Modeling Study of Si3N4 Waveguides on a Sapphire Platform for Photonic Integration Applications

Abstract

1. Introduction

2. Simulation Method

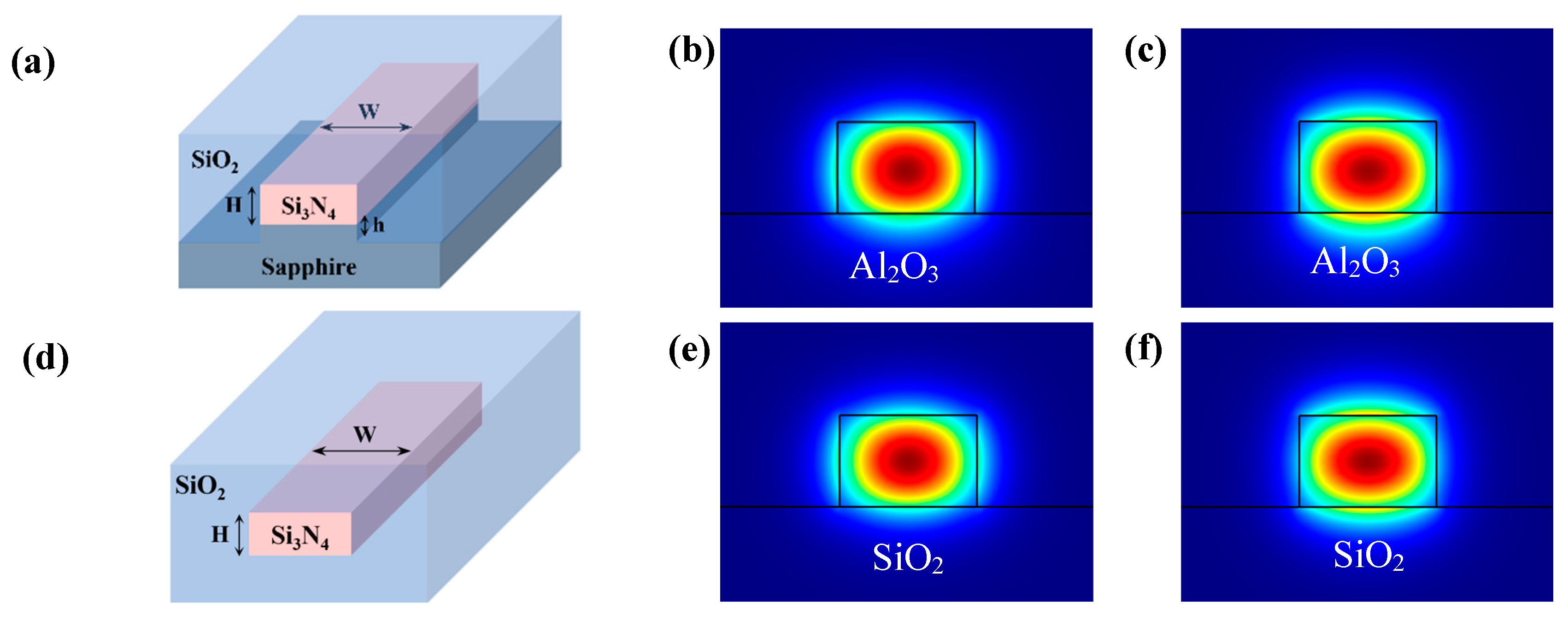

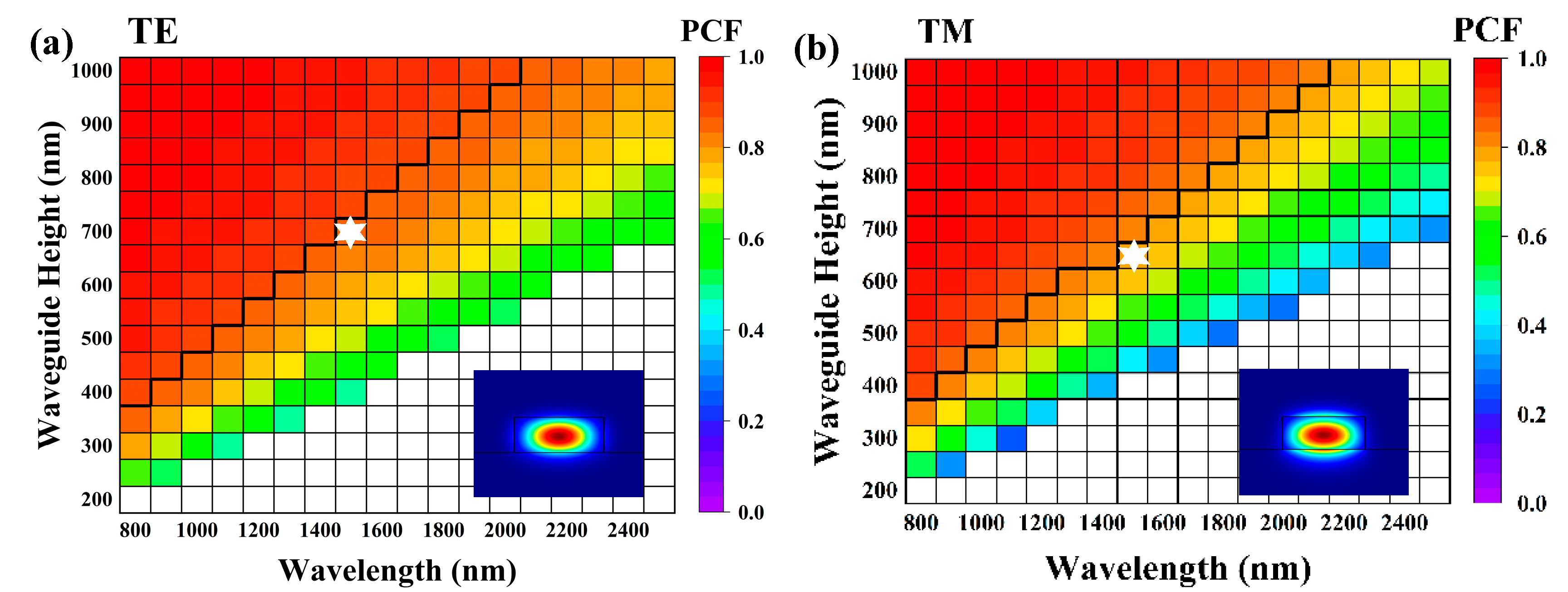

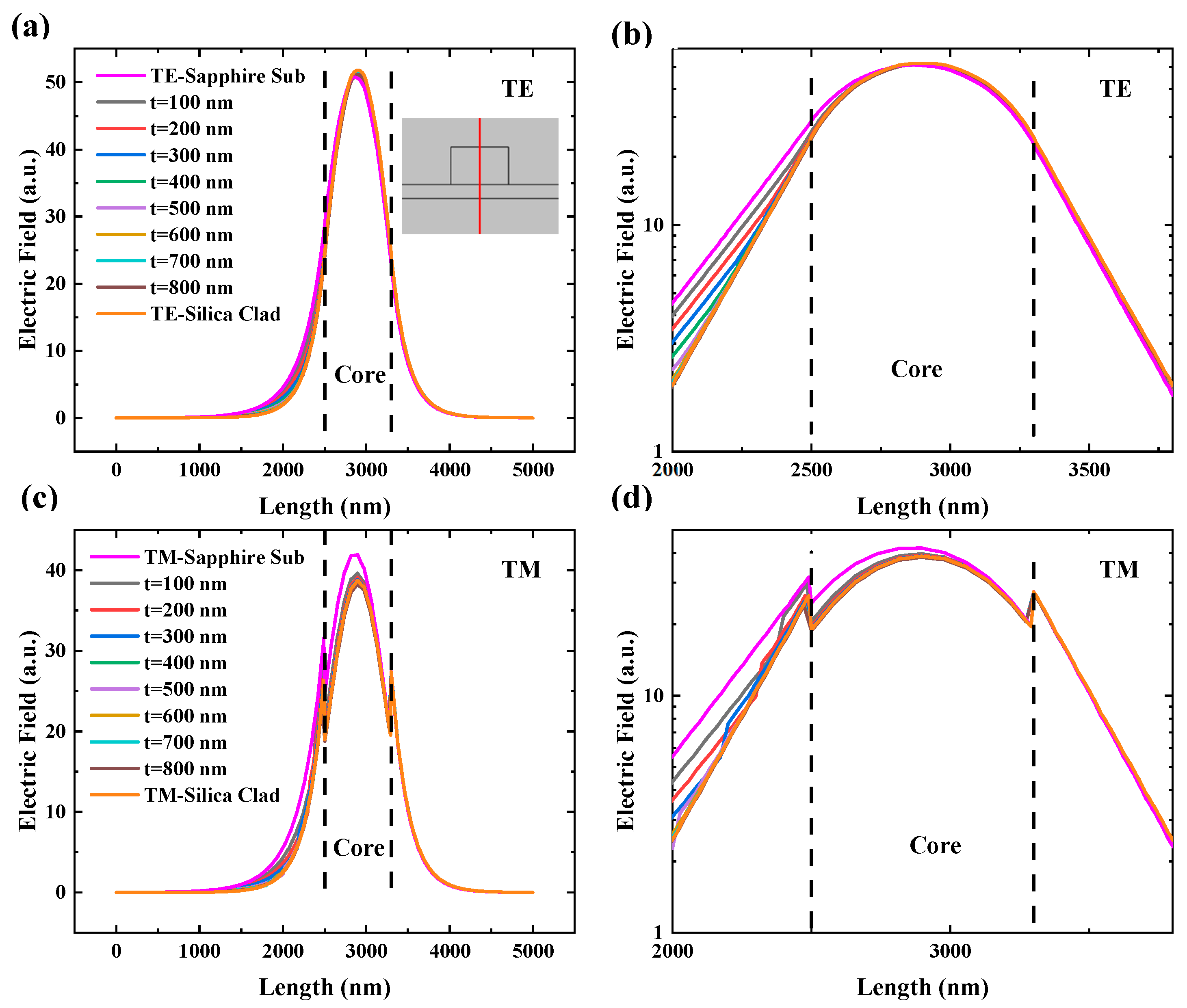

2.1. Straight Waveguide

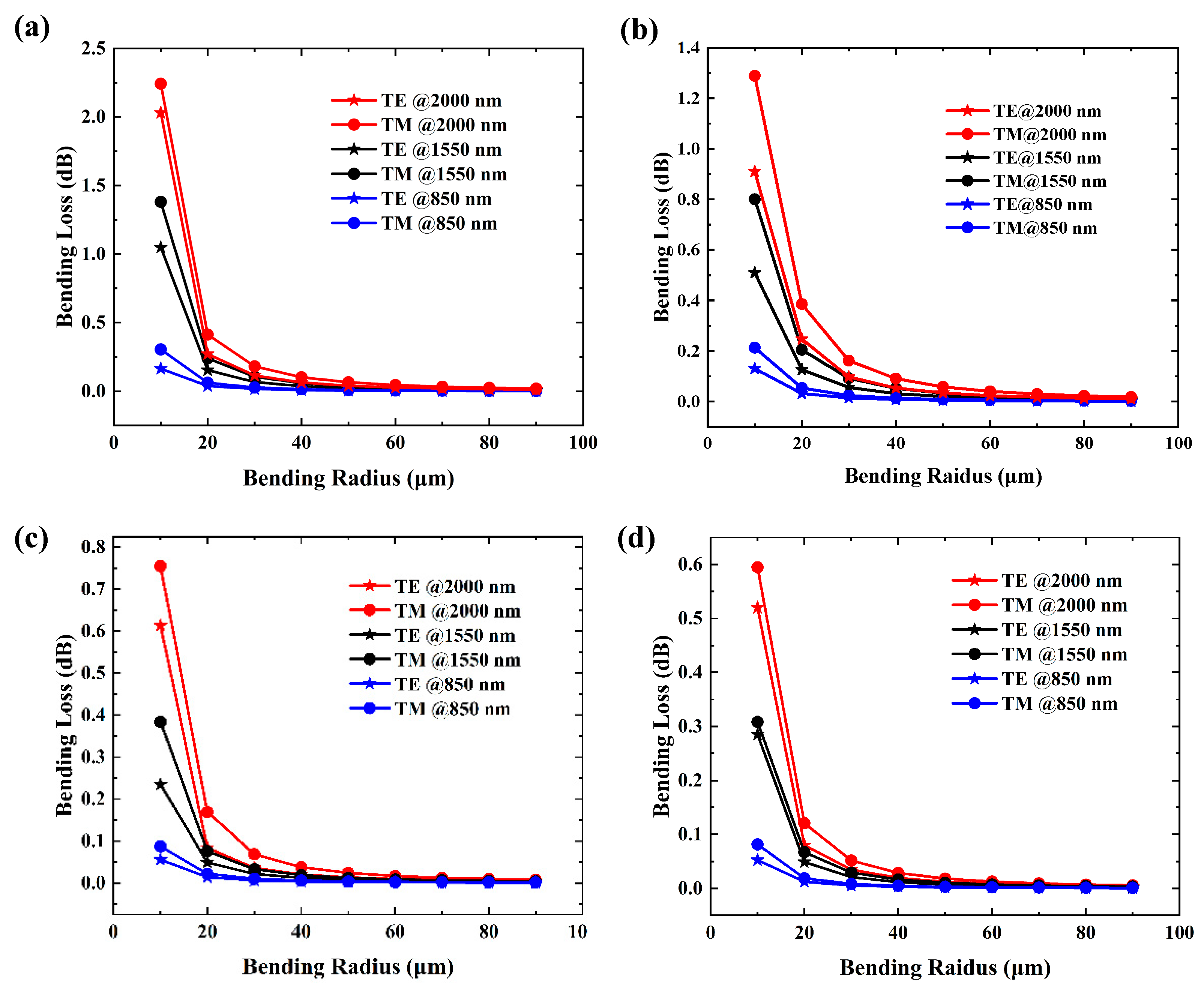

2.2. Bending Loss

3. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadiq, M.U.; Gleeson, M.R.; Ye, N.; O’Callaghan, J.; Morrissey, P.; Zhang, H.Y.; Thomas, K.; Gocalinska, A.; Pelucchi, E.; Gunning, F.C.G.; et al. 10 Gb/s InP-based Mach-Zehnder modulator for operation at 2 mum wavelengths. Opt. Express 2015, 23, 10905–10913. [Google Scholar] [CrossRef] [PubMed]

- Smit, M.; Williams, K.; van der Tol, J. Past, present, and future of InP-based photonic integration. APL Photonics 2019, 4, 050901. [Google Scholar] [CrossRef]

- Smit, M.; Leijtens, X.; Ambrosius, H.; Bente, E.; Van der Tol, J.; Smalbrugge, B.; De Vries, T.; Geluk, E.J.; Bolk, J.; Van Veldhoven, R.; et al. An introduction to InP-based generic integration technology. Semicond. Sci. Technol. 2014, 29, 083001. [Google Scholar] [CrossRef]

- Kish, F.A.; Welch, D.; Nagarajan, R.; Pleumeekers, J.L.; Lal, V.; Ziari, M.; Nilsson, A.; Kato, M.; Murthy, S.; Evans, P.; et al. Current Status of Large-Scale InP Photonic Integrated Circuits. IEEE J. Sel. Top. Quantum Electron. 2011, 17, 1470–1489. [Google Scholar] [CrossRef]

- Vyas, K.; Espinosa, D.H.G.; Hutama, D.; Jain, S.K.; Mahjoub, R.; Mobini, E.; Awan, K.M.; Lundeen, J.; Dolgaleva, K. Group III-V semiconductors as promising nonlinear integrated photonic platforms. Adv. Phys. X 2022, 7, 2097020. [Google Scholar] [CrossRef]

- Yan, Z.; Han, Y.; Lin, L.; Xue, Y.; Ma, C.; Ng, W.K.; Wong, K.S.; Lau, K.M. A monolithic InP/SOI platform for integrated photonics. Light. Sci. Appl. 2021, 10, 1–10. [Google Scholar] [CrossRef]

- Chang, L.; Boes, A.; Guo, X.; Spencer, D.T.; Kennedy, M.J.; Peters, J.D.; Volet, N.; Chiles, J.; Kowligy, A.; Nader, N.; et al. Heterogeneously Integrated GaAs Waveguides on Insulator for Efficient Frequency Conversion. Laser Photonics Rev. 2018, 12, 1800149. [Google Scholar] [CrossRef]

- Inoue, H.; Hiruma, K.; Ishida, K.; Asai, T.; Matsumura, H. Low loss GaAs optical waveguides. IEEE Trans. Electron Devices 1985, 32, 2662–2668. [Google Scholar] [CrossRef]

- Sugimoto, Y.; Tanaka, Y.; Ikeda, N.; Nakamura, Y.; Asakawa, K.; Inoue, K. Low propagation loss of 0.76 dB/mm in GaAs-based single-line-defect two-dimensional photonic crystal slab waveguides up to 1 cm in length. Opt. Express 2004, 12, 1090–1096. [Google Scholar] [CrossRef]

- Shah, M.; Soref, R.; Du, W.; Salamo, G.; Yu, S.-Q.; Mortazavi, M. Low-Loss GaAs/AlGaAs-On-Sapphire Waveguides for Sapphire Based Photonic Integrated Circuits. In CLEO: Applications and Technology; Optica Publishing Group: San Jose, CA, USA, 2023; p. AM4M.4. [Google Scholar]

- Deri, R.; Kapon, E. Low-loss III-V semiconductor optical waveguides. IEEE J. Quantum Electron. 1991, 27, 626–640. [Google Scholar] [CrossRef]

- Byun, Y.; Park, H.; Kim, S.; Choi, S.; Lim, T. Single-mode GaAs/AIGaAs W waveguides with a low propagation loss. Appl. Opt. 1996, 35, 928–933. [Google Scholar] [CrossRef] [PubMed]

- Morichetti, F.; Melloni, A.; Martinelli, M.; Heideman, R.G.; Leinse, A.; Geuzebroek, D.H.; Borreman, A. Box-Shaped Dielectric Waveguides: A New Concept in Integrated Optics? J. Light. Technol. 2007, 25, 2579–2589. [Google Scholar] [CrossRef]

- Roeloffzen, C.G.H.; Hoekman, M.; Klein, E.J.; Wevers, L.S.; Timens, R.B.; Marchenko, D.; Geskus, D.; Dekker, R.; Alippi, A.; Grootjans, R.; et al. Low-Loss Si3N4 TriPleX Optical Waveguides: Technology and Applications Overview. IEEE J. Sel. Top. Quantum Electron. 2018, 24, 4400321. [Google Scholar] [CrossRef]

- Blumenthal, D.J.; Heideman, R.; Geuzebroek, D.; Leinse, A.; Roeloffzen, C. Silicon Nitride in Silicon Photonics. Proc. IEEE 2018, 106, 2209–2231. [Google Scholar] [CrossRef]

- Liu, J.; Huang, G.; Wang, R.N.; He, J.; Raja, A.S.; Liu, T.; Engelsen, N.J.; Kippenberg, T.J. High-yield, wafer-scale fabrication of ultralow-loss, dispersion-engineered silicon nitride photonic circuits. Nat. Commun. 2021, 12, 1–9. [Google Scholar] [CrossRef]

- Victor Torres-Company; Ye, Z.; Zhao, P.; Karlsson, M.; Andrekson, P.A. Ultralow-loss Silicon Nitride Waveguides for Parametric Amplification. In Proceedings of the 2022 Optical Fiber Communications Conference and Exhibition (OFC), San Diego, CA, USA, 6–10 March 2022; p. W4J.3. [Google Scholar]

- Li, D.; Li, B.; Tang, B.; Zhang, P.; Yang, Y.; Liu, R.; Xie, L.; Li, Z. Broadband Silicon Nitride Power Splitter Based on Bent Directional Couplers with Low Thermal Sensitivity. Micromachines 2022, 13, 559. [Google Scholar] [CrossRef]

- Gundavarapu, S.; Brodnik, G.M.; Puckett, M.; Huffman, T.; Bose, D.; Behunin, R.; Wu, J.; Qiu, T.; Pinho, C.; Chauhan, N.; et al. Sub-hertz fundamental linewidth photonic integrated Brillouin laser. Nat. Photonics 2018, 13, 60–67. [Google Scholar] [CrossRef]

- Rahim, A.; Ryckeboer, E.; Subramanian, A.Z.; Clemmen, S.; Kuyken, B.; Dhakal, A.; Raza, A.; Hermans, A.; Muneeb, M.; Dhoore, S.; et al. Expanding the Silicon Photonics Portfolio with Silicon Nitride Photonic Integrated Circuits. J. Light. Technol. 2016, 35, 639–649. [Google Scholar] [CrossRef]

- Nishi, H.; Fuji, T.; Diamantopoulos, N.-P.; Takeda, K.; Kanno, E.; Kakitsuka, T.; Tsuchizawa, T.; Fukuda, H.; Matsuo, S. Integration of Eight-Channel Directly Modulated Membrane-Laser Array and SiN AWG Multiplexer on Si. J. Light. Technol. 2018, 37, 266–273. [Google Scholar] [CrossRef]

- Roeloffzen, C.G.H.; Zhuang, L.; Taddei, C.; Leinse, A.; Heideman, R.G.; van Dijk, P.W.L.; Oldenbeuving, R.M.; Marpaung, D.A.I.; Burla, M.; Boller, K.J. Silicon nitride microwave photonic circuits. Opt. Express 2013, 21, 22937–22961. [Google Scholar] [CrossRef]

- Zhang, W.; Yao, J. Silicon-Based Integrated Microwave Photonics. IEEE J. Quantum Electron. 2015, 52, 1–12. [Google Scholar] [CrossRef]

- Marpaung, D.; Yao, J.; Capmany, J. Integrated microwave photonics. Nat. Photonics 2019, 13, 80–90. [Google Scholar] [CrossRef]

- Saha, S.K.; Kumar, R.; Kuchuk, A.; Alavijeh, M.Z.; Maidaniuk, Y.; Mazur, Y.I.; Yu, S.-Q.; Salamo, G.J. Crystalline GaAs Thin Film Growth on a c-Plane Sapphire Substrate. Cryst. Growth Des. 2019, 19, 5088–5096. [Google Scholar] [CrossRef]

- Kumar, R.; Saha, S.K.; Kuchuk, A.; de Oliveira, F.M.; Khiangte, K.R.; Yu, S.-Q.; Mazur, Y.I.; Salamo, G.J. Improving the Material Quality of GaAs Grown on the c-Plane Sapphire by Molecular Beam Epitaxy to Achieve Room-Temperature Photoluminescence. Cryst. Growth Des. 2023, 23, 7385–7393. [Google Scholar] [CrossRef]

- Kumar, R.; Saha, S.K.; Kuchuk, A.; Maidaniuk, Y.; de Oliveira, F.M.; Yan, Q.; Benamara, M.; Mazur, Y.I.; Yu, S.-Q.; Salamo, G.J. GaAs layer on c-plane sapphire for light emitting sources. Appl. Surf. Sci. 2020, 542, 148554. [Google Scholar] [CrossRef]

- Cimalla, V.; Pezoldt, J.; Ecke, G.; Kosiba, R.; Ambacher, O.; Spieß, L.; Teichert, G.; Lu, H.; Schaff, W.J. Growth of cubic InN on r-plane sapphire. Appl. Phys. Lett. 2003, 83, 3468–3470. [Google Scholar] [CrossRef]

- Chandrasekaran, R.; Ozcan, A.S.; Deniz, D.; Ludwig, K.F.; Moustakas, T.D. Growth of non-polar (10) and semi-polar (16) AlN and GaN films on the R-plane sapphire. Phys. Status Solidi C 2007, 4, 1689–1693. [Google Scholar] [CrossRef]

- Yin, J.; Wu, Z.H.; Sun, Y.Q.; Fang, Y.Y.; Wang, H.; Feng, C.; Zhang, J.; Dai, J.N.; Chen, C.Q. The effects of V/III ratio on nonpolar a-plane GaN films grown on r-plane sapphire by MOCVD. J. Phys. Conf. Ser. 2011, 276, 012199. [Google Scholar] [CrossRef]

- Li, C.; Zhang, K.; Zeng, Q.; Wang, Q.; Li, Z.; Zhao, W.; Chen, Z. Effect of V/III ratio on the surface morphologies of N-polar GaN films grown on offcut sapphire substrates. J. Cryst. Growth 2020, 536, 125599. [Google Scholar] [CrossRef]

- Streicher, I.; Leone, S.; Kirste, L.; Ambacher, O. Effect of V/III ratio and growth pressure on surface and crystal quality of AlN grown on sapphire by metal-organic chemical vapor deposition. J. Vac. Sci. Technol. A 2022, 40, 032702. [Google Scholar] [CrossRef]

- Bauters, J.F.; Heck, M.J.R.; John, D.; Dai, D.; Tien, M.-C.; Barton, J.S.; Leinse, A.; Heideman, R.G.; Blumenthal, D.J.; Bowers, J.E. Ultra-low-loss high-aspect-ratio Si_3N_4 waveguides. Opt. Express 2011, 19, 3163–3174. [Google Scholar] [CrossRef]

- Lindecrantz, S.M.; Helleso, O.G. Estimation of Propagation Losses for Narrow Strip and Rib Waveguides. IEEE Photonics Technol. Lett. 2014, 26, 1836–1839. [Google Scholar] [CrossRef]

- Chen, H.; Fu, H.; Zhou, J.; Huang, X.; Yang, T.-H.; Fu, K.; Yang, C.; Montes, J.A.; Zhao, Y. Study of crystalline defect induced optical scattering loss inside photonic waveguides in UV–visible spectral wavelengths using volume current method. Opt. Express 2019, 27, 17262–17273. [Google Scholar] [CrossRef]

- Barwicz, T.; Haus, H.; Smith, H. A Three-Dimensional Analysis of Scattering Losses Due to Sidewall Roughness in Integrated Optical Waveguides. Infosecurity Today, 1 January 2003. [Google Scholar]

- Barwicz, T.; Haus, H. Three-dimensional analysis of scattering losses due to sidewall roughness in microphotonic waveguides. J. Light. Technol. 2005, 23, 2719–2732. [Google Scholar] [CrossRef]

- Bienstman, P.; Six, E.; Roelens, A.; Vanwolleghem, M.; Baets, R. Calculation of bending losses in dielectric waveguides using eigenmode expansion and perfectly matched layers. IEEE Photonics Technol. Lett. 2002, 14, 164–166. [Google Scholar] [CrossRef]

- Vogelbacher, F.; Nevlacsil, S.; Sagmeister, M.; Kraft, J.; Unterrainer, K.; Hainberger, R. Analysis of silicon nitride partial Euler waveguide bends. Opt. Express 2019, 27, 31394–31406. [Google Scholar] [CrossRef]

- Song, J.H.; Kongnyuy, T.D.; Stassen, A.; Mukund, V.; Rottenberg, X. Adiabatically Bent Waveguides on Silicon Nitride Photonics for Compact and Dense Footprints. IEEE Photonics Technol. Lett. 2016, 28, 2164–2167. [Google Scholar] [CrossRef]

- Hinum-Wagner, J.W.; Hoermann, S.M.; Sattelkow, J.; Buchberger, A.; Schörner, C.; Janka, S.; Rossbach, G.; Rist, D.; Kraft, J.; Bergmann, A. Ab-initio modeling of bend-losses in silicon nitride waveguides from visible to near-infrared. In Proceedings of the Optical Modeling and Performance Predictions XIII, San Diego, CA, USA, 28 September 2023; p. 1266405. [Google Scholar] [CrossRef]

| Material | CTE |

|---|---|

| Sapphire | 6.66 × 10−6 °C−1 parallel 5.00 × 10−6 °C−1 perpendicular |

| GaAs | Linear 5.73 × 10−6 °C−1 |

| AlAs | Linear 5.23 × 10−6 °C−1 |

| GaSb | Linear 7.75 × 10−6 °C−1 |

| InP | Linear 4.60 × 10−6 °C−1 |

| InSb | Linear 4.52 × 10−6 °C−1 |

| InAs | 6.50 × 10−6 °C−1 at 80 K 5.04 × 10−6 °C−1 at 300 K |

| Si | Linear 2.60 × 10−6 °C−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Yu, S.-Q.; Salamo, G.J.; Soref, R.A.; Du, W. Modeling Study of Si3N4 Waveguides on a Sapphire Platform for Photonic Integration Applications. Materials 2024, 17, 4148. https://doi.org/10.3390/ma17164148

Zhang D, Yu S-Q, Salamo GJ, Soref RA, Du W. Modeling Study of Si3N4 Waveguides on a Sapphire Platform for Photonic Integration Applications. Materials. 2024; 17(16):4148. https://doi.org/10.3390/ma17164148

Chicago/Turabian StyleZhang, Diandian, Shui-Qing Yu, Gregory J. Salamo, Richard A. Soref, and Wei Du. 2024. "Modeling Study of Si3N4 Waveguides on a Sapphire Platform for Photonic Integration Applications" Materials 17, no. 16: 4148. https://doi.org/10.3390/ma17164148

APA StyleZhang, D., Yu, S.-Q., Salamo, G. J., Soref, R. A., & Du, W. (2024). Modeling Study of Si3N4 Waveguides on a Sapphire Platform for Photonic Integration Applications. Materials, 17(16), 4148. https://doi.org/10.3390/ma17164148