Evaluation of Macro- and Micro-Geometry of Models Made of Photopolymer Resins Using the PolyJet Method

Abstract

1. Introduction

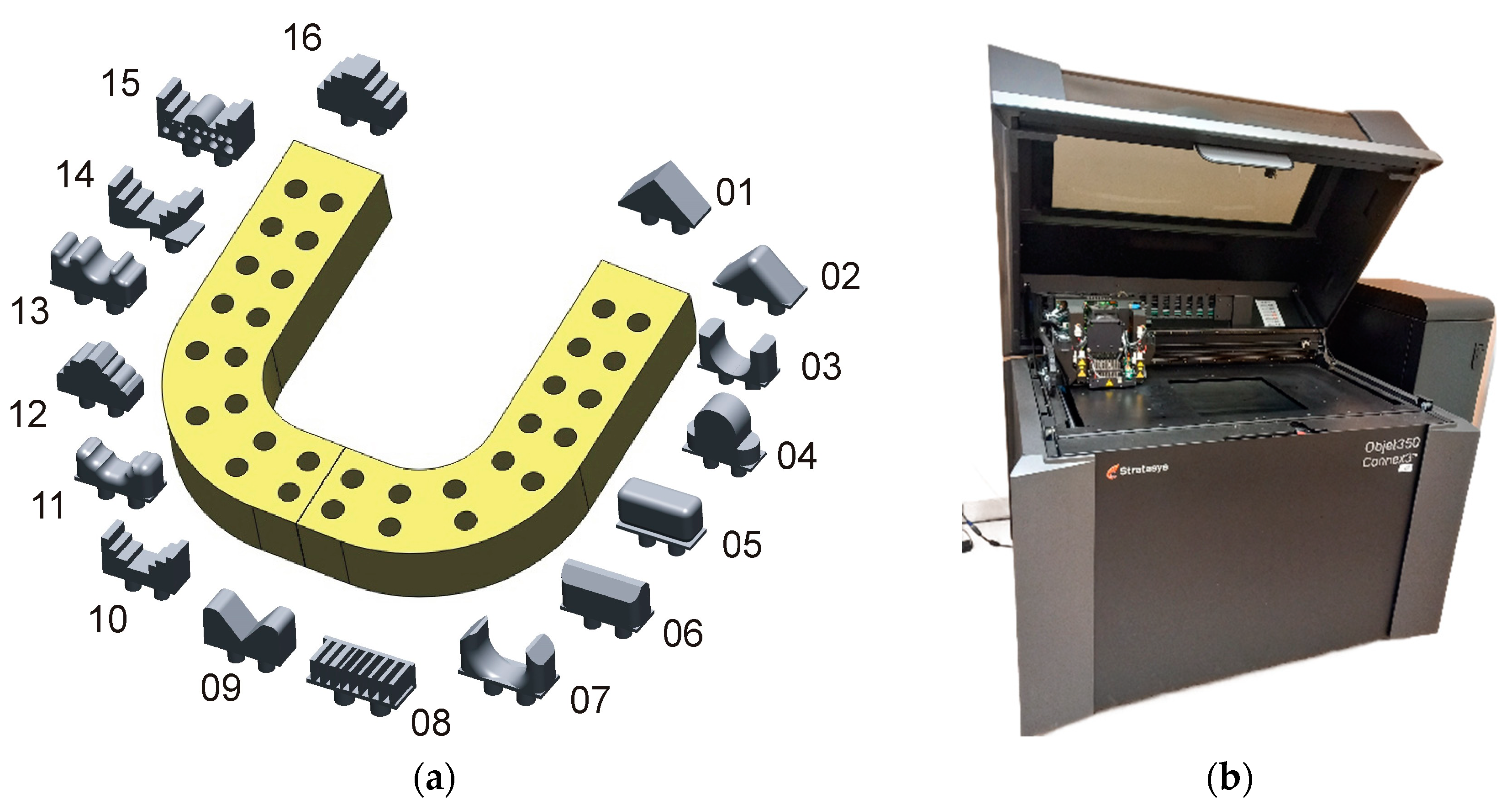

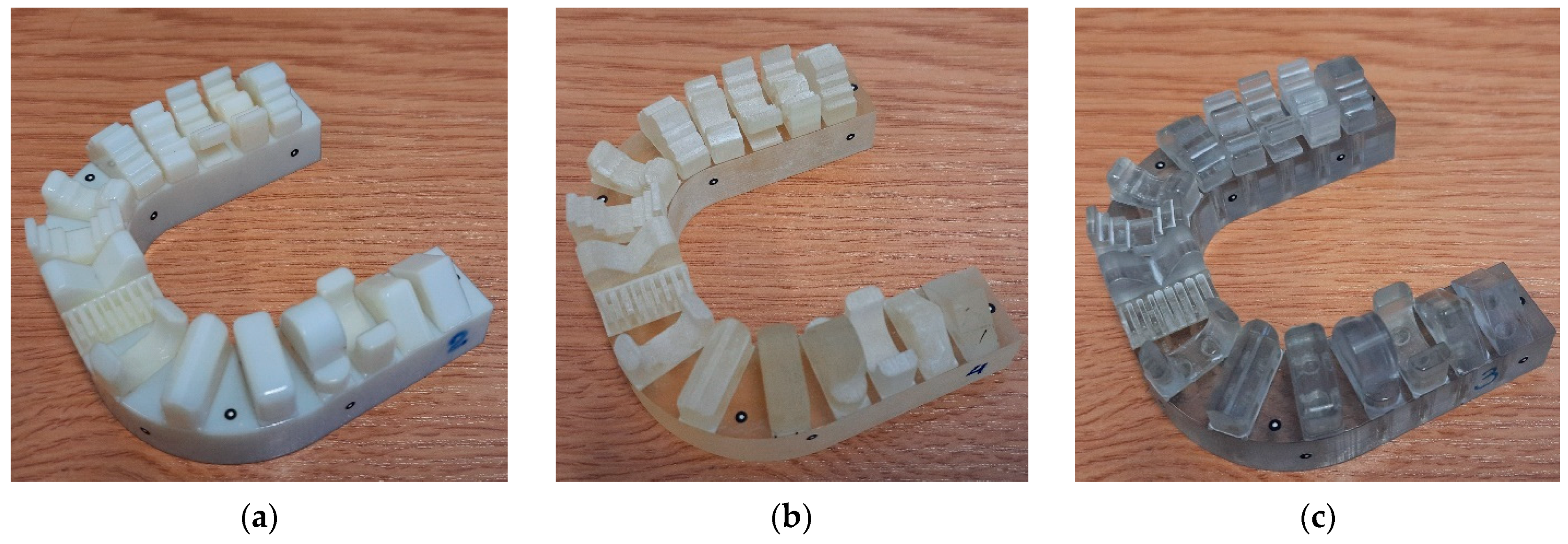

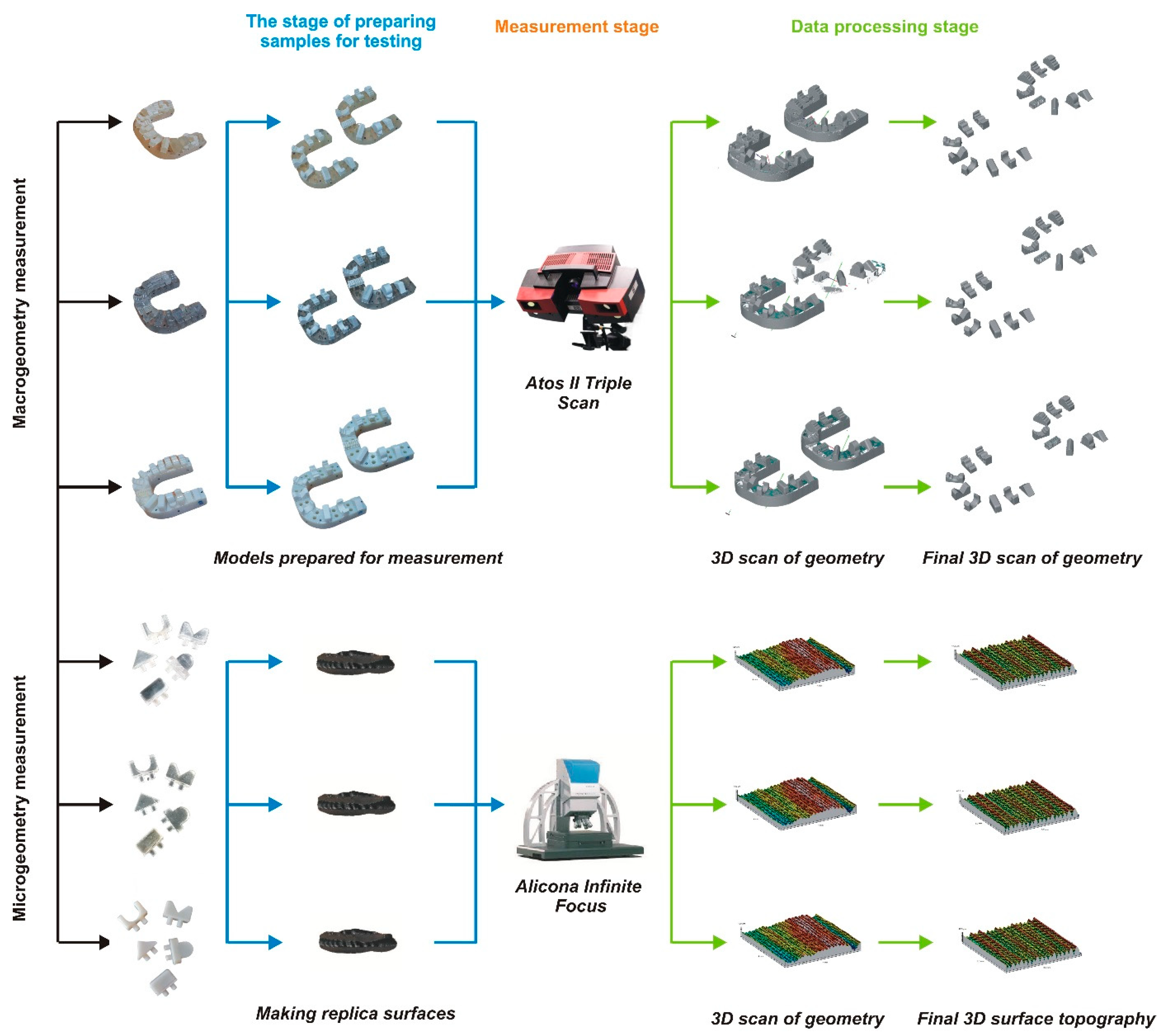

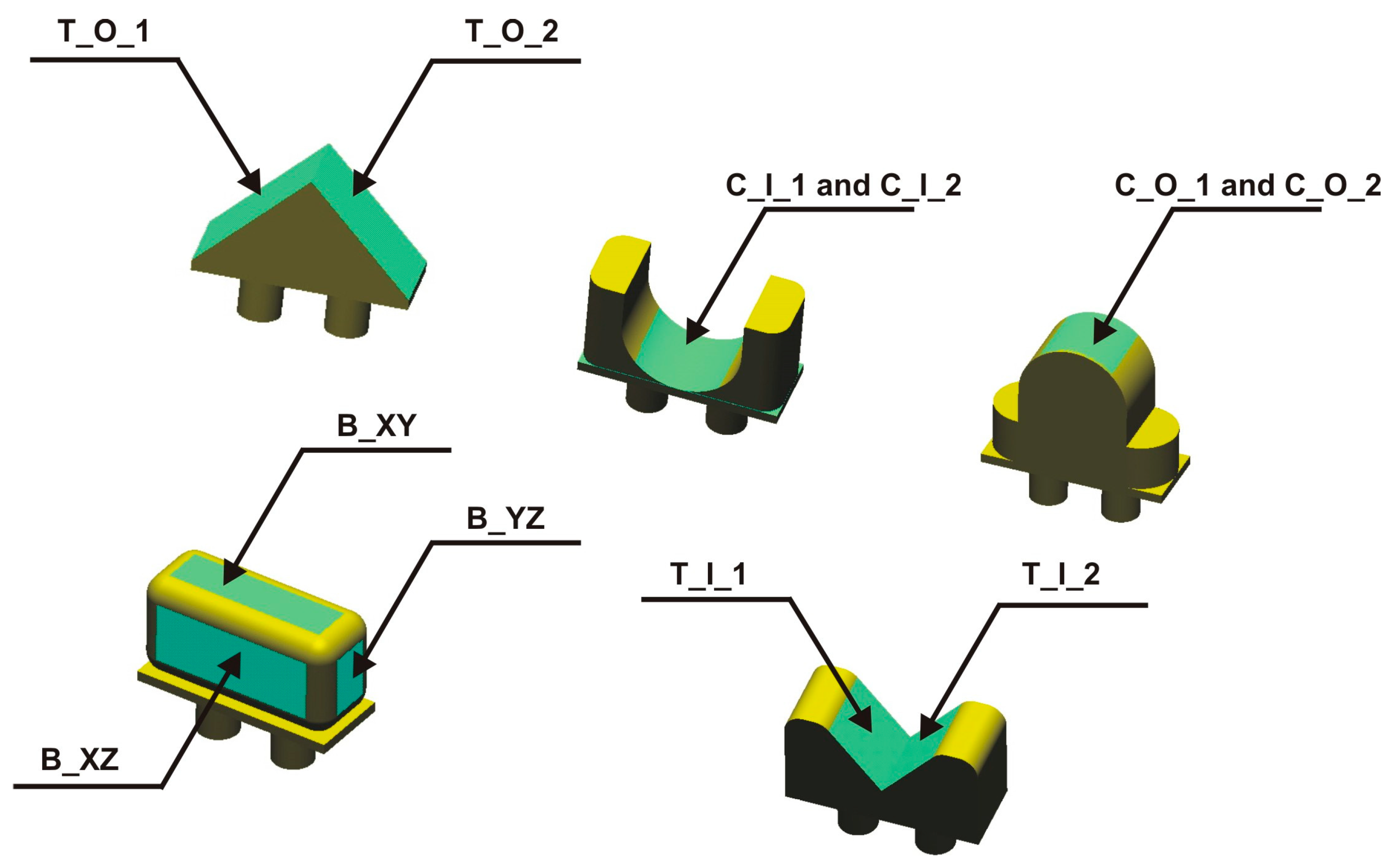

2. Materials and Methods

3. Results

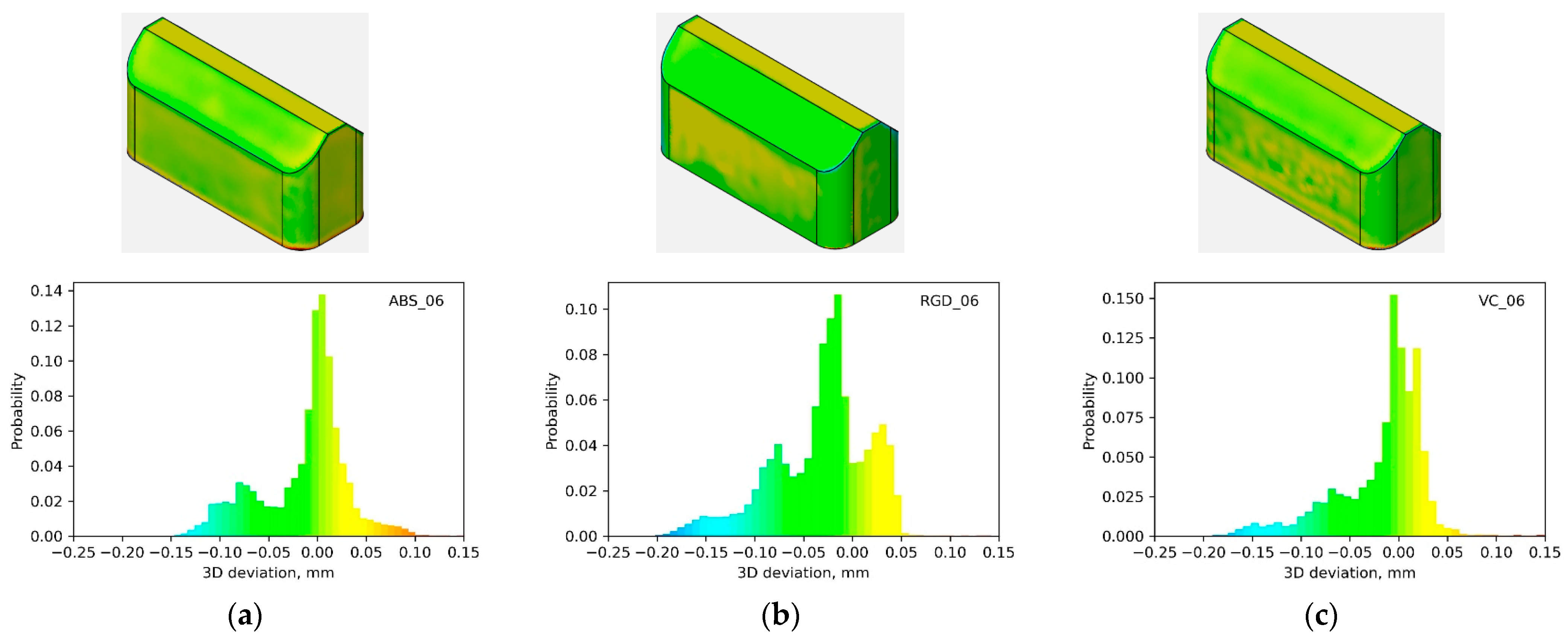

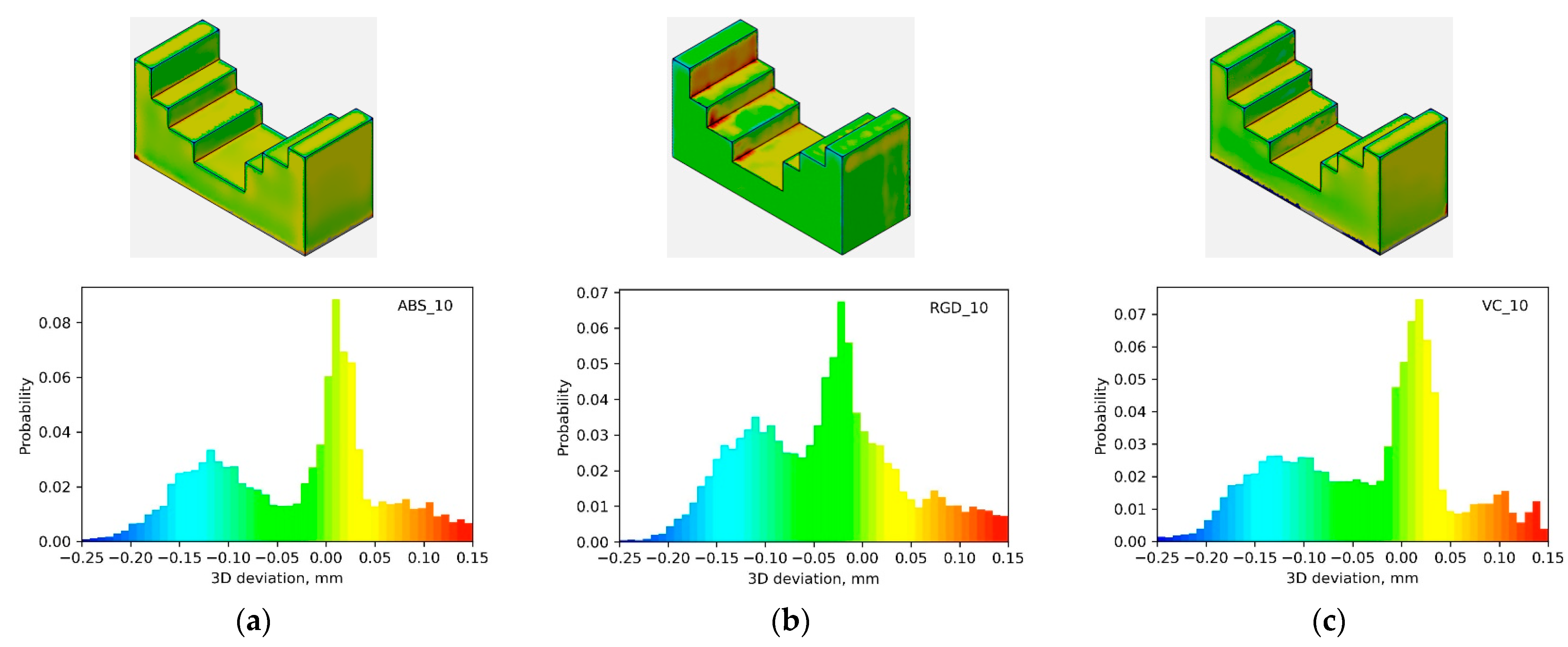

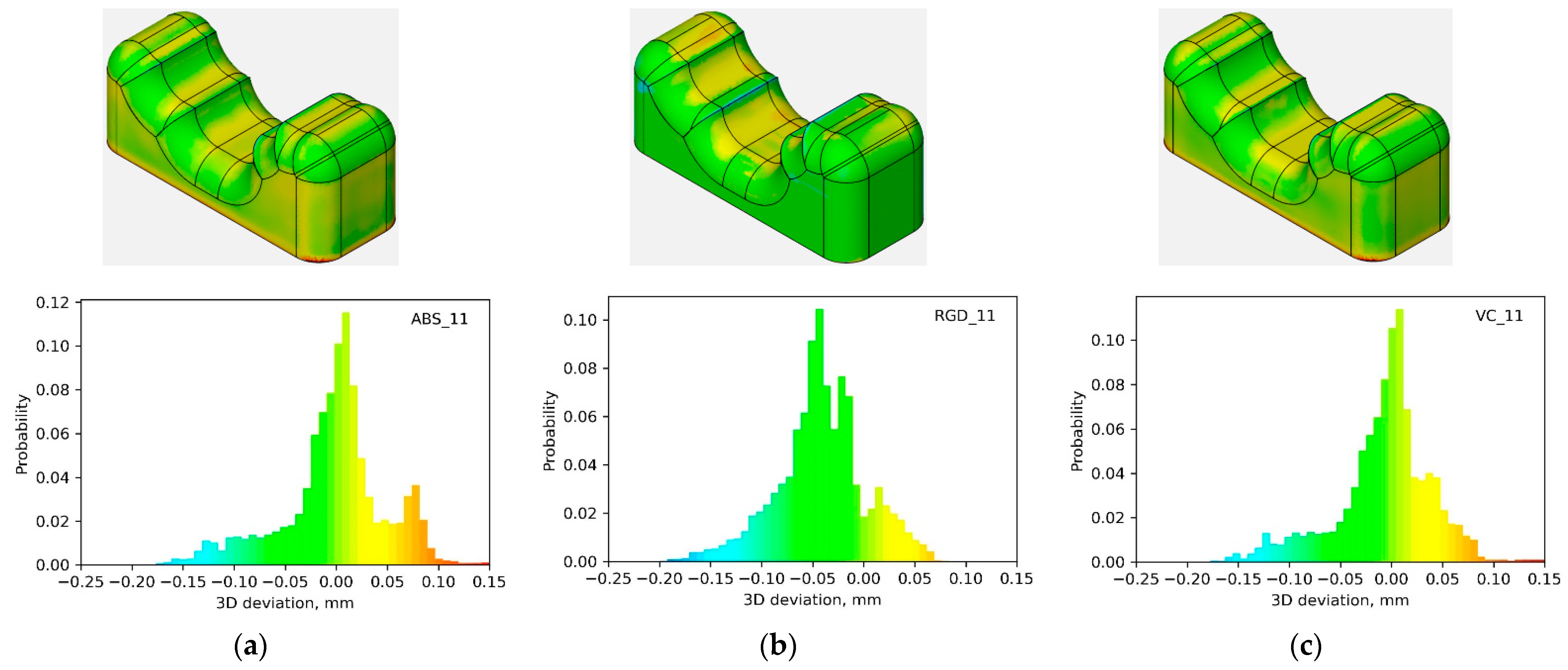

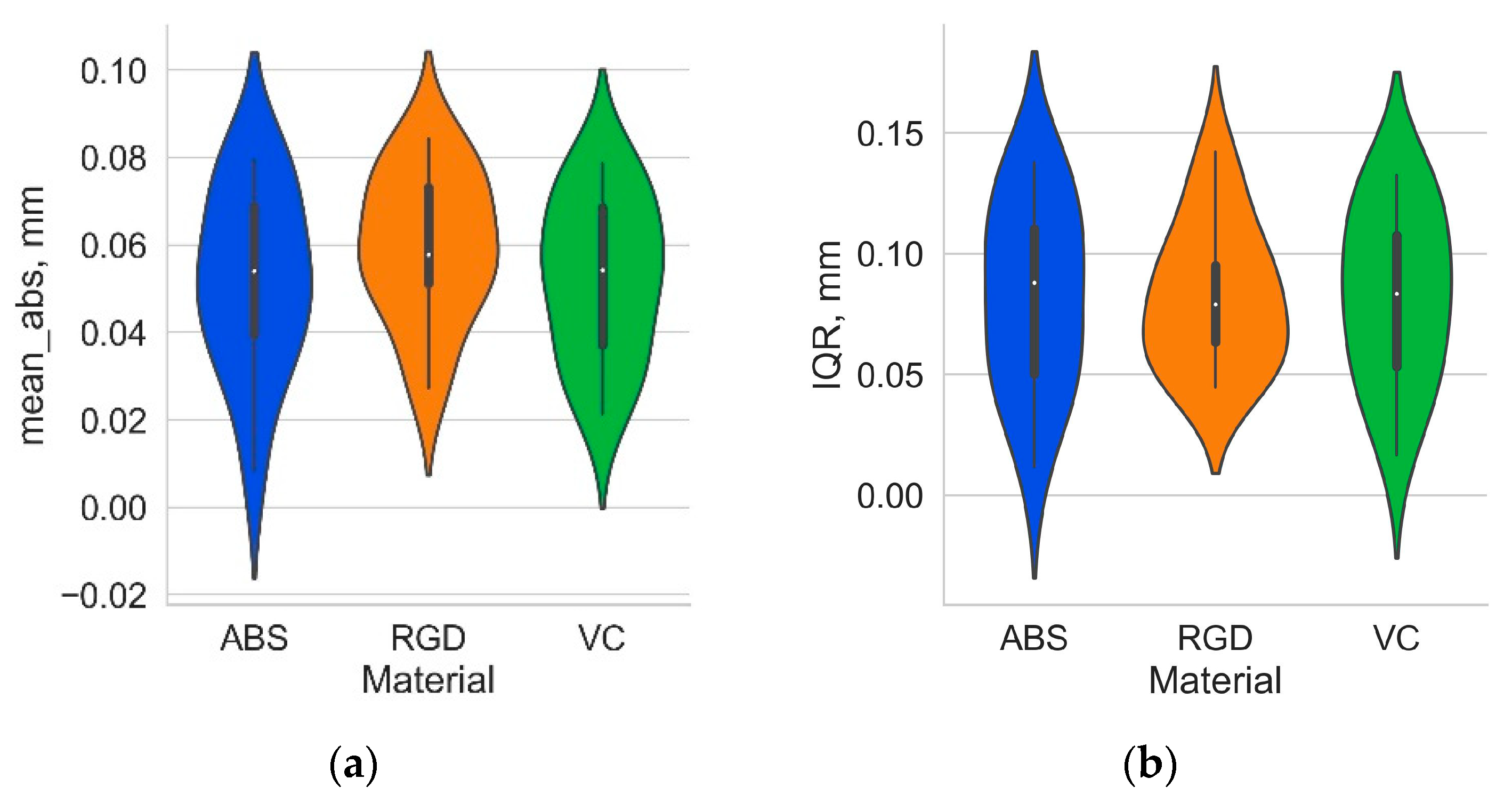

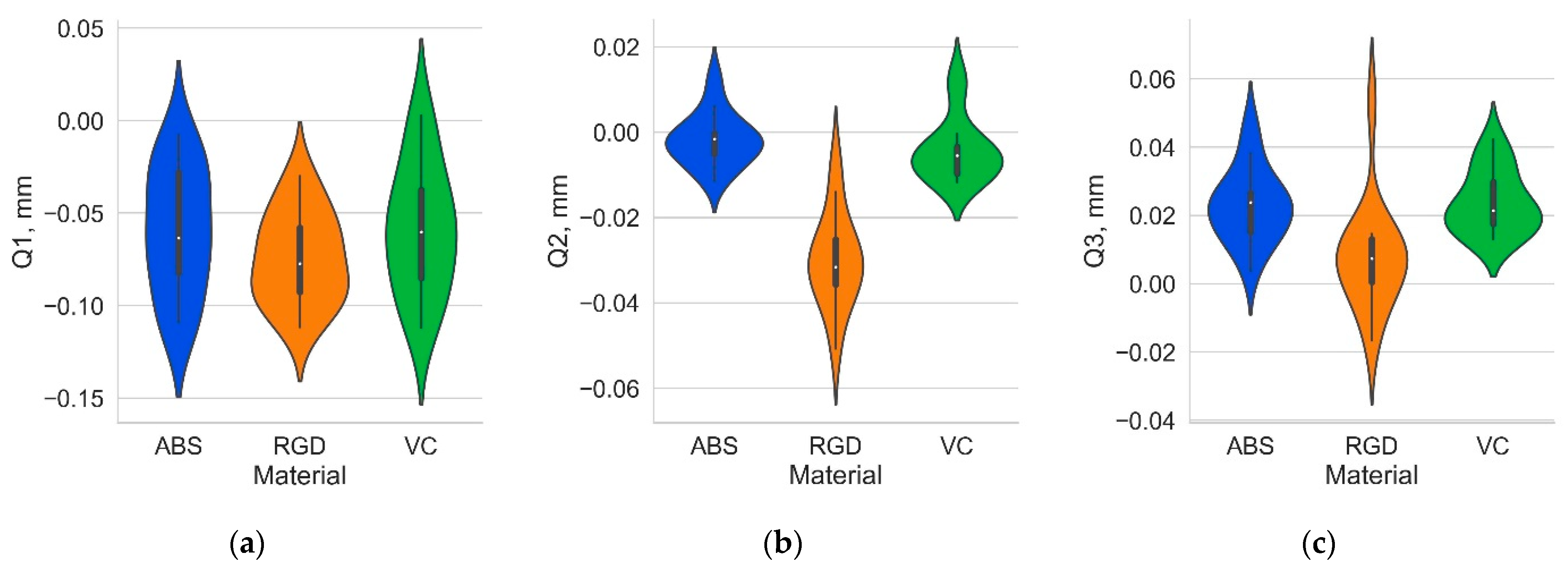

3.1. Macro-Geometry Analysis

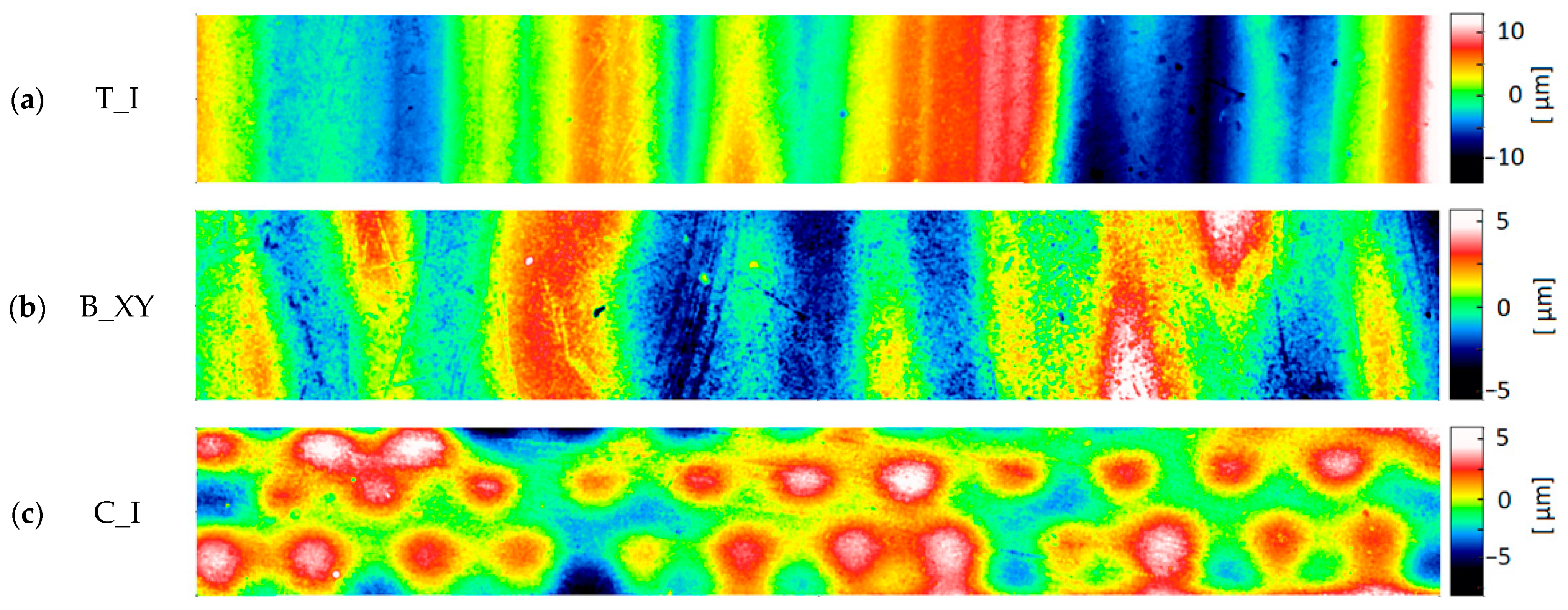

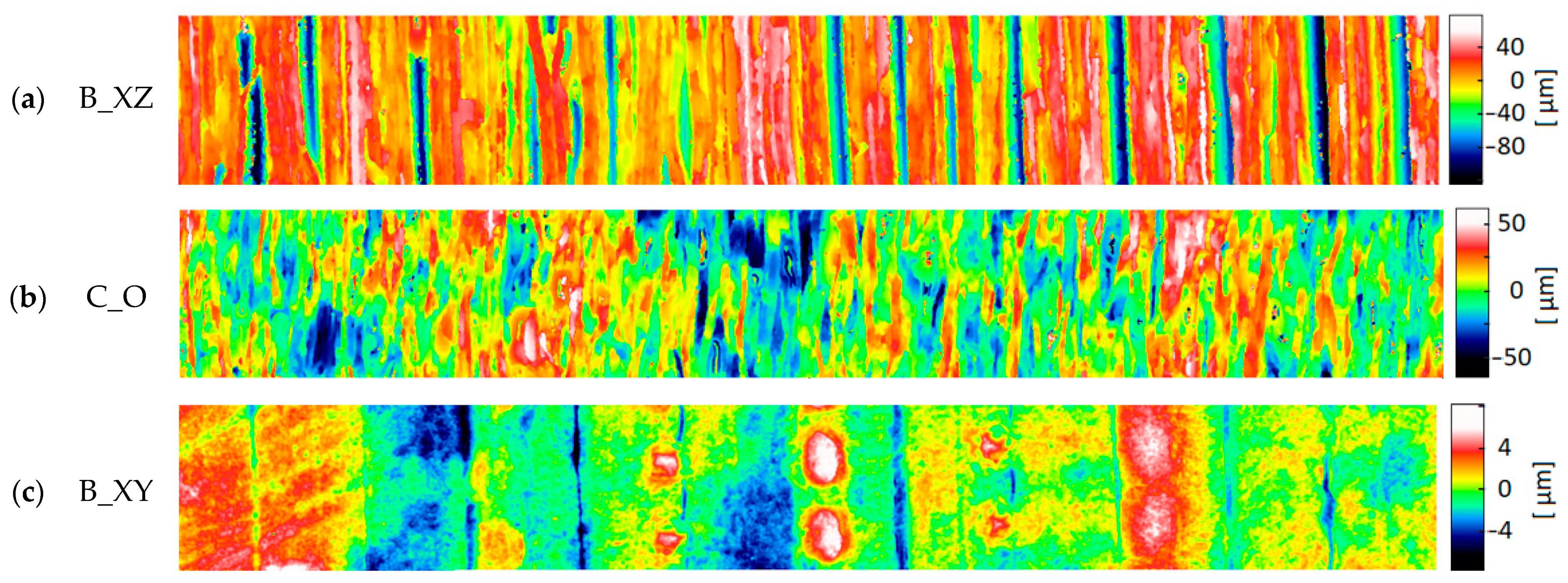

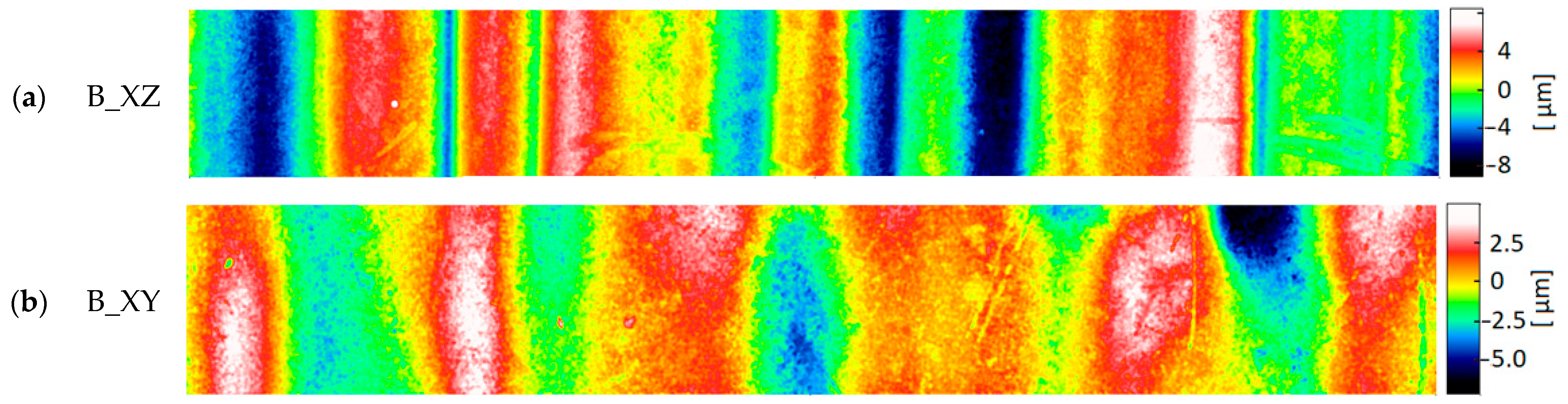

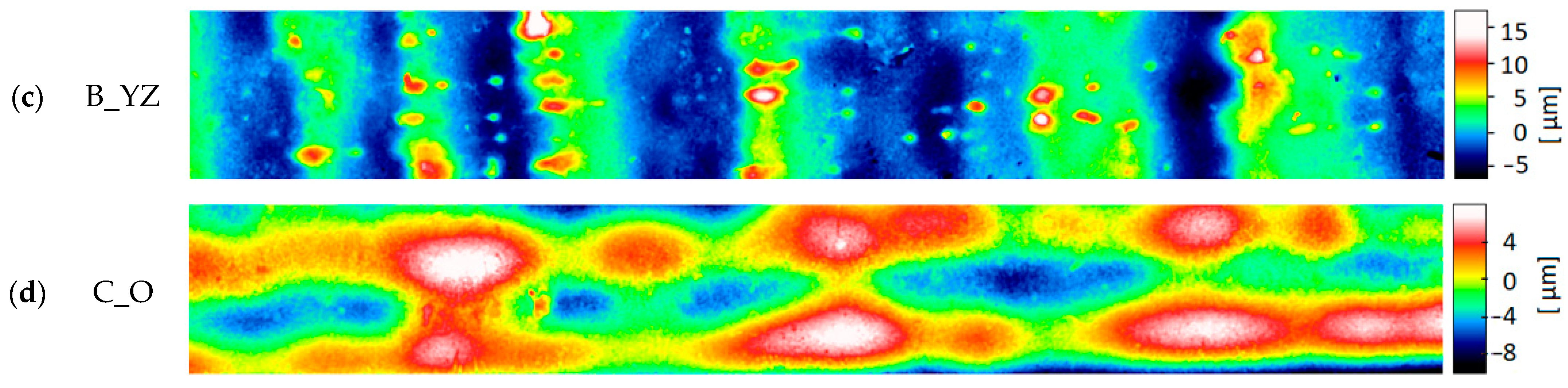

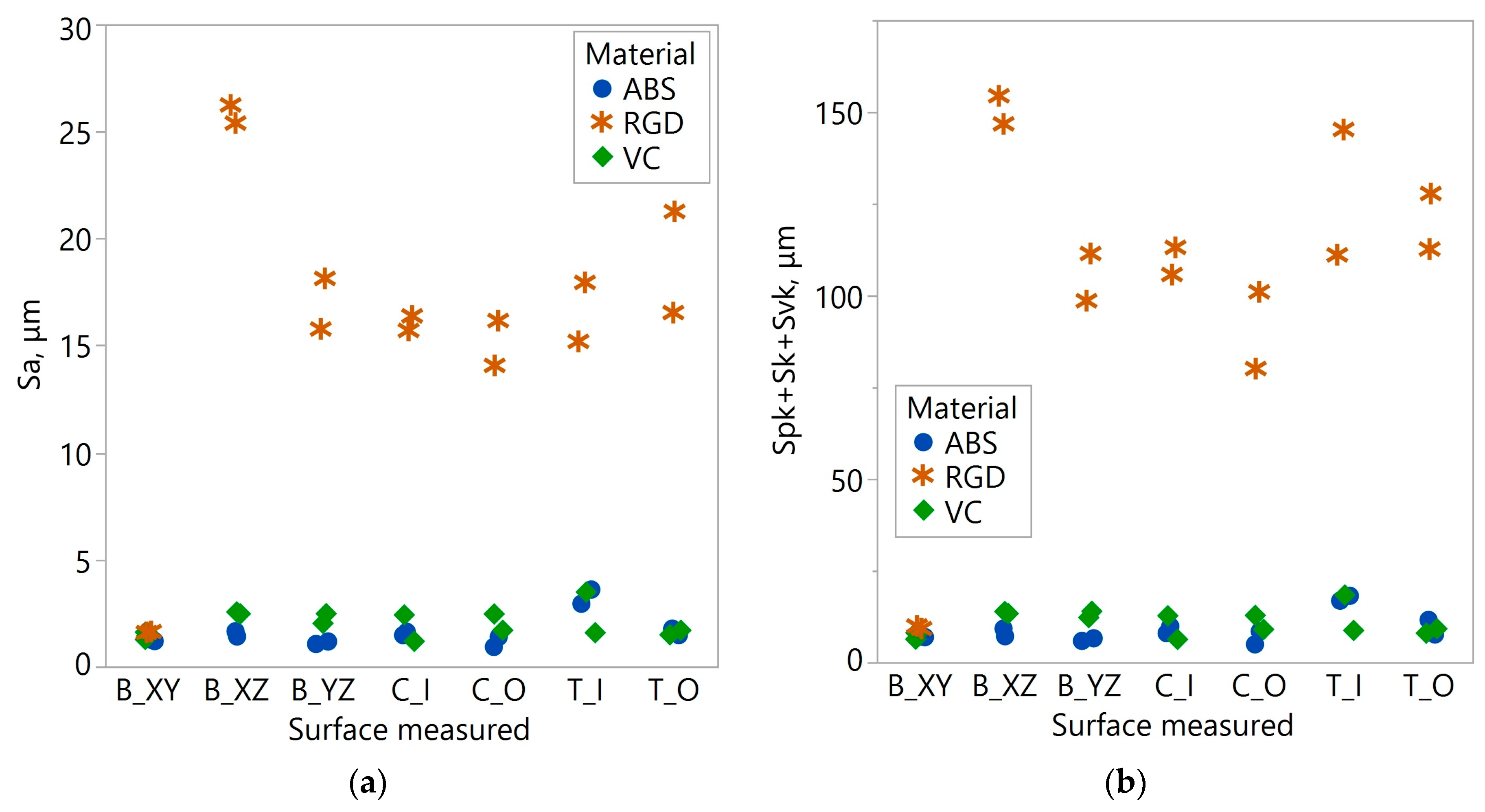

3.2. Micro-Geometry Analysis

4. Discussion

5. Conclusions

6. Patents

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Arslan, A.; Masjuki, H.H.; Kalam, M.A.; Varman, M.; Mufti, R.A.; Mosarof, M.H.; Quazi, M.M. Surface texture manufacturing techniques and tribological effect of surface texturing on cutting tool performance: A review. Crit. Rev. Solid State Mater. Sci. 2016, 41, 447–481. [Google Scholar] [CrossRef]

- Triantaphyllou, A.; Giusca, C.L.; Macaulay, G.D.; Roerig, F.; Hoebel, M.; Leach, R.K.; Milne, K.A. Surface texture measurement for additive manufacturing. Surf. Topogr. Metrol. Prop. 2015, 3, 024002. [Google Scholar] [CrossRef]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Parametric characterization of machined textured surfaces. Materials 2022, 16, 163. [Google Scholar] [CrossRef] [PubMed]

- Pawlus, P.; Reizer, R.; Wieczorowski, M. Functional importance of surface texture parameters. Materials 2021, 14, 5326. [Google Scholar] [CrossRef] [PubMed]

- Leach, R. (Ed.) Characterisation of Areal Surface Texture; Springer Science & Business Media: Cham, Switzerland, 2013. [Google Scholar]

- Gardan, J. Additive manufacturing technologies. In Additive Manufacturing Handbook; CRC Press: Boca Raton, FL, USA, 2017; pp. 149–168. [Google Scholar] [CrossRef]

- Thompson, M.K.; Moroni, G.; Vaneker, T.; Fadel, G.; Campbell, R.I.; Gibson, I.; Bernard, A.; Schulz, J.; Graf, P.; Ahuja, B.; et al. Design for Additive Manufacturing: Trends, opportunities, considerations, and constraints. CIRP Ann. 2016, 65, 737–760. [Google Scholar] [CrossRef]

- Gibson, I.; Rosen, D.W.; Stucker, B. Additive Manufacturing Technologies; Springer: Cham, Switzerland, 2021. [Google Scholar]

- Gisario, A.; Kazarian, M.; Martina, F.; Mehrpouya, M. Metal additive manufacturing in the commercial aviation industry: A review. J. Manuf. Syst. 2019, 53, 124–149. [Google Scholar] [CrossRef]

- Chu, M.Q.; Wang, L.; Ding, H.Y.; Sun, Z.G. Additive Manufacturing for Aerospace Application. Appl. Mech. Mater. 2015, 798, 457–461. [Google Scholar] [CrossRef]

- Rokicki, P.; Budzik, G.; Kubiak, K.; Dziubek, T.; Zaborniak, M.; Kozik, B.; Bernaczek, J.; Przeszlowski, L.; Nowotnik, A. The assessment of geometric accuracy of aircraft engine blades with the use of an optical coordinate scanner. Aircr. Eng. Aerosp. Technol. 2016, 88, 374–381. [Google Scholar] [CrossRef]

- Leal, R.; Barreiros, F.M.; Alves, L.; Romeiro, F.; Vasco, J.C.; Santos, M.; Marto, C. Additive manufacturing tooling for the automotive industry. Int. J. Adv. Manuf. Technol. 2017, 92, 1671–1676. [Google Scholar] [CrossRef]

- Negrea, A.P.; Cojanu, V. Innovation as Entrepreneurial Drives in the Romanian Automotive Industry. J. Econ. Bus. Manag. 2016, 4, 58–64. [Google Scholar] [CrossRef]

- Salmi, M. Additive Manufacturing Processes in Medical Applications. Materials 2021, 14, 191. [Google Scholar] [CrossRef]

- Turek, P.; Filip, D.; Przeszłowski, Ł.; Łazorko, A.; Budzik, G.; Snela, S.; Oleksy, M.; Jabłoński, J.; Sęp, J.; Bulanda, K. Manufacturing Polymer Model of Anatomical Structures with Increased Accuracy Using CAx and AM Systems for Planning Orthopedic Procedures. Polymers 2022, 14, 2236. [Google Scholar] [CrossRef] [PubMed]

- Martorelli, M.; Gerbino, S.; Giudice, M.; Ausiello, P. A comparison between customized clear and removable orthodontic appliances manufactured using RP and CNC techniques. Dent. Mater. 2013, 29, e1–e10. [Google Scholar] [CrossRef] [PubMed]

- Umaras, E.; Tsuzuki, M.S. Additive manufacturing-considerations on geometric accuracy and factors of influence. IFAC-PapersOnLine 2017, 50, 14940–14945. [Google Scholar] [CrossRef]

- Obilanade, D.; Dordlofva, C.; Törlind, P. Surface roughness considerations in design for additive manufacturing—A literature review. Proc. Des. Soc. 2021, 1, 2841–2850. [Google Scholar] [CrossRef]

- Dziubek, T.; Oleksy, M. Application of ATOS II optical system in the techniques of rapid prototyping of epoxy resin-based gear models. Polimery 2017, 62, 44–52. [Google Scholar] [CrossRef]

- Kozior, T.; Mamun, A.; Trabelsi, M.; Sabantina, L.; Ehrmann, A. Quality of the Surface Texture and Mechanical Properties of FDM Printed Samples after Thermal and Chemical Treatment. Stroj. Vestn.-J. Mech. Eng. 2020, 66, 105–113. [Google Scholar] [CrossRef]

- Bazan, A.; Turek, P.; Przeszłowski, Ł. Assessment of InfiniteFocus system measurement errors in testing the accuracy of crown and tooth body model. J. Mech. Sci. Technol. 2021, 35, 1167–1176. [Google Scholar] [CrossRef]

- Bazan, A.; Turek, P.; Przeszłowski, Ł. Comparison of the contact and focus variation measurement methods in the process of surface topography evaluation of additively manufactured models with different geometry complexity. Surf. Topogr. Metrol. Prop. 2022, 10, 035021. [Google Scholar] [CrossRef]

- Turek, P. The Influence of the Layer Thickness Change on the Accuracy of the Zygomatic Bone Geometry Manufactured Using the FDM Technology. Proc. Eng. 2022, 24, 26. [Google Scholar] [CrossRef]

- Leutenecker-Twelsiek, B.; Klahn, C.; Meboldt, M. Considering part orientation in design for additive manufacturing. Procedia Cirp 2016, 50, 408–413. [Google Scholar] [CrossRef]

- Langelaar, M. Combined optimization of part topology, support structure layout and build orientation for additive manufacturing. Struct. Multidiscip. Optim. 2018, 57, 1985–2004. [Google Scholar] [CrossRef]

- Zhang, Y.; Bernard, A.; Gupta, R.K.; Harik, R. Feature based building orientation optimization for additive manufacturing. Rapid Prototyp. J. 2016, 22, 358–376. [Google Scholar] [CrossRef]

- Dizon, J.R.C.; Gache, C.C.L.; Cascolan, H.M.S.; Cancino, L.T.; Advincula, R.C. Post-Processing of 3D-Printed Polymers. Technologies 2021, 9, 61. [Google Scholar] [CrossRef]

- Tamburrino, F.; Barone, S.; Paoli, A.; Razionale, A.V. Post-processing treatments to enhance additively manufactured polymeric parts: A review. Virtual Phys. Prototyp. 2021, 16, 221–254. [Google Scholar] [CrossRef]

- Wörz, A.; Wiedau, L.C.; Wudy, K.; Wegner, A.; Witt, G.; Drummer, D. Influence of chemical postprocessing on mechanical properties of laser-sintered polyamide 12 parts. J. Polym. Eng. 2021, 39, 830–837. [Google Scholar] [CrossRef]

- Wohlers, T.T.; Campbell, I.; Diegel, O.; Huff, R.; Kowen, J. Wohlers Report 2021—3D Printing and Additive Manufacturing Global State of the Industry; Wohlers Associates: Fort Collins, CO, USA, 2021. [Google Scholar]

- Böckin, D.; Tillman, A.M. Environmental assessment of additive manufacturing in the automotive industry. J. Clean. Prod. 2019, 226, 977–987. [Google Scholar] [CrossRef]

- Ciocca, L.; Mazzoni, S.; Fantini, M.; Persiani, F.; Baldissara, P.; Marchetti, C.; Scotti, R. A CAD/CAM-prototyped anatomical condylar prosthesis connected to a custom-made bone plate to support a fibula free flap. Med. Biol. Eng. Comput. 2012, 50, 743–749. [Google Scholar] [CrossRef] [PubMed]

- Kim, S.Y.; Shin, Y.S.; Jung, H.D.; Hwang, C.J.; Baik, H.S.; Cha, J.Y. Precision and trueness of dental models manufactured with different 3-dimensional printing techniques. Am. J. Orthod. Dentofac. Orthop. 2018, 153, 144–153. [Google Scholar] [CrossRef]

- Camardella, L.T.; de Vasconcellos Vilella, O.; Breuning, H. Accuracy of printed dental models made with 2 prototype technologies and different designs of model bases. Am. J. Orthod. Dentofac. Orthop. 2017, 151, 1178–1187. [Google Scholar] [CrossRef]

- Volpato, N.; Solis, D.M.; Costa, C.A. An Analysis of Digital ABS as a Rapid Tooling Material for Polymer Injection Moulding. Int. J. Mater. Prod. Technol. 2016, 52, 3–16. [Google Scholar] [CrossRef]

- Bagalkot, A.; Pons, D.; Clucas, D.; Symons, D. A methodology for setting the injection moulding process parameters for polymer rapid tooling inserts. Rapid Prototyp. J. 2019, 25, 1493–1505. [Google Scholar] [CrossRef]

- Kampker, A.; Triebs, J.; Kawollek, S.; Ayvazand, P.; Beyer, T. Direct Polymer Additive Tooling–effect of Additive Manufactured Polymer Tools on Partmaterial Properties for Injection Moulding. Rapid Prototyp. J. 2019, 25, 1575–1584. [Google Scholar] [CrossRef]

- Bell, M.A.; Becker, K.P.; Wood, R.J. Injection molding of soft robots. Adv. Mater. Technol. 2022, 7, 2100605. [Google Scholar] [CrossRef]

- Patpatiya, P.; Chaudhary, K.; Shastri, A.; Sharma, S. A review on polyjet 3D printing of polymers and multi-material structures. Proc. Inst. Mech. Eng. Part. C J. Mech. Eng. Sci. 2022, 236, 7899–7926. [Google Scholar] [CrossRef]

- Yap, Y.L.; Wang, C.; Sing, S.L.; Dikshit, V.; Yeong, W.Y.; Wei, J. Material jetting additive manufacturing: An experimental study using designed metrological benchmarks. Precis. Eng. 2017, 50, 275–285. [Google Scholar] [CrossRef]

- ISO/ASTM 52902:2023; Additive Manufacturing—Test Artefacts—Geometric Capability Assessment of Additive Manufacturing Systems. ISO: Geneva, Switzerland, 2023.

- Budzik, G.; Turek, P.; Dziubek, T.; Gdula, M. Elaboration of the measuring procedure facilitating precision assessment of the geometry of mandible anatomical model manufactured using additive methods. Meas. Control 2019, 53, 181–191. [Google Scholar] [CrossRef]

- Gülcan, O.; Günaydın, K.; Çelik, A. Investigation on Surface Roughness of PolyJet-Printed Airfoil Geometries for Small UAV Applications. Aerospace 2022, 9, 82. [Google Scholar] [CrossRef]

- Udroiu, R.; Braga, I.C.; Nedelcu, A. Evaluating the Quality Surface Performance of Additive Manufacturing Systems: Methodology and a Material Jetting Case Study. Materials 2019, 12, 995. [Google Scholar] [CrossRef]

- Kumar, K.; Kumar, G.S. An experimental and theoretical investigation of surface roughness of poly-jet printed parts: This paper explains how local surface orientation affects surface roughness in a poly-jet process. Virtual Phys. Prototyp. 2015, 10, 23–34. [Google Scholar] [CrossRef]

- Kechagias, J.P.A.I.; Stavropoulos, P.; Koutsomichalis, A.; Ntintakis, I.; Vaxevanidis, N. Dimensional accuracy optimization of prototypes produced by PolyJet direct 3D printing technology. Adv. Eng. Mech. Mater. 2014, 978, 61–65. [Google Scholar]

- Maurya, N.K.; Rastogi, V.; Singh, P. Comparative study and measurement of form errors for the component printed by FDM and PolyJet process. J. Homepage Httpiieta Orgjournalsi2m 2019, 18, 353–359. [Google Scholar] [CrossRef]

- Kozior, T.; Gogolewski, D. Dimensional and shape accuracy of foundry patterns fabricated through photo-curing. Teh. Vjesn. 2019, 26, 1576–1584. [Google Scholar] [CrossRef]

- Kozior, T.; Bochnia, J.; Gogolewski, D.; Zmarzły, P.; Rudnik, M.; Szot, W.; Szczygieł, P.; Musiałek, M. Analysis of Metrological Quality and Mechanical Properties of Models Manufactured with Photo-Curing PolyJet Matrix Technology for Medical Applications. Polymers 2022, 14, 408. [Google Scholar] [CrossRef]

- Dziubek, T. Application of coordination measuring methods for assessing the performance properties of polymer gears. Polimery 2018, 63, 49–52. [Google Scholar] [CrossRef]

- Dietrich, C.A.; Ender, A.; Baumgartner, S.; Mehl, A. A validation study of reconstructed rapid prototyping models produced by two technologies. Angle Orthod. 2017, 87, 782–787. [Google Scholar] [CrossRef]

- Turek, P. Automating the process of designing and manufacturing polymeric models of anatomical structures of mandible with Industry 4.0 convention. Polimery 2019, 64, 522–529. [Google Scholar] [CrossRef]

- Emir, F.; Ayyildiz, S. Accuracy evaluation of complete-arch models manufactured by three different 3D printing technologies: A three-dimensional analysis. J. Prosthodont. Res. 2021, 65, 365–370. [Google Scholar] [CrossRef] [PubMed]

- Cazón, A.; Morer, P.; Matey, L. PolyJet technology for product prototyping: Tensile strength and surface roughness properties. Proc. Inst. Mech. Eng. Part. B J. Eng. Manuf. 2014, 228, 1664–1675. [Google Scholar] [CrossRef]

| Material | Mean Absolute Deviation Mean_abs, mm | First Quartile Q1, mm | Median Q2, mm | Third Quartile Q3, mm | Interquartile Range IQR, mm | |||||

|---|---|---|---|---|---|---|---|---|---|---|

| Mean | Std | Mean | Std | Mean | Std | Mean | Std | Mean | Std | |

| Digital ABS Plus | 0.052 | 0.021 | −0.060 | 0.034 | −0.002 | 0.006 | 0.023 | 0.011 | 0.083 | 0.039 |

| RGD 720 | 0.059 | 0.017 | −0.074 | 0.025 | −0.030 | 0.011 | 0.008 | 0.016 | 0.082 | 0.030 |

| Vero Clear | 0.052 | 0.018 | −0.059 | 0.035 | −0.004 | 0.008 | 0.024 | 0.009 | 0.083 | 0.036 |

| Dependent Variable | p-Value |

|---|---|

| Mean absolute deviation (mean_abs) | 0.002 |

| Interquartile range (IQR) | 0.998 |

| First quartile (Q1) | 0.016 |

| Median (Q2) | 2.07 × 10−10 |

| Third quartile (Q3) | 4.21 × 10−04 |

| Dependent Variable | Contrast | A | B | p-Value | Common Language Effect Size (CLES) |

|---|---|---|---|---|---|

| Mean absolute deviation (mean_abs) | Material | Digital ABS Plus | RGD 720 | 0.011 | 0.40 |

| Digital ABS Plus | Vero Clear | 0.758 | 0.52 | ||

| RGD 720 | Vero Clear | 0.006 | 0.60 | ||

| First quartile (Q1) | Material | Digital ABS Plus | RGD 720 | 0.054 | 0.63 |

| Digital ABS Plus | Vero Clear | 0.831 | 0.49 | ||

| RGD 720 | Vero Clear | 0.013 | 0.38 | ||

| Median (Q2) | Material | Digital ABS Plus | RGD 720 | 3.44 × 10−06 | 0.99 |

| Digital ABS Plus | Vero Clear | 0.359 | 0.65 | ||

| RGD 720 | Vero Clear | 3.41 × 10−08 | 0.03 | ||

| Third quartile (Q3) | Material | Digital ABS Plus | RGD 720 | 0.006 | 0.87 |

| Digital ABS Plus | Vero Clear | 0.765 | 0.51 | ||

| RGD 720 | Vero Clear | 0.001 | 0.10 |

| Parameter | Statistics | Material | ||

|---|---|---|---|---|

| Digital ABS Plus | RGD 720 | Vero Clear | ||

| Arithmetical mean height (Sa) | mean, μm | 1.63 | 15.86 | 1.96 |

| median, μm | 1.43 | 16.27 | 1.69 | |

| std, μm | 0.74 | 7.06 | 0.62 | |

| CV, % | 45.3 | 44.5 | 31.65 | |

| Reduced peak height (Spk) + core height (Sk) + reduced dale depth (Svk) | mean, μm | 9.10 | 101.88 | 10.51 |

| median, μm | 7.74 | 111.21 | 9.04 | |

| std, μm | 3.92 | 44.10 | 3.40 | |

| CV, % | 43.1 | 43.29 | 32.33 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Turek, P.; Bazan, A.; Budzik, G.; Dziubek, T.; Przeszłowski, Ł. Evaluation of Macro- and Micro-Geometry of Models Made of Photopolymer Resins Using the PolyJet Method. Materials 2024, 17, 4315. https://doi.org/10.3390/ma17174315

Turek P, Bazan A, Budzik G, Dziubek T, Przeszłowski Ł. Evaluation of Macro- and Micro-Geometry of Models Made of Photopolymer Resins Using the PolyJet Method. Materials. 2024; 17(17):4315. https://doi.org/10.3390/ma17174315

Chicago/Turabian StyleTurek, Paweł, Anna Bazan, Grzegorz Budzik, Tomasz Dziubek, and Łukasz Przeszłowski. 2024. "Evaluation of Macro- and Micro-Geometry of Models Made of Photopolymer Resins Using the PolyJet Method" Materials 17, no. 17: 4315. https://doi.org/10.3390/ma17174315

APA StyleTurek, P., Bazan, A., Budzik, G., Dziubek, T., & Przeszłowski, Ł. (2024). Evaluation of Macro- and Micro-Geometry of Models Made of Photopolymer Resins Using the PolyJet Method. Materials, 17(17), 4315. https://doi.org/10.3390/ma17174315