Comparison of Levitation Properties between Bulk High-Temperature Superconductor Blocks and High-Temperature Superconductor Tape Stacks Prepared from Commercial Coated Conductors

Abstract

1. Introduction

2. Experiment

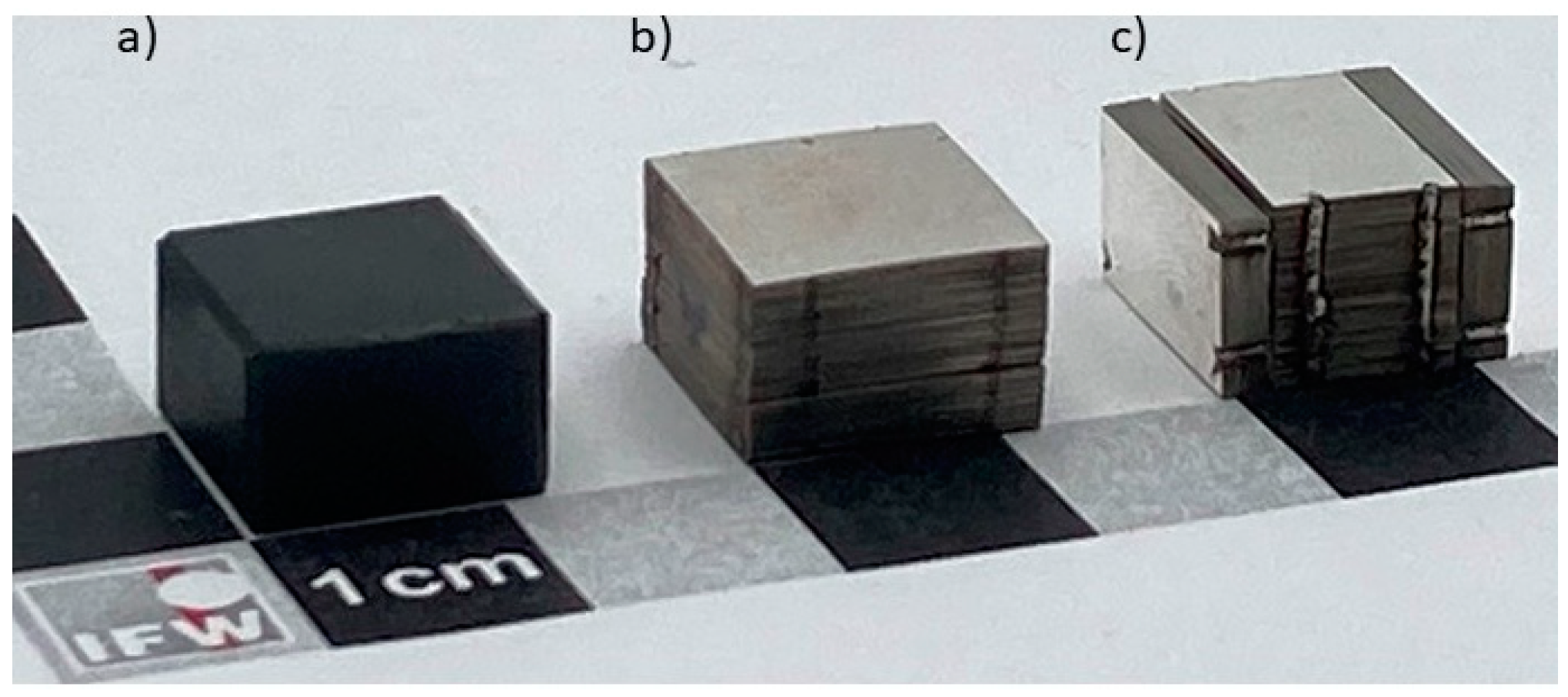

2.1. Sample Preparation

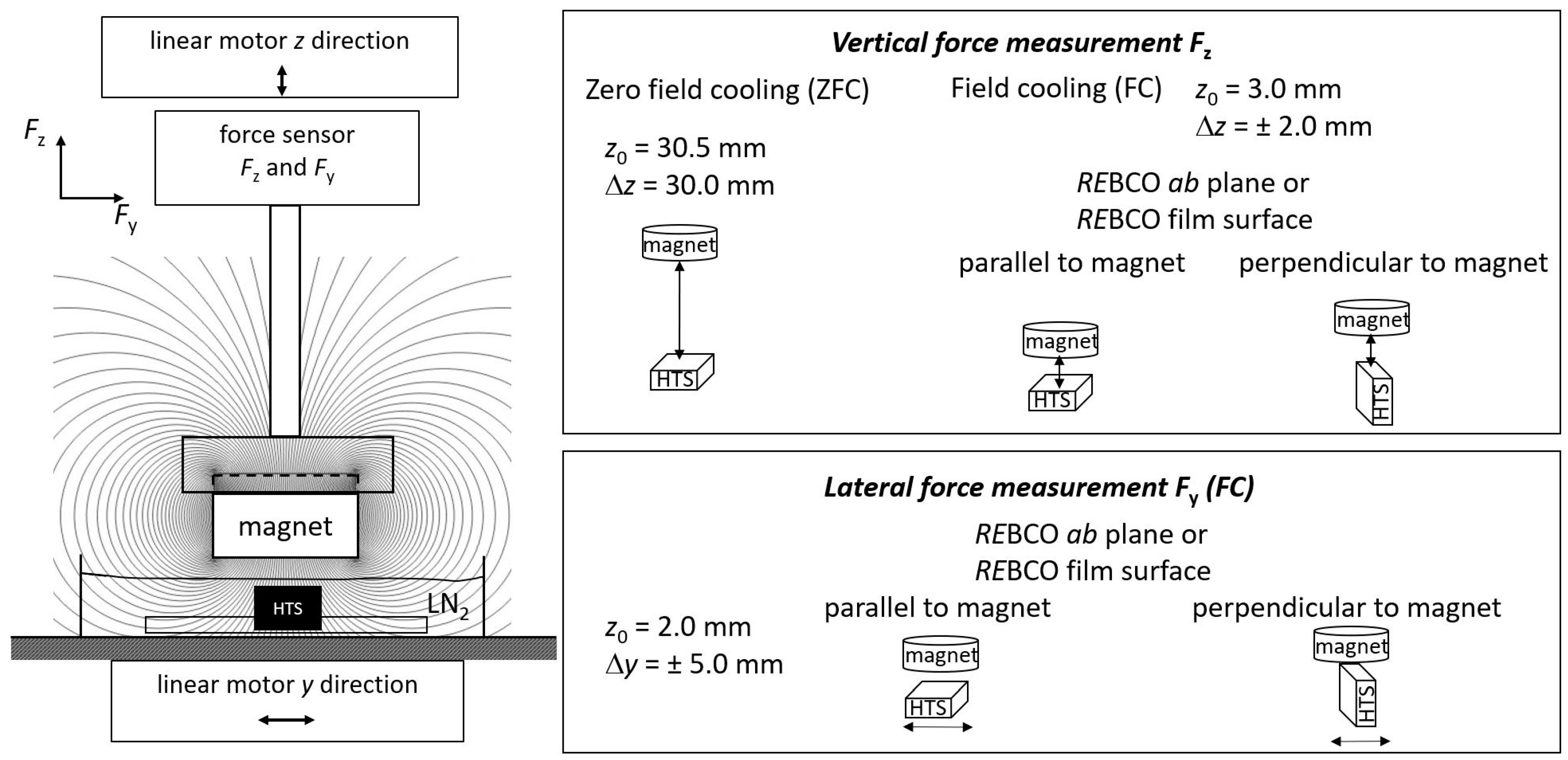

2.2. Characterization

3. Results and Discussion

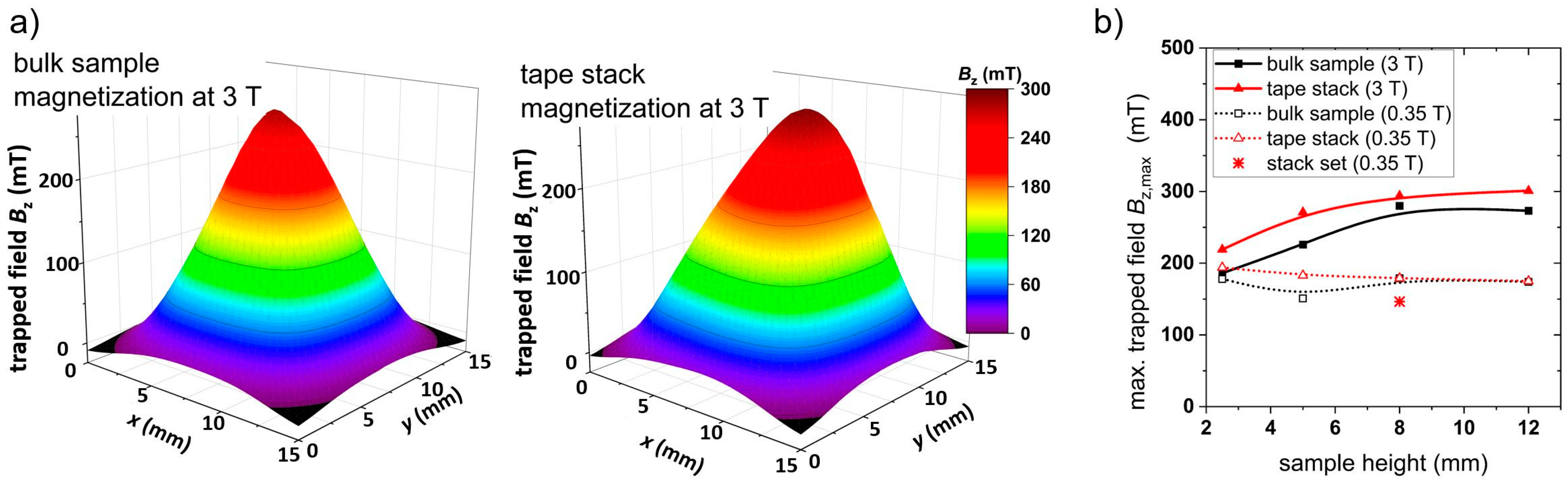

3.1. Trapped Field Measurements

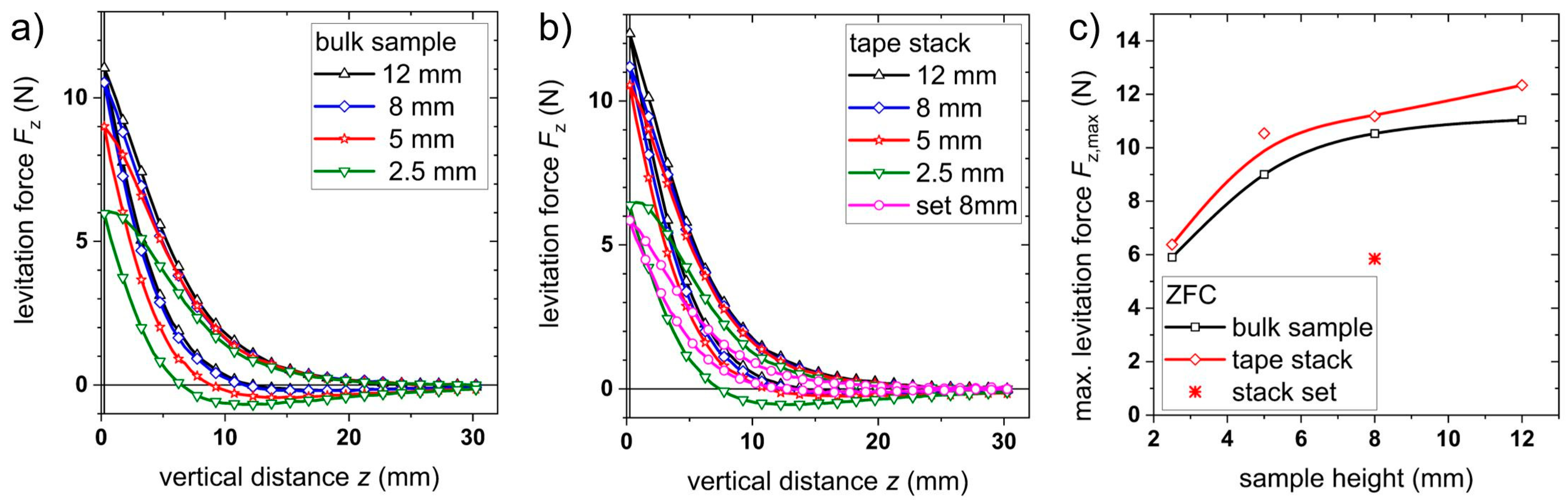

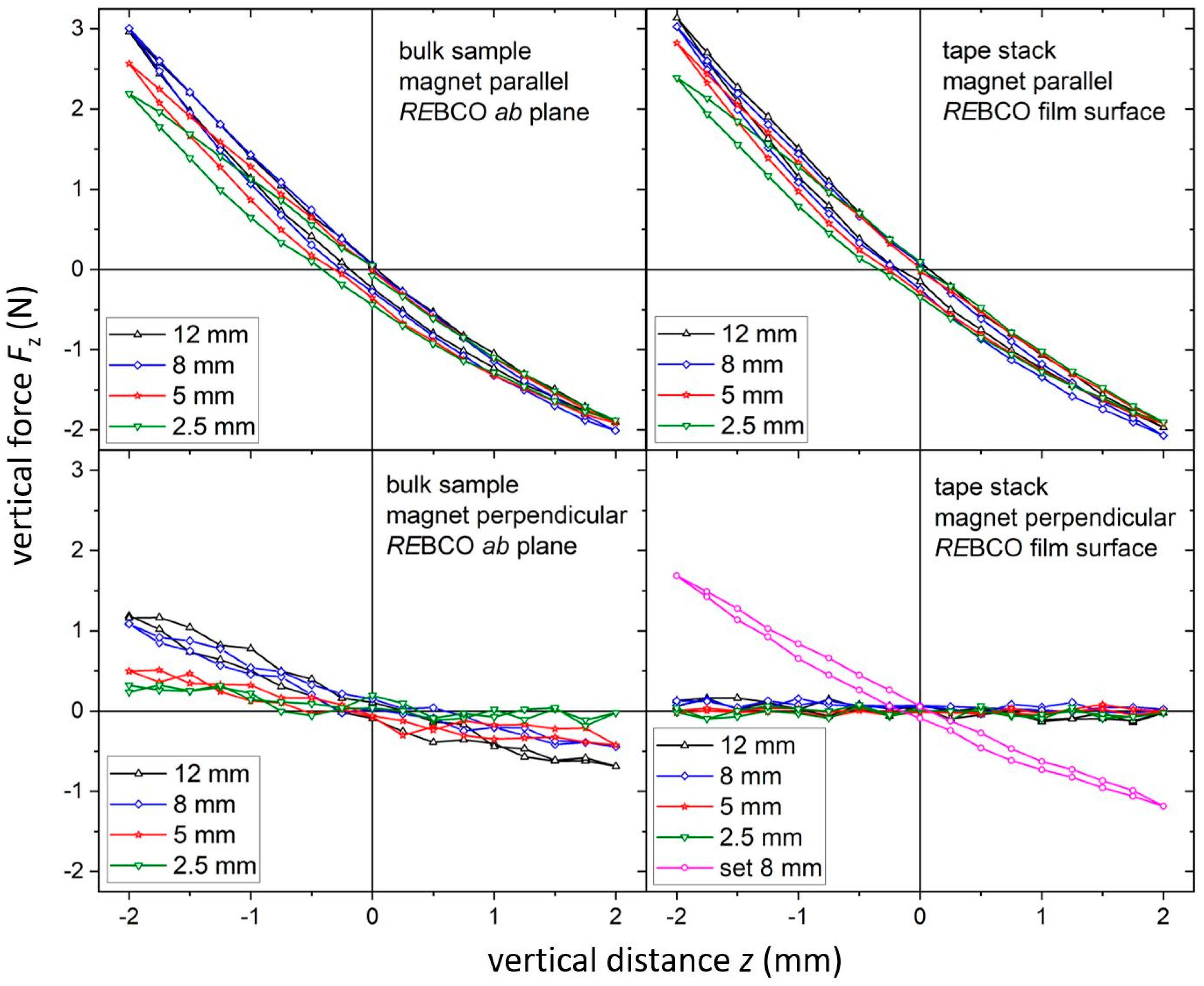

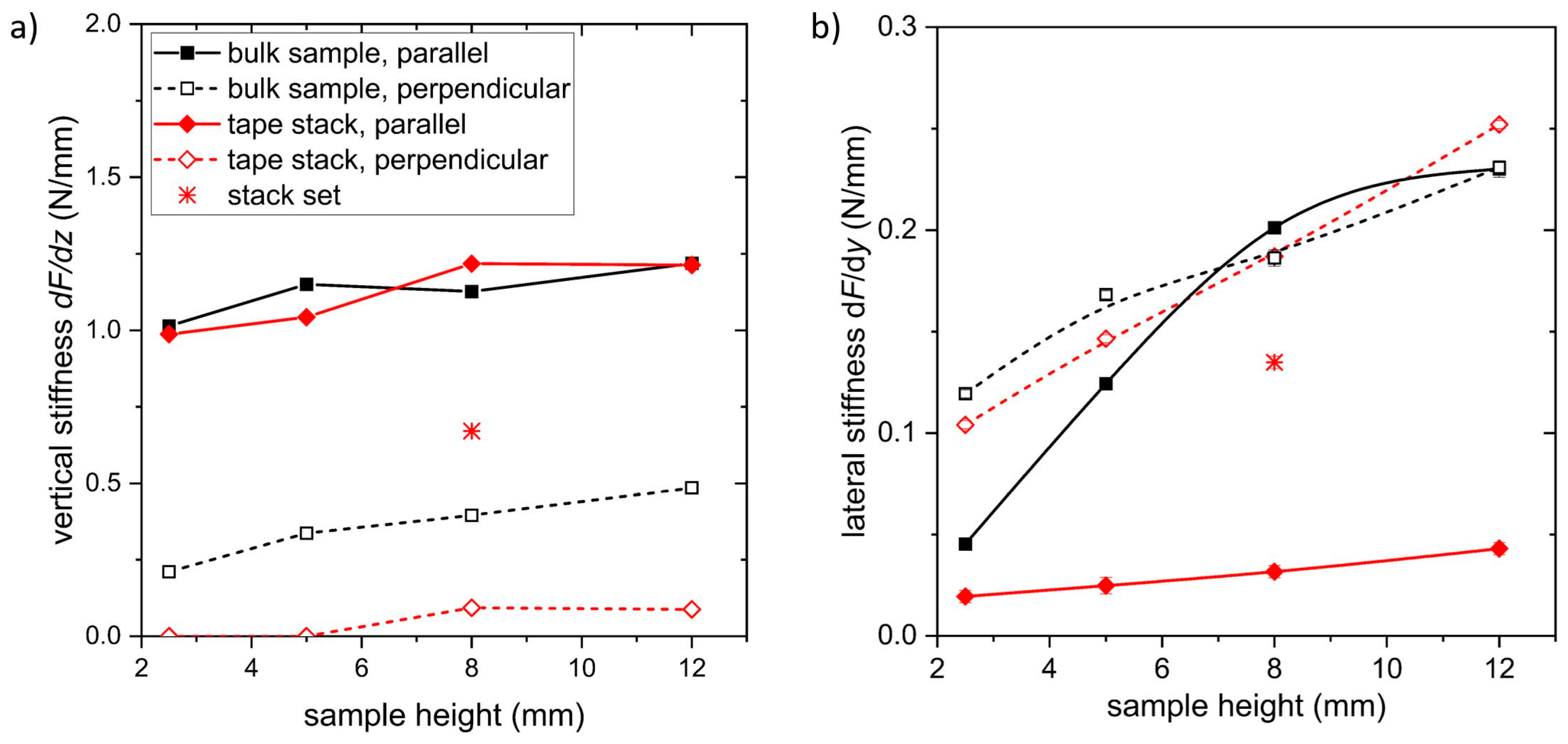

3.2. Vertical Levitation Force Measurements

3.3. Lateral Levitation Force Measurements

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haran, K.S.; Kalsi, S.; Arndt, T.; Karmaker, H.; Badcock, R.; Buckley, B.; Haugan, T.; Izumi, M.; Loder, D.; Bray, J.W.; et al. High power density superconducting rotating machines—Development status and technology roadmap. Supercond. Sci. Technol. 2017, 30, 123002. [Google Scholar] [CrossRef]

- Yazdani-Asrami, M.; Seyyedbarzegar, S.; Sadeghi, A.; de Sousa, W.T.B.; Kottonau, D. High temperature superconducting cables and their performance against short circuit faults: Current development, challenges, solutions, and future trends. Supercond. Sci. Technol. 2022, 35, 083002. [Google Scholar] [CrossRef]

- Hull, J.R. Superconducting bearings. Supercond. Sci. Technol. 2000, 13, R1. [Google Scholar] [CrossRef]

- Moon, F.C.; Chang, P.-Z. High-speed rotation of magnets on high Tc superconducting bearings. Appl. Phys. Lett. 1990, 56, 397–399. [Google Scholar] [CrossRef]

- Ma, K.B.; Postrekhin, Y.V.; Chu, W.K. Superconductor and magnet levitation devices. Rev. Sci. Instrum. 2003, 74, 4989–5017. [Google Scholar] [CrossRef]

- Filion, G.; Ruel, J.; Dubois, M.R. Reduced-Friction Passive Magnetic Bearing: Innovative Design and Novel Characterization Technique. Machines 2013, 1, 98–115. [Google Scholar] [CrossRef]

- Werfel, F.N.; Floegel-Delor, U.; Rothfeld, R.; Riedel, T.; Goebel, B.; Wippich, D.; Schirrmeister, P. Superconductor bearings, flywheels and transportation. Supercond. Sci. Technol. 2012, 25, 014007. [Google Scholar] [CrossRef]

- Sparing, M.; Berger, A.; Wall, F.; Lux, V.; Hameister, S.; Berger, D.; Hossain, M.; Abdkader, A.; Fuchs, G.; Cherif, C.; et al. Dynamics of Rotating Superconducting Magnetic Bearings in Ring Spinning. IEEE Trans. Appl. Supercond. 2016, 26, 3600804. [Google Scholar] [CrossRef]

- Sparing, M.; Espenhahn, T.; Fuchs, G.; Hossain, M.; Abdkader, A.; Nielsch, K.; Cherif, C.; Hühne, R. Analysis of the high-speed rotary motion of a superconducting magnetic bearing during ring spinning. Eng. Res. Express 2020, 2, 035039. [Google Scholar] [CrossRef]

- Hossain, M.; Sparing, M.; Espenhahn, T.; Abdkader, A.; Cherif, C.; Hühne, R.; Nielsch, K. In situ measurement of the dynamic yarn path in a turbo ring spinning process based on the superconducting magnetic bearing twisting system. Text. Res. J. 2020, 90, 951–968. [Google Scholar] [CrossRef]

- Krabbes, G.; Schätzle, P.; Bieger, W.; Fuchs, G. Modified melt crystallization processes for improved RE-123 based bulk materials (RE = Y,Nd). Appl. Supercond. 1998, 6, 61. [Google Scholar] [CrossRef]

- Osipov, M.; Abin, D.; Pekrovskii, S.; Rudnev, I. Investigation of HTS Tape Stacks for Levitation Applications. IEEE Trans. Appl. Supercond. 2016, 26, 3601704. [Google Scholar] [CrossRef]

- Patel, A.; Kalitka, V.; Hopkins, S.C.; Baskys, A.; Albisetti, A.F.; Giunchi, G.; Molodyk, A.; Glowacki, B.A. Magnetic levitation between a slab of soldered HTS tape and a cylindrical permanent magnet. IEEE Trans. Appl. Supercond. 2016, 26, 3601305. [Google Scholar] [CrossRef]

- Samoilenkov, S.; Molodyk, A.; Lee, S.; Petrykin, V.; Valitka, V.; Martynova, I.; Makerevich, A.; Mayzykh, A.; Blednov, A. Customised 2G HTS wire for applications. Supercond. Sci. Technol. 2016, 29, 024001. [Google Scholar] [CrossRef]

- Liu, K.; Yang, W.; Ma, G.; Quéval, L.; Gong, T.; Ye, C.; Li, X.; Luo, Z. Experiment and simulation of superconducting magnetic levitation with REBCO coated conductor stacks. Supercond. Sci. Technol. 2018, 31, 015013. [Google Scholar] [CrossRef]

- Sass, F.; Dias, D.H.N.; Sotelo, G.G.; de Andrade, R., Jr. Superconducting levitation using coated conductors. IEEE Trans. Appl. Supercond. 2013, 23, 3600905. [Google Scholar] [CrossRef]

- MacManus-Driscoll, J.L.; Wimbush, S.C. Processing and application of high- temperature superconducting coated conductors. Nat. Rev. Mater. 2021, 6, 587–604. [Google Scholar] [CrossRef]

- Bean, C.P. Magnetization of high-field superconductors. Rev. Mod. Phys. 1964, 36, 31. [Google Scholar] [CrossRef]

- Rudnev, I.; Osipov, M.; Pokrovskii, S.; Podlivaev, A. The influence of cyclical lateral displacements on levitation and guidance force for the system of coated conductor stacks and permanent magnets. Mater. Res. Express 2019, 6, 036001. [Google Scholar] [CrossRef]

- Osipov, M.; Starikovskii, A.; Abin, D.; Rudnev, I. Influence of the critical current on the levitation force of stacks of coated conductor superconducting tapes. Supercond. Sci. Technol. 2019, 32, 054003. [Google Scholar] [CrossRef]

- Liu, Z.; Yang, W.; Yu, L.; Li, Y.; Bai, M.; Fawzi; Li, X. Testing and Comparison of Levitation Forces and Rotational Friction in Different Superconducting Tape Stacks. J. Supercond. Nov. Magn. 2020, 33, 3035. [Google Scholar] [CrossRef]

- Osipov, M.; Starikovskii, A.; Anishenko, I.; Pokrovskii, S.; Abin, D.; Rudnev, I. Magnetic-force characteristics of hybrid levitation systems based on CC-tapes. IEEE Trans. Appl. Supercond. 2022, 32, 3600405. [Google Scholar] [CrossRef]

- Baloochi, M.; Espenhahn, T.; Hossain, M.; Perez-Delgado, Y.; Abdkader, A.; Beitelschmidt, M.; Nielsch, K.; Hühne, R. Analysis of a passive vibration damper for high-speed superconducting magnetic bearings. Mater. Res. Express 2024, 6, 035524. [Google Scholar] [CrossRef]

- Lao, M.; Bernardi, J.; Bauer, M.; Eisterer, M. Critical current anisotropy of GdBCO tapes grown on ISD-MgO buffered substrate. Supercond. Sci Technol. 2015, 28, 124002. [Google Scholar] [CrossRef]

- Nagashima, K.; Higuchi, T.; Sok, J.; Yoo, S.I.; Fujimoto, H.; Murakami, M. The trapped field of YBCO bulk superconducting magnets. Cryogenics 1997, 37, 577–581. [Google Scholar] [CrossRef]

- Antoncík, F.; Lojka, M.; Hlásek, T.; Valiente-Blanco, I.; Perez-Diaz, J.L.; Jankovský, O. Artificially perforated single grain YBCO bulks: Dependence of superconducting properties on the bulk thickness. J. Am. Ceram. Soc. 2020, 103, 5169–5177. [Google Scholar] [CrossRef]

- Rudnev, I.; Abin, D.; Osipov, M.; Pokrovskiy, S.; Ermolaev, Y.; Mineev, N. Magnetic properties of the stack of HTSC tapes in a wide temperature range. Phys. Procedia 2015, 65, 141–144. [Google Scholar] [CrossRef]

- Ghabeli, A.; Fuchs, G.; Hänisch, J.; Zhou, P.; de Haas, O.; Morandi, A.; Grilli, F. 3D modeling and measurement of HTS tape stacks in linear superconducting magnetic bearings. Supercond. Sci. Technol. 2024, 37, 065003. [Google Scholar] [CrossRef]

- Gao, P.; Yang, W.-M.; Wu, T.-T.; Wang, M.; Liu, K. Effect of thickness on magnetic properties of single domain GdBCO bulk superconductors. Chin. Phys. B 2023, 32, 027401. [Google Scholar] [CrossRef]

- Antoncík, F.; Lojka, M.; Hlásek, T.; Bartůněk, V.; Valiente-Blanco, I.; Perez-Diaz, J.L.; Jankovský, O. Radial and axial stiffness of superconducting bearings based on YBCO single-domain bulks processed with artificial holes. Supercond. Sci. Technol. 2020, 33, 045010. [Google Scholar] [CrossRef]

- Morandi, A.; Fabbri, M.; Ribani, P.L.; Dennis, A.; Durrell, J.; Shi, Y.; Cardwell, D. The measurement and modeling of the levitation force between single-grain YBCO bulk superconductors and permanent magnets. IEEE Trans. Appl. Supercond. 2018, 28, 3601310. [Google Scholar] [CrossRef]

- Osipov, M.; Starikovskii, A.; Anishenko, I.; Pokrovskii, S.; Abin, D.; Rudnev, I. Influence of temperature on levitation characteristics of the system CC tapes—Permanent magnets at lateral displacements. J. Magn. Magn. Mater. 2022, 546, 168896. [Google Scholar] [CrossRef]

| Trapped Field Bz max (mT) (Magnetization at 0.35 T) | ZFC Fz max (N) | Vertical Stiffness dF/dz (N mm−1) | Lateral Stiffness dF/dy (N mm−1) | |||

|---|---|---|---|---|---|---|

| ǁ | ┴ | ǁ | ┴ | |||

| Bulk sample | 179 | 10.5 | 1.1 | 0.4 | 0.21 | 0.19 |

| Tape stack | 179 | 11.2 | 1.2 | 0.1 | 0.03 | 0.19 |

| Stack set | 146 | 5.9 | 0.7 | 0.13 | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kirchner, A.; Espenhahn, T.; Klug, S.; Nielsch, K.; Hühne, R. Comparison of Levitation Properties between Bulk High-Temperature Superconductor Blocks and High-Temperature Superconductor Tape Stacks Prepared from Commercial Coated Conductors. Materials 2024, 17, 4516. https://doi.org/10.3390/ma17184516

Kirchner A, Espenhahn T, Klug S, Nielsch K, Hühne R. Comparison of Levitation Properties between Bulk High-Temperature Superconductor Blocks and High-Temperature Superconductor Tape Stacks Prepared from Commercial Coated Conductors. Materials. 2024; 17(18):4516. https://doi.org/10.3390/ma17184516

Chicago/Turabian StyleKirchner, Anke, Tilo Espenhahn, Sebastian Klug, Kornelius Nielsch, and Ruben Hühne. 2024. "Comparison of Levitation Properties between Bulk High-Temperature Superconductor Blocks and High-Temperature Superconductor Tape Stacks Prepared from Commercial Coated Conductors" Materials 17, no. 18: 4516. https://doi.org/10.3390/ma17184516

APA StyleKirchner, A., Espenhahn, T., Klug, S., Nielsch, K., & Hühne, R. (2024). Comparison of Levitation Properties between Bulk High-Temperature Superconductor Blocks and High-Temperature Superconductor Tape Stacks Prepared from Commercial Coated Conductors. Materials, 17(18), 4516. https://doi.org/10.3390/ma17184516