Rheological Performance and Differences between Laboratory-Aged and RAP Bitumen

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Methods

3. Results and Discussion

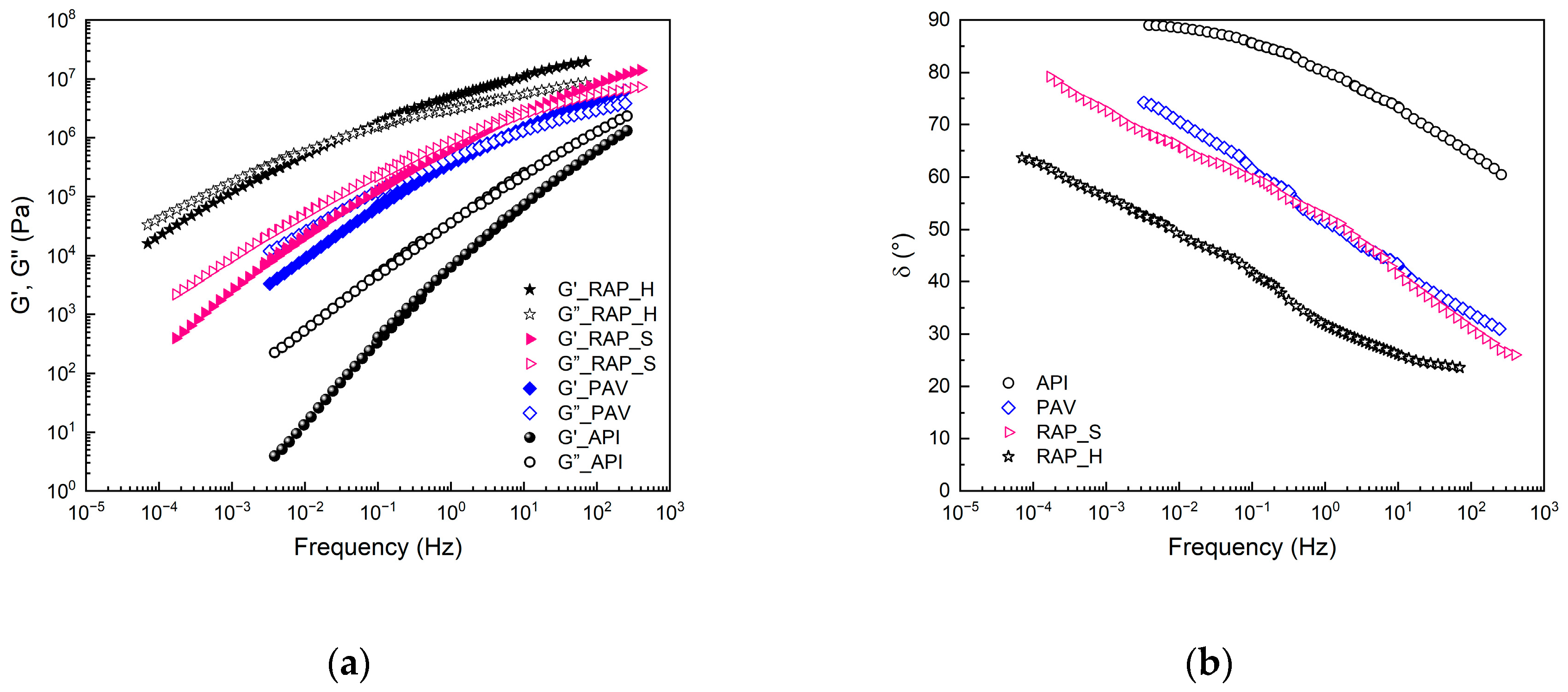

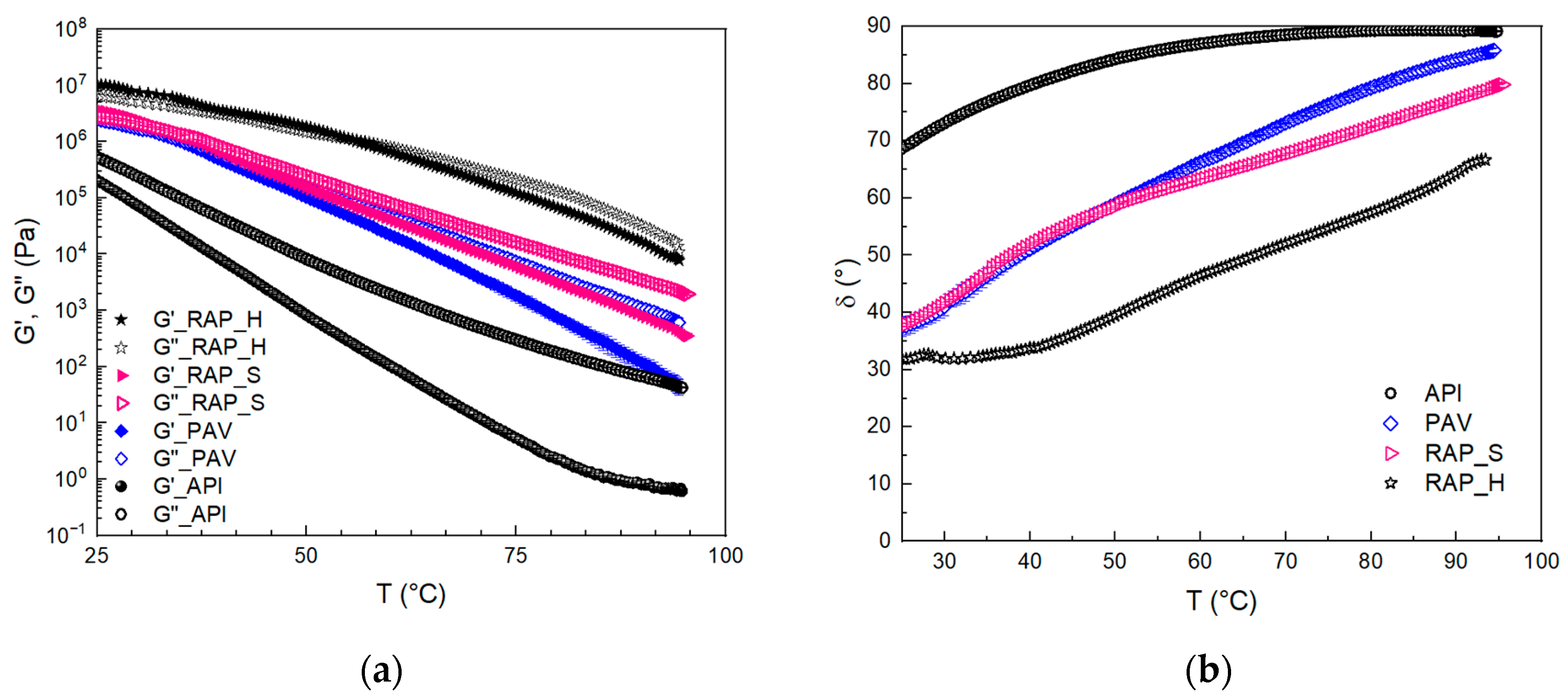

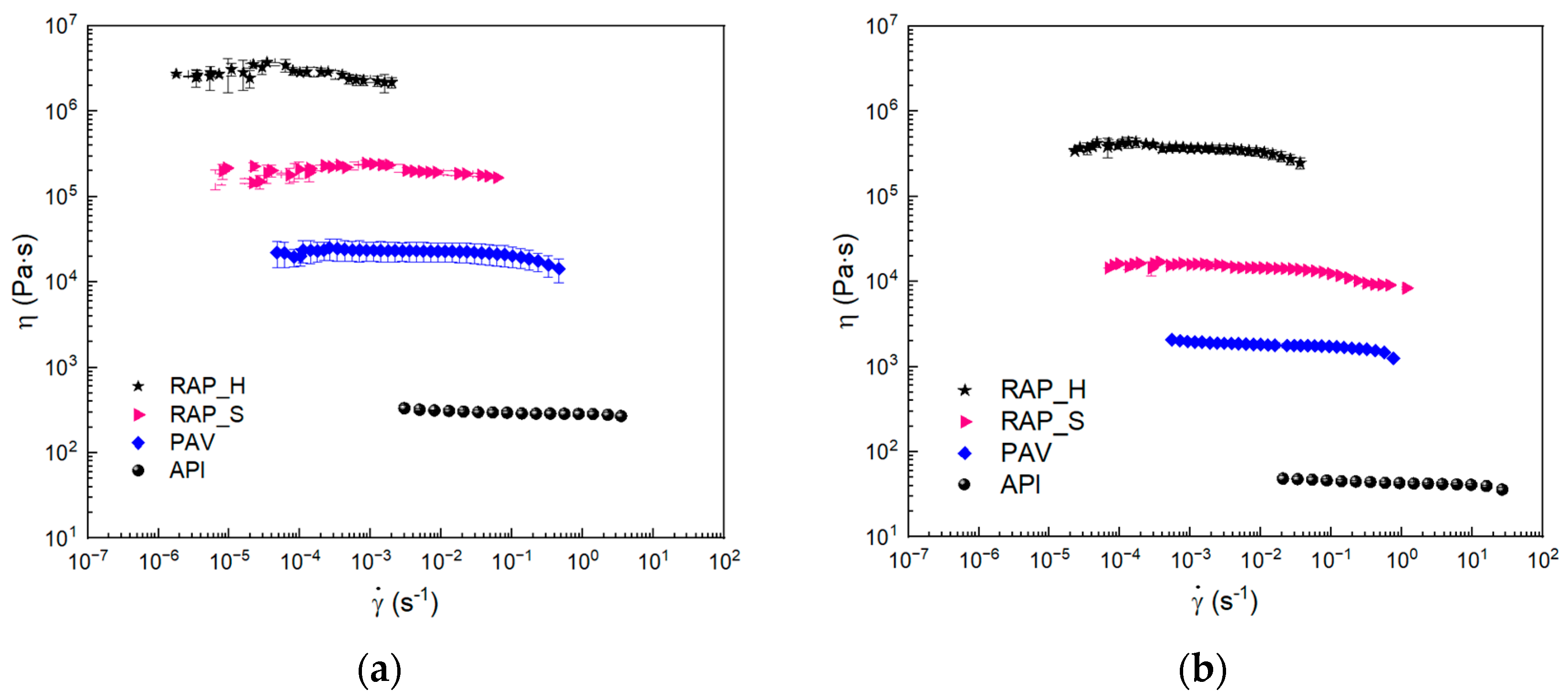

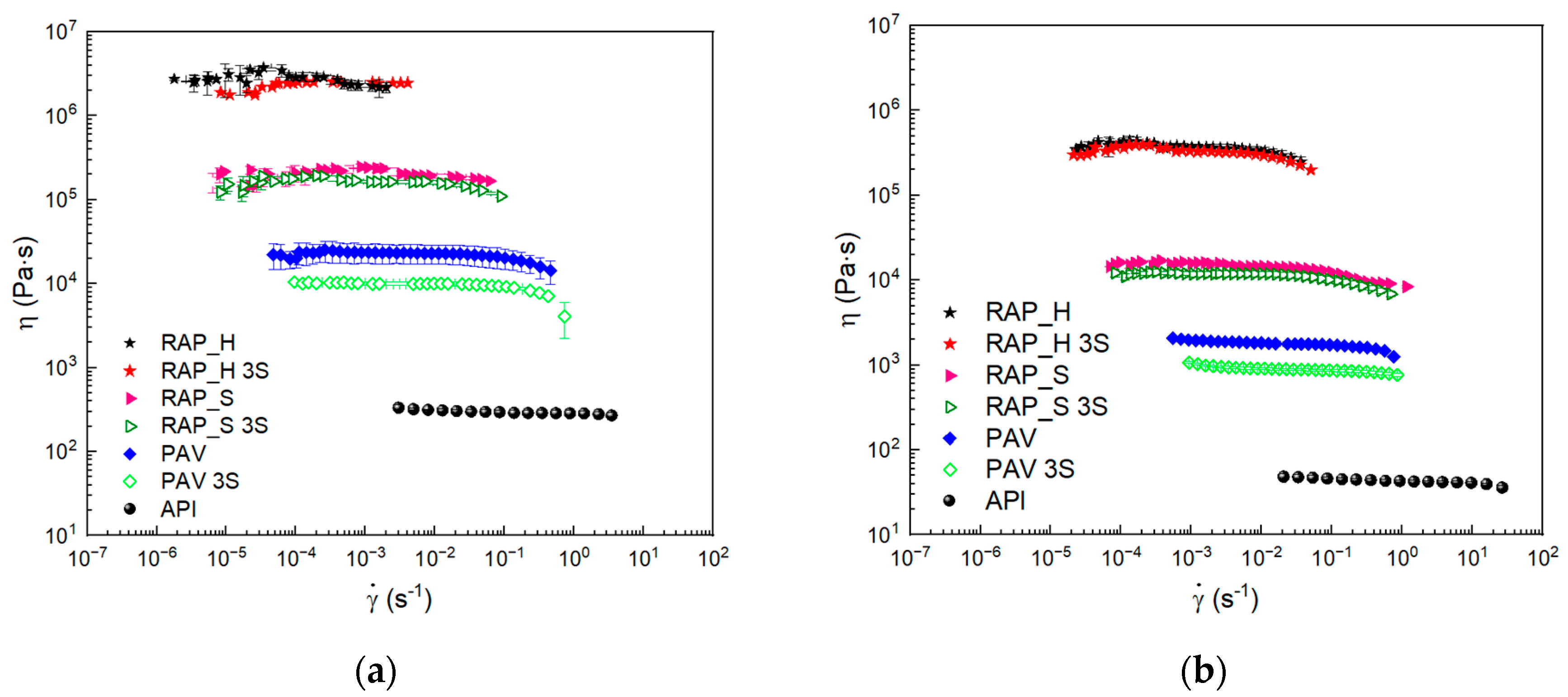

3.1. Rheological Results

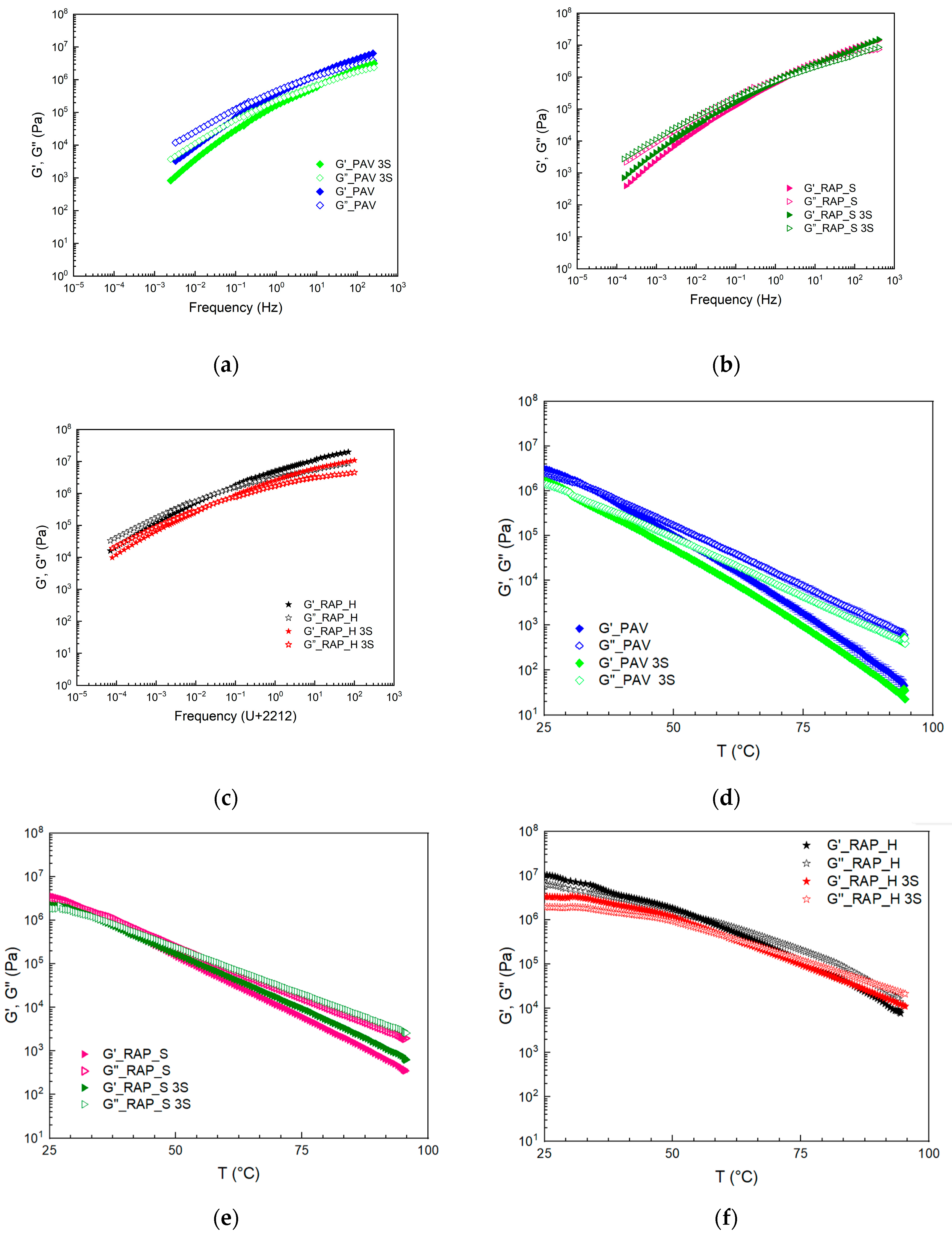

3.2. Rheology of Modified Samples

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xing, C.; Tang, S.; Chang, Z.; Han, Z.; Li, H.; Zhu, B. A Comprehensive Review on the Plant-Mixed Cold Recycling Technology of Emulsified Asphalt: Raw Materials and Factors Affecting Performances. Constr. Build. Mater. 2024, 439, 137344. [Google Scholar] [CrossRef]

- Wang, H.; Liu, X.; Apostolidis, P.; van de Ven, M.; Erkens, S.; Skarpas, A. Effect of Laboratory Aging on Chemistry and Rheology of Crumb Rubber Modified Bitumen. Mater. Struct. 2020, 53, 26. [Google Scholar] [CrossRef]

- Prosperi, E.; Bocci, E. A Review on Bitumen Aging and Rejuvenation Chemistry: Processes, Materials and Analyses. Sustainability 2021, 13, 6523. [Google Scholar] [CrossRef]

- Ongel, A.; Hugener, M. Aging of Bituminous Mixes for Rap Simulation. Constr. Build. Mater. 2014, 68, 49–54. [Google Scholar] [CrossRef]

- Qin, Q.; Schabron, J.F.; Boysen, R.B.; Farrar, M.J. Field Aging Effect on Chemistry and Rheology of Asphalt Binders and Rheological Predictions for Field Aging. Fuel 2014, 121, 86–94. [Google Scholar] [CrossRef]

- Petersen, J.C.; Harnsberger, P.M. Asphalt Aging: Dual Oxidation Mechanism and Its Interrelationships with Asphalt Composition and Oxidative Age Hardening. Transp. Res. Rec. 1998, 1638, 47–55. [Google Scholar] [CrossRef]

- Zhang, M.; Wang, X.; Zhang, W.; Ding, L. Study on the Relationship between Nano-Morphology Parameters and Properties of Bitumen during the Ageing Process. Materials 2020, 13, 1472. [Google Scholar] [CrossRef] [PubMed]

- Li, N.; Zhao, X.; Du, C.; Zhang, C.; Xiao, Q. Effect of Aging on Urban Asphalt Pavement. Adv. Mater. Res. 2013, 671–674, 1287–1290. [Google Scholar] [CrossRef]

- Suchismita, A.; Singh, D. Rheological Performance of Bitumen Mixed with Laboratory Simulated Polymerized RAP Binders. Constr. Build. Mater. 2023, 400, 132706. [Google Scholar] [CrossRef]

- Zhang, Y.; Wei, H.; Dai, Y. Influence of Different Aging Environments on Rheological Behavior and Structural Properties of Rubber Asphalt. Materials 2020, 13, 3376. [Google Scholar] [CrossRef] [PubMed]

- Petersen, J.C.; Glaser, R. Asphalt Oxidation Mechanisms and the Role of Oxidation Products on Age Hardening Revisited. Road Mater. Pavement Des. 2011, 12, 795–819. [Google Scholar] [CrossRef]

- Zhao, X.; Shen, A.; Ma, B. Temperature Adaptability of Asphalt Pavement to High Temperatures and Significant Temperature Differences. Adv. Mater. Sci. Eng. 2018, 2018, 9436321. [Google Scholar] [CrossRef]

- Liang, Y.; Wu, R.; Harvey, J.T.; Jones, D.; Alavi, M.Z. Investigation into the Oxidative Aging of Asphalt Binders. Transp. Res. Rec. 2019, 2673, 368–378. [Google Scholar] [CrossRef]

- Bastola, N.R.; Olson, B.; Teixeira, J.E.S.L.; Fatmehsari, H.H. Effects of the Simultaneous Use of Post-Industrial Polypropylene Waste Plastic and Soybean Oil Recycling Additive on the Performance of High-RAP Recycled Mixtures. Constr. Build. Mater. 2024, 424, 135945. [Google Scholar] [CrossRef]

- Chen, C.; Lu, J.; Ma, T.; Zhang, Y.; Gu, L.; Chen, X. Applications of Vegetable Oils and Their Derivatives as Bio-Additives for Use in Asphalt Binders: A Review. Constr. Build. Mater. 2023, 383, 131312. [Google Scholar] [CrossRef]

- Eltwati, A.; Mohamed, A.; Hainin, M.R.; Jusli, E.; Enieb, M. Rejuvenation of Aged Asphalt Binders by Waste Engine Oil and SBS Blend: Physical, Chemical, and Rheological Properties of Binders and Mechanical Evaluations of Mixtures. Constr. Build. Mater. 2022, 346, 128441. [Google Scholar] [CrossRef]

- Elkashef, M.; Podolsky, J.; Williams, R.C.; Cochran, E. Preliminary Examination of Soybean Oil Derived Material as a Potential Rejuvenator through Superpave Criteria and Asphalt Bitumen Rheology. Constr. Build. Mater. 2017, 149, 826–836. [Google Scholar] [CrossRef]

- Ji, J.; Yao, H.; Suo, Z.; You, Z.; Li, H.; Xu, S.; Sun, L. Effectiveness of Vegetable Oils as Rejuvenators for Aged Asphalt Binders. J. Mater. Civ. Eng. 2017, 29, D4016003. [Google Scholar] [CrossRef]

- Rogel, E.; Ovalles, C.; Moir, M. Asphaltene Chemical Characterization as a Function of Solubility: Effects on Stability and Aggregation. Energy Fuels 2012, 26, 2655–2662. [Google Scholar] [CrossRef]

- Portugal, A.C.X.; Lucena, L.C.d.F.L.; Lucena, A.E.d.F.L.; Beserra da Costa, D. Rheological Performance of Soybean in Asphalt Binder Modification. Road Mater. Pavement Des. 2018, 19, 768–782. [Google Scholar] [CrossRef]

- Baldino, N.; Marchesano, Y.M.; Mileti, O.; Lupi, F.R.; Gabriele, D. Thermo-Rheological Behaviour of Styrene-Butadiene-Styrene, Hard Plastics with or without Graphene Oxide Modified Bitumens. Case Stud. Constr. Mater. 2024, 20, e03354. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Rossi, C.O.; Seta, L.; Lupi, F.R.; Caputo, P. Low Temperature Rheology of Polyphosphoric Acid (PPA) Added Bitumen. Constr. Build. Mater. 2012, 36, 592–596. [Google Scholar] [CrossRef]

- Henning Winter, H. Soft Polymeric Materials near the Transition from Liquid to Solid State. Korea-Aust. Rheol. J. 1999, 11, 275–278. [Google Scholar]

- Becker M, Y.; Müller, A.; Rodriguez, Y. Use of Rheological Compatibility Criteria to Study SBS Modified Asphalts. J. Appl. Polym. Sci. 2003, 90, 1772–1782. [Google Scholar] [CrossRef]

- Baldino, N.; Gabriele, D.; Lupi, F.R.; Seta, L.; Zinno, R. Rheological Behaviour of Fresh Cement Pastes: Influence of Synthetic Zeolites, Limestone and Silica Fume. Cem. Concr. Res. 2014, 63, 38–45. [Google Scholar] [CrossRef]

- Ljubić, D.; Stamenović, M.; Smithson, C.; Nujkić, M.; Međo, B.; Putić, S. Time-Temperature Superposition Principle-Application of WLF Equation in Polymer Analysis and Composites. Zast. Mater. 2014, 55, 395–400. [Google Scholar] [CrossRef]

- Seidel, J.C.; Haddock, J.E. Rheological Characterization of Asphalt Binders Modified with Soybean Fatty Acids. Constr. Build. Mater. 2014, 53, 324–332. [Google Scholar] [CrossRef]

- Giulia, T.; Aikaterini, V.; Claudio, L.; Athanasios, S.; Cesare, S. Effects of Different Aging Methods on Chemical and Rheological Properties of Bitumen. J. Mater. Civ. Eng. 2018, 30, 04018009. [Google Scholar] [CrossRef]

- Zhang, X.; Ning, Y.; Zhou, X.; Xu, X.; Chen, X. Quantifying the Rejuvenation Effects of Soybean-Oil on Aged Asphalt-Binder Using Molecular Dynamics Simulations. J. Clean. Prod. 2021, 317, 128375. [Google Scholar] [CrossRef]

| SARA Component | % w/w |

|---|---|

| Satures | 5.70 |

| Aromatics | 48.60 |

| Resins | 20.90 |

| Asphaltenes | 25.80 |

| ID Sample | fc, Hz | Tc, °C | k, Pasn | n, - | R2 |

|---|---|---|---|---|---|

| API | - | - | 50,100 ± 900 | 0.718 ± 0.004 | 0.999 |

| PAV | 6.5 ± 2.0 | 33.5 ± 1.0 | 691,000 ± 15,000 | 0.438 ± 0.005 | 0.996 |

| RAP_S | 4.5 ± 0.5 | 32.4 ± 0.5 | 1,390,000 ± 30,000 | 0.417 ± 0.005 | 0.995 |

| RAP_H | 0.042 ± 0.011 | 58.0 ± 0.4 | 5,728,000 ± 60,000 | 0.329 ± 0.004 | 0.995 |

| PAV 3S | 14.7 ± 2.4 | 30.0 ± 0.5 | 316,000 ± 6000 | 0.462 ± 0.004 | 0.998 |

| RAP_S 3S | 2.05 ± 0.66 | 34.5 ± 0.3 | 1,101,000 ± 10,000 | 0.459 ± 0.002 | 0.999 |

| RAP_H 3S | 0.045 ± 0.020 | 59.5 ± 1.0 | 3,098,000 ± 50,000 | 0.308 ± 0.005 | 0.988 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baldino, N.; Mileti, O.; Marchesano, Y.M.; Lupi, F.R.; Gabriele, D.; Paolini, M. Rheological Performance and Differences between Laboratory-Aged and RAP Bitumen. Materials 2024, 17, 3954. https://doi.org/10.3390/ma17163954

Baldino N, Mileti O, Marchesano YM, Lupi FR, Gabriele D, Paolini M. Rheological Performance and Differences between Laboratory-Aged and RAP Bitumen. Materials. 2024; 17(16):3954. https://doi.org/10.3390/ma17163954

Chicago/Turabian StyleBaldino, Noemi, Olga Mileti, Ylenia Maria Marchesano, Francesca R. Lupi, Domenico Gabriele, and Massimo Paolini. 2024. "Rheological Performance and Differences between Laboratory-Aged and RAP Bitumen" Materials 17, no. 16: 3954. https://doi.org/10.3390/ma17163954

APA StyleBaldino, N., Mileti, O., Marchesano, Y. M., Lupi, F. R., Gabriele, D., & Paolini, M. (2024). Rheological Performance and Differences between Laboratory-Aged and RAP Bitumen. Materials, 17(16), 3954. https://doi.org/10.3390/ma17163954