Blistering Behavior of Beryllium and Beryllium Alloy under High-Dose Helium Ion Irradiation

Abstract

:1. Introduction

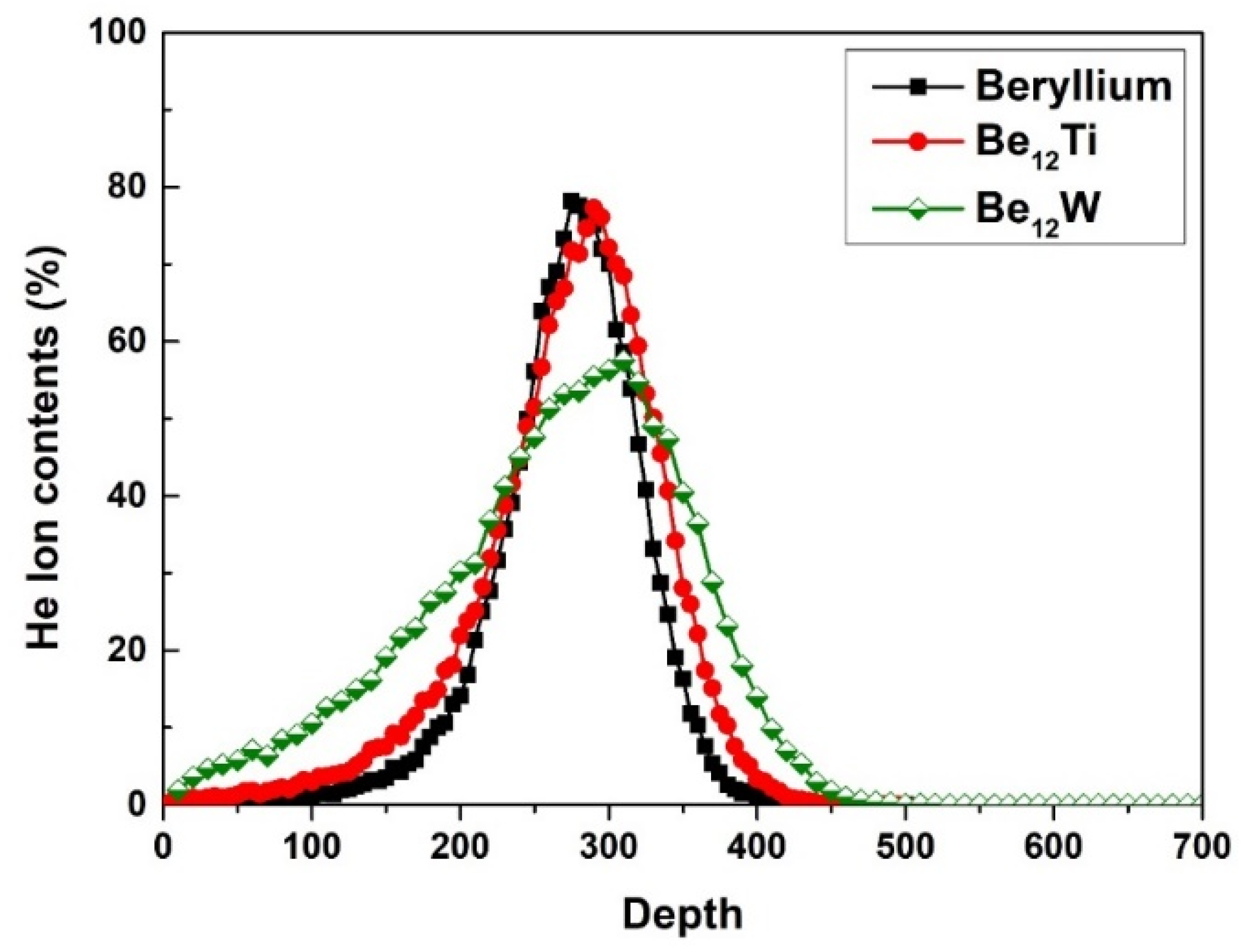

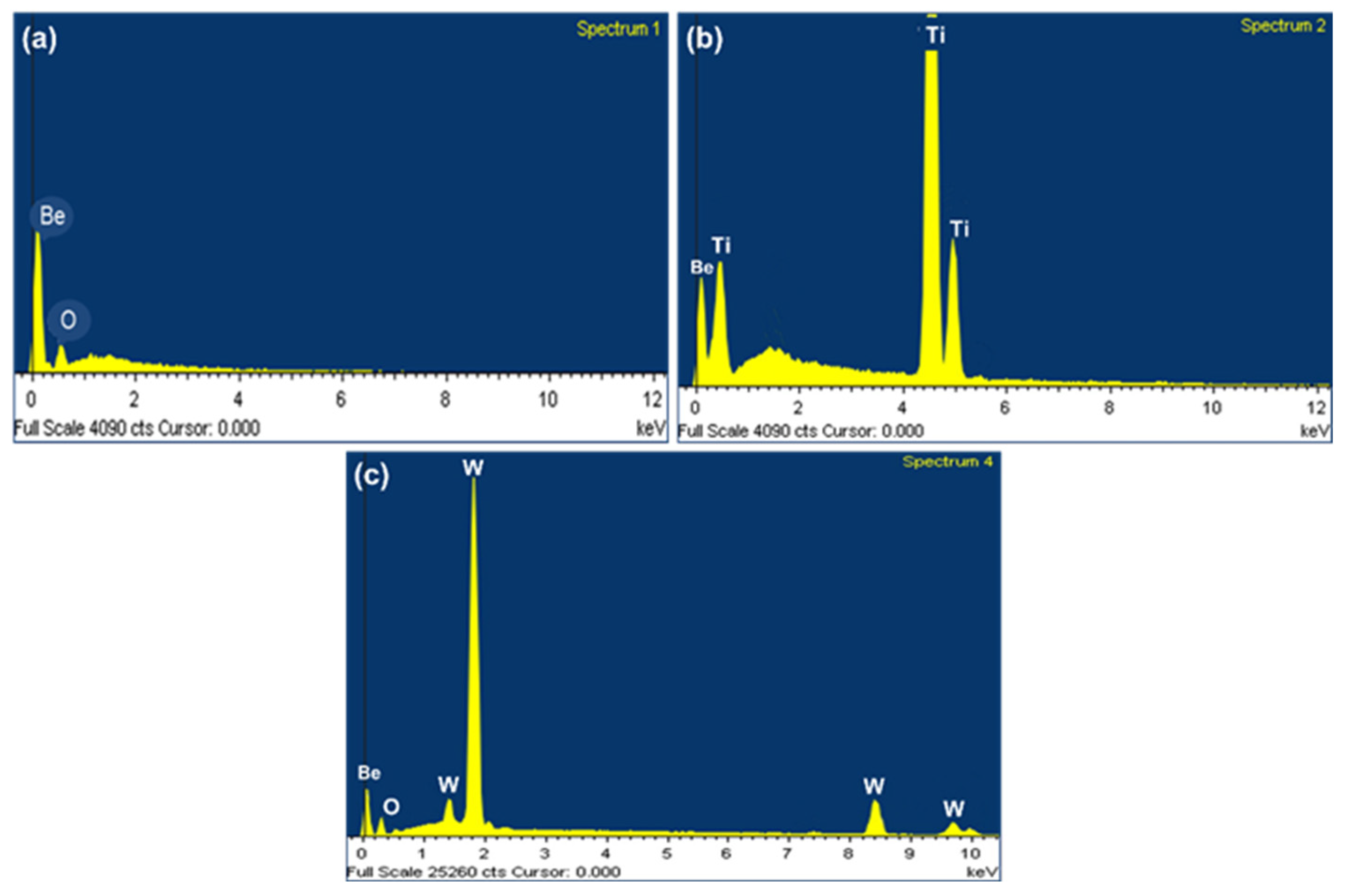

2. Experimental Procedure

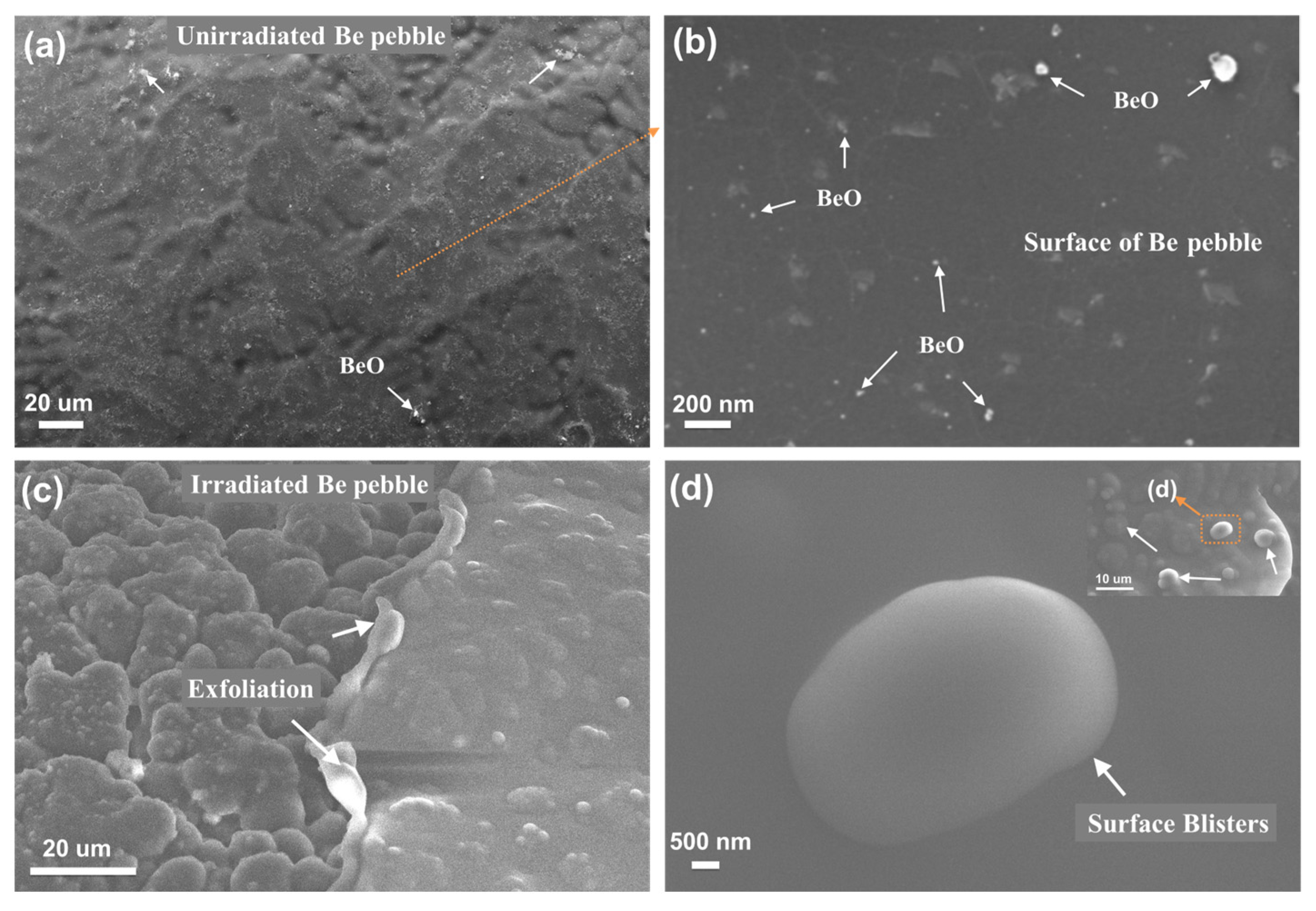

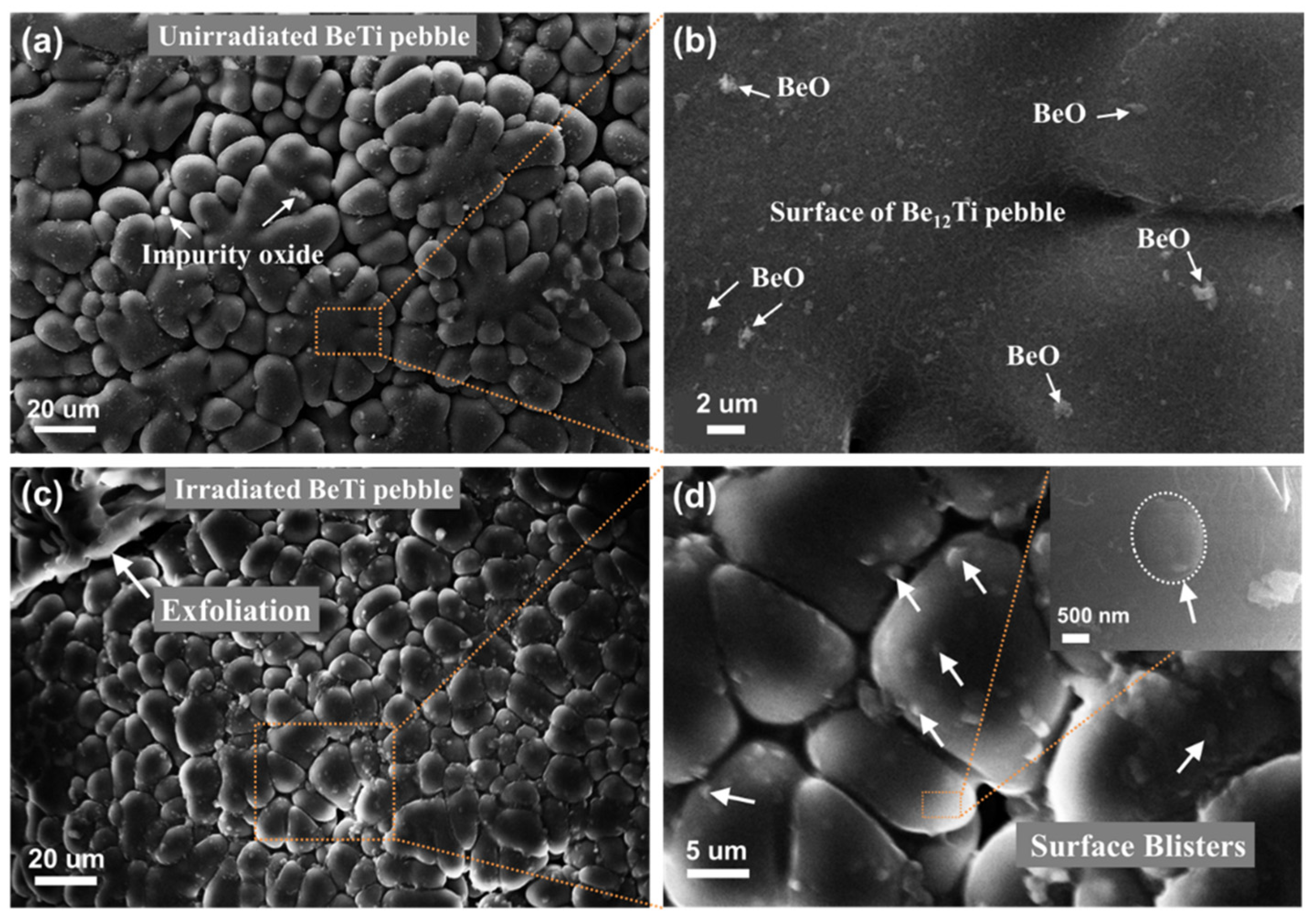

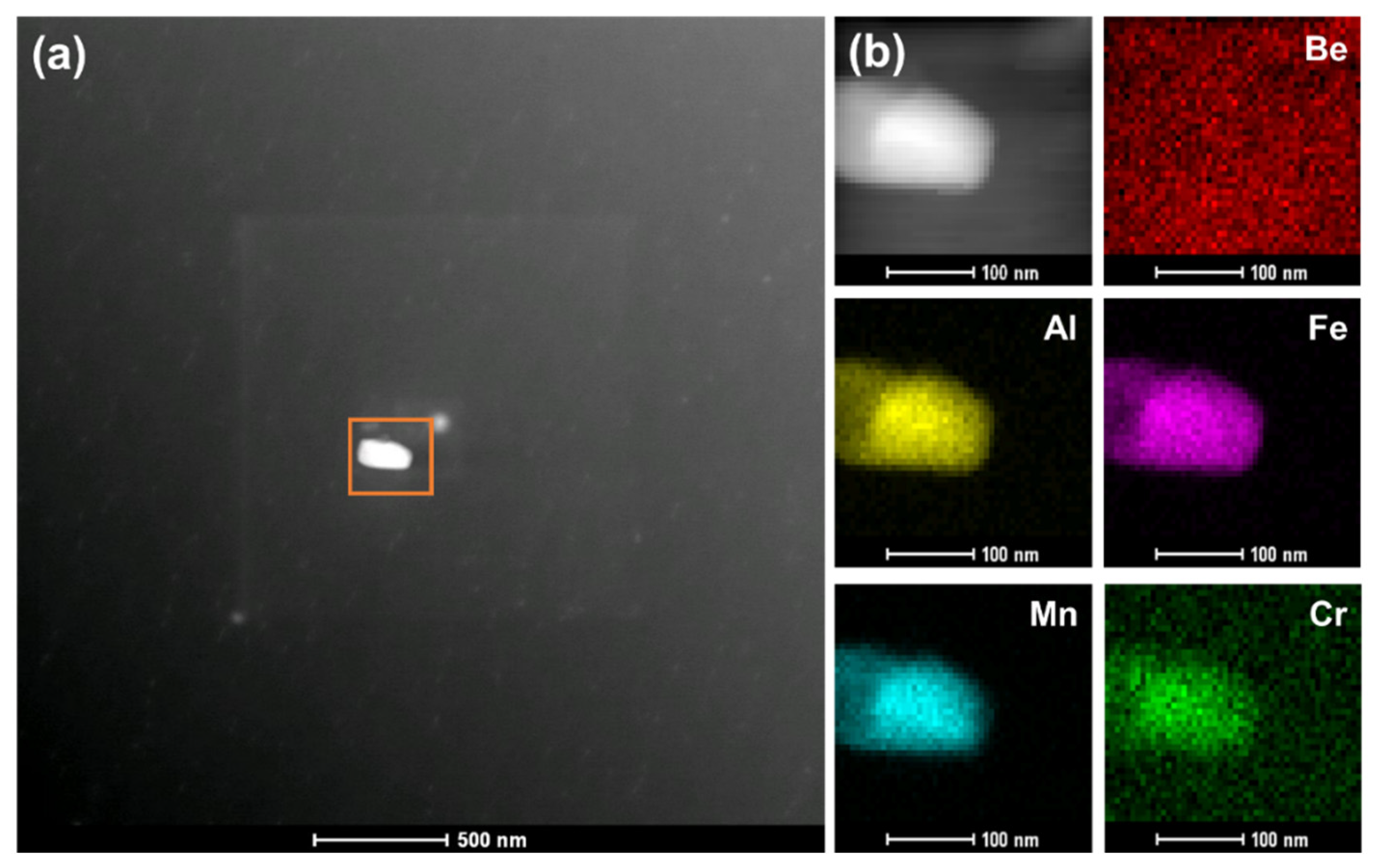

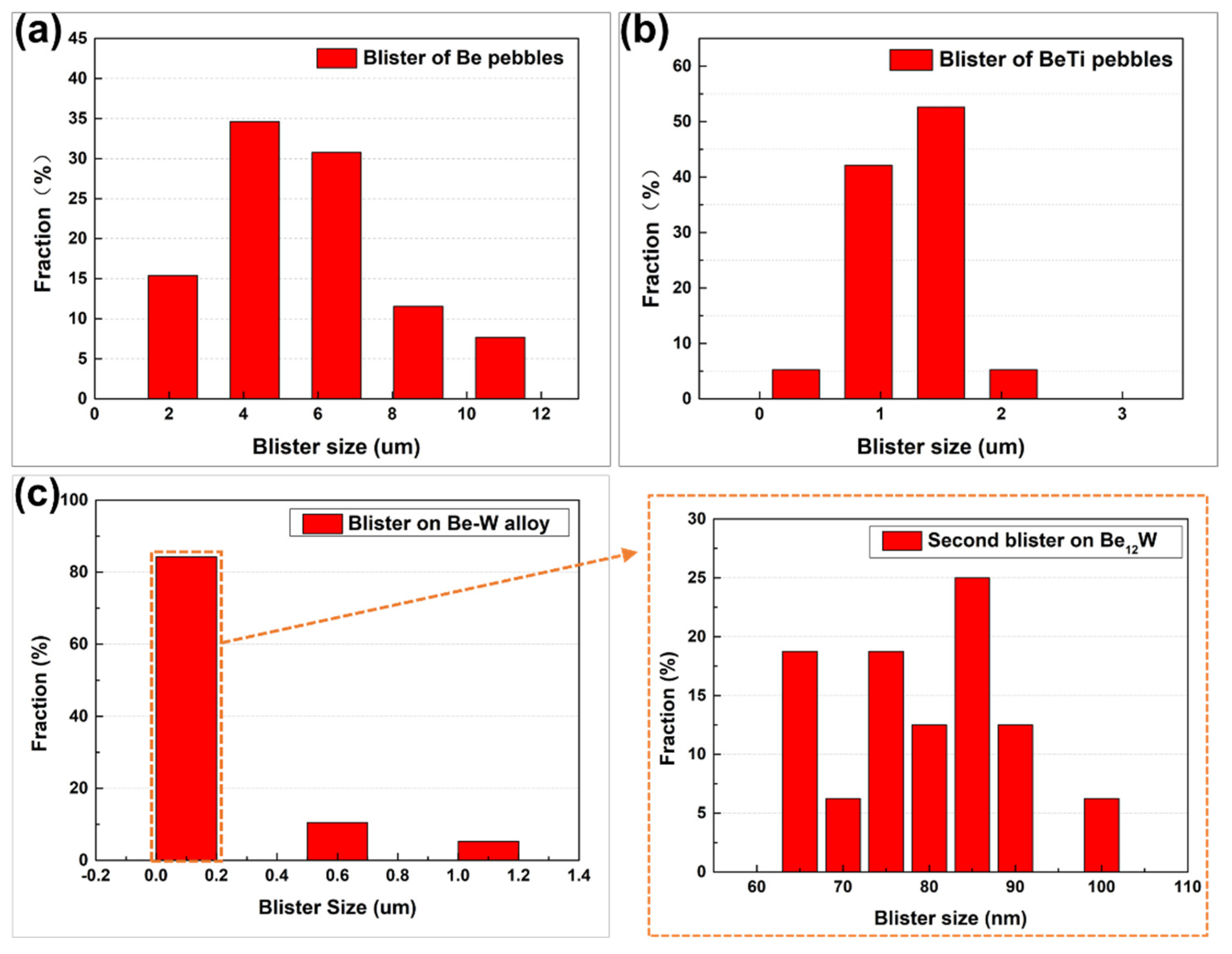

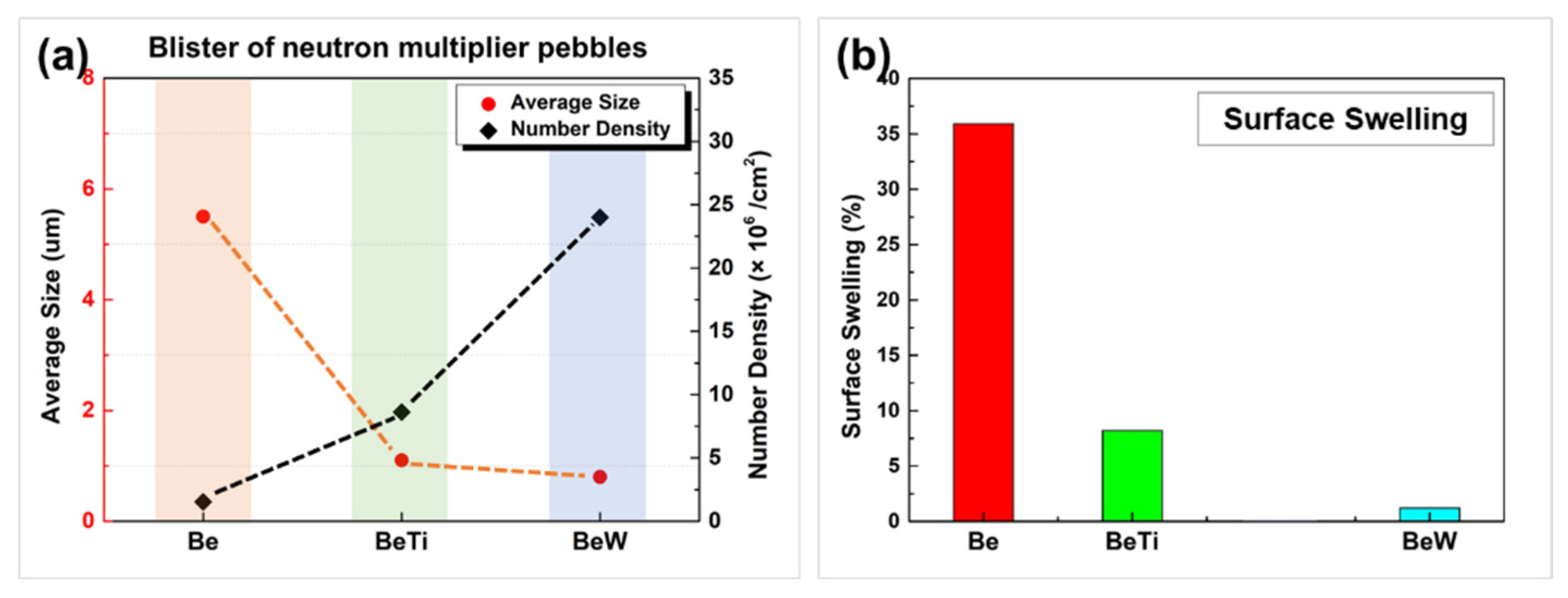

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Field, G.B.; Bahcall, J.N. Lyman Spitzer Jr (1914-97). Nature 1997, 387, 244. [Google Scholar] [CrossRef]

- Bondarenko, B.D. Role played by O A Lavrent’ev in the formulation of the problem and the initiation of research into controlled nuclear fusion in the USSR. Phys. Usp. 2001, 8, 844–851. [Google Scholar] [CrossRef]

- Giancarli, L.M.; Abdou, M.; Campbell, D.J.; Chuyanov, V.A.; Ahn, M.Y.; Enoeda, M.; Pan, C.; Poitevin, Y.; Kumar, E.R.; Ricapito, I.; et al. Overview of the ITER TBM Program. Fusion Eng. Des. 2012, 87, 395–402. [Google Scholar] [CrossRef]

- Zinkle, S.J.; Was, G.S. Materials challenges in nuclear energy. Acta Mater. 2013, 61, 735–758. [Google Scholar] [CrossRef]

- Poitevin, Y.; Boccaccini, L.V.; Zmitko, M.; Ricapito, I.; Salavy, J.F.; Diegele, E.; Gabriel, F.; Magnani, E.; Neuberger, H.; Lässer, R.; et al. Tritium breeder blankets design and technologies in Europe: Development status of ITER Test Blanket Modules, test & qualification strategy and roadmap towards DEMO. Fusion Eng. Des. 2010, 85, 2340–2347. [Google Scholar]

- Feng, K.M.; Pan, C.H.; Zhang, G.S.; Luo, T.Y.; Zhao, Z.; Chen, Y.J.; Feng, Y.J.; Ye, X.F.; Hu, G.; He, K.H. Progress on design and R&D for helium-cooled ceramic breeder TBM in China. Fusion Eng. Des. 2012, 87, 1138–1145. [Google Scholar]

- Liu, P.; Zhan, Q.; Hu, W.; Jia, Y.; Han, W.; Yi, X.; Wan, F. Microstructure evolution of beryllium with argon ion irradiation. Nucl. Mater. Energy 2017, 13, 99–103. [Google Scholar] [CrossRef]

- Gao, X.; Wan, B.; Song, Y.; Li, J.; Wan, Y. Progress on CFETR physics and engineering. Sci. Sin. Phys. Mech. Astron. 2019, 49, 045202. [Google Scholar] [CrossRef]

- Vladimirov, P.; Bachurin, D.; Borodin, V.; Chakin, V.; Ganchenkova, M.; Fedorov, A.; Klimenkov, M.; Kupriyanov, I.; Moeslang, A.; Nakamichi, M. Current Status of Beryllium Materials for Fusion Blanket Applications. Fusion Sci. Technol. 2014, 66, 28–37. [Google Scholar] [CrossRef]

- Chakin, V.; Rolli, R.; Moeslang, A.; Klimenkov, M.; Kolb, M.; Vladimirov, P.; Kurinskiy, P.; Schneider, H.; van Til, S.; Magielsen, A.J. Tritium release and retention properties of highly neutron-irradiated beryllium pebbles from HIDOBE-01 experiment. J. Nucl. Mater. 2013, 442, S483–S489. [Google Scholar] [CrossRef]

- Klimenkov, M.; Vladimirov, P.; Jäntsch, U.; Kuksenko, V.; Rolli, R.; Möslang, A.; Zimber, N. New insights into microstructure of irradiated beryllium based on experiments and computer simulations. Sci. Rep. 2020, 10, 8042. [Google Scholar] [CrossRef] [PubMed]

- Kawamura, H.; Takahashi, H.; Yoshida, N.; Shestakov, V.; Ito, Y.; Uchida, M.; Yamada, H.; Nakamichi, M.; Ishitsuka, E. Application of beryllium intermetallic compounds to neutron multiplier of fusion blanket. Fusion Eng. Des. 2002, 61–62, 391–397. [Google Scholar] [CrossRef]

- Kurinskiy, P.; Moeslang, A.; Chakin, V.; Klimenkov, M.; Rolli, R.; van Til, S.; Goraieb, A.A. Characteristics of microstructure, swelling and mechanical behaviour of titanium beryllide samples after high-dose neutron irradiation at 740 and 873 K. Fusion Eng. Des. 2013, 88, 2198–2201. [Google Scholar] [CrossRef]

- Hwang, T.; Kim, J.; Sugimoto, Y.; Akatsu, Y.; Nakano, S.; Nakamichi, M. Development of advanced ternary beryllium intermetallic compounds. Fusion Eng. Des. 2024, 200, 114221. [Google Scholar] [CrossRef]

- Hwang, T.; Kim, J.; Sugimoto, Y.; Akatsu, Y.; Nakano, S.; Nakamichi, M. Tensile properties of beryllium-titanium intermetallic compounds. Fusion Eng. Des. 2023, 191, 113739. [Google Scholar] [CrossRef]

- Hwang, T.; Kim, J.; Nakano, S.; Nakamichi, M. Mechanical properties of beryllium-titanium intermetallic compounds fabricated by plasma sintering. Nucl. Mater. Energy 2022, 30, 101117. [Google Scholar] [CrossRef]

- Gaisin, R.; Frants, Y.; Kolmakov, M.; Zorin, B.; Kylyshkanov, M.; Podoinikov, M.; Udartsev, S.; Vechkutov, A.; Chakin, V.; Vladimirov, P. Beryllium intermetallics: Industrial experience on development and manufacture. Nucl. Mater. Energy 2023, 35, 101444. [Google Scholar] [CrossRef]

- Kawamura, H.; Uchida, M.; Shestakov, V. Compatibility between Be12Ti and SS316LN. J. Nucl. Mater. 2002, 307–311, 638–642. [Google Scholar] [CrossRef]

- Iwakiri, H.; Yasunaga, K.; Yoshida, N.; Uchida, M.; Kawamura, H. Thermal desorption of deuterium from ion irradiated Be12Ti. J. Nucl. Mater. 2004, 329–333, 880–884. [Google Scholar] [CrossRef]

- Munakata, K.; Kawamura, H.; Uchida, M. Stability of titanium beryllide under water vapor. J. Nucl. Mater. 2004, 329–333, 1357–1360. [Google Scholar] [CrossRef]

- Zimber, N.; Lammer, J.; Vladimirov, P.; Kothleitner, G.; Keast, V.J.; Dürrschnabel, M.; Klimenkov, M. Hydrogen and helium trapping in hcp beryllium. Commun. Chem. 2023, 6, 76. [Google Scholar] [CrossRef] [PubMed]

- Chakin, V.; Rolli, R.; Klimenkov, M.; Zmitko, M. Tritium release and retention in beryllium pebbles irradiated up to 640 appm tritium and 6000 appm helium. J. Nucl. Mater. 2020, 542, 152521. [Google Scholar] [CrossRef]

- Chakin, V.; Rolli, R.; Gaisin, R.; Hoeppener-Kramar, U.; Nakamichi, M.; Zmitko, M. Tritium release and retention in beryllium and titanium beryllide after neutron irradiation up to damage doses of 23-38 dpa. Fusion Eng. Des. 2020, 161, 111938. [Google Scholar] [CrossRef]

- Chakin, V.; Klimenkov, M.; Rolli, R.; Kurinskiy, P.; Moeslang, A.; Dorn, C. Microstructural and tritium release examination of titanium beryllides. J. Nucl. Mater. 2011, 417, 769–774. [Google Scholar] [CrossRef]

- Nakamichi, M.; Kim, J.; Wakai, D.; Yonehara, K. Development of a synthesis method of beryllides as advanced neutron multiplier for DEMO reactors. Fusion Eng. Des. 2012, 87, 896–899. [Google Scholar] [CrossRef]

- Nakamichi, M.; Kim, J.H. Homogenization treatment to stabilize the compositional structure of beryllide pebbles. J. Nucl. Mater. 2013, 440, 530–533. [Google Scholar] [CrossRef]

- Nakamichi, M.; Kim, J.H.; Miyamoto, M. Fabrication and characterization of advanced neutron multipliers for DEMO blanket. Nucl. Mater. Energy 2016, 9, 55–58. [Google Scholar] [CrossRef]

- Kim, J.H.; Hwang, T.; Nakano, S.; Miyamoto, M.; Nakamichi, M. Deuterium desorption and retention of Beryllium intermetallic compounds for fusion applications. J. Nucl. Mater. 2021, 550, 152936. [Google Scholar] [CrossRef]

- Liu, P.P.; Xue, L.W.; Hu, W.; Yu, L.P.; Zhao, H.F.; Wang, K.; Xue, F.J.; Jia, Y.M.; Zhan, Q.; Wan, F.R. Mechanical compression behaviors of single phase Be and binary Be12Ti pebbles. Fusion Eng. Des. 2019, 144, 202–208. [Google Scholar] [CrossRef]

- Ziegler, J.F. SRIM-2013 Program. 2013. Available online: http://www.srim.org/ (accessed on 8 August 2024).

- Sun, Y.; Diao, S.Z.; Liu, P.P.; Zhan, Q.; Wan, F.R. Anomalies in the calculation of dpa by using damage energy method based on full-cascades option of SRIM. Ann. Nucl. Energy 2023, 183, 109667. [Google Scholar] [CrossRef]

- Jia, Y.M.; Feng, Y.J.; Zhang, J.L.; Liu, P.P.; Zhan, Q.; Wan, F.R. Synthesis of beryllium pebbles using plasma rotating electrode process. In High Performance Structural Materials, Proceedings of the Chinese Materials Conference 2017 18th, Yinchuan, China, 6–12 July 2017; Springer: Singapore, 2018; pp. 17–23. [Google Scholar] [CrossRef]

- Liu, P.P.; Hu, W.; Song, J.; Jia, Y.M.; Zhan, Q.; Wan, F.R. Effect of high dose helium ion irradiation on the surface microstructure of a new neutron multiplying Be−W alloy. Chin. J. Eng. 2020, 42, 128–133. [Google Scholar]

- Nakamichi, M.; Kim, J.H. Fabrication and hydrogen generation reaction with water vapor of prototypic pebbles of binary beryllides as advanced neutron multiplier. Fusion Eng. Des. 2015, 98–99, 1838–1842. [Google Scholar] [CrossRef]

- Nakamichi, M.; Kim, J.H.; Munakata, K.; Shibayama, T.; Miyamoto, M. Preliminary characterization of plasma-sintered beryllides as advanced neutron multipliers. J. Nucl. Mater. 2013, 442 (Suppl. S1), S465–S471. [Google Scholar] [CrossRef]

- Kim, J.; Nakamichi, M. Optimization of synthesis conditions for plasma-sintered beryllium–titanium intermetallic compounds. J. Alloys Compd. 2013, 577, 90–96. [Google Scholar] [CrossRef]

- Trinkaus, H. Modeling of helium effects in metals: High temperature embrittlement. J. Nucl. Mater. 1985, 133, 105–112. [Google Scholar] [CrossRef]

- Trinkaus, H. On the modeling of the high-temperature embrittlement of metals containing helium. J. Nucl. Mater. 1983, 118, 39–49. [Google Scholar] [CrossRef]

- Zhang, C.H.; Chen, K.Q.; Wang, Y.S.; Sun, J.G.; Shen, D.Y. Formation of bubbles in helium implanted 316L stainless steel at temperatures between 25 and 550 °C. J. Nucl. Mater. 1997, 245, 210–216. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Yu, Y.; Luo, G.; Shu, X.; Lu, G. Helium defects interactions and mechanism of helium bubble growth in tungsten: A molecular dynamics simulation. J. Nucl. Mater. 2014, 451, 356–360. [Google Scholar] [CrossRef]

- Trinkaus, H.; Singh, B.N. Helium accumulation in metals during irradiation-where do we stand? J. Nucl. Mater. 2003, 323, 229–242. [Google Scholar] [CrossRef]

- Stoller, R.E.; Odette, G.R. Analytical Solutions For Hellium Bubble And Critical Radius Parameters. J. Nucl. Mater. 1985, 131, 118–125. [Google Scholar] [CrossRef]

- Taller, S.; Was, G.S. Understanding bubble and void nucleation in dual ion irradiated T91 steel using single parameter experiments. Acta Mater. 2020, 198, 47–60. [Google Scholar] [CrossRef]

- Evans, J.H. An interbubble fracture mechanism of blister formation on helium-irradiated metals. J. Nucl. Mater. 1977, 68, 129–140. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.-P.; Wang, Q.-C.; Jia, Y.-M.; Han, W.-T.; Yi, X.-O.; Zhan, Q.; Wan, F.-R. Blistering Behavior of Beryllium and Beryllium Alloy under High-Dose Helium Ion Irradiation. Materials 2024, 17, 3997. https://doi.org/10.3390/ma17163997

Liu P-P, Wang Q-C, Jia Y-M, Han W-T, Yi X-O, Zhan Q, Wan F-R. Blistering Behavior of Beryllium and Beryllium Alloy under High-Dose Helium Ion Irradiation. Materials. 2024; 17(16):3997. https://doi.org/10.3390/ma17163997

Chicago/Turabian StyleLiu, Ping-Ping, Qi-Cong Wang, Yu-Mei Jia, Wen-Tuo Han, Xiao-Ou Yi, Qian Zhan, and Fa-Rong Wan. 2024. "Blistering Behavior of Beryllium and Beryllium Alloy under High-Dose Helium Ion Irradiation" Materials 17, no. 16: 3997. https://doi.org/10.3390/ma17163997