Study of Prefabricated Crack Propagation on Monocrystalline Silicon Surfaces for Grinding Damage Analysis

Abstract

:1. Introduction

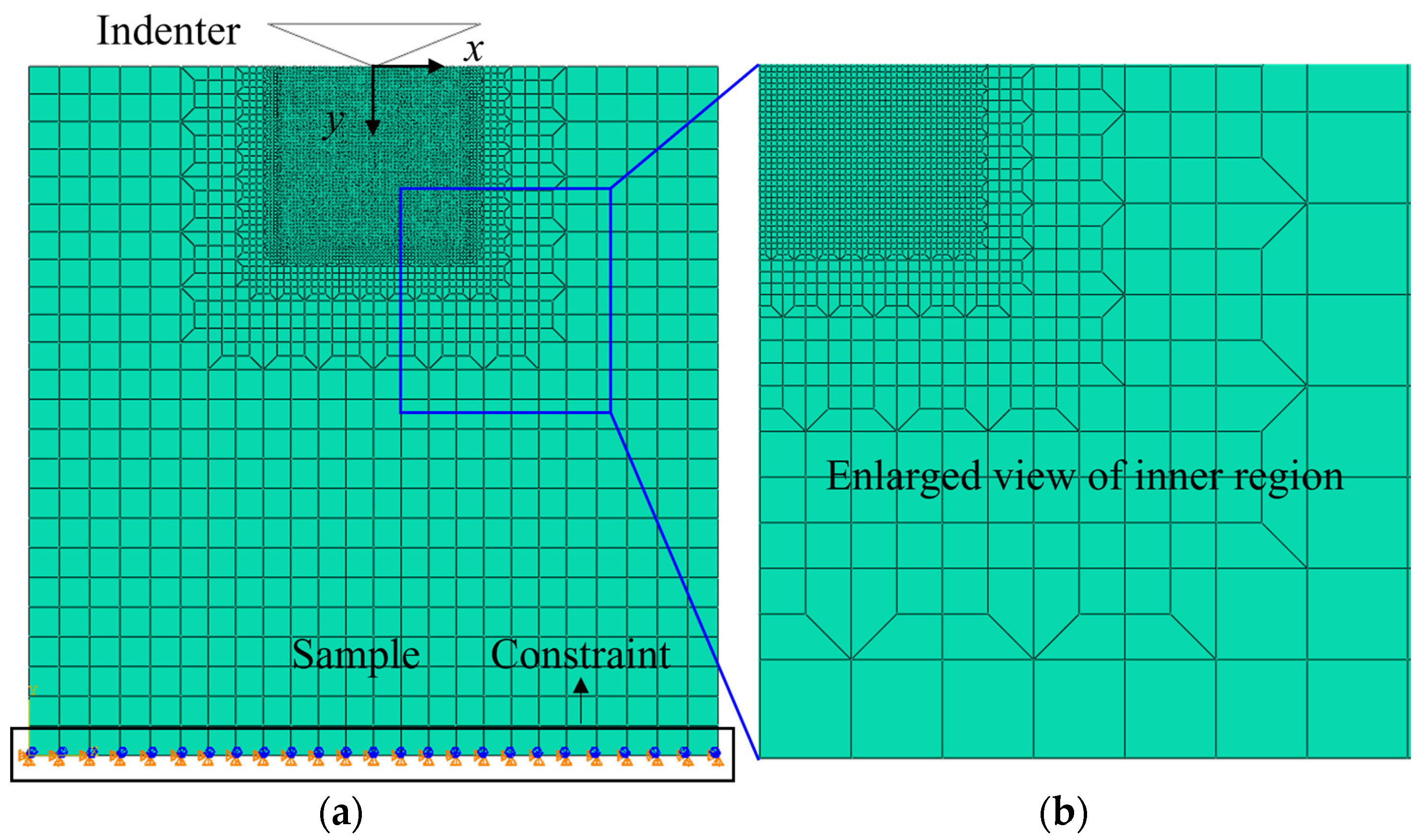

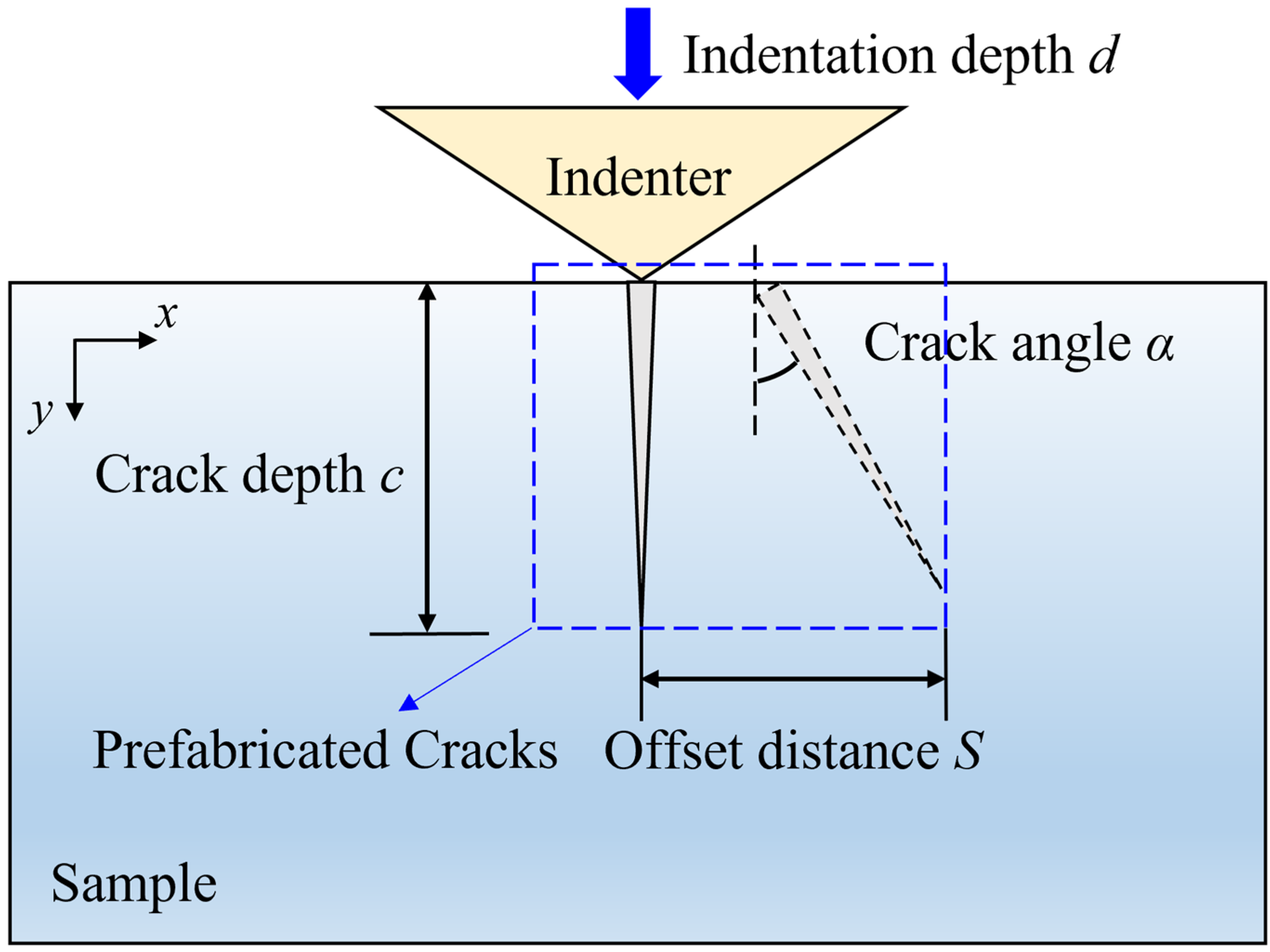

2. Prefabricated Crack Simulation

2.1. Simulation Model

2.2. Material Properties

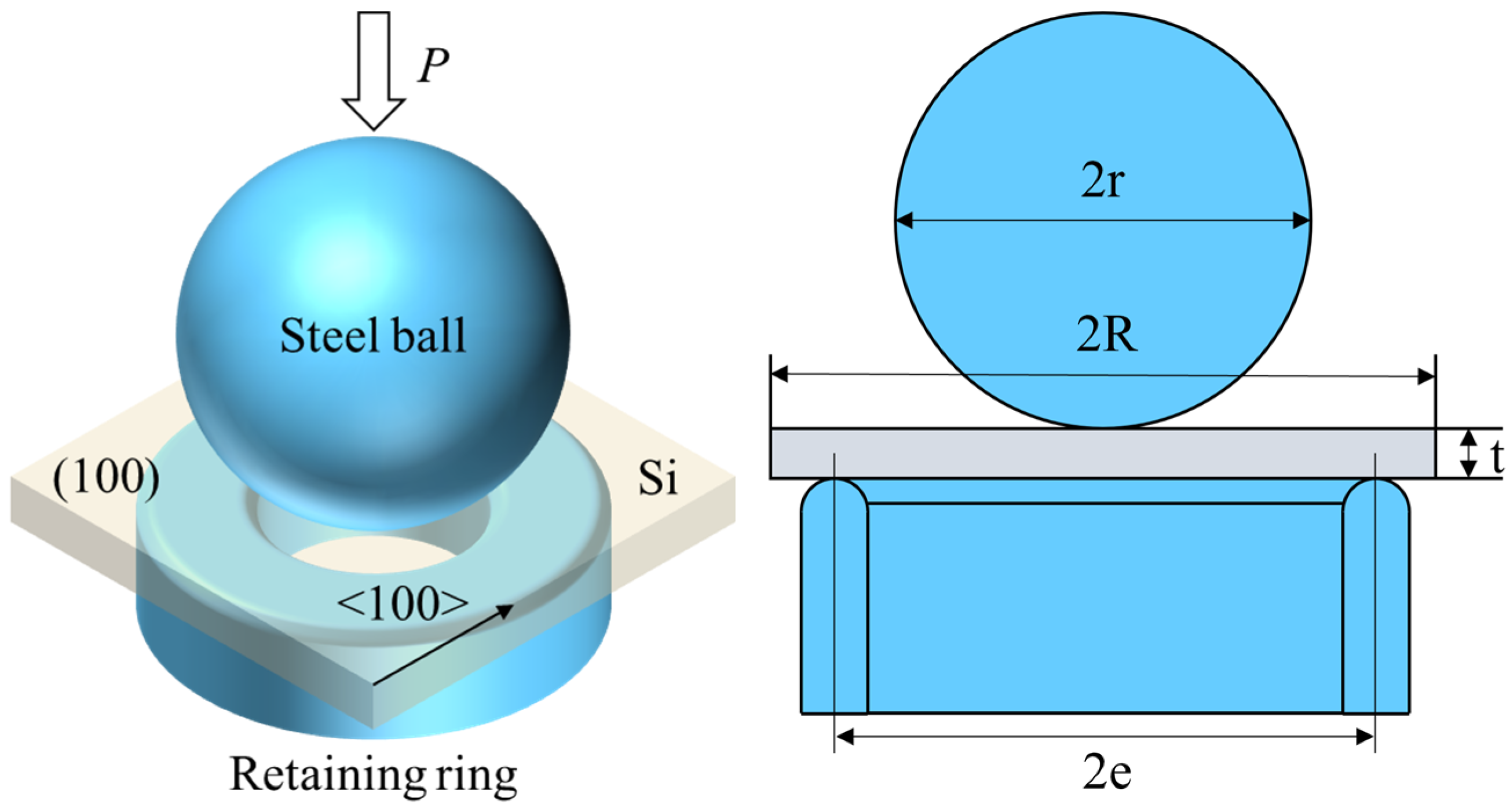

3. Experiments

3.1. Crack Propagation Law Test

3.1.1. Prefabricating Cracks

3.1.2. Fracture Strength Test

3.2. Grinding Process Test

3.3. SSD Measurement

4. Results and Discussion

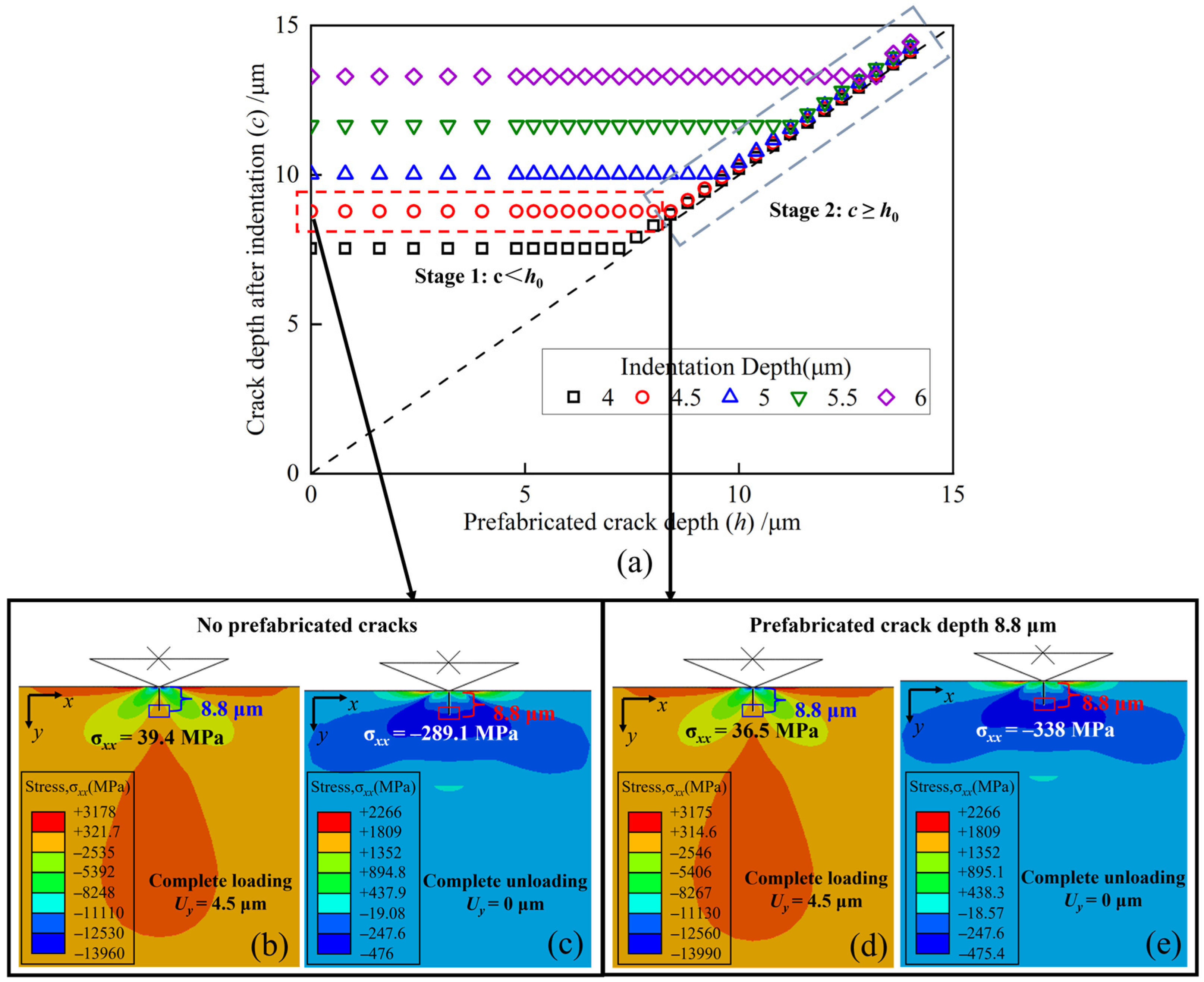

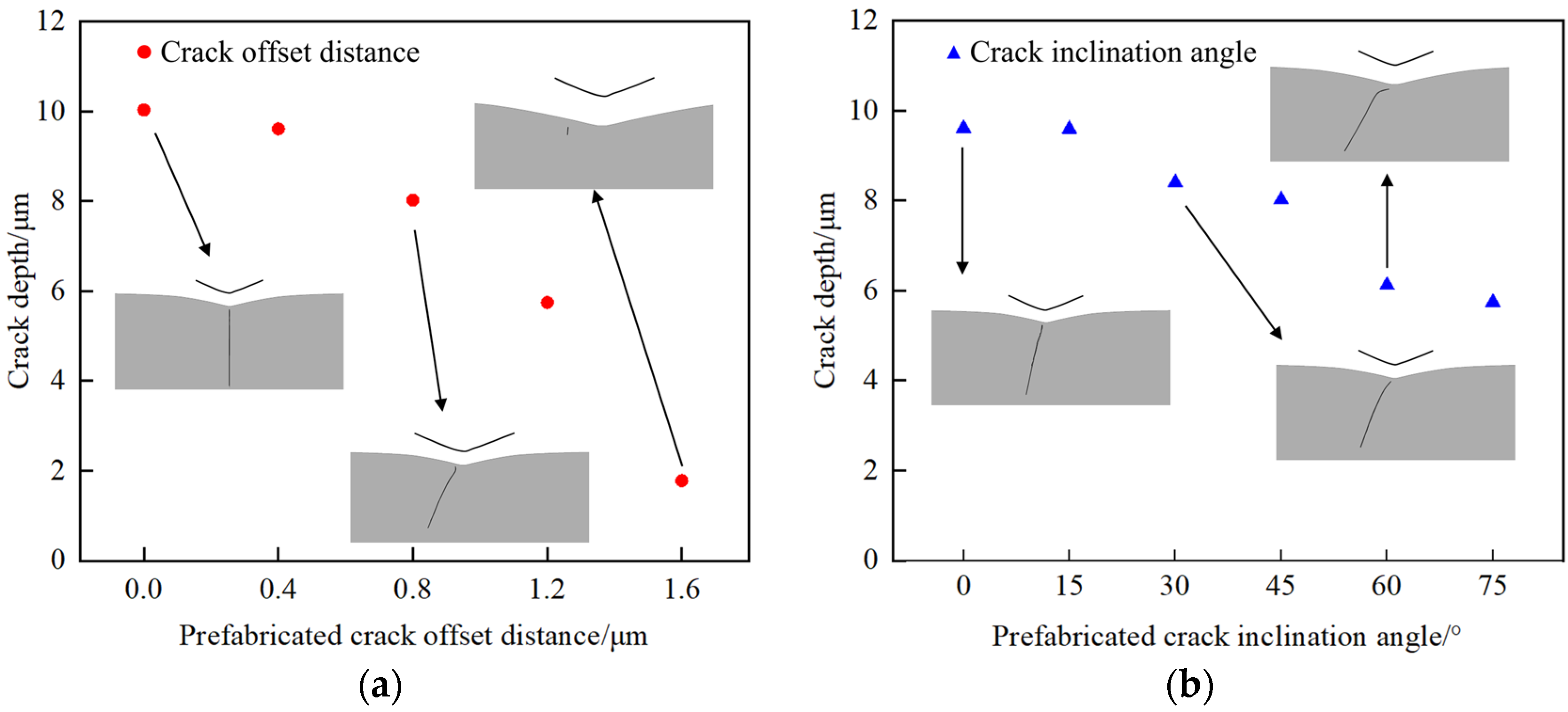

4.1. Crack Evolution

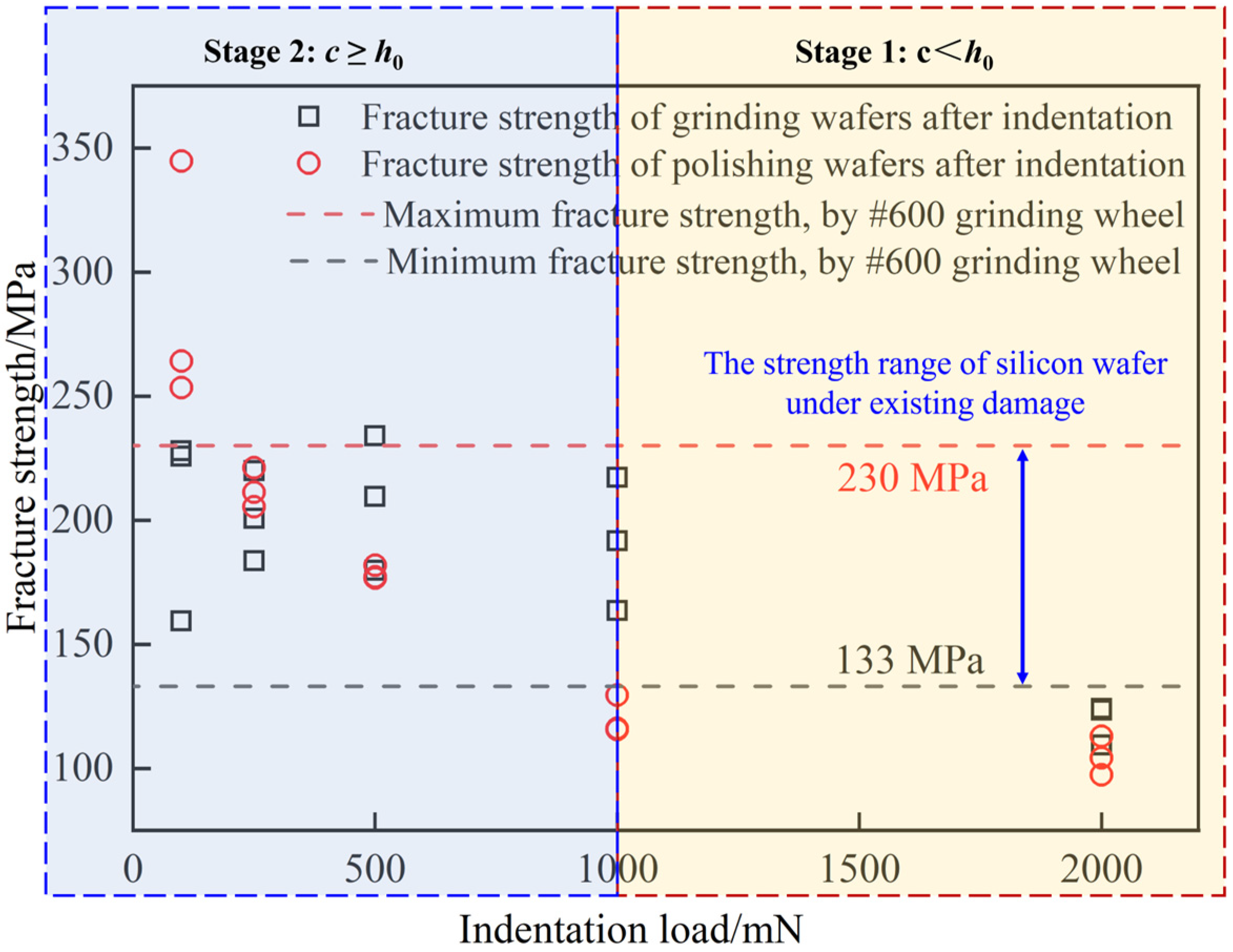

4.2. Fracture Strength to Determine Crack Propagation

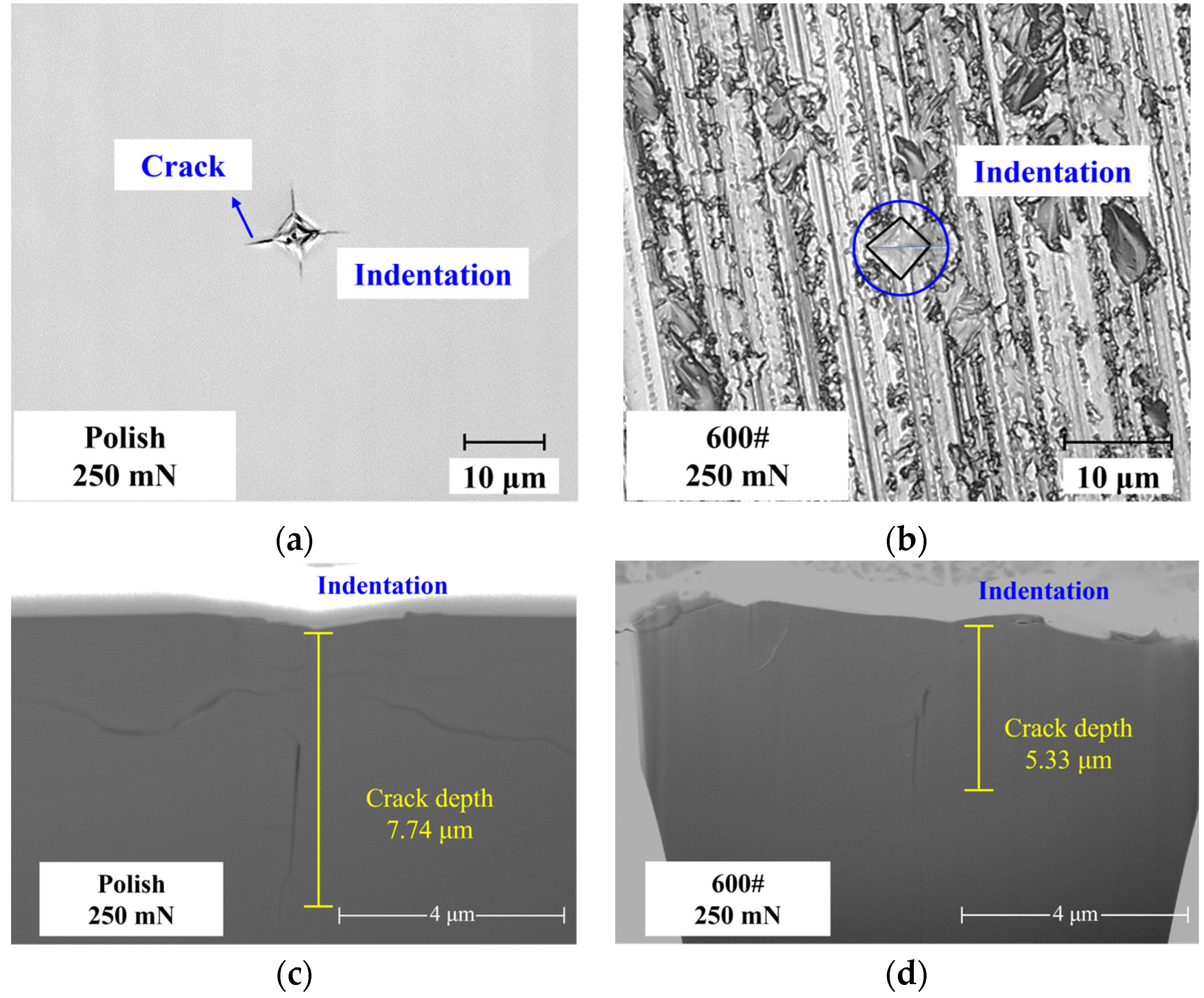

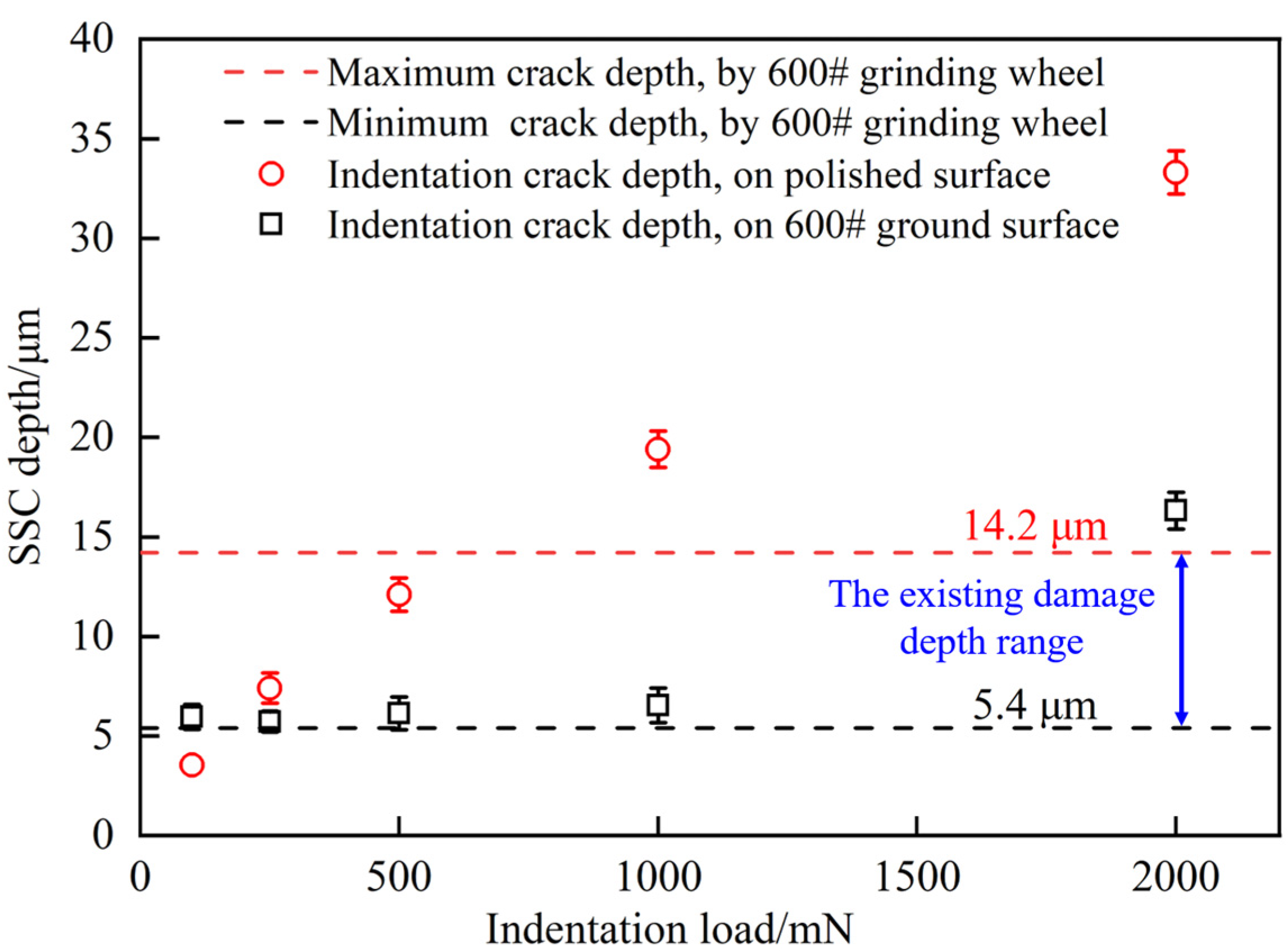

4.2.1. Subsurface Crack Depth

4.2.2. Fracture Strength

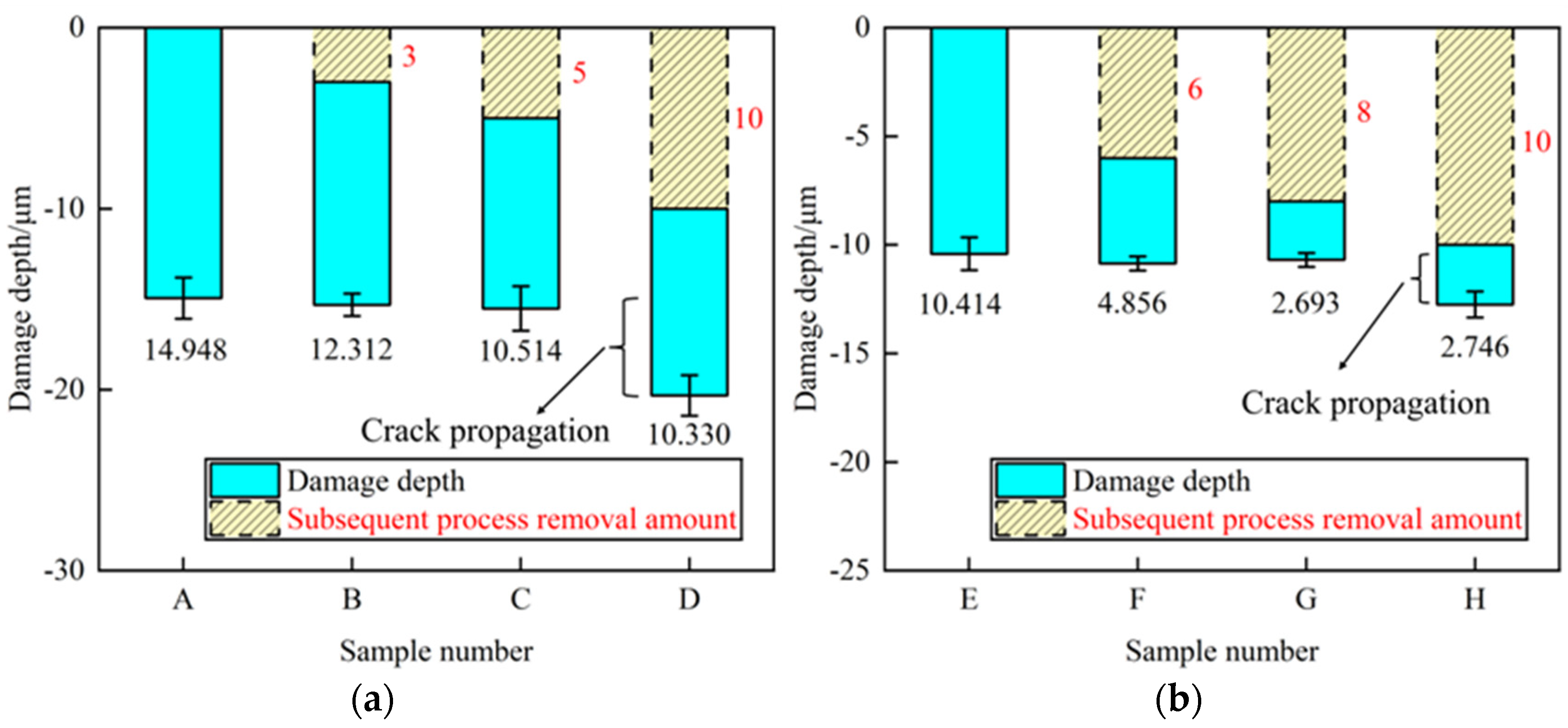

4.3. Grinding Process Verification

5. Conclusions

- Utilizing an extended finite element analysis, the crack propagation law for material with existing damage is elucidated. At a consistent indentation depth, if the prefabricated crack is shallower than the crack depth generated on the ideal surface, the crack tip stress field induced by the secondary action of the abrasive grits promotes the prefabricated crack, causing it to expand further but not exceed the latter. Conversely, when the prefabricated crack depth exceeds the crack depth generated on an undamaged surface, the secondary action of the abrasive grits has minimal impact on existing cracks, leading to negligible expansion.

- A novel approach combining indentation, prefabricated cracks, and a fracture strength test is proposed to determine crack propagation. Analyzing the variation in fracture strength reveals that, at loads below 1000 mN, cracks in the ground indentation sample exhibit insignificant expansion. This methodology verifies the accuracy of the crack propagation law.

- Through experiments involving different monocrystalline silicon grinding processes, it is observed that damage depth remains relatively constant during process transitions. This further validates the correctness of the existing crack propagation law under the secondary action of abrasive grits. The feasibility of assessing existing crack propagation is demonstrated by a combined utilization of the indentation method and fracture strength analysis. It also shows that the residual cracks from coarse grinding can be safely ignored when predicting the maximum damage depth in the fine grinding stage. This implies that substantial material removal is unnecessary to ensure the stability of the experimental results.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Menapace, J.A.; Davis, P.J.; Steele, W.A.; Wong, L.L.; Suratwala, T.I.; Miller, P.E. MRF Applications: Measurement of Process-Dependent Subsurface Damage in Optical Materials Using the MRF Wedge Technique. In Laser-Induced Damage in Optical Materials; SPIE: Boulder, CO, USA, 2005; p. 599103. [Google Scholar] [CrossRef]

- Lin, B.; Zhu, H.T.; Han, L.; Yu, S.Y. Prediction of Surface/Subsurface Crack Damage of Ground Ceramics. KEM 2006, 304–305, 271–275. [Google Scholar] [CrossRef]

- Zhu, D.; Yan, S.; Li, B. Single-Grit Modeling and Simulation of Crack Initiation and Propagation in SiC Grinding Using Maximum Undeformed Chip Thickness. Comput. Mater. Sci. 2014, 92, 13–21. [Google Scholar] [CrossRef]

- Mosavat, M.; Rahimi, A.; Eshraghi, M.J.; Karami, S. Nano-Finishing of the Monocrystalline Silicon Wafer Using Magnetic Abrasive Finishing Process. Appl. Opt. 2019, 58, 3447. [Google Scholar] [CrossRef] [PubMed]

- Mosavat, M.; Rahimi, A. Numerical-Experimental Study on Polishing of Silicon Wafer Using Magnetic Abrasive Finishing Process. Wear 2019, 424–425, 143–150. [Google Scholar] [CrossRef]

- Tonnellier, X. Precision Grinding for Rapid Manufacturing of Large Optics. Ph.D. Thesis, Cranfield University, Cranfield, UK, 2009. [Google Scholar]

- Mizushima, Y.; Kim, Y.; Nakamura, T.; Sugie, R.; Hashimoto, H.; Uedono, A.; Ohba, T. Impact of Back-Grinding-Induced Damage on Si Wafer Thinning for Three-Dimensional Integration. Jpn. J. Appl. Phys. 2014, 53, 05GE04. [Google Scholar] [CrossRef]

- Jiang, B.; Chen, Y.; Fang, A.; Liu, B.; Liu, Y.; Liang, H.; Lu, X. Surface Stress Evolution in Through Silicon Via Wafer during a Backside Thinning Process. IEEE Trans. Semicond. Manufact. 2019, 32, 589–595. [Google Scholar] [CrossRef]

- Inoue, F.; Jourdain, A.; Peng, L.; Phommahaxay, A.; De Vos, J.; Rebibis, K.J.; Miller, A.; Sleeckx, E.; Beyne, E.; Uedono, A. Influence of Si Wafer Thinning Processes on (Sub)Surface Defects. Appl. Surf. Sci. 2017, 404, 82–87. [Google Scholar] [CrossRef]

- Evans Iii, B.M.; Miller, A.C., Jr.; Egert, C.M. Comparison of Materials for Use in the Precision Grinding of Optical Components. In Optical Manufacturing and Testing II; SPIE: San Diego, CA, USA, 1997; pp. 190–197. [Google Scholar] [CrossRef]

- Tonnellier, X.; Morantz, P.; Shore, P.; Baldwin, A.; Evans, R.; Walker, D.D. Subsurface Damage in Precision Ground ULE® and Zerodur® Surfaces. Opt. Express 2007, 15, 12197. [Google Scholar] [CrossRef]

- Wang, Z.B.; Su, H.Y.; Tang, Y.C. The Design of CNC Grinding Processing for Glass-Ceramic Convex. Appl. Mech. Mater. 2013, 274, 41–44. [Google Scholar] [CrossRef]

- Li, P.; Chen, S.; Jin, T.; Yi, J.; Liu, W.; Wu, Q.; Peng, W.; Dai, H. Machining Behaviors of Glass-Ceramics in Multi-Step High-Speed Grinding: Grinding Parameter Effects and Optimization. Ceram. Int. 2021, 47, 4659–4673. [Google Scholar] [CrossRef]

- Li, P.; Jin, T.; Guo, Z.; Yi, J.; Qu, M. Analysis on the Effects of Grinding Wheel Speed on Removal Behavior of Brittle Optical Materials. J. Manuf. Sci. Eng. 2017, 139, 031014. [Google Scholar] [CrossRef]

- Zhou, L.; Tian, Y.B.; Huang, H.; Sato, H.; Shimizu, J. A Study on the Diamond Grinding of Ultra-Thin Silicon Wafers. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 66–75. [Google Scholar] [CrossRef]

- Zhang, L.; Chen, P.; An, T.; Dai, Y.; Qin, F. Analytical Prediction for Depth of Subsurface Damage in Silicon Wafer Due to Self-Rotating Grinding Process. Curr. Appl. Phys. 2019, 19, 570–581. [Google Scholar] [CrossRef]

- Yin, J.; Bai, Q.; Goel, S.; Zhou, P.; Zhang, B. An Analytical Model to Predict the Depth of Sub-Surface Damage for Grinding of Brittle Materials. CIRP J. Manuf. Sci. Technol. 2021, 33, 454–464. [Google Scholar] [CrossRef]

- Chen, J.; Fang, Q.; Li, P. Effect of Grinding Wheel Spindle Vibration on Surface Roughness and Subsurface Damage in Brittle Material Grinding. Int. J. Mach. Tools Manuf. 2015, 91, 12–23. [Google Scholar] [CrossRef]

- Sun, J.; Qin, F.; Chen, P.; An, T. A Predictive Model of Grinding Force in Silicon Wafer Self-Rotating Grinding. Int. J. Mach. Tools Manuf. 2016, 109, 74–86. [Google Scholar] [CrossRef]

- Li, H.N.; Yu, T.B.; Zhu, L.D.; Wang, W.S. Evaluation of Grinding-Induced Subsurface Damage in Optical Glass BK7. J. Mater. Process. Technol. 2016, 229, 785–794. [Google Scholar] [CrossRef]

- Li, H.N.; Yu, T.B.; Zhu, L.D.; Wang, W.S. Analytical Modeling of Grinding-Induced Subsurface Damage in Monocrystalline Silicon. Mater. Des. 2017, 130, 250–262. [Google Scholar] [CrossRef]

- Lawn, B.; Wilshaw, R. Indentation Fracture: Principles and Applications. J. Mater. Sci. 1975, 10, 1049–1081. [Google Scholar] [CrossRef]

- Suratwala, T.; Wong, L.; Miller, P.; Feit, M.D.; Menapace, J.; Steele, R.; Davis, P.; Walmer, D. Sub-Surface Mechanical Damage Distributions during Grinding of Fused Silica. J. Non-Cryst. Solids 2006, 352, 5601–5617. [Google Scholar] [CrossRef]

- Li, Y.; Zheng, N.; Li, H.; Hou, J.; Lei, X.; Chen, X.; Yuan, Z.; Guo, Z.; Wang, J.; Guo, Y.; et al. Morphology and Distribution of Subsurface Damage in Optical Fused Silica Parts: Bound-Abrasive Grinding. Appl. Surf. Sci. 2011, 257, 2066–2073. [Google Scholar] [CrossRef]

- Xiao, H.; Chen, Z.; Wang, H.; Wang, J.; Zhu, N. Effect of Grinding Parameters on Surface Roughness and Subsurface Damage and Their Evaluation in Fused Silica. Opt. Express 2018, 26, 4638. [Google Scholar] [CrossRef] [PubMed]

- Liu, W.; Zhang, L.; Fang, Q.; Chen, J. A Predictive Model of Subsurface Damage and Material Removal Volume for Grinding of Brittle Materials Considering Single Grit Micro-Geometry. Int. J. Adv. Manuf. Technol. 2019, 102, 2231–2243. [Google Scholar] [CrossRef]

- Cook, R.F.; Pharr, G.M. Direct Observation and Analysis of Indentation Cracking in Glasses and Ceramics. J. Am. Ceram. Soc. 1990, 73, 787–817. [Google Scholar] [CrossRef]

- Jiang, C.; Cheng, J.; Wu, T. Theoretical Model of Brittle Material Removal Fraction Related to Surface Roughness and Subsurface Damage Depth of Optical Glass during Precision Grinding. Precis. Eng. 2017, 49, 421–427. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G.; Marshall, D.B. Elastic/Plastic Indentation Damage in Ceramics: The Median/Radial Crack System. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Marshall, D.B.; Lawn, B.R.; Evans, A.G. Elastic/Plastic Indentation Damage in Ceramics: The Lateral Crack System. J. Am. Ceram. Soc. 1982, 65, 561–566. [Google Scholar] [CrossRef]

- Chen, J.; Fang, Q.; Du, J.; Xie, C.; Liu, F. Impact of Process Parameters on Subsurface Crack Growth in Brittle Materials Grinding. Arch. Appl. Mech. 2017, 87, 201–217. [Google Scholar] [CrossRef]

- Wang, W.; Yao, P.; Wang, J.; Huang, C.; Zhu, H.; Liu, H.; Zou, B.; Liu, Y. Controlled Material Removal Mode and Depth of Micro Cracks in Precision Grinding of Fused Silica—A Theoretical Model and Experimental Verification. Ceram. Int. 2017, 43, 11596–11609. [Google Scholar] [CrossRef]

- Wang, P.; Ge, P.; Ge, M.; Bi, W.; Meng, J. Material Removal Mechanism and Crack Propagation in Single Scratch and Double Scratch Tests of Single-Crystal Silicon Carbide by Abrasives on Wire Saw. Ceram. Int. 2019, 45, 384–393. [Google Scholar] [CrossRef]

- Wang, P.; Ge, P.; Bi, W.; Meng, J. Interaction of Lateral Cracks in Double Scratching of Single-Crystal Silicon Carbide. Theor. Appl. Fract. Mech. 2019, 104, 102378. [Google Scholar] [CrossRef]

- Feng, J.; Wan, Z.; Wang, W.; Huang, X.; Ding, X.; Tang, Y. Unique Crack Behaviors of Glass BK7 Occurred in Successive Double Scratch under Critical Load of Median Crack Initiation. J. Eur. Ceram. Soc. 2020, 40, 3279–3290. [Google Scholar] [CrossRef]

- Feng, J.; Wan, Z.; Wang, W.; Huang, X.; Ding, X.; Jiang, Z. Scratch with Double-Tip Tool: Crack Behavior during Simultaneous Double Scratch on BK7 Glass. J. Eur. Ceram. Soc. 2020, 40, 4202–4216. [Google Scholar] [CrossRef]

- Yang, X.; Gao, S. Analysis of the Crack Propagation Mechanism of Multiple Scratched Glass-Ceramics by an Interference Stress Field Prediction Model and Experiment. Ceram. Int. 2022, 48, 2449–2458. [Google Scholar] [CrossRef]

- Jiang, Q.; Zhang, L.; Yang, C. Analysis of Crack Initiation Load and Stress Field in Double Scratching of Single Crystal Gallium Nitride. Eng. Fract. Mech. 2022, 274, 108732. [Google Scholar] [CrossRef]

- Yang, X.J.; Zhang, W.X. The Research of Nano-Mechanical Properties of Mono-Crystalline Silicon. Adv. Mater. Res. 2013, 834–836, 18–22. [Google Scholar] [CrossRef]

- Marimuthu, K.P.; Rickhey, F.; Lee, J.H.; Lee, H. Spherical Indentation for Brittle Fracture Toughness Evaluation by Considering Kinked-Cone-Crack. J. Eur. Ceram. Soc. 2017, 37, 381–391. [Google Scholar] [CrossRef]

- Anderson, T.L. Fracture Mechanics: Fundamentals and Applications; CRC Press: Boca Raton, FL, USA, 2017; Available online: https://www.taylorfrancis.com/books/mono/10.1201/9781315370293/fracture-mechanics-ted-anderson (accessed on 22 June 2024).

- Yin, J.; Bai, Q.; Zhang, B. Methods for Detection of Subsurface Damage: A Review. Chin. J. Mech. Eng. 2018, 31, 41. [Google Scholar] [CrossRef]

- Zhao, B.; Wang, Y.; Yan, Y.; Wang, K.; Zhou, P. Distribution Characteristics of Sub-Surface Cracks in Fused Quartz Ground with Different Worn Wheels. Materials 2022, 15, 2443. [Google Scholar] [CrossRef]

- Young, H.T.; Liao, H.T.; Huang, H.Y. Surface Integrity of Silicon Wafers in Ultra Precision Machining. Int. J. Adv. Manuf. Technol. 2006, 29, 372–378. [Google Scholar] [CrossRef]

- Zhao, J.-H.; Tellkamp, J.; Gupta, V.; Edwards, D.R. Experimental Evaluations of the Strength of Silicon Die by 3-Point-Bend versus Ball-on-Ring Tests. IEEE Trans. Electron. Packag. Manuf. 2009, 32, 248–255. [Google Scholar] [CrossRef]

- Kirstein, A.F.; Woolley, R.M. Symmetrical Bending of Thin Circular Elastic Plates on Equally Spaced Point Supports. J. Res. Natl. Bur. Stand. Sect. C Eng. Instr. 1967, 71C, 1. [Google Scholar] [CrossRef]

- Dai, S.; Zhou, P.; Guo, D. The Influence of Subsurface Damage Depth on Fracture Strength of Ground Silicon Wafers. Mater. Today Proc. 2022, 64, 1170–1174. [Google Scholar] [CrossRef]

- Li, M.; Guo, X.; Dai, S.; Yuan, S.; Ma, J.; Liu, F.; Zhang, L.; Guo, D.; Zhou, P. Effect of Grinding Damage on Cutting Force and Ductile Machining during Single Grain Scratching of Monocrystalline Silicon. Mater. Sci. Semicond. Process. 2022, 151, 107019. [Google Scholar] [CrossRef]

| Indentation Depth d (μm) | Prefabricated Crack Depth c (μm) | Offset Indenter Distance S (μm) | Crack Angle α (°) |

|---|---|---|---|

| 4–6 Step size 0.5 | 0–14 Step size 0.4 | 0.4–1.6 Step size 0.4 | 15–75 Step size 15 |

| Sample | Indentation Load (mN) | Holding Time (s) | Total Number of Samples |

|---|---|---|---|

| Polished silicon wafer | 100, 250, 500, 1000, 2000 | 15 | 15 |

| #600 ground silicon wafer |

| Sample | Process 1 | Process 2 | Process 3 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Abrasive Grit Size | Feed Speed (μm/s) | Removal Thickness (μm) | Abrasive Grit Size | Feed Speed (μm/s) | Removal Thickness (μm) | Abrasive Grit Size | Feed Speed (μm/s) | Removal Thickness (μm) | |

| A | 400# | 5 | 300 | - | - | - | - | - | - |

| B | 400# | 5 | 300 | 400# | 1 | 3 | - | - | - |

| C | 400# | 5 | 300 | 400# | 1 | 5 | - | - | - |

| D | 400# | 5 | 300 | 400# | 1 | 10 | - | - | - |

| E | 400# | 5 | 300 | 400# | 1 | 50 | - | - | - |

| F | 400# | 5 | 300 | 400# | 1 | 50 | 2000 | 0.3 | 6 |

| G | 400# | 5 | 300 | 400# | 1 | 50 | 2000 | 0.3 | 8 |

| H | 400# | 5 | 300 | 400# | 1 | 50 | 2000 | 0.3 | 10 |

| Average Particle Size (nm) | Polishing Plate Rotation Speed (r/min) | Workpiece Speed (r/min) | Polishing Pressure (psi) |

|---|---|---|---|

| 72 | 300 | 50 | 1.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, B.; Huang, N.; Dai, S.; Zhou, P. Study of Prefabricated Crack Propagation on Monocrystalline Silicon Surfaces for Grinding Damage Analysis. Materials 2024, 17, 3852. https://doi.org/10.3390/ma17153852

Zhao B, Huang N, Dai S, Zhou P. Study of Prefabricated Crack Propagation on Monocrystalline Silicon Surfaces for Grinding Damage Analysis. Materials. 2024; 17(15):3852. https://doi.org/10.3390/ma17153852

Chicago/Turabian StyleZhao, Bingyao, Ning Huang, Siyang Dai, and Ping Zhou. 2024. "Study of Prefabricated Crack Propagation on Monocrystalline Silicon Surfaces for Grinding Damage Analysis" Materials 17, no. 15: 3852. https://doi.org/10.3390/ma17153852

APA StyleZhao, B., Huang, N., Dai, S., & Zhou, P. (2024). Study of Prefabricated Crack Propagation on Monocrystalline Silicon Surfaces for Grinding Damage Analysis. Materials, 17(15), 3852. https://doi.org/10.3390/ma17153852