Microstructure and Mechanical Properties of the Powder Metallurgy Nb-16Si-24Ti-2Al-2Cr Alloy

Abstract

1. Introduction

2. Experimental Procedure

3. Results and Discussion

4. Conclusions

- (1)

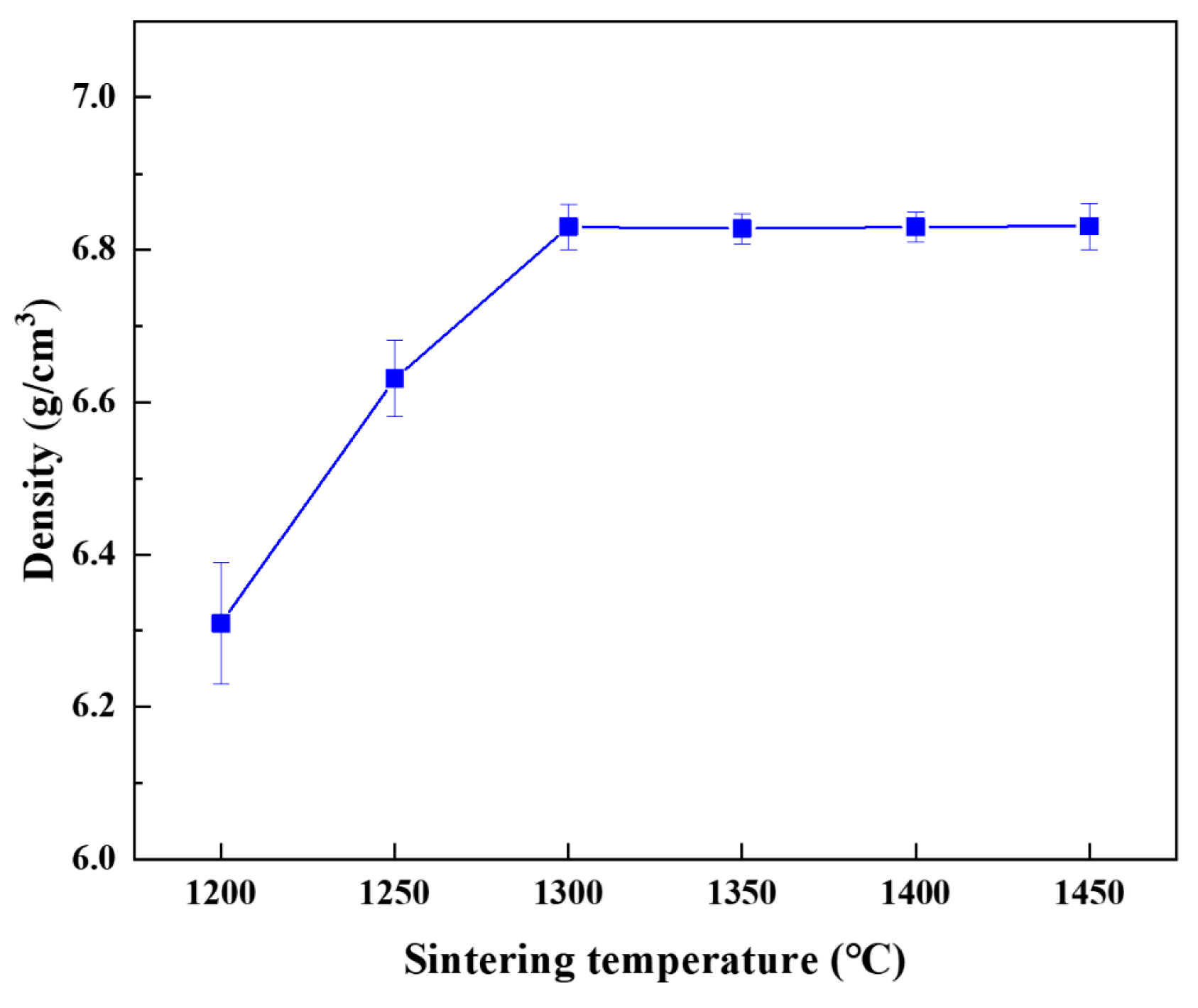

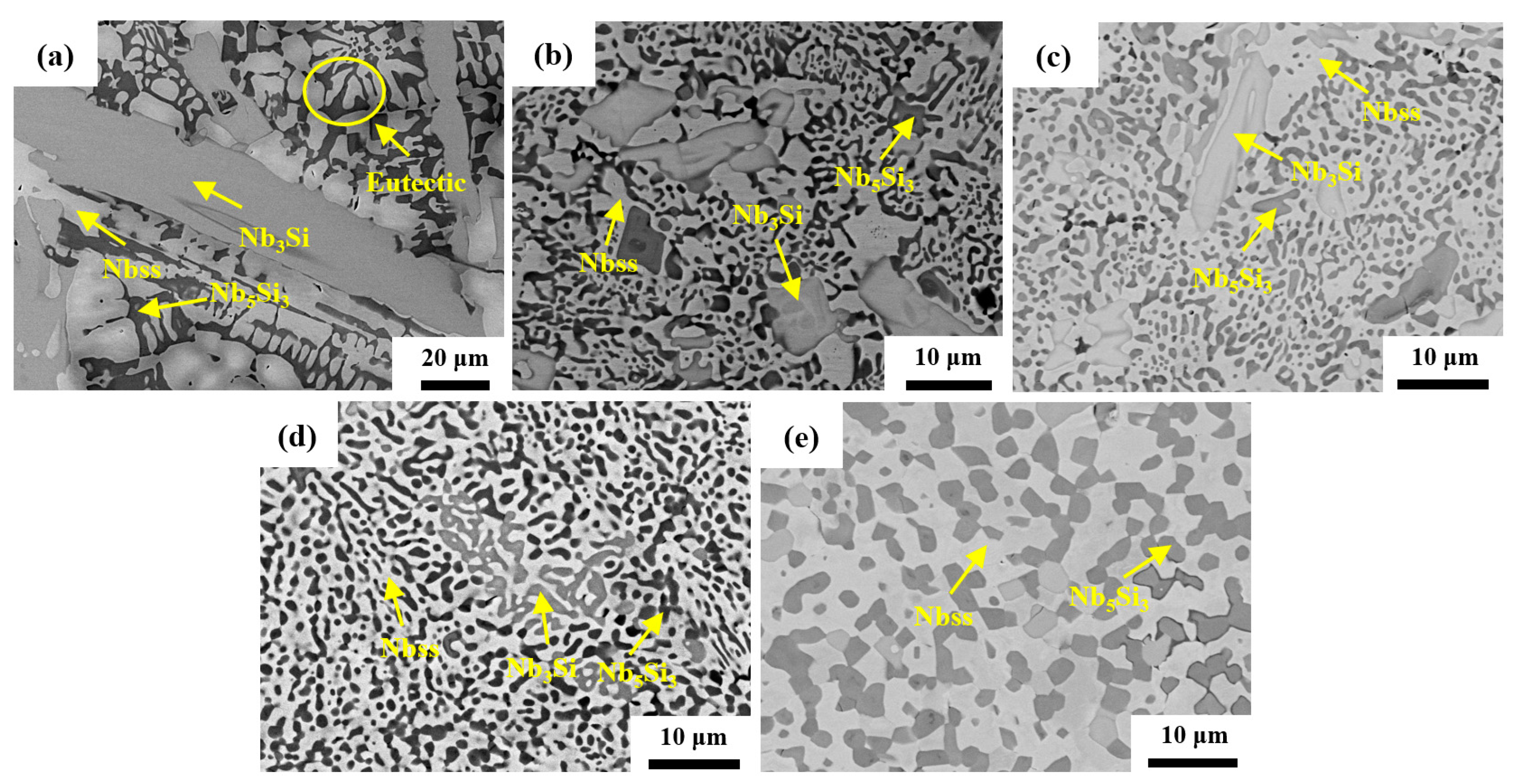

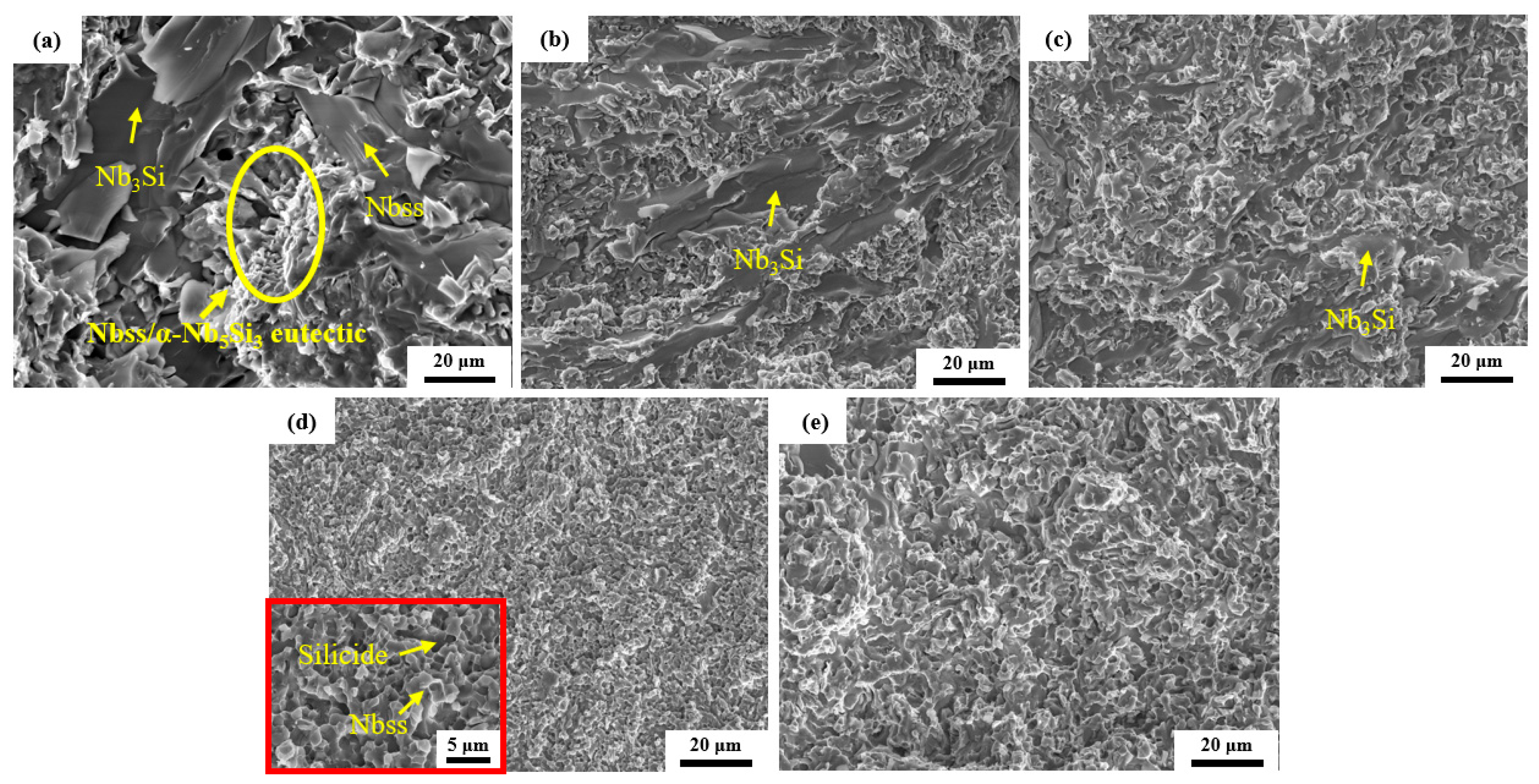

- The alloys sintered at temperatures below 1400 °C consist of Nbss, Nb3Si and Nb5Si3 phases. When the sintering temperature reaches 1450 °C, the Nb3Si phase is completely decomposed into Nbss and Nb5Si3 phases. Meanwhile, the microstructure coarsens significantly.

- (2)

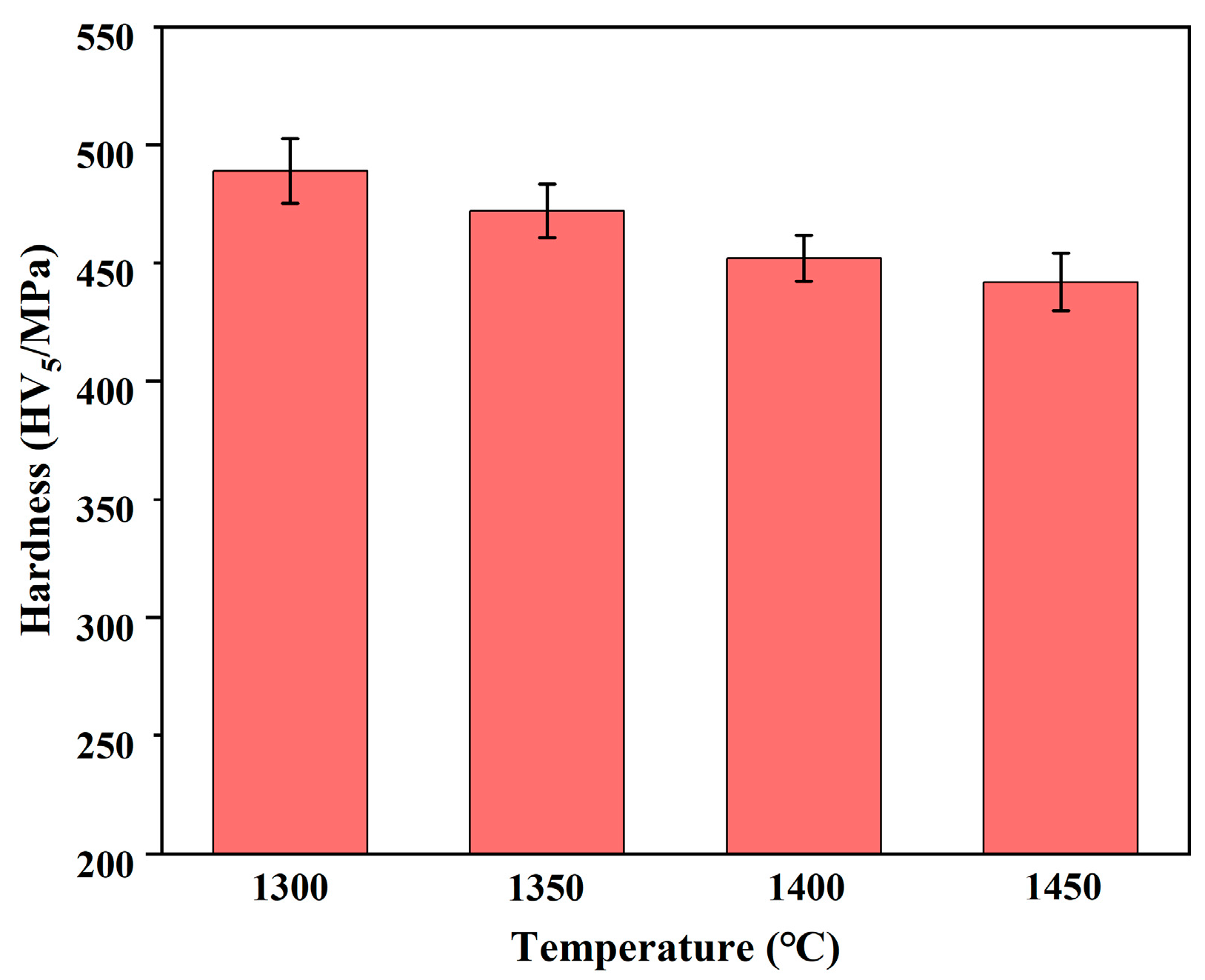

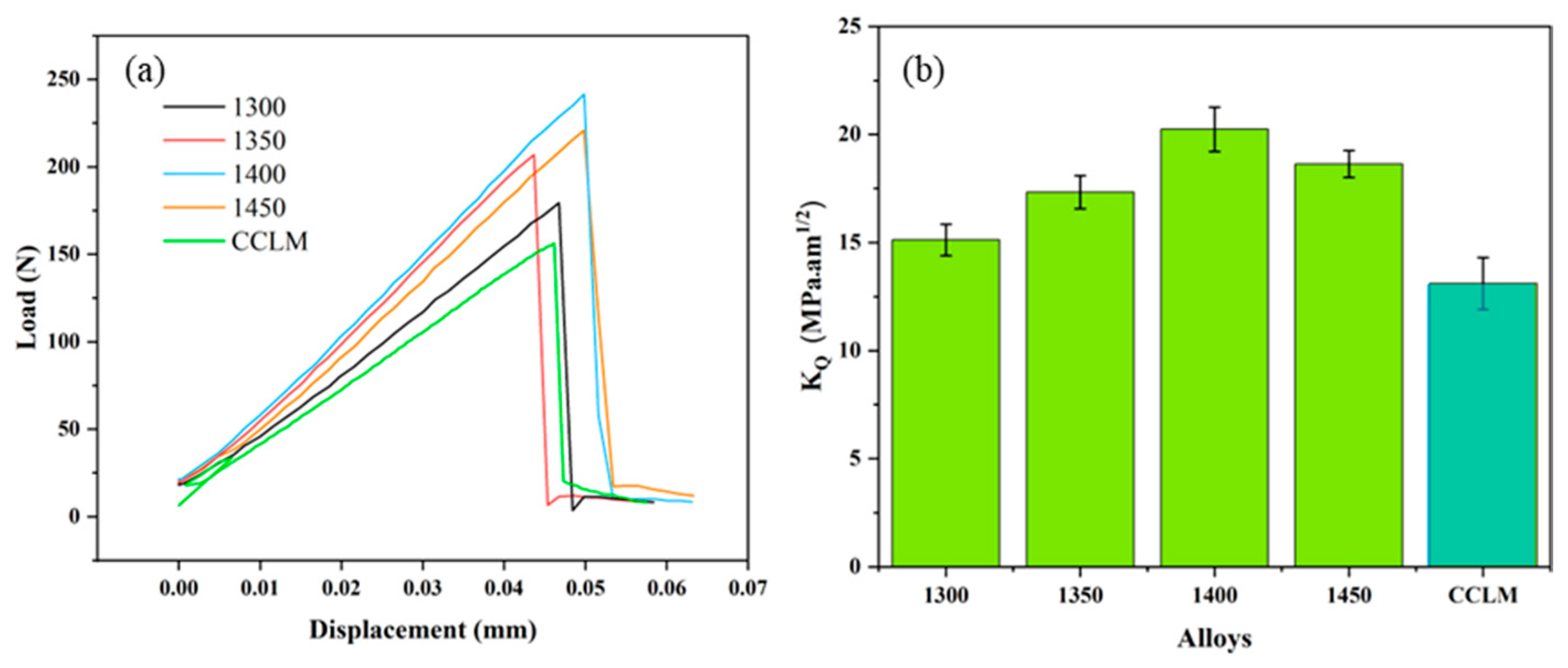

- With the increase in sintering temperature, the fracture toughness first increases and then decreases, while the yield strength decreases slightly. The fracture toughness of the alloy sintered at 1400 °C reaches 20.2 MPa·m1/2, exceeding the application threshold. Meanwhile, the fracture toughness of the HP alloy is nearly 1.34 times that of the cast alloy.

- (3)

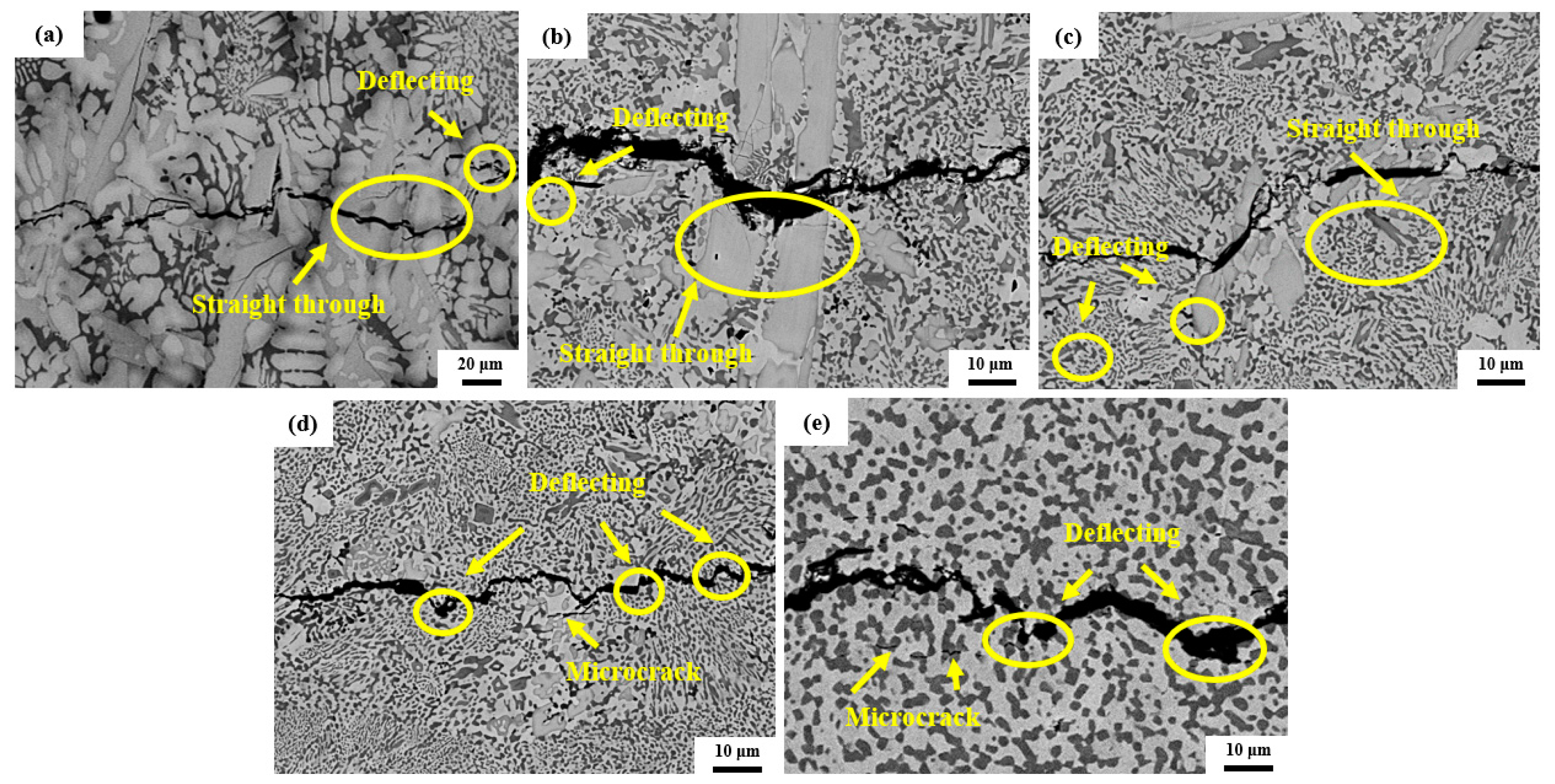

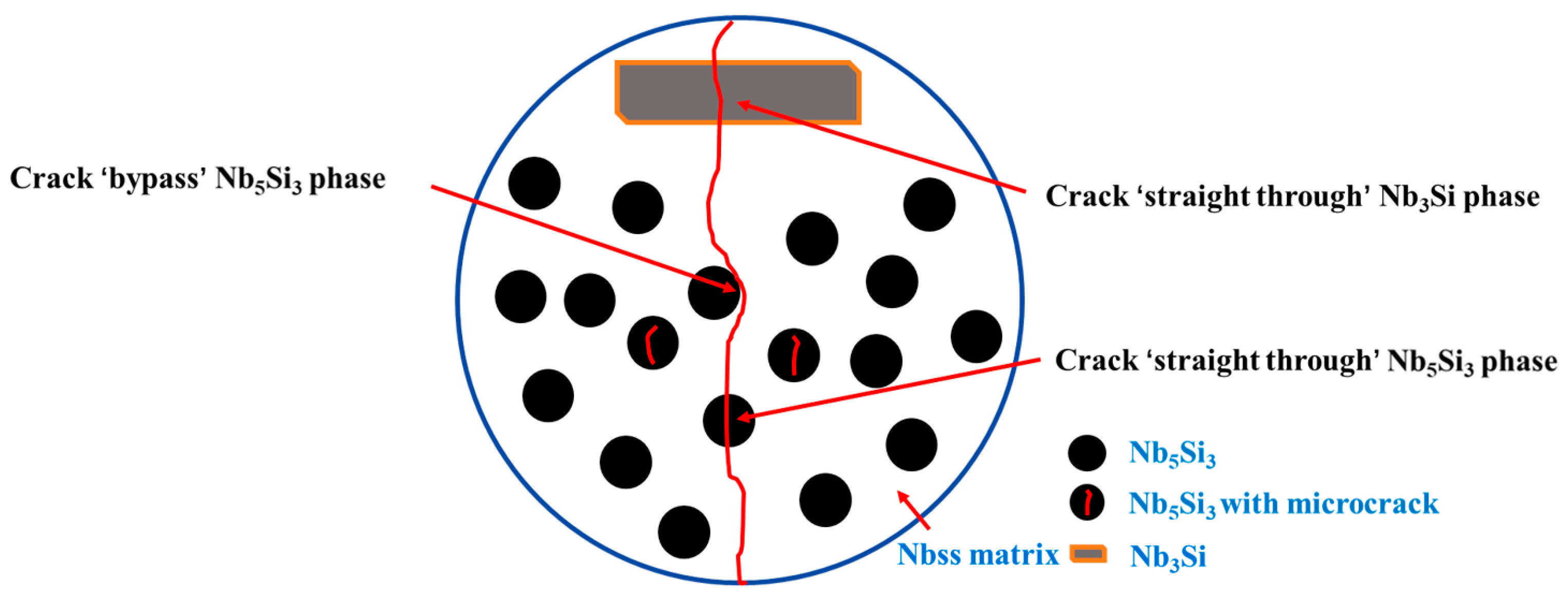

- The main reason for the highest fracture toughness is attributed to the decomposition of the large-sized brittle Nb3Si phase and the formation of a fine microstructure, which greatly increases the number of phase interfaces and improves the chance of crack deflection. In addition, the reduction in the size and content of silicides also reduces their plastic constraints on the ductile Nbss phase.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pan, Y.; Lin, Y.; Wang, H.; Zhang, C. Vacancy induced brittle-to-ductile transition of Nb5Si3 alloy from first-principles. Mater. Des. 2015, 86, 259–265. [Google Scholar] [CrossRef]

- Pollock, T.M. Alloy design for aircraft engines. Nat. Mater. 2016, 15, 809–815. [Google Scholar] [CrossRef] [PubMed]

- Sha, J.B.; Hirai, H.; Ueno, H.; Tabaru, T.; Kitahara, A.; Hanada, S. Mechanical properties of as-cast and directionally solidified Nb-Mo-W-Ti-Si in-situ composites at high temperatures. Metall. Mater. Trans. A 2003, 34, 85–94. [Google Scholar] [CrossRef]

- Wang, F.; Luo, L.; Meng, X.; Xu, Y.; Wang, L.; Su, Y.; Guo, J.; Fu, H. Morphological evolution of primary β-Nb5Si3 phase in Nb-Mo-Si alloys. J. Alloys Compd. 2018, 741, 51–58. [Google Scholar] [CrossRef]

- Kim, J.H.; Tabaru, T.; Sakamoto, M.; Hanada, S. Mechanical properties and fracture behavior ofan NbSS/Nb5Si3 in-situ composite modifiedby Mo and Hf alloying. Mater. Sci. Eng. A 2004, 372, 137–144. [Google Scholar] [CrossRef]

- Kang, Y.W.; Yan, Y.C.; Song, J.X.; Ding, H.S. Microstructures and mechanical properties of Nbss/Nb5Si3 in-situ composite prepared by electromagnetic cold crucible directional solidification. Mater. Sci. Eng. A 2014, 599, 87. [Google Scholar] [CrossRef]

- Schlesinger, M.E.; Okamoto, H.; Gokhale, A.B.; Abbaschian, R.; Phase, J. The Nb-Si (niobium-silicon) system. Equilibria 1993, 14, 502–509. [Google Scholar] [CrossRef]

- Yu, J.L.; Zhang, K.F. Tensile properties of multiphase refractory Nb-16Si-2Fe in situ composite. Scr. Mater. 2008, 59, 714. [Google Scholar] [CrossRef]

- Massalski, T.B. Binary alloy phase diagrams. ASM Int. Met. Park 1990, 3, 2295–2296. [Google Scholar]

- Zhao, J.C.; Bewlay, B.P.; Jackson, M.R. Determination of Nb-Hf-Si phase equilibria. Intermetallics 2001, 9, 681–689. [Google Scholar] [CrossRef]

- Kim, W.Y.; Tanaka, H.; Hanada, S. Microstructure and high temperature strength at 1773 K of NbSS/Nb5Si3 composites alloyed with molybdenum. Intermetallics 2002, 10, 625–634. [Google Scholar] [CrossRef]

- Wu, M.L.; Li, S.S.; Jiang, L.W.; Gong, S.K.; Han, Y.F. Effect of trace Zn, P and Mg additions on the microstructure and mechanical properties of Nb-Si-Ti alloys. Prog. Nat. Sci. 2011, 21, 139–145. [Google Scholar] [CrossRef]

- Fan, G.J.; Quan, M.X.; Hu, Z.Q.; Eckert, J.; Schultz, L. In-situ explosive formation of NbSi2 based namocomposites by mechanical alloying. Scr. Mater. 1999, 41, 1147–1151. [Google Scholar] [CrossRef]

- Fang, X.; Guo, X.P.; Qiao, Y.Q. Effect of Ti addition on microstructure and crystalline orientations of directionally solidified Nb-Si based alloys. Intermetallics 2020, 122, 106798. [Google Scholar] [CrossRef]

- Huang, Q.; Guo, X.P.; Kang, Y.W.; Song, J.X.; Qu, S.Y.; Han, Y.F. Microstructures and mechanical properties of a directionally solidified multi-element Nb-Si Alloy. Prog. Nat. Sci. Mater. Int. 2012, 21, 146–152. [Google Scholar] [CrossRef]

- Ma, C.L.; Li, J.G.; Tan, Y.; Tanaka, R.; Hanada, S. Microstructure and mechanical properties of Nb/Nb5Si3 in situ composites in Nb-Si-Mo and Nb-Si-W system. Mater. Sci. Eng. A 2004, 386, 375–383. [Google Scholar] [CrossRef]

- Li, Y.; Ma, C.; Zhang, H.; Miura, S. Mechanical properties of directionally solidified Nb-Mo-Si-based alloys with aligned Nbss/Nb5Si3 lamellar structure. Mater. Sci. Eng. A 2011, 528, 5772–5777. [Google Scholar] [CrossRef]

- Geng, J.; Tsakiropoulos, P.; Shao, G. A study of the effects of Hf and Sn additions on the microstructure of Nbss/Nb5Si3 based in-situ composites. Intermetallics 2007, 15, 69–76. [Google Scholar] [CrossRef]

- Bewlay, B.P.; Jackson, M.R.; Subramanian, P.R.; Zhao, J.C. A review of very-high-temperature Nb-silicide-based composites. Metall. Mater. Trans. A 2003, 34, 2043–2052. [Google Scholar] [CrossRef]

- Chan, K.S. Alloying effects on fracture mechanisms in Nb-based intermetallic in-situ composites. Mater. Sci. Eng. A 2002, 329–331, 513–522. [Google Scholar] [CrossRef]

- Chan, K.S.; Davidson, D.L. Effects of Ti addition on cleavage fracture in Nb-Cr-Ti solid-solution alloys. Metall. Mater. Trans. A 1999, 30, 925–939. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, Q.; Chen, R.; Zhou, Z.; Su, Y.; Fu, H. Microstructure and mechanical properties of Nb-Si alloy with addition of Mn. J. Mater. Res. Technol. 2022, 20, 708–719. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Liu, B.; Cao, Y.K.; Wang, J.; Liao, T.; Li, J.; Fang, Q.H.; Liaw, P.K.; Liu, Y. A novel cobalt-free oxide dispersion strengthened medium-entropy alloy with outstanding mechanical properties and irradiation resistance. J. Mater. Sci. Technol. 2023, 152, 190–200. [Google Scholar] [CrossRef]

- Wang, J.; Fu, A.; Liu, B.; Chen, Y.; Cao, Y.; Zhou, H.; Wang, B.; Li, X.; Li, J.; Fang, Q.; et al. Weakening the mechanical property anisotropy of additively manufactured medium entropy alloy by controlling the cellular structure. Addit. Manuf. 2024, 89, 104303. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Tan, F.; Cao, Y.; Li, J.; Liu, B.; Fang, Q.; Liaw, P.K.; Liu, Y. Structural damage and phase stability of cobalt-free FeCrNi medium-entropy alloy under high-fluence ion irradiation. Appl. Surf. Sci. 2024, 657, 159669. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhao, P.; Tong, Y.; Dong, H.; Zhou, J.; Qin, F.; Bi, Y.; Li, P. Microstructure and Mechanical Properties of Powder Metallurgy Superalloy Joints Welded by Inertia Friction Welding. Materials 2024, 17, 1342. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Lu, W.; Liu, B.; Li, J.; Fang, Q.; Li, Z.; Liu, Y. A novel supersaturated medium entropy alloy with superior tensile properties and corrosion resistance. Scripta Mater. 2020, 186, 381–386. [Google Scholar] [CrossRef]

- Liu, W.; Sha, J.B. Failure mode transition of Nb phase from cleavage to dimple/tear in Nb-16Si-based alloys prepared via spark plasma sintering. Mater. Des. 2016, 111, 301–311. [Google Scholar] [CrossRef]

- Mendiratta, M.G.; Dimiduk, D.M. Strength and toughness of a Nb/Nb5Si3 composite. Metall. Mater. Trans. A 1993, 24, 501–504. [Google Scholar] [CrossRef]

- Liu, T.; Li, T.; Cao, Y.; Fu, A.; Xie, Z.; Wang, J.; Liu, B.; Liu, Y. Improvement in the oxidation resistance of Nb-16Si-24Ti-2Al-2Cr alloy by hot pressing. Int. J. Refract. Met. Hard Mater. 2024, 120, 106605. [Google Scholar] [CrossRef]

- Guo, E.; Singh, S.S.; Kaira, C.S.; Meng, X.; Xu, Y.; Luo, L.; Wang, M.; Chawla, N. Mechanical properties of microconstituents in Nb-Si-Ti alloy by micropillar compression and nanoindentation. Mater. Sci. Eng. A 2017, 687, 99–106. [Google Scholar] [CrossRef]

- Chen, D.D.; Wang, Q.; Chen, R.R. A study on fine Nbss/γ-(Nb, X)5Si3 eutectic with significantly improved room-temperature fracture toughness by added ZrB2. Int. J. Refract. Met. Hard Mater. 2022, 108, 105935. [Google Scholar] [CrossRef]

- Fei, T.; Yu, Y.; Zhou, C.; Sha, J. The deformation and fracture modes of fine and coarsened NbSS phase in a Nb-20Si-24Ti-2Al-2Cr alloy with a NbSS/Nb5Si3 microstructure. Mater. Des. 2017, 116, 92–98. [Google Scholar] [CrossRef]

- Wang, Y.; Jia, L.; Ye, C.; Zhang, H. Achieving an appropriate strength-ductility synergy of Nbss/Nb5Si3 in situ composites governed by gradient annealing heat treatment. Mater. Charact. 2022, 193, 112312. [Google Scholar] [CrossRef]

- Sun, G.; Jia, L.; Ye, C.; Jin, Z.; Wang, Y.; Li, H.; Zhang, H. Balancing the fracture toughness and tensile strength by multiple additions of Zr and Y in Nb-Si based alloys. Intermetallics 2021, 133, 107172. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, X.; Chen, R.; Zhou, Z.; Su, Y.; Fu, H. Improvement of microstructure and fracture toughness of MASC alloy by element substitution of Zr for Hf. J. Alloys Compd. 2022, 892, 162127. [Google Scholar] [CrossRef]

- Wang, Q.; Zhao, T.; Chen, R.; Zhou, Z.; Su, Y.; Fu, H. Effect of C addition on microstructure and mechanical properties of Nb-Si-Ti based alloys. Mater. Sci. Eng. A 2021, 804, 140789. [Google Scholar] [CrossRef]

- Guo, Y.; Jia, L.; Kong, B.; Zhang, H.; Zhang, H. Simultaneous improvement in fracture toughness and oxidation resistance of Nb-Si based alloys by vanadium addition. Mater. Sci. Eng. A 2017, 701, 149–157. [Google Scholar] [CrossRef]

- Liao, J.; Fei, T.; Li, Y.; Yu, Y.; Sha, J. A comparison study on microstructures and fracture behaviours of a single NbSS solid solution alloy and a two-phase Nbss/Nb5Si3 alloy prepared by spark plasma sintering and arc melting. Mater. Charact. 2021, 178, 111259. [Google Scholar] [CrossRef]

- Zhao, T.; Wang, Q.; Chen, R.; Wang, X.; Su, Y.; Fu, H. Mechanism of interstitial atoms on oxidation and fracture of niobium-silicon alloys. Mater. Charact. 2024, 208, 113570. [Google Scholar] [CrossRef]

- Chen, D.; Wang, Q.; Chen, R.; Zhou, Z.; Su, Y.; Fu, H. Effect of Ni on microstructures and mechanical properties for multielemental Nb-Si-based alloys. Metall. Mater. Trans. A 2022, 53, 1793–1805. [Google Scholar] [CrossRef]

- Liu, W.; Sha, J. Effect of Nb and Nb5Si3 powder size on microstructure and fracture behavior of an Nb-16Si alloy fabricated by spark plasma sintering. Metall. Mater. Trans. A 2014, 45, 4316–4323. [Google Scholar] [CrossRef]

- Papadimitriou, I.; Utton, C.; Scott, A.; Tsakiropoulos, P. Ab initio study of the intermetallics in Nb-Si binary system. Intermetallics 2014, 54, 125. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, F.; Liu, W.; Fu, A.; Huang, Q.; Wang, J.; Cao, Y.; Qiu, J.; Liu, B. Microstructure and Mechanical Properties of the Powder Metallurgy Nb-16Si-24Ti-2Al-2Cr Alloy. Materials 2024, 17, 4155. https://doi.org/10.3390/ma17164155

Wen F, Liu W, Fu A, Huang Q, Wang J, Cao Y, Qiu J, Liu B. Microstructure and Mechanical Properties of the Powder Metallurgy Nb-16Si-24Ti-2Al-2Cr Alloy. Materials. 2024; 17(16):4155. https://doi.org/10.3390/ma17164155

Chicago/Turabian StyleWen, Feng, Wentao Liu, Ao Fu, Qianli Huang, Jian Wang, Yuankui Cao, Jingwen Qiu, and Bin Liu. 2024. "Microstructure and Mechanical Properties of the Powder Metallurgy Nb-16Si-24Ti-2Al-2Cr Alloy" Materials 17, no. 16: 4155. https://doi.org/10.3390/ma17164155

APA StyleWen, F., Liu, W., Fu, A., Huang, Q., Wang, J., Cao, Y., Qiu, J., & Liu, B. (2024). Microstructure and Mechanical Properties of the Powder Metallurgy Nb-16Si-24Ti-2Al-2Cr Alloy. Materials, 17(16), 4155. https://doi.org/10.3390/ma17164155