Thermally Sprayed Coatings for the Protection of Industrial Fan Blades

Abstract

:1. Introduction

2. Materials and Methods

3. Results

4. Discussion

5. Conclusions

- It was found that the coatings most resistant to particle impact erosion were WC-Co, HV0.2 = 1240; WC-Co-CrC-Ni, HV0.2 = 1195; and Cr3C2-NiCr, HV0.2 = 863 deposited by the HVOF method and coating Cr3C2NiCr deposited by the PS method.

- The WC-Co-CrC-Ni coating showed the highest, simultaneous resistance to the impact of a stream of corundum particles and SiO2 particles.

- The greatest resistance of the WC-Co-CrC-Ni coating to the erosive impact of dynamic particle streams results from the synergistic effect of tungsten and chromium carbides.

Funding

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kania, H. Corrosion and Anticorrosion of Alloys/Metals: The Important Global Issue. Coatings 2023, 13, 216. [Google Scholar] [CrossRef]

- Hubicki, R.; Richert, M.; Łebkowski, P. Influence of Operating Temperature on the Service Life of Aluminum Extrusion Dies. Materials 2022, 15, 6656. [Google Scholar] [CrossRef] [PubMed]

- Li, H.; Li, L.; Li, D.; Tang, L.; Luo, Y.; Li, G.; Wu, Y.; Li, G.; Xu, Y.; Han, M.; et al. Erosion Performance of TiAlSiN Coatings Prepared by High-Power Pulsed Magnetron Sputtering. Metals 2023, 13, 1306. [Google Scholar] [CrossRef]

- Mishnaevsky, L., Jr.; Tempelis, A.; Kuthe, N.; Mahajan, P. Recent developments in the protection of wind turbine blades against leading erosion: Materials solutions and predictive modelling, Edge. Renew. Energy 2023, 215, 118966. [Google Scholar] [CrossRef]

- Maurer, C.; Shulz, U. Erosion resistant titanium based PVD coatings on CFRP. Wear 2013, 302, 937–945. [Google Scholar] [CrossRef]

- Zhang, Z.; Yang, M.; He, G. Structure, mechanical, and sand erosion behavior of TiN/Ti coating deposited at various temperature. Ceram. Int. 2023, 49, 16786–16795. [Google Scholar] [CrossRef]

- Dobrzańska-Danikiewicz, A.D.; Gołombek, K.; Pakuła, D.; Mikuła, J.; Staszuk, M.; Żukowska, L.W. Long-term development directions of PVD/CVD coatings deposited onto sintered tool materials. Mater. Surf. Eng. 2011, 6, 278–330. Available online: http://openaccesslibrary.com/vol06/8.pdf (accessed on 5 July 2024).

- Daniel, J.; Grossman, J.; Houdková, Š.; Bystrianský, M. Impact Wear of the Protective Cr3C2-Based HVOF-Sprayed Coatings. Materials 2020, 13, 2132. [Google Scholar] [CrossRef]

- Yanjun, Z.; Shiqi, Z.; Qiuyu, Y.; Biyu, H. An Approach to Simulate the Manufacturing Process of Thermal Spray Coatings. In Proceedings of the 5th International Conference on Mechanical Engineering, Materials and Energy (ICMEME 2016), Hong Kong, China, 10–11 December 2016; Atlantis Press: Amsterdam, The Netherlands, 2016. [Google Scholar]

- Szczucka-Lasota, B.; Węgrzyn, T.; Stanik, Z.; Piwnik, J.; Sidun, P. Selected parameters of microjet cooling gases in hybrid spraying process. Arch. Metall. Mater. 2016, 61, 621–624. [Google Scholar] [CrossRef]

- Feltrin, A.C.; Xing, Q.; Akinwekomi, A.D.; Waseem, O.A.; Akhtar, F. Review of Novel High-Entropy Protective Materials: Wear, Irradiation, and Erosion Resistance Properties, Review. Entropy 2023, 25, 73. [Google Scholar] [CrossRef]

- Keshavamurthy, R.; Naveena, B.E.; Sekhar, N. Thermal Spray Coatings for Erosion-Corrosion Protection. In Production, Properties, and Applications of High Temperature Coatings; Book Chapture in Advances in Chemical and Materials Engineering (ACME); IGI Global: Hershey, PA, USA, 2018; pp. 246–267. [Google Scholar] [CrossRef]

- Amin, S.; Panchal, H. A Review on Thermal Spray Coating Processes. Int. J. Curr. Trends Eng. Res. IJCTER 2016, 2, 556–563. Available online: https://www.ijcter.com (accessed on 5 July 2024).

- Łatka, L.; Pawłowski, L.; Winnicki, M.; Sokołowski, P.; Małachowska, A.; Kozerski, S. Review of Functionally Graded Thermal Sprayed Coatings. Appl. Sci. 2020, 10, 5153. [Google Scholar] [CrossRef]

- Siao, A.; Ming Ang, M.; Berndt, C.C. A review of testing methods for thermal spray coatings. Int. Mater. Rev. 2014, 59, 179–223. [Google Scholar] [CrossRef]

- Tejero-Martin, D.; Rezvani Rad, M.; McDonald, A.; Hussain, T. Beyond Traditional Coatings: A Review on Thermal-Sprayed Functional and Smart Coatings. J. Therm. Spray Technol. 2019, 28, 598–644. [Google Scholar] [CrossRef]

- Shuo Yin, S.; Cizek, J.; Suo, X.; Li, W.; Liao, H. Thermal Spray Technology. Adv. Mater. Sci. Eng. 2019, 2019, 8654764. [Google Scholar] [CrossRef]

- Gaur, U.P.; Kamari, E. Applications of Thermal Spray Coatings: A Review. J. Therm. Spray Eng. 2024, 4, 106–114. [Google Scholar] [CrossRef] [PubMed]

- Fauchais, P.L.; Heberlein, J.V.R.; Boulos, M.I. Thermal Spray Fundamentals, From Powder to Part; Springer Science + Business Media: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Venkatachalapathy, V.; Katiyar, N.K.; Matthews, A.; Endrino, J.L.; Goel, S.A. Guiding Framework for Process Parameter Optimisation of Thermal Spraying. Coatings 2023, 13, 713. [Google Scholar] [CrossRef]

- Guilemany, J.M.; Nin, J. Thermal spraying methods for protection against wear. In Surface Coatings for Protection Against Wear; Mellor, B.G., Ed.; Woodhead Publishing in Material: Cambridge, UK, 2006. [Google Scholar]

- Hu, C.; He, G.; Chen, J.; Fang, Z.; Yang, Z.; Zhang, Z. Research on Cleaning Mechanism of Anti-Erosion Coating Based on Thermal and Force Efects of Laser Shock. Coatings 2020, 10, 683. [Google Scholar] [CrossRef]

- Kay, C.M. ASB Industries, Inc. Thermal Spray Applications in the Steel Industry. In ASM Handbook; Tucker, R.C., Jr., Ed.; Thermal Spray Technology; ASM International: Detroit, MI, USA, 2013; Volume 5A, Available online: https://www.asbindustries.com/uploads/Handbook%205A%20Thermal%20Spray%20Apps%20in%20Steel%20Industry.pdf (accessed on 5 July 2024).

- Hardwicke, C.U.; Lau, Y.C. Advances in Thermal Spray Coatings for Gas Turbines and Energy Generation: A Review. J. Therm. Spray Technol. 2013, 22, 564–576. [Google Scholar] [CrossRef]

- Baiamonte, L.; Pulci, G.; Hlede, E.; Marra, F.; Bartuli, C. Corrosione Thermal spray coatings for corrosion and wear protection of naval Diesel engines components. Metall. Ital. 2014, 6, 9. Available online: http://www.aimnet.it/allpdf/pdf_pubbli/giu14/Bartuli.pdf (accessed on 5 July 2024).

- Singh, S.; Berndt, C.C.; Singh Raman, R.K.; Singh, H.; Ang, A.S.M. Applications and Developments of Thermal Spray Coatings for the Iron and Steel Industry. Materials 2023, 16, 516. [Google Scholar] [CrossRef] [PubMed]

- Fauchais, P.; Vardelle, A. Thermal Sprayed Coatings Used Against Corrosion and Corrosive Wear, Advanced Plasma Spray Applications. 2012. Available online: https://cdn.intechopen.com/pdfs/32974/InTech-Thermal_sprayed_coatings_used_against_corrosion_and_corrosive_wear.pdf (accessed on 5 July 2024).

- Miller, R.A. History of Thermal Barrier Coatings for Gas Turbine Engines Emphasizing NASA’s Role from 1942 to 1990, NASA/TM—2009-215459. 2009. Available online: https://ntrs.nasa.gov/api/citations/20090018047/downloads/20090018047.pdf (accessed on 5 July 2024).

- Brezinová, J.; Guzanová, A.; Draganovská, D.; Maruschak, P.O.; Landová, M. Study of Selected Properties of Thermally Sprayed Coatings Containing WC and WB Hard Particles. Acta Mech. Et Autom. 2016, 10, 4. [Google Scholar] [CrossRef]

- Özbek, Y.Y.; Canikoğlu, N.; Ipek, M. The Mechanical Properties and Wear Resistance of HVOF Sprayed WC–Co Coatings. Acta Phys. Pol. A 2016, 129, 600–603. [Google Scholar] [CrossRef]

- Myalska, H.; Szymański, J.K.; Moskal, G. Microstructure and properties of WC-Co HVOF coatings obtained from standard, superfine and modified by sub-micrometric carbide powders. Arch. Metall. Mater. 2014, 60, 759–766. [Google Scholar] [CrossRef]

- Abderrahmane, A.; Gaceb, M.; Cheikh, M.; Le Roux, S. Wear Behavior and Microstructure of Thermally Sprayed NiCrBSiFeC and Composite NiCrBSiFeC-WC(Co) Coatings. 2021. Available online: https://imt-mines-albi.hal.science/hal-03149468/file/Wear-Behavior-and-Microstructure-of-Thermally-Sprayed.pdf (accessed on 5 July 2024).

- Rachidi, R.; El Kihel1, B.; Delaunois, F.; Vitry, V.; Deschuyteneer, D. Wear Performance of Thermally Sprayed NiCrBSi and NiCrBSi-WC Coatings Under Two Different Wear Modes. J. Mater. Environ. Sci. 2017, 8, 4550–4559. [Google Scholar] [CrossRef]

- Sharmaa, M.; Goyalb, D.K.; Kaushal, G. Tribological investigation of HVOF-spray Cr3C2-25NiCr and WC-10Co-4Cr coated turbine steel under varied slurry erosion conditions. Indian J. Eng. Mater. Sci. 2020, 27, 150–167. [Google Scholar]

- Chang, L.; Wang, W.; Ma, D.; Douqin, M.; Jingpei, X. Deposition effects and interface structure of HVOF-sprayed multimodal WC-CoCr coatings. J. Mater. Res. 2023, 38, 4345–4356. [Google Scholar] [CrossRef]

- Wang, Q.; Zhong, Y.; Li, H.; Wang, S.; Liu, J.; Wang, Y.; Ramachandran, C.S. Effect of Cobalt and Chromium Content on Microstructure and Properties of WC-Co-Cr Coatings Prepared by High-Velocity Oxy-Fuel Spraying. Materials 2023, 16, 7003. [Google Scholar] [CrossRef] [PubMed]

- Jiang, H.; Zhao, X.; Song, H.; Li, C. The Effect of High-Velocity Air-Fuel WC-12Co Coatings on the Wear and Corrosion Resistance of TC18 Titanium Alloy. Coatings 2023, 13, 755. [Google Scholar] [CrossRef]

- Maiti, A.K.; Mukhopadhyay, N.; Raman, R. Effect of adding WC powder to the feedstock of WC–Co–Cr based HVOF coating and its impact on erosion and abrasion resistance. Surf. 2007, 201, 7781–7788. [Google Scholar] [CrossRef]

- Szala, M.; Walczak, M.; Świetlicki, A. Effect of Microstructure and Hardness on Cavitation Erosion and Dry Sliding Wear of HVOF Deposited CoNiCrAlY, NiCoCrAlY and NiCrMoNbTa Coatings. Materials 2022, 15, 93. [Google Scholar] [CrossRef]

- Bulnes, A.G.; Fuentes, V.A.; Cano, I.G.; Dosta, S. Understanding the Influence of High Velocity Thermal Spray Techniques on the Properties of Different Anti-Wear WC-Based Coatings. Coatings 2020, 10, 1157. [Google Scholar] [CrossRef]

- Cesanek, Z.; Schubert, J. Abrasive resistance of HVOF thermally sprayed coatings based on alloys and cermets compared to nitrided stainless steel. Arch. Mater. Sci. Eng. 2014, 67, 18–23. [Google Scholar]

- Sundararajan, G. The differential effect of the hardness of metallic materials on their erosion and abrasion resistance. Wear 1993, 162–164, 773–781. [Google Scholar] [CrossRef]

- Oka, Y.; Hutchings, J.M. Dependence of Material Hardness on Erosion by Solid Particle Impact. Corros. Eng. 1990, 39, 610–616. [Google Scholar] [CrossRef]

- Sheldon, G.L. Effects of Surface Hardness and Other Material Properties on Erosive Wear of Metals by Solid Particles. J. Eng. Mater. Technol. 1977, 99, 133–137. [Google Scholar] [CrossRef]

- Wang, S.; Liu, G.; Mao, J.; He, Q.; Feng, Z. Effects of Coating Thickness, Test Temperature, and Coating Hardness on the Erosion Resistance of Steam Turbine Blades. J. Eng. Gas Turbines Power 2010, 132, 022102. [Google Scholar] [CrossRef]

- Levy, A.V.; Wang, B. Erosion of hard material coating systems. Wear 1988, 121, 325–346. [Google Scholar] [CrossRef]

- Wheeler, D.W.; Wood, R.J.K. Erosion of hard surface coatings for use in offshore gate valves. Wear 2005, 258, 526–536. [Google Scholar] [CrossRef]

- Wen, D.C. Influence of Material Surface Hardness and Particle Size on the Erosion of DC 11 Tool Steel. J. China Inst. Technol. 2007, 36, 157–170. Available online: https://www.yoke.net/Pic/PublicFile/X0KFKHUAWAJN0036.pdf (accessed on 5 July 2024).

- Saha, G.C.; Khan, T.I.; Zhang, G.A. Erosion–corrosion resistance of microcrystalline and near-nanocrystalline WC–17Co high velocity oxy-fuel thermal spray coatings. Corros. Sci. 2011, 53, 2106–2114. [Google Scholar] [CrossRef]

- Mehta, J.; Mittal, V.K.; Gupta, P. Role of Thermal Spray Coatings on Wear, Erosion and Corrosion Behavior: A Review. J. Appl. Sci. Eng. 2017, 20, 445–452. [Google Scholar] [CrossRef]

- Kosa, E.; Göksenli, A. Influence of Material Hardness and Particle Velocity on Erosive Wear Rate. J. Mech. Eng. 2017, 47, 1–14. [Google Scholar] [CrossRef]

- Malik, J.; Toor, I.H.; Ahmed, W.H.; Gasem, Z.M.; Habib, M.A.; Mansour, R.B.; Badr, H.M. Evaluating the Effect of Hardness on Erosion Characteristics of Aluminum and Steels. J. Mater. Eng. Perform. 2016, 23, 2274–2282. [Google Scholar] [CrossRef]

- Stack, M.M.; Jana, B.D.; Abdelrahman, S.M. Erosion-Corrosion Mechanisms and Maps. 2011. Strathprints. Available online: https://strathprints.strath.ac.uk (accessed on 5 July 2024).

- Govande, A.R.; Chandak, A.; Sunil, B.R.; Dumpala, R. Carbide-based thermal spray coatings: A review on performance characteristics and post-treatment. Int. J. Refract. Met. Hard Mater. 2022, 103, 105772. [Google Scholar] [CrossRef]

- Bhatia, A. Thermal Spraying Technology and Applications. 2024. Available online: https://www.cedengineering.com/userfiles/T04-002%20-%20Thermal%20Spraying%20Technology%20and%20Applications%20-%20US.pdf (accessed on 5 July 2024).

- Brezinová, J.; Guzanová, A.; Draganovská, D.; Brezina, J. Characterization of selected properties of WC–WB–Co and WC–FeCrAl coatings. Výzkumné Články Koroze A Ochr. Mater. 2019, 63, 167–173. [Google Scholar] [CrossRef]

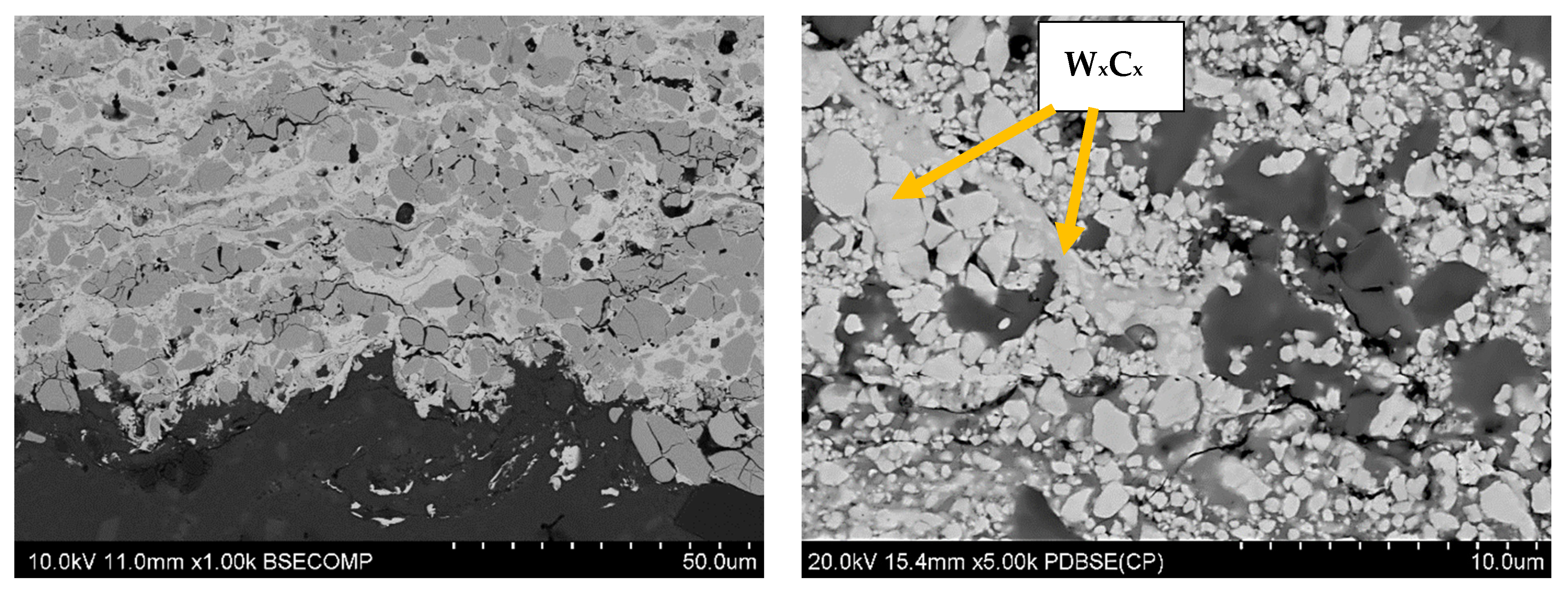

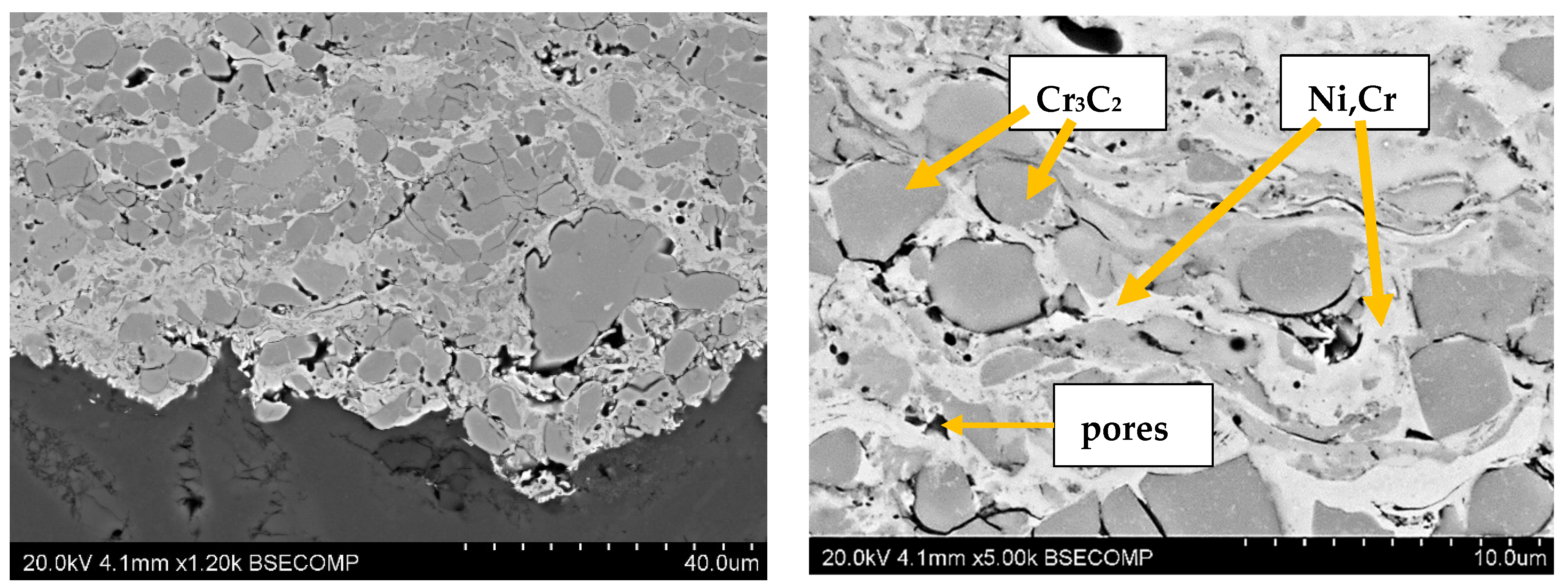

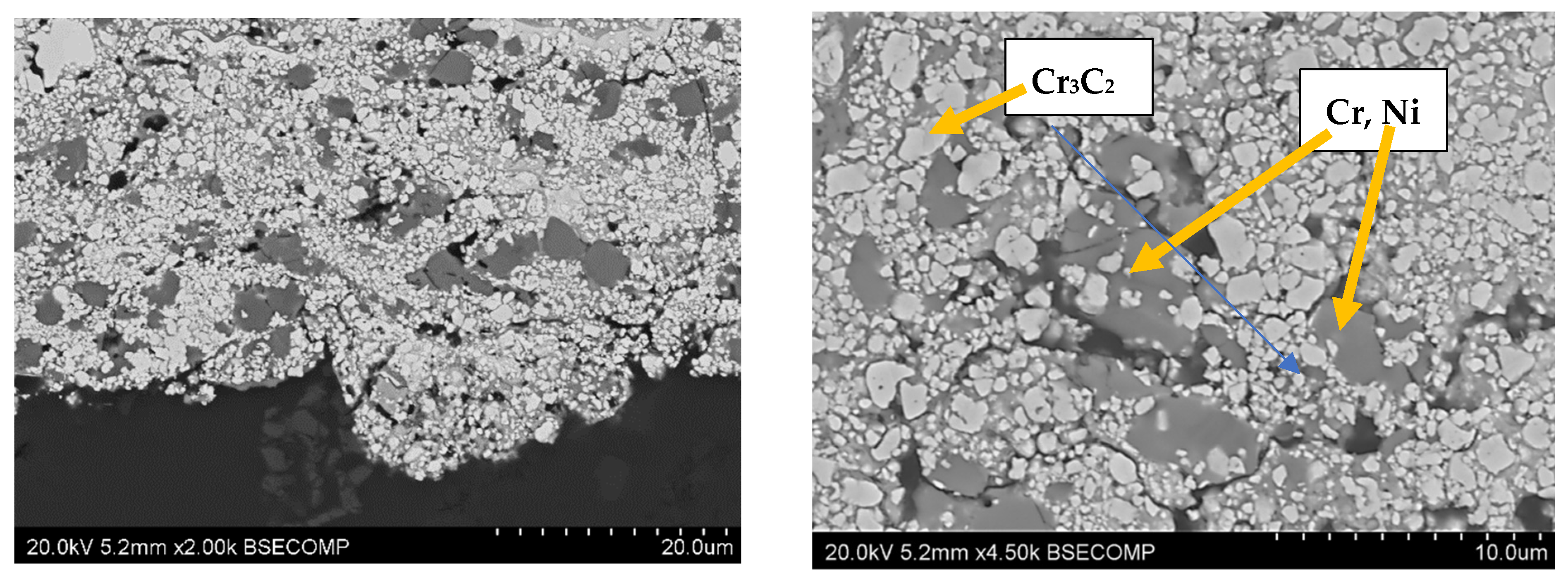

- Richert, M.; Mikułowski, B.; Pałka, P.; Hotloś, A.; Perek-Nowak, M. The Effect of Chemical Composition and Thermal Sprayed Method on the Chromium and Tungsten Carbides Coatings Microstructure. J. Surf. Eng. Mater. Adv. Technol. 2013, 3, 1–5. [Google Scholar] [CrossRef]

- Blum, M.; Krieg, P.; Killinger, A.; Gadow, R.; Luth, J.; Trenkle, F. High Velocity Suspension Flame Spraying (HVSFS)of Metal Suspensions. Materials 2020, 13, 621. [Google Scholar] [CrossRef]

- Najari, M.R.; Sajjadi, S.A.; Ganji, O. Microstructural evolution and wear properties of chromium carbide coating formed by thermo-reactive diffusion (TRD) process on a cold-work tool steel. Results Surf. Interfaces 2022, 8, 1. [Google Scholar] [CrossRef]

- Zong, X.; Jiang, W.; Fan, Z. Evaluation of Chromium Carbide Coatings on AISI 52100 Steel Obtained by Thermo-Reactive Diffusion Technique. Mater. Sci. Medžiagotyra 2018, 25, 1. [Google Scholar] [CrossRef]

- Sun, L.; Ji, X.; Zhao, L.; Zhai, W.; Xu, L.; Dong, H.; Liu, Y.; Peng, J. First Principles Investigation of Binary Chromium Carbides Cr7C3, Cr3C2 and Cr23C6: Electronic Structures, Mechanical Properties and Thermodynamic Properties under Pressure. Materials 2022, 15, 558. [Google Scholar] [CrossRef]

- Marques, A.S.; Dalcin, R.L.; Oliveira, L.F.; Vitor da Silva, L.A.; dos Santos, G.R.; da Silva Rocha, A. Comparative Analysis of the Friction and Microstructural Properties of WC-10Co-4Cr and Cr3C2-25NiCr Coatings Sprayed by High-Velocity Oxy-fuel (HVO). Am. J. Mater. Sci. 2018, 8, 51–57. [Google Scholar]

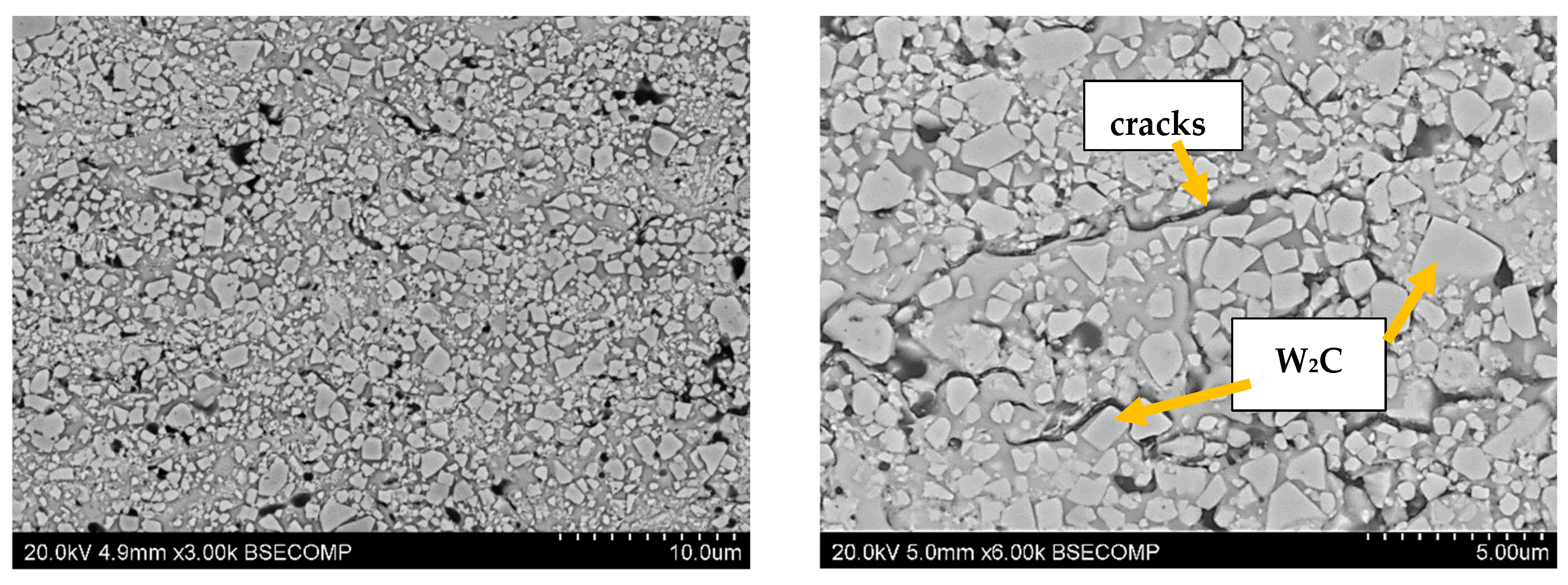

- Wang, H.; Li, Y.; Gee, M.; Zhang, H.; Liu, X.; Sang, X. Sliding wear resistance enhancement by controlling W2C precipitation in HVOF sprayed WC-based cermet coating. Surf. Coat. Technol. 2020, 387, 125533. [Google Scholar] [CrossRef]

- Fan, L.; Peng Ou, P.; Rong, J.; Yu, X. Preparation of high wear resistance nickel based WC coating by carefully adjusting interface structure. Mater. Res. Express 2022, 9, 086402. [Google Scholar] [CrossRef]

- Méndez-Medrano, K.O.; Martínez-González, C.J.; Alvarado-Hernández, F.; Jiménez, O.; Baltazar-Hernández, V.H.; Ruiz-Luna, H. Microstructure and Properties Characterization of WC-Co-Cr Thermal Spray Coatings. J. Miner. Mater. Charact. Eng. 2018, 6, 4. [Google Scholar] [CrossRef]

- Staia, M.H.; Valente, T.; Bartuli, C.; Lewis, D.B.; Constable, C.P. Part I: Characterization of Cr3C2-25% NiCr reactive plasma sprayed coatings produced at different pressures. Surf. Coat. Technol. 2001, 146-147, 553–562. [Google Scholar] [CrossRef]

- Katranidis, V.; Gu, S.; Cox, D.C.; Whiting, M.J.; Kamnis, S. FIB-SEM Sectioning Study of Decarburization Products in the Microstructure of HVOF-Sprayed WC-Co Coatings. J. Therm. Spray Technol. 2018, 27, 898–908. [Google Scholar] [CrossRef]

- Ahmed, R.; Ali, O.; Berndt, C.C.; Fardan, A. Sliding Wear of Conventional and Suspension Sprayed Nanocomposite WC-Co Coatings: An Invited Review. J. Therm. Spray Technol. 2021, 30, 800–861. [Google Scholar] [CrossRef]

- Yuan, J.; Ma, C.; Yang, S.; Yu, Z.; Li, H. Improving the Wear Resistance of HVOF Sprayed WC-Co Coatings by Adding Submicron-Sized WC Particles at the Splats’ Interfaces. Surf. Coat. Technol. 2016, 285, 17–23. [Google Scholar] [CrossRef]

- Kekes, D.; Psyllaki, P.; Vardavoulias, M. Wear Micro-Mechanisms of Composite WC-Co/Cr -NiCrFeBSiC Coatings. Part I: Dry Sliding. Tribol. Ind. 2014, 36, 361–374. Available online: https://www.tribology.rs/journals/2014/2014-4/4.pdf (accessed on 5 July 2024).

- Wielage, B.; Pokhmurska, H.; Wank, A.; Reisel, G.; Steinhaeuser, S.; Woezel, M. Influence of thermal spraying method on the properties of tungsten carbide coatings. In Proceedings of the Conference on Modern Wear and Corrosion Resistant Coatings Obtained by Thermal Spraying, Warsaw, Poland, 20–21 November 2003. [Google Scholar]

- Berger, L.-M. Binary WC– and Cr3C2–containing hardmetal compositions for thermally sprayed coatings. IOP Conf. Ser. Mater. Sci. Eng. 2016, 118, 012010. [Google Scholar] [CrossRef]

- Fan, K.; Jiang, W.; Luzin, V.; Gong, T.; Feng, W.; Ruiz-Hervias, J.; Yao, P. Influence of WC Particle Size on the Mechanical Properties and Residual Stress of HVOF Thermally Sprayed WC-10Co-4Cr Coatings. Materials 2022, 15, 5537. [Google Scholar] [CrossRef] [PubMed]

- Jonda, E.; Łatka, L. Comparative Analysis of Mechanical Properties of WC-Based Cermet Coatings Sprayed by HVOF onto AZ31 Magnesium Alloy Substrates. Adv. Sci. Technol. Res. J. 2021, 15, 57–64. [Google Scholar] [CrossRef]

- Avcu, Y.Y.; Guney, M.; Avcu, E. High-velocity air fuel coatings for steel for erosion-resistant applications. J. Electrochem. Sci. Eng. 2023, 13, 407–420. [Google Scholar] [CrossRef]

- Korobov, H.; Alwan, N.; Soboleva, A.; Makarov, N.; Lezhnin, V.; Shumyakov, M.; Antonov, M. Deviatiarov. J. Therm. Spray Technol. 2021, 31, 234–246. [Google Scholar] [CrossRef]

- Siwak, P.; Garbiec, D. Microstructure and mechanical properties of WC−Co, WC−Co−Cr3C2 and WC−Co−TaC cermets fabricated by spark plasma sintering. Trans. Nonferrous Met. Soc. China 2016, 26, 2641–2646. [Google Scholar] [CrossRef]

| Si | Cu | Mg | Mn | Ti | Zn | Fe | Al |

|---|---|---|---|---|---|---|---|

| 8.5–10.5 | 0.3 | 0.25–0.4 | 0.25–0.5 | 0.15 | 0.2 | 0.6 | rest |

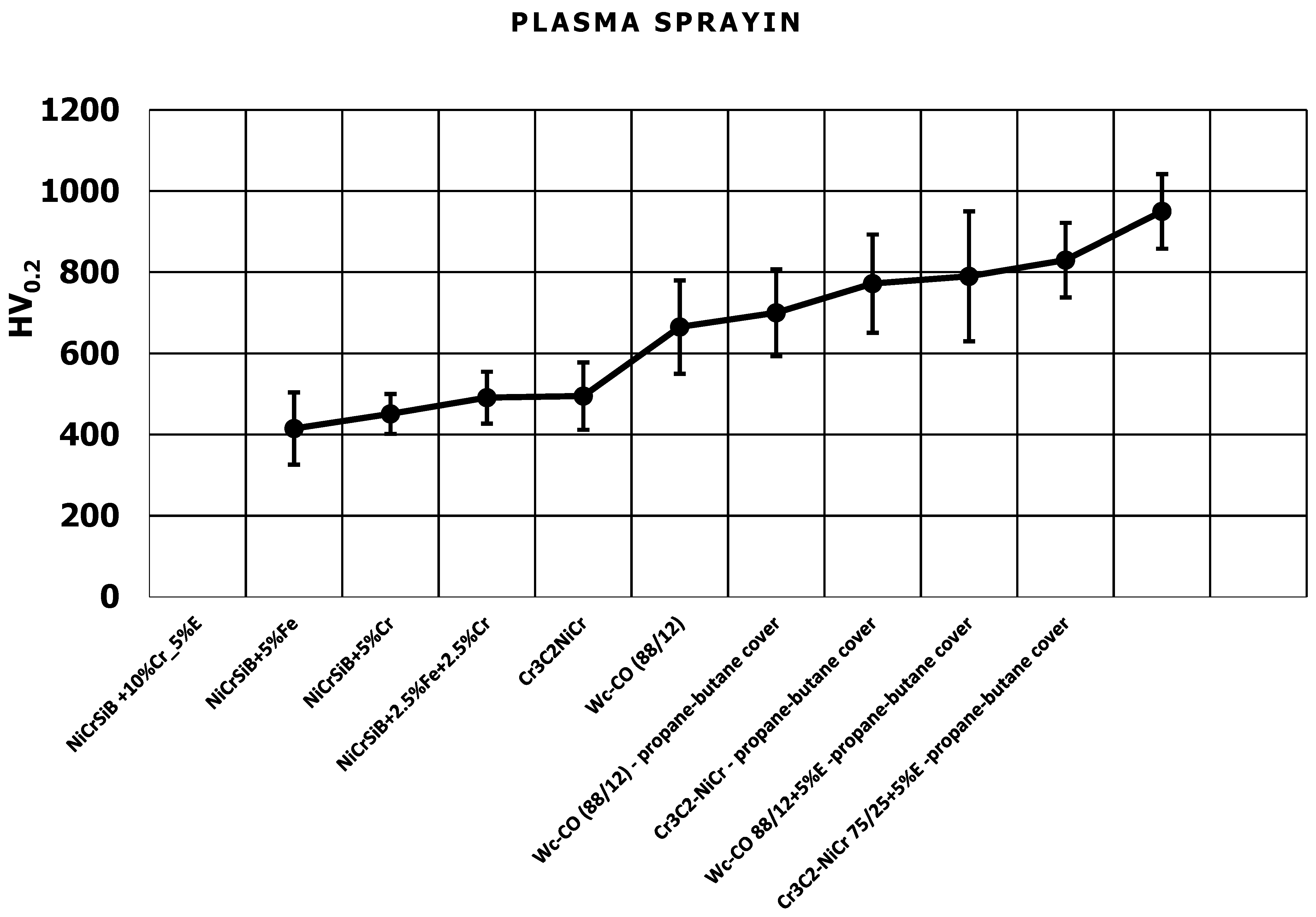

| Powder Composition | Plasma Spray Parameters | Coating Thickness [µm] | |||

|---|---|---|---|---|---|

| Ar [L/h] | Voltage [V] | Current [A] | Distance [mm] | ||

| WC-Co 88/12 | 3000 | 52 | 500 | 90 | 300 ± 20 |

| WC-Co 88/12 (+propane–butane cover) | 3000 | 52 | 500 | 90 | |

| NiCrSiB | 2500 | 48 | 480 | 90 | |

| NiCrSiB + 5% Fe | 2500 | 48 | 480 | 90 | |

| NiCrSiB + 5% Cr | 2500 | 48 | 480 | 90 | |

| NiCrSiB + 2.5% Fe + 2.5% Cr | 2500 | 48 | 480 | 90 | |

| Cr3C2—NiCr 75–25 | 3000 | 52 | 500 | 90 | |

| Cr3C2—NiCr 75–25 -45+ (+propane–butane cover) | 3000 | 52 | 500 | 90 | |

| WC-Co + 5%(NiCrFeBSi) (+propane–butane cover) | 3000 | 52 | 500 | 90 | |

| Powder Composition | HVOF Spray Parameters | Coating Thickness [µm] | ||||

|---|---|---|---|---|---|---|

| O2 [L/min] | Kerosene [L/h] | N2 [L/min] | Distance [mm] | Powder [g/min] | ||

| WC-Co 88-12 | 944 | 25.5 | 9.5 | 370 | 92 | 300+80 |

| NiCrSiB | 920 | 21.5 | 11 | 355 | 95 | |

| NiCrSiB+5%Fe—nanopowder | 920 | 21.5 | 11 | 355 | 95 | |

| NiCrSiB+5%Cr—nanopowder | 920 | 21.5 | 11 | 355 | 95 | |

| NiCrSiB + 2.5%Fe + 2.5%Cr—nanopowder | 920 | 21.5 | 11 | 355 | 95 | |

| Cr3C2-NiCr 75–25 | 850 | 24 | 9.5 | 370 | 65 | |

| WC-Co + 5%(NiCrFeBSi) | 944 | 25.5 | 9.5 | 370 | 92 | |

| WC-CrC-Ni 73/20/7 | 944 | 24 | 10 | 370 | 75 | |

| WC-Co-Cr 86/10/4 nanopowder | 944 | 25.5 | 9.5 | 370 | 92 | 300+50 |

| Ni-Cr-B-Si | 944 | 24 | 10 | 370 | 75 | 300+50 |

| Inconel 625 | 944 | 24 | 10 | 370 | 75 | 300+50 |

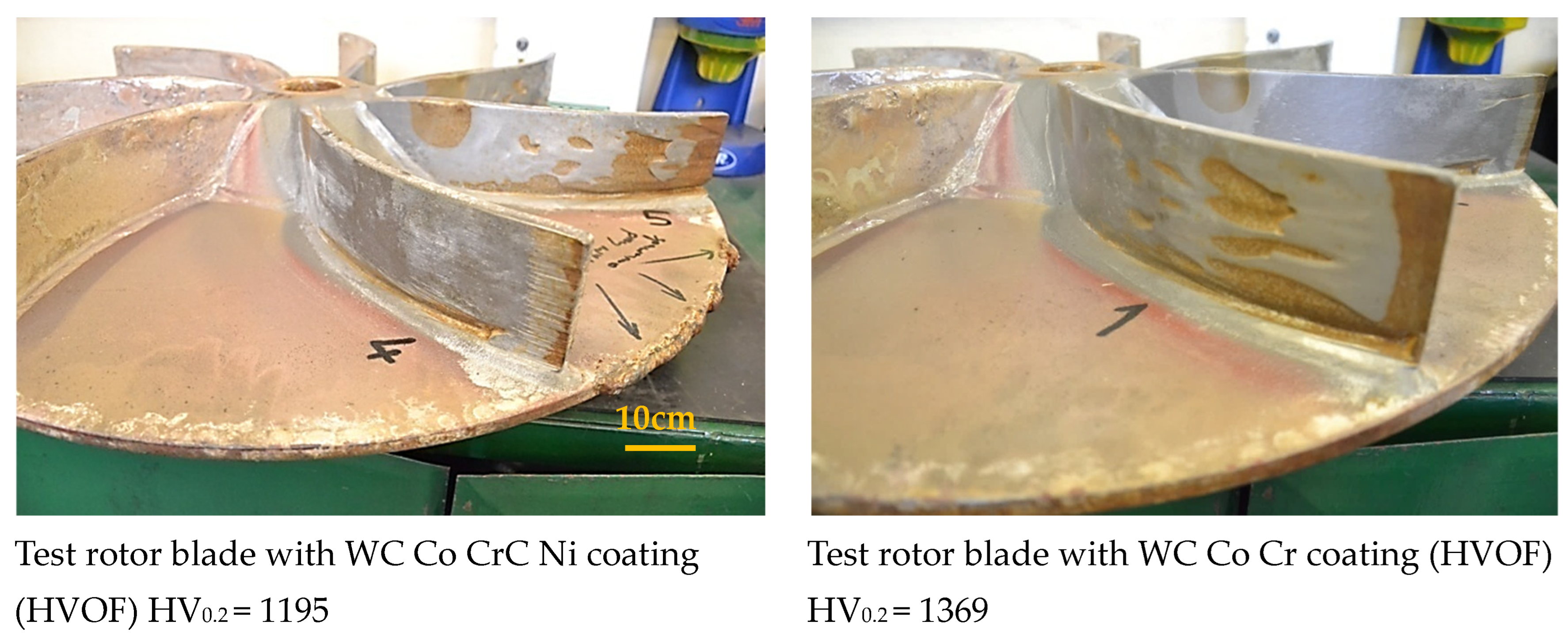

| Rotor Blade No | Chemical Composition | Thermal Spray Method | HV0.2 |

|---|---|---|---|

| 1 | WC-Co-Cr | HVOF | 1369 (±100) |

| 2 | WC-Co | HVOF | 1240 (±138) |

| 3 | WC-Co + 5% NiCrBSi | plasma spray | 1218 (±166) |

| 4 | WC-Co-CrC-Ni | HVOF | 1195 (±112) |

| 5 | Cr3C2-NiCr + 5% NiCrBSi | plasma spray | 967 (±98) |

| 6 | NiCrBSi | HVOF | 950 (±92) |

| 7 | Cr3C2-NiCr | HVOF | 863 ± (138) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Richert, M. Thermally Sprayed Coatings for the Protection of Industrial Fan Blades. Materials 2024, 17, 3903. https://doi.org/10.3390/ma17163903

Richert M. Thermally Sprayed Coatings for the Protection of Industrial Fan Blades. Materials. 2024; 17(16):3903. https://doi.org/10.3390/ma17163903

Chicago/Turabian StyleRichert, Maria. 2024. "Thermally Sprayed Coatings for the Protection of Industrial Fan Blades" Materials 17, no. 16: 3903. https://doi.org/10.3390/ma17163903