Influence of Accelerated Carbonation on the Physico-Mechanical Properties of Natural Fiber-Reinforced Lime Mortars

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Mortar Composition

2.2. Curing Conditions

2.3. Methods

3. Results

4. Discussion

5. Conclusions

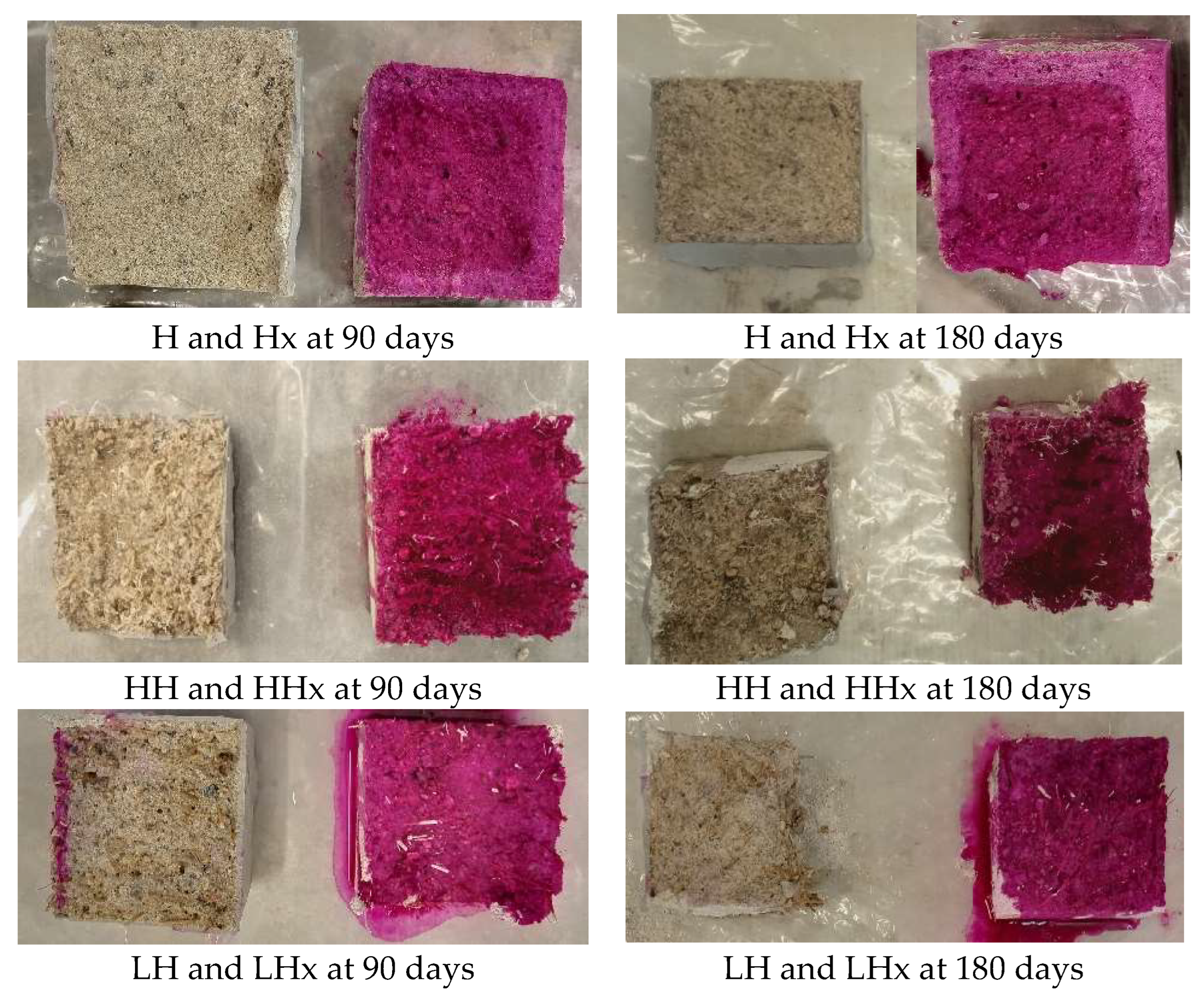

- A different technology of lime mortars is tested (hot-lime and powdered air lime) in an accelerated CO2 environment. The results of this research prove that the hot lime mixing technique and natural reinforcement can be combined with accelerated carbonation conditions to improve the physico-mechanical properties of the mortars. In conclusion, all the mortars were fully carbonated at 90 days when kept at 3% CO2.

- The exposure of the lime mortars to 3% CO2 greatly improved the strength development, especially at early ages.

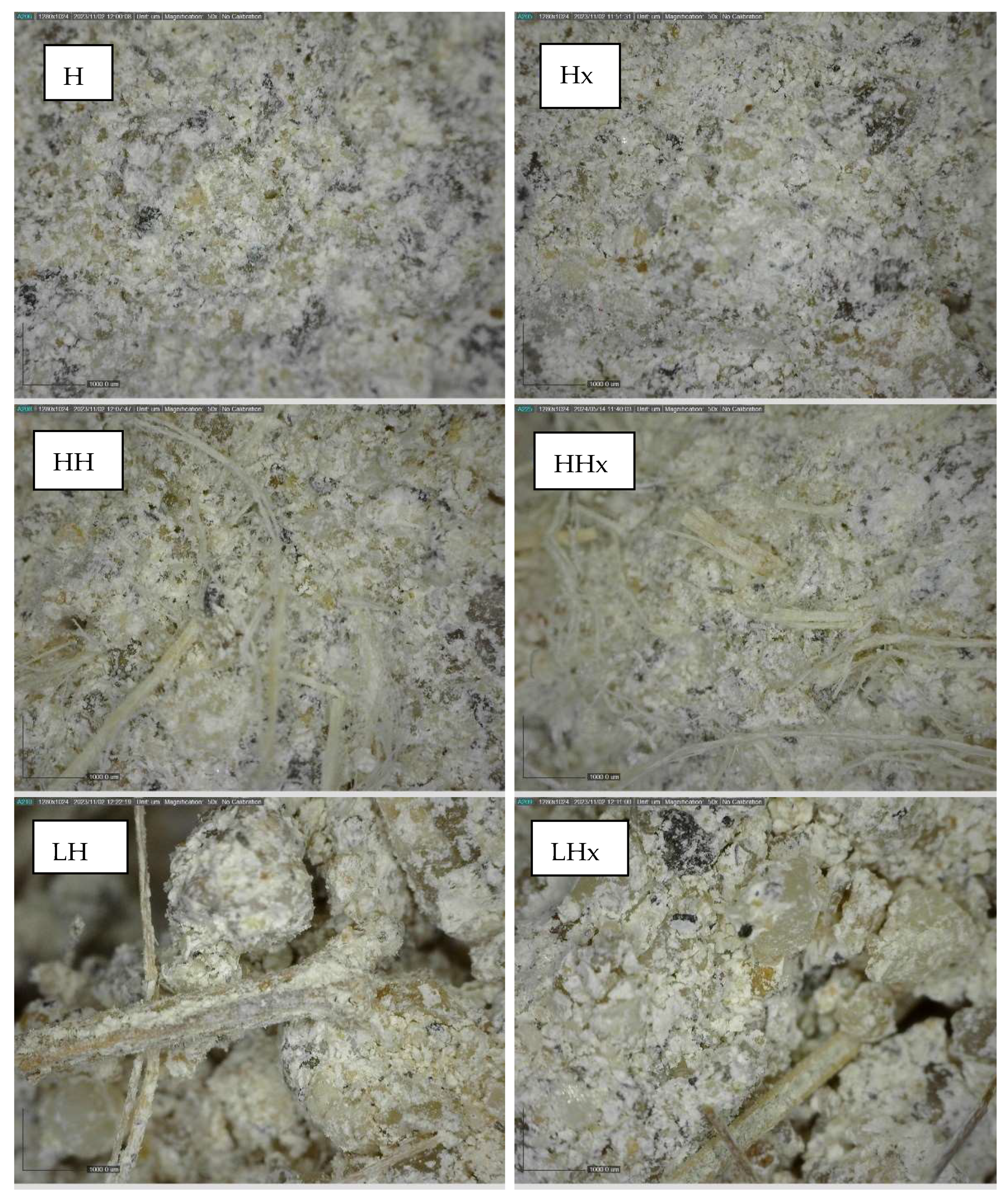

- Hemp fibers enhanced the diffusion of CO2 in the mortars, thus resulting in better mechanical properties.

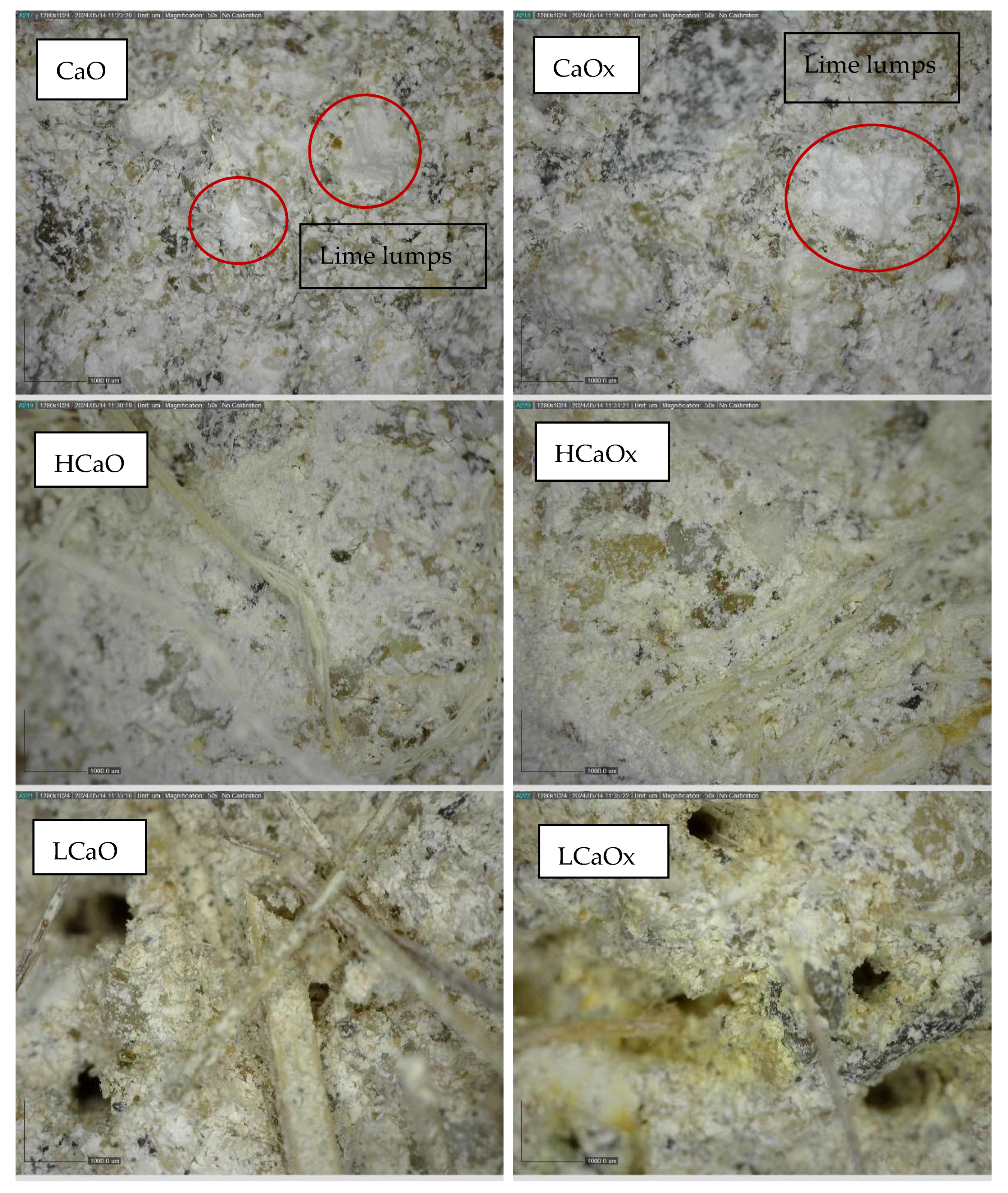

- Hemp fibers had a good dispersion and adhesion within the mortar structure. On the contrary, the lavender fibers cooperated poorly with the binder, resulting in lower strength results.

- The accelerated carbonation conditions seemed to work better in hot lime mixtures and improved the mechanical performance of the lime mortars more quickly. This was confirmed by the higher carbon and calcium carbonate content of the samples at 90 days.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pachta, V.; Stefanidou, M.; Konopisi, S.; Papayianni, I. Technological Evolution of Historic Structural Mortars. J. Civ. Eng. Archit. 2014, 8, 846–854. [Google Scholar] [CrossRef]

- Faria, P.; Henriques, F.; Rato, V. Comparative evaluation of lime mortars for architectural conservation. J. Cult. Herit. 2008, 9, 338–346. [Google Scholar] [CrossRef]

- Campo, F.P.; Tua, C.; Biganzoli, L.; Pantini, S.; Grosso, M. Natural and enhanced carbonation of lime in its different applications: A review. Environ. Technol. Rev. 2021, 10, 224–237. [Google Scholar] [CrossRef]

- Groot, C.; Veiga, R.; Papayianni, I.; Van Hees, R.; Secco, M.; Alvarez, J.I.; Faria, P.; Stefanidou, M. RILEM TC 277-LHS report: Lime-based mortars for restoration–a review on long-term durability aspects and experience from practice. Mater. Struct./Mater. Constr. 2022, 55, 245. [Google Scholar] [CrossRef]

- Pavia, S.; Veiga, R.; Hughes, J.; Pesce, G.; Valek, J.; Alvarez, J.I.; Faria, P.; Padovnik, A. RILEM TC 277-LHS report: How hot are hot-lime-mixed mortars? A review. Mater. Struct./Mater. Constr. 2023, 56, 87. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kesikidou, F.; Kouroutzidou, C.; Copsey, N. Testing air lime mortars produced with lime of different technology. In Proceedings of the 4th International Congress on Materials & Structural Stability & RILEM Spring Convention, Rabat, Morocco, 8–10 March 2023; pp. 8–10. [Google Scholar]

- Silva, B.A.; Ferreira Pinto, A.P.; Gomes, A.; Candeias, A. Effects of natural and accelerated carbonation on the properties of lime-based materials. J. CO2 Util. 2021, 49, 101552. [Google Scholar] [CrossRef]

- Lawrence, M. A Study of Carbonation in Non-Hydraulic Lime Mortars. Ph.D. Thesis, University of Bath, Bath, UK, 2006. [Google Scholar]

- Van Balen, K. Carbonation reaction of lime, kinetics at ambient temperature. Cem. Concr. Res. 2005, 35, 647–657. [Google Scholar] [CrossRef]

- Rakhsh Mahpour, A.; Ventura, H.; Ardanuy, M.; Rosell, J.R.; Claramunt, J. The effect of fibres and carbonation conditions on the mechanical properties and microstructure of lime/flax composites. Cem. Concr. Compos. 2023, 136, 104981. [Google Scholar] [CrossRef]

- Rashmi Nayak, J.; Bochen, J.; Gołaszewska, M. Experimental studies on the effect of natural and synthetic fibers on properties of fresh and hardened mortar. Constr. Build. Mater. 2022, 347, 128550. [Google Scholar] [CrossRef]

- Ramezani, M.; Ozbulut, O.E.; Sherif, M.M. Mechanical characterization of high-strength and ultra-high-performance engineered cementitious composites reinforced with polyvinyl alcohol and polyethylene fibers subjected to monotonic and cyclic loading. Cem. Concr. Compos. 2024, 148, 105472. [Google Scholar] [CrossRef]

- Hamada, H.M.; Shi, J.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Kaplan, G. Application of natural fibres in cement concrete: A critical review. Mater. Today Commun. 2023, 35, 105833. [Google Scholar] [CrossRef]

- Hwang, C.L.; Tran, V.A.; Hong, J.W.; Hsieh, Y.C. Effects of short coconut fiber on the mechanical properties, plastic cracking behavior, and impact resistance of cementitious composites. Constr. Build. Mater. 2016, 127, 984–992. [Google Scholar] [CrossRef]

- Majumder, A.; Stochino, F.; Frattolillo, A.; Valdes, M.; Mancusi, G.; Martinelli, E. Jute fiber-reinforced mortars: Mechanical response and thermal performance. J. Build. Eng. 2023, 66, 105888. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Konstantinidis, A.; Koltsou, P.; Papadopoulos, S. Use of Posidonia oceanica fibres in lime mortars. Constr. Build. Mater. 2021, 298, 123881. [Google Scholar] [CrossRef]

- Yao, W.; Li, Z. Flexural behavior of bamboo-fiber-reinforced mortar laminates. Cem. Concr. Res. 2003, 33, 15–19. [Google Scholar] [CrossRef]

- Ajouguim, S.; Stefanidou, M.; Abdelouahdi, K.; Waqif, M.; Saâdi, L. Influence of treated bio-fibers on the mechanical and physical properties of cement mortars. Eur. J. Environ. Civ. Eng. 2022, 26, 3120–3135. [Google Scholar] [CrossRef]

- Gagana, S.M.; Nancy, S.M. Hempcrete-Potential Green Bulding Material. 2021. Available online: https://www.jetir.org/papers/JETIRES06045.pdf (accessed on 15 April 2024).

- Williams, J. The Climate Possibilities of Hemp. 2023. Available online: https://earthbound.report/2023/07/11/the-climate-possibilities-of-hemp/ (accessed on 15 April 2024).

- Gencel, O.; Yavuz Bayraktar, O.; Kaplan, G.; Benli, A.; Martínez-Barrera, G.; Brostow, W.; Tek, M.; Bodur, B. Characteristics of hemp fibre reinforced foam concretes with fly ash and Taguchi optimization. Constr. Build. Mater. 2021, 294, 123607. [Google Scholar] [CrossRef]

- Pickering, K.L.; Beckermann, G.W.; Alam, S.N.; Foreman, N.J. Optimising industrial hemp fibre for composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 461–468. [Google Scholar] [CrossRef]

- de Azevedo, A.R.G.; Cruz, A.S.A.; Marvila, M.T.; de Oliveira, L.B.; Monteiro, S.N.; Vieira, C.M.F.; Fediuk, R.; Timokhin, R.; Vatin, N.; Daironas, M. Natural fibers as an alternative to synthetic fibers in reinforcement of geopolymer matrices: A comparative review. Polymers 2021, 15, 2493. [Google Scholar] [CrossRef]

- Mwaikambo, L.Y.; Ansell, M.P. Chemical modification of hemp, sisal, jute, and kapok fibers by alkalization. J. Appl. Polym. Sci. 2002, 84, 2222–2234. [Google Scholar] [CrossRef]

- Kesikidou, F.; Stefanidou, M. Natural fiber-reinforced mortars. J. Build. Eng. 2019, 25, 100786. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Kouroutzidou, C.; Kampragkou, P. Utilization of Lavender Waste in Traditional Mortars. In Conservation and Restoration of Historic Mortars and Masonry Structures; HMC: Lublijana, Slovenia, 2022. [Google Scholar]

- Pizzol, V.D.; Mendes, L.M.; Frezzatti, L.; Savastano, H.; Tonoli, G.H.D. Effect of accelerated carbonation on the microstructure and physical properties of hybrid fiber-cement composites. Miner. Eng. 2014, 59, 101–106. [Google Scholar] [CrossRef]

- Artis, R. Mortar Mix Ratios A Practical Guide to Making Repeatable and Consistent Mortars. 2022. Available online: https://www.buildingconservation.com/articles/mortar-mix-ratios/mortar-mix-ratios.html (accessed on 31 March 2024).

- Copsey, N. Hot Mixed Lime and Traditional Mortars: A Practical Guide to Their Use in Conservation and Repair; The Crowood Press: Marlborough, UK, 2019. [Google Scholar]

- EN 12390-12; Testing Hardened Concrete Determination of the Carbonation Resistance of Concrete. Accelerated Carbonation Method. European Committee for Standardization (CEN): Brussels, Belgium, 2020.

- EN 1015-11; Methods of Test for Mortar for Masonry. Part 11. Determination of Flexural and Compressive Strength of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 1999.

- BS 1881-203; Testing Concrete/Part 203, Recommendations for Measurement of Velocity of Ultrasonic Pulses in Concrete. BSI: Belgium, The Netherlands, 1986.

- EN 1015-18; Methods of Test for Mortar for Masonry-Part 18: Determination of Water Absorption Coefficient Due to Capillary Action of Hardened Mortar. European Committee for Standardization (CEN): Brussels, Belgium, 2002.

- Ramezani, M.; Kim, Y.H.; Sun, Z. Mechanical properties of carbon-nanotube-reinforced cementitious materials: Database and statistical analysis. Mag. Concr. Res. 2020, 72, 1047–1071. [Google Scholar] [CrossRef]

- Anupama, V.A.; Santhanam, M. Morphological Evolution of Calcium Carbonate Crystals in Dry Hydrated Lime Mortar. In Conservation and Restoration of Historic Mortars and Masonry Structures; Bokan Bosiljkov, V., Padovnik, A., Turk, T., Eds.; HMC: Ljubljana, Slovenia, 2022; pp. 469–475. [Google Scholar]

- Ergenç, D.; Fort, R. Accelerating carbonation in lime-based mortar in high CO2 environments. Constr. Build. Mater. 2018, 188, 314–325. [Google Scholar] [CrossRef]

- Oliveira, M.A.; Azenha, M.; Lourenço, P.B.; Meneghini, A.; Guimarães, E.T.; Castro, F.; Soares, D. Experimental analysis of the carbonation and humidity diffusion processes in aerial lime mortar. Constr. Build. Mater. 2017, 148, 38–48. [Google Scholar] [CrossRef]

- Bui, H.; Boutouil, M.; Levacher, D.; Sebaibi, N. Evaluation of the influence of accelerated carbonation on the microstructure and mechanical characteristics of coconut fibre-reinforced cementitious matrix. J. Build. Eng. 2021, 39, 102269. [Google Scholar] [CrossRef]

- Brown, A. Hot-Mixed Mortars Advantages and Limitations. 2019. Available online: https://www.buildingconservation.com/articles/hot-mixed-mortars/hot-mixed-mortars.htm (accessed on 9 April 2024).

| Material | Ca(OH)2 (%wt) | CaCO3 (%wt) | Thickness (mm) | Specific Gravity (g/mL) | Water Absorption (%) |

|---|---|---|---|---|---|

| Quicklime | 4.48 | 0.86 | - | 3.231 | - |

| Air lime | 82.99 | 11.53 | - | 2.279 | - |

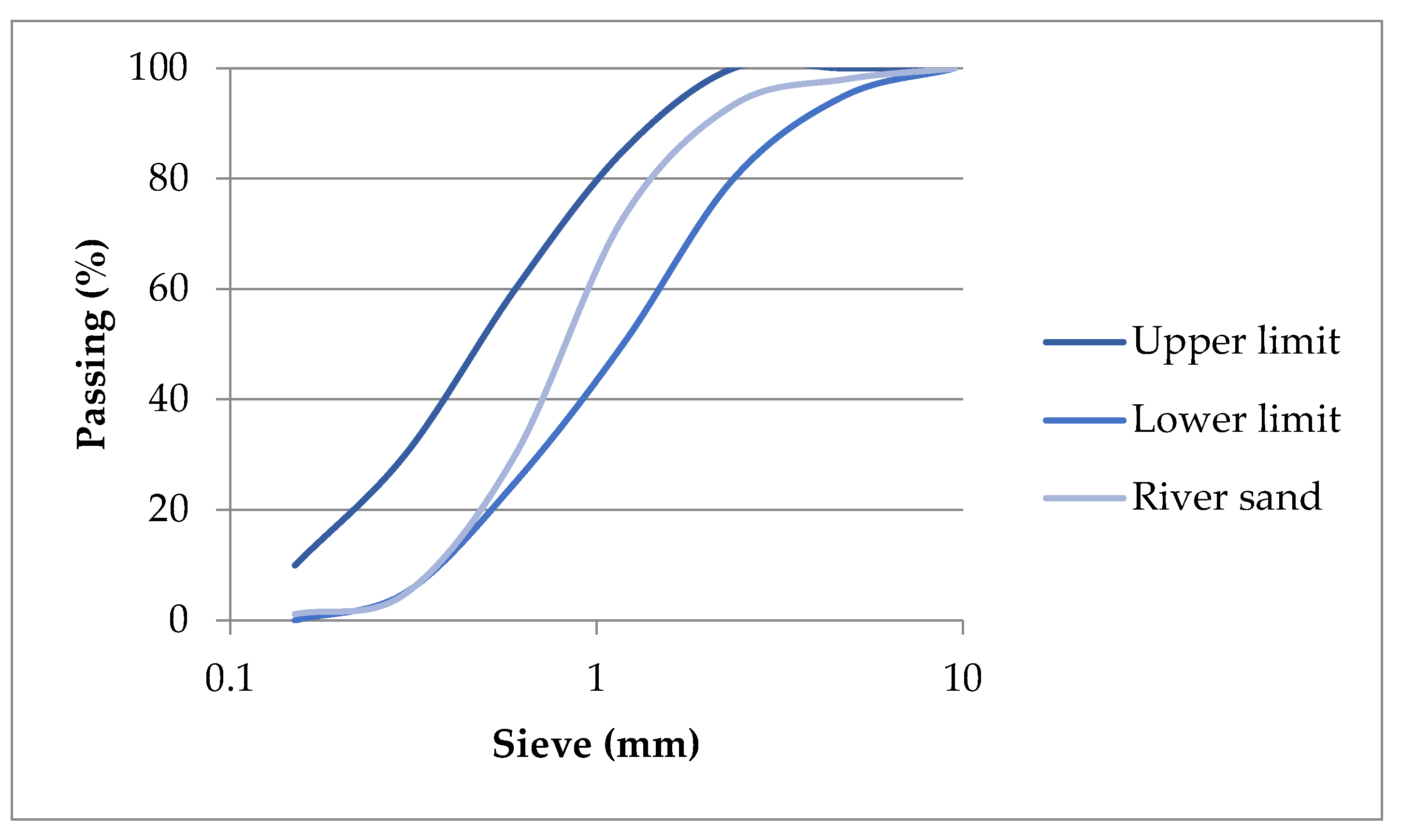

| River Sand (0–4 mm) (siliceous) | - | - | - | 2.655 | - |

| Hemp | - | - | 0.1–0.2 | 1.661 | 75 |

| Lavender | - | - | 0.3–0.6 | 1.273 | 78 |

| Mixture | Quicklime | Air Lime | River Sand (0–4) mm | Water | Hemp Fibers (% by Vol.) | Lavender Fibers (% by Vol.) |

|---|---|---|---|---|---|---|

| CaO | 1 | - | 3 | 2 | - | - |

| HCaO | 1 | 3 | 2 | 1 | - | |

| LCaO | 1 | - | 3 | 2 | - | 1 |

| H | - | 1 | 3 | 1 | - | - |

| HH | - | 1 | 3 | 1 | 1 | - |

| LH | - | 1 | 3 | 1 | - | 1 |

| Mixture | Chamber with Natural Carbonation (0.05% CO2), 21 °C, 60%RH | Chamber with Accelerated Carbonation (3% CO2), 21 °C, 60%RH |

|---|---|---|

| CaO, HCaO, LCaO, H, HH, LH | v | |

| CaOx, HCaOx, LCaOx, Hx, HHx, LHx | v |

| Mixture | Workability (cm) | Flexural Strength at 28 d (MPa) | Compressive Strength at 28 d (MPa) |

|---|---|---|---|

| CaO | 13.5 | 0.32 | 1.06 |

| HCaO | 12.8 | - | - |

| LCaO | 12.0 | - | - |

| H | 16.2 | 0.29 | 0.80 |

| HH | 13.5 | - | - |

| LH | 14.7 | - | - |

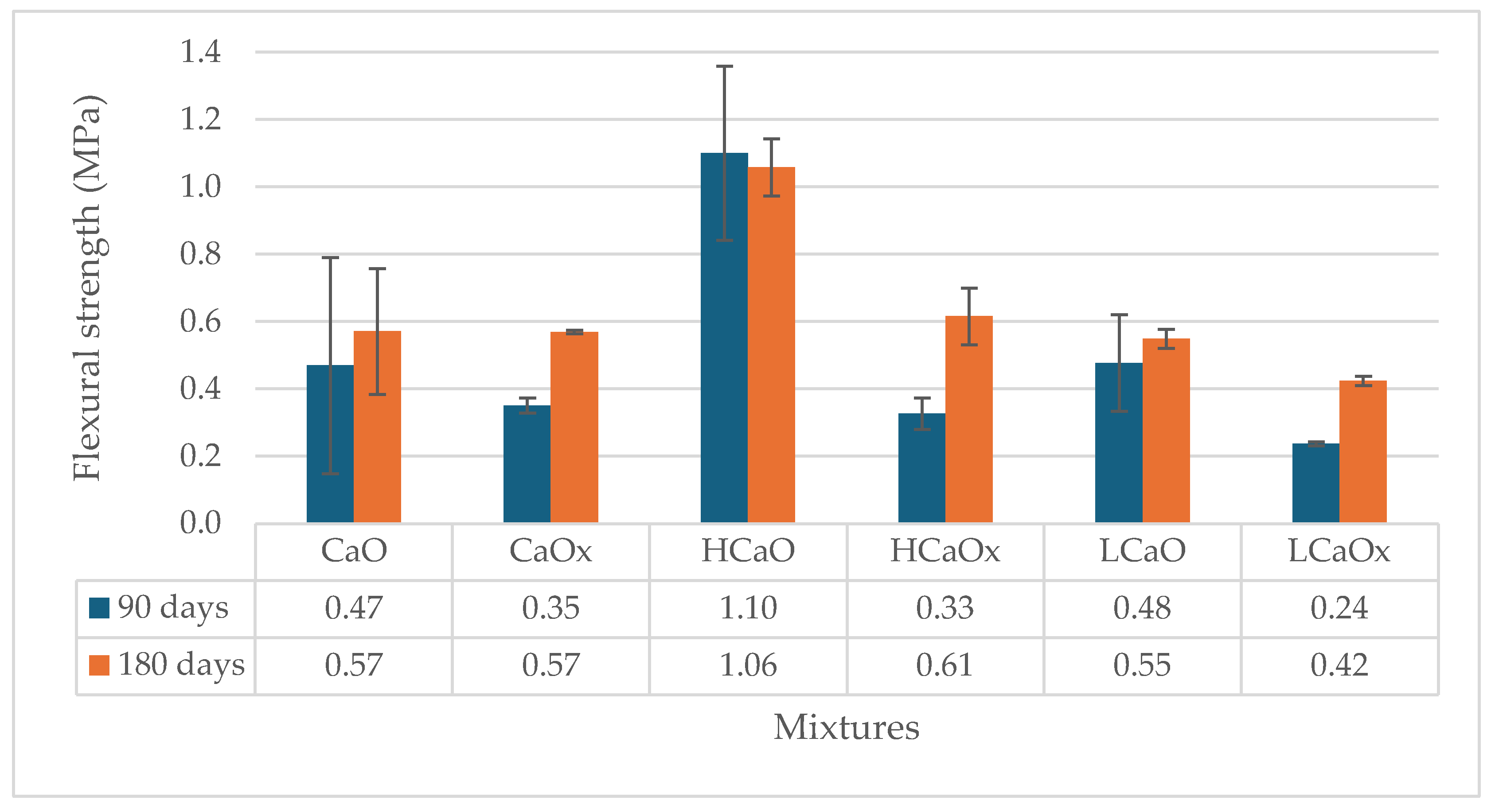

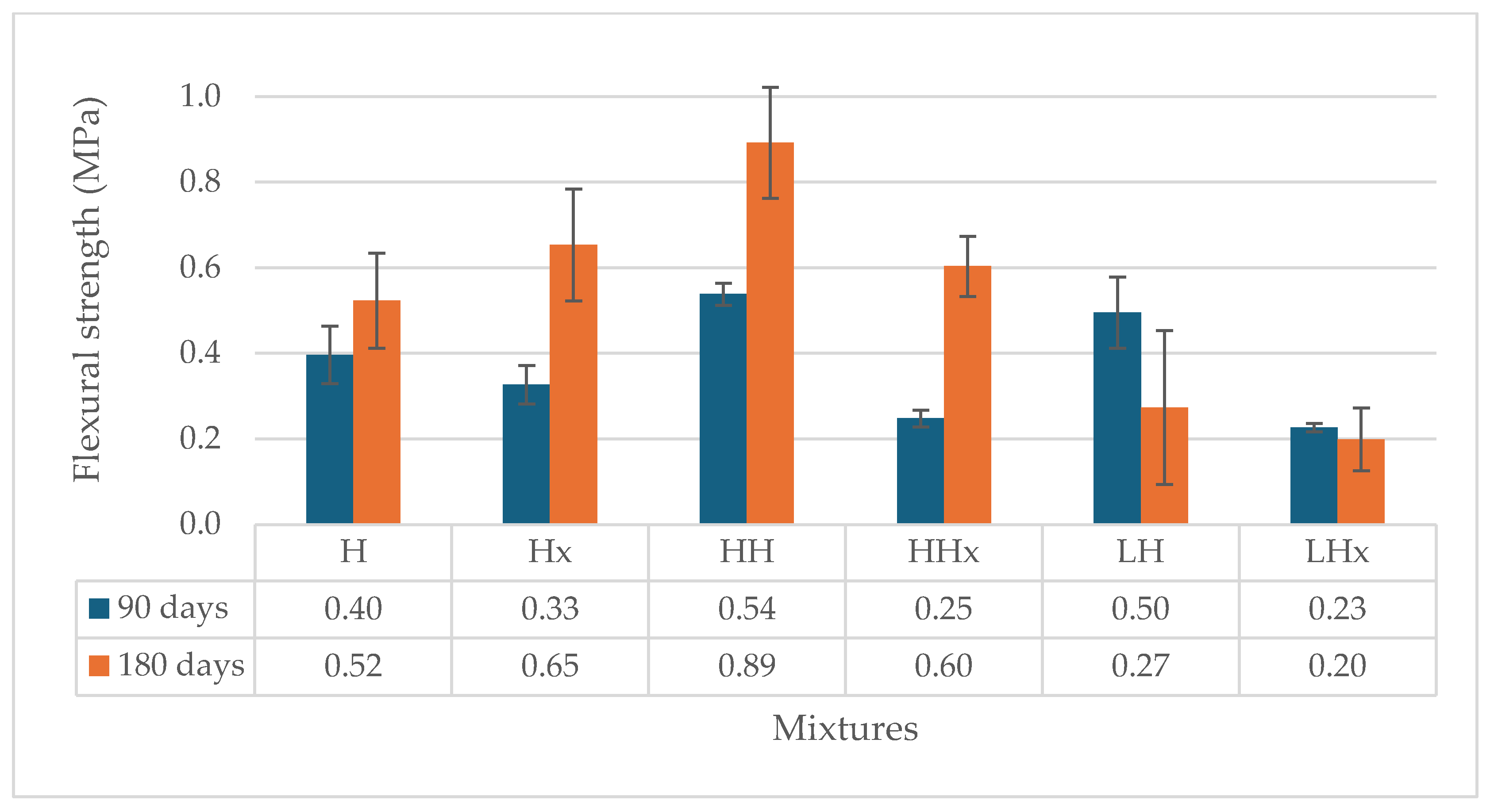

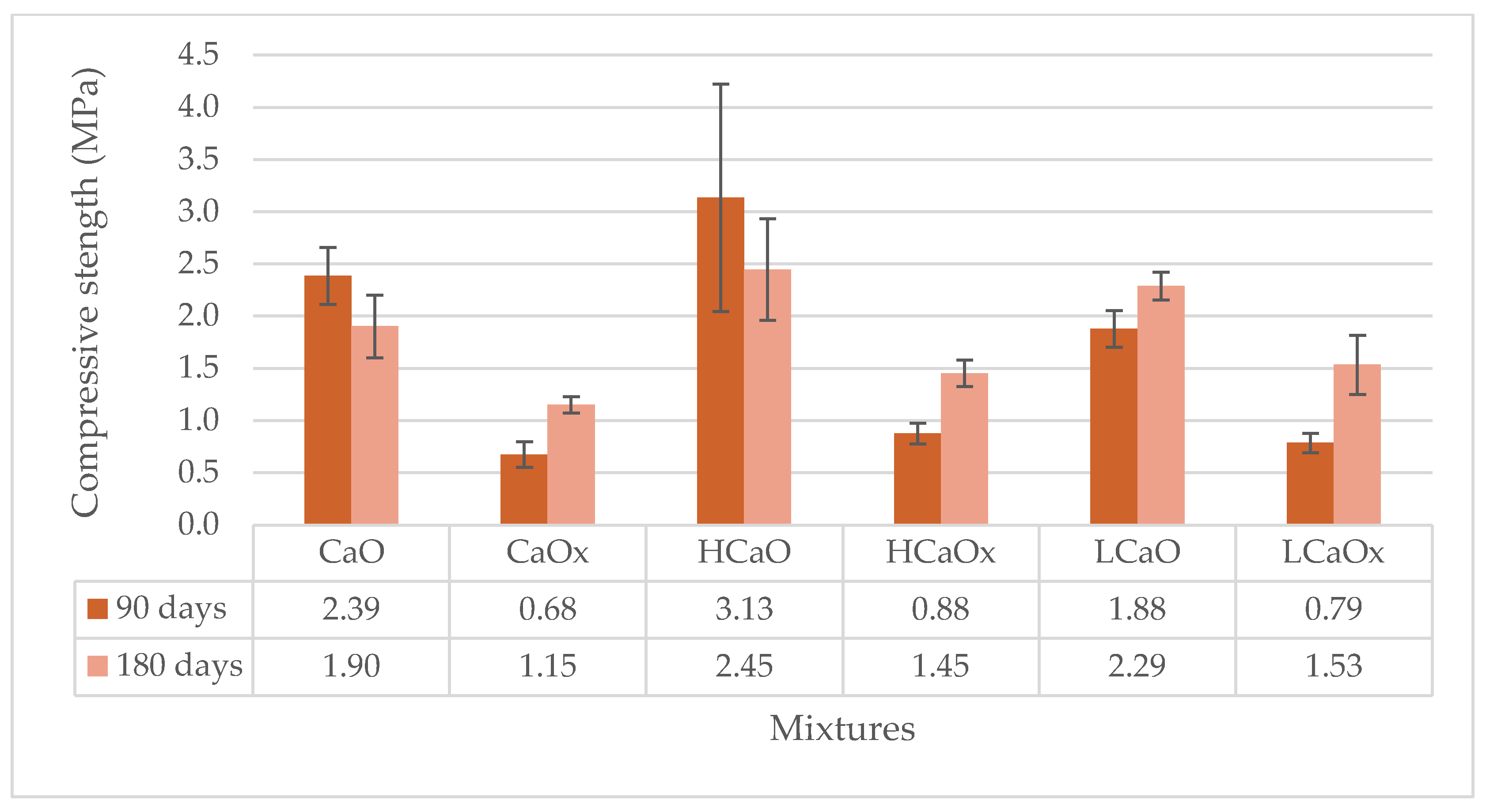

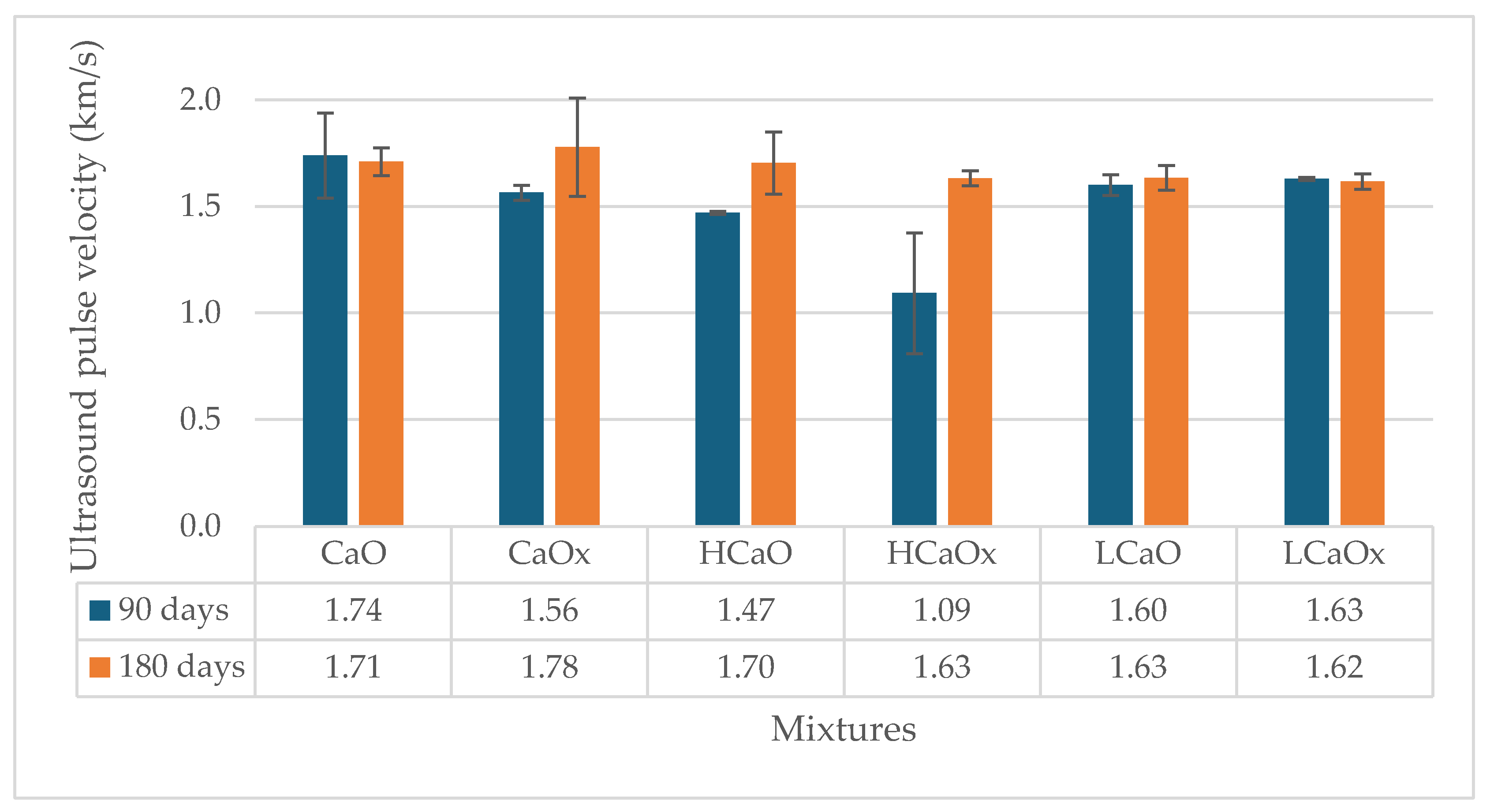

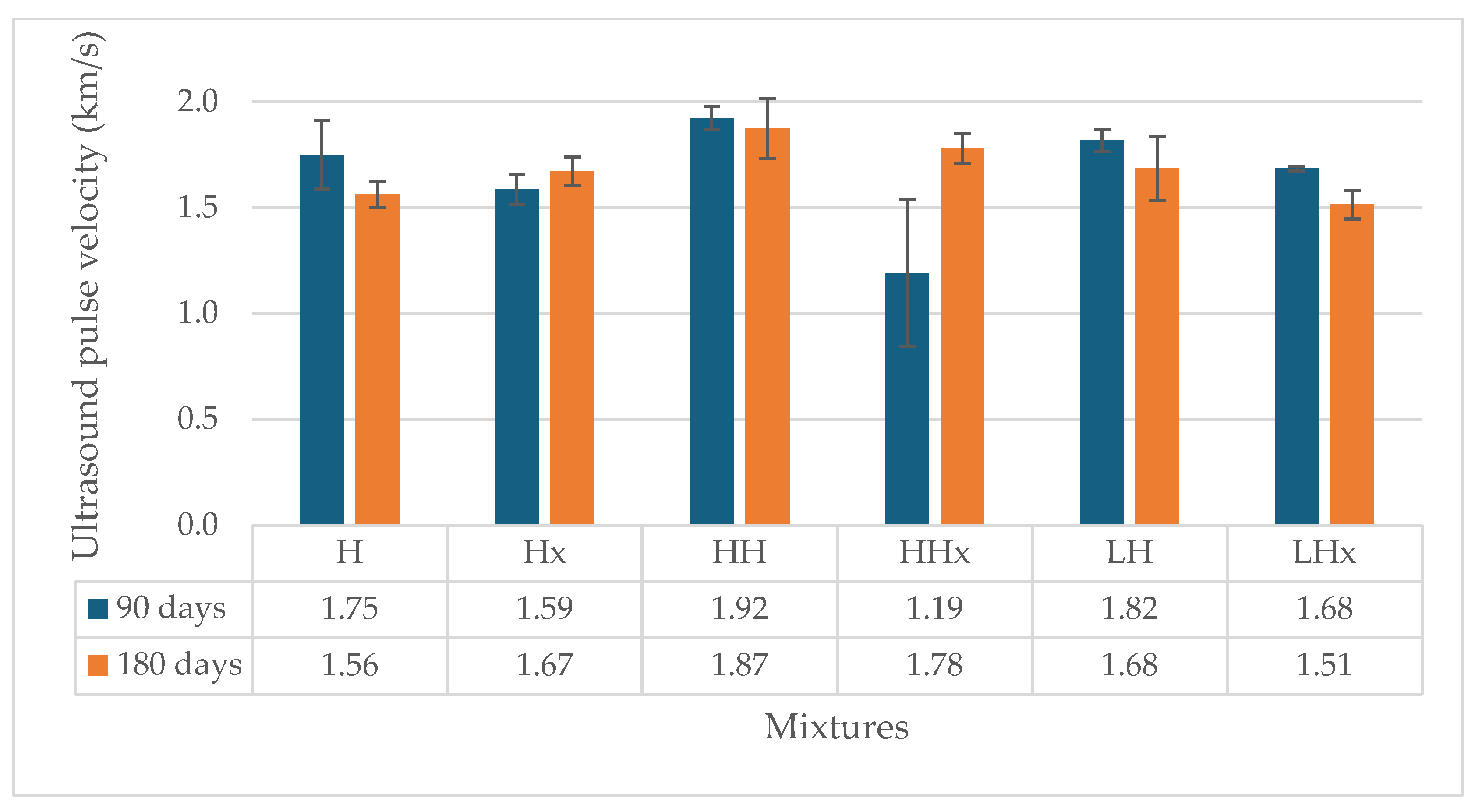

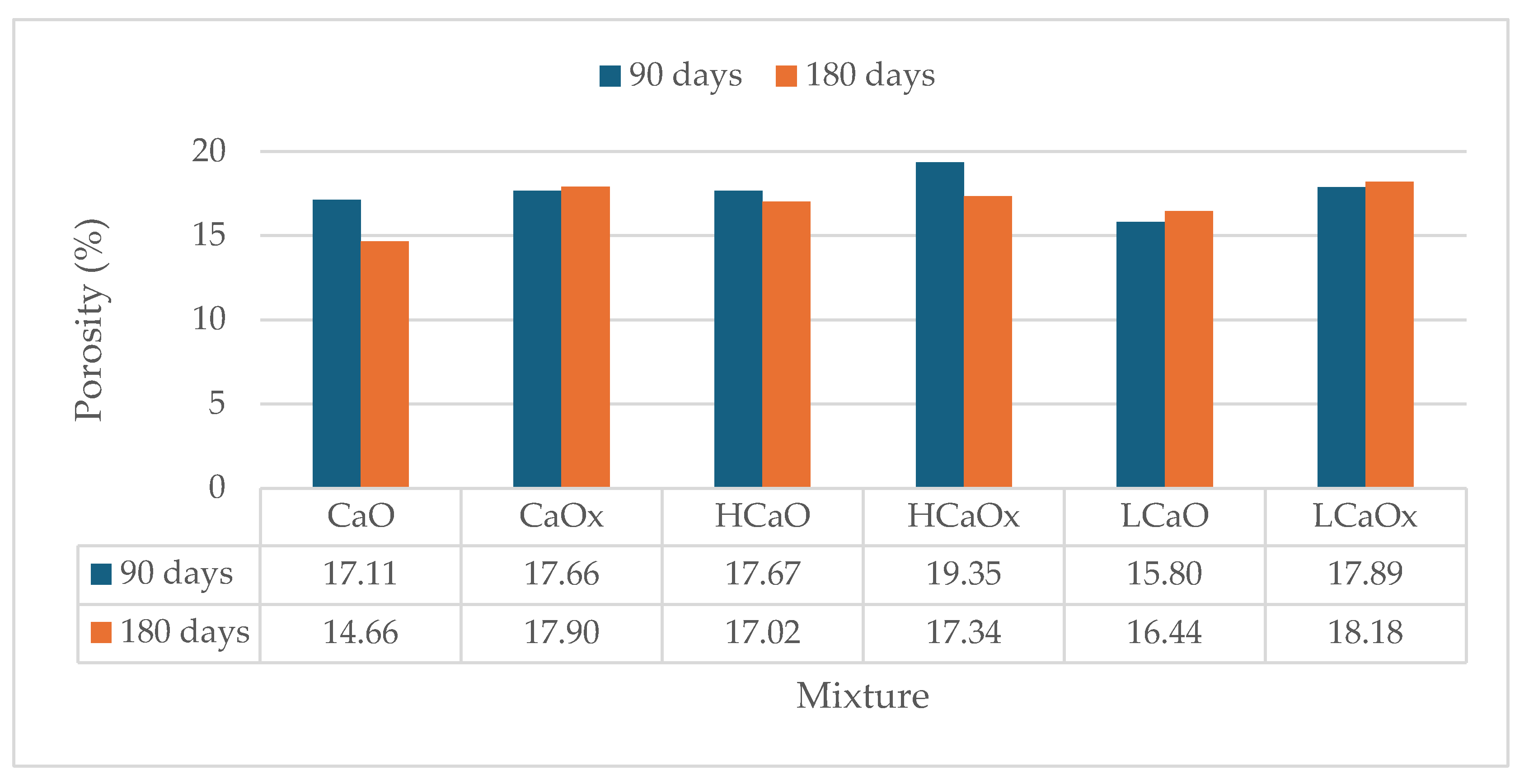

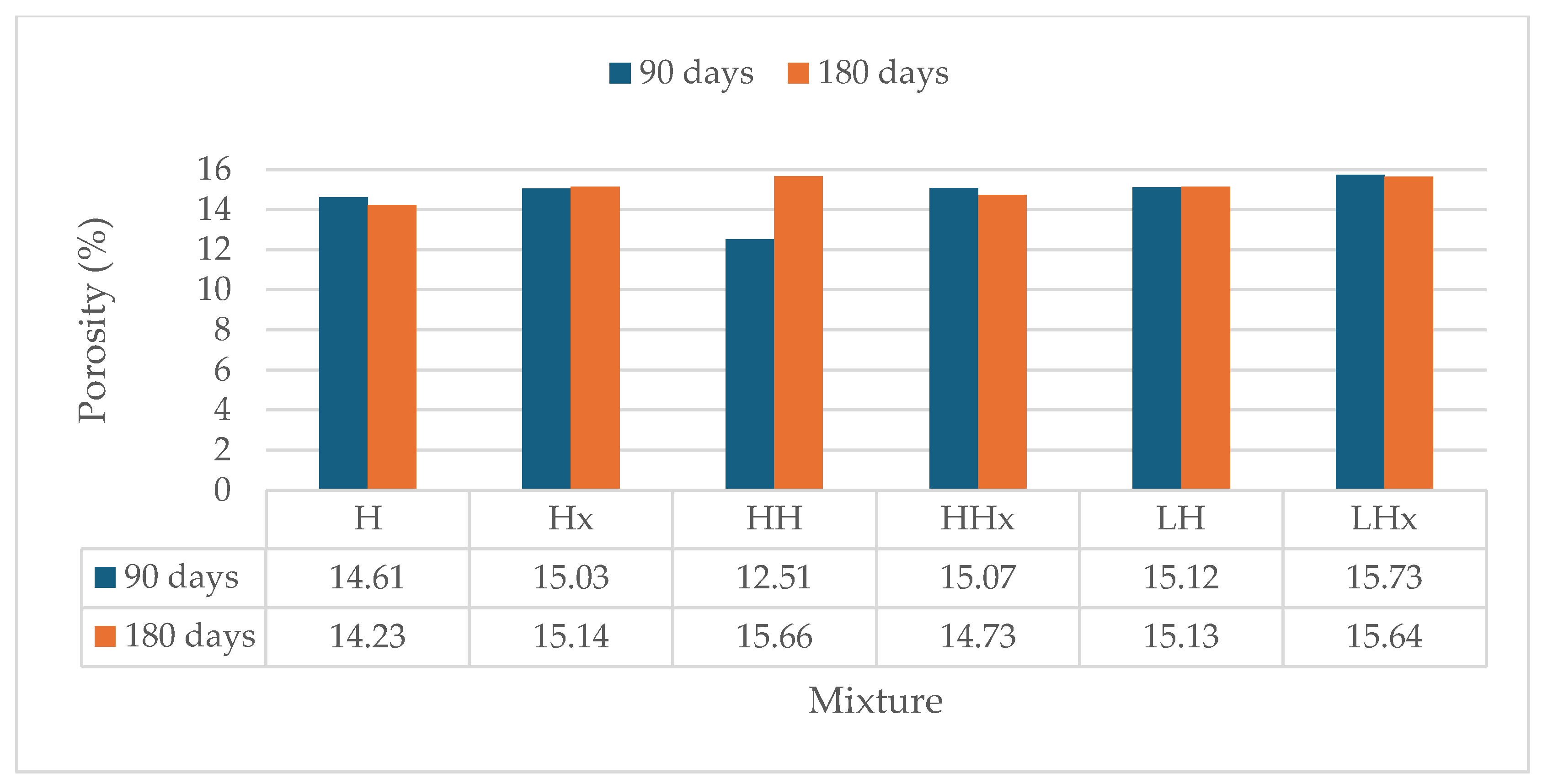

| Mixture | Age (Days) | Flexural Strength (MPa) | STDEV | Compressive Strength (MPa) | STDEV | Ultrasound Pulse Velocity (km/s) | STDEV |

|---|---|---|---|---|---|---|---|

| CaO | 90 | 0.47 | 0.32 | 2.39 | 0.27 | 1.74 | 0.20 |

| CaOx | 90 | 0.35 | 0.02 | 0.68 | 0.12 | 1.56 | 0.03 |

| H | 90 | 0.40 | 0.07 | 1.00 | 0.12 | 1.75 | 0.16 |

| Hx | 90 | 0.33 | 0.05 | 0.92 | 0.02 | 1.59 | 0.07 |

| HCaO | 90 | 1.10 | 0.26 | 3.13 | 1.09 | 1.47 | 0.01 |

| HCaOx | 90 | 0.33 | 0.05 | 0.88 | 0.10 | 1.09 | 0.28 |

| HH | 90 | 0.54 | 0.03 | 3.17 | 0.14 | 1.92 | 0.06 |

| HHx | 90 | 0.25 | 0.02 | 1.58 | 0.19 | 1.19 | 0.35 |

| LCaO | 90 | 0.48 | 0.14 | 1.88 | 0.18 | 1.60 | 0.05 |

| LCaOx | 90 | 0.24 | 0.01 | 0.79 | 0.09 | 1.63 | 0.01 |

| LH | 90 | 0.50 | 0.08 | 1.37 | 0.21 | 1.82 | 0.05 |

| LHx | 90 | 0.23 | 0.01 | 0.41 | 0.10 | 1.68 | 0.01 |

| CaO | 180 | 0.57 | 0.19 | 1.90 | 0.30 | 1.71 | 0.07 |

| CaOx | 180 | 0.57 | 0.01 | 1.15 | 0.08 | 1.78 | 0.23 |

| H | 180 | 0.52 | 0.11 | 1.11 | 0.07 | 1.56 | 0.06 |

| Hx | 180 | 0.65 | 0.13 | 1.21 | 0.23 | 1.67 | 0.07 |

| HCaO | 180 | 1.06 | 0.08 | 2.45 | 0.49 | 1.70 | 0.15 |

| HCaOx | 180 | 0.61 | 0.08 | 1.45 | 0.13 | 1.63 | 0.04 |

| HH | 180 | 0.89 | 0.13 | 2.38 | 0.23 | 1.87 | 0.14 |

| HHx | 180 | 0.60 | 0.07 | 1.54 | 0.11 | 1.78 | 0.07 |

| LCaO | 180 | 0.55 | 0.03 | 2.29 | 0.13 | 1.63 | 0.06 |

| LCaOx | 180 | 0.42 | 0.01 | 1.53 | 0.28 | 1.62 | 0.04 |

| LH | 180 | 0.27 | 0.18 | 1.67 | 0.12 | 1.68 | 0.15 |

| LHx | 180 | 0.20 | 0.07 | 0.99 | 0.00 | 1.51 | 0.07 |

| Capillary Absorption Coefficient kg/(m2·min0.5) | 3% CO2 | 0.05% CO2 |

|---|---|---|

| CaO | 4.061 | 4.609 |

| HCaO | 3.922 | 4.756 |

| LCaO | 4.501 | 4.208 |

| H | 3.838 | 4.151 |

| HH | 3.341 | 4.132 |

| LH | 3.787 | 4.101 |

| Sample | Carbon (%) |

|---|---|

| CaO | 2.915 |

| CaOx | 1.740 |

| H | 1.432 |

| Hx | 1.290 |

| Sample | Ca(OH)2 | CaCO3 |

|---|---|---|

| CaO | 5.38 | 16.93 |

| H | <0.01 | 13.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kesikidou, F.; Matamadiotou, I.; Stefanidou, M. Influence of Accelerated Carbonation on the Physico-Mechanical Properties of Natural Fiber-Reinforced Lime Mortars. Materials 2024, 17, 4461. https://doi.org/10.3390/ma17184461

Kesikidou F, Matamadiotou I, Stefanidou M. Influence of Accelerated Carbonation on the Physico-Mechanical Properties of Natural Fiber-Reinforced Lime Mortars. Materials. 2024; 17(18):4461. https://doi.org/10.3390/ma17184461

Chicago/Turabian StyleKesikidou, Fotini, Ioanna Matamadiotou, and Maria Stefanidou. 2024. "Influence of Accelerated Carbonation on the Physico-Mechanical Properties of Natural Fiber-Reinforced Lime Mortars" Materials 17, no. 18: 4461. https://doi.org/10.3390/ma17184461

APA StyleKesikidou, F., Matamadiotou, I., & Stefanidou, M. (2024). Influence of Accelerated Carbonation on the Physico-Mechanical Properties of Natural Fiber-Reinforced Lime Mortars. Materials, 17(18), 4461. https://doi.org/10.3390/ma17184461