The Application of Converter Sludge and Slag to Produce Ecological Cement Mortars

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

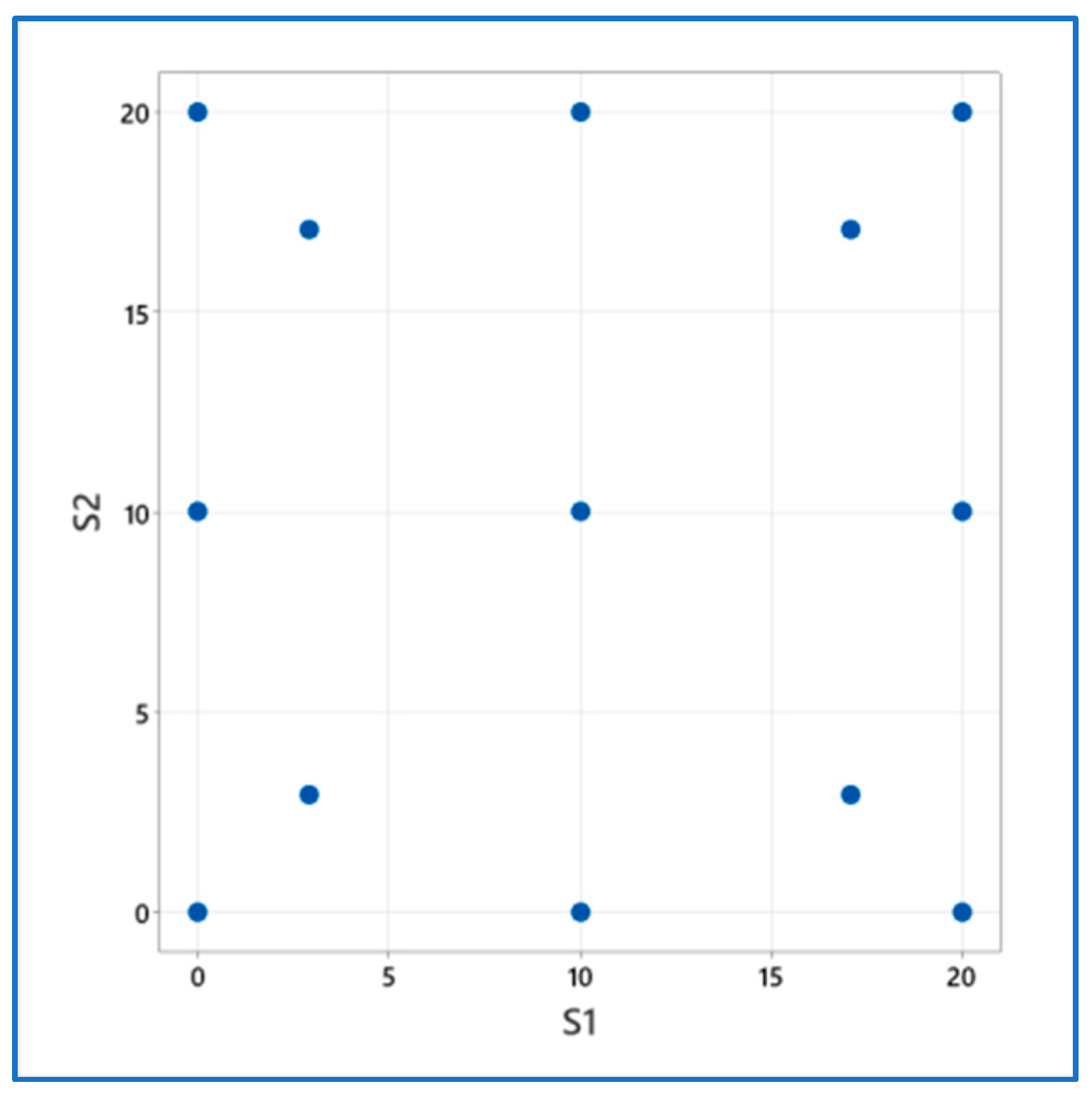

2.2. Research Methods

3. Results

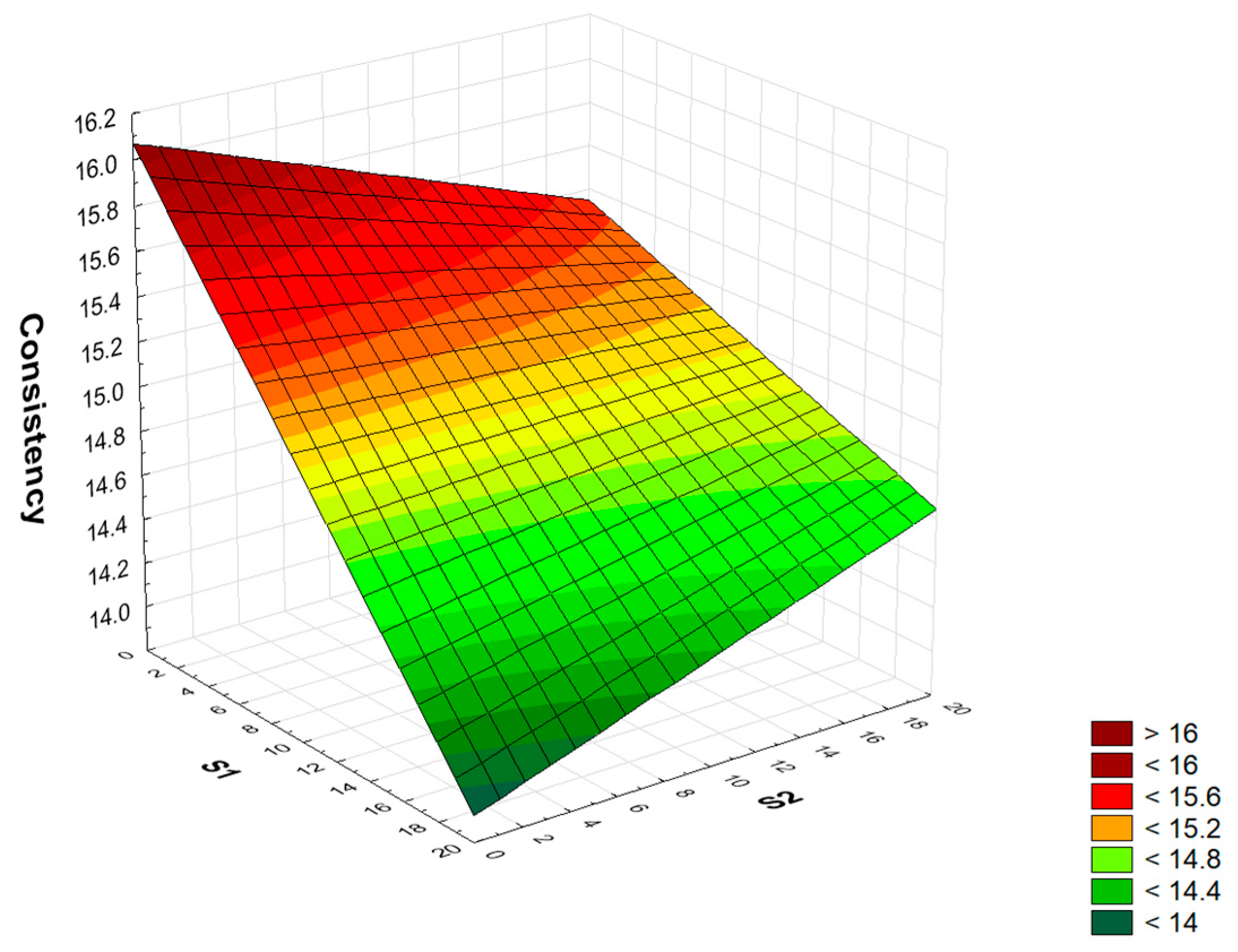

3.1. Consistency Analysis

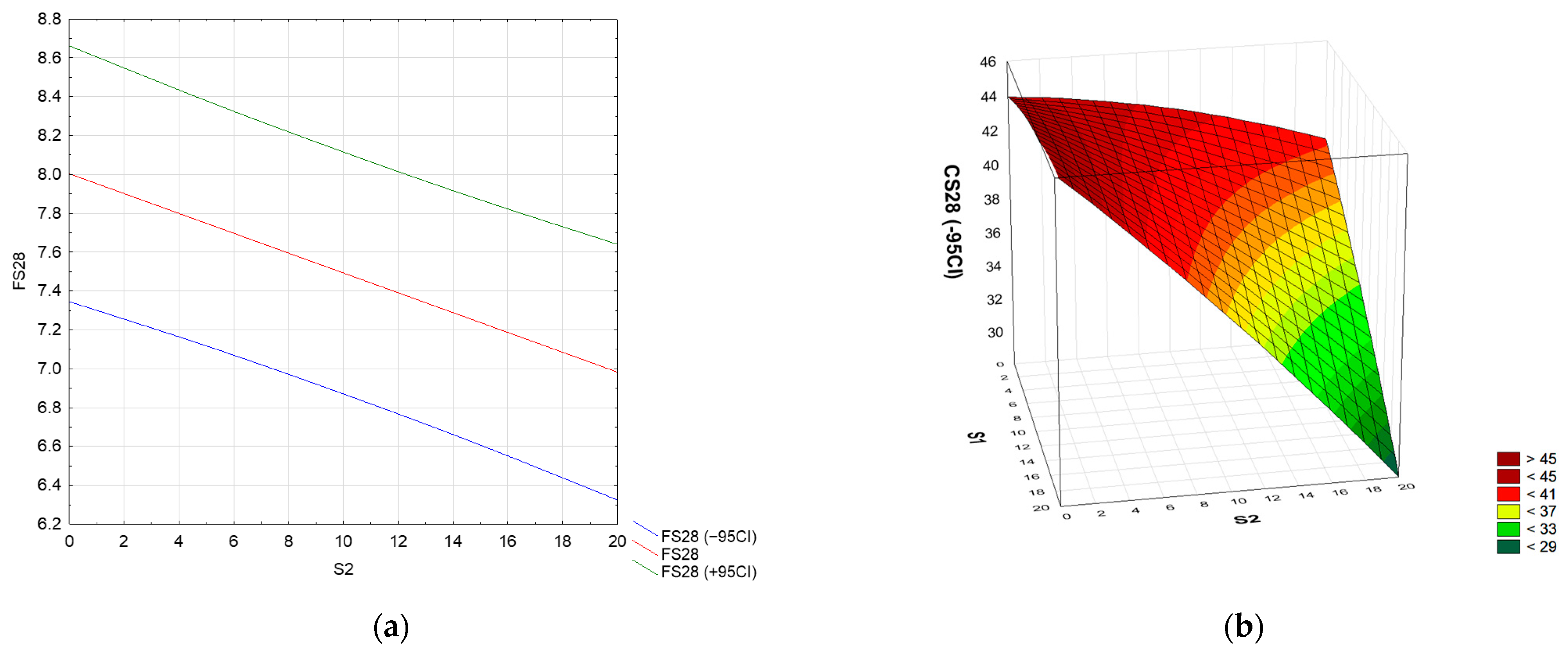

3.2. Analysis of Standard Flexural and Compressive Strength

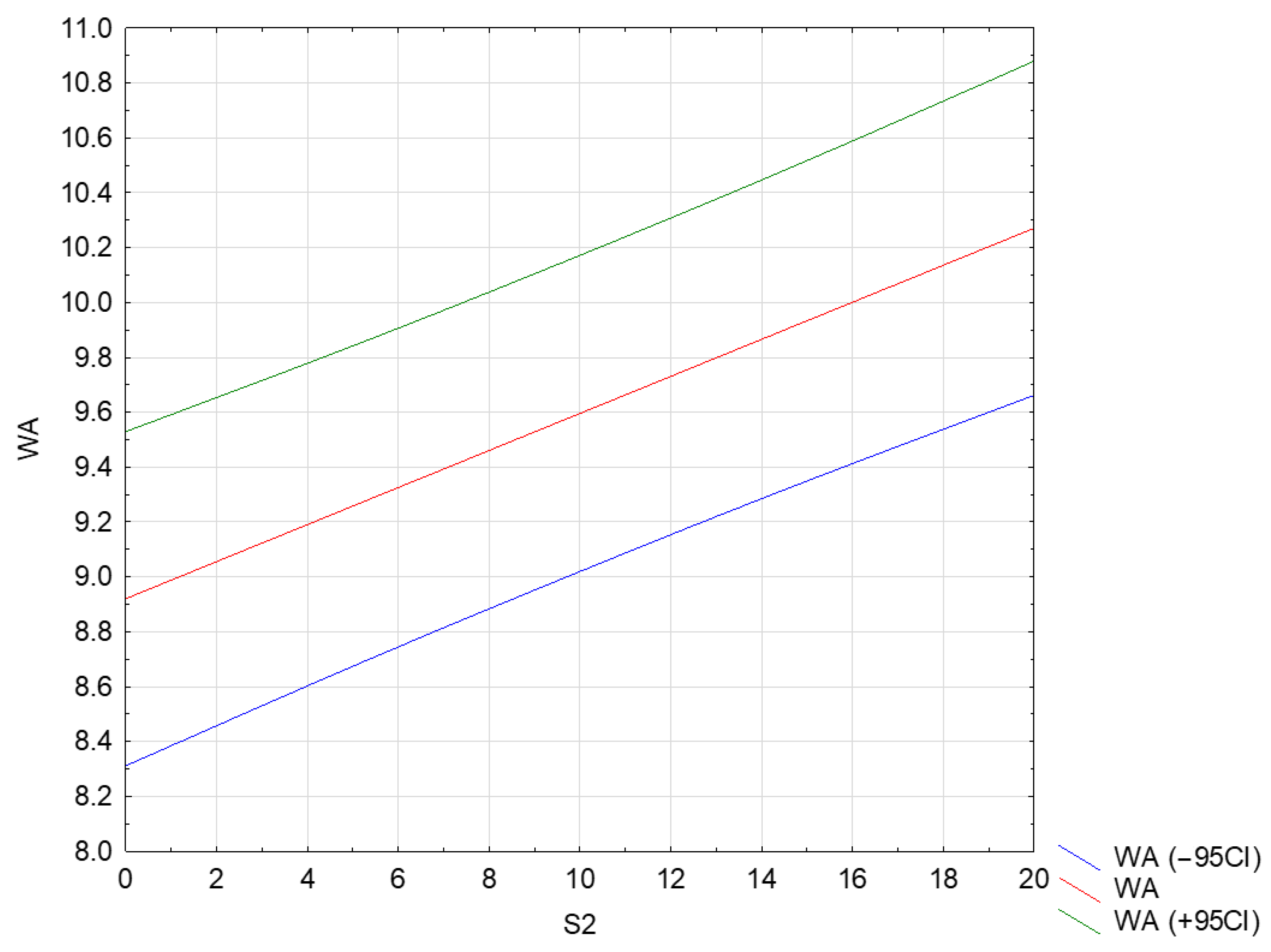

3.3. Water Absorption Analysis (WA)

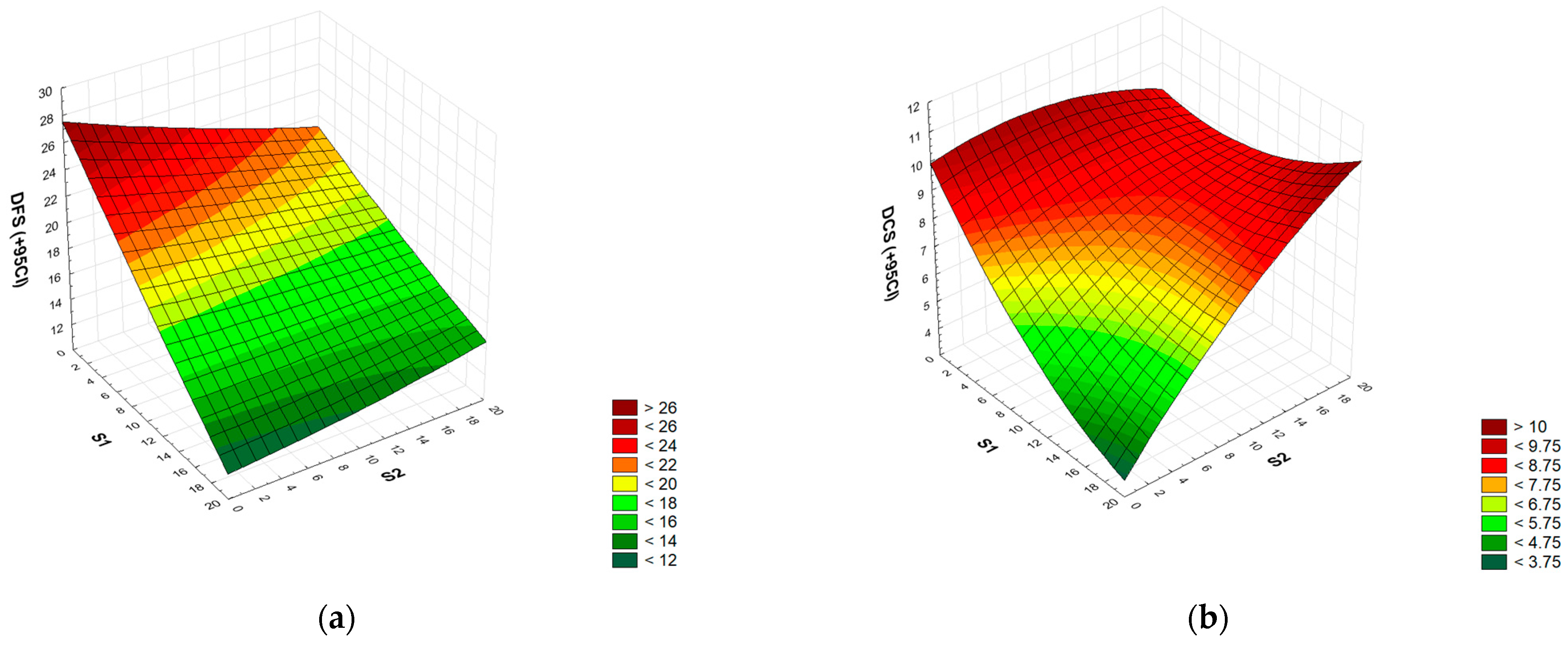

3.4. Analysis of the Decrease in Flexural and Compressive Strength after Frost Resistance Tests

3.5. Mass Loss Analysis (ML)

3.6. Metal Ion Leaching Test

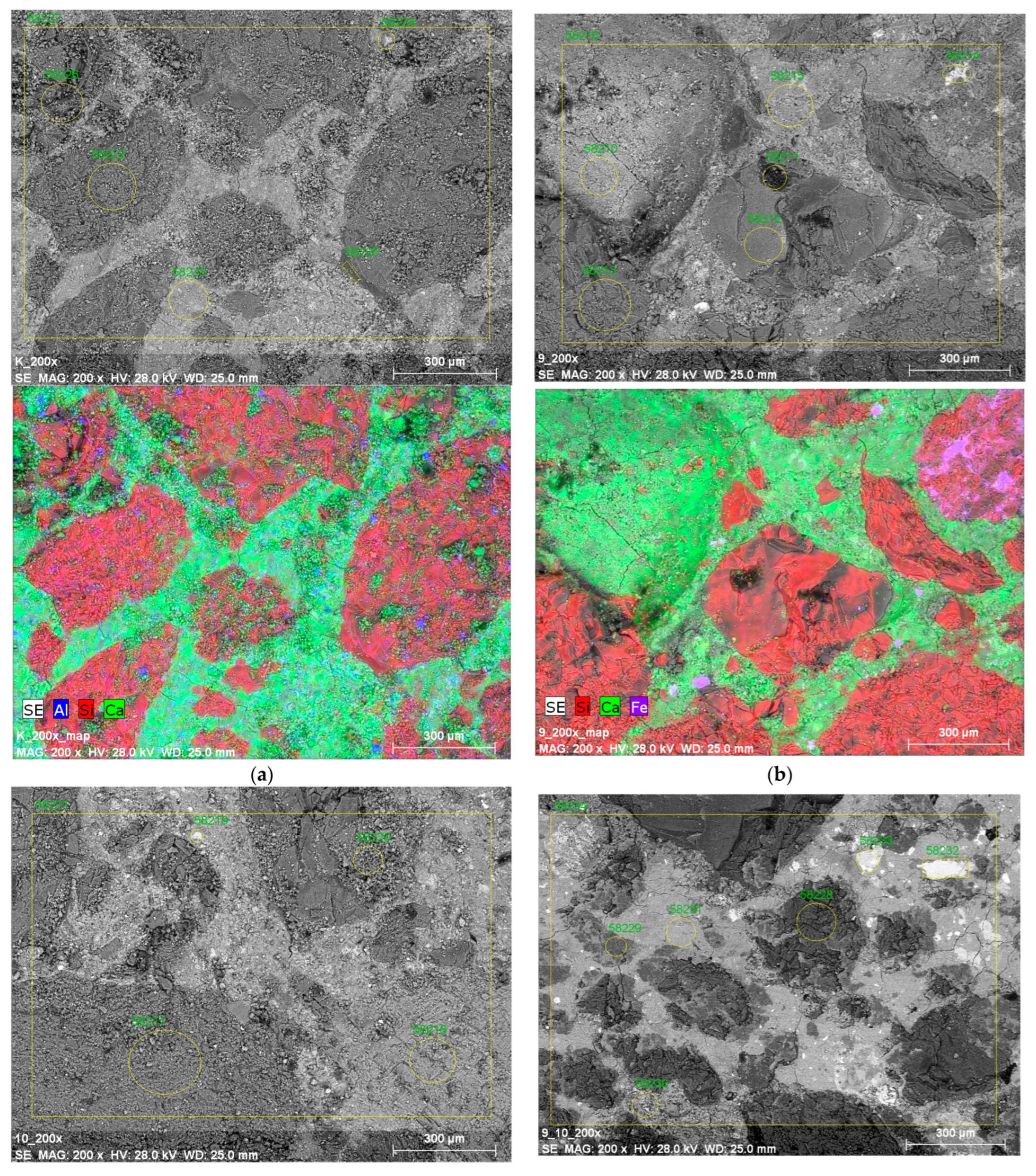

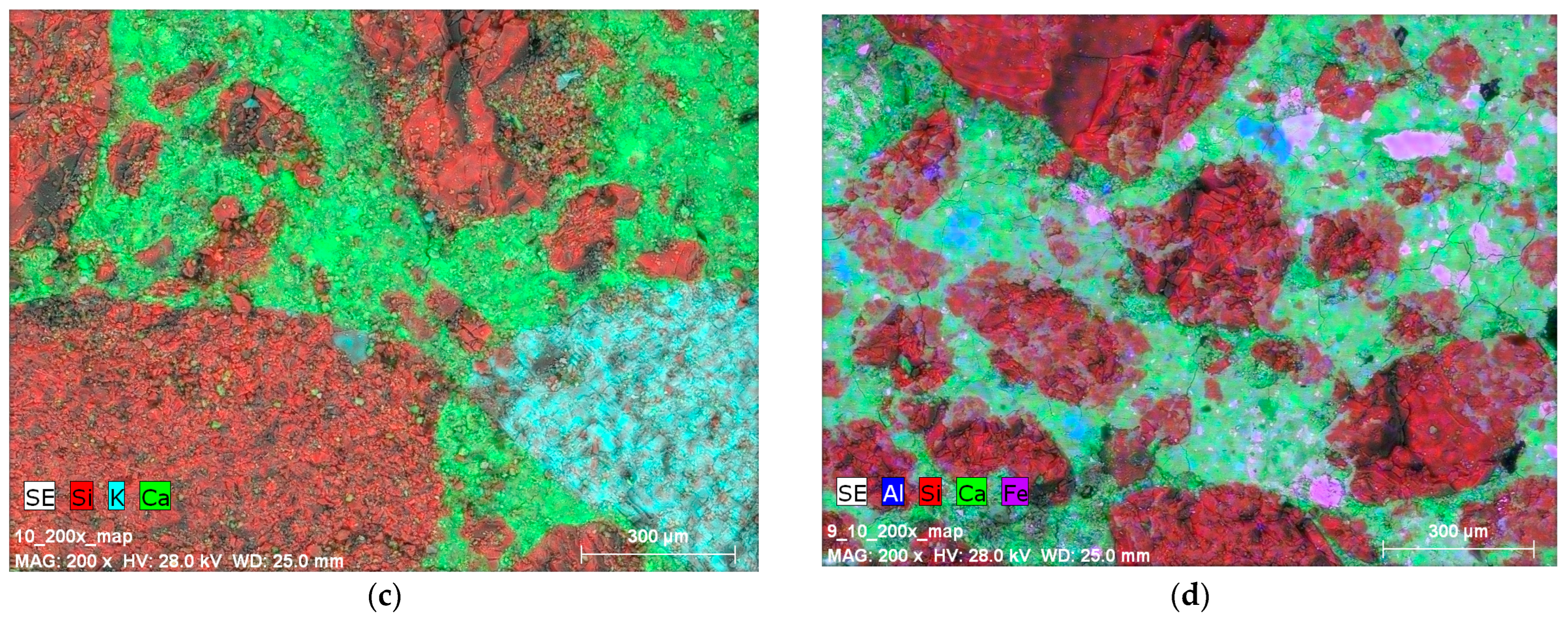

3.7. Microstructure

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Statista Raport. Industrial Sand and Gravel Production Worldwide from 2010 to 2023. 2024. Available online: https://www.statista.com/statistics/728756/industrial-sand-and-gravel-production-worldwide/ (accessed on 21 March 2024).

- United Nations Environment Programme, 2022. Report Sand and Sustainability: 10 Strategic Recommendations to Avert a Crisis, No: DTI/2430/GE. Available online: https://www.unep.org/resources/report/sand-and-sustainability-10-strategic-recommendations-avert-crisis (accessed on 21 March 2024).

- Letelier, V.; Henríquez-Jara, B.I.; Manosalva, M.; Parodi, C.; Ortega, J.M. Use of waste glass as a replacement for raw materials in mortars with a lower environmental impact. Energies 2019, 12, 1974. [Google Scholar] [CrossRef]

- Dębska, B.; Krasoń, J.; Lichołai, L. The evaluation of the possible utilization of waste glass in sustainable mortars. CoOEP 2020, 9, 7–15. [Google Scholar] [CrossRef]

- Ulewicz, M.; Pietrzak, A. Properties and structure of concretes doped with production waste of thermoplastic elastomers from the production of car floor mats. Materials 2021, 14, 872. [Google Scholar] [CrossRef] [PubMed]

- Pietrzak, A.; Ulewicz, M. Influence of Post-Consumer Waste Thermoplastic Elastomers Obtained from Used Car Floor Mats on Concrete Properties. Materials 2023, 16, 2231. [Google Scholar] [CrossRef] [PubMed]

- Ulewicz, M.; Jura, J.; Gnatowski, A. Cement Mortars Based on Polyamide Waste Modified with Fly Ash from Biomass Combustion—A New Material for Sustainable Construction. Sustainability 2024, 16, 3079. [Google Scholar] [CrossRef]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.O.A.; Alao, K.T. Potential use of biomass ash as a sustainable alternative for fly ash in concrete production: A review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- Jura, J.; Ulewicz, M. Assessment of the Possibility of Using Fly Ash from Biomass Combustion for Concrete. Materials 2021, 14, 6708. [Google Scholar] [CrossRef]

- Liang, C.; Le, X.; Fang, W.; Zhao, J.; Fang, L.; Hou, S. The Utilization of Recycled Sewage Sludge Ash as a Supplementary Cementitious Material in Mortar: A Review. Sustainability 2022, 14, 4432. [Google Scholar] [CrossRef]

- Pietrzak, A. The effect of ashes generated from the combustion of sewage sludge on the basic mechanical properties of concrete. CoOEP 2019, 8, 29–35. [Google Scholar] [CrossRef]

- Kalak, T.; Szypura, P.; Cierpiszewski, R.; Ulewicz, M. Modification of Concrete Composition Doped by Sewage Sludge Fly Ash and Its Effect on Compressive Strength. Materials 2023, 16, 4043. [Google Scholar] [CrossRef]

- Chen, H.; Chow, C.L.; Lau, D. Developing green and sustainable concrete in integrating with different urban wastes. J. Clean. Prod. 2022, 368, 133057. [Google Scholar] [CrossRef]

- Korentz, J.; Jurczak, R.; Szmatuła, F. Properties of concrete with the addition of copper slag aggregate. Cem.-Wapno-Beton Cem. Lime Concr. 2020, 25, 367–375. [Google Scholar] [CrossRef]

- Prem, P.R.; Verma, M.; Ambily, P.S. Sustainable cleaner production of concrete with high volume copper slag. J. Clean. Prod. 2018, 193, 43–58. [Google Scholar] [CrossRef]

- Yang, T.; Zhang, Z.; Wang, Q.; Wu, Q. ASR potential of nickel slag fine aggregate in blast furnace slag-fly ash geopolymer and Portland cement mortars. Constr. Build. Mater. 2020, 262, 119990. [Google Scholar] [CrossRef]

- Zhao, Q.; Pang, L.; Wang, D. Adverse Effects of Using Metallurgical Slags as Supplementary Cementitious Materials and Aggregate: A Review. Materials 2022, 15, 3803. [Google Scholar] [CrossRef]

- Gholizadeh Vayghan, A.; Horckmans, L.; Snellings, R.; Peys, A.; Teck, P.; Maier, J.; Friedrich, B.; Klejnowska, K. Use of Treated Non-Ferrous Metallurgical Slags as Supplementary Cementitious Materials in Cementitious Mixtures. Appl. Sci. 2021, 11, 4028. [Google Scholar] [CrossRef]

- Saafan, M.A.; Etman, Z.A.; El-Lakany, D.M. Microstructure and Durability of Ground Granulated Blast Furnace Slag Cement Mortars. Iran J. Sci. Technol. Trans Civ. Eng. 2021, 45, 1457–1465. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, H.S. Improvement of Early Strength of Cement Mortar Containing Granulated Blast Furnace Slag Using Industrial Byproducts. Materials 2017, 10, 1050. [Google Scholar] [CrossRef]

- Rakhimova, N.R.; Rakhimov, R.Z. Alkali-activated cements and mortars based on blast furnace slag and red clay brick waste. Mater. Des. 2015, 85, 324–331. [Google Scholar] [CrossRef]

- Figueredo, P.K. Utilisation of Blast-Furnace Slag as an Alternative of Natural Sand in Cement-Mortar and Concrete. Iconic Res. Eng. J. 2023, 6, 157–161. [Google Scholar]

- Pachideh, G.; Gholhaki, M. Assessment of post-heat behavior of cement mortar incorporating silica fume and granulated blast-furnace slag. J. Struct. Fire Eng. 2020, 11, 221–246. [Google Scholar] [CrossRef]

- Rashad, A.M.; Sadek, D.M.; Hassan, H.A. An investigation on blast-furnace slag as fine aggregate in alkali-activated slag mortars subjected to elevated temperatures. J. Clean. Prod. 2016, 112, 1086–1096. [Google Scholar] [CrossRef]

- Sellitto, M.A.; Murakami, F.K. Destination of the waste generated by a steelmaking plant: A case study in Latin America. AESTIMUM 2020, 77, 127–144. [Google Scholar] [CrossRef]

- Das, B.; Prakash, S.; Reddy, P.S.R.; Misra, V.N. An overview of utilization of slag and sludge from steel industries. Resour. Conserv. Recycl. 2007, 50, 40–57. [Google Scholar] [CrossRef]

- Kaja, A.M.; Schollbach, K.; Melzer, S.V.; van der Laan, S.R.; Brouwers, H.J.H.; Yu, Q. Hydration of potassium citrate-activated BOF slag. Cem. Concr. Res. 2021, 140, 106291. [Google Scholar] [CrossRef]

- Gargul, K.; Boryczko, B. Removal of zinc from dusts and sludges from basic oxygen furnaces in the process of ammoniacal leaching. Arch. Civil Mech. Eng. 2015, 15, 179–187. [Google Scholar] [CrossRef]

- Nair, A.T.; Mathew, A.; Archana, A.R.; Akbar, M.A. Use of hazardous electric arc furnace dust in the construction industry: A cleaner production approach. J. Clean. Prod. 2022, 377, 134282. [Google Scholar] [CrossRef]

- World Steel in Figures. 2022. Available online: https://worldsteel.org/steel-topics/statistics/world-steel-in-figures-2022/ (accessed on 21 March 2024).

- Rashad, A.M. Behavior of steel slag aggregate in mortar and concrete—A comprehensive overview. J. Build. Eng. 2022, 53, 104536. [Google Scholar] [CrossRef]

- Gencel, O.; Karadag, O.; Oren, O.H.; Bilir, T. Steel slag and its applications in cement and concrete technology: A review. Constr. Build. Mater. 2021, 283, 122783. [Google Scholar] [CrossRef]

- Bang, J.H.; Lee, S.W.; Jeon, C.; Park, S.; Song, K.; Jo, W.J.; Chae, S. Leaching of Metal Ions from Blast Furnace Slag by Using Aqua Regia for CO2 Mineralization. Energies 2016, 9, 996. [Google Scholar] [CrossRef]

- Mizerna, K.; Król, A. Leaching of heavy metals from monolithic waste, Environment Protection Engineering. Environ. Prot. Eng. 2018, 44, 143–158. [Google Scholar] [CrossRef]

- Vishweshwaraiah, R.T.; Patnaikuni, C.K. Optimized potential performance of slag sand in cement mortar through micro-mechanical and durability investigation. Innov. Infrastruct. Solut. 2024, 9, 9. [Google Scholar] [CrossRef]

- Alzaza, A.; Ohenoja, K.; Shaikh, F.U.A.; Illikainen, M. Mechanical and durability properties of C–S–H-seeded cement mortar cured at fluctuating low temperatures with granulated blast furnace slag as fine aggregates. J. Build. Eng. 2022, 57, 104879. [Google Scholar] [CrossRef]

- Na, S.; Zhang, W.; Taniguchi, M.; Quy, N.X.; Hama, Y. Experimental Investigation of Material Properties and Self-Healing Ability in a Blended Cement Mortar with Blast Furnace Slag. Materials 2020, 13, 2564. [Google Scholar] [CrossRef]

- Li, L.; Ye, T.; Li, Y.; Wang, Z.; Feng, Z.; Liu, Z. Improvement of microporous structure and impermeability of cement mortars using fly ash and blast furnace slag under low curing pressures. Constr. Build. Mater. 2023, 401, 132890. [Google Scholar] [CrossRef]

- Liu, G.; Tang, Y.; Wang, J. Recycling and valorization of hydrated cement blends in mortars via semi-dry carbonation—The role of waste glass, granulated blast furnace slag and fly ash. Constr. Build. Mater. 2023, 401, 132987. [Google Scholar] [CrossRef]

- Filazi, A.; Tortuk, S.; Pul, M. Determination of optimum blast furnace slag ash and hemp fiber ratio in cement mortars. Structures 2023, 57, 105024. [Google Scholar] [CrossRef]

- Kishimoto, G.; Kim, J.; Choi, H.; Hama, Y. Influence of Silicone Oil on Durability of Portland Blast Furnace Slag Cement Mortar. J. Adv. Concr. Technol. 2018, 16, 110–123. [Google Scholar] [CrossRef]

- Fan, W.; Zhuge, Y.; Ma, X.; Chow, C.W.K.; Gorjian, N.; Oh, J.A.; Duan, W. Durability of Fibre-Reinforced Calcium Aluminate Cement (CAC)–Ground Granulated Blast Furnace Slag (GGBFS) Blended Mortar after Sulfuric Acid Attack. Materials 2020, 13, 3822. [Google Scholar] [CrossRef]

- Ahmad, J.; Kontoleon, K.J.; Majdi, A.; Naqash, M.T.; Deifalla, A.F.; Ben Kahla, N.; Isleem, H.F.; Qaidi, S.M.A. A comprehensive review on the ground granulated blast furnace slag (GGBS) in concrete production. Sustainability 2022, 14, 8783. [Google Scholar] [CrossRef]

- Ismail, Z.Z.; AL-Hashmi, E.A. Reuse of waste iron as a partial replacement of sand in concrete. Waste Manag. 2008, 28, 2048–2053. [Google Scholar] [CrossRef]

- Zago, S.C.; Vernilli, F.; Cascudo, O. The Reuse of Basic Oxygen Furnace Slag as Concrete Aggregate to Achieve Sustainable Development: Characteristics and Limitations. Buildings 2023, 13, 1193. [Google Scholar] [CrossRef]

- Kong, D.; Chen, M.; Xie, J.; Zhao, M.; Yang, C. Geometric Characteristics of BOF Slag Coarse Aggregate and its Influence on Asphalt Concrete. Materials 2019, 12, 741. [Google Scholar] [CrossRef]

- López-Díaz, A.; Ochoa-Díaz, R.; Grimaldo-León, G.E. Use of BOF slag and blast furnace dust in asphalt concrete: An alternative for the construction of pavements. Revista DYNA 2018, 85, 24–30. [Google Scholar] [CrossRef]

- Lee, K.M.; Lee, H.K.; Lee, S.H.; Kim, G.Y. Autogenous shrinkage of concrete containing granulated blast-furnace slag. Cem. Concr. Res. 2006, 36, 1279–1285. [Google Scholar] [CrossRef]

- Guo, L.P.; Sun, W.; Zheng, K.R.; Chen, H.J.; Liu, B. Study on the flexural fatigue performance and fractal mechanism of concrete with high proportions of ground phosphogypsum waste slag. Cem. Concr. Res. 2007, 37, 242–250. [Google Scholar] [CrossRef]

- Mandal, R.; Panda, S.K.; Nayak, S.; Chakraborty, S. Efficacy of pond ash (PA) combined with ground granulated blast furnace slag (GGBFS) in producing cement-less mortar. Structures 2022, 45, 748–757. [Google Scholar] [CrossRef]

- Kang, S.M.; Na, S.H.; Lee, S.H.; Song, M.S.; Lee, G.W.; Song, Y.J. Effects of ettringite formation on the compressive strength of mortar during activation of blast-furnace slag without ordinary Portland cement. Mater. Res. Innov. 2015, 19 (Suppl. S8), S8-545–S8-548. [Google Scholar] [CrossRef]

- Hermawan; Djayaprabha, H.S.; Nguyen, H.A. Hermawan; Djayaprabha, H.S.; Nguyen, H.A. Utilizing phosphogypsum waste to improve the mechanical and durability performances of cement-free structural mortar containing ground granulated blast furnace slag and calcium oxide. J. Build. Eng 2023, 72, 106557. [Google Scholar] [CrossRef]

- Wieczorek, M. The effect of fly ash and granulated blast-furnace slag on slip and tensile adhesion strength of tile adhesives mortars. MATEC Web Conf. 2020, 322, 01017. [Google Scholar] [CrossRef]

- Li, Y.; Fang, J.; Cheng, L.; He, X.; Su, Y.; Tan, H. Mechanical performance, hydration characteristics and microstructures of high volume blast furnace ferronickel slag cement mortar by wet grinding activation. Constr. Build. Mater. 2022, 320, 126148. [Google Scholar] [CrossRef]

- Guan, Q.; Xia, J.; Leng, F.; Zhou, Y. Utilizing blast furnace ferronickel slag as paste replacement to reduce white Portland cement content and improve performance of mortar. Adv. Bridge Eng. 2021, 2, 18. [Google Scholar] [CrossRef]

- Bae, S.H.; Lee, J.I.; Choi, S.J. Characteristics of Mortars with Blast Furnace Slag Powder and Mixed Fine Aggregates Containing Ferronickel-Slag Aggregate. Materials 2021, 14, 5879. [Google Scholar] [CrossRef] [PubMed]

- Santamaría, A.; González, J.; Losáňez, M.; Skaf, M.; Ortega-López, V. The design of self-compacting structural mortar containing steelmaking slags as aggregate. Cement Concr. Compos. 2020, 111, 103627. [Google Scholar] [CrossRef]

- Santamaría-Vicario, I.; Rodríguez, A.; Junco, C.; Gutiérrez-González, S.; Calderón, V. Durability behavior of steelmaking slag masonry mortars. Mater. Des. 2016, 97, 307–315. [Google Scholar] [CrossRef]

- Faraone, N.; Tonello, G.; Furlani, E.; Maschio, S. Steelmaking slag as aggregate for mortars: Effects of particle dimension on compression strength. Chemosphere 2009, 77, 1152–1156. [Google Scholar] [CrossRef]

- Alwaeli, M.; Gołaszewski, J.; Niesler, M.; Pizoń, J.; Gołaszewska, M. Recycle option for metallurgical sludge waste as a partial replacement for natural sand in mortars containing CSA cement to save the environment and natural resources. J. Hazard. Mater. 2020, 398, 123101. [Google Scholar] [CrossRef]

- Rooholamini, H.; Sedghi, R.; Ghobadipour, B.; Adresi, M. Effect of electric arc furnace steel slag on the mechanical and fracture properties of roller-compacted concrete. Construct. Build. Mater. 2019, 211, 88–98. [Google Scholar] [CrossRef]

- Roslan, N.H.; Ismail, M.; Khalid, N.H.A.; Muhammad, B. Properties of concrete containing electric arc furnace steel slag and steel sludge. J. Build. Eng. 2020, 28, 101060. [Google Scholar] [CrossRef]

- Lehner, P.; Horňáková, M.; Pizoń, J.; Gołaszewski, J. Effect of Chemical Admixtures on Mechanical and Degradation Properties of Metallurgical Sludge Waste Concrete. Materials 2022, 15, 8287. [Google Scholar] [CrossRef] [PubMed]

- Pizoń, J.; Gołaszewski, J.; Alwaeli, M.; Szwan, P. Properties of Concrete with Recycled Concrete Aggregate Containing Metallurgical Sludge Waste. Materials 2020, 13, 1448. [Google Scholar] [CrossRef]

- Roslan, N.H.; Ismail, M.; Abdul-Majid, Z.; Ghoreishiamiri, S.; Muhammad, B. Performance of steel slag and steel sludge in concrete. Constr. Build. Mater. 2016, 104, 16–24. [Google Scholar] [CrossRef]

- Wei, Y.; Ko, G. Recycling steel wastewater sludges as raw materials for preparing lightweight aggregates. J. Clean. Prod. 2017, 165, 905–916. [Google Scholar] [CrossRef]

- Folliard, K.J.; Ohta, M.; Rathje, E.; Collins, P. Influence of mineral admixtures on expansive cement mortars. Cem. Concr. Res. 1994, 24, 424–432. [Google Scholar] [CrossRef]

- Mehmetoğulları, E.; Güneyli, H.; Karahan, S. The Effect of Gradation and Grain-Size Properties of Fine Aggregate on the Building Mortars. Prod. Eng. Arch. 2020, 26, 121–126. [Google Scholar] [CrossRef]

- PN-EN 197; Cement—Part 1: Composition, Requirements and Conformity Criteria for Common Cements. European Committee for Standardization: Warsaw, Poland, 2012.

- PN EN 196-1:2016; Methods of Testing Cement—Part 1: Determination of Strength. European Committee for Standardization: Warsaw, Poland, 2016.

- PN-EN 1008:2004; Mixing Water for Concrete—Specification for Sampling, Testing and Evaluation of Suitability of Mixing Water for Concrete, Including Water Recovered from Concrete Production Processes. European Committee for Standardization: Warsaw, Poland, 2004.

- EN 998-2:2016-12; Specification for Mortar for Masonry—Part 2: Masonry Mortar. European Committee for Standardization: Warsaw, Poland, 2016.

- Ryan, T.P. Modern Experimental Design; Wiley: Hoboken, NJ, USA, 2007. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments, EMEA Edition, 10th ed.; Wiley: Hoboken, NJ, USA, 2023. [Google Scholar]

- Styrylska, T.; Pietraszek, J. Numerical Modeling of Non-Steady-State Temperature-Fields with Supplementary Data. Z. Für Angew. Math. Und Mech. 1992, 72, T537–T539. [Google Scholar] [CrossRef]

- Pietraszek, J. Response surface methodology at irregular grids based on Voronoi scheme with neural network approximator. Neural Networks and Soft Computing. Adv. Soft Comput. 2003, 19, 250–255. [Google Scholar] [CrossRef]

- Selejdak, J.; Bobalo, T.; Blikharskyy, Y.; Dankevych, I. Mathematical modelling of stress-strain state of steel-concrete beams with combined reinforcement. Prod. Eng. Arch. 2023, 29, 108–115. [Google Scholar] [CrossRef]

- PN-EN 1015-3; Test Methods for Masonry Mortars - Determination of the Consistency of Fresh Mortar (Using a Flow Table). Polish Committee for Standardization: Warsaw, Poland, 2013.

- EN 1015-11:2020-04; Test Methods for Masonry Mortars—Part 11: Determination of Flexural and Compressive Strength of Hardened Mortar. Polish Committee for Standardization: Warsaw, Poland, 2020.

- PN-85/B-04500; Construction Mortars. Research of Physical and Strength Characteristics. Polish Committee for Standardization: Warsaw, Poland, 1985.

- EN-12457-2:2006; Characterization of Waste—Leaching—Compliance Test for Leaching of Granular Waste Materials and Sludges—Part 2: One Stage Batch Test at a Liquid to Solid Ratio of 10 L/kg for Materials with Particle Size below 4 mm (Without or with Size Reduction). Polish Committee for Standardization: Warsaw, Poland, 2013.

- Rashad, A.M. A synopsis manual about recycling steel slag as a cementitious material. J. Mater. Res. Technol. 2019, 8, 4940–4955. [Google Scholar] [CrossRef]

- Fisher, L.V.; Barron, A.R. The recycling and reuse of steelmaking slags—A review. Resour. Conserv. Recycl. 2019, 146, 244–255. [Google Scholar] [CrossRef]

- Jura, J. Analysis of the impact of sludge and slag waste on basic properties of cement mortars. CzOTO 2023, 5, 130–141. [Google Scholar] [CrossRef]

- Liu, Q.; Singh, A.; Xiao, J.; Li, B.; Tam, V.W.Y. Workability and mechanical properties of mortar containing recycled sand from aerated concrete blocks and sintered clay bricks. Resour. Conserv. Recycl. 2020, 157, 104728. [Google Scholar] [CrossRef]

- Qasrawi, H.; Shalabi, F.; Asi, I. Use of low CaO unprocessed steel slag in concrete as fine aggregate. Constr. Build. Mater. 2009, 23, 1118–1125. [Google Scholar] [CrossRef]

- Öműr, T.; Miyan, N.; Kabay, N.; Ozkan, H. Utilization and optimization of unweathered and weathered basic oxygen furnace slag aggregates in cement based mortar. J. Build. Eng. 2023, 64, 105634. [Google Scholar] [CrossRef]

- Ozturk, M.; Akgol, O.; Sevim, U.K.; Karaaslan, M.; Demirci, M.; Unal, E. Experimental work on mechanical, electromagnetic and microwave shielding effectiveness properties of mortar containing electric arc furnace slag. Constr. Build. Mater. 2018, 165, 58–63. [Google Scholar] [CrossRef]

- Da Silva Magalhães, M.; Faleschini, F.; Pellegrino, C.; Brunelli, K. Cementing efficiency of electric arc furnace dust in mortars. Constr. Build. Mater. 2017, 157, 141–150. [Google Scholar] [CrossRef]

- Bodor, M.; Santos, R.M.; Cristea, G.; Salman, M.; Cizer, O.; Iacobescu, R.I.; Chiang, Y.W.; Van Balen, K.; Vlad, M.; Van Gerven, T. Laboratory investigation of carbonated BOF slag used as partial replacement of natural aggregate in cement mortars. Cement Concr. Compos. 2016, 65, 55–66. [Google Scholar] [CrossRef]

- Arribas, I.; Vegas, I.; San-José, S.T.; Manso, J.M. Durability studies on steelmaking slag concretes. Mater. Des. 2014, 63, 168–176. [Google Scholar] [CrossRef]

- Kuterasińska-Warwas, J.; Król, A. Leaching of heavy metals from cementitious composites made of new ternary cements. E3S Web Conf. 2017, 19, 02019. [Google Scholar] [CrossRef]

- Dijkstra, J.J.; Van der Sloot, H.A.; Spanka, G.; Thilen, G. How to Judge Release of Dangerous Substances from Construction Products to Soil and Groundwater. CPD Topic 1. Soil and Groundwater Impact. Netherlands: N. Web. 2005. Available online: https://www.osti.gov/etdeweb/biblio/20767393 (accessed on 21 March 2024).

- Proctor, D.M.; Fehling, K.A.; Shay, E.C.; Wittenborn, J.L.; Green, J.J.; Avent, C.; Bigham, R.D.; Connolly, M.; Lee, B.; Shepker, T.O.; et al. Physical and chemical characteristics of blast furnace, basic oxygen furnace, and electric arc furnace steel industry slags. Environ. Sci. Technol. 2000, 34, 1576. [Google Scholar] [CrossRef]

- Li, M.; Lu, Y.; Liu, Y.; Chu, J.; Zhang, T.; Wang, W. Influence of the Steel Slag Particle Size on the Mechanical Properties and Microstructure of Concrete. Sustainability 2024, 16, 2083. [Google Scholar] [CrossRef]

- Keertan, T.S.; Kumar, V.P.; Bommisetty, J.; Ramanjaneyulu, B.; Kumar, M.A. High strength fiber reinforced concrete with steel slag as partial replacement of coarse aggregate: Overview on mechanical and microstructure analysis. Mater. Today Proc. 2023. [Google Scholar] [CrossRef]

| Component | Sludge (S1) | Slag (S2) | Component | Sludge (S1) | Slag (S2) |

|---|---|---|---|---|---|

| SiO2 | 5.44 | 9.56 | Sr | 0.01 | 0.01 |

| Al2O3 | 3.90 | 5.83 | Cr | 0.01 | 0.08 |

| CaO | 13.09 | 38.54 | Cu | 0.03 | - |

| K2O | 0.32 | 0.04 | TiO2 | 0.06 | 0.09 |

| MgO | 1.72 | 5.15 | Pb | 0.50 | - |

| Fe2O3 | 55.66 | 18.70 | V | - | 0.03 |

| Na2O | 0.10 | 1.07 | P | 0.08 | 1.00 |

| Mn | 0.46 | 1.67 | SO3 | 1.68 | 0.43 |

| Ba | - | 0.02 | Cl- | 0.70 | 0.03 |

| Zn | 2.47 | 0.01 | Sr | 0.01 | 0.01 |

| SiO2 | 5.44 | 9.56 |

| No. | S1 | S2 |

|---|---|---|

| Actual values for plan levels | ||

| 1 | 0 | 0 |

| 2 | 2.93 | 2.93 |

| 3 | 10 | 10 |

| 4 | 17.07 | 17.07 |

| 5 | 20 | 20 |

| Experimental plan without replication | ||

| 1 | 0 | 0 |

| 2 | 0 | 10 |

| 3 | 0 | 20 |

| 4 | 10 | 20 |

| 5 | 20 | 20 |

| 6 | 20 | 10 |

| 7 | 20 | 0 |

| 8 | 10 | 0 |

| 9 | 10 | 10 |

| 10 | 2.93 | 2.93 |

| 11 | 2.93 | 17.07 |

| 12 | 17.07 | 17.07 |

| 13 | 17.07 | 2.93 |

| No. | S1 | S2 | C | FS28 | CS28 | WA | ML | DFS | DCS |

|---|---|---|---|---|---|---|---|---|---|

| [%] | [%] | [cm] | [MPa] | [MPa] | [%] | [%] | [%] | [%] | |

| 1 | 0 | 0 | 15.90 | 8.72 | 50.60 | 8.72 | 0.82 | 25.3 | 8.7 |

| 2 | 0 | 10 | 15.50 | 7.44 | 48.09 | 9.50 | 0.14 | 21.4 | 8.8 |

| 3 | 0 | 20 | 14.90 | 6.89 | 45.22 | 10.16 | 0.15 | 18.0 | 8.4 |

| 4 | 10 | 20 | 14.60 | 7.38 | 43.40 | 10.20 | 0.22 | 16.2 | 7.6 |

| 5 | 20 | 20 | 14.30 | 7.15 | 29.41 | 10.37 | 0.30 | 11.1 | 9.8 |

| 6 | 20 | 10 | 14.10 | 7.51 | 48.45 | 9.78 | 0.17 | 13.6 | 6.6 |

| 7 | 20 | 0 | 13.65 | 7.75 | 51.19 | 8.78 | 0.10 | 9.2 | 2.8 |

| 8 | 10 | 0 | 14.65 | 8.05 | 51.55 | 9.08 | 0.3 | 15.8 | 4.5 |

| 9 | 10 | 10 | 15.10 | 7.42 | 46.75 | 9.40 | 0.11 | 15.0 | 7.7 |

| 15.05 | 7.30 | 45.07 | 10.24 | 0.35 | 15.4 | 7.0 | |||

| 14.85 | 7.58 | 46.97 | 9.17 | 0.34 | 14.6 | 7.2 | |||

| 15.20 | 7.36 | 47.03 | 9.96 | 0.16 | 15.0 | 7.1 | |||

| 15.10 | 7.67 | 47.25 | 9.26 | 0.20 | 15.3 | 7.4 | |||

| 15.15 | 7.04 | 46.24 | 9.71 | 0.06 | 15.3 | 7.6 | |||

| 15.10 | 7.02 | 46.16 | 9.70 | 0.09 | 14.9 | 7.3 | |||

| 10 | 2.93 | 2.93 | 17.1 | 7.67 | 48.10 | 9.04 | 0.02 | 22.0 | 8.6 |

| 11 | 2.93 | 17.07 | 15.55 | 7.09 | 43.91 | 9.77 | 0.09 | 18.0 | 7.8 |

| 12 | 17.07 | 17.07 | 15.50 | 7.26 | 38.65 | 10.26 | 0.17 | 10.7 | 8.7 |

| 13 | 17.07 | 2.93 | 14.90 | 8.07 | 46.18 | 9.22 | 0.19 | 10.4 | 4.1 |

| Element | PK | S1 | S2 | Limit Values * | |||

|---|---|---|---|---|---|---|---|

| A, mg/dm3 | s | A, mg/dm3 | s | A, mg/dm3 | s | mg/dm3 | |

| Zn | <0.005 | - | 0.127 | 0.049 | <0.005 | - | 2 |

| Pb | <0.005 | - | 0.022 | 0.007 | <0.005 | - | 0.5 |

| Cr | 0.018 | 0.009 | <0.005 | - | 0.027 | 0.009 | 0.5 |

| Cu | <0.005 | - | 0.023 | 0.009 | <0.005 | - | 0.5 |

| Fe | 0.251 | 0.059 | 0.379 | 0.058 | 0.398 | 0.067 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ulewicz, M.; Jura, J.; Zieliński, A.; Pietraszek, J. The Application of Converter Sludge and Slag to Produce Ecological Cement Mortars. Materials 2024, 17, 4295. https://doi.org/10.3390/ma17174295

Ulewicz M, Jura J, Zieliński A, Pietraszek J. The Application of Converter Sludge and Slag to Produce Ecological Cement Mortars. Materials. 2024; 17(17):4295. https://doi.org/10.3390/ma17174295

Chicago/Turabian StyleUlewicz, Malgorzata, Jakub Jura, Adam Zieliński, and Jacek Pietraszek. 2024. "The Application of Converter Sludge and Slag to Produce Ecological Cement Mortars" Materials 17, no. 17: 4295. https://doi.org/10.3390/ma17174295

APA StyleUlewicz, M., Jura, J., Zieliński, A., & Pietraszek, J. (2024). The Application of Converter Sludge and Slag to Produce Ecological Cement Mortars. Materials, 17(17), 4295. https://doi.org/10.3390/ma17174295