Influence of Test Method on the Determination of Tensile Strength Perpendicular to Grain of Timber for Civil Construction

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test of Tensile Strength Perpendicular to Grain

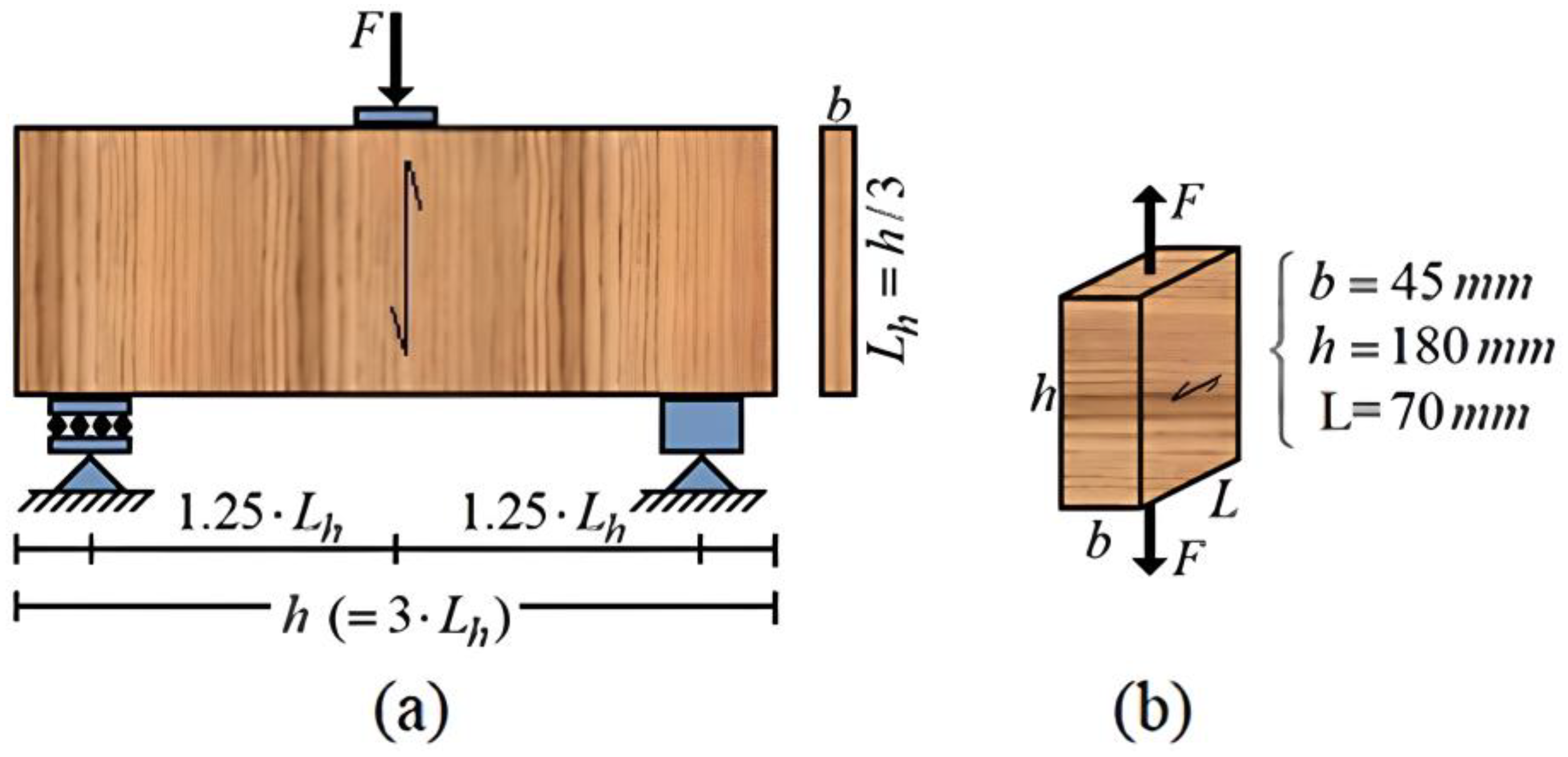

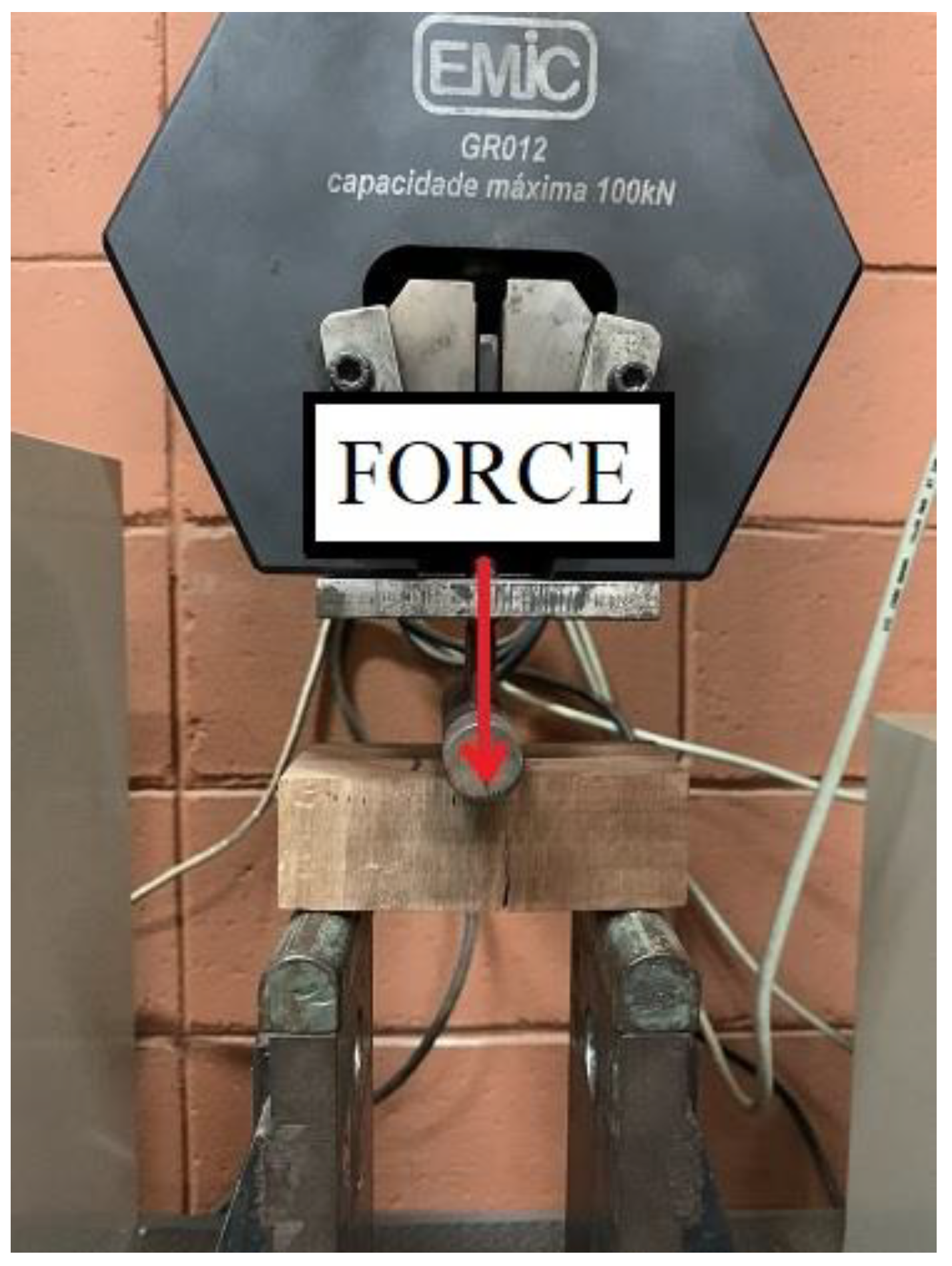

2.2.1. ABNT NBR 7190-3

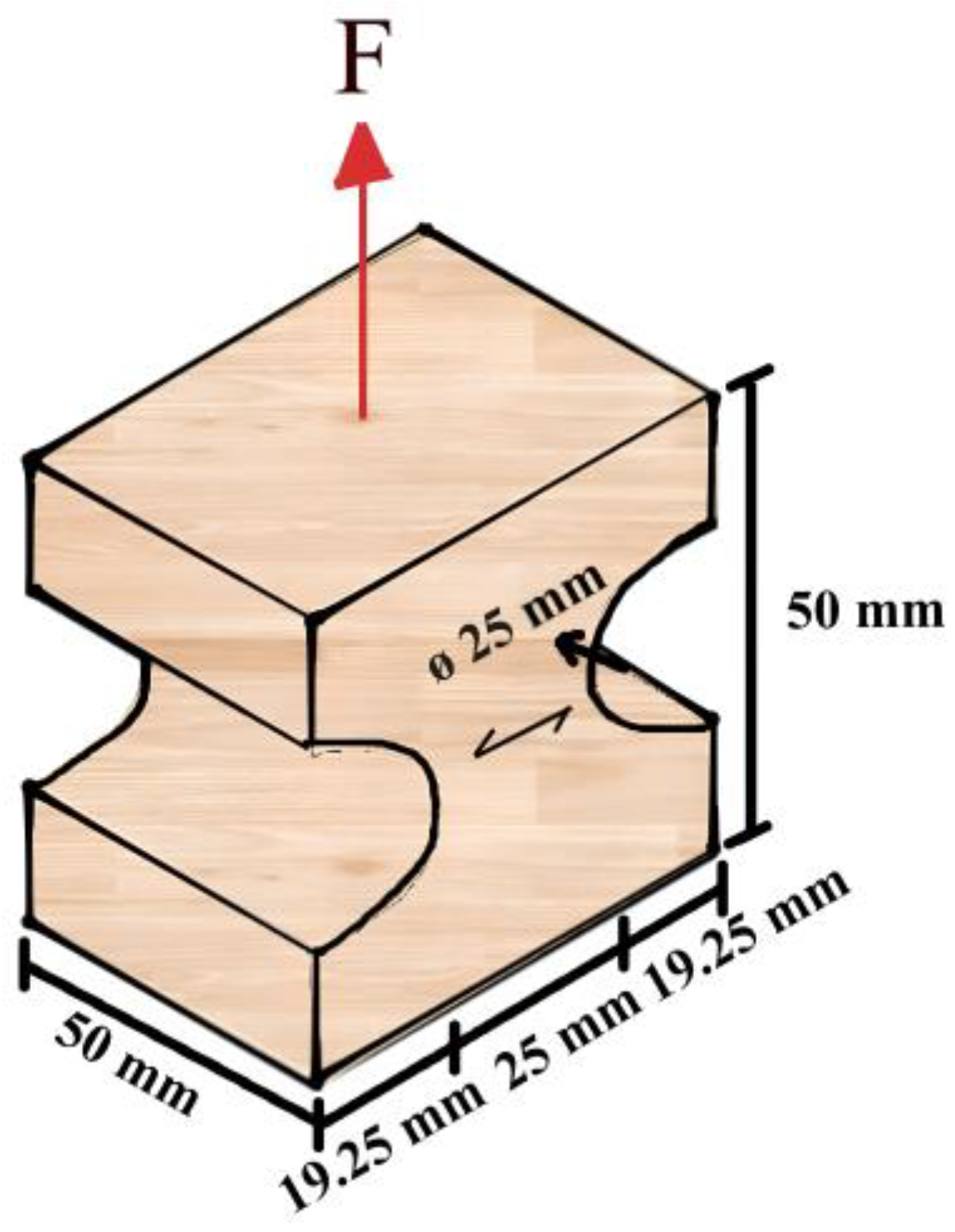

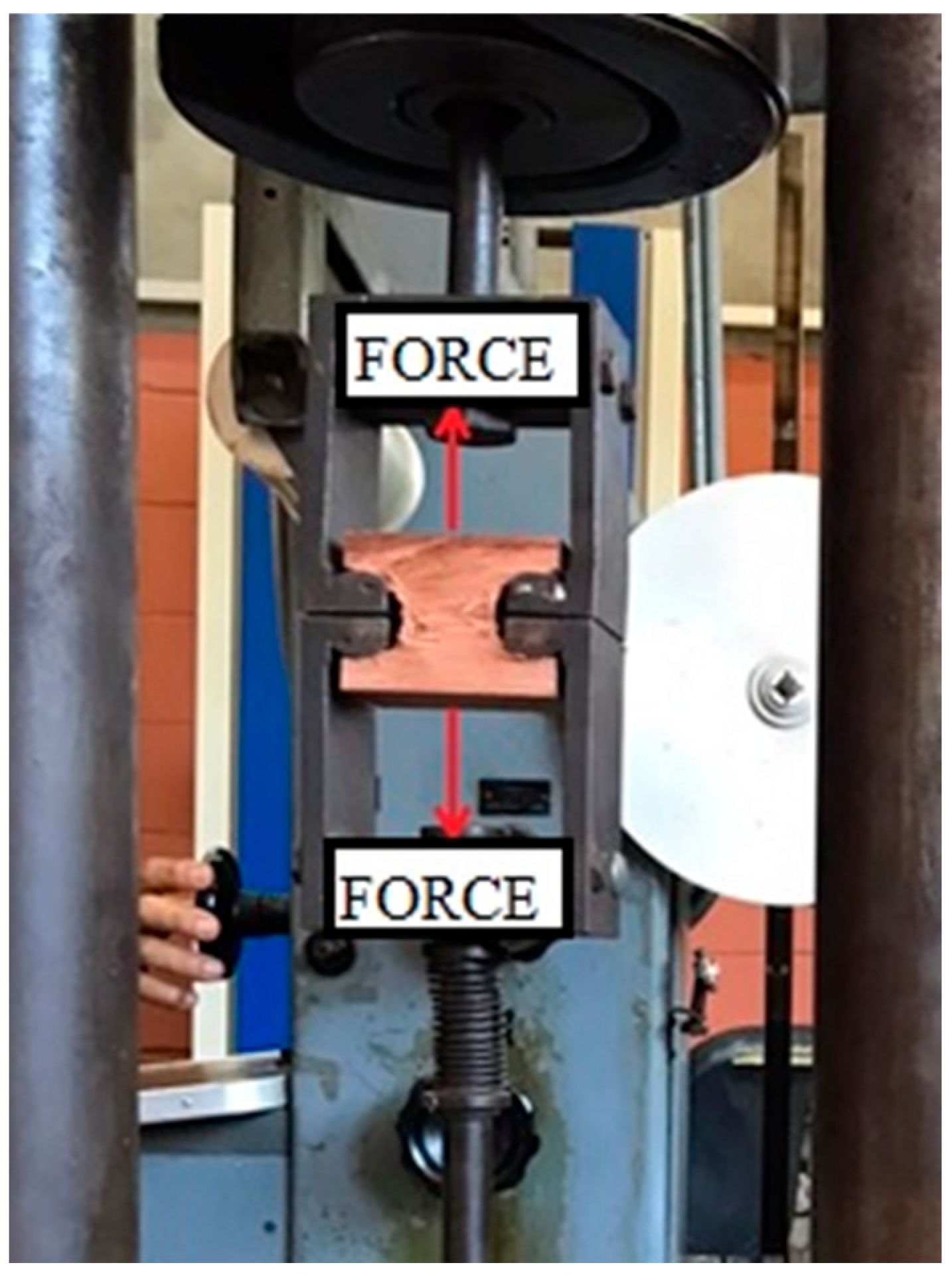

2.2.2. ISO 13910

2.3. Moisture Content

2.4. Tensile Strength Perpendicular to Grain with Moisture Content of the 12%

2.5. Statistical Analyses

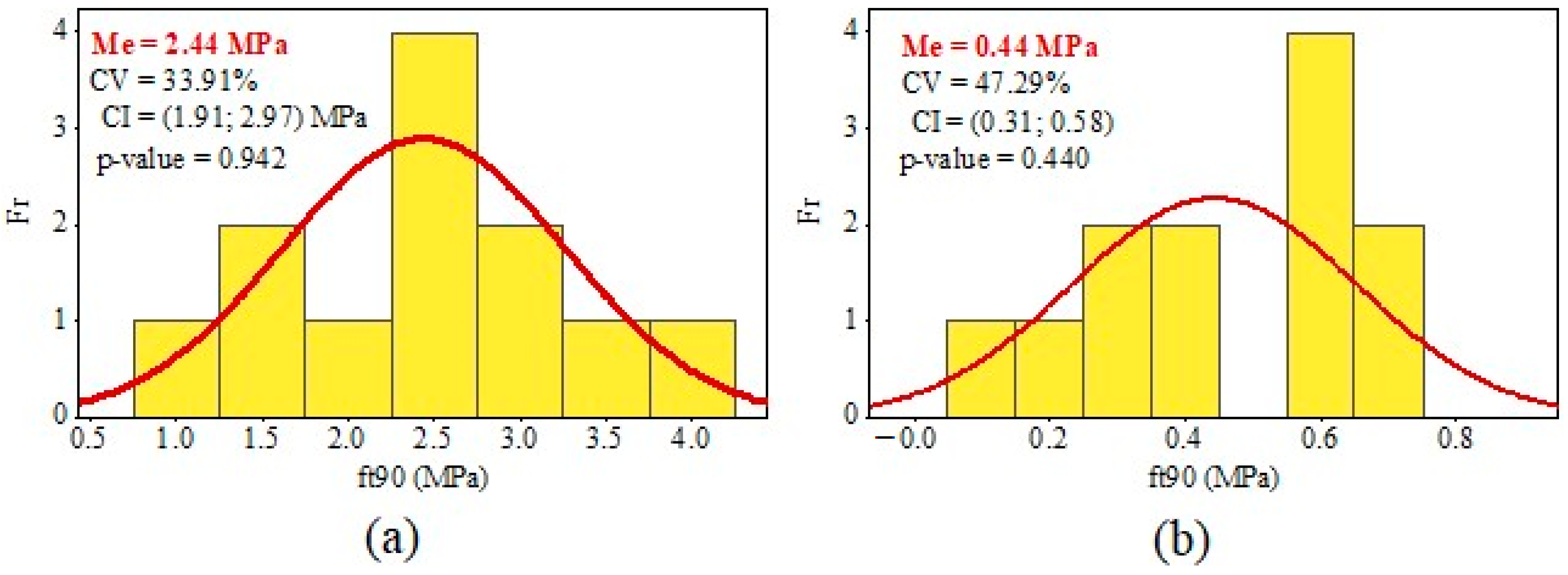

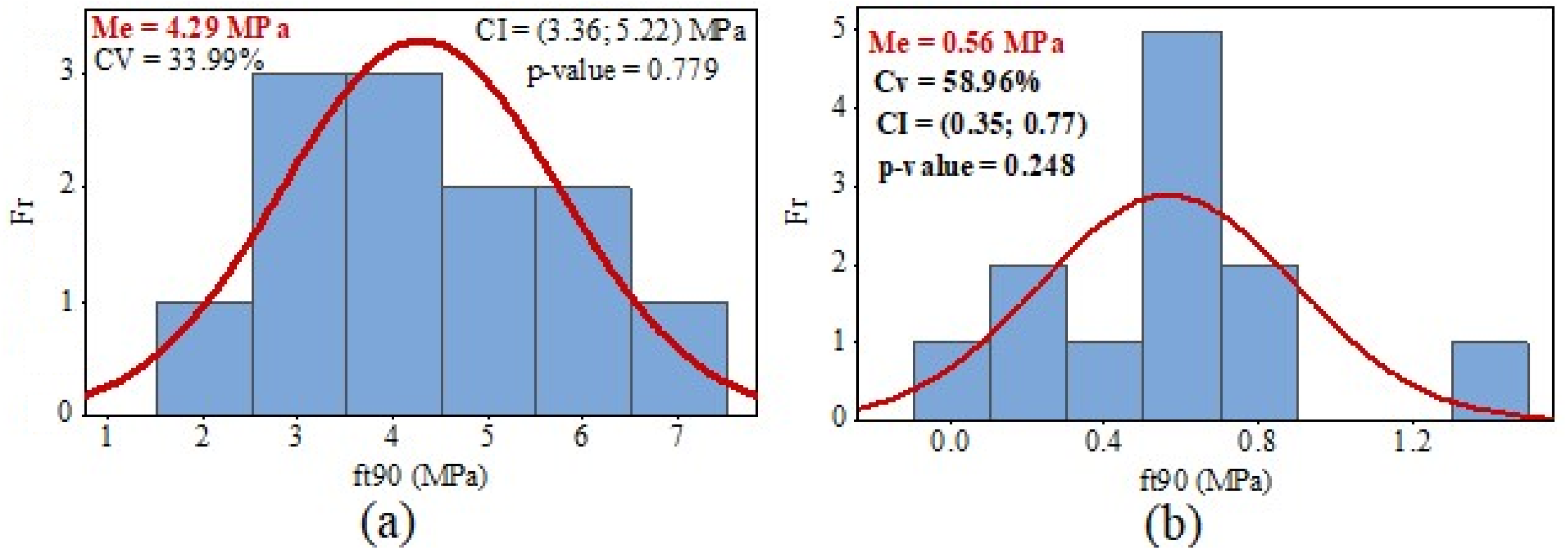

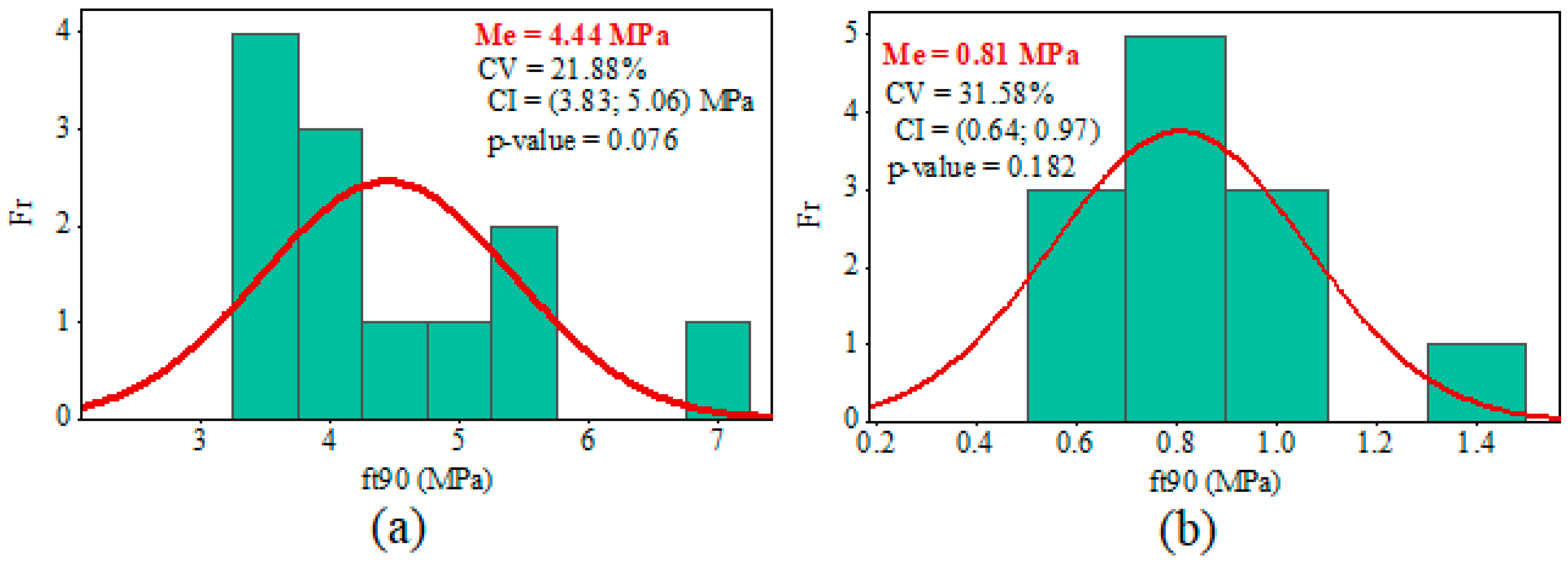

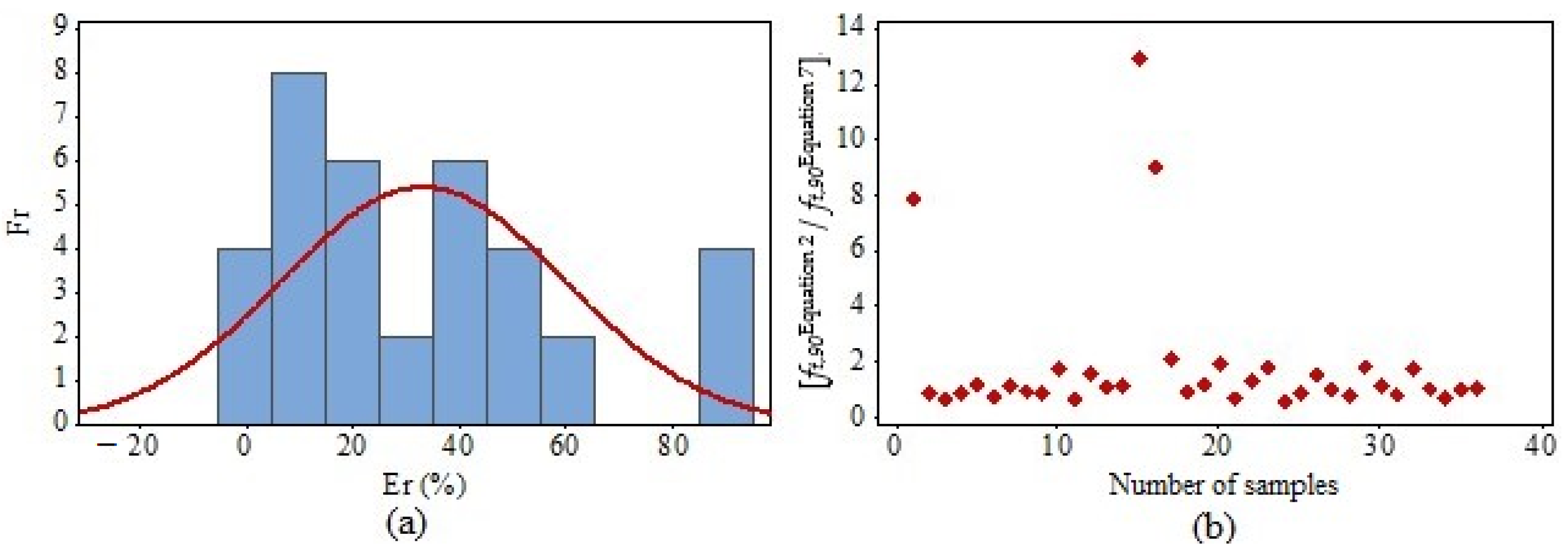

3. Results and Discussion

4. Conclusions

- Tensile strength values perpendicular to grain (ft,90) of the samples obtained from the uniaxial tensile test were significantly higher (around 5.55 and 7.7 times) than the values determined by the three-point static bending test.

- Correction factor for the equation from Code ISO 13910 [20], used to estimate ft,90 based on three-point bending test, was the term that had a significant impact on the obtained results. This impact resulted in much lower bending strength values compared with those obtained from the uniaxial tensile test.

- The values of the mean absolute percentage error were very similar to the results obtained with the adoption of the proposed coefficients for Equation (1). The model with a smaller adaptation of the equation from Code ISO/FDIS 13910 [20] was adopted in this research. Therefore, the coefficient 5.233, inserted into the term [(3.75·Fult)/b·Lh] of the equation from Code ISO/FDIS 13910 [20] and Brazilian Code ABNT NBR 7190-4 [24], produced results more similar when compared with the uniaxial tensile test results.

- The disparity in outcomes can be attributed to the different stress conditions inherent to each testing method. In the three-point bending test, wood grains and parenchyma cells are subjected to both normal and tangential stresses. In contrast, only normal stress is applied in wood grains in the uniaxial tensile test.

- In the design of timber structures, the tensile strength perpendicular to grain affects the dimensions of double tapered, curved, and pitched cambered beams. Thus, the design of these beams becomes more conservative by taking into account the most unfavorable conditions in the structural design (tensile strength obtained from the three-point static bending test).

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Follesa, M.; Fragiacomo, M.; Casagrande, D.; Tomasi, R.; Piazza, M.; Vassallo, D.; Canetti, D.; Rossi, S. The new provisions for the seismic design of timber buildings in Europe. Eng. Struct. 2018, 168, 736–747. [Google Scholar] [CrossRef]

- Stocchero, A.; Seadon, J.K.; Falshaw, R.; Edwards, M. Urban Equilibrium for sustainable cities and the contribution of timber buildings to balance urban carbon emissions: A New Zealand case study. J. Clean. Prod. 2017, 143, 1001–1010. [Google Scholar] [CrossRef]

- Calil Júnior, C.; Dias, A.A. Utilização da madeira em construções rurais. Rev. Bras. Eng. Agric. Ambient. 1997, 1, 71–77. [Google Scholar] [CrossRef]

- Ramage, M.H.; Burridge, H.; Busse-Wicher, M.; Fereday, G.; Reynolds, T.; Shah, D.U.; Wu, G.; Yu, L.; Fleming, P.; Densley-Tingley, D.; et al. The wood from the trees: The use of timber in construction. Renew. Sustain. Energy Rev. 2017, 68, 333–359. [Google Scholar] [CrossRef]

- FAO. Global Forest Resources Assessment 2020: Main Report, 1st ed.; Food and Agriculture Organization of the United Nations: Rome, Italy, 2020; pp. 1–184. [Google Scholar] [CrossRef]

- Brazilian Tree Industry. Report 2019. Available online: https://iba.org/datafiles/publicacoes/relatorios/iba-relatorioanual2019.pdf (accessed on 7 February 2023).

- Iwuoha, S.E.; Seim, W.; Onyekwelu, J.C. Mechanical properties of Gmelina arborea for engineering design. Constr. Build. Mater. 2021, 288, 123123. [Google Scholar] [CrossRef]

- Aquino, V.B.M.; de Freitas, M.V.P.; de Vasconcelos, C.Q.; Almeida, J.P.B.; Arroyo, F.N.; Rodrigues, E.F.C.; Christoforo, A.L.; de Almeida, D.H.; Silva, S.A.M.; Silva, D.A.L.; et al. Physical and mechanical characterization of planchonella pachycarpa wood species for use in structural purpose. Wood Res. 2021, 66, 267–276. [Google Scholar] [CrossRef]

- Teixeira, J.N.; Wolenski, A.R.V.; Aquino, V.B.M.; Panzera, T.H.; Silva, D.A.L.; Campos, C.I.; Silva, S.A.M.; Lahr, F.A.R.; Christoforo, A.L. Influence of provenance on physical and mechanical properties of Angelim-pedra (Hymenolobium petraeum Ducke.) wood species. Eur. J. Wood Prod. 2021, 79, 1241–1251. [Google Scholar] [CrossRef]

- Crespo, J.; Majano-Majano, A.; Lara-Bocanegra, A.J.; Guaita, M. Mechanical Properties of Small Clear Specimens of Eucalyptus globulus Labill. Materials 2020, 13, 906. [Google Scholar] [CrossRef] [PubMed]

- Derikvand, M.; Kotlarewski, N.; Lee, M.; Jiao, H.; Nolan, G. Characterisation of Physical and Mechanical Properties of Unthinned and Unpruned Plantation-Grown Eucalyptus nitens H.Deane & Maiden Lumber. Forests 2019, 10, 194. [Google Scholar] [CrossRef]

- Nogueira, M.C.J.A.; de Almeida, D.H.; de Araujo, V.A.; Vasconcelos, J.S.; Christoforo, A.L.; de Almeida, T.H.; Lahr, F.A.R. Physical and mechanical properties of Eucalyptus saligna wood for timber structures. Ambient. Construído 2019, 19, 233–239. [Google Scholar] [CrossRef]

- EN 1995-1-1; Eurocode 5: Design of Timber Structures—Part 1-1: General—Common Rules and Rules for Buildings. European Committee for Standardization: Brussels, Belgium, 2004.

- ABNT NBR 7190-1; Timber Structures—Part 1: Design Criteria. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2022.

- Ehlbeck, J.; Görlacher, R. Tension perpendicular to the grain in joints. Step lecture C2. In Timber Engineering—STEP 1, 1st ed.; Blass, H.J., Aune, P., Choo, B.S., Görlacher, R., Griffiths, D.R., Hilson, B.O., Racher, P., Steck, G., Eds.; Salland De Lange: Deventer, The Netherlands, 1995; pp. C2/1–C2/7. [Google Scholar]

- Wang, T.; Wang, Y.; Crocetti, R.; Wålinder, M. In-plane mechanical properties of birch plywood. Constr. Build. Mater. 2022, 340, 127852. [Google Scholar] [CrossRef]

- Nguyen, H.H.; McGavin, R.L.; Gilbert, B.P.; Bailleres, H. Key Mechanical Properties of Cross-banded Laminated Veneer Lumbers Manufactured from Blending Spotted Gum and Hoop Pine Veneers. BioResources 2019, 14, 9117–9131. [Google Scholar] [CrossRef]

- Gilbert, B.P.; Husson, J.M.; Bailleres, H.; McGavin, R.L.; Fischer, M.F. Perpendicular to grain and shear mechanical properties of veneer based elements glued from single veneer sheets recovered from three species of juvenile subtropical hardwood plantation logs. Eur. J. Wood Prod. 2018, 76, 1637–1652. [Google Scholar] [CrossRef]

- ASTM D143-21; Standard Test Methods for Small Clear Specimens of Timber. American Society for Testing and Materials: West Conshohocken, PA, USA, 2021.

- ISO/FDIS 13910; Timber Structures—Strength Graded Timber—Test Methods for Structural Properties. International Organization for Standardization: Geneva, Switzerland, 2014.

- BS EN 408:2010+A1; Timber Structures—Structural Timber and Glued Laminated Timber—Determination of Some Physical and Mechanical Properties. British Standards Institution: London, UK, 2012.

- ABNT NBR 7190-3; Timber Structures—Part 3: Test Methods for Characterization of Defect-Free Specimens for Timber of Native Forests. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2022.

- AS/NZS 4063.1; Characterization of Structural Timber. Standards Australia: Sydney, Australia, 2010.

- ABNT NBR 7190-4; Timber Structures—Part 4: Test Methods for Characterization of Structural Lumber. Brazilian Association of Technical Standards: Rio de Janeiro, Brazil, 2022.

- Tannert, T.; Vallée, T.; Franke, S.; Quenneville, P. Comparison of test methods to determine weibull parameters for wood. In Proceedings of the WCTE 2012—World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012. [Google Scholar]

- Timoshenko, S.P. Strength of Materials, Part 2: Advanced Theory and Problems, 3rd ed.; CBS Publishers & Distributors: New Delhi, India, 2002; pp. 1–563. [Google Scholar]

- Christoforo, A.L. Simulation and Analysis of Deformable Solids—Vol. 1., 1st ed.; Lambert Academic Publishing (LAP): Saarbrüken, Germany, 2021; pp. 1–156. [Google Scholar]

| Wood Species | Number of Boards | Width (mm) | Thickness (mm) | Length (cm) | Mean Density (kg/m3) |

|---|---|---|---|---|---|

| Pinus spp. | 6 | 120 | 50 | 200 | 589.96 (64.3) 1 |

| Eucalyptus saligna | 6 | 120 | 50 | 200 | 738.21 (114.6) |

| Corymbia citriodora | 6 | 120 | 50 | 200 | 916.64 (40.5) |

| Wood Species | Equation (7) | Equation (2) | MAPE (%) |

|---|---|---|---|

| Pinus spp. | 2.23 (46.27%) | 2.44 (33.91%) | 34.11 |

| Eucalyptus saligna | 3.02 (57.59%) | 4.29 (33.99%) | 44.82 |

| Corymbia citriodora | 4.25 (31.23%) | 4.44 (21.88%) | 20.48 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nogueira, R.d.S.; Moritani, F.Y.; Christoforo, A.L.; Monteiro, S.N.; de Azevedo, A.R.G.; dos Santos, H.F.; Lahr, F.A.R. Influence of Test Method on the Determination of Tensile Strength Perpendicular to Grain of Timber for Civil Construction. Materials 2024, 17, 4506. https://doi.org/10.3390/ma17184506

Nogueira RdS, Moritani FY, Christoforo AL, Monteiro SN, de Azevedo ARG, dos Santos HF, Lahr FAR. Influence of Test Method on the Determination of Tensile Strength Perpendicular to Grain of Timber for Civil Construction. Materials. 2024; 17(18):4506. https://doi.org/10.3390/ma17184506

Chicago/Turabian StyleNogueira, Rodrigo de Souza, Fabiana Yukiko Moritani, André Luis Christoforo, Sergio Neves Monteiro, Afonso Rangel Garcez de Azevedo, Herisson Ferreira dos Santos, and Francisco Antonio Rocco Lahr. 2024. "Influence of Test Method on the Determination of Tensile Strength Perpendicular to Grain of Timber for Civil Construction" Materials 17, no. 18: 4506. https://doi.org/10.3390/ma17184506

APA StyleNogueira, R. d. S., Moritani, F. Y., Christoforo, A. L., Monteiro, S. N., de Azevedo, A. R. G., dos Santos, H. F., & Lahr, F. A. R. (2024). Influence of Test Method on the Determination of Tensile Strength Perpendicular to Grain of Timber for Civil Construction. Materials, 17(18), 4506. https://doi.org/10.3390/ma17184506