Cryogenic Investigations into the Effect of Impact-Oscillatory Loading on Changes in the Mechanical Properties and Structural Condition of VT23M Two-Phase Titanium Alloy

Abstract

1. Introduction

- -

- Cooling of titanium alloys in liquid nitrogen + DNP + static tensioning (ST);

- -

- DNP + cooling in liquid nitrogen + ST.

2. Materials and Methods

3. Results and Discussion

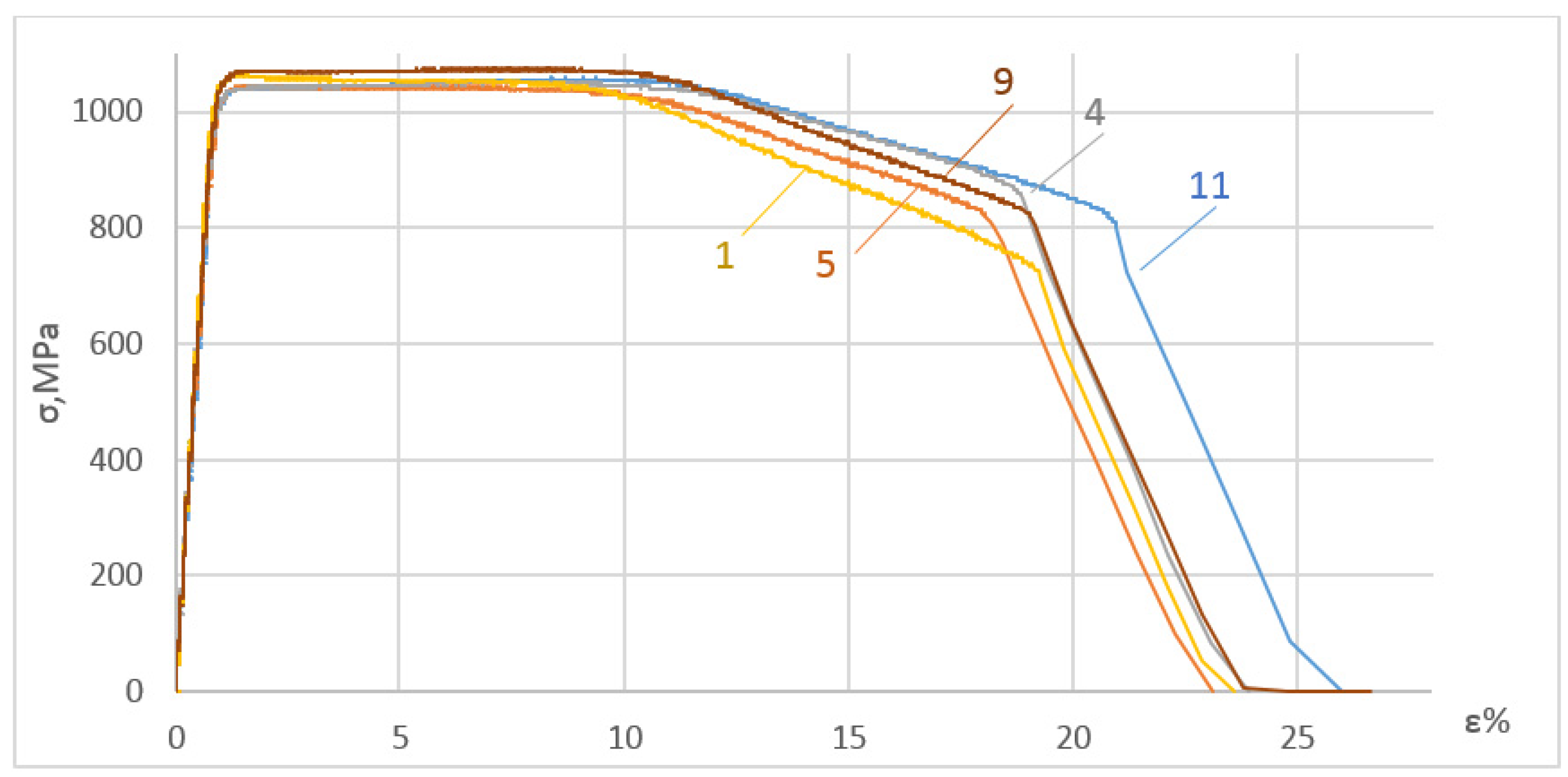

3.1. Mechanical Tests

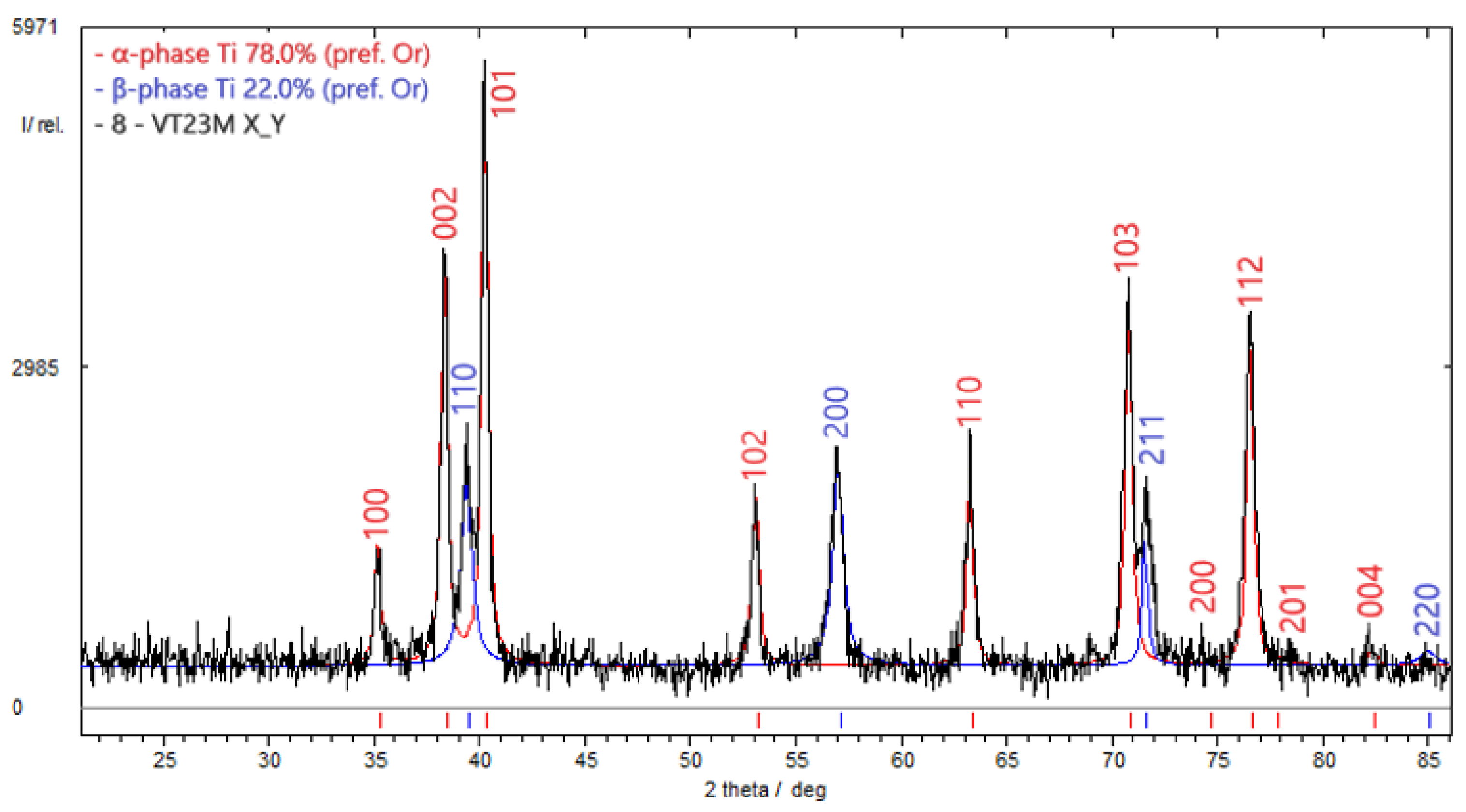

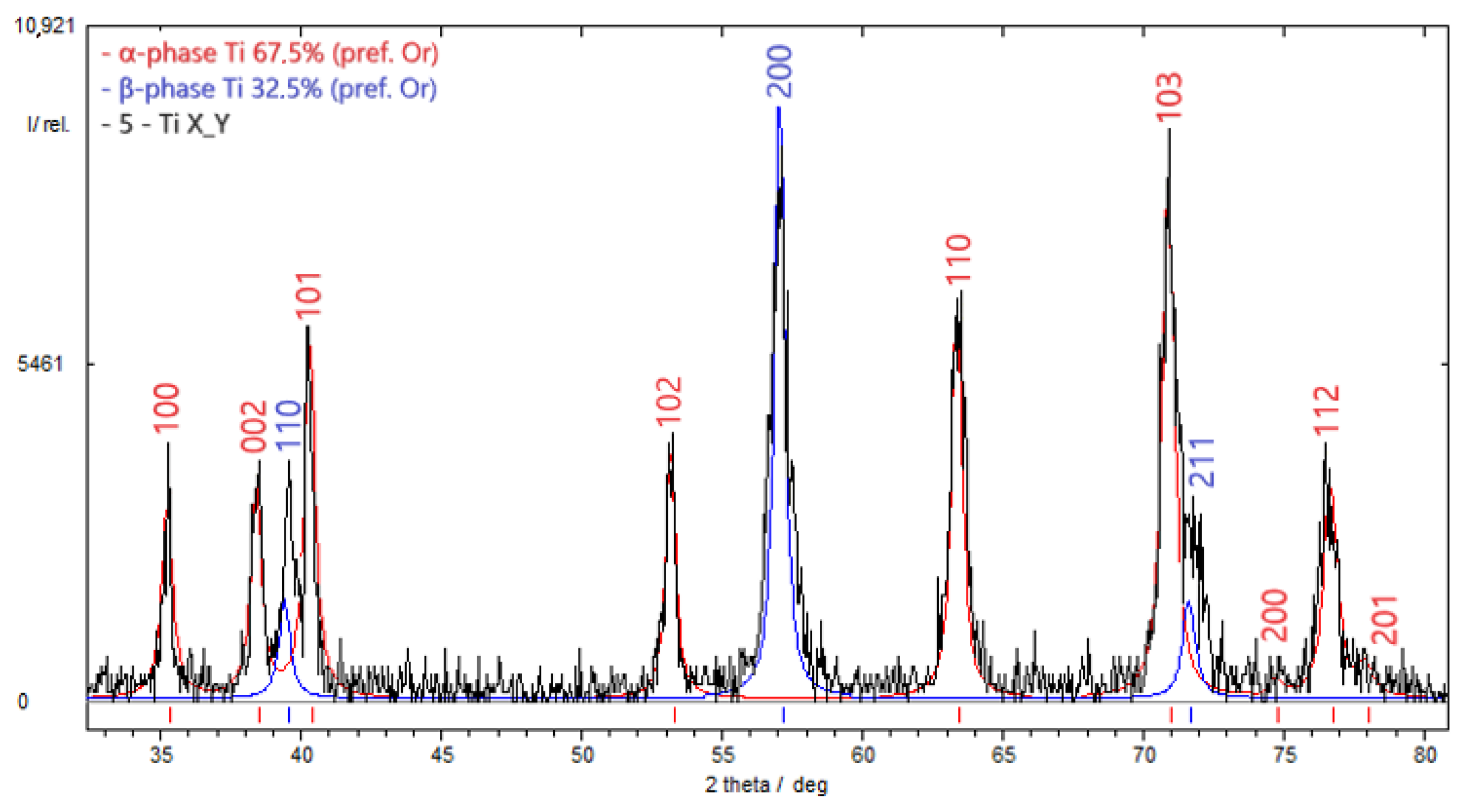

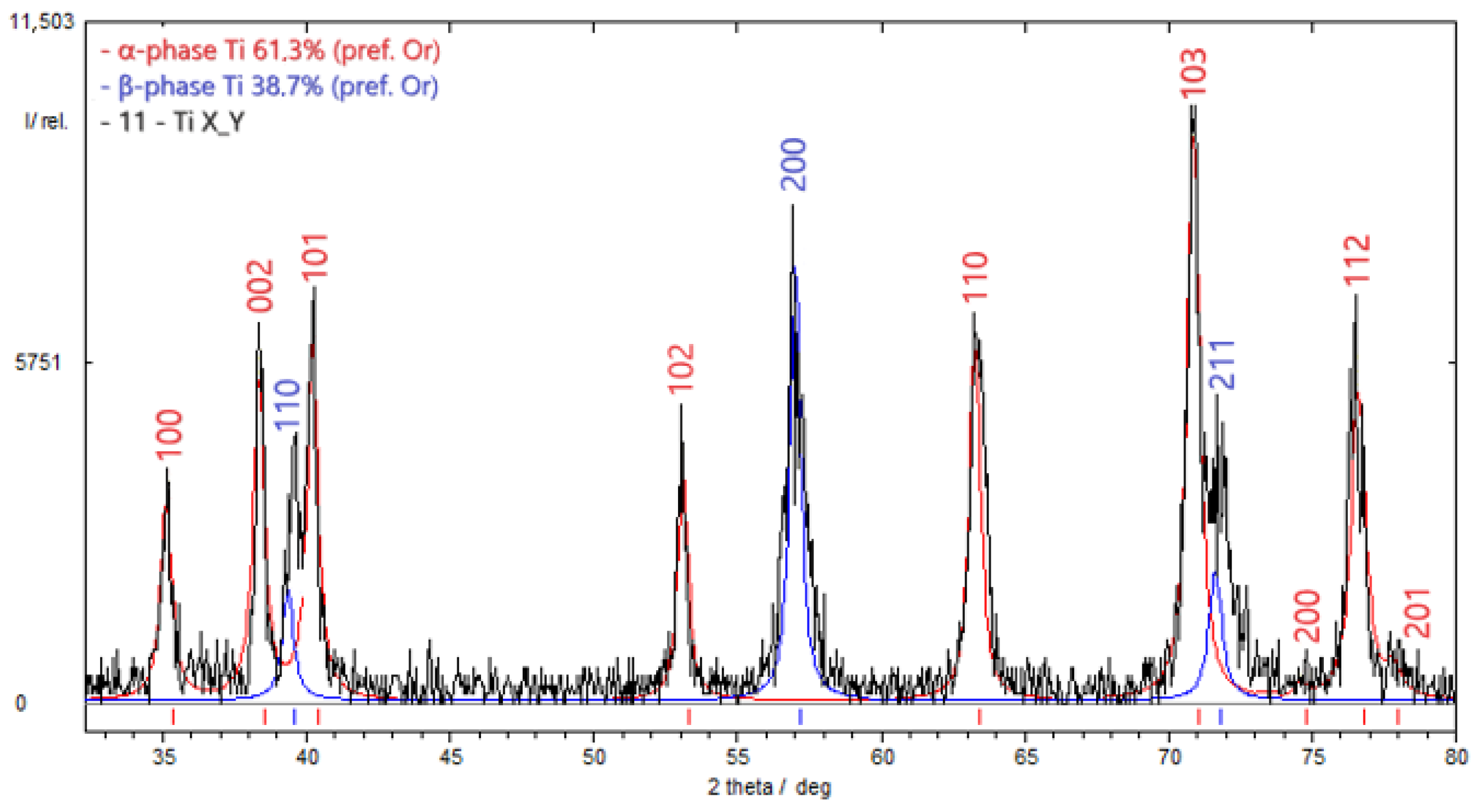

3.2. Diffractometric Research Findings

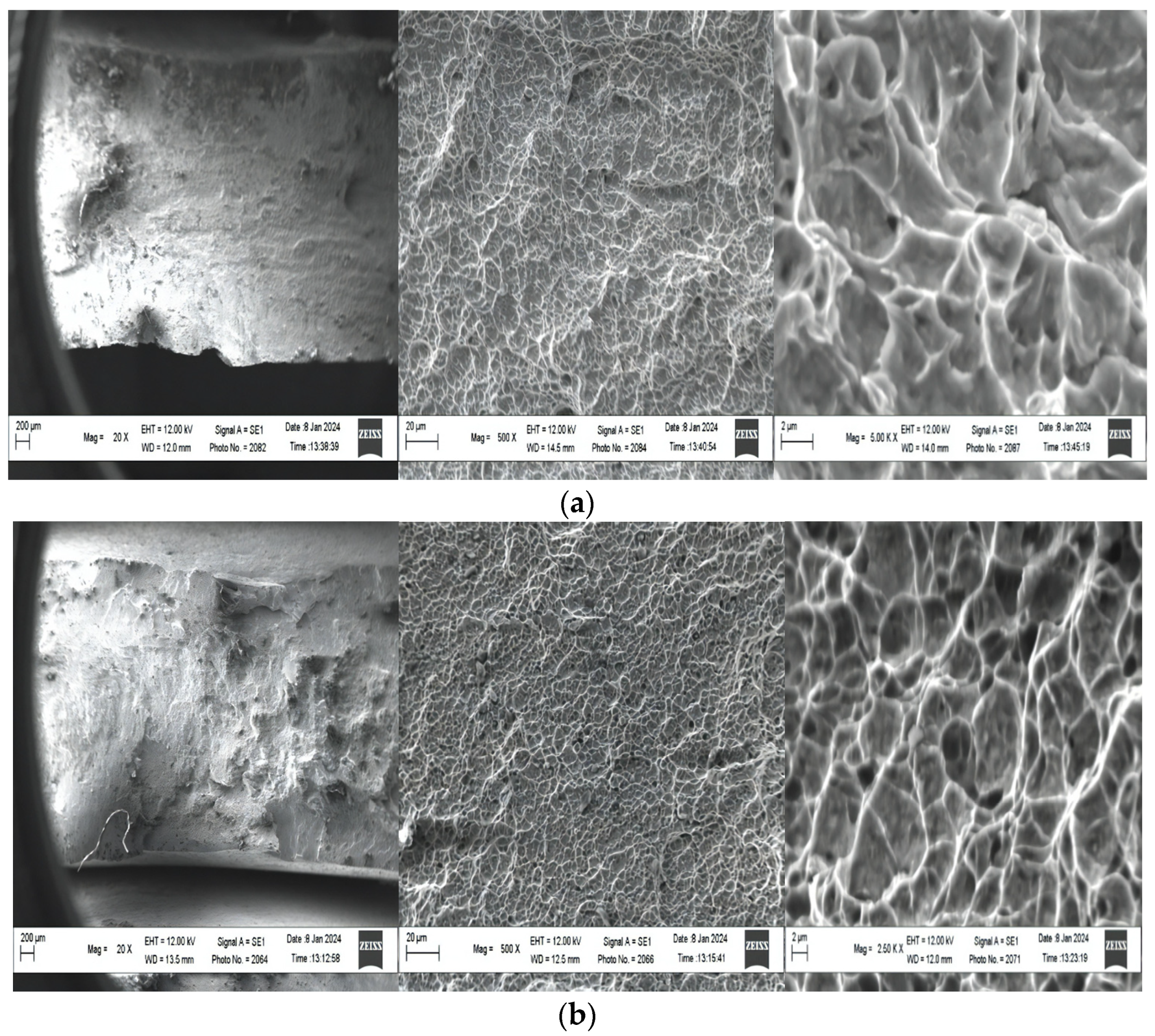

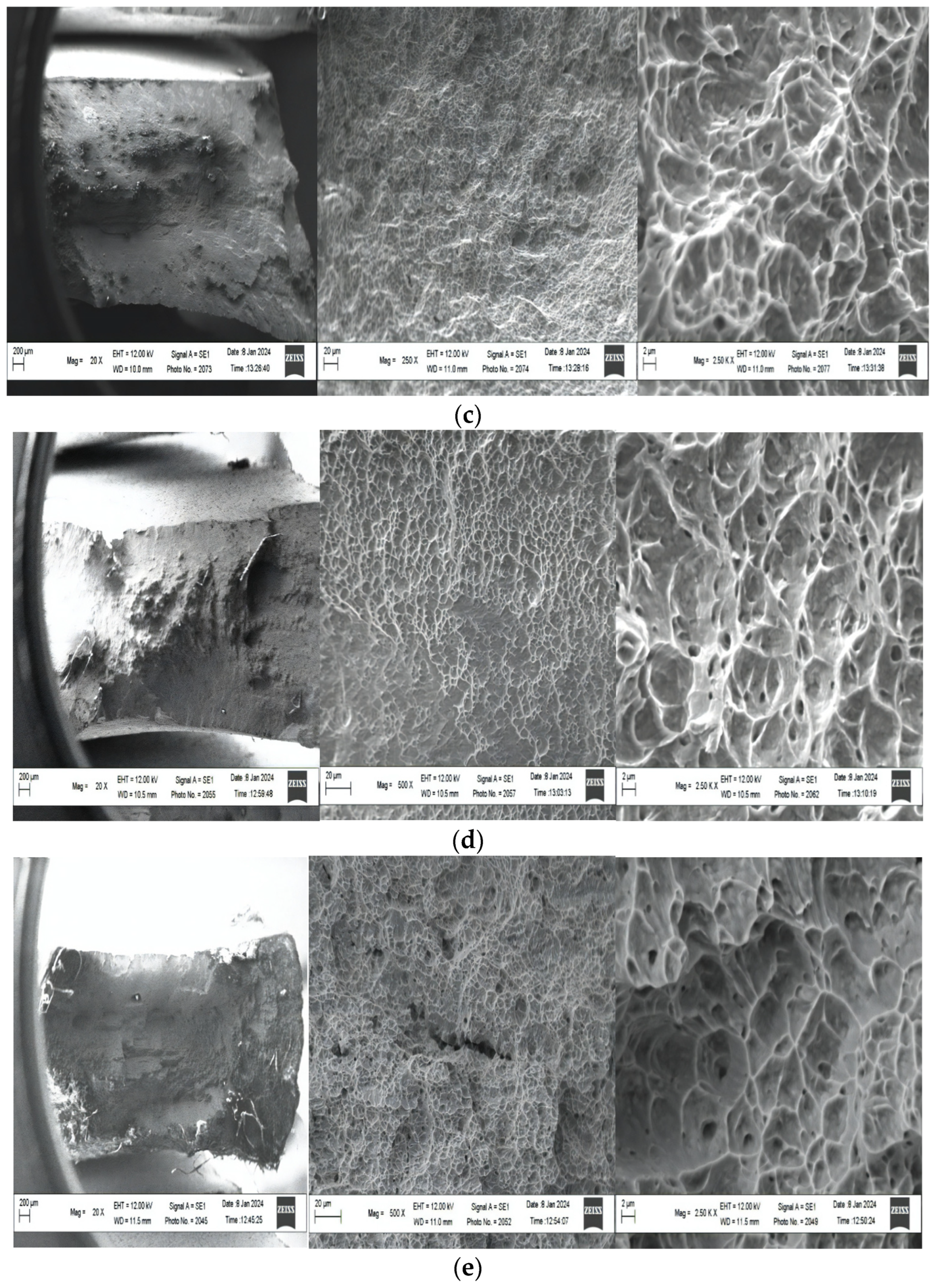

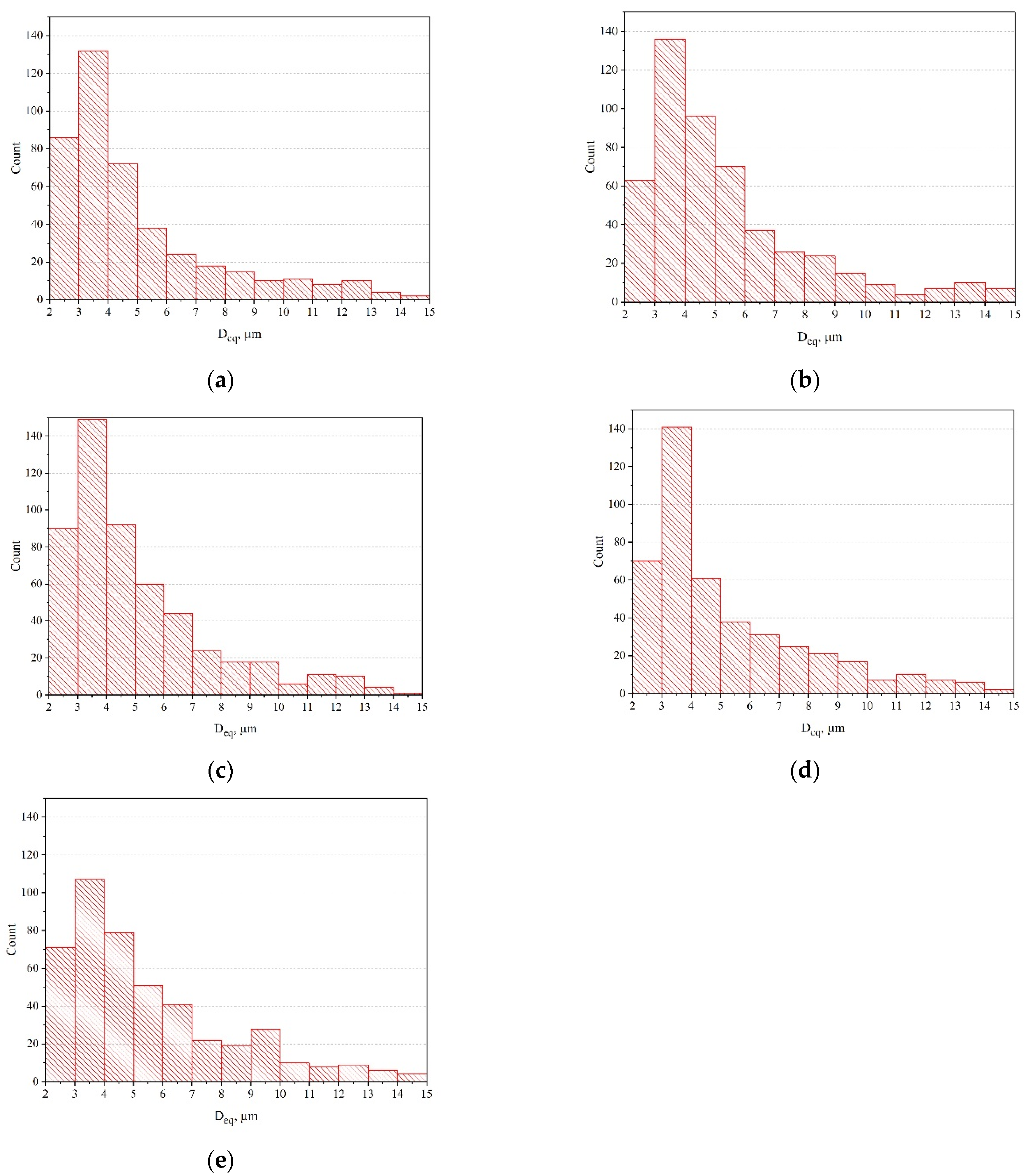

3.3. Fractographic Research Findings

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Khorev, A.I. High-strength titanium alloy VT23 and its applications in advanced welded and brazed structures. Weld. Int. 2010, 24, 276–281. [Google Scholar] [CrossRef]

- Khorev, A.I. Alloying titanium alloys with rare-earth metals. Russ. Eng. Res. 2011, 31, 1087–1094. [Google Scholar] [CrossRef]

- Illarionov, A.G.; Popov, A.A.; Illarionova, S.M. Effect of Microalloying, with Rem Inclusively, on the Structure, Phase Composition and Properties of (α + β)-Titanium Alloy. Met. Sci. Heat. Treat. 2016, 57, 719–725. [Google Scholar] [CrossRef]

- Khorev, A.I. Complex-alloyed titanium alloy VT23 for universal use. Mech. Eng. Technol. 2007, 7, 5–11. (In Russian) [Google Scholar]

- Khorev, A.I. Complex alloying and microalloying of titanium alloys. Weld. Int. 2011, 25, 56–63. [Google Scholar] [CrossRef]

- Gladkovskii, S.V.; Volkov, V.P.; Salikhyanov, D.R.; Veselova, V.E.; Patselov, A.M. Rheological Behavior of a VT23 Alloy during Deformation in a Wide Temperature Range. Russ. Met. 2020, 2020, 1147–1150. [Google Scholar] [CrossRef]

- Khorev, A.I. Alloying and heat treatment of structural (α + β) titanium alloys of high and superhigh strength. Russ. Eng. Res. 2010, 30, 682–688. [Google Scholar] [CrossRef]

- D’yakova, M.A.; L’vova, E.A. Phase transformations in dual-phase titanium alloys during mechanical testing at various temperatures. Met. Sci. Heat. Treat. 1988, 30, 205–211. [Google Scholar] [CrossRef]

- Gladkovskii, S.V.; Veselova, V.E.; Vichuzhanin, D.I.; Zichenkov, M.C.; Dubinskii, S.V.; Kovalev, N.I.; Kulemin, A.V.; Kovalev, I.E. Effect of Heat-Treatment Conditions on the Microstructure and the Static Fracture Toughness of an α + β VT23 Titanium Alloy. Russ. Met. 2023, 2023, 425–432. [Google Scholar] [CrossRef]

- Skvortsova, S.V.; Shalin, A.V.; Gvozdeva, O.N.; Stepushin, A.S.; Gurtovaya, G.V. Formation of a Lamellar Structure in α + β Titanium Alloys. Russ. Met. 2023, 2023, 1433–1438. [Google Scholar] [CrossRef]

- Pumpyanskiy, D.A.; Illarionov, A.G.; Vodolazskiy, F.V.; Kosmatskiy, Y.I.; Popov, A.A. Promising Titanium Alloys for Cold-Worked Pipe Manufacture. Metallurgist 2023, 67, 25–40. [Google Scholar] [CrossRef]

- Kondrat’eva, O.V.; Kondrat’ev, S.Y.; Shvetsov, O.V. A Study of Modes of Hardening Heat Treatment of Titanium Alloy VT23. Met. Sci. Heat. Treat. 2019, 60, 715–721. [Google Scholar] [CrossRef]

- Komshina, A.V.; Pomel’nikova, A.S.; Nochovnaya, N.A. Improvement of Alloy VT23 Surface Quality with Magnetic-Pulse Treatment. Met. Sci. Heat. Treat. 2015, 57, 359–363. [Google Scholar] [CrossRef]

- Putyrsky, S.V.; Arislanov, A.A.; Yakovlev, A.L.; Nochovnaya, N.A. Study of the mechanical properties of deformed semi-finished products of VT23M and VT43 alloys, assessment of their climatic resistance in the Arctic climate. Proc. VIAM 2018, 44, 101–110. [Google Scholar] [CrossRef]

- Shapovalova, O.M.; Ivanova, L.N. Properties of titanium alloys for aerospace technology at negative and cryogenic temperatures. Space Sci. Technol. Appl. 2002, 8, 152–155. [Google Scholar] [CrossRef]

- Chausov, N.G.; Voityuk, D.G.; Pilipenko, A.P.; Kuz’menko, A.M. Setup for testing materials with plotting complete stress–strain diagrams. Strength. Mater. 2004, 36, 532–537. [Google Scholar] [CrossRef]

- Chausov, M.; Brezinová, J.; Pylypenko, A.; Maruschak, P.; Titova, L.; Guzanová, A. Modification of mechanical properties of high-strength titanium alloys VT23 and VT23M due to impact-oscillatory loading. Metals 2019, 9, 80. [Google Scholar] [CrossRef]

- Chausov, M.G.; Pylypenko, A.P.; Berezin, V.B.; Markashova, L.I.; Kushnariova, O.S.; Hutsaylyuk, V.B. Influence of impact-oscillatory loading upon the mechanical properties of the VT-22 titanium alloy sheet. Mater. Eng. Perform. 2016, 25, 3482–3492. [Google Scholar] [CrossRef]

- Hutsaylyuk, V.; Chausov, M.; Berezin, V.; Pylypenko, A. Strength analysis of mechanical systems at dynamic non-equilibrium processes. Eng. Fail. Anal. 2013, 35, 636–644. [Google Scholar] [CrossRef]

- Chausov, M.G.; Maruschak, P.O.; Hutsaylyuk, V.; Sniezek, L.; Pylypenko, A.P. Effect of complex combined loading mode on the fracture toughness of titanium alloys. Vacuum 2018, 147, 51–57. [Google Scholar] [CrossRef]

- Maruschak, P.; Konovalenko, I.; Sorochak, A. Methods for evaluating fracture patterns of polycrystalline materials based on the parameter analysis of ductile separation dimples: A review. Eng. Fail. Anal. 2023, 153, 107587. [Google Scholar] [CrossRef]

- Konovalenko, I.; Maruschak, P.; Prentkovskis, O. Automated Method for Fractographic Analysis of Shape and Size of Dimples on Fracture Surface of High-Strength Titanium Alloys. Metals 2018, 8, 161. [Google Scholar] [CrossRef]

- Hait, P.; Sil, A.; Choudhury, S. Overview of damage assessment of structures. Curr. Sci. 2019, 117, 64–70. [Google Scholar] [CrossRef]

- Madhu, K.S.; Urs, N.; Hegde, M.N. Damage assessment and analysis of steel plate for different loading conditions. Mater. Today Proceeding 2017, 4, 9695–9699. [Google Scholar] [CrossRef]

- Chausov, M.G.; Pylypenko, A.P.; Kutsenko, A.H. The Method of Assessing the Degradation of the Material Due to the Accumulation of Damage during the Working Process. Patent No. 76274, 17 July 2006. [Google Scholar]

- Chausov, N.G. Full deformation diagram as source of information about accumulation of damages and materials crack resistance. Zavod. Laboratoriya. Diagn. Mater. 2004, 70, 42–49. [Google Scholar]

- Polyanskii, V.M.; Klyatskina, V.Y.; Silis, M.I. Evaluation of the Brittleness of Titanium Alloys in Terms of Mechanical Properties and Fracture Patterns. Met. Sci. Heat. Treat. 2003, 45, 61–64. [Google Scholar] [CrossRef]

- Panin, V.E.; Panin, S.V.; Pochivalov, Y.I.; Smirnova, A.S.; Eremin, A.V. Structural Scale Levels of Plastic Deformation and Fracture of High-Strength Titanium Alloy Welds. Phys. Mesomech. 2018, 21, 464–474. [Google Scholar] [CrossRef]

| Titanium Alloy | Mechanical Properties | ||

|---|---|---|---|

| σys, MPa | σus, MPa | δ, % | |

| VT23M | 1000–1150 | 1080–1180 | 20–21 |

| Chemical Composition, % by Weight | |||||

|---|---|---|---|---|---|

| Fe | Cr | Mo | V | Ti | Al |

| 0.7 | 1.1 | 2.2 | 4.5 | 86.7 | 4.8 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chausov, M.; Hutsaylyuk, V.; Maruschak, P.; Pylypenko, A.; Karpets, M.; Shmanenko, V. Cryogenic Investigations into the Effect of Impact-Oscillatory Loading on Changes in the Mechanical Properties and Structural Condition of VT23M Two-Phase Titanium Alloy. Materials 2024, 17, 3913. https://doi.org/10.3390/ma17163913

Chausov M, Hutsaylyuk V, Maruschak P, Pylypenko A, Karpets M, Shmanenko V. Cryogenic Investigations into the Effect of Impact-Oscillatory Loading on Changes in the Mechanical Properties and Structural Condition of VT23M Two-Phase Titanium Alloy. Materials. 2024; 17(16):3913. https://doi.org/10.3390/ma17163913

Chicago/Turabian StyleChausov, Mykola, Volodymyr Hutsaylyuk, Pavlo Maruschak, Andrii Pylypenko, Myroslav Karpets, and Vladyslav Shmanenko. 2024. "Cryogenic Investigations into the Effect of Impact-Oscillatory Loading on Changes in the Mechanical Properties and Structural Condition of VT23M Two-Phase Titanium Alloy" Materials 17, no. 16: 3913. https://doi.org/10.3390/ma17163913

APA StyleChausov, M., Hutsaylyuk, V., Maruschak, P., Pylypenko, A., Karpets, M., & Shmanenko, V. (2024). Cryogenic Investigations into the Effect of Impact-Oscillatory Loading on Changes in the Mechanical Properties and Structural Condition of VT23M Two-Phase Titanium Alloy. Materials, 17(16), 3913. https://doi.org/10.3390/ma17163913