The Influence and Mechanism of Curing Methods and Curing Age on the Mechanical Properties of Yellow River Sand Engineered Cementitious Composites

Abstract

1. Introduction

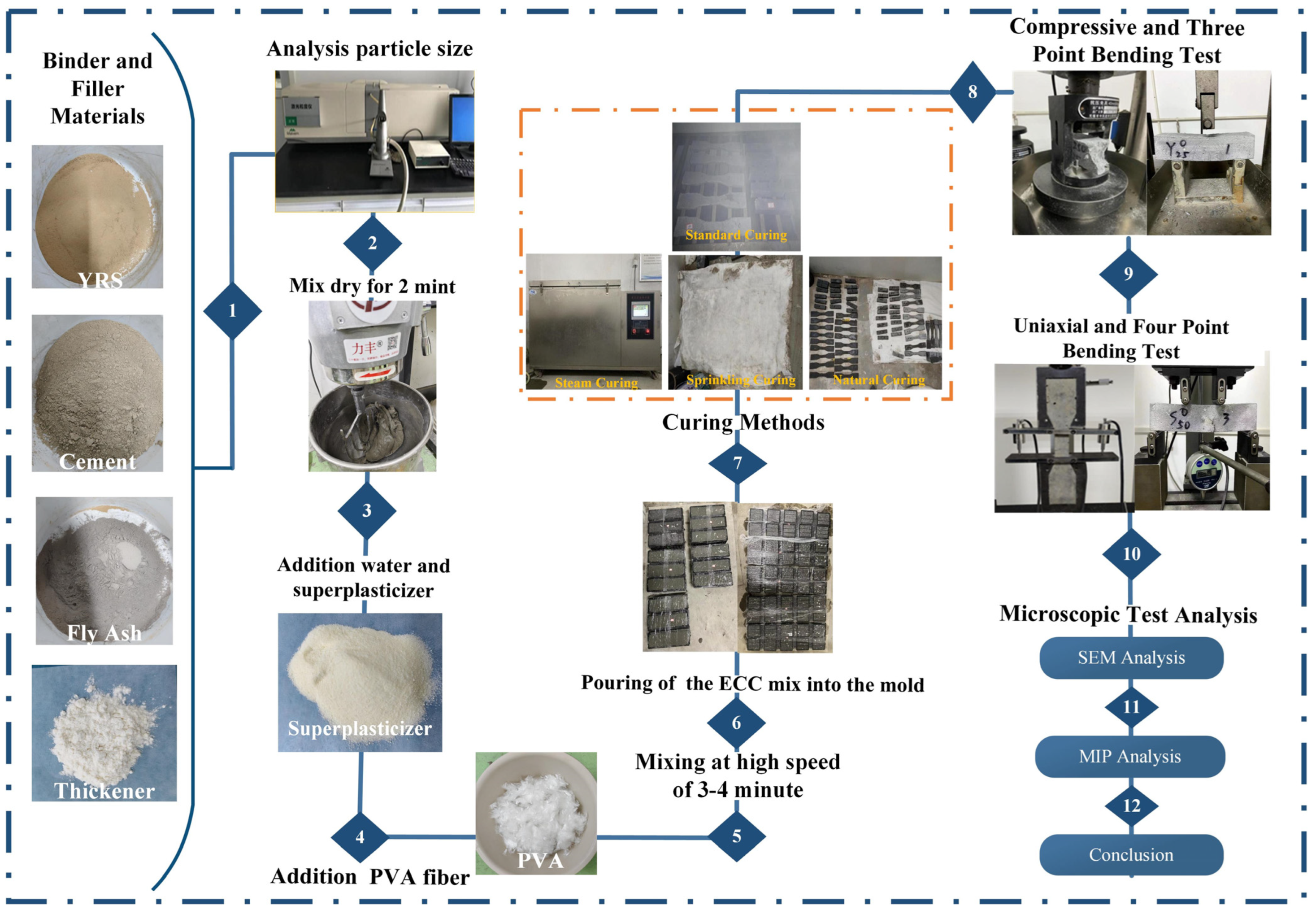

2. Materials and Methods

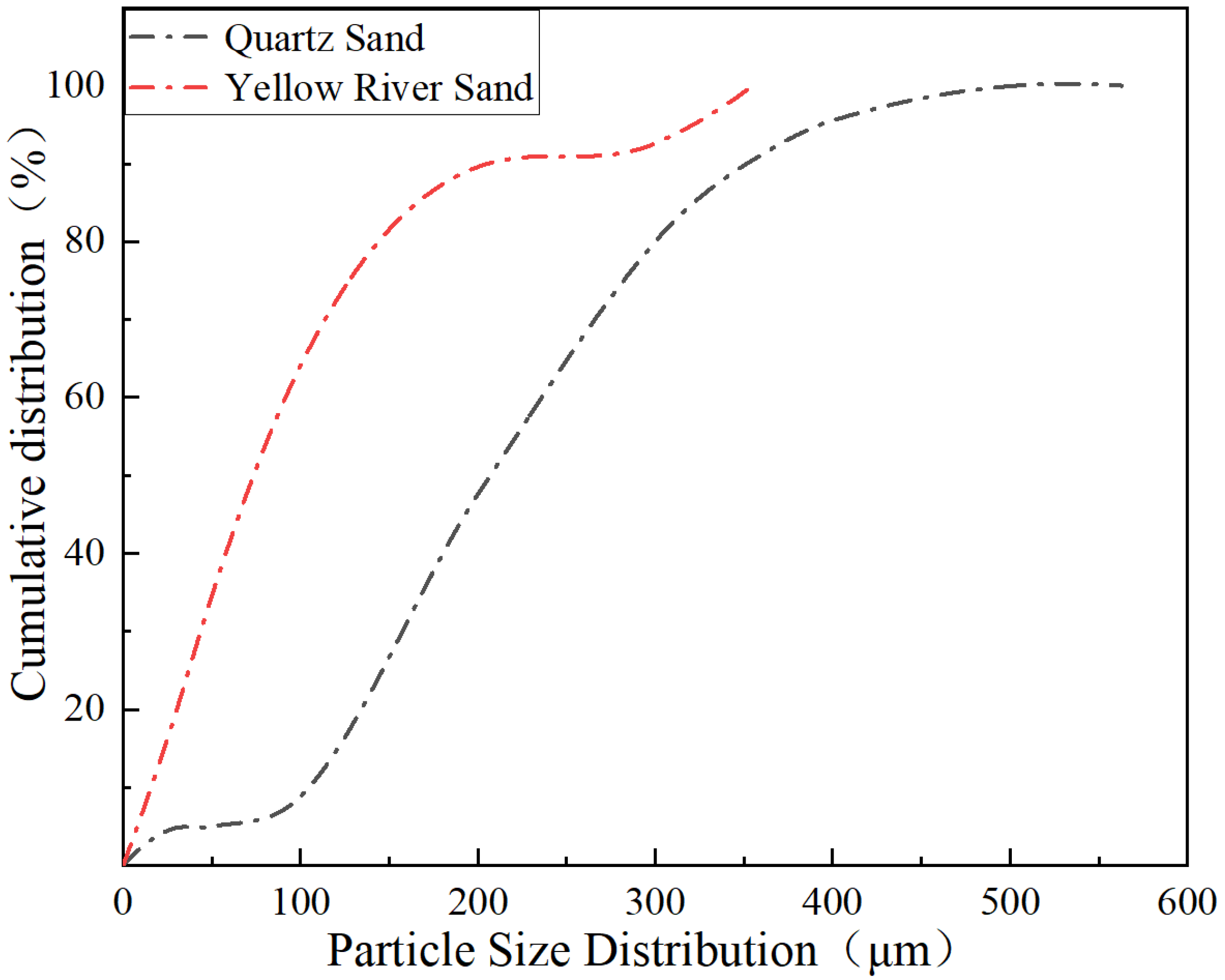

2.1. Raw Material

2.2. Mix Proportion

2.3. Specimen Preparation

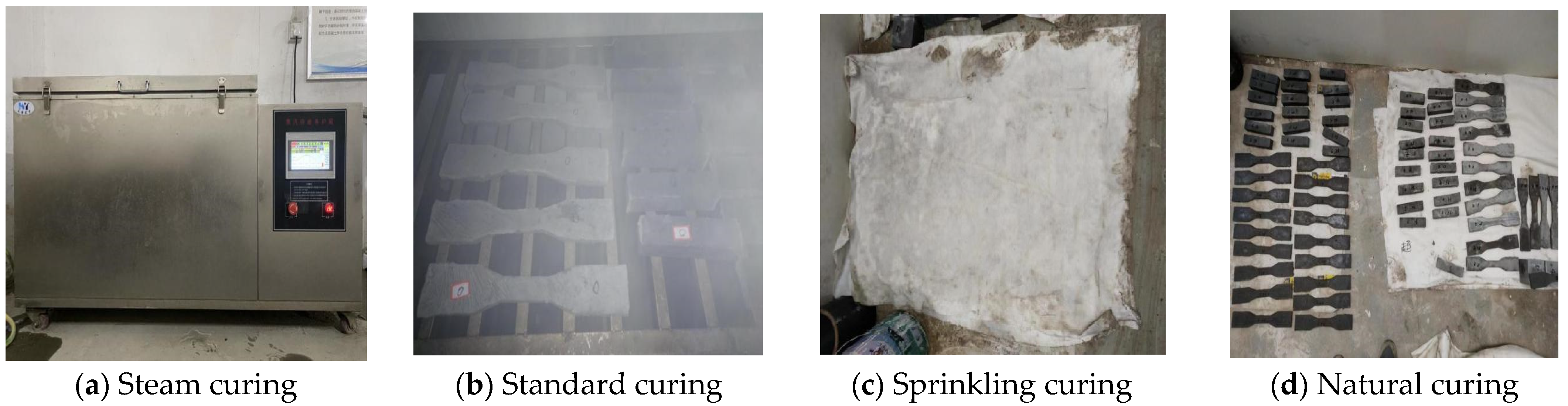

2.4. Curing Method

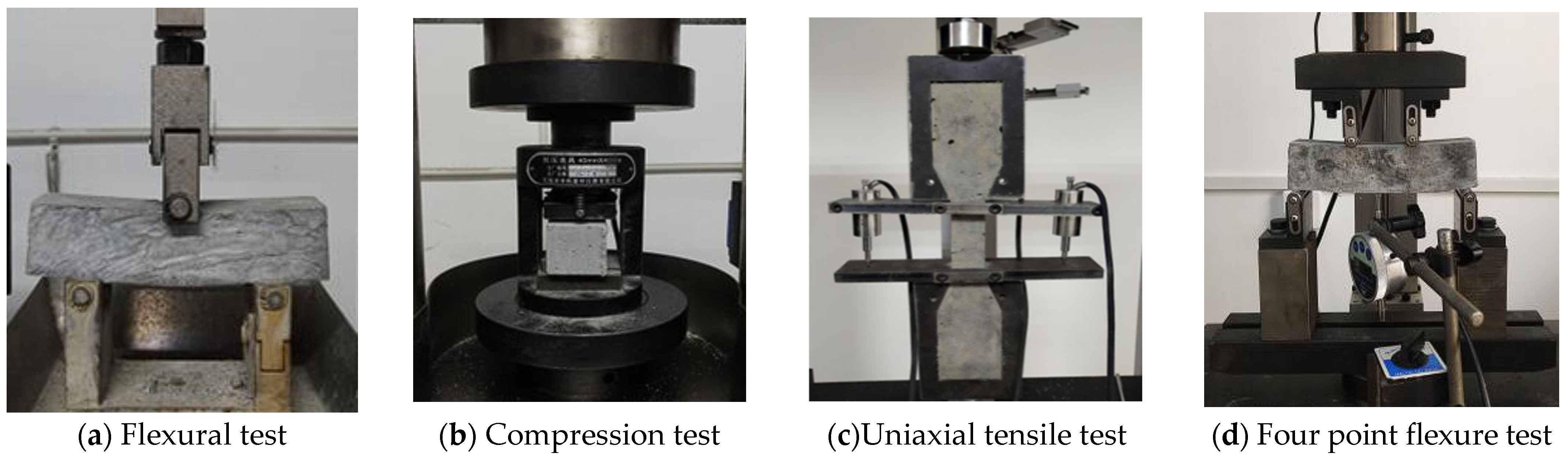

2.5. Test Method

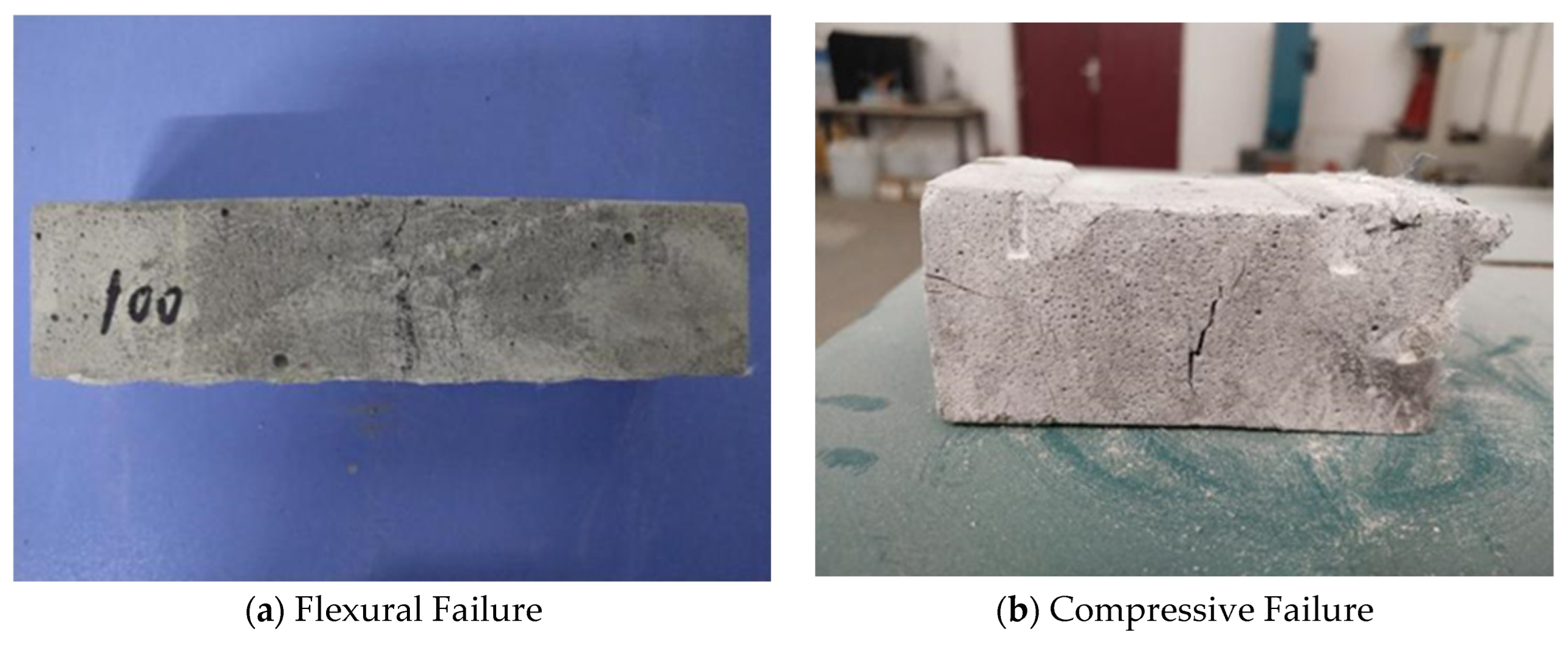

2.5.1. Compressive and Flexural Tests

2.5.2. Uniaxial Tensile Test

2.5.3. Four Point Flexural Test

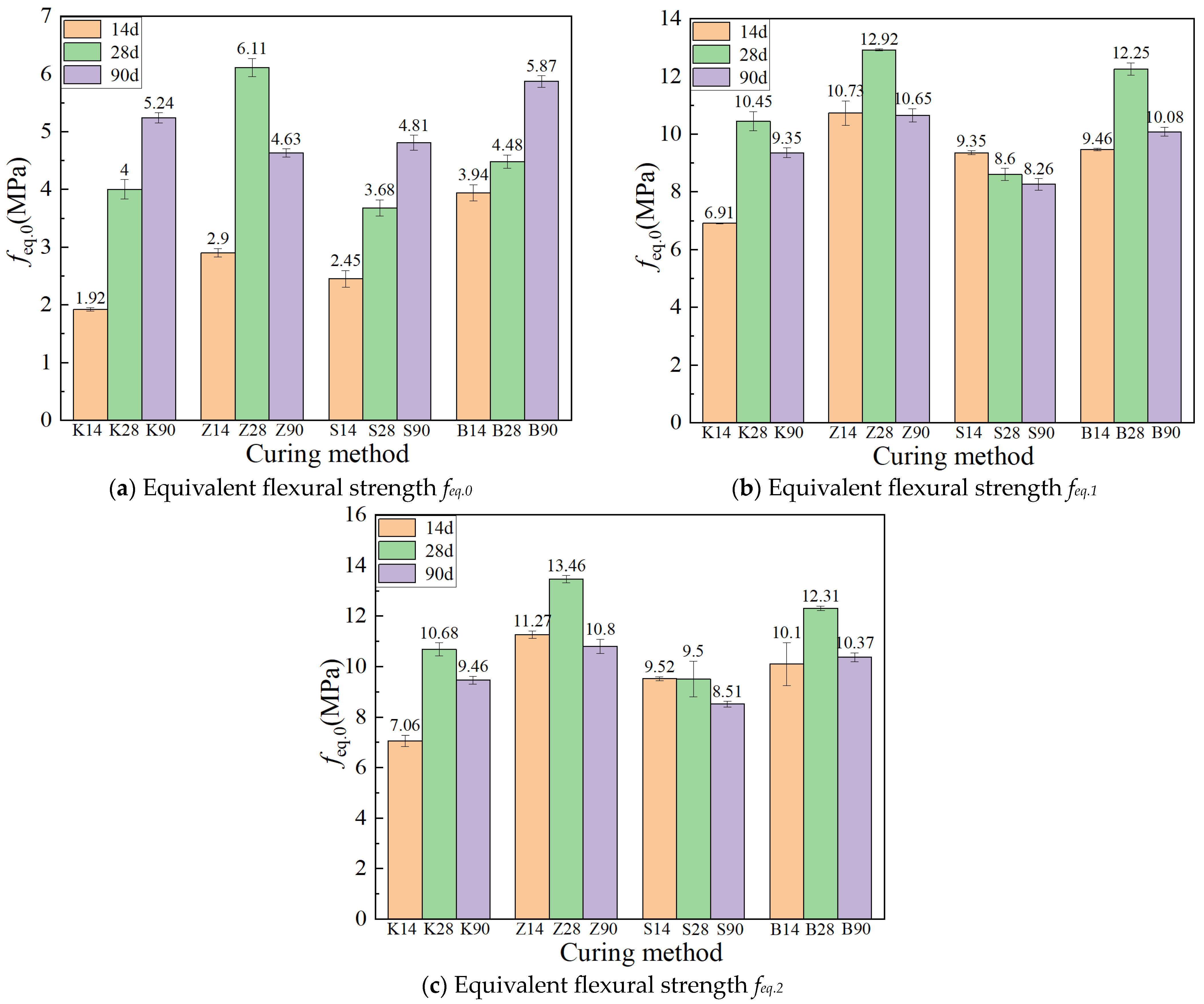

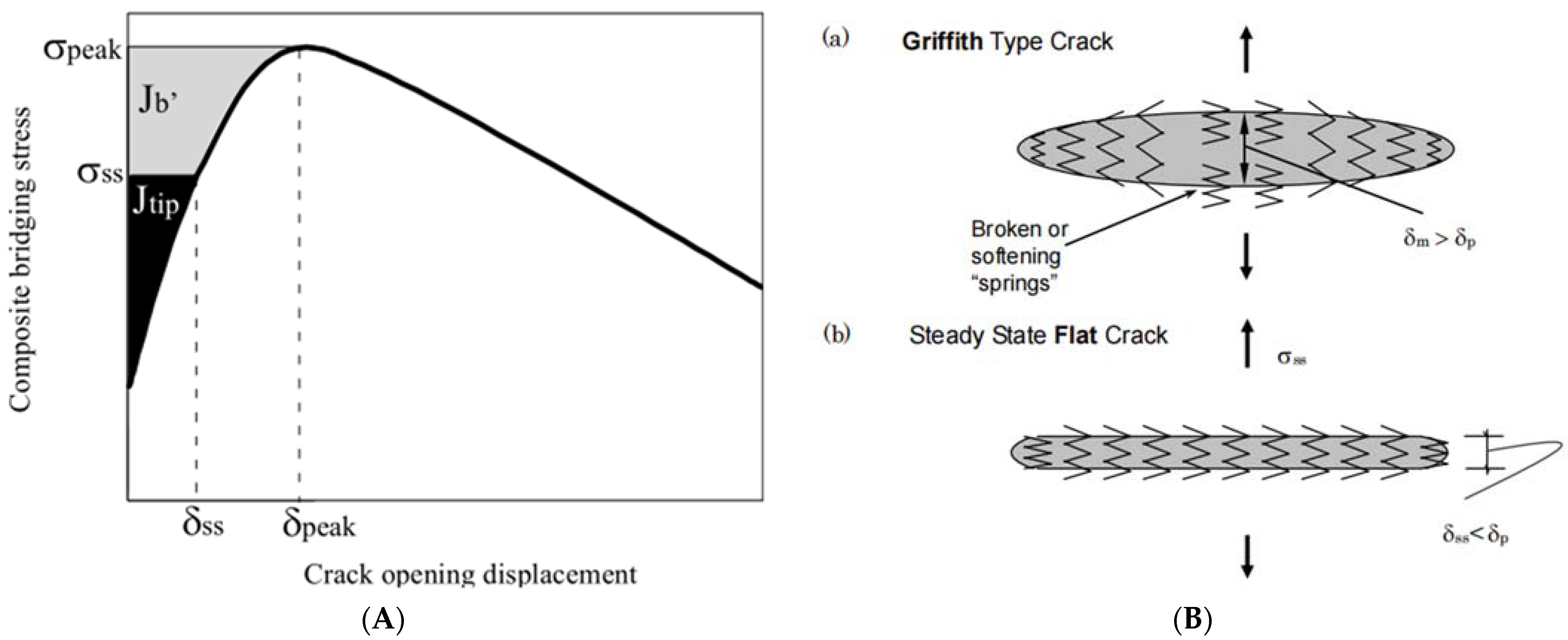

2.5.4. Flexural Toughness Evaluation

2.5.5. SEM Experiments

2.5.6. MIP Experiments

3. Results and Discussion

3.1. Effect of Curing Methods on Mechanical Properties

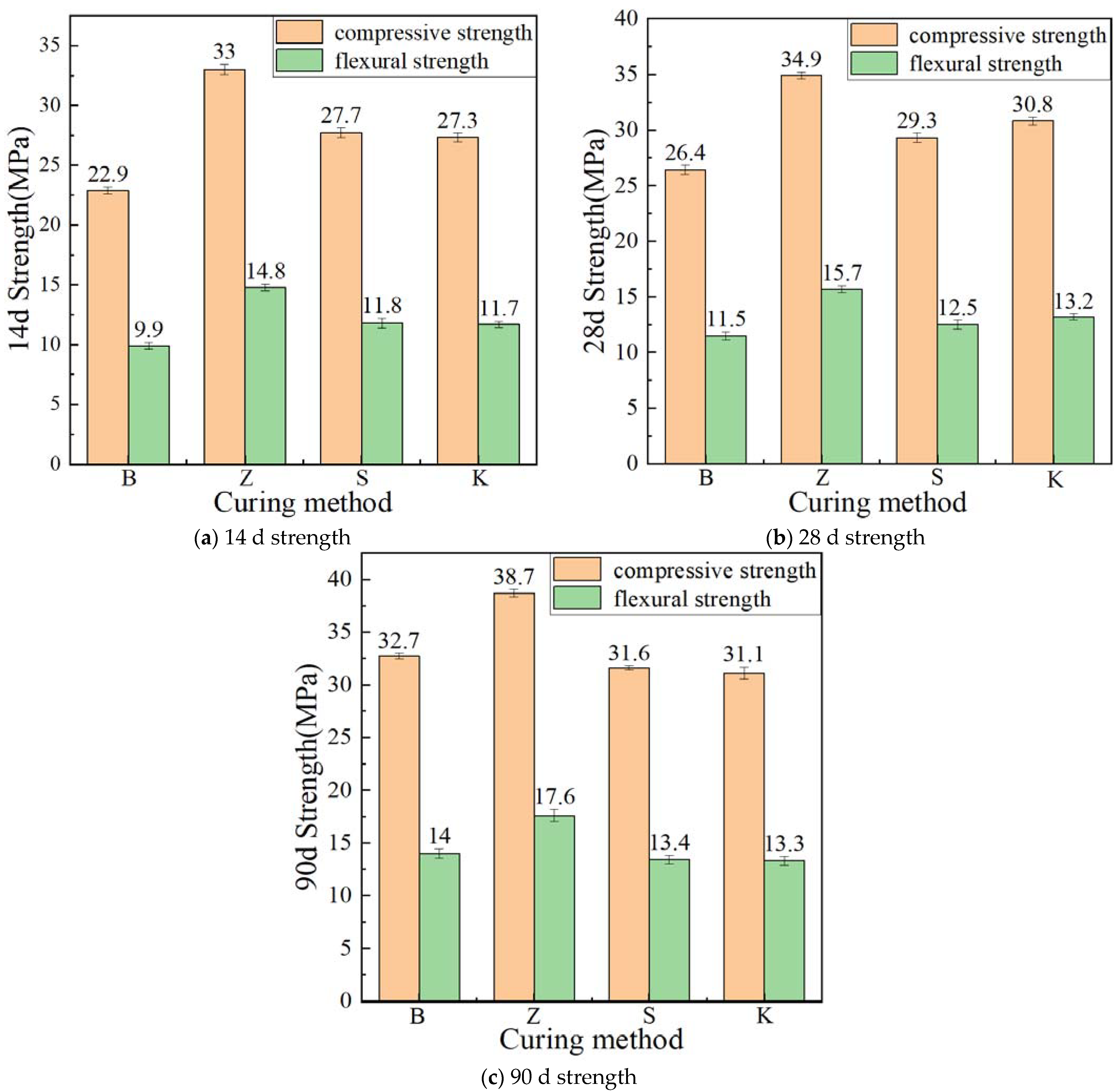

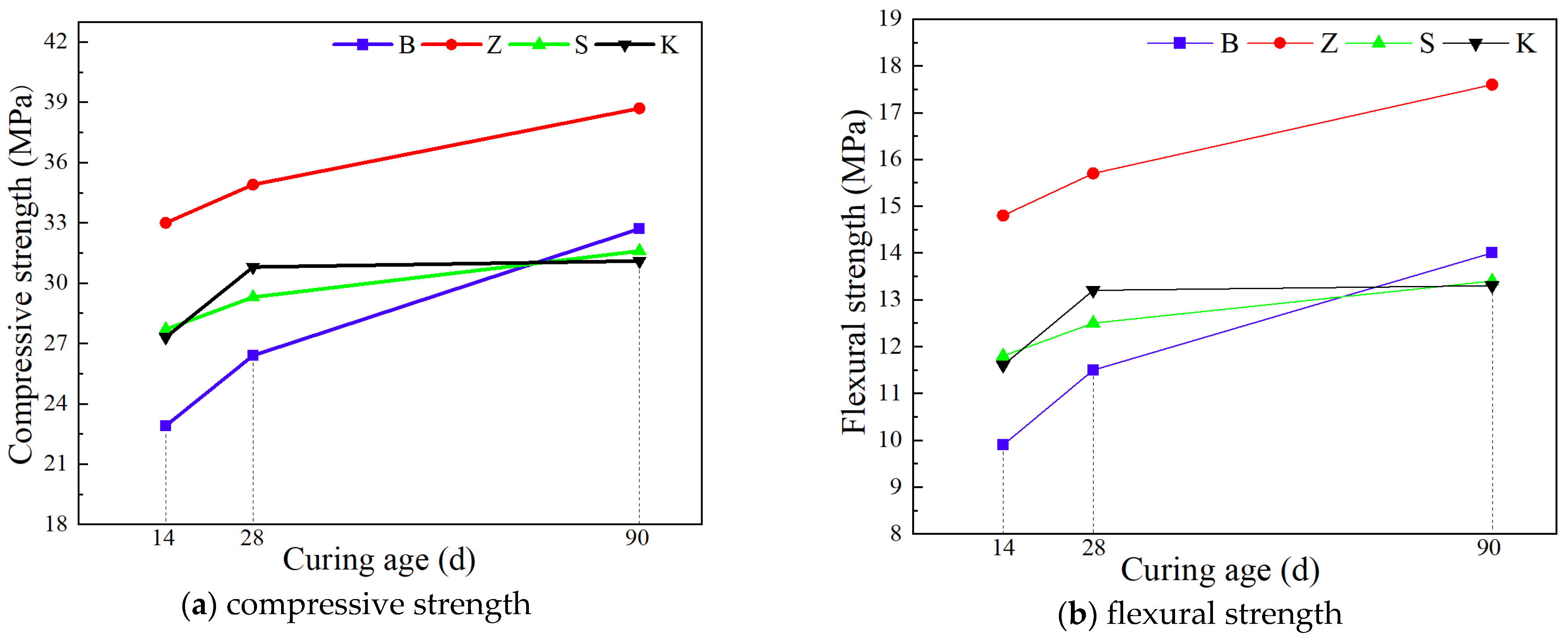

3.1.1. Compressive and Flexural Strength

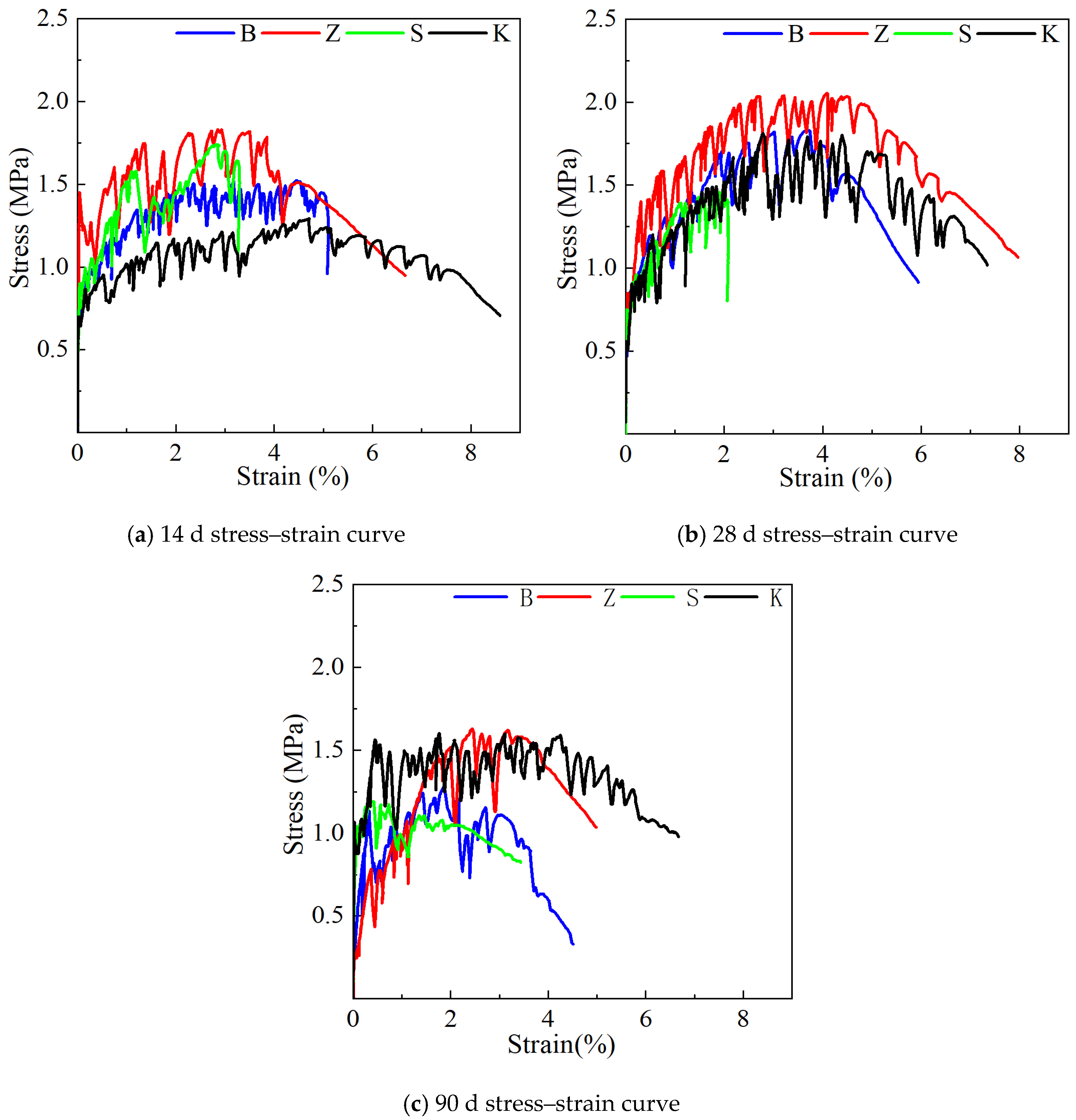

3.1.2. Uniaxial Tensile Property

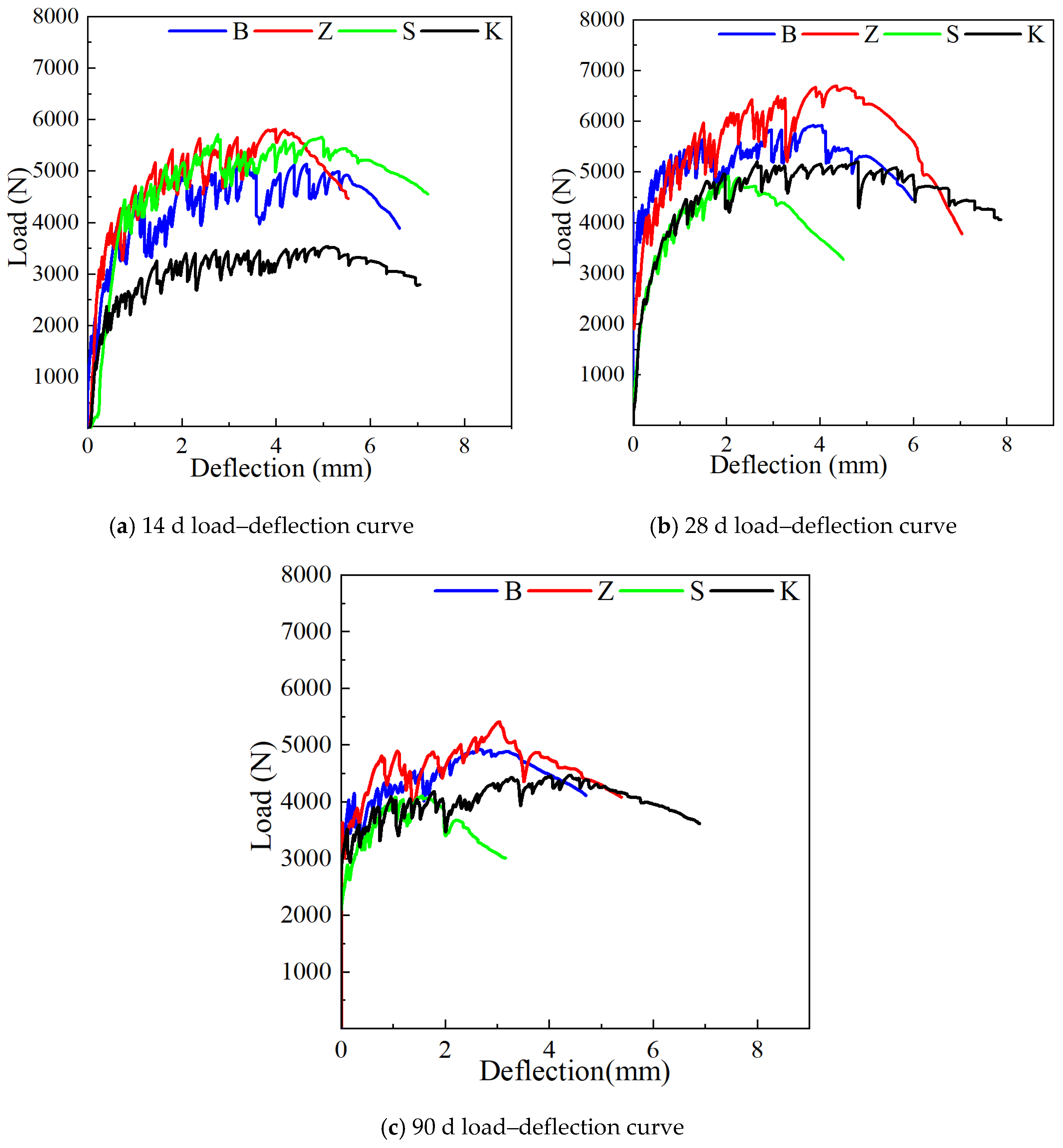

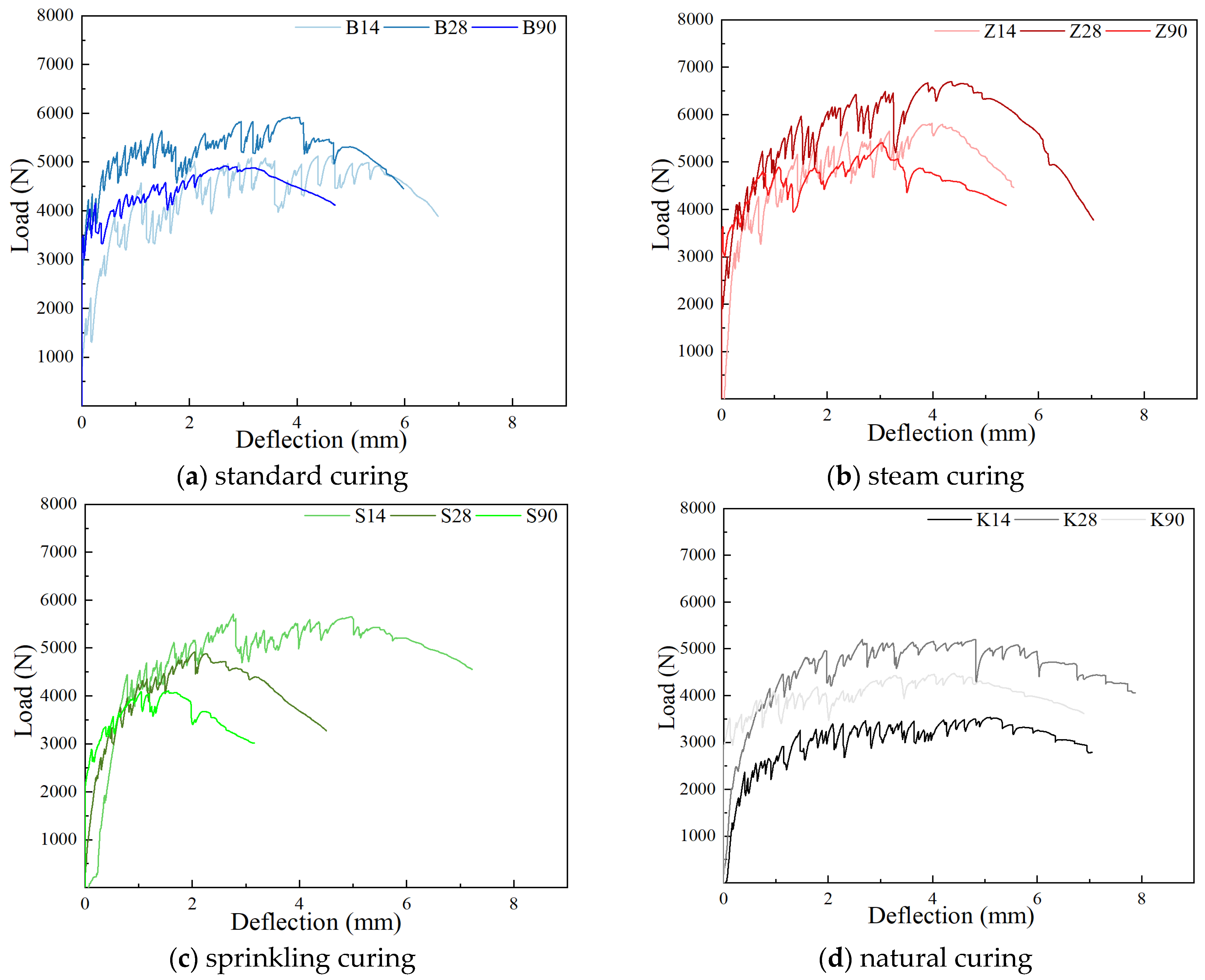

3.1.3. Four-Point Bending Test

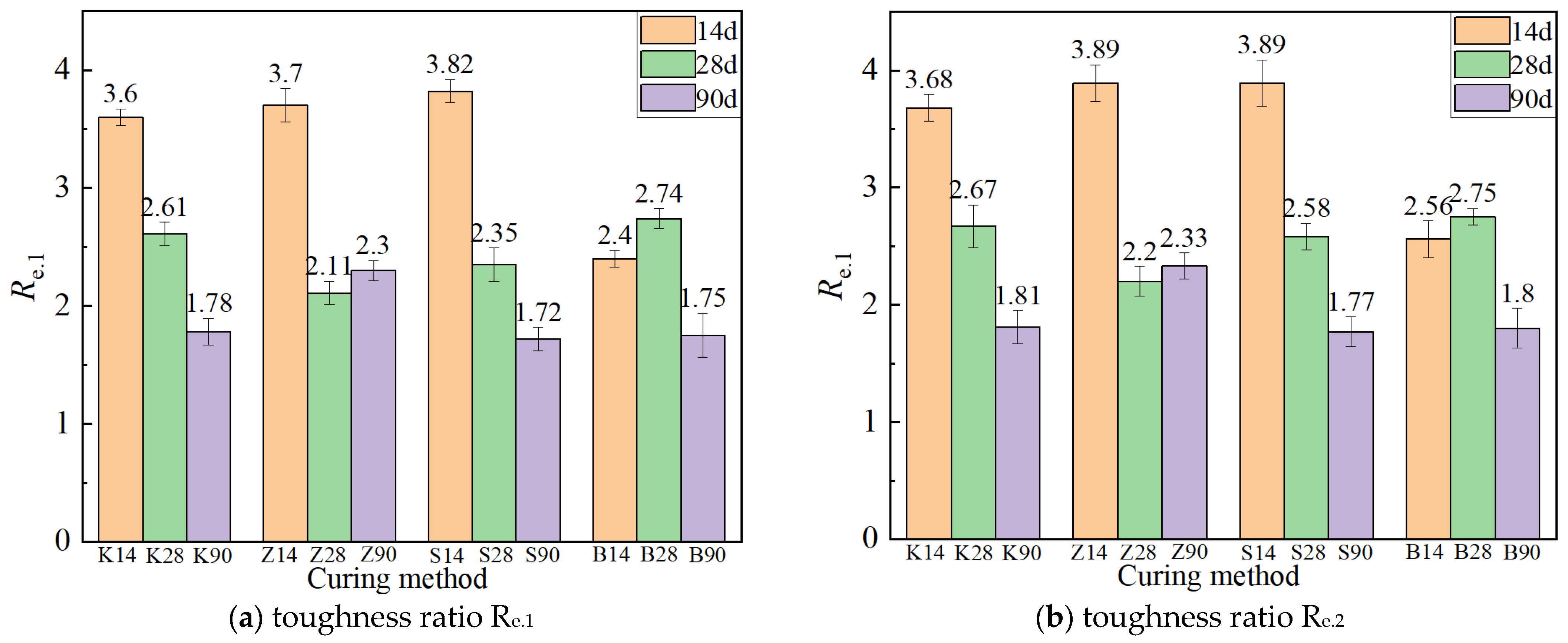

3.1.4. Flexural Toughness

3.2. Effect of Curing Age on Mechanical Properties

3.2.1. Compressive and Flexural Strength

3.2.2. Uniaxial Tensile Property

3.2.3. Four-Point Bending Test

3.3. Material Microstructure Analysis

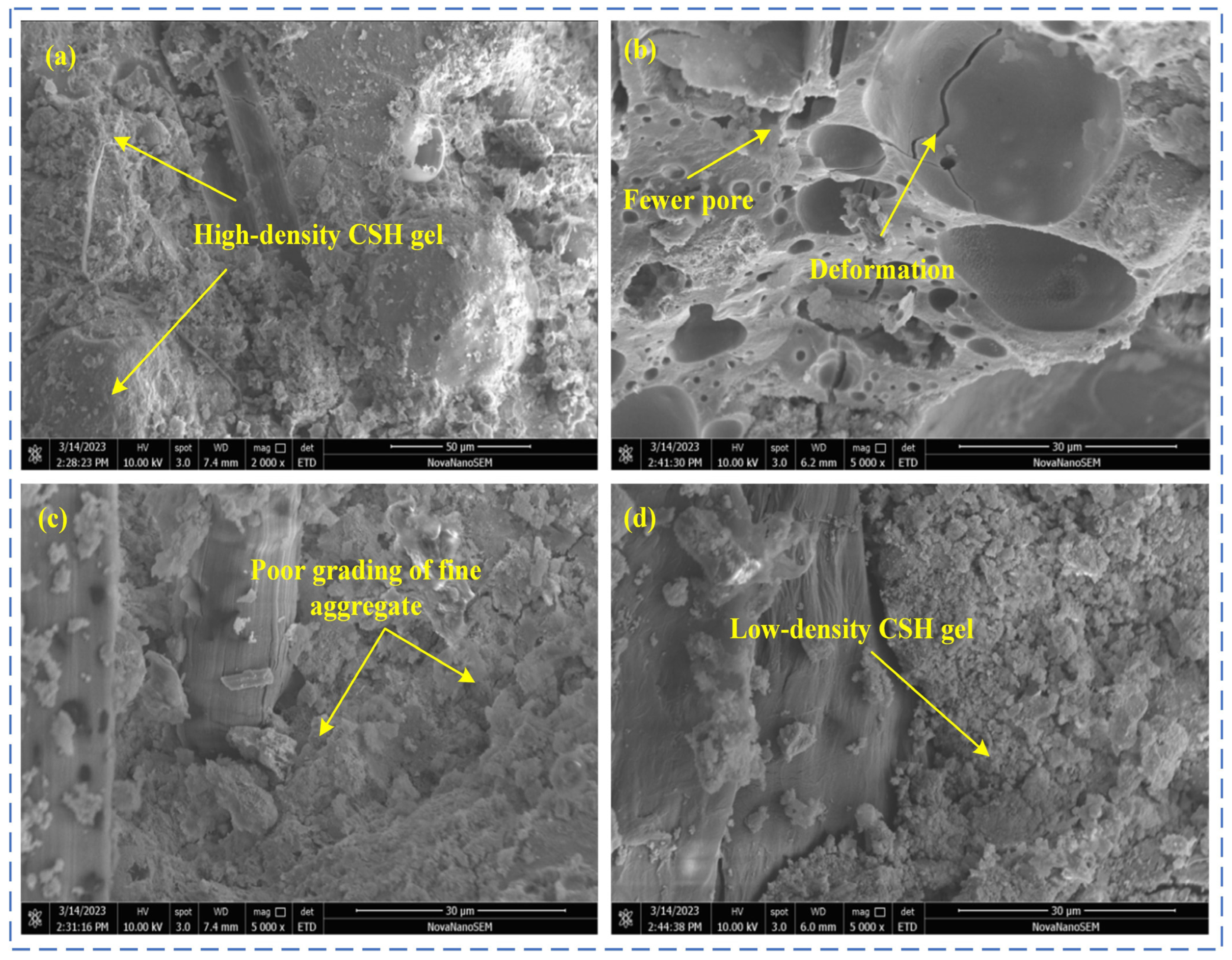

3.3.1. SEM Experiments

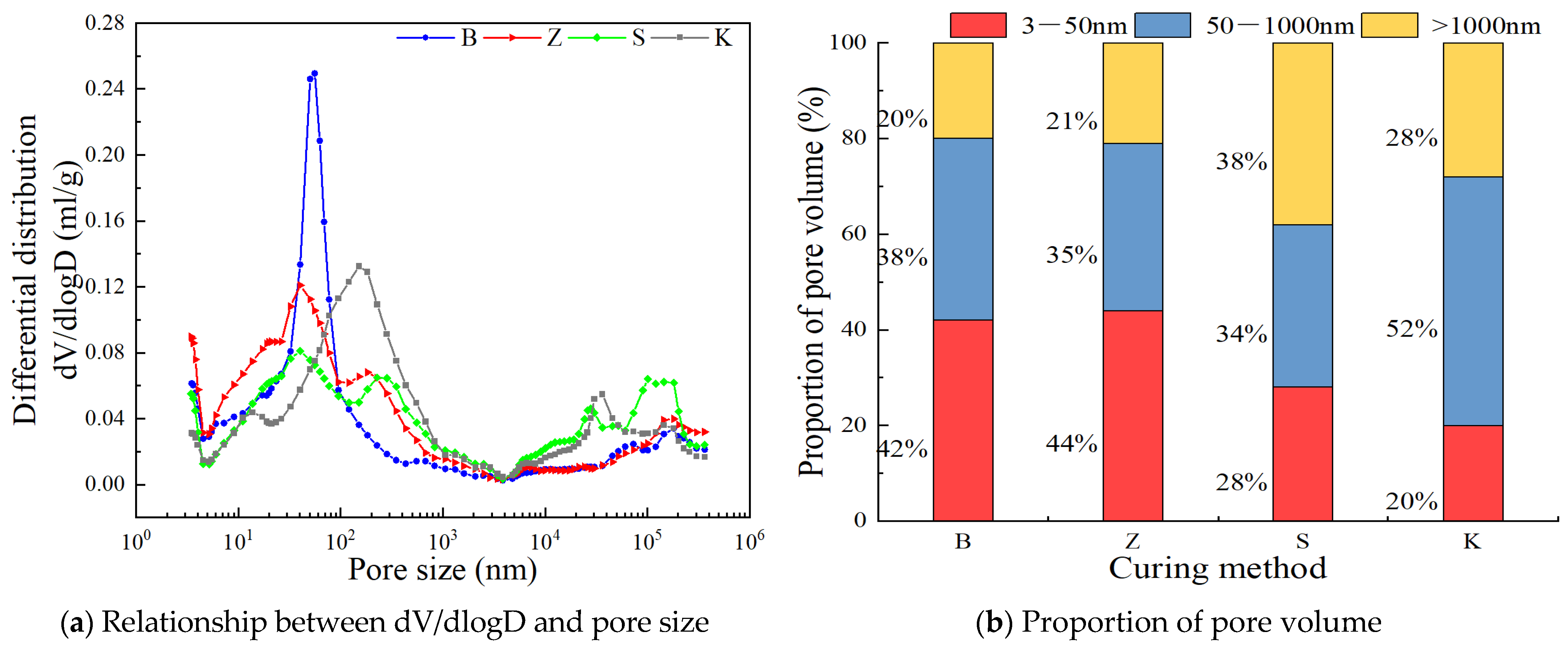

3.3.2. MIP Experiments

4. Mechanical Properties of YRS-ECC and Traditional Sand ECC

4.1. Compressive and Flexural Strength

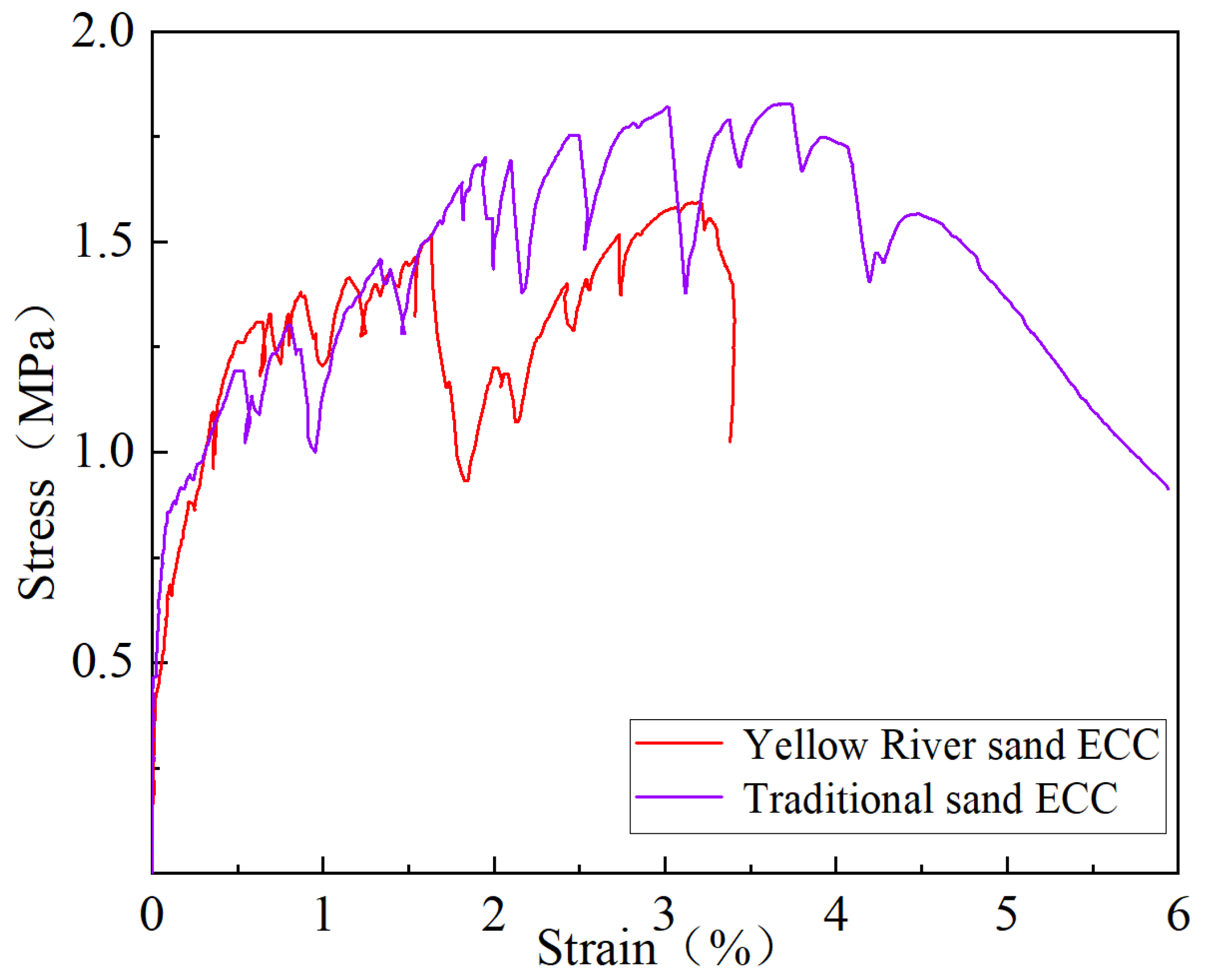

4.2. Uniaxial Tensile Property

4.3. Four-Point Bending Test

4.4. Five-Dimensional Evaluation Diagram

5. Conclusions

- (1)

- Steam curing significantly enhances the compressive strength of YRS-ECC, exhibiting peak strengths at 14 days, 28 days, and 90 days. Natural curing and sprinkler curing initially show higher early strengths compared to standard curing, but their strength gains decelerate between 28 days and 90 days, lagging behind standard curing.

- (2)

- ECC specimens made with YRS achieve the highest ductility under natural curing at 14 days, 28 days, and 90 days, with the ultimate tensile strain still exceeding 4% at 90 days. Steam curing maintains a 3% strain at 90 days. Specimens under standard curing and sprinkler curing fail to meet the 3% strain requirement beyond 14 days. Natural curing results in fine cracks post-failure, exhibiting a superior crack index compared to other curing methods.

- (3)

- Ductility decreases as specimens age from 14 days to 90 days across all curing methods. Natural curing shows the least decline, achieving a maximum ultimate flexural deflection of 4.42 mm at 90 days. Steam curing achieves the highest ultimate flexural load of 5004.82 N, with the largest toughness ratio at 90 days among all methods.

- (4)

- Steam curing promotes the formation of dense C-S-H gel with micro-gaps that facilitate fiber pull-out. Standard and sprinkler curing methods generate extensive C-S-H gel but cause significant fiber damage upon pull-out. Natural curing produces flocculent C-S-H gel, maintaining better fiber integrity after pull-out. Additionally, natural curing exhibits the highest porosity (32.86%) and average pore size (51.69 nm). Steam curing results in the smallest average pore size, with a notable fraction of pores less than 50 nm (44%).

- (5)

- Based on compressive strength, uniaxial tensile, four-point flexural tests, and microscopic analysis, natural curing emerges as the most suitable maintenance method for 100% YRS-ECC in practical engineering applications.

- (6)

- Under the standard curing conditions, the flexural strength, uniaxial tensile test and four-point bending test were carried out on the two test blocks of 14 days. The results show that the ultimate bending load and deflection of YRS-ECC are 5.7% and 9.4% higher than those of traditional sand ECC, respectively, and the ultimate tensile strength and strain are also improved. These results show that the YRS-ECC has obvious advantages in improving the ductility and bending properties of the material, thus verifying its effectiveness in ECC applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jabir, H.A.; Abid, S.R.; Murali, G.; Ali, S.H.; Klyuev, S.; Fediuk, R.; Vatin, N.; Promakhov, V.; Vasilev, Y. Experimental tests and reliability analysis of the cracking impact resistance of uhpfrc. Fibers 2020, 8, 74. [Google Scholar] [CrossRef]

- Yoo, D.-Y.; Banthia, N. Mechanical properties of ultra-high-performance fiber-reinforced concrete: A review. Cem. Concr. Compos. 2016, 73, 267–280. [Google Scholar] [CrossRef]

- Wang, C.; Sun, R.; Hu, X.; Guan, Y.; Yang, Y.; Lu, W.; Tian, J.; Zhang, H.; Ge, Z.; Šavija, B. Chloride penetration resistance of engineered cementitious composite (ECC) subjected to sustained flexural loading. Mater. Today Commun. 2023, 35, 106080. [Google Scholar] [CrossRef]

- Sivakumar, A.; Santhanam, M. Mechanical properties of high strength concrete reinforced with metallic and non-metallic fibres. Cem. Concr. Compos. 2007, 29, 603–608. [Google Scholar] [CrossRef]

- Bhat, T.; Chevali, V.; Liu, X.; Feih, S.; Mouritz, A.P. Fire structural resistance of basalt fibre composite. Compos. Part A Appl. Sci. Manuf. 2015, 71, 107–115. [Google Scholar] [CrossRef]

- Serrano, R.; Cobo, A.; Prieto, M.I.; de las Nieves González, M. Analysis of fire resistance of concrete with polypropylene or steel fibers. Constr. Build. Mater. 2016, 122, 302–309. [Google Scholar] [CrossRef]

- Bothra, S.R.; Ghugal, Y.M. Polymer-Modified concrete. Int. J. Res. Eng. Technol. 2015, 4, 845–848. [Google Scholar] [CrossRef]

- Shah, I.; Li, J.; Khan, N.; Almujibah, H.R.; Rehman, M.M.; Raza, A.; Peng, Y. Bond-Slip Behavior of Steel Bar and Recycled Steel Fibre-Reinforced Concrete. J. Renew. Mater. 2024, 12, 167–186. [Google Scholar] [CrossRef]

- Yuhazri, M.Y.; Zulfikar, A.J.; Ginting, A. Fiber reinforced polymer composite as a strengthening of concrete structures: A review. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 1003, p. 012135. [Google Scholar] [CrossRef]

- Razzak, A.; Memon, B.A.; Oad, M.; Raza, A. Effects of height to diameter ratio on compressive strength of recycled aggregate concrete. Quest. Res. J. 2020, 18, 60–65. [Google Scholar]

- Chen, L.; Yan, J.; Xiang, N.; Zhong, J. Shear performance of ultra-high performance concrete multi-keyed epoxy joints in precast segmental bridges. Structures 2022, 46, 1696–1708. [Google Scholar] [CrossRef]

- Singh, M.; Saini, B.; Chalak, H.D. Performance and composition analysis of engineered cementitious composite (ECC)–A review. J. Build. Eng. 2019, 26, 100851. [Google Scholar] [CrossRef]

- Chengfang, Y.; Raza, A.; Manan, A.; Ahmad, S.; Chao, W.; Umar, M. Experimental and FEM analysis on the impact of Yellow River Sand replacement rate on Engineered Cementitious Composite (ECC). Proc. Inst. Civ. Eng. Eng. Sustain. 2024, 1–18. [Google Scholar] [CrossRef]

- Li, V.C. Engineered cementitious composites (ECC)-tailored composites through micromechanical modeling. In Fiber Reinforced Concrete: Present and the Future; Banthia, N., Bentur, A., Mufti, A.A., Eds.; Canadian Society for Civil Engineering: Montreal, QC, Canada, 1998; pp. 64–97. [Google Scholar]

- Li, V.C.; Leung, C.K.Y. Steady-state and multiple cracking of short random fiber composites. J. Eng. Mech. 1992, 118, 2246–2264. [Google Scholar] [CrossRef]

- Yang, E.-H.; Yang, Y.; Li, V.C. Use of high volumes of fly ash to improve ECC mechanical properties and material greenness. ACI Mater. J. 2007, 104, 620. [Google Scholar] [CrossRef]

- Shanour, A.S.; Said, M.; Arafa, A.I.; Maher, A. Flexural performance of concrete beams containing engineered cementitious composites. Constr. Build. Mater. 2018, 180, 23–34. [Google Scholar] [CrossRef]

- Qian, H.; Umar, M.; Khan, M.N.A.; Shi, Y.; Manan, A.; Raza, A.; Li, F.; Li, Z.; Chen, G. A State-of-the-Art Review on Shape Memory Alloys (SMA) in Concrete: Mechanical Properties, Self-Healing Capabilities, and Hybrid Composite Fabrication. Mater. Today Commun. 2024, 109738. [Google Scholar] [CrossRef]

- Zhou, J.; Qian, S.; Ye, G.; Copuroglu, O.; van Breugel, K.; Li, V.C. Improved fiber distribution and mechanical properties of engineered cementitious composites by adjusting the mixing sequence. Cem. Concr. Compos. 2012, 34, 342–348. [Google Scholar] [CrossRef]

- Gao, W.-B.; Su, Q.-K.; Zhang, J.-W.; Xie, H.-B.; Wen, F.; Li, F.; Liu, J.-Z. Steel Bridge Construction of Hong Kong–Zhuhai–Macao Bridge. Int. J. Steel Struct. 2020, 20, 1498–1508. [Google Scholar] [CrossRef]

- Qin, Y.; Zheng, B. The Qinghai–Tibet Railway: A landmark project and its subsequent environmental challenges. Environ. Dev. Sustain. 2010, 12, 859–873. [Google Scholar] [CrossRef]

- Yuan, C.; Xu, S.; Raza, A.; Wang, C.; Wang, D. Influence and Mechanism of Curing Methods on Mechanical Properties of Manufactured Sand UHPC. Materials 2022, 15, 6183. [Google Scholar] [CrossRef]

- Zhang, Y.; Raza, A.; Umar, M.; Chen, Y.; Yuan, C. Study on Frost Resistance and Interface Bonding Performance through the Integration of Recycled Brick Powder in Ultra-High-Performance Concrete for Structural Reinforcement. Materials 2023, 16, 6999. [Google Scholar] [CrossRef] [PubMed]

- Junjie, Z.; Raza, A.; Weicheng, F.; Chengfang, Y. Research on uniaxial compression performance and constitutive relationship of RBP-UHPC after high temperature. Sci. Eng. Compos. Mater. 2024, 31, 20240011. [Google Scholar] [CrossRef]

- Yuan, C.; Fu, W.; Raza, A.; Li, H. Study on Mechanical Properties and Mechanism of Recycled Brick Powder UHPC. Buildings 2022, 12, 1622. [Google Scholar] [CrossRef]

- Jialing, C. Experimental research on mechanical properties of desert sand steel-PVA fiber engineered cementitious composites. Funct. Mater. 2017, 24, 584–592. [Google Scholar] [CrossRef]

- Che, J.; Wang, D.; Liu, H.; Zhang, Y. Mechanical Properties of Desert Sand-Based Fiber Reinforced Concrete (DS-FRC). Appl. Sci. 2019, 9, 1857. [Google Scholar] [CrossRef]

- Wang, F.; Yu, J.; Ding, Y.; Ma, J.; Yu, K. Performance enhancement of engineered cementitious composite through tailoring recycled iron sand. J. Clean. Prod. 2024, 449, 141570. [Google Scholar] [CrossRef]

- Zhu, M.; Chen, B.; Wu, M.; Han, J. Preparation and mechanical characterization of cost-effective low-carbon engineered cementitious composites with seawater and sea-sand. Cem. Concr. Compos. 2023, 136, 104883. [Google Scholar] [CrossRef]

- Huang, B.T.; Yu, J.; Wu, J.Q.; Dai, J.-G.; Leung, C.K. Seawater sea-sand Engineered Cementitious Composites (SS-ECC) for marine and coastal applications. Compos. Commun. 2020, 20, 100353. [Google Scholar] [CrossRef]

- Raza, A.; Junjie, Z.; Shiwen, X.; Umar, M.; Chengfang, Y. Experimental analysis of frost resistance and failure models in engineered cementitious composites with the integration of YRS. Sci. Eng. Compos. Mater. 2024, 31, 20240017. [Google Scholar] [CrossRef]

- Raza, A.; Memon, B.A.; Oad, M. Effect of Curing Types on Compressive Strength of Recycled Aggregates Concrete. QUEST Res. J. 2019, 17, 7–12. [Google Scholar] [CrossRef]

- Memon, B.A.; Oad, M.; Buller, A.H.; Raza, A. Effect of Curing Methods on Tensile Strength of Green Concrete Cylinders Made with Demolishing Coarse Aggregates. World J. Eng. Res. Technol. 2020, 6, 66–75. [Google Scholar] [CrossRef]

- Feng, H.; Shaukat, A.J.; Rin, D.; Zhang, P.; Gao, D.; Sheikh, M.N. Mechanical properties of high-ductility magnesium phosphate cement composite cured at low temperatures. J. Build. Eng. 2021, 44, 103275. [Google Scholar] [CrossRef]

- Liu, W.; Hu, Z.; Liu, C.; Huang, X.; Hou, J. Mechanical properties under triaxial compression of coal gangue-fly ash cemented backfill after cured at different temperatures. Constr. Build. Mater. 2024, 411, 134268. [Google Scholar] [CrossRef]

- Mi, Z.; Hu, Y.; Li, Q.; An, Z. Effect of curing humidity on the fracture properties of concrete. Constr. Build. Mater. 2018, 169, 403–413. [Google Scholar] [CrossRef]

- Zhu, Y.; Zhang, Z.; Yao, Y.; Guan, X.; Yang, Y. Effect of Water-Curing Time on the Mechanical Properties of Engineered Cementitious Composites. J. Mater. Civ. Eng. 2016, 28, 04016123. [Google Scholar] [CrossRef]

- Guan, Y.; Li, Y.; Zhang, H.; Sun, R.; Tian, J.; Yang, Y. Preparation of low-cost green engineered cementitious composites (ECC) using gold tailings and unoiled PVA fiber. J. Build. Eng. 2023, 78, 107455. [Google Scholar] [CrossRef]

- Kim, M.J.; Oh, T.; Yoo, D.Y. Influence of curing conditions on the mechanical performance of ultra-high-performance strain-hardening cementitious composites. Arch. Civ. Mech. Eng. 2021, 21, 121. [Google Scholar] [CrossRef]

- Xu, M.; Yu, J.; Zhou, J.; Bao, Y.; Li, V.C. Effect of curing relative humidity on mechanical properties of engineered cementitious composites at multiple scales. Constr. Build. Mater. 2021, 284, 122834. [Google Scholar] [CrossRef]

- Jiang, B.; Qian, Z.; Pan, J. Influence of expansive agent and curing method on the mechanical and drying deformation properties of Engineered Cementitious Composites (ECC). Mater. Struct. 2022, 55, 58. [Google Scholar] [CrossRef]

- JGJ 52-2006; Standard for Technical Requirements and Test Method of Sand and Crushed Stone (or Gravel) for Ordinary Concrete. China Architecture & Building Press: Bejing, China, 2007.

- GB/T 17671-2021; Test Method of Cement Mortar Strength (ISO Method). China Building Materials Industry Press: Bejing, China, 2021.

- JCT 2461-2018; Standard Test Method for the Mechanical Properties of Ductile Fiber Reinforced Cementitious Composites. China Building Materials Industry Press: Bejing, China, 2018.

- DBJ61/T 112-2021; Technical Specification for Application of High Ductility Concrete. Shaanxi Provincial Department of Housing and Urban-Rural Development: Shanxi, China, 2021.

- Dai, J. Experimental Study on the Mechanical Behavior of HDC and Shear Performance of HDC Beams. Ph.D. Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2017. [Google Scholar]

- CECS 13:2009; Standard Test Methods for Fiber Reinforced Concrete. Metallurgical Industry Press: Bejing, China, 2009.

- Kanda, T.; Li, V.C. Multiple cracking sequence and saturation in fiber reinforced cementitious composites. Concr. Res. Technol. 1998, 9, 13–33. [Google Scholar]

- Kanda, T.; Li, V.C. New Micromechanics Design Theory for Pseudostrain Hardening Cementitious Composite. J. Eng. Mech. 1999, 125, 373–381. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Practical Design Criteria for Saturated Pseudo Strain Hardening Behavior in ECC. J. Adv. Concr. Technol. 2006, 4, 59–72. [Google Scholar] [CrossRef]

- Li, V.C. On Engineered Cementitious Composites (ECC) a review of the material and its applications. J. Adv. Concr. Technol. 2003, 1, 215–230. [Google Scholar] [CrossRef]

- Deng, G.; He, Y.; Lu, L.; Wang, F.; Hu, S. Pore structure evolution and sulfate attack of high-volume slag blended mortars under standard curing and steam curing. Constr. Build. Mater. 2023, 363, 129878. [Google Scholar] [CrossRef]

- Huang, B.T.; Wu, J.; Yu, J.; Dai, J.-G.; Leung, C.K.; Li, V.C. Seawater sea-sand engineered/strain-hardening cementitious composites (ECC/SHCC): Assessment and modeling of crack characteristics. Cem. Concr. Res. 2021, 140, 106292. [Google Scholar] [CrossRef]

| Diameter (µm) | Length (mm) | Tensile Strength (MPa) | Elastic Modulus (GPa) | Elongation at Break (%) | Density (g·cm−3) |

|---|---|---|---|---|---|

| 40 | 12 | 1560 | 41 | 6.5 | 1.3 |

| Type of Fine Aggregate | Apparent Density/kg·m−3 | Bulk Density/kg·m−3 | Water Absorption at Saturated Surface-Dry Basis/% | Specific Surface Area/m2·g−1 |

|---|---|---|---|---|

| Quartz sand | 2650 | 1675 | 0.2 | 0.073 |

| YRS | 2647 | 1418 | 1.1 | 0.435 |

| Types of ECC | Water | Fly Ash | Cement | Quartz Sand | YRS | Water Reducer | Thickener | PVA Fiber |

|---|---|---|---|---|---|---|---|---|

| YRS-ECC | 410 | 585 | 585 | 0 | 700 | 3.5 | 1.8 | 19 |

| Traditional sand ECC | 410 | 585 | 585 | 700 | 0 | 3.5 | 1.8 | 19 |

| Performance Index | Peer Group | Specimen Size | Quantity |

|---|---|---|---|

| compressive and flexural strength | B14, B28, B90 | 160 mm × 40 mm × 40 mm | 39 |

| Z14, Z28, Z90 | |||

| S14, S28, S90 | |||

| K14, K28, K90 B’28 | |||

| uniaxial tensile property | B14, B28, B90 | 330 mm × 60 mm × 13 mm | 78 |

| Z14, Z28, Z90 | |||

| S14, S28, S90 | |||

| K14, K28, K90 B’28 | |||

| four-point bending test | B14, B28, B90 | 160 mm × 40 mm × 40 mm | 39 |

| Z14, Z28, Z90 | |||

| S14, S28, S90 | |||

| K14, K28, K90 B’28 |

| Serial Number | Curing Age | Flexural Strength (MPa) | Variation Trend | Compressive Strength (MPa) | Variation Trend |

|---|---|---|---|---|---|

| B14 | 14 d | 9.9 | - | 22.9 | - |

| Z14 | 14.8 | 49.50% | 33.0 | 44.10% | |

| S14 | 11.8 | 19.20% | 27.7 | 20.96% | |

| K14 | 11.7 | 18.19% | 27.3 | 19.21% | |

| B28 | 28 d | 11.5 | - | 26.4 | - |

| Z28 | 15.7 | 36.52% | 34.9 | 32.20% | |

| S28 | 12.5 | 8.70% | 29.3 | 10.98% | |

| K28 | 13.2 | 14.78% | 30.8 | 16.67% | |

| B90 | 90 d | 14.0 | - | 32.7 | - |

| Z90 | 17.6 | 25.71% | 38.7 | 18.35% | |

| S90 | 13.4 | −4.29% | 31.6 | −3.36% | |

| K90 | 13.3 | −5.00% | 31.1 | −4.93% |

| Serial Number | Curing Method | Flexural Strength (MPa) | Variation Trend | Compressive Strength (MPa) | Variation Trend |

|---|---|---|---|---|---|

| B14 | Standard curing | 9.9 | - | 22.9 | - |

| B28 | 11.5 | 16.16% | 26.4 | 15.28% | |

| B90 | 14.0 | 21.74% | 32.7 | 23.86% | |

| Z14 | Steam curing | 14.8 | - | 33.0 | - |

| Z28 | 15.7 | 6.08% | 34.9 | 5.76% | |

| Z90 | 17.6 | 12.10% | 38.7 | 10.89% | |

| S14 | Sprinkler curing | 11.8 | - | 27.7 | - |

| S28 | 12.5 | 5.93% | 29.3 | 5.78% | |

| S90 | 13.4 | 7.20% | 31.6 | 7.85% | |

| K14 | Natural curing | 11.6 | - | 27.3 | - |

| K28 | 13.2 | 13.80% | 30.8 | 12.82% | |

| K90 | 13.3 | 0.75% | 31.1 | 0.97% |

| Types of Sand | Initial Crack Strength σfc (MPa) | Initial Cracking Strain εfc (%) | Ultimate Tensile Strength σtu (MPa) | Tensile Strain Capacity εtu (%) |

|---|---|---|---|---|

| Quartz sand | 0.48 | 0.05 | 1.60 | 3.20 |

| Yellow River sand | 0.47 | 0.02 | 1.83 | 3.71 |

| Types of Sand | Initial Crack Load Ffc (N) | Initial Crack Deflection δfc (mm) | Ultimate Bending Load Ftu (N) | Ultimate Bending Deflection δtu (mm) |

|---|---|---|---|---|

| Quartz sand | 3133.13 | 0.01 | 5596.81 | 3.71 |

| Yellow River sand | 2867.15 | 0.02 | 5917.73 | 4.05 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, K.; Wu, W.; Fan, J.; Yuan, C. The Influence and Mechanism of Curing Methods and Curing Age on the Mechanical Properties of Yellow River Sand Engineered Cementitious Composites. Materials 2024, 17, 4307. https://doi.org/10.3390/ma17174307

Zhang K, Wu W, Fan J, Yuan C. The Influence and Mechanism of Curing Methods and Curing Age on the Mechanical Properties of Yellow River Sand Engineered Cementitious Composites. Materials. 2024; 17(17):4307. https://doi.org/10.3390/ma17174307

Chicago/Turabian StyleZhang, Kunpeng, Weijun Wu, Jiahui Fan, and Chengfang Yuan. 2024. "The Influence and Mechanism of Curing Methods and Curing Age on the Mechanical Properties of Yellow River Sand Engineered Cementitious Composites" Materials 17, no. 17: 4307. https://doi.org/10.3390/ma17174307

APA StyleZhang, K., Wu, W., Fan, J., & Yuan, C. (2024). The Influence and Mechanism of Curing Methods and Curing Age on the Mechanical Properties of Yellow River Sand Engineered Cementitious Composites. Materials, 17(17), 4307. https://doi.org/10.3390/ma17174307