The Influence of Weld Interface Characteristics on the Bond Strength of Collision Welded Aluminium–Steel Joints

Abstract

1. Introduction

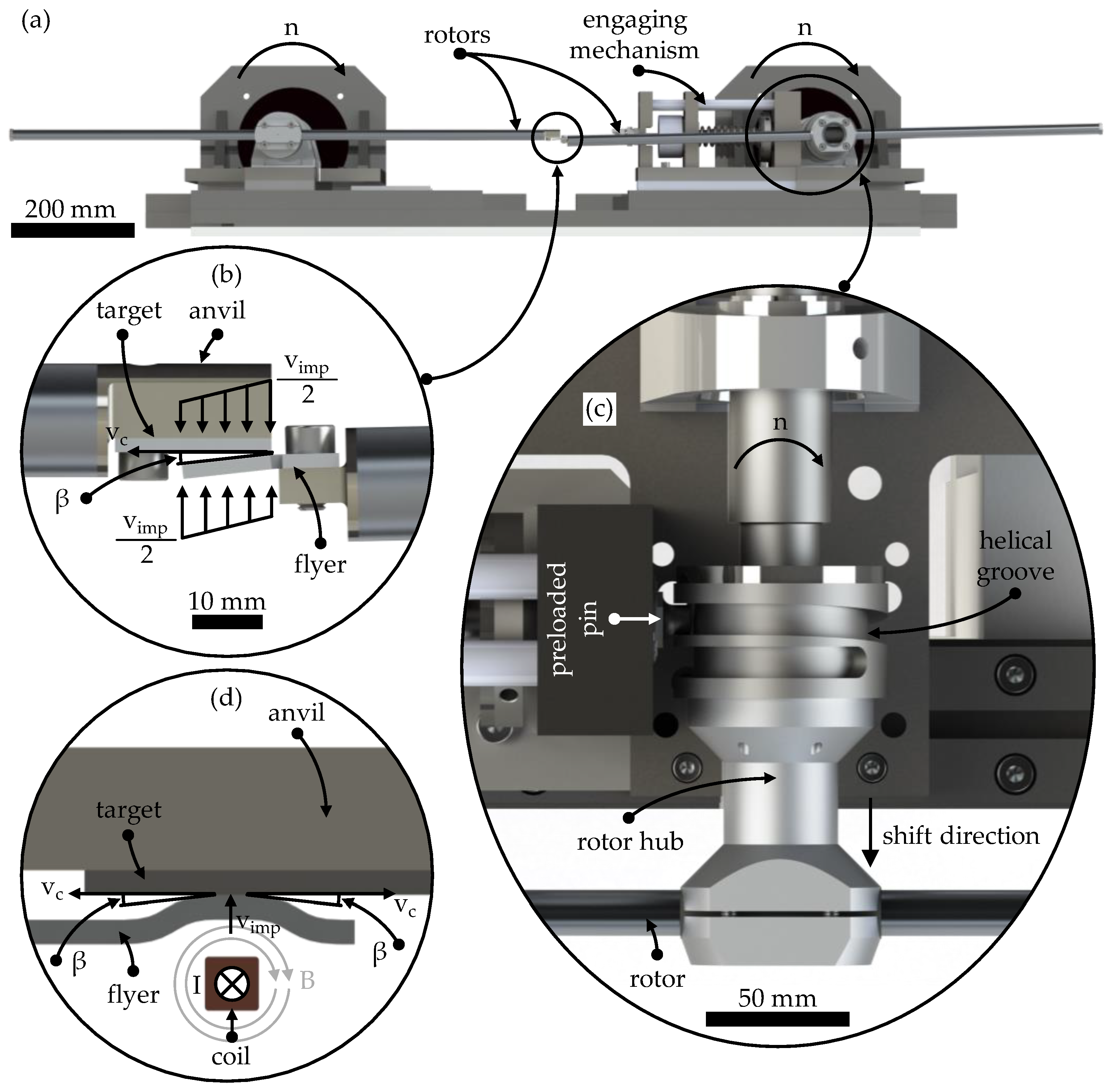

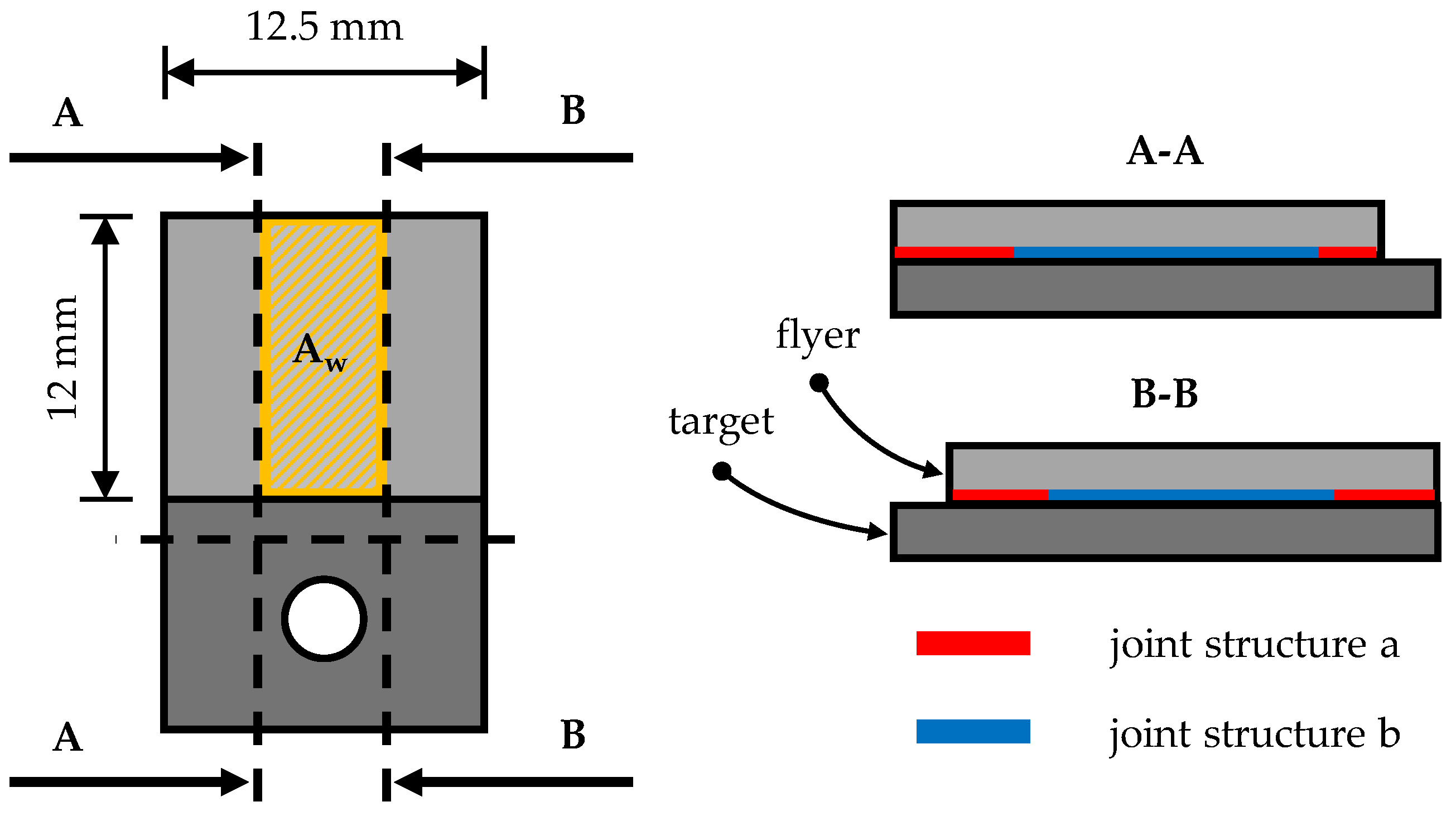

2. Materials and Methods

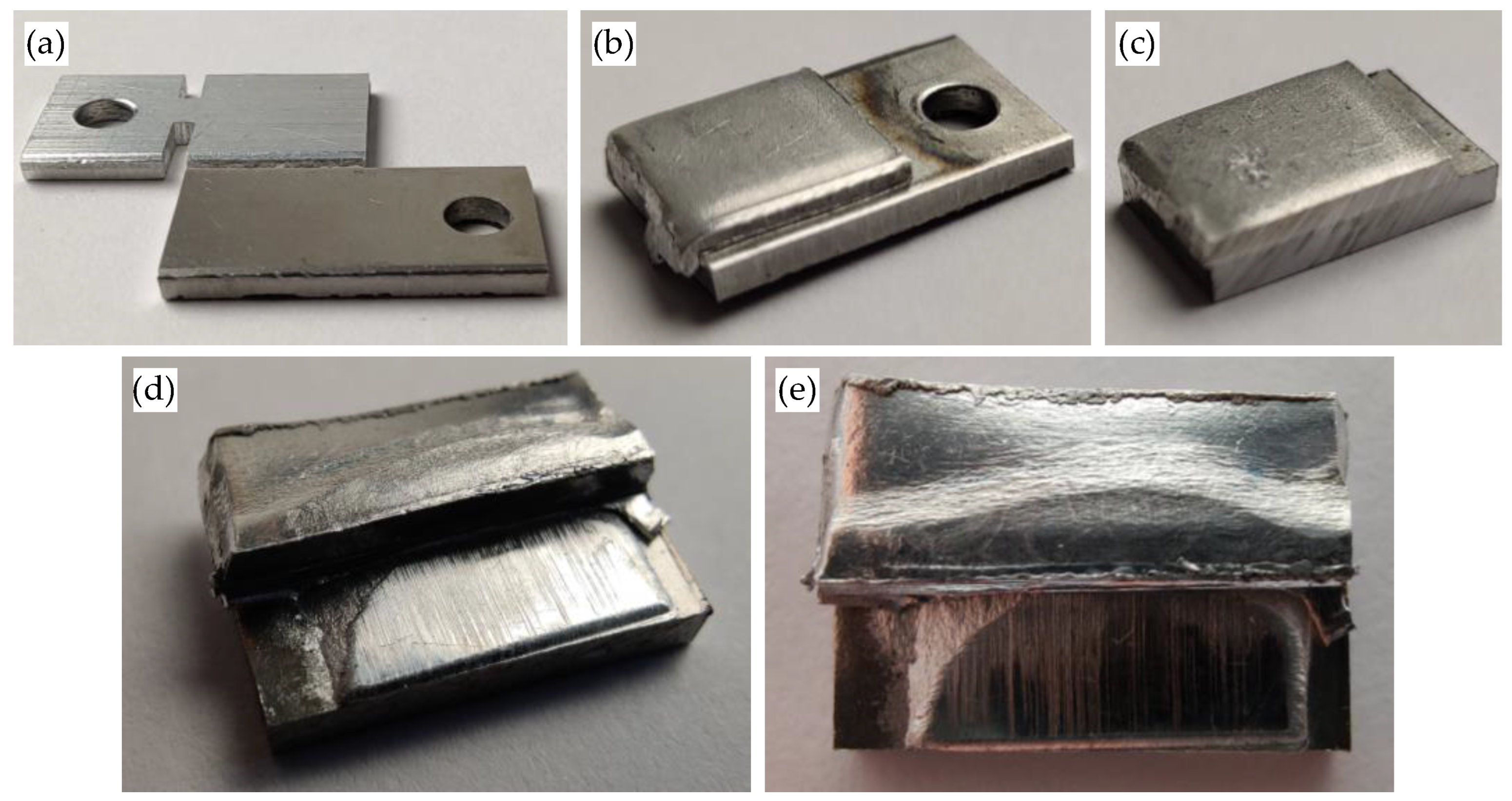

3. Results

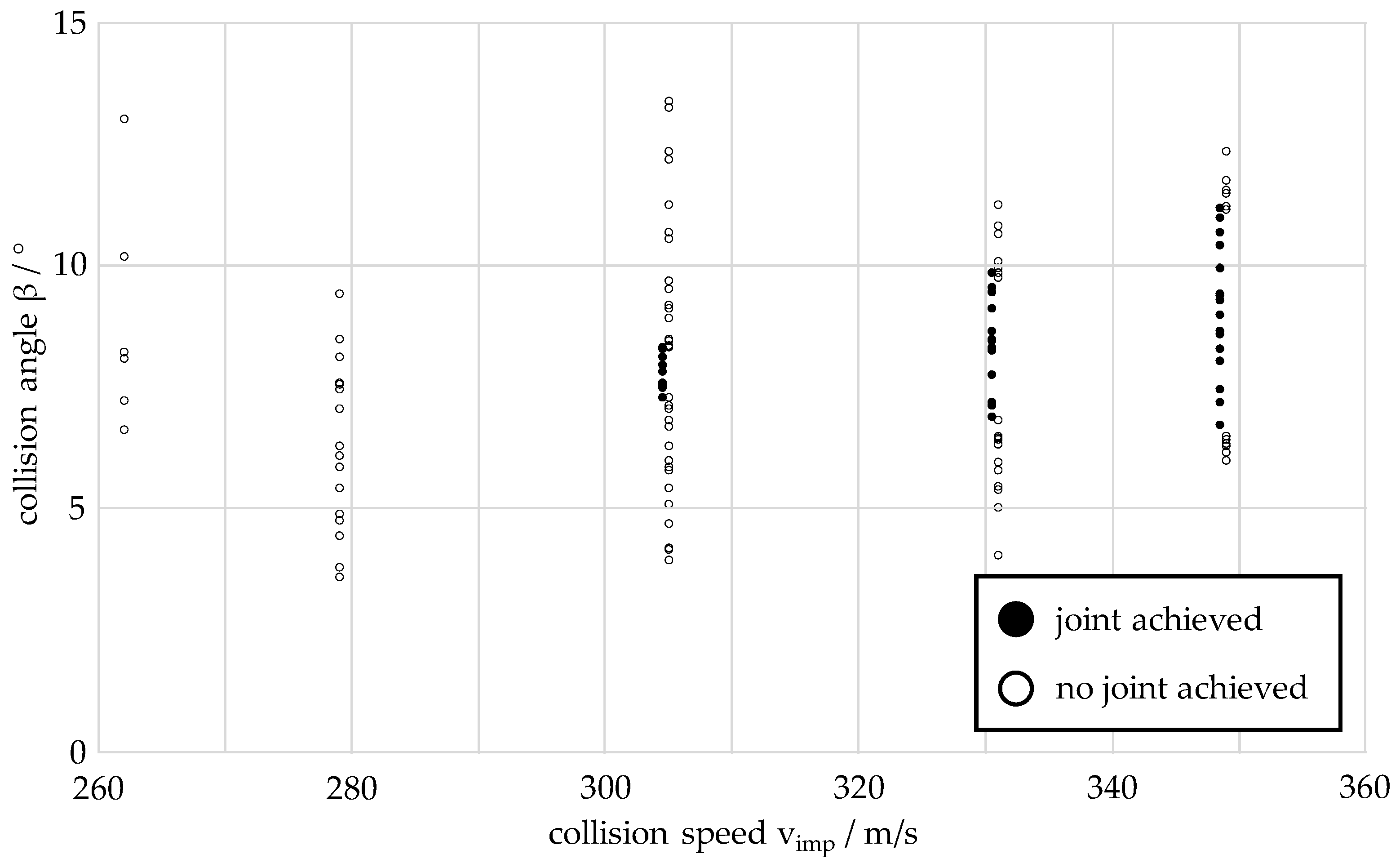

3.1. Welding Process Window

3.2. Tensile Shear Strength of Welded Joints in the Center of the Welding Window at 305 m/s, 331 m/s and 349 m/s

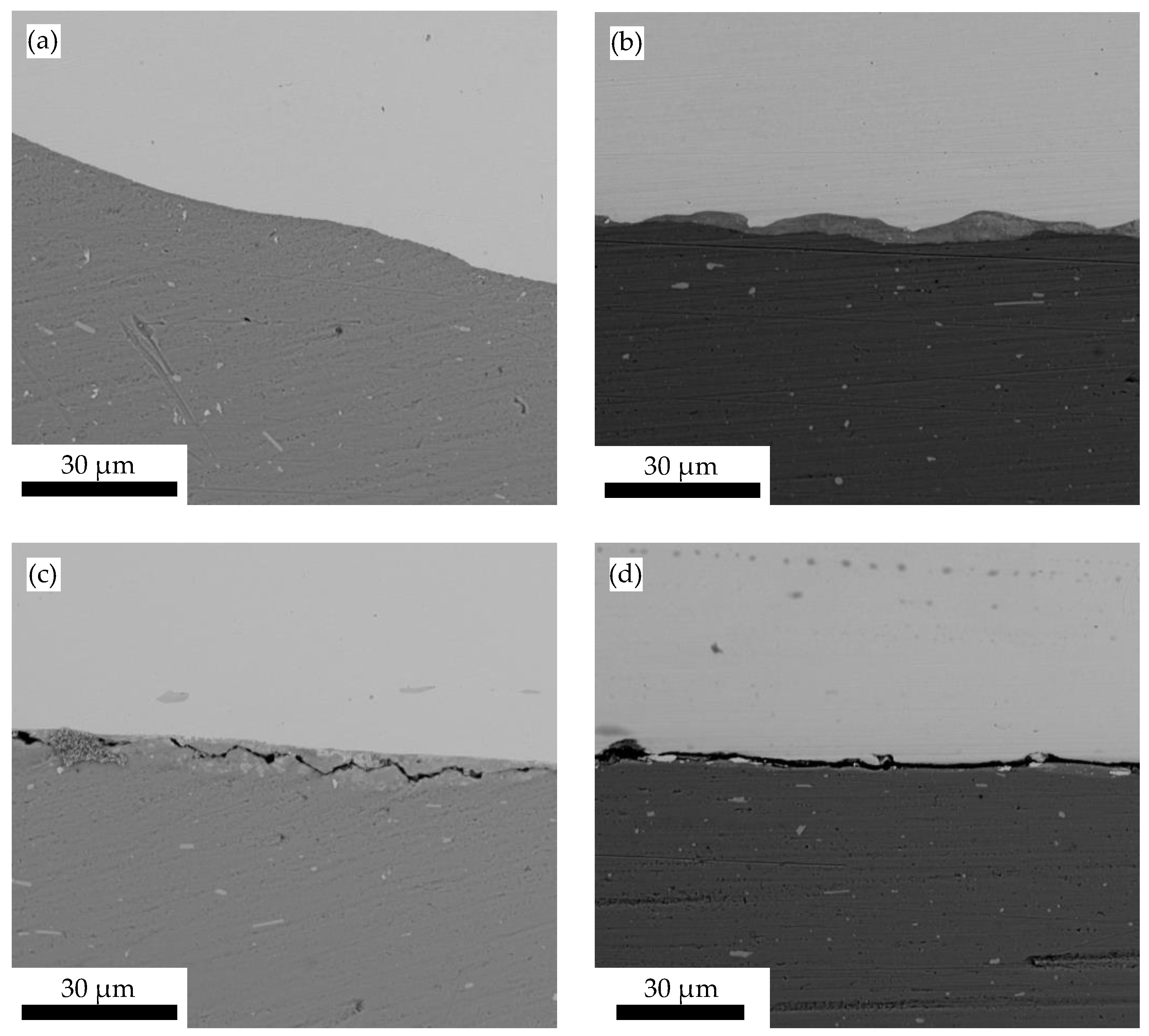

3.3. Joint Structures in the Weld Zone

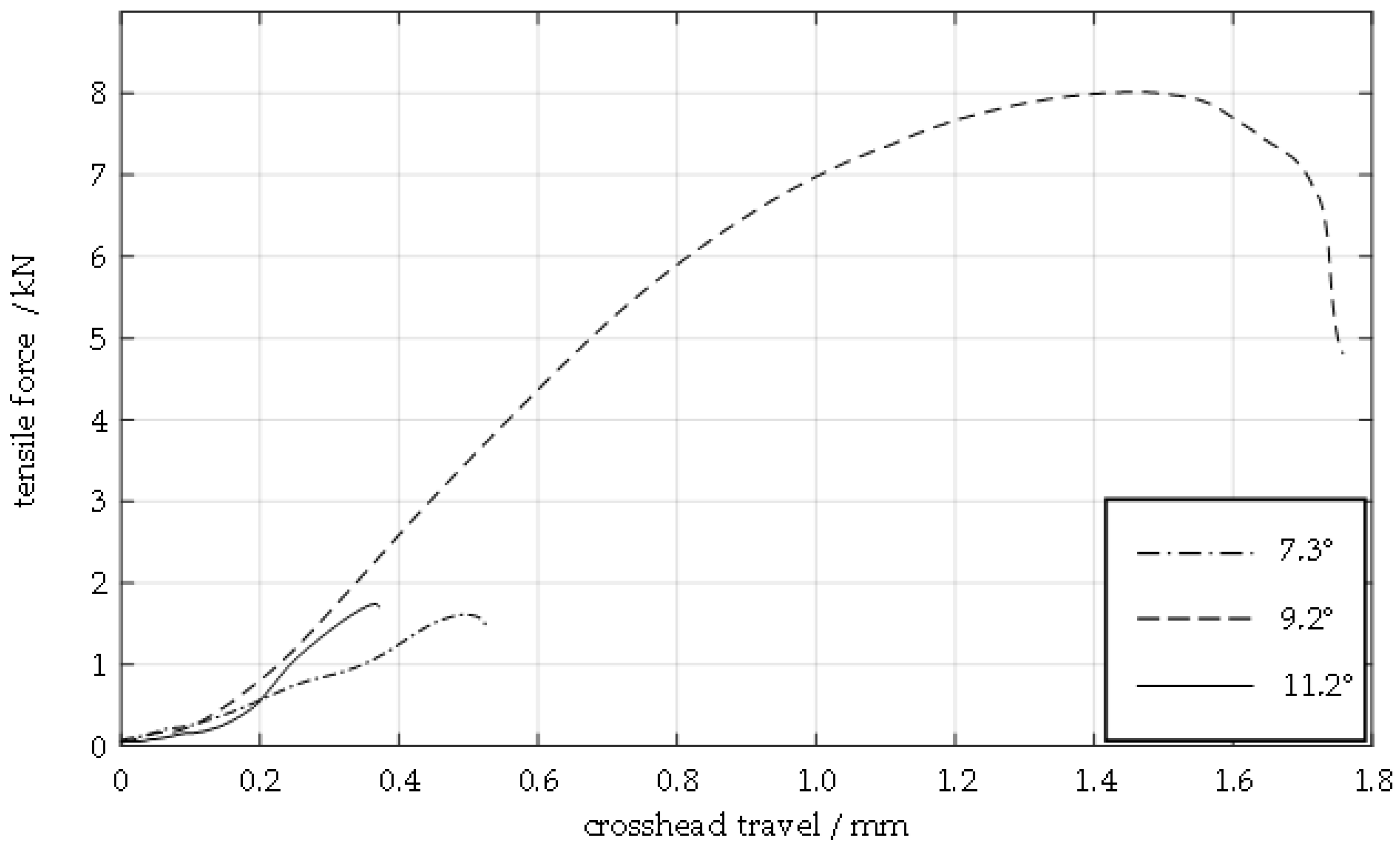

3.4. Tensile Shear Strength as a Function of Collision Angle

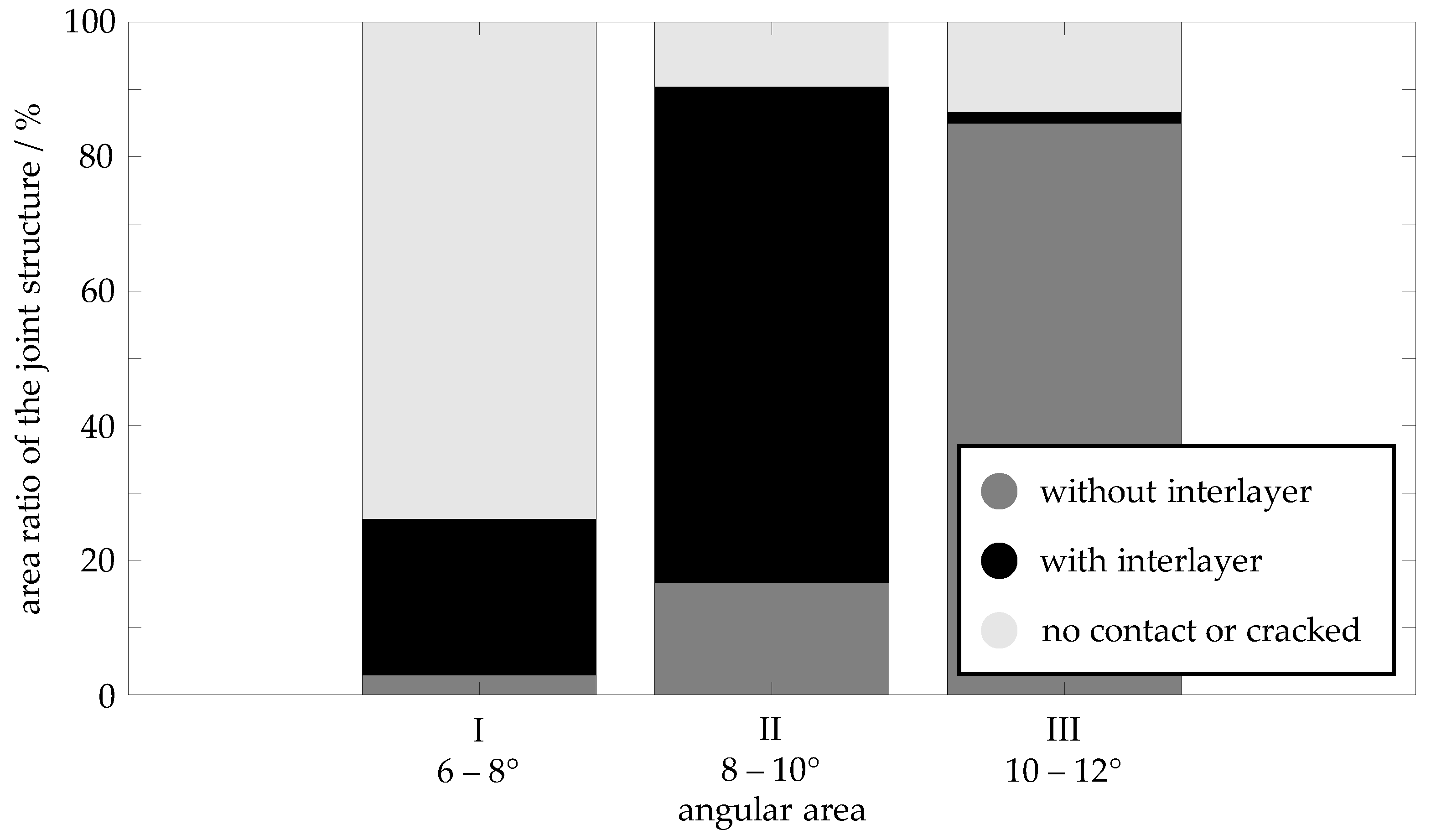

3.5. Area Ratios of the Joint Structures as a Function of Collision Angle

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Miraftabzadeh, S.M.; Longo, M.; Foiadelli, F. Mobility and Future Trends. In Emerging Battery Technologies to Boost the Clean Energy Transition, 1st ed.; Passerini, S., Barelli, L., Baumann, M., Peters, J., Weil, M., Eds.; Springer: Cham, Switzerland, 2024; Volume 1, pp. 3–11. [Google Scholar] [CrossRef]

- Statista Global Carbon Dioxide Emissions from 1970 to 2022, by Sector. Statistic 2023. Available online: https://www.statista.com/statistics/276480/world-carbon-dioxide-emissions-by-sector/ (accessed on 10 May 2024).

- Statista Distribution of Carbon Dioxide Emissions Produced by the Transportation Sector Worldwide in 2022, by Sub Sector. Available online: https://www.statista.com/statistics/1185535/transport-carbon-dioxide-emissions-breakdown/ (accessed on 10 May 2024).

- Timmers, V.R.J.H.; Achten, P.A.J. Non-exhaust PM emissions from electric vehicles. Atmos. Environ. 2016, 134, 10–17. [Google Scholar] [CrossRef]

- Lopez, B.; Wang, X.; Chen, L.W.A.; Ma, T.; Mendez-Jimenez, D.; Cobb, L.C.; Frederickson, C.; Fang, T.; Hwang, B.; Shiraiwa, M.; et al. Metal contents and size distributions of brake and tire wear particles dispersed in the near-road environment. Sci. Total Environ. 2023, 883, 163561. [Google Scholar] [CrossRef]

- European Environment Agency (EEA). Air Quality in Europe 2022. Available online: https://www.eea.europa.eu/publications/air-quality-in-europe-2022 (accessed on 10 May 2024).

- Köllner, C. Unterschätzte Umweltgefahr Reifenabrieb. Available online: https://www.springerprofessional.de/fahrwerk/schadstoffe/unterschaetzte-umweltgefahr-reifenabrieb-/15490524 (accessed on 10 May 2024).

- Organisation for Economic Co-Operation and Development (OECD). Non-Exhaust Particulate Emissions from Road Transport. Available online: https://www.oecd.org/en/publications/2020/12/non-exhaust-particulate-emissions-from-road-transport_707739b7.html (accessed on 10 May 2024).

- European Commission. Questions and Answers: Commission Proposal on the New Euro 7 Standards. Available online: https://ec.europa.eu/commission/presscorner/detail/en/QANDA_22_6496 (accessed on 10 May 2024).

- Allgemeiner Deutscher Automobil-Club e.V. (ADAC). Euro-7-Abgasnorm: Anforderungen, Grenzwerte, Einführungsfristen. Available online: https://www.adac.de/rund-ums-fahrzeug/autokatalog/abgasnormen/euro-7/ (accessed on 10 May 2024).

- Visnic, B. Europe’s Dust Buster. Available online: https://www.sae.org/news/2023/05/brakes-sustainability-dust-regulations/ (accessed on 10 May 2024).

- Kole, P.J.; Löhr, A.J.; Van Belleghem, F.G.; Ragas, A.M. Wear and Tear of Tyres: A Stealthy Source of Microplastics in the Environment. Int. J. Environ. Res. Public Health 2017, 14, 1265. [Google Scholar] [CrossRef] [PubMed]

- The International Transport Forum (OECD). Lightening Up: How Less Heavy Vehicles Can Help Cut CO2 Emissions. Available online: https://www.itf-oecd.org/less-heavy-vehicles-cut-co2-emissions (accessed on 10 May 2024).

- Bandivadekar, A.; Bodek, K.; Cheah, L.; Evans, C.; Groode, T.; Heywood, J.; Kasseris, E.; Kromer, M.; Weiss, M. On the Road in 2035: Reducing Transportation’s Petroleum Consumption and GHG Emissions; MIT Laboratory for Energy and the Environment: Cambridge, MA, USA, 2008; Available online: http://web.mit.edu/sloan-auto-lab/research/beforeh2/otr2035/ (accessed on 10 May 2024).

- Köllner, C. So Lassen sich Brems- und Reifenabrieb Reduzieren. Available online: https://www.springerprofessional.de/fahrwerk/partikel---feinstaub/so-lassen-sich-brems--und-reifenabrieb-reduzieren/18816284 (accessed on 10 May 2024).

- Beddows, D.C.S.; Harrison, R.M. PM10 and PM2.5 emission factors for non-exhaust particles from road vehicles: Dependence upon vehicle mass and implications for battery electric vehicles. Atmos. Environ. 2021, 244, 117886. [Google Scholar] [CrossRef]

- Tisza, M.; Lukács, Z. High strength aluminum alloys in car manufacturing. IOP Conf. Ser. Mater. Sci. Eng. 2018, 418, 012033. [Google Scholar] [CrossRef]

- Carlone, P.; Astarita, A. Dissimilar Metal Welding. Metals 2019, 9, 1206. [Google Scholar] [CrossRef]

- Atabaki, M.M.; Nikodinovski, M.; Chenier, P.; Ma, J.; Harooni, M.; Kovacevic, R. Welding of Aluminum Alloys to Steels: An Overview. J. Manuf. Sci. Prod. 2014, 14, 59–78. [Google Scholar] [CrossRef]

- Agudo, L.; Eyidi, D.; Schmaranzer, C.H.; Arenholz, E.; Jank, N.; Bruckner, J.; Pyzalla, A.R. Intermetallic FexAly-phases in a steel/Al-alloy fusion weld. J. Mater. Sci. 2007, 42, 4205–4214. [Google Scholar] [CrossRef]

- Khedr, M.; Hamada, A.; Järvenpää, A.; Elkatatny, S.; Abd-Elaziem, W. Review on the Solid-State Welding of Steels: Diffusion Bonding and Friction Stir Welding Processes. Metals 2023, 13, 54. [Google Scholar] [CrossRef]

- Kapil, A.; Sharma, A. Magnetic pulse welding: An efficient and environmentally friendly multi-material joining technique. J. Clean. Prod. 2015, 100, 35–58. [Google Scholar] [CrossRef]

- Niessen, B. Untersuchungen zur Robustheit von Kollisionsschweißprozessen bei minimalem Energieeintrag. Ph.D. Thesis, TU Darmstadt, Darmstadt, Germany, 2022. [Google Scholar] [CrossRef]

- Golovashchenko, S. Electromagnetic Forming and Joining for Automotive Applications. In Proceedings of the 2nd International Conference on High Speed Forming, March 20th–21st, 2006, Dortmund, Germany; Kleiner, M., Ed.; Institute of Forming Technology an Lightweight Construction, Universität Dortmund: Dortmund, Germany, 2006; Volume 1, pp. 201–206. [Google Scholar] [CrossRef]

- Weddeling, C.; Woodward, S.; Nellesen, J.; Psyk, V.; Marré, M.; Brosius, A.; Tekkaya, A.E.; Daehn, G.S.; Tillmann, W. Development of design principles for form-fit joints in lightweight frame structures. In Proceedings of the 4th International Conference on High Speed Forming, March 9th–10th 2010 Columbus, OH, USA; Babusci, K., Daehn, G., Marré, M., Tekkaya, A.E., Weddeling, C., Zhang, Y., Eds.; Manufacturing Institute, The Ohio State University: Columbus, OH, USA, 2010; Volume 1, pp. 137–148. [Google Scholar] [CrossRef]

- Wang, X.; Li, C.; Zhou, Y.; Xu, C.; Dai, M. Mechanism of the discharge behavior in electromagnetic pulse welding: Combination of electron emission and electric field. Mater. Today Commun. 2023, 36, 106726. [Google Scholar] [CrossRef]

- Stankevic, V.; Lueg-Althoff, J.; Hahn, M.; Tekkaya, A.E.; Zurauskiene, N.; Dilys, J.; Klimantavicius, J.; Kersulis, S.; Simkevicius, C.; Balevicius, S. Magnetic Field Measurements during Magnetic Pulse Welding Using CMR-B-Scalar Sensors. Sensors 2020, 20, 5925. [Google Scholar] [CrossRef] [PubMed]

- Marschner, O.; Pabst, C.; Schäfer, R.; Pasquale, P. Suitable Design for Electromagnetic Pulse Processes. In Proceedings of the 9th International Conference on High Speed Forming, Online, 13–15 October 2021; Institute of Forming Technology an Lightweight Construction, Universität Dortmund: Dortmund, Germany, 2021; Volume 1, pp. 1–9. [Google Scholar] [CrossRef]

- Tsakiris, V.; Kappel, W.; Alecu, G. Solid State diffusion welding of Cu-Fe/Al/Ag and Al-Ni dissimilar metals. J. Optoel. Adv. Mat. 2011, 13, 1176–1180. [Google Scholar] [CrossRef]

- Niessen, B.; Schumacher, E.; Lueg-Althoff, J.; Bellmann, J.; Böhme, M.; Böhm, S.; Tekkaya, A.E.; Beyer, E.; Leyens, C.; Wagner, M.F.X.; et al. Interface Formation during Collision Welding of Aluminum. Metals 2020, 10, 1202. [Google Scholar] [CrossRef]

- Groche, P.; Becker, M.; Pabst, C. Process window acquisition for impact welding processes. Mater. Des. 2017, 118, 286–293. [Google Scholar] [CrossRef]

- Groche, P.; Niessen, B.; Pabst, C. Process boundaries of collision welding at low energies. Materialwiss. Werkstofftech. 2019, 50, 940–948. [Google Scholar] [CrossRef]

- Böhme, M.; Sharafiev, S.; Schumacher, E.; Böhm, S.; Wagner, M.F.X. On the microstructure and the origin of intermetallic phase seams in magnetic pulse welding of aluminium and steel. Materialwiss. Werkstofftech. 2019, 50, 958–964. [Google Scholar] [CrossRef]

- Carpenter, S.H.; Wittmann, R.H. Explosion Welding. Annu. Rev. Mater. Res. 1975, 5, 177–199. [Google Scholar] [CrossRef]

- Wittman, R.H. The influence of collision parameters of the strength and microstructure of an explosion welded aluminium alloy. In Proceedings of the 2nd International Symposium on Use of an Explosive Energy in Manufacturing Metallic Materials; 1973; pp. 153–168. [Google Scholar]

- Lysak, V.I.; Kuzmin, S.V. Explosive Welding of Metal Layered Composite Materials; Paton Electric Welding Institute, National Academy of Sciences of Ukraine: Kiev, Ukraine, 2003. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kraus, S.O.; Bruder, J.; Groche, P. The Influence of Weld Interface Characteristics on the Bond Strength of Collision Welded Aluminium–Steel Joints. Materials 2024, 17, 3863. https://doi.org/10.3390/ma17153863

Kraus SO, Bruder J, Groche P. The Influence of Weld Interface Characteristics on the Bond Strength of Collision Welded Aluminium–Steel Joints. Materials. 2024; 17(15):3863. https://doi.org/10.3390/ma17153863

Chicago/Turabian StyleKraus, Stefan Oliver, Johannes Bruder, and Peter Groche. 2024. "The Influence of Weld Interface Characteristics on the Bond Strength of Collision Welded Aluminium–Steel Joints" Materials 17, no. 15: 3863. https://doi.org/10.3390/ma17153863

APA StyleKraus, S. O., Bruder, J., & Groche, P. (2024). The Influence of Weld Interface Characteristics on the Bond Strength of Collision Welded Aluminium–Steel Joints. Materials, 17(15), 3863. https://doi.org/10.3390/ma17153863