Towards the Reuse of Fire Retarded Polyamide 12 for Laser Sintering

Abstract

:1. Introduction

2. Materials and Methods

- Warm-up temperature: 151 °C

- Printing temperature: 153 °C

- Laser scan speed: 2.85 m·s−1

- Laser power: 3.64 W

- Layer height: 0.1 mm

- Time to ignition (TTI)

- Peak of rate release rate (pHRR)

- Mass loss rate

- Total heat released (THR)

- Maximum of average rate of heat emission (MARHE) as a function of time.

3. Results and Discussions

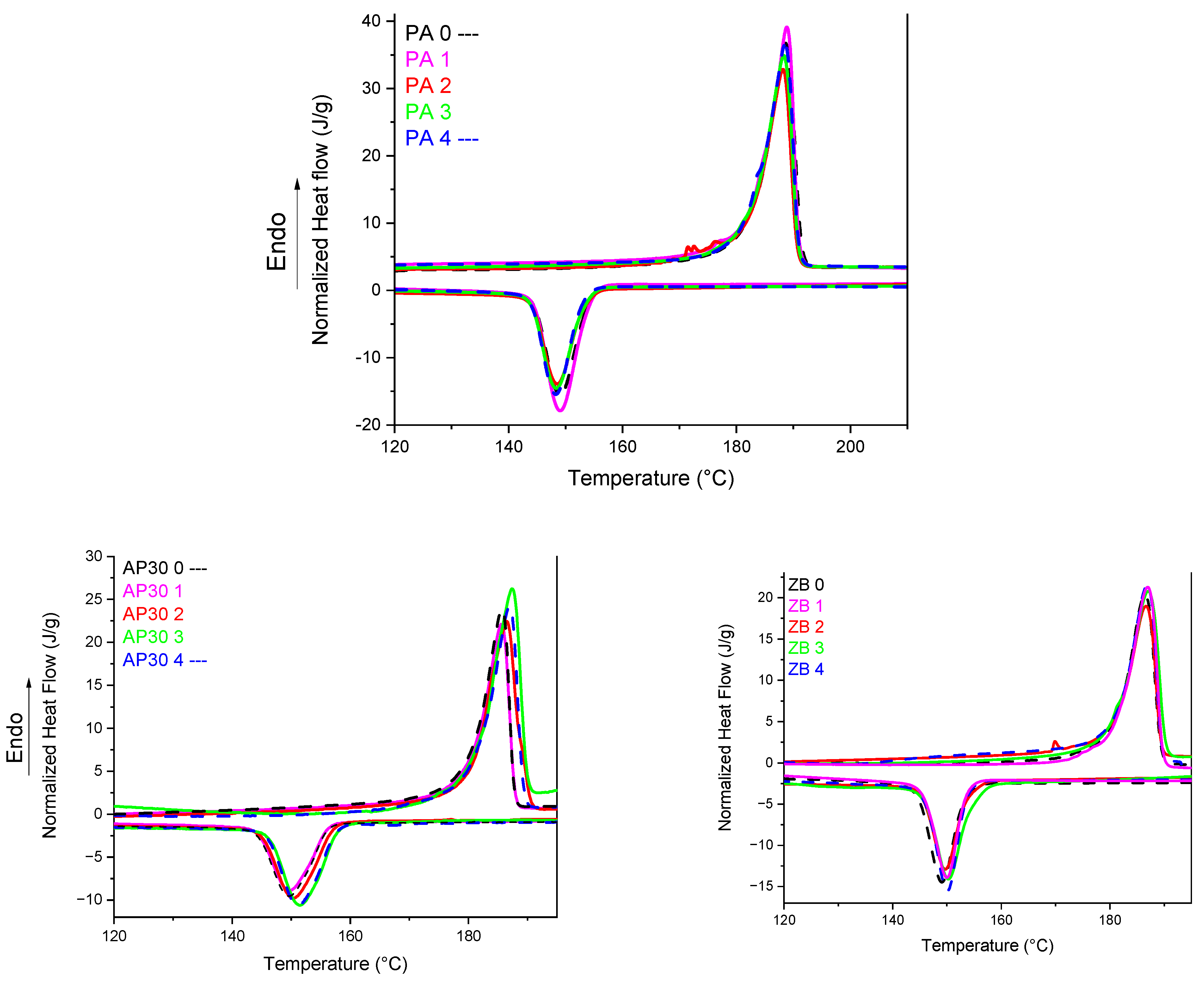

3.1. DSC Thermograms

3.1.1. Analysis of Initial and Reused Powder Blends

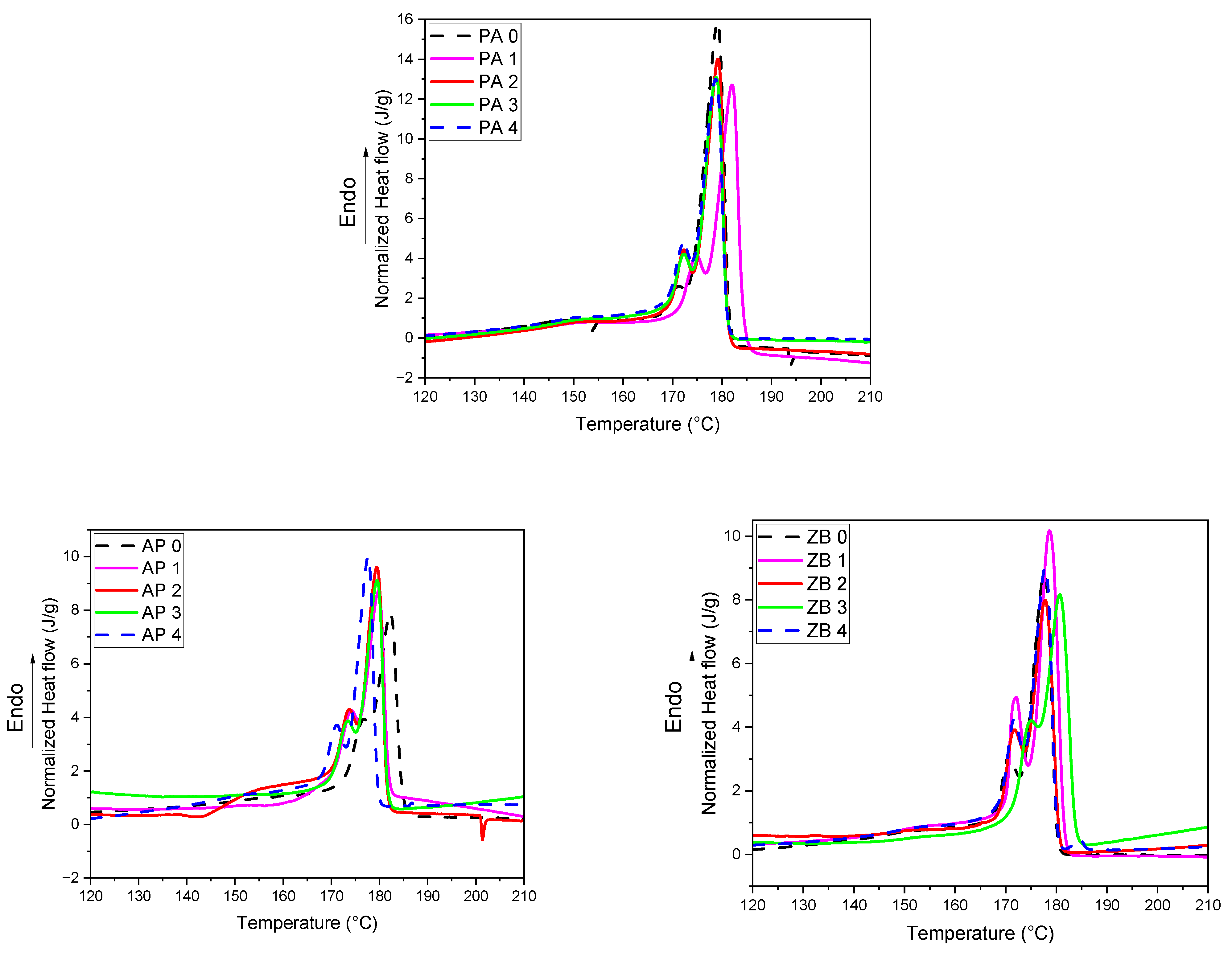

3.1.2. Analysis of Specimens as Function of Reuse Cycles and Compositions

3.2. Porosity of Specimens

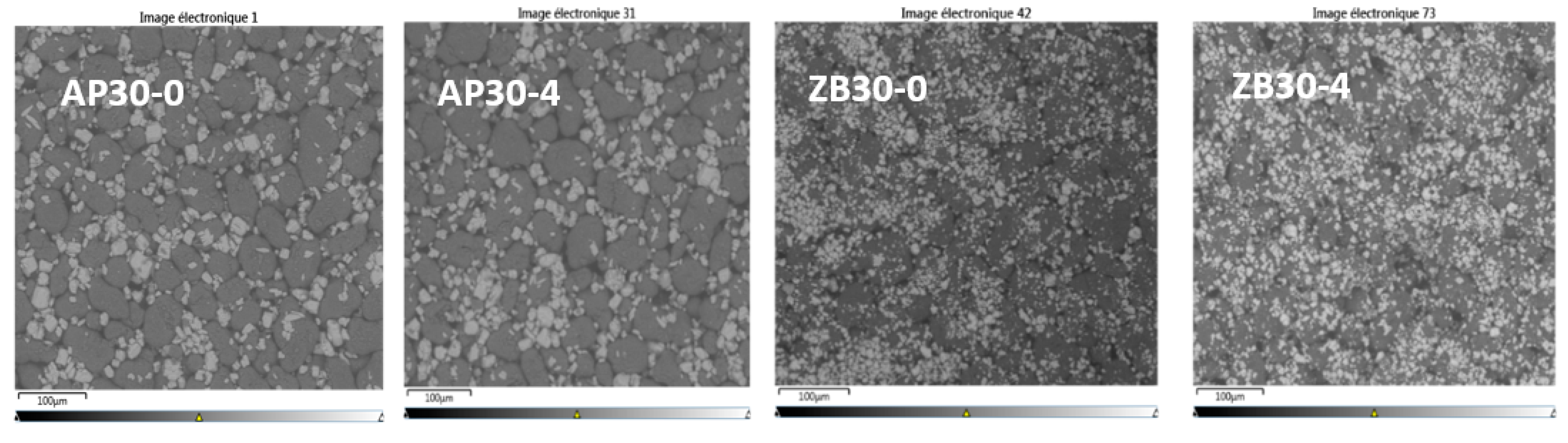

3.3. EDX of Powders

3.4. Properties of LS Parts

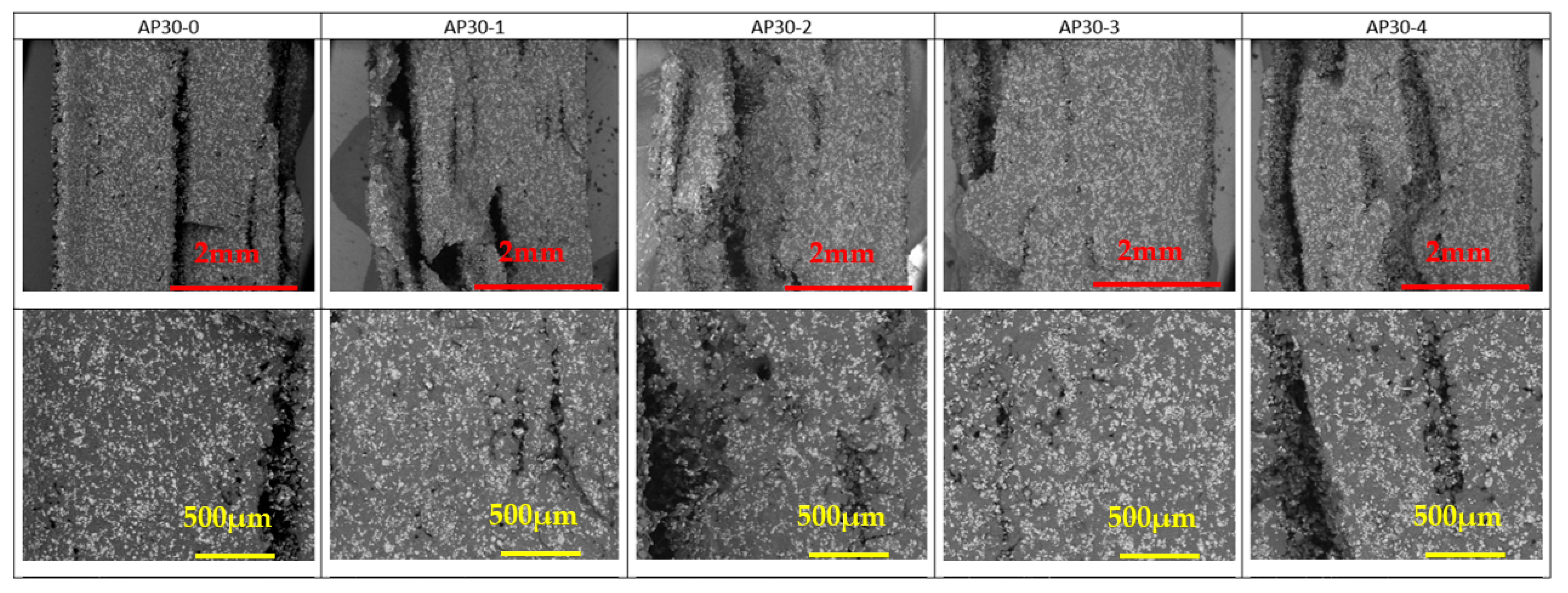

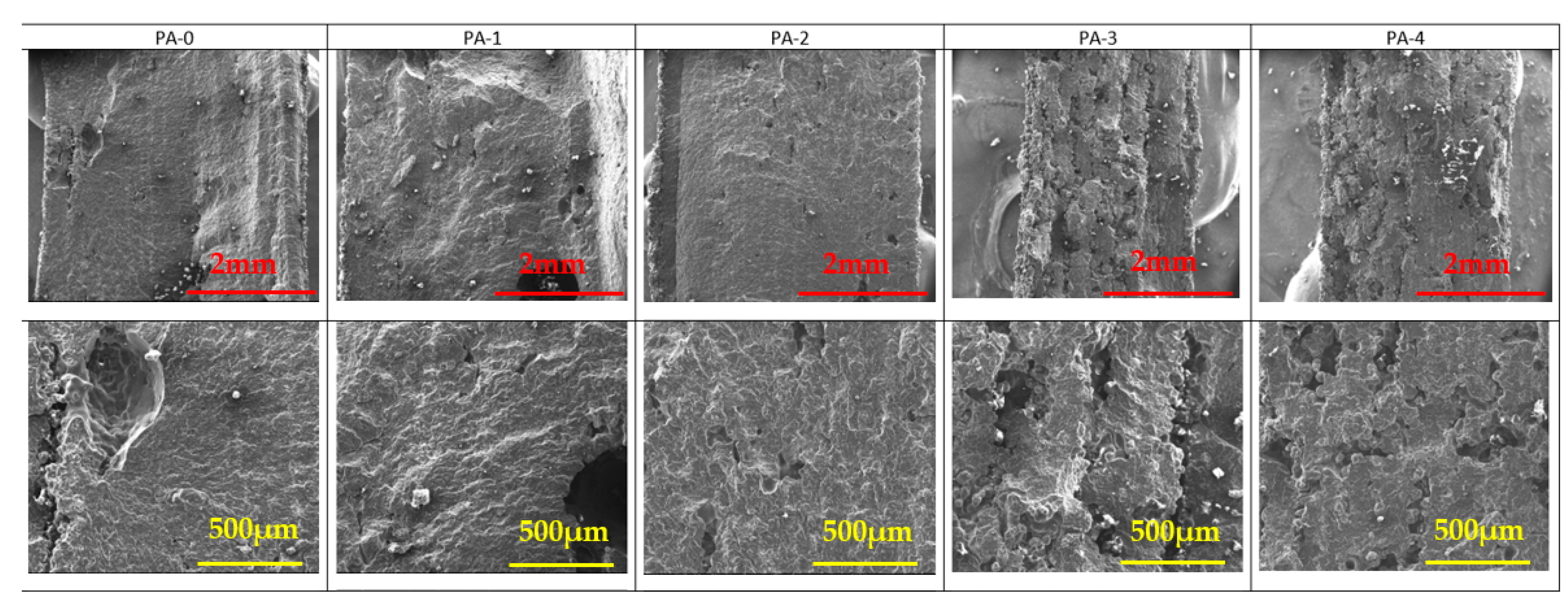

3.4.1. Scanning Electron Microscopy (SEM)

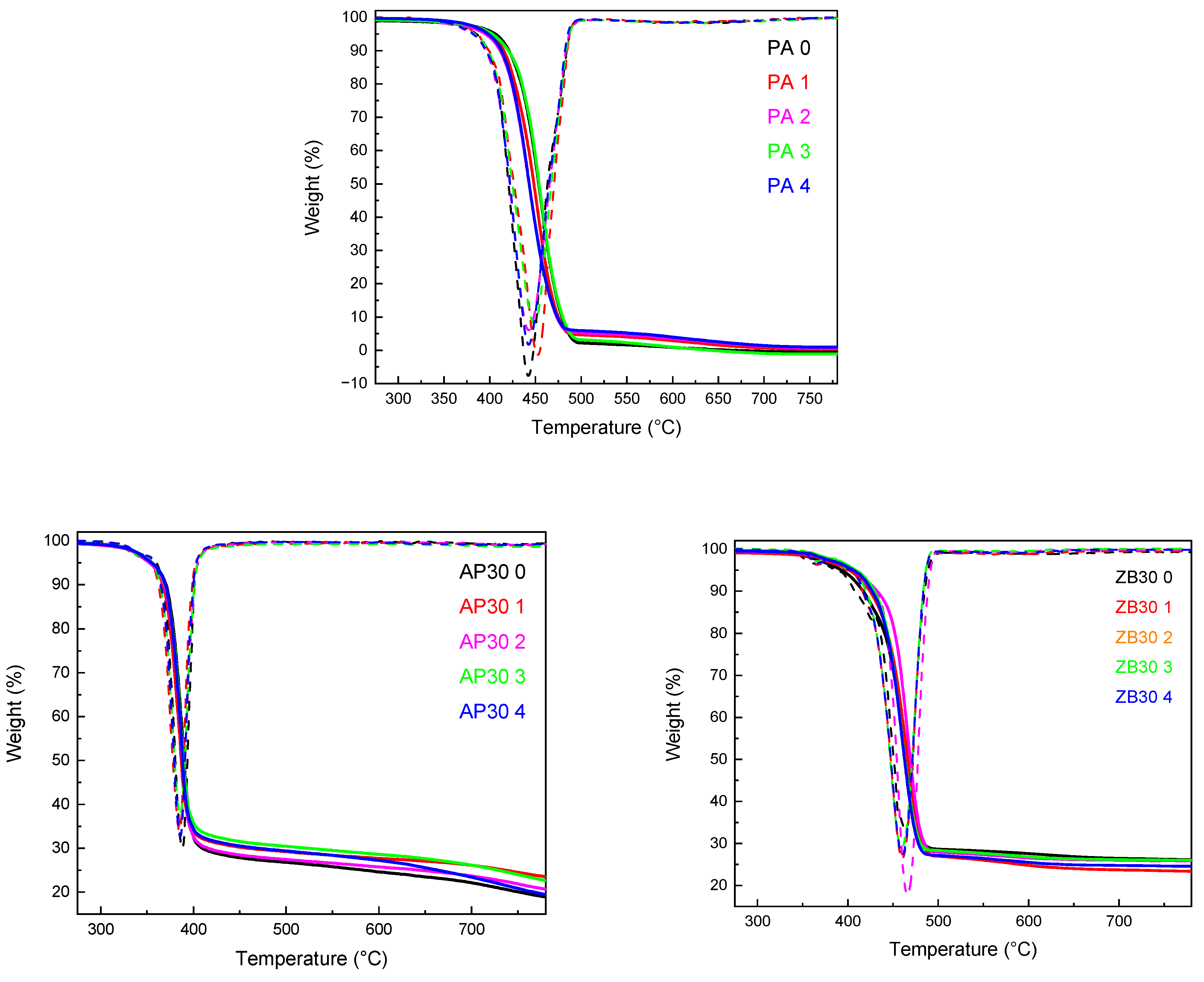

3.4.2. Thermal Stability (Thermogravimetric Analysis—TGA)

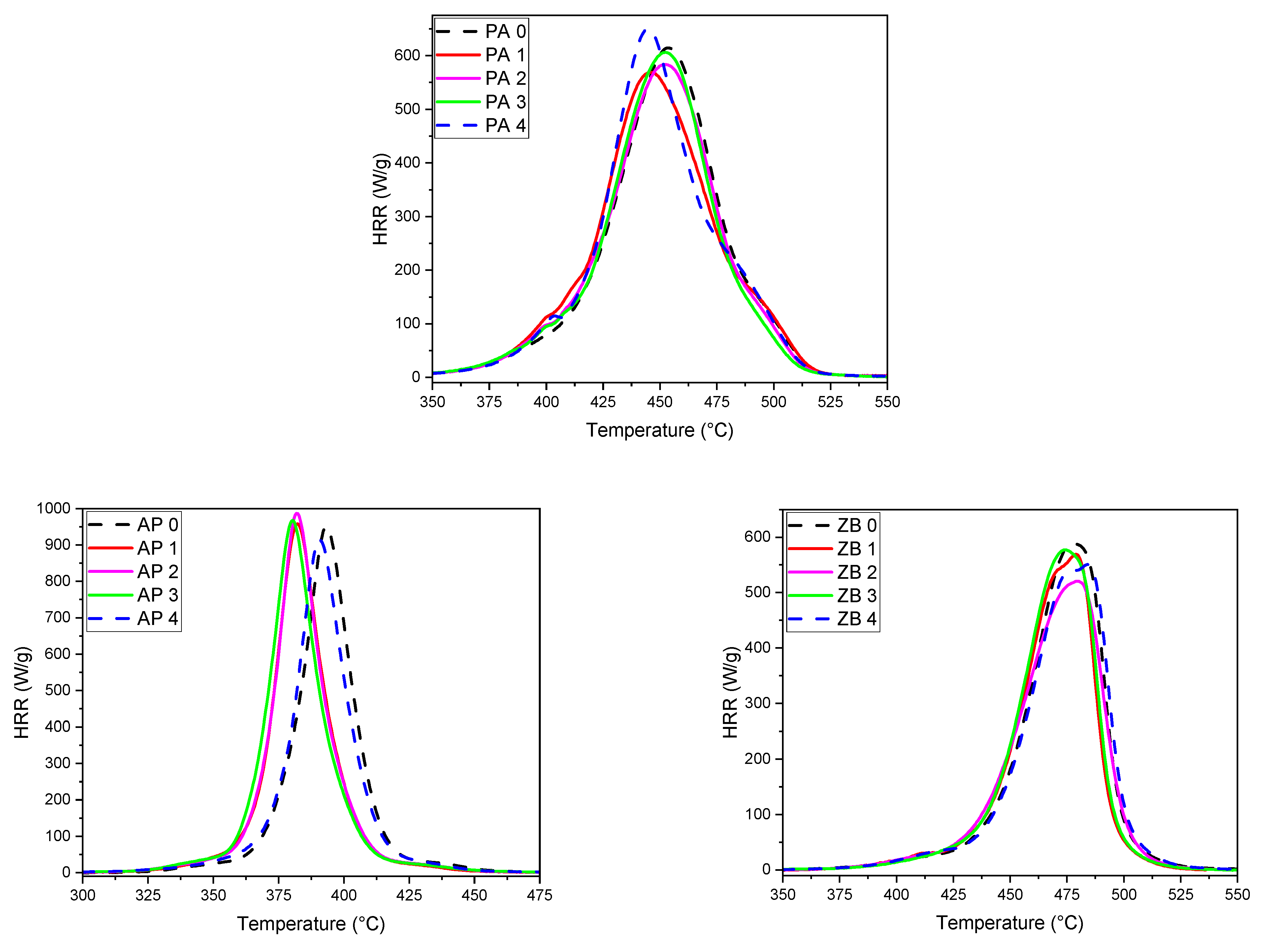

3.4.3. Fire Behavior at Microscopic Scale—PCFC

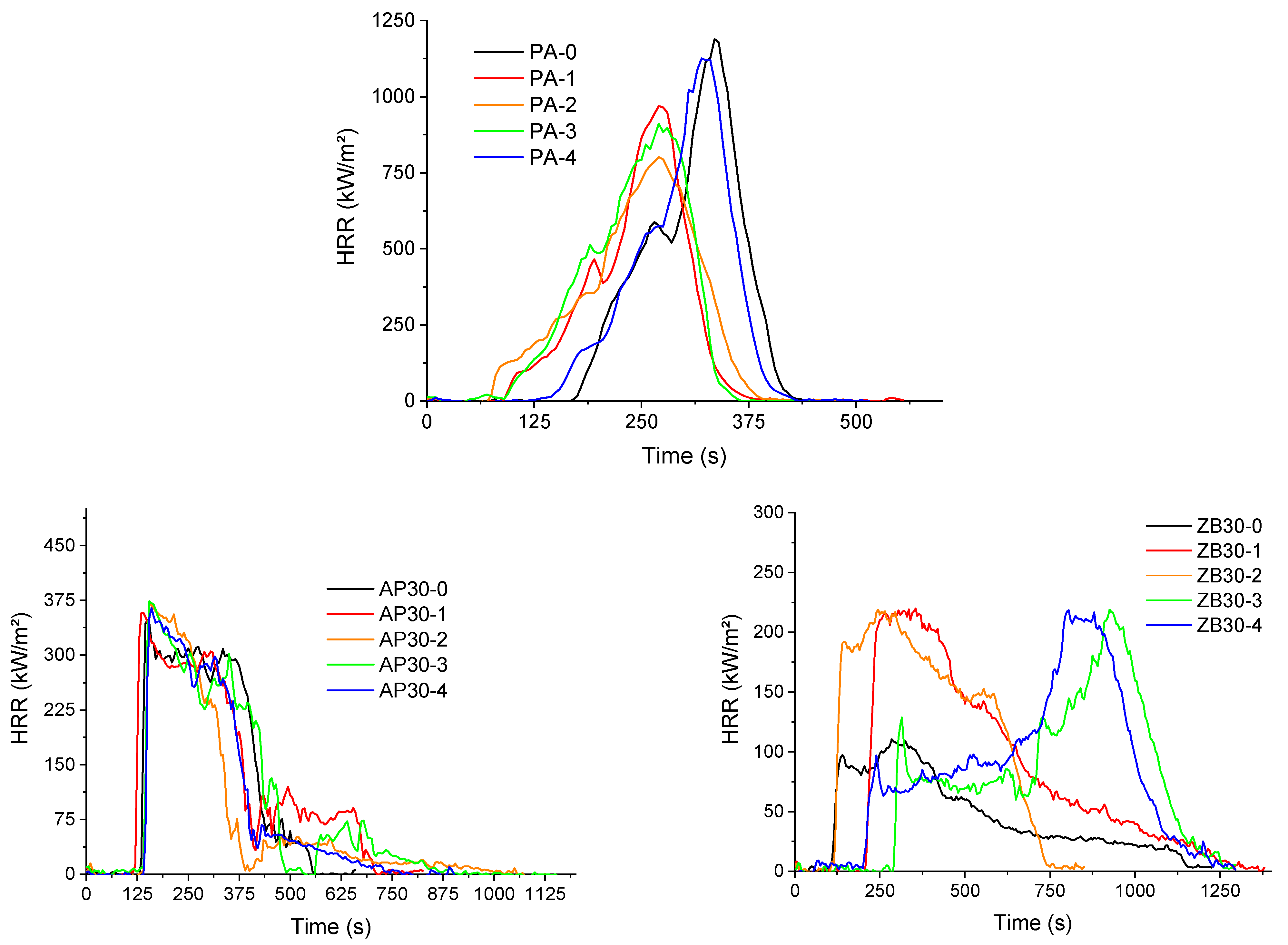

3.4.4. Fire Behavior—Cone Calorimeter

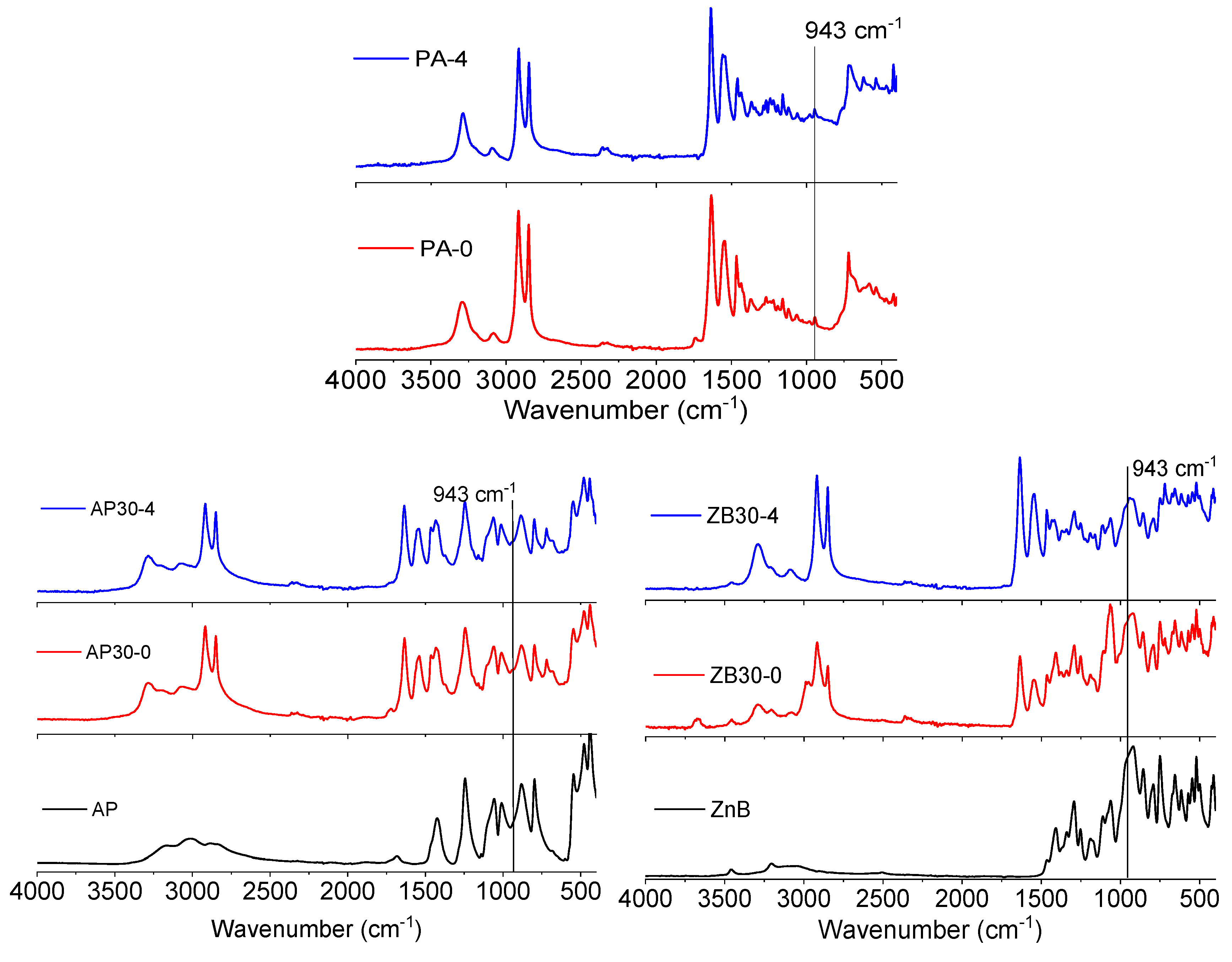

3.4.5. Fourier Transform Infrared Spectra of LS Samples

3.4.6. Polyamide 12 Phase Analysis—XRD

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Goodridge, R.D.; Tuck, C.J.; Hague, R.J.M. Laser Sintering of Polyamides and Other Polymers. Prog. Mater. Sci. 2012, 57, 229–267. [Google Scholar] [CrossRef]

- Ronca, A.; Rollo, G.; Cerruti, P.; Fei, G.; Gan, X.; Buonocore, G.; Lavorgna, M.; Xia, H.; Silvestre, C.; Ambrosio, L. Selective Laser Sintering Fabricated Thermoplastic Polyurethane/Graphene Cellular Structures with Tailorable Properties and High Strain Sensitivity. Appl. Sci. 2019, 9, 864. [Google Scholar] [CrossRef]

- Hoskins, T.J.; Dearn, K.D.; Kukureka, S.N. Mechanical Performance of PEEK Produced by Additive Manufacturing. Polym. Test. 2018, 70, 511–519. [Google Scholar] [CrossRef]

- Han, W.; Kong, L.; Xu, M. Advances in Selective Laser Sintering of Polymers. Int. J. Extrem. Manuf. 2022, 4, 042002. [Google Scholar] [CrossRef]

- Chen, P.; Wu, H.; Zhu, W.; Yang, L.; Li, Z.; Yan, C.; Wen, S.; Shi, Y. Investigation into the Processability, Recyclability and Crystalline Structure of Selective Laser Sintered Polyamide 6 in Comparison with Polyamide 12. Polym. Test. 2018, 69, 366–374. [Google Scholar] [CrossRef]

- Dotchev, K.; Yusoff, W. Recycling of Polyamide 12 Based Powders in the Laser Sintering Process. Rapid Prototyp. J. 2009, 15, 192–203. [Google Scholar] [CrossRef]

- Diogo, O.O. Thermo-oxydation des polyamides. Ph.D. Thesis, Ecole Nationale Supérieure d’arts et Métiers—ENSAM, Paris, France, 2015. [Google Scholar]

- Paolucci, F.; van Mook, M.J.H.; Govaert, L.E.; Peters, G.W.M. Influence of Post-Condensation on the Crystallization Kinetics of PA12: From Virgin to Reused Powder. Polymer 2019, 175, 161–170. [Google Scholar] [CrossRef]

- Drummer, D.; Wudy, K.; Drexler, M. Influence of Energy Input on Degradation Behavior of Plastic Components Manufactured by Selective Laser Melting. Phys. Procedia 2014, 56, 176–183. [Google Scholar] [CrossRef]

- Yang, F.; Schnuerch, A.; Chen, X. Quantitative Influences of Successive Reuse on Thermal Decomposition, Molecular Evolution, and Elemental Composition of Polyamide 12 Residues in Selective Laser Sintering. Int. J. Adv. Manuf. Technol. 2021, 115, 3121–3138. [Google Scholar] [CrossRef]

- Greiner, S.; Wudy, K.; Wörz, A.; Drummer, D. Thermographic Investigation of Laser-Induced Temperature Fields in Selective Laser Beam Melting of Polymers. Opt. Laser Technol. 2019, 109, 569–576. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D. Aging Effects of Polyamide 12 in Selective Laser Sintering: Molecular Weight Distribution and Thermal Properties. Addit. Manuf. 2019, 25, 1–9. [Google Scholar] [CrossRef]

- Pham, D.T.; Dotchev, K.D.; Yusoff, W.A.Y. Deterioration of Polyamide Powder Properties in the Laser Sintering Process. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2008, 222, 2163–2176. [Google Scholar] [CrossRef]

- Yang, F.; Jiang, T.; Lalier, G.; Bartolone, J.; Chen, X. Process Control of Surface Quality and Part Microstructure in Selective Laser Sintering Involving Highly Degraded Polyamide 12 Materials. Polym. Test. 2021, 93, 106920. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D. Aging Behavior of Polyamide 12: Interrelation between Bulk Characteristics and Part Properties. In Solid Freeform Fabrication 2016: Proceedings of the 27th Annual International Solid Freeform Fabrication Symposium—An Additive Manufacturing Conference, SFF 2016, Austin, TX, USA, 8–10 August 2016; University of Texas at Austin: Austin, TX, USA, 2016; pp. 770–781. [Google Scholar]

- Drummer, D.; Wudy, K.; Drexler, M. Modelling of the Aging Behavior of Polyamide 12 Powder during Laser Melting Proceb. AIP Conf. Proc. 2015, 1664, 160007. [Google Scholar] [CrossRef]

- du Maire, P.; Sert, E.; Deckert, M.; Johlitz, M.; Öchsner, A. Characterisation of the Thermal Ageing Effects on the Mechanical Properties When Reusing Polyamide 12 in the Selective Laser Sintering Process. Mater. Und Werkst. 2022, 53, 503–508. [Google Scholar] [CrossRef]

- Wudy, K.; Drummer, D.; Kühnlein, F.; Drexler, M. Influence of Degradation Behavior of Polyamide 12 Powders in Laser Sintering Process on Produced Parts. AIP Conf. Proc. 2014, 1593, 691–695. [Google Scholar] [CrossRef]

- Alo, O.A.; Otunniyi, I.O.; Mauchline, D. Aging Due to Successive Reuse of Polyamide 12 Powder during Laser Sintering: Extrinsic Powder Properties and Quality of Sintered Parts. MATEC Web Conf. 2022, 370, 03011. [Google Scholar] [CrossRef]

- Zarringhalam, H.; Hopkinson, N.; Kamperman, N.F.; De Vlieger, J.J. Effects of Processing on Microstructure and Properties of SLS Nylon 12. Mater. Sci. Eng. A 2006, 435–436, 172–180. [Google Scholar] [CrossRef]

- Caulfield, B.; McHugh, P.E.; Lohfeld, S. Dependence of Mechanical Properties of Polyamide Components on Build Parameters in the SLS Process. J. Mater. Process. Technol. 2007, 182, 477–488. [Google Scholar] [CrossRef]

- Yao, B.; Li, Z.; Zhu, F. Effect of Powder Recycling on Anisotropic Tensile Properties of Selective Laser Sintered PA2200 Polyamide. Eur. Polym. J. 2020, 141, 110093. [Google Scholar] [CrossRef]

- Batistella, M.; Regazzi, A.; Pucci, M.F.; Lopez-Cuesta, J.-M.; Kadri, O.; Bordeaux, D.; Ayme, F. Selective Laser Sintering of Polyamide 12/Flame Retardant Compositions. Polym. Degrad. Stab. 2020, 181, 109318. [Google Scholar] [CrossRef]

- Schneider, K.; Wudy, K.; Drummer, D. Flame-Retardant Polyamide Powder for Laser Sintering: Powder Characterization, Processing Behavior and Component Properties. Polymers 2020, 12, 1697. [Google Scholar] [CrossRef] [PubMed]

- Levchik, S.V.; Weil, E.D.; Lewin, M. Thermal Decomposition of Aliphatic Nylons. Polym. Int. 1999, 48, 532–557. [Google Scholar] [CrossRef]

- Savas, L.A.; Dogan, M. Flame Retardant Effect of Zinc Borate in Polyamide 6 Containing Aluminum Hypophosphite. Polym. Degrad. Stab. 2019, 165, 101–109. [Google Scholar] [CrossRef]

- Lyon, R.E.; Walters, R.N. Pyrolysis Combustion Flow Calorimetry. J. Anal. Appl. Pyrolysis 2004, 71, 27–46. [Google Scholar] [CrossRef]

- ISO 5660-1:2015; Reactions to-Fire Tests—Heat Release, Smoke Production and Mass Loss Rate, 3rd edition. ISO: Geneva, Switzerland, 2015; corrected in 2021. pp. 1–55. Available online: https://www.iso.org/standard/57957.html (accessed on 9 August 2024).

- Gomes, P.C.; Piñeiro, O.G.; Alves, A.C.; Carneiro, O.S. On the Reuse of SLS Polyamide 12 Powder. Materials 2022, 15, 5486. [Google Scholar] [CrossRef] [PubMed]

- Duddleston, L.; Puck, A.; Harris, A.; Doll, N.; Osswald, T. Differential Scanning Calorimetry (DSC) Quantification of Polyamide 12 (Nylon 12) Degradation during the Selective Laser Sintering (SLS) Process. In Proceedings of the Society of Plastics Engineers—ANTEC 2016, Indianapolis, Indiana, 23–25 May 2016. [Google Scholar]

- Wudy, K.; Lanzl, L.; Drummer, D. Selective Laser Sintering of Filled Polymer Systems: Bulk Properties and Laser Beam Material Interaction. Phys. Procedia 2016, 83, 991–1002. [Google Scholar] [CrossRef]

- Schmid, M. Laser Sintering with Plastics. In Laser Sintering with Plastics; Schmid, M., Ed.; Hanser: Munich, Germany, 2018; pp. I–XIII. ISBN 978-1-56990-683-5. [Google Scholar]

- Cojazzi, G.; Fichera, A.; Garbuglio, C.; Malta, V.; Zannetti, R. The Crystal Structure of Polylauryllactam (Nylon 12). Die Makromol. Chem. 1973, 168, 289–301. [Google Scholar] [CrossRef]

- Majewski, C.; Zarringhalam, H.; Hopkinson, N. Effect of the Degree of Particle Melt on Mechanical Properties in Selective Laser-Sintered Nylon-12 Parts. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2008, 222, 1055–1064. [Google Scholar] [CrossRef]

- Levchik, S.; Luigi, C.; Camino, G. Effect of the Fire-Retardant, Ammonium Polyphosphate, on the Thermal Decomposition of Aliphatic Polyamides. I. Polyamides 11 and 12. Polym. Degrad. Stab. 1992, 36, 31–41. [Google Scholar] [CrossRef]

- Camino, G.; Costa, L.; Martinasso, G. Intumescent Fire-Retardant Systems. Polym. Degrad. Stab. 1989, 23, 359–376. [Google Scholar] [CrossRef]

- Schubert, D.M. Hydrated Zinc Borates and Their Industrial Use. Molecules 2019, 24, 2419. [Google Scholar] [CrossRef] [PubMed]

- Schartel, B.; Hull, T.R. Development of Fire-Retarded Materials—Interpretation of Cone Calorimeter Data. Fire Mater. 2007, 31, 327–354. [Google Scholar] [CrossRef]

- Ni, J.; Chen, L.; Zhao, K.; Hu, Y.; Song, L. Preparation of Gel-Silica/Ammonium Polyphosphate Core-Shell Flame Retardant and Properties of Polyurethane Composites: A GEL-SILICA/APP CORE-SHELL FLAME RETARDANT. Polym. Adv. Technol. 2011, 22, 1824–1831. [Google Scholar] [CrossRef]

- Wang, W.; Peng, Y.; Chen, H.; Gao, Q.; Li, J.; Zhang, W. Surface Microencapsulated Ammonium Polyphosphate with Beta-Cyclodextrin and Its Application in Wood-Flour/Polypropylene Composites. Polym. Compos. 2017, 38, 2312–2320. [Google Scholar] [CrossRef]

- Ersan, A.C.; Kipcak, A.S.; Ozen, M.Y.; Tugrul, N. An Accelerated and Effective Synthesis of Zinc Borate from Zinc Sulfate Using Sonochemistry. Main Group Met. Chem. 2020, 43, 7–14. [Google Scholar] [CrossRef]

| Sample | Tic (°C) | Tc Peak (°C) | Tim (°C) | Tm Peak (°C) | ΔHc (J/g) | Processing Window ΔT (°C) | ΔHF (J/g) |

|---|---|---|---|---|---|---|---|

| PA-0 | 153.8 | 148.2 | 182.4 | 183.9 | 45.0 | 29.1 | 88.1 |

| PA-1 | 154.1 | 148.8 | 182.3 | 183.4 | 46.0 | 28.7 | 83.3 |

| PA-2 | 153.2 | 148.6 | 183.5 | 183.5 | 46.1 | 30.3 | 86.6 |

| PA-3 | 153.2 | 148.4 | 182.5 | 182.5 | 45.4 | 29.3 | 85.6 |

| PA-4 | 153.2 | 148.3 | 182.1 | 182.1 | 45.7 | 28.9 | 88.8 |

| AP30-0 | 155.7 | 152.7 | 181.0 | 184.8 | 45.9 | 25.3 | 80.2 |

| AP30-1 | 155.6 | 149.4 | 181.2 | 184.2 | 45.7 | 25.6 | 79.9 |

| AP30-2 | 158.2 | 151.6 | 183.4 | 185.0 | 45.1 | 25.2 | 78.0 |

| AP30-3 | 158.0 | 152.0 | 182.6 | 186.2 | 47.7 | 24.6 | 78.9 |

| AP30-4 | 156.8 | 150.4 | 181.8 | 185.6 | 46.6 | 25.0 | 76.3 |

| ZB30-0 | 153.0 | 148.5 | 180.5 | 186.0 | 47.8 | 27.5 | 76.8 |

| ZB30-1 | 154.2 | 149.0 | 182.0 | 187.6 | 47.1 | 27.8 | 76.8 |

| ZB30-2 | 154.5 | 150.0 | 182.6 | 188.2 | 47.7 | 28.0 | 76.5 |

| ZB30-3 | 153.2 | 149.4 | 182.6 | 186.5 | 47.8 | 29.4 | 80.0 |

| ZB30-4 | 153.0 | 150.5 | 181.9 | 187.1 | 46.8 | 28.9 | 78.2 |

| Sample | Tic (°C) | Tc Peak (°C) | Tim (°C) | Tm Peak (°C) | ΔHc (J/g) | ΔHF (J/g) |

|---|---|---|---|---|---|---|

| PA-0 | 152.6 | 148.7 | 173.3 | 183.3 | 50.2 | 58.0 |

| PA-1 | 153.0 | 149.4 | 172.4 | 182.6 | 49.5 | 56.9 |

| PA-2 | 153.1 | 149.3 | 173.0 | 181.9 | 49.7 | 57.0 |

| PA-3 | 153.1 | 149.6 | 174.9 | 182.2 | 46.6 | 55.5 |

| PA-4 | 154.0 | 149.8 | 176.7 | 184.2 | 49.2 | 50.9 |

| AP30-0 | 159.2 | 153.4 | 175.9 | 182.9 | 45.5 | 57.3 |

| AP30-1 | 158.9 | 153.8 | 177.1 | 183.3 | 40.1 | 54.9 |

| AP30-2 | 158.6 | 153.7 | 176.4 | 184.4 | 42.5 | 57.7 |

| AP30-3 | 158.5 | 153.6 | 177.3 | 183.1 | 41.1 | 58.4 |

| AP30-4 | 158.8 | 154.0 | 177.1 | 183.1 | 42.4 | 56.5 |

| ZB30-0 | 159.3 | 154.2 | 176.1 | 183.4 | 46.0 | 58.0 |

| ZB30-1 | 160.1 | 152.7 | 175.1 | 183.6 | 46.8 | 46.3 |

| ZB30-2 | 160.0 | 152.5 | 176.2 | 183.5 | 45.4 | 52.2 |

| ZB30-3 | 160.0 | 153.2 | 175.8 | 183.0 | 47.7 | 49.8 |

| ZB30-4 | 160.0 | 153.2 | 176.0 | 183.7 | 46.9 | 48.0 |

| Sample | Theoretical P Content (%) | P (%) | Theoretical Zn Content (%) | Zn (%) |

|---|---|---|---|---|

| AP30-0 | 9.57 | 9.3 ± 0.3 | - | - |

| AP30-1 | 9.57 | 9.6 ± 1 | - | - |

| AP30-2 | 9.57 | 10.1 ± 0.8 | - | - |

| AP30-3 | 9.57 | 10.4 ± 0.3 | - | - |

| AP30-4 | 9.57 | 9.5 ± 0.4 | - | - |

| ZB30-0 | - | - | 15.5 | 15.5 ± 0.5 |

| ZB30-1 | - | - | 15.5 | 11.8 ± 2 |

| ZB30-2 | - | - | 15.5 | 12.5 ± 1.3 |

| ZB30-3 | - | - | 15.5 | 12.8 ± 1.2 |

| ZB30-4 | - | - | 15.5 | 12.6 ± 0.9 |

| Sample | T5% | T20% | T50% | Residue at 750 °C (%) |

|---|---|---|---|---|

| PA-0 | 395.2 | 432.8 | 451.3 | 0 |

| PA-1 | 399.9 | 427.9 | 448.2 | 0.4 |

| PA-2 | 396.0 | 424.9 | 443.7 | 0.7 |

| PA-3 | 397.3 | 425.1 | 443.9 | 0.9 |

| PA-4 | 398.7 | 425.4 | 443.7 | 1.0 |

| AP30-0 | 354.1 | 378.5 | 389.9 | 20.0 |

| AP30-1 | 352.3 | 374.7 | 386.5 | 22.5 |

| AP30-2 | 352.6 | 376.6 | 387.4 | 21.9 |

| AP30-3 | 355.2 | 377.5 | 389.0 | 23.0 |

| AP30-4 | 355.0 | 377.0 | 388.0 | 20.9 |

| ZB30-0 | 405.8 | 447.3 | 466.1 | 25.1 |

| ZB30-1 | 398.9 | 441.3 | 463.6 | 23.5 |

| ZB30-2 | 406.4 | 452.1 | 468.9 | 25.9 |

| ZB30-3 | 408.1 | 443.7 | 462.5 | 26.1 |

| ZB30-4 | 406.2 | 443.5 | 462.9 | 24.6 |

| Sample | THR (kJ/g) | pHRR (W/g) | Peak Temperature (°C) |

|---|---|---|---|

| PA-0 | 34.7 | 699 | 454.5 |

| PA-1 | 33.6 | 573 | 460.4 |

| PA-2 | 35.2 | 586 | 454.7 |

| PA-3 | 34.2 | 575 | 466.6 |

| PA-4 | 34.3 | 592 | 461.7 |

| AP30-0 | 24.7 | 951 | 393.4 |

| AP30-1 | 24.1 | 958 | 381.9 |

| AP30-2 | 24.4 | 987 | 381.8 |

| AP30-3 | 25.7 | 968 | 380.4 |

| AP30-4 | 24.1 | 935 | 390.5 |

| ZB30-0 | 24.5 | 588 | 477.3 |

| ZB30-1 | 22.8 | 569 | 478.7 |

| ZB30-2 | 23.8 | 521 | 479.8 |

| ZB30-3 | 23.7 | 577 | 474.6 |

| ZB30-4 | 24.0 | 550 | 483.8 |

| Sample | TTI (s) | pHRR (kW/m²) | THR (MJ/m²) | MAHRE (kW/m²) | Residue (%) |

|---|---|---|---|---|---|

| PA-0 | 154 ± 10 | 1416 ± 200 | 131 ± 5 | 337 ± 25 | - |

| PA-1 | 94 ± 3 | 942 ± 37 | 117 ± 3 | 328 ± 7 | - |

| PA-2 | 80 ± 5 | 893 ± 98 | 120 ± 1 | 345 ± 15 | - |

| PA-3 | 88 ± 5 | 827 ± 95 | 115 ± 5 | 324 ± 23 | - |

| PA-4 | 193 ± 20 | 1037 ± 102 | 115 ± 4 | 320 ± 15 | - |

| AP30-0 | 122 ± 10 | 351 ± 5 | 92 ± 6 | 196 ± 4 | 31 ± 2 |

| AP30-1 | 118 ± 3 | 347 ± 14 | 105 ± 5 | 197 ± 5 | 30 ± 3 |

| AP30-2 | 144 ± 1 | 373 ± 2 | 81 ± 6 | 180 ± 10 | 27 ± 1 |

| AP30-3 | 139 ± 3 | 363 ± 15 | 88 ± 8 | 192 ± 8 | 26 ± 1 |

| AP30-4 | 143 ± 2 | 374 ± 14 | 86 ± 5 | 180 ± 10 | 27 ± 1 |

| ZB30-0 | 115 ± 20 | 125 ± 15 | 95 ± 8 | 120 ± 10 | 38 ± 3 |

| ZB30-1 | 214 ± 6 | 163 ± 70 | 92 ± 13 | 115 ± 15 | 35 ± 3 |

| ZB30-2 | 189 ± 5 | 175 ± 61 | 98 ± 6 | 130 ± 14 | 33 ± 1 |

| ZB30-3 | 252 ± 20 | 204 ± 19 | 101 ± 8 | 65 ± 8 | 25 ± 1 |

| ZB30-4 | 180 ± 20 | 220 ± 22 | 95 ± 5 | 72 ± 5 | 29 ± 2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Seigler, D.; Batistella, M.; Lopez-Cuesta, J.-M. Towards the Reuse of Fire Retarded Polyamide 12 for Laser Sintering. Materials 2024, 17, 4064. https://doi.org/10.3390/ma17164064

Seigler D, Batistella M, Lopez-Cuesta J-M. Towards the Reuse of Fire Retarded Polyamide 12 for Laser Sintering. Materials. 2024; 17(16):4064. https://doi.org/10.3390/ma17164064

Chicago/Turabian StyleSeigler, Dylan, Marcos Batistella, and José-Marie Lopez-Cuesta. 2024. "Towards the Reuse of Fire Retarded Polyamide 12 for Laser Sintering" Materials 17, no. 16: 4064. https://doi.org/10.3390/ma17164064

APA StyleSeigler, D., Batistella, M., & Lopez-Cuesta, J.-M. (2024). Towards the Reuse of Fire Retarded Polyamide 12 for Laser Sintering. Materials, 17(16), 4064. https://doi.org/10.3390/ma17164064