Alkali-Activated Slag as Sustainable Binder for Pervious Concrete and Structural Plaster: A Feasibility Study

Abstract

:1. Introduction

- Structural plaster (Section 2):

- Pervious Concrete (Section 3):

2. Alkali-Activated Slag-Based Plaster

2.1. Materials

2.2. Methods

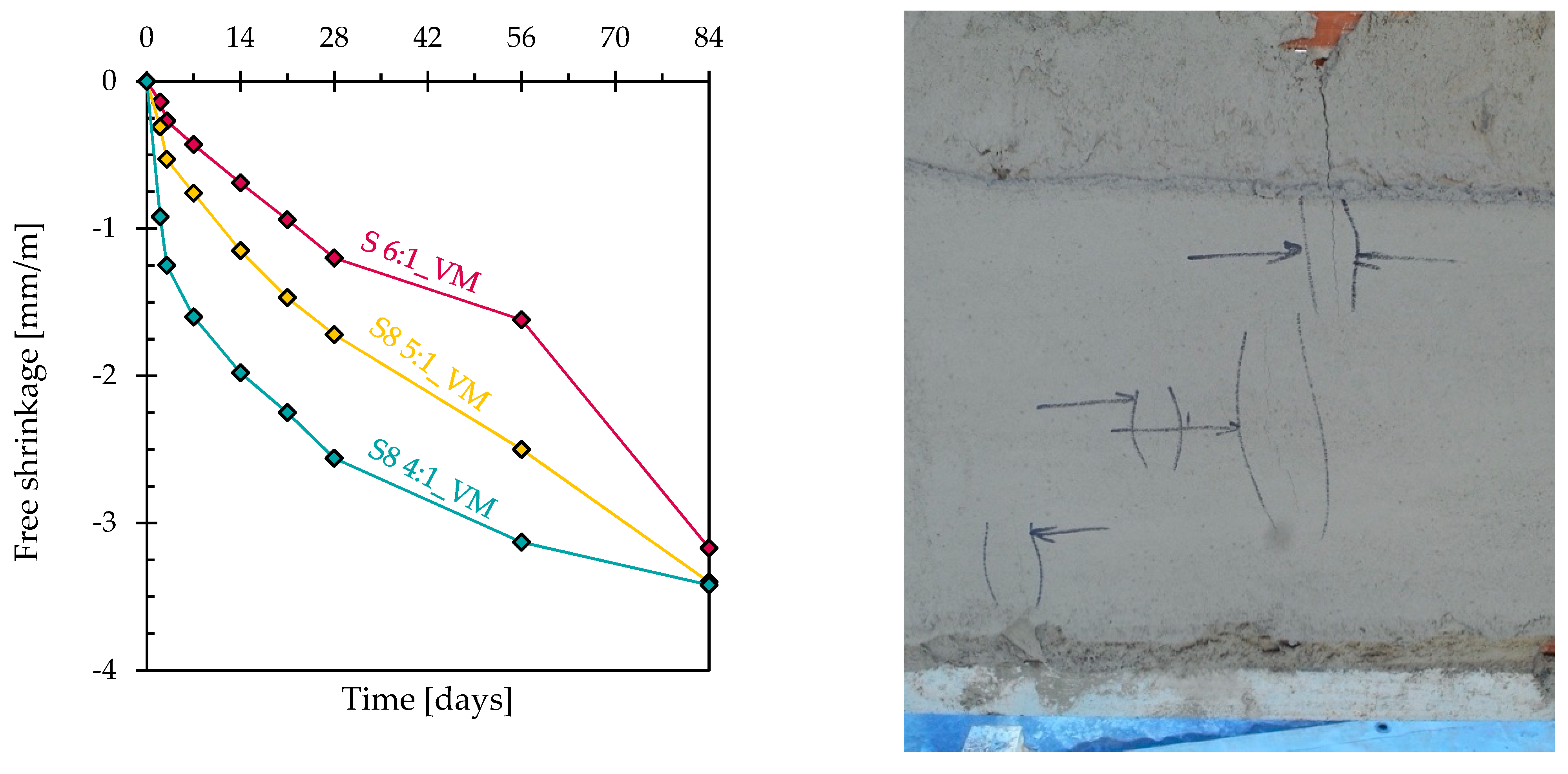

2.3. First Stage: Effect of Sand-to-Binder Ratio

2.4. Second Stage: Effect of Viscosity Modifiers

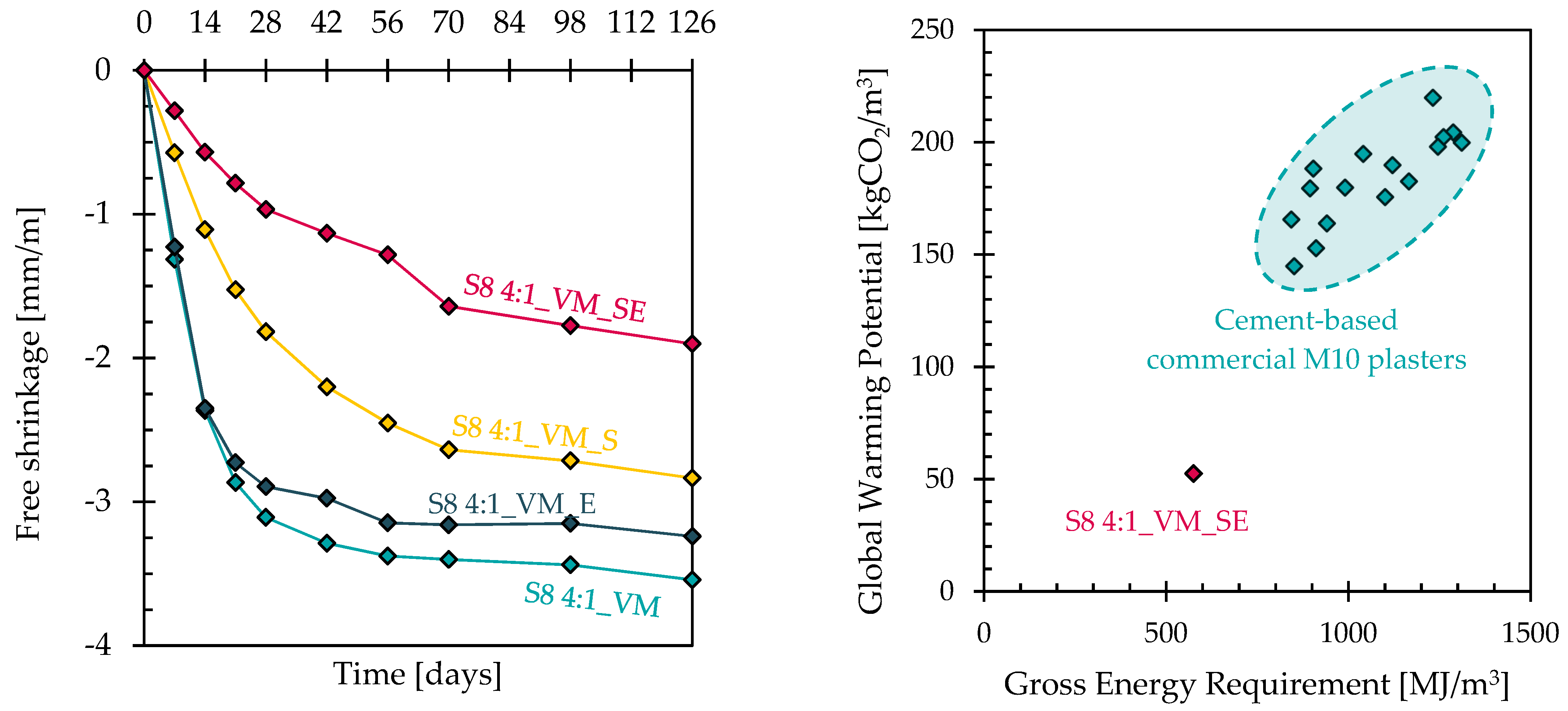

2.5. Third Stage: Effect of Shrinkage-Reducing Admixtures and Environmental Impact

3. Totally Recycled Pervious Concrete

3.1. Materials and Methods

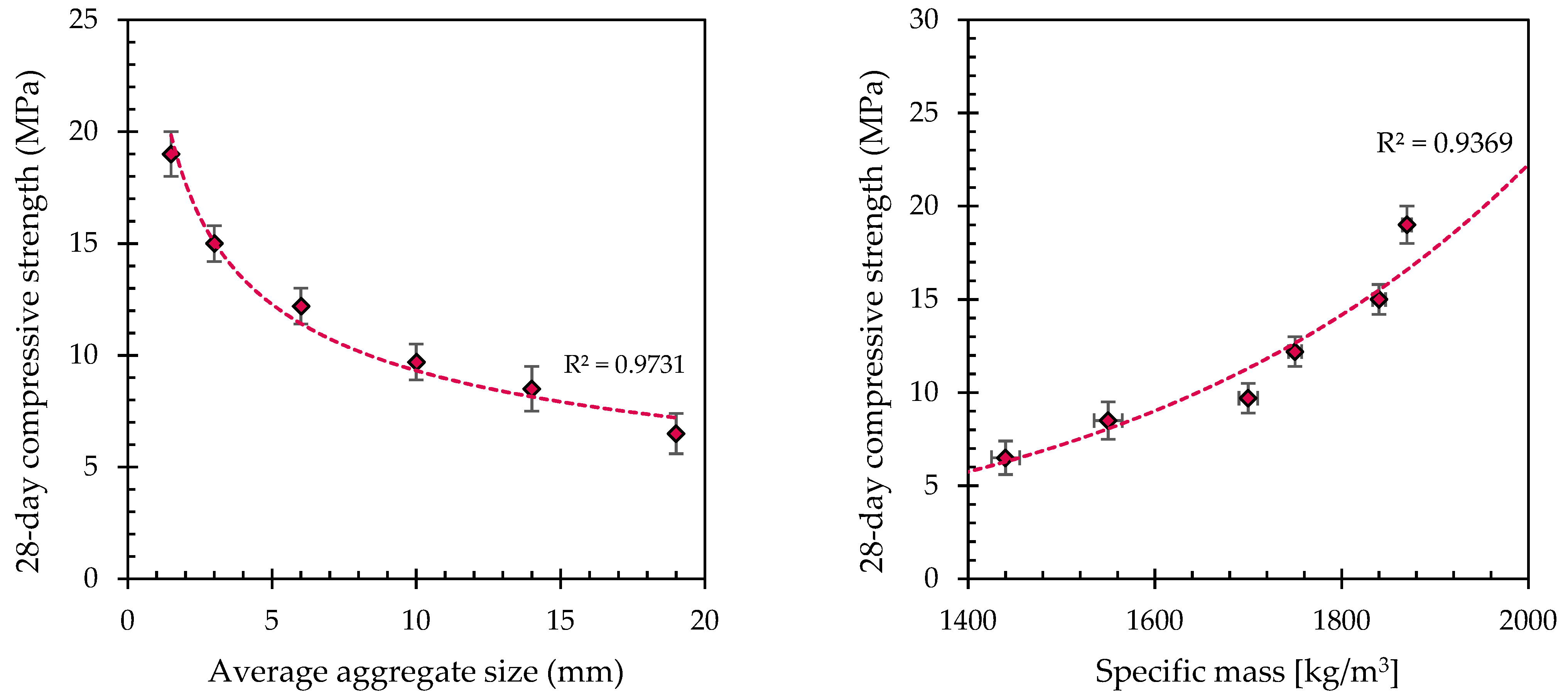

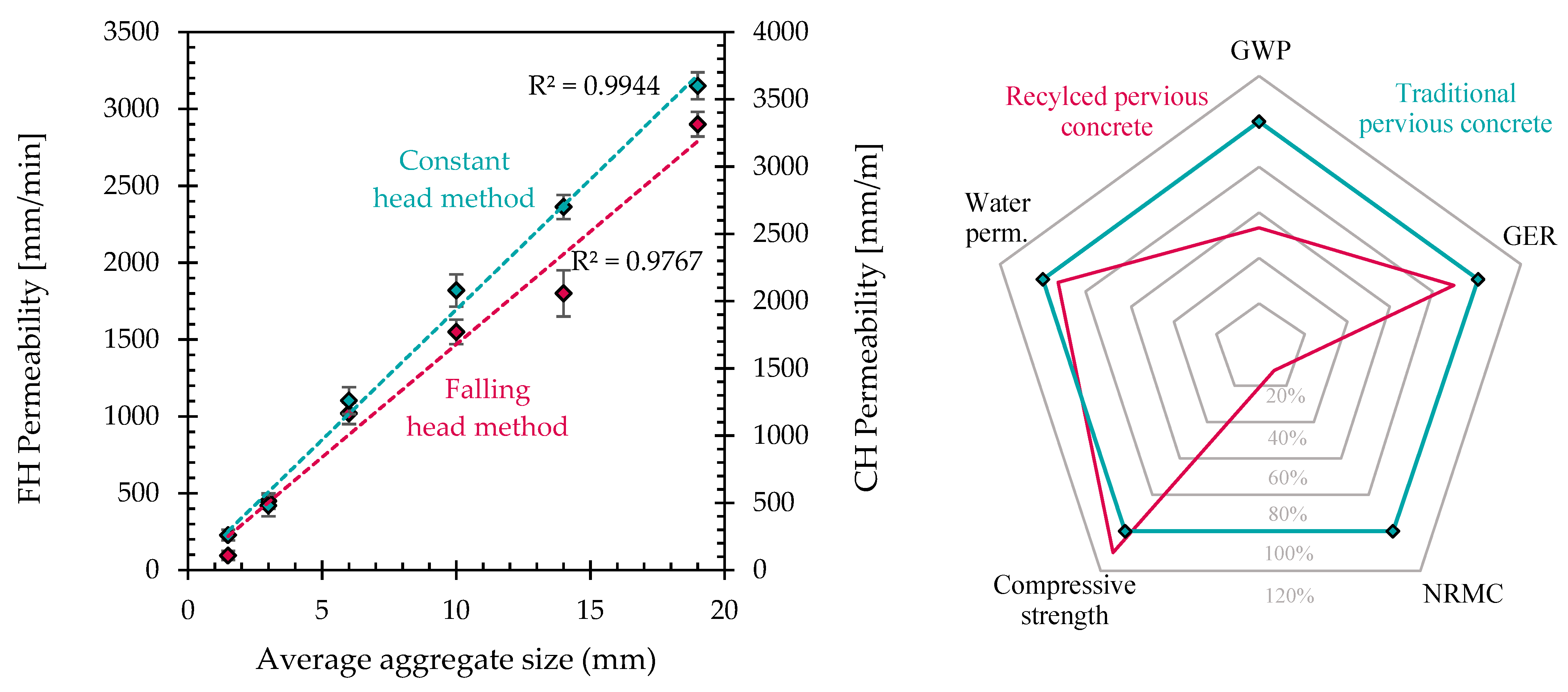

Experimental Results

4. Conclusions

- Structural Plaster

- ○

- The developed AAS-based plaster achieved a 28-day compressive strength of at least 10 MPa, making it suitable for the structural retrofitting of masonry buildings;

- ○

- Its fresh-state properties, shrinkage and applicability to masonry were thoroughly investigated, ensuring the practicality of the plaster in real-world applications;

- ○

- The addition of viscosity modifiers, including methylcellulose and modified starch, improved its applicability by trowel but resulted in a reduction in compressive strength (on average, by −40% with respect to the non-admixed mortars) due to the increased air content and altered hydration processes;

- ○

- The use of shrinkage-reducing admixtures successfully mitigated the high level of shrinkage associated with AAS plasters, making them viable for thin-section applications.

- Pervious Concrete

- ○

- AAS-based pervious concrete was successfully manufactured using tunnel muck (TM) as a recycled aggregate, demonstrating a sustainable approach to aggregate utilization;

- ○

- The relationship between aggregate size and the physical and mechanical properties of no-fines concrete was evaluated, confirming the correlations evidenced for traditional cement-based pervious concretes;

- ○

- The developed pervious concrete exhibited a compressive strength up to about 20 MPa and permeability ranging from 500 to 3000 mm/min, making it suitable for applications requiring enhanced drainage and reduced surface runoff.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Global Alliance for Buildings and Construction–United Nations Environment Programme. 2020 Global Status Report for Buildings and Construction. 2020. Available online: https://globalabc.org/resources/publications/2020-global-status-report-buildings-and-construction (accessed on 4 July 2024).

- Coffetti, D.; Crotti, E.; Gazzaniga, G.; Carrara, M.; Pastore, T.; Coppola, L. Pathways towards sustainable concrete. Cem. Concr. Res. 2022, 154, 106718. [Google Scholar] [CrossRef]

- Liew, K.M.; Sojobi, A.O.; Zhang, L.W. Green concrete: Prospects and challenges. Constr. Build. Mater. 2017, 156, 1063–1095. [Google Scholar] [CrossRef]

- de Brito, J.; Kurda, R. The past and future of sustainable concrete: A critical review and new strategies on cement-based materials. J. Clean. Prod. 2020, 281, 123558. [Google Scholar] [CrossRef]

- Assi, L.; Carter, K.; Deaver, E. (Eddie); Anay, R.; Ziehl, P. Sustainable concrete: Building a greener future. J. Clean. Prod. 2018, 198, 1641–1651. [Google Scholar] [CrossRef]

- Gartner, E.; Sui, T. Alternative cement clinkers. Cem. Concr. Res. 2018, 114, 27–39. [Google Scholar] [CrossRef]

- Ding, Y.; Dai, J.G.; Shi, C.J. Mechanical properties of alkali-activated concrete: A state-of-the-art review. Constr. Build. Mater. 2016, 127, 68–79. [Google Scholar] [CrossRef]

- Luukkonen, T.; Abdollahnejad, Z.; Yliniemi, J.; Kinnunen, P.; Illikainen, M. One-part alkali-activated materials: A review. Cem. Concr. Res. 2018, 103, 21–34. [Google Scholar] [CrossRef]

- Ye, H.; Radlińska, A. Shrinkage mitigation strategies in alkali-activated slag. Cem. Concr. Res. 2017, 101, 131–143. [Google Scholar] [CrossRef]

- Shahrajabian, F.; Behfarnia, K. The effects of nano particles on freeze and thaw resistance of alkali-activated slag concrete. Constr. Build. Mater. 2018, 176, 172–178. [Google Scholar] [CrossRef]

- Li, Q.; Yang, K.; Yang, C. An alternative admixture to reduce sorptivity of alkali-activated slag cement by optimising pore structure and introducing hydrophobic film. Cem. Concr. Compos. 2019, 95, 183–192. [Google Scholar] [CrossRef]

- Elzeadani, M.; Bompa, D.V.; Elghazouli, A.Y. One part alkali activated materials: A state-of-the-art review. J. Build. Eng. 2022, 57, 104871. [Google Scholar] [CrossRef]

- Habert, G.; Miller, S.A.; John, V.M.; Provis, J.L.; Favier, A.; Horvath, A.; Scrivener, K.L. Environmental impacts and decarbonization strategies in the cement and concrete industries. Nat. Rev. Earth Environ. 2020, 1, 559–573. [Google Scholar] [CrossRef]

- Provis, J.L. Alkali-activated materials. Cem. Concr. Res. 2018, 114, 40–48. [Google Scholar] [CrossRef]

- Barbhuiya, S.; Kanavaris, F.; Das, B.B.; Idrees, M. Decarbonising cement and concrete production: Strategies, challenges and pathways for sustainable development. J. Build. Eng. 2024, 86, 108861. [Google Scholar] [CrossRef]

- Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Feng, W.; Jin, Y.; Zheng, D.; Li, Z.; Cui, H. Synergic effect of compositions and processing method on the performance of high strength alkali activated slag foam. Constr. Build. Mater. 2022, 352, 128991. [Google Scholar] [CrossRef]

- Souza, T.B.; Lima, V.M.E.; Araújo, F.W.C.; Miranda, L.F.R.; Melo Neto, A.A. Alkali-activated slag cellular concrete with expanded polystyrene (EPS)–physical, mechanical, and mineralogical properties. J. Build. Eng. 2021, 44, 103387. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Yu, R.; Zhang, J.J.; Shui, Z.H. A low-carbon alkali activated slag based ultra-high performance concrete (UHPC): Reaction kinetics and microstructure development. J. Clean. Prod. 2022, 363, 132416. [Google Scholar] [CrossRef]

- Cai, R.; Ye, H. Clinkerless ultra-high strength concrete based on alkali-activated slag at high temperatures. Cem. Concr. Res. 2021, 145, 106465. [Google Scholar] [CrossRef]

- Alnuaim, A.; Abbas, Y.M.; Iqbal Khan, M. Sustainable application of processed TBM excavated rock material as green structural concrete aggregate. Constr. Build. Mater. 2021, 274, 121245. [Google Scholar] [CrossRef]

- Chang, J.J.; Yeih, W.; Chung, T.J.; Huang, R. Properties of pervious concrete made with electric arc furnace slag and alkali-activated slag cement. Constr. Build. Mater. 2016, 109, 34–40. [Google Scholar] [CrossRef]

- Coffetti, D.; Crotti, E.; Coppola, L. Long-term properties of self-cleaning alkali-activated slag-based mortars with titanium dioxide nanoparticles. Constr. Build. Mater. 2023, 392, 131976. [Google Scholar] [CrossRef]

- Coffetti, D.; Candamano, S.; Crea, F.; Coppola, L. On the role of alkali content on one-part alkali activated slag pastes produced with tri- blend solid activators. Constr. Build. Mater. 2023, 409, 133868. [Google Scholar] [CrossRef]

- Bayuaji, R.; Yasin, A.K.; Susanto, T.E.; Darmawan, M.S.; Darmawan, S. A review in geopolymer binder with dry mixing method (geopolymer cement). AIP Conf. Proc. 2017, 1887, 20042. [Google Scholar] [CrossRef]

- Coppola, L.; Coffetti, D.; Crotti, E.; Candamano, S.; Crea, F.; Gazzaniga, G.; Pastore, T. The combined use of admixtures for shrinkage reduction in one-part alkali activated slag-based mortars and pastes. Constr. Build. Mater. 2020, 248, 118682. [Google Scholar] [CrossRef]

- EN 1015-3; Methods of Test for Mortar for Masonry. Determination of Consistence of Fresh Mortar (by Flow Table). CEN: Brussels, Belgium, 1999.

- EN 1015-6; Methods of Test for Mortar for Masonry. Determination of Bulk Density of Fresh Mortar. CEN: Brussels, Belgium, 1998.

- EN 1015-7; Methods of Test for Mortar for Masonry. Determination of Air Content of Fresh Mortar. CEN: Brussels, Belgium, 1998.

- EN 1015-9; Methods of Test for Mortar for Masonry. Determination of Workable Life and Correction Time of Fresh Mortar. CEN: Brussels, Belgium, 1999.

- EN 1015-11; Methods of Test for Mortar for Masonry. Determination of Flexural and Compressive Strength of Hardened Mortar. CEN: Brussels, Belgium, 2019.

- EN 12617-4Products and Systems for the Protection and Repair of Concrete Structures. Test Methods. Determination of Shrinkage and Expansion; CEN: Brussels, Belgium, 2002.

- Chi, M.; Chang, J.; Huang, R. Strength and Drying Shrinkage of Alkali-Activated Slag Paste and Mortar. Adv. Civ. Eng. 2012, 2012, 579732. [Google Scholar] [CrossRef]

- Omur, T.; Kabay, N.; Miyan, N.; Özkan, H.; Özkan, Ç. The effect of alkaline activators and sand ratio on the physico-mechanical properties of blast furnace slag based mortars. J. Build. Eng. 2022, 58, 104998. [Google Scholar] [CrossRef]

- Li, Y.; Shen, J.; Lin, H.; Li, Y. The autogenous shrinkage mitigation mechanism and mechanical properties of Alkali-activated High Strength Mortar (AAHSM) incorporating hydroxypropyl methylcellulose (HPMC). Constr. Build. Mater. 2024, 442, 137708. [Google Scholar] [CrossRef]

- Bai, Y.; Bai, Y.; Tang, J.; Su, H.; Zhang, F.; Ma, H.; Ge, L.; Cai, Y. Effects of hydroxypropyl methylcellulose on anti-dispersion and rheology of alkali-activated materials in underwater engineering. Constr. Build. Mater. 2023, 393, 132135. [Google Scholar] [CrossRef]

- Bílek, V.; Kalina, L.; Novotný, R.; Tkacz, J.; Pařízek, L. Some Issues of Shrinkage-Reducing Admixtures Application in Alkali-Activated Slag Systems. Materials 2016, 9, 462. [Google Scholar] [CrossRef]

- Al Makhadmeh, W.; Soliman, A. On the mechanisms of shrinkage reducing admixture in alkali activated slag binders. J. Build. Eng. 2022, 56, 104812. [Google Scholar] [CrossRef]

- Komkova, A.; Habert, G. Environmental impact assessment of alkali-activated materials: Examining impacts of variability in constituent production processes and transportation. Constr. Build. Mater. 2023, 363, 129032. [Google Scholar] [CrossRef]

- Ramagiri, K.K.; Kar, A. Environmental impact assessment of alkali-activated mortar with waste precursors and activators. J. Build. Eng. 2021, 44, 103391. [Google Scholar] [CrossRef]

- Spathis, A.T.; Gupta, R.N. Tunneling in Rock by Drilling and Blasting; CRC Press: Boca Raton, FL, USA, 2012; ISBN 1299703054. [Google Scholar]

- EN 12390-7; Testing Hardened Concrete. Density of Hardened Concrete. CEN: Brussels, Belgium, 2019.

- EN 12390-3; Testing Hardened Concrete. Compressive Strength of Test Specimens. CEN: Brussels, Belgium, 2019.

- ACI Committee 522. 522R-10: Report on Pervious Concrete; American Concrete Institute: Farmington Hills, MI, USA, 2010. [Google Scholar]

- Fu, T.C.; Yeih, W.; Chang, J.J.; Huang, R. The Influence of Aggregate Size and Binder Material on the Properties of Pervious Concrete. Adv. Mater. Sci. Eng. 2014, 2014, 963971. [Google Scholar] [CrossRef]

- Chockalingam, T.; Vijayaprabha, C.; Leon Raj, J. Experimental study on size of aggregates, size and shape of specimens on strength characteristics of pervious concrete. Constr. Build. Mater. 2023, 385, 131320. [Google Scholar] [CrossRef]

- Yahia, A.; Kabagire, K.D. New approach to proportion pervious concrete. Constr. Build. Mater. 2014, 62, 38–46. [Google Scholar] [CrossRef]

| Component wt.% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| CaO | Al2O3 | SiO2 | Fe2O3 | SO3 | TiO2 | K2O | MgO | Others | |

| GGBFS | 45.8 | 10.0 | 32.8 | 1.5 | 0.2 | 2.0 | 0.5 | 6.4 | 0.8 |

| S8 4:1 | S8 5:1 | S8 6:1 | |

|---|---|---|---|

| GGBFS (kg/m3) | 365 | 305 | 260 |

| Calcareous filler (kg/m3) | 145 | 150 | 155 |

| Sand (kg/m3) | 1320 | 1375 | 1410 |

| Alkaline activators (kg/m3) | 29 | 24 | 21 |

| Water (kg/m3) | 256 | 253 | 252 |

| Initial workability (mm) | 170 | 170 | 170 |

| Workability at 60 min (mm) | 150 | 160 | 160 |

| Workability life (min) | 110 | 110 | 120 |

| Air content (%) | 4.5 | 5.0 | 5.0 |

| Density of fresh mortar (kg/m3) | 2115 | 2105 | 2100 |

| 1-day compressive strength (MPa) | 4.9 | - | - |

| 7-day compressive strength (MPa) | 17.6 | 15.3 | 14.0 |

| 28-day compressive strength (MPa) | 24.0 | 18.9 | 17.3 |

| S8 4:1_VM | S8 5:1_VM | S8 6:1_VM | |

|---|---|---|---|

| GGBFS (kg/m3) | 315 | 245 | 205 |

| Calcareous filler (kg/m3) | 125 | 120 | 120 |

| Sand (kg/m3) | 1135 | 1105 | 1110 |

| Alkaline activators (kg/m3) | 25 | 20 | 16 |

| Water (kg/m3) | 240 | 220 | 215 |

| Methylcellulose | 0.03 wt.% vs. dry powder mass | ||

| Modified starch | 0.01 wt.% vs. dry powder mass | ||

| Air entraining agent | 0.04 wt.% vs. dry powder mass | ||

| Initial workability (mm) | 170 | 170 | 170 |

| Workability at 60 min (mm) | 165 | 165 | 170 |

| Workability life (min) | >120 | >120 | >120 |

| Air content (%) | 15 | 19 | 20 |

| Density of fresh mortar (kg/m3) | 1850 | 1710 | 1680 |

| 1-day compressive strength (MPa) | - | - | - |

| 7-day compressive strength (MPa) | 13.1 | 9.2 | 5.1 |

| 28-day compressive strength (MPa) | 15.4 | 11.3 | 5.5 |

| S8 4:1_VM | S8 4:1_VM_S | S8 4:1_VM_E | S8 4:1_VM_SE | |

|---|---|---|---|---|

| GGBFS (kg/m3) | 315 | 290 | 325 | 300 |

| Calcareous filler (kg/m3) | 125 | 115 | 130 | 120 |

| Sand (kg/m3) | 1135 | 1045 | 1170 | 1080 |

| Alkaline activators (kg/m3) | 25 | 23 | 26 | 24 |

| Water (kg/m3) | 240 | 210 | 235 | 220 |

| Methylcellulose | 0.03 wt.% vs. dry powder mass | |||

| Modified starch | 0.01 wt.% vs. dry powder mass | |||

| Air entraining agent | 0.04 wt.% vs. dry powder mass | |||

| Polymeric fibres (wt.% vs. dry powder mass) | - | 0.06 | 0.06 | 0.06 |

| Expansive agent (wt.% vs. dry powder mass) | - | - | 0.08 | 0.08 |

| Shrinkage reducing admixture (wt.% vs. binder mass) | - | 0.50 | - | 0.50 |

| Initial workability (mm) | 170 | 170 | 170 | 170 |

| Workability at 60 min (mm) | 165 | 145 | 170 | 150 |

| Workability life (min) | >120 | 120 | >>120 | >120 |

| Air content (%) | 15 | 20 | 13 | 18 |

| Density of fresh mortar (kg/m3) | 1850 | 1680 | 1900 | 1755 |

| 1-day compressive strength (MPa) | - | - | - | - |

| 7-day compressive strength (MPa) | 13.1 | 6.5 | 11.5 | 8.9 |

| 28-day compressive strength (MPa) | 15.4 | 7.0 | 12.3 | 10.8 |

| TM 1-2 | TM 2-4 | TM 4-8 | TM 8-12 | TM 12-16 | TM 16-22 | |

|---|---|---|---|---|---|---|

| Size (mm) | 1–2 | 2–4 | 4–8 | 8–12 | 12–16 | 16–22 |

| Specific mass s.s.d. (g/cm3) | 2.65 | 2.65 | 2.64 | 2.65 | 2.64 | 2.64 |

| Water absorption s.s.d. (%) | 2.0 | 1.9 | 2.0 | 1.7 | 1.5 | 1.2 |

| Flakiness index | - | - | FI15 | FI15 | FI15 | FI15 |

| Shape index | - | - | SI15 | SI15 | SI15 | SI15 |

| PC 1-2 | PC 2-4 | PC 4-8 | PC 8-12 | PC 12-16 | PC 16-22 | |

|---|---|---|---|---|---|---|

| GGBFS (kg/m3) | 350 | 350 | 350 | 350 | 350 | 350 |

| Alkaline activators (kg/m3) | 70 | 70 | 70 | 70 | 70 | 70 |

| TM 1-2 (kg/m3) | 1450 | - | - | - | - | - |

| TM 2-4 (kg/m3) | - | 1450 | - | - | - | - |

| TM 4-8 (kg/m3) | - | - | 1450 | - | - | - |

| TM 8-12 (kg/m3) | - | - | - | 1450 | - | - |

| TM 12-16 (kg/m3) | - | - | - | - | 1450 | - |

| TM 16-22 (kg/m3) | - | - | - | - | - | 1450 |

| Natural sand (kg/m3) | 80 | 80 | 80 | 80 | 80 | 80 |

| Water (kg/m3) | 110 | 110 | 110 | 110 | 110 | 110 |

| Air entraining agent (g/m3) | 20 | 20 | 20 | 20 | 20 | 20 |

| Superplasticizer (kg/m3) | 5.0 | 4.2 | 3.5 | 1.75 | - | - |

| PC 1-2 | PC 2-4 | PC 4-8 | PC 8-12 | PC 12-16 | PC 16-22 | |

|---|---|---|---|---|---|---|

| 1-day compressive strength (MPa) | 10.7 | 9.5 | 6.0 | 7.2 | 6.5 | 5.0 |

| 7-day compressive strength (MPa) | 12.0 | 11.5 | 7.5 | 8.0 | 7.0 | 6.0 |

| 28-day compressive strength (MPa) | 19.0 | 15.0 | 12.2 | 9.7 | 8.5 | 6.5 |

| Specific mass (kg/m3) | 1870 | 1840 | 1750 | 1700 | 1550 | 1440 |

| Permeability KFH (mm/min) | 95 | 450 | 1020 | 1550 | 1800 | 2900 |

| Permeability KCH (mm/min) | 260 | 480 | 1260 | 2080 | 2700 | 3600 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Coffetti, D.; Rapelli, S.; Coppola, L. Alkali-Activated Slag as Sustainable Binder for Pervious Concrete and Structural Plaster: A Feasibility Study. Materials 2024, 17, 4084. https://doi.org/10.3390/ma17164084

Coffetti D, Rapelli S, Coppola L. Alkali-Activated Slag as Sustainable Binder for Pervious Concrete and Structural Plaster: A Feasibility Study. Materials. 2024; 17(16):4084. https://doi.org/10.3390/ma17164084

Chicago/Turabian StyleCoffetti, Denny, Simone Rapelli, and Luigi Coppola. 2024. "Alkali-Activated Slag as Sustainable Binder for Pervious Concrete and Structural Plaster: A Feasibility Study" Materials 17, no. 16: 4084. https://doi.org/10.3390/ma17164084