for Its Potential Application in 3D Printing. Iran. J. Sci. Technol. Trans. Civ. Eng. 2024. [Google Scholar] [CrossRef]

- Khan, S.; İlcan, H.; Imran, R.; Aminipour, E.; Şahin, O.; Al Rashid, A.; Şahmaran, M.; Koç, M. The Impact of Nozzle Diameter and Printing Speed on Geopolymer-Based 3D-Printed Concrete Structures: Numerical Modeling and Experimental Validation. Results Eng. 2024, 21, 101864. [Google Scholar] [CrossRef]

- Chen, K.; Liu, Q.; Chen, B.; Zhang, S.; Ferrara, L.; Li, W. Effect of Raw Materials on the Performance of 3D Printing Geopolymer: A Review. J. Build. Eng. 2024, 84, 108501. [Google Scholar] [CrossRef]

- Růžek, V.; Louda, P.; Buczkowska, K. Geopolymer Concrete for Sustainable Construction and Other Applications. Proceedings of World Engineering Convention 2023 Conference, Prague, Czech Republic, 11–13 October 2023. [Google Scholar]

- Roviello, G.; Ricciotti, L.; Tarallo, O.; Ferone, C.; Colangelo, F.; Roviello, V.; Cioffi, R. Innovative Fly Ash Geopolymer-Epoxy Composites: Preparation, Microstructure and Mechanical Properties. Materials 2016, 9, 461. [Google Scholar] [CrossRef]

- Pi, Y.; Lu, C.; Yao, Y.; Li, B. A Rheological-Based Printability Assessment Method for 3D Printing Engineered Cementitious Composites Considering Fiber Dispersion. Case Stud. Constr. Mater. 2024, 20, e02898. [Google Scholar] [CrossRef]

- Shilar, F.A.; Ganachari, S.V.; Patil, V.B.; Bhojaraja, B.E.; Yunus Khan, T.M.; Almakayeel, N. A Review of 3D Printing of Geopolymer Composites for Structural and Functional Applications. Constr. Build. Mater. 2023, 400, 132869. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, Q.; Xia, R.; Zhang, P.; Zhou, H.; Zhao, B.; Li, G. Automatic Defect Prediction in Glass Fiber Reinforced Polymer Based on THz-TDS Signal Analysis with Neural Networks. Infrared Phys. Technol. 2021, 115, 103673. [Google Scholar] [CrossRef]

- Altin Karataş, M.; Gökkaya, H. A Review on Machinability of Carbon Fiber Reinforced Polymer (CFRP) and Glass Fiber Reinforced Polymer (GFRP) Composite Materials. Def. Technol. 2018, 14, 318–326. [Google Scholar] [CrossRef]

- De, B.; Bera, M.; Bhattacharjee, D.; Ray, B.C.; Mukherjee, S. A Comprehensive Review on Fiber-Reinforced Polymer Composites: Raw Materials to Applications, Recycling, and Waste Management. Prog. Mater. Sci. 2024, 146, 101326. [Google Scholar] [CrossRef]

- Garcia-Espinel, J.D.; Alvarez-Garcia-Luben, R.; Gonzalez-Herrero, J.M.; Castro-Fresno, D. Glass Fiber-Reinforced Polymer Caissons Used for Construction of Mooring Dolphins in Puerto Del Rosario Harbor (Fuerteventura, Canary Islands). Coast. Eng. 2015, 98, 16–25. [Google Scholar] [CrossRef]

- Demirdağ, C.; Nodehi, M.; Bideci, A.; Bideci, Ö.S.; Tuncer, M.; Gencel, O.; Ozbakkaloglu, T. The Use of Natural (Coconut) and Artificial (Glass) Fibers in Cement—Polymer Composites: An Experimental Study. Constr. Build. Mater. 2024, 412, 134895. [Google Scholar] [CrossRef]

- Zhang, S.; Caprani, C.C.; Heidarpour, A. Strain Rate Studies of Pultruded Glass Fibre Reinforced Polymer Material Properties: A Literature Review. Constr. Build. Mater. 2018, 171, 984–1004. [Google Scholar] [CrossRef]

- Geier, N.; Patra, K.; Anand, R.S.; Ashworth, S.; Balázs, B.Z.; Lukács, T.; Magyar, G.; Tamás-Bényei, P.; Xu, J.; Davim, J.P. A Critical Review on Mechanical Micro-Drilling of Glass and Carbon Fibre Reinforced Polymer (GFRP and CFRP) Composites. Compos. Part B Eng. 2023, 254, 110589. [Google Scholar] [CrossRef]

- Ismail, K.B.M.; Kumar, M.A.; Mahalingam, S.; Raj, B.; Kim, J. Carbon Fiber-Reinforced Polymers for Energy Storage Applications. J. Energy Storage 2024, 84, 110931. [Google Scholar] [CrossRef]

- Park, J.; Yoon, S.; Kim, E.; Kim, M. Flame-Retardant Aramid Felt-Reinforced Phenolic Coatings for Carbon Fiber-Reinforced Polymers (CFRPs). Polym. Test. 2024, 135, 108468. [Google Scholar] [CrossRef]

- Wei, L.; Zhu, J.-H.; Dong, Z.; Liu, J.; Liu, W.; Su, M.; Xing, F. Anodic and Mechanical Behavior of Carbon Fiber Reinforced Polymer as a Dual-Functional Material in Chloride-Contaminated Concrete. Materials 2020, 13, 222. [Google Scholar] [CrossRef] [PubMed]

- Jiang, Q.; Beutl, A.; Kühnelt, H.; Bismarck, A. Structural Composite Batteries Made from Carbon Fibre Reinforced Electrodes/Polymer Gel Electrolyte Prepregs. Compos. Sci. Technol. 2023, 244, 110312. [Google Scholar] [CrossRef]

- Tan, Y.; Liu, J.; Li, Y.; Wang, Q.; Zhou, W.; Ao, Y.; Li, M. Constructing a New Multiscale “Soft-Rigid-Soft” Interfacial Structure at the Interphase to Improve the Interfacial Performance of Carbon Fiber Reinforced Polymer Composites. Compos. Sci. Technol. 2024, 248, 110458. [Google Scholar] [CrossRef]

- Ateeq, M.; Shafique, M.; Azam, A.; Rafiq, M. A Review of 3D Printing of the Recycled Carbon Fiber Reinforced Polymer Composites: Processing, Potential, and Perspectives. J. Mater. Res. Technol. 2023, 26, 2291–2309. [Google Scholar] [CrossRef]

- Sreekumar Kavitha, S.; Joseph, L.; Madhavan, M.K.; Jayanarayanan, K. Comparative Study of Carbon and Glass Fiber Reinforced Polymer Composites for the Confinement of Concrete Columns. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Qi, X.; Tian, J.; Xian, G. Hydrothermal Ageing of Carbon Fiber Reinforced Polymer Composites Applied for Construction: A Review. J. Mater. Res. Technol. 2023, 27, 1017–1045. [Google Scholar] [CrossRef]

- Aishwarya, R.; Priya Rachel, P. Comparative Study on Atterberg Limits of Soil and Basalt Fiber Composite as an Eco-Friendly Construction Material. Mater. Today Proc. 2023, 77, 563–567. [Google Scholar] [CrossRef]

- AL-Kharabsheh, B.N.; Arbili, M.M.; Majdi, A.; Alogla, S.M.; Hakamy, A.; Ahmad, J.; Deifalla, A.F. Basalt Fibers Reinforced Concrete: Strength and Failure Modes. Materials 2022, 15, 7350. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Wang, B.; Yu, Y.; Dai, M.; Zhang, W.; Zhou, Z. Construction of Multi-Scaled Interfaces for Synergetic Enhancement in Mechanical Properties of Basalt Fiber/Nylon-6 Composites. Mater. Lett. 2023, 331, 133540. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Rangappa, S.M.; Siengchin, S. Basalt Fibers: An Environmentally Acceptable and Sustainable Green Material for Polymer Composites. Constr. Build. Mater. 2024, 436, 136834. [Google Scholar] [CrossRef]

- Deng, G.; Guo, R.; Ma, L.; Long, Z.; Xu, F.; Yin, C.; Xu, X. Study on Dynamic Mechanical Properties and Microstructure of Basalt Fiber Reinforced Coral Sand Cement Composite *. Constr. Build. Mater. 2024, 425, 136024. [Google Scholar] [CrossRef]

- Song, P.; Wang, X.; Wang, Y.; Taylor, P.; Li, C.; Sun, Q.; Ma, Y. Assessment of Rheological and Toughening Behavior of Basalt Fiber Sprayed Cementitious Composites (BFSCC). Constr. Build. Mater. 2024, 426, 136169. [Google Scholar] [CrossRef]

- Xu, Y.; Han, Y.; Zhao, G.; Meng, S. Enhancing Geotechnical Reinforcement: Exploring Molybdenum Tailings and Basalt Fibre-Modified Composites for Sustainable Construction. Constr. Build. Mater. 2024, 411, 134452. [Google Scholar] [CrossRef]

- Muntongkaw, S.; Pianklang, S.; Tangboriboon, N. Modifications to Improve Properties of Gypsum Ceiling Composites as Multifunctional Construction by Embedding Typha Angustifolia Fiber and Natural Rubber Latex Compound. Case Stud. Constr. Mater. 2021, 15, e00658. [Google Scholar] [CrossRef]

- Silva, G.; Kim, S.; Bertolotti, B.; Nakamatsu, J.; Aguilar, R. Optimization of a Reinforced Geopolymer Composite Using Natural Fibers and Construction Wastes. Constr. Build. Mater. 2020, 258, 119697. [Google Scholar] [CrossRef]

- Cao, C. Sustainability and Life Assessment of High Strength Natural Fibre Composites in Construction. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 529–544. ISBN 978-0-08-100411-1. [Google Scholar]

- Fan, M. Future Scope and Intelligence of Natural Fibre Based Construction Composites. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 545–556. ISBN 978-0-08-100411-1. [Google Scholar]

- Kim, Y.K.; Chalivendra, V. Natural Fibre Composites (NFCs) for Construction and Automotive Industries. In The Textile Institute Book Series; Kozłowski, R.M., Mackiewicz-Talarczyk, E., Eds.; Woodhead Publishing: Sawston, UK, 2020; pp. 469–498. ISBN 978-0-12-818782-1. [Google Scholar]

- Fan, M.; Fu, F. Introduction: A Perspective—Natural Fibre Composites in Construction. In Advanced High Strength Natural Fibre Composites in Construction; Fan, M., Fu, F., Eds.; Woodhead Publishing: Sawston, UK, 2017; pp. 1–20. ISBN 978-0-08-100411-1. [Google Scholar]

- Akindoyo, J.O.; Pickering, K.; Mucalo, M.; Beg, M.D.; Hicks, J. Mechanenzymatic Production of Natural Fibre from Harakeke (New Zealand Flax) and Its Characterization for Potential Use in Composites for Building and Construction Applications. Ind. Crops Prod. 2024, 214, 118507. [Google Scholar] [CrossRef]

- Panza Uguzzoni, A.M.; Fregonara, E.; Ferrando, D.G.; Anglani, G.; Antonaci, P.; Tulliani, J.-M. Concrete Self-Healing for Sustainable Buildings: A Focus on the Economic Evaluation from a Life-Cycle Perspective. Sustainability 2023, 15, 13637. [Google Scholar] [CrossRef]

- Fregonara, E.; Ferrando, D.G. How to Model Uncertain Service Life and Durability of Components in Life Cycle Cost Analysis Applications? The Stochastic Approach to the Factor Method. Sustainability 2018, 10, 3642. [Google Scholar] [CrossRef]

- Rui, A.; Wang, L.; Lin, W.; Ma, G. Experimental Study on Damage Anisotropy of 3D-Printed Concrete Exposed to Sulfate Attack. Constr. Build. Mater. 2023, 407, 133590. [Google Scholar] [CrossRef]

- Liao, C.-Y.; Zhang, L.; Hu, S.-Y.; Xia, S.-J.; Li, D.M. Recent Advances of Self-Healing Materials for Civil Engineering: Models and Simulations. Buildings 2024, 14, 961. [Google Scholar] [CrossRef]

- Fernández, F.; Jarabo, R.; Asensio, E.; Guerrero, A. Non-Destructive Tests to Evaluate the Self-Healing Capacity for a 3D Printing ECC Material. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

- Amran, M.; Onaizi, A.M.; Fediuk, R.; Vatin, N.I.; Muhammad Rashid, R.S.; Abdelgader, H.; Ozbakkaloglu, T. Self-Healing Concrete as a Prospective Construction Material: A Review. Materials 2022, 15, 3214. [Google Scholar] [CrossRef] [PubMed]

- Sahai, R.; Bisht, R.S.; Malviya, N.K.; Kumar, S.; Singh, S.; Panigrahi, S.K. Aspects of Waste Material Utilization and 3D Concrete Printer Development Approach: A Review. Trans. Indian Natl. Acad. Eng. 2024, 9, 45–69. [Google Scholar] [CrossRef]

- Al-Jumaily, A.; Crippa, P.; Mansour, A. Non-Invasive Health Systems Based on Advanced Biomedical Signal and Image Processing; CRC Press: Boca Raton, FL, USA, 2024; ISBN 9781003346678. [Google Scholar]

- Haldar, B. Enhancing Dimensional Accuracy in Budget-Friendly 3D Printing through Solid Model Geometry Tuning and Its Use in Rapid Casting. Machines 2023, 11, 1020. [Google Scholar] [CrossRef]

- Alzahrani, F.J.; Noor, H.; Coulter, J.P. An Investigation of the Effect of Layer-Building Time on the Interlayer Adhesion Strength in Polymer Additive Manufacturing. In Proceedings of the ASME 2023 International Mechanical Engineering Congress and Exposition, New Orleans, LA, USA, 29 October–2 November 2023; Volume 3, p. V003T03A001. [Google Scholar]

- Westphal, E.; Seitz, H. Machine Learning for the Intelligent Analysis of 3D Printing Conditions Using Environmental Sensor Data to Support Quality Assurance. Addit. Manuf. 2022, 50, 102535. [Google Scholar] [CrossRef]

- Razvi, S.S.; Feng, S.; Narayanan, A.; Lee, Y.-T.; Witherell, P. A Review of Machine Learning Applications in Additive Manufacturing. In Proceedings of the ASME 2019 International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Anaheim, CA, USA, 18–21 August 2019. [Google Scholar]

- Mohammadi, M.G.; Elbestawi, M. Real Time Monitoring in L-PBF Using a Machine Learning Approach. Procedia Manuf. 2020, 51, 725–731. [Google Scholar] [CrossRef]

- García-Alvarado, R.; Soza, P.; Moroni, G.; Pedreros, F.; Avendaño, M.; Banda, P.; Berríos, C. From BIM Model to 3D Construction Printing: A Framework Proposal. Front. Archit. Res. 2024, 13, 912–927. [Google Scholar] [CrossRef]

- Regassa Hunde, B.; Debebe Woldeyohannes, A. Future Prospects of Computer-Aided Design (CAD)—A Review from the Perspective of Artificial Intelligence (AI), Extended Reality, and 3D Printing. Results Eng. 2022, 14, 100478. [Google Scholar] [CrossRef]

- Liu, K.; Takasu, K.; Jiang, J.; Zu, K.; Gao, W. Mechanical Properties of 3D Printed Concrete Components: A Review. Dev. Built Environ. 2023, 16, 100292. [Google Scholar] [CrossRef]

- Shuaib, M.; Haleem, A.; Kumar, S.; Javaid, M. Impact of 3D Printing on the Environment: A Literature-Based Study. Sustain. Oper. Comput. 2021, 2, 57–63. [Google Scholar] [CrossRef]

| 3D Printing Technology | Material Used | Key Applications | Advantages | Disadvantages |

|---|---|---|---|---|

| Fused Deposition Modeling (FDM) | Thermoplastics | Prototypes, structural elements | Low cost, variety of materials | Lower strength, less precision |

| Selective Laser Sintering (SLS) | Powdered materials | High-strength components | High strength, complex shapes | High cost, slower process |

| Stereolithography (SLA) | Photopolymer resins | Architectural models, decorative elements | High precision, surface quality | Limited material choices, post-processing needed |

| Property | Requirement |

|---|---|

| High compressive strength | Withstand significant loads |

| Durability | Resist moisture, temperature changes, chemicals, and corrosion |

| Workability | Easy mixing, transporting, placing, and compacting |

| Sustainability | Use of recycled materials, reduced CO2 emissions |

| Property | Description | Example value | References |

|---|---|---|---|

| Composition | Types and proportions of materials used in the concrete mix | Cement, sand, water, additives | [64,65,66] |

| Compressive strength | The maximum stress that the mixture can withstand before failure | 20–50 MPa | [67,68,69,70] |

| Open time | Open time is the period at which the material can be extruded continuously without separation | 15–90 min | [65,71,72] |

| Plastic shrinkage | Reduction in the volume of fresh concrete mix during drying out | Depends on the additives used, mostly less than 2% | [73,74,75] |

| Criteria | Geocement | Portland Cement |

|---|---|---|

| CO2 emissions | Low to none | Extremely high |

| Sustainability | High | Low |

| Energy saving | High with no embodied energy | Low with greater embodied energy |

| Costs (production, sales, etc.) | Low | Extremely high |

| Eco-friendliness | High | Low |

| Water requirement | Low | High |

| Availability of raw materials | Abundant and cheap | Non-abundant and costly |

| Thermal conductivity | Low | High |

| Ability to adsorb and immobilize toxic substances | High | Moderate to high |

| Preparation technique | Simple | Complex |

| Volume stability | Good | Fair |

| Setting time | Short (about 10–60 min) | Long (about 30–300 min) |

| Global warming contribution | Low to none | High |

| Type of Fiber | Advantages | Disadvantages |

|---|---|---|

| Glass Fibers |

|

|

| Carbon Fibers |

|

|

| Basalt Fibers |

|

|

| Natural Fibers |

|

|

| Parameter | Value |

|---|---|

| Specific gravity | 2.65 |

| Water Absorption (%) | 3.60 |

| Density (g/cm3) | 2.64–2.75 |

| Tensile Strength (MPa) | 2800–4800 |

| Elastic modulus (GPa) | 89–110 |

| Elongation (%) | 3.05–4.00 |

| Process | Positive Impact | Negative Impact |

|---|---|---|

| EBM, SLS, SLM |

|

|

| SLA |

|

|

| FDM |

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hutyra, A.; Bańkosz, M.; Tyliszczak, B. Technology for Automated Production of High-Performance Building Compounds for 3D Printing. Materials 2024, 17, 3829. https://doi.org/10.3390/ma17153829

Hutyra A, Bańkosz M, Tyliszczak B. Technology for Automated Production of High-Performance Building Compounds for 3D Printing. Materials. 2024; 17(15):3829. https://doi.org/10.3390/ma17153829

Chicago/Turabian StyleHutyra, Adam, Magdalena Bańkosz, and Bożena Tyliszczak. 2024. "Technology for Automated Production of High-Performance Building Compounds for 3D Printing" Materials 17, no. 15: 3829. https://doi.org/10.3390/ma17153829

APA StyleHutyra, A., Bańkosz, M., & Tyliszczak, B. (2024). Technology for Automated Production of High-Performance Building Compounds for 3D Printing. Materials, 17(15), 3829. https://doi.org/10.3390/ma17153829