Mechanical Properties of Silicon Nitride in Different Morphologies: In Situ Experimental Analysis of Bulk and Whisker Structures

Abstract

1. Introduction

2. Sample and Experimental Methods

2.1. Fabrication of Si3N4 Bulk Sample

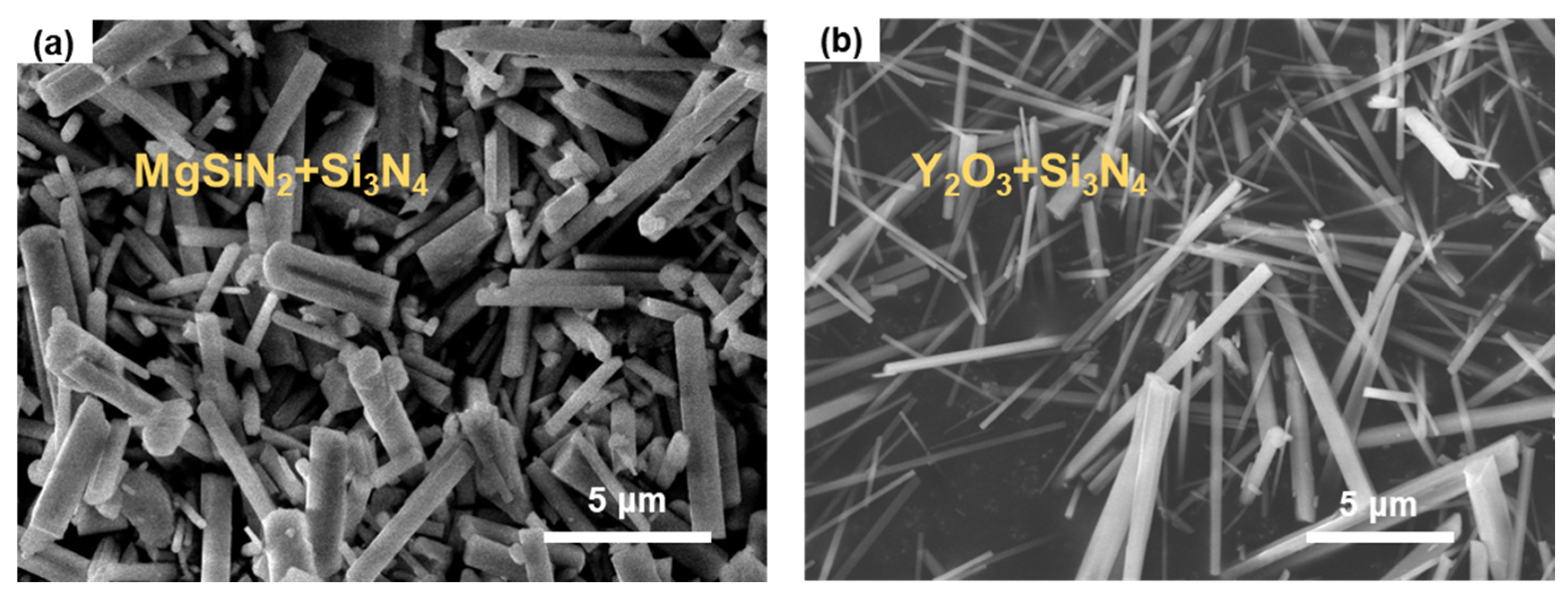

2.2. Fabrication and Microstructural Characterization of Si3N4 Whiskers

2.3. In Situ SEM Nanomechanical Characterizations

3. Results and Discussion

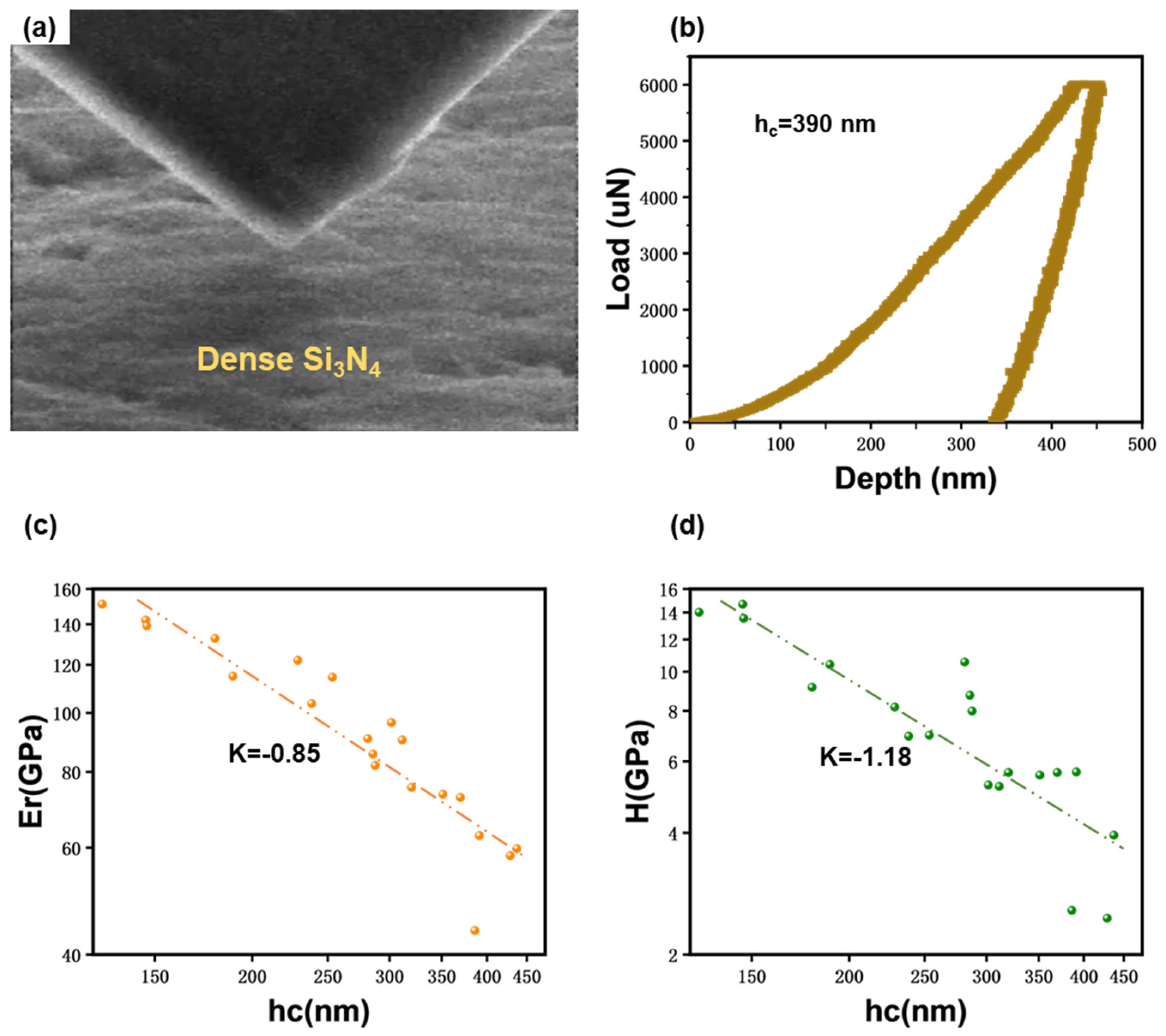

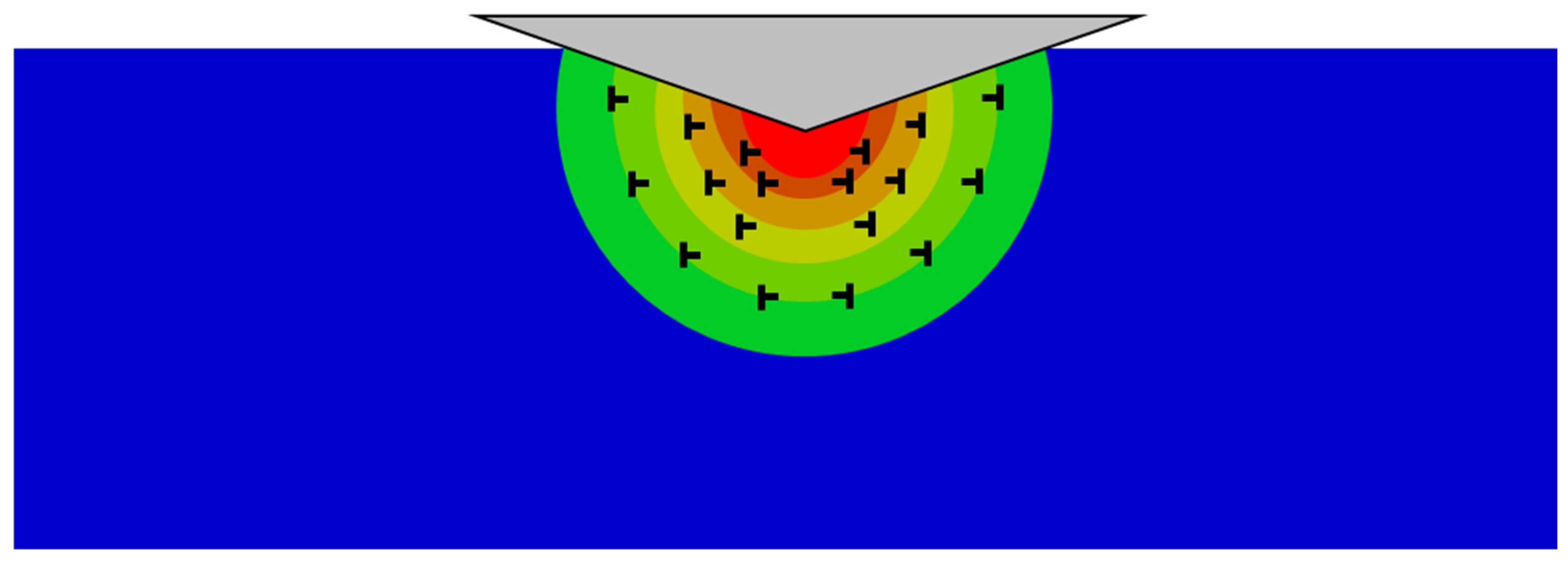

3.1. In Situ Nanoindentation Testing

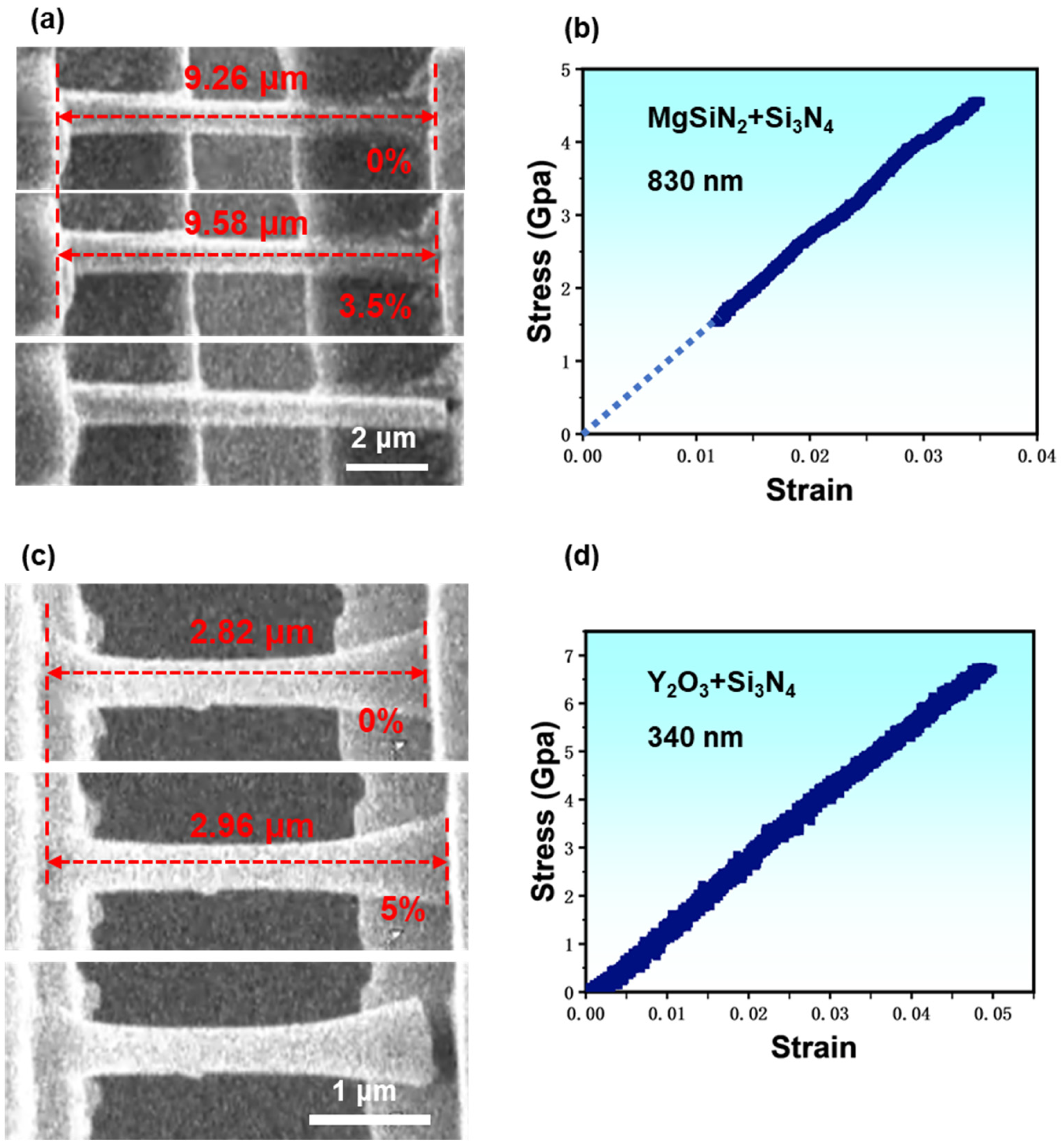

3.2. In Situ SEM Tensile Test

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Riedel, R.; Kien, A.; Dressler, W.; Ruwisch, L.; Bill, J.; Aldinger, F. A silicoboron carbonitride ceramic stable to 2,000 °C. Nature 1996, 382, 796–798. [Google Scholar] [CrossRef]

- Hampshire, S. Silicon nitride ceramics-review of structure, processing and properties. J. Achiev. Mater. Manuf. Eng. 2007, 24, 43–50. [Google Scholar]

- Golla, B.R.; Mukhopadhyay, A.; Basu, B.; Thimmappa, S.K. Review on ultra-high temperature boride ceramics. Prog. Mater. Sci. 2020, 111, 100651. [Google Scholar]

- Banerjee, A.; Bernoulli, D.; Zhang, H.; Yuen, M.F.; Liu, J.; Dong, J.; Ding, F.; Lu, J.; Dao, M.; Zhang, W.; et al. Ultralarge elastic deformation of nanoscale diamond. Science 2018, 360, 300–302. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Tersoff, J.; Xu, S.; Chen, H.; Zhang, Q.; Zhang, K.; Yang, Y.; Lee, C.S.; Tu, K.N.; Li, J.; et al. Approaching the ideal elastic strain limit in silicon nanowires. Sci. Adv. 2016, 2, e1501382. [Google Scholar] [CrossRef]

- Chakraborty, D.; Mukerji, J. Effect of crystal orientation, structure and dimension on vickers microhardness anisotropy of β-, α-Si3N4, α-SiO2 and α-SiC single crystals. Mater. Res. Bull. 1982, 17, 843–849. [Google Scholar] [CrossRef]

- Dusza, J.; Eschner, T.; Rundgren, K. Hardness anisotropy in bimodal grained gas pressure sintered Si3N4. J. Mater. Sci. Lett. 1997, 16, 1664–1667. [Google Scholar] [CrossRef]

- Dusza, J.; Steen, M. Microhardness load size effect in individual grains of a gas pressure sintered silicon nitride. J. Am. Ceram. Soc. 1998, 81, 3022–3024. [Google Scholar] [CrossRef]

- Hay, J.C.; Sun, E.Y.; Pharr, G.M.; Becher, P.F.; Alexander, K.B. Elastic anisotropy of ß-silicon nitride whiskers. J. Am. Ceram. Soc. 1998, 81, 2661–2669. [Google Scholar] [CrossRef]

- Milhet, X.; Garem, H.; Demmenet, J.; Rabier, J.; Rouxel, T. Dislocations studies in β-silicon nitride. J. Mater. Sci. 1997, 32, 3733–3738. [Google Scholar] [CrossRef]

- Yoon, K.J.; Wiederhorn, S.M.; Luecke, W.E. Comparison of Tensile and Compressive Creep Behavior in Silicon Nitride. J. Am. Ceram. Soc. 2000, 83, 2017–2022. [Google Scholar] [CrossRef]

- Csanádi, T.; Chinh, N.Q.; Szommer, P.; Dusza, J.; Lenčés, Z.; Šajgalík, P.; Reimanis, I. Deformation and Fracture of β-Silicon Nitride Micropillars. J. Am. Ceram. Soc. 2015, 98, 374–377. [Google Scholar] [CrossRef]

- Zhang, X.; Cui, S.; Ma, S.; Chen, W.; Ge, Y.; Zhao, X.; Li, H.; Lian, M.; Tao, Q.; Cui, T.; et al. Hardness, elastic modulus and their correlations in the transparent silicon nitrides. Mater. Today Commun. 2024, 38, 108320. [Google Scholar] [CrossRef]

- Xing, H.; Liu, B.; Sun, J.; Zou, B. Mechanical properties of Si3N4 ceramics from an in-situ synthesized α-Si3N4/β-Si3N4 composite powder. Ceram. Int. 2017, 43, 2150–2154. [Google Scholar] [CrossRef]

- Chen, F.; Yan, K.; Zhou, J.; Zhu, Y.; Hong, J. Multilayer graphene and β-Si3N4 whisker-reinforced porous Si3N4 ceramics by spark plasma incomplete sintering. Mater. Sci. Eng. A 2021, 823, 141770. [Google Scholar] [CrossRef]

- Dai, J.; Gao, W.; Liu, B.; Cao, X.; Tao, T.; Xie, Z.; Zhao, H.; Chen, D.; Ping, H.; Zhang, R. Design and fabrication of UV band-pass filters based on SiO2/Si3N4 dielectric distributed bragg reflectors. Appl. Surf. Sci. 2016, 364, 886–891. [Google Scholar] [CrossRef]

- Li, J.D.; Shen, G.S.; Chen, W.L.; Li, Z.; Hong, R.J. Preparation of SiNx multilayer films by mid-frequency magnetron sputtering for crystalline silicon solar cells. Mater. Sci. Semicond. Process. 2017, 59, 40–44. [Google Scholar] [CrossRef]

- Soman, A.; Antony, A. Tuneable and spectrally selective broadband reflector—Modulated photonic crystals and its application in solar cells. Sol. Energy 2018, 162, 525–532. [Google Scholar] [CrossRef]

- Soman, A.; Antony, A. Colored solar cells with spectrally selective photonic crystal reflectors for application in building integrated photovoltaics. Sol. Energy 2019, 181, 1–8. [Google Scholar] [CrossRef]

- Rahaman, M.; Xiao, W. Silicon nitride bioceramics in healthcare. Int. J. Appl. Ceram. Technol. 2017, 15, 861–872. [Google Scholar] [CrossRef]

- Shekaari, A.; Jafari, M. Biocompatibility of 2D silicon nitride: Interaction at the nano-bio interface. Mater. Res. Express 2021, 8, 095404. [Google Scholar] [CrossRef]

- Bahri, M.; Baraket, A.; Zine, N.; Ali, M.B.; Bausells, J.; Errachid, A. Capacitance electrochemical biosensor based on silicon nitride transducer for TNF-alpha cytokine detection in artificial human saliva: Heart failure (HF). Talanta 2020, 209, 120501. [Google Scholar] [CrossRef] [PubMed]

- Kadhum, F.J.; Kafi, S.H.; Karam, A.J.; Al-Zuky, A.A.; Al-Kadhemy, M.F.H.; Al-Saleh, A.H. Simulation of surface plasmon resonance (SPR) layers of gold with silicon nitride as a Bi-layer biosensor. Dig. J. Nanomater. Biostructures 2022, 17, 623–633. [Google Scholar] [CrossRef]

- Singh, L.; Pareek, P.; Kumar, R.; Agarwal, V.; Maurya, N.K.; Bage, A. Investigation of SPR sensor for immunoglobulin detection by using Ag–Si3N4-BP on the sensing layer. Opt. Quantum Electron. 2024, 56, 771. [Google Scholar] [CrossRef]

- Pirhaghshenasvali, S.; Ghayour, R.; Vaghefi, M. Highly sensitive biosensor based on nanoparticle/grating: A case study on detecting waterborne bacteria in drinking water. Opt. Quantum Electron. 2024, 56, 602. [Google Scholar] [CrossRef]

- Chen, Z.; Fan, X.; Yuan, T.; Chen, W. Compact hybrid silicon nitride and lithium niobate nano-film photoelectronic reversible logic gate. AEU—Int. J. Electron. Commun. 2024, 174, 155076. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef]

- Yang, L.W.; Li, J.H.; Wang, R.J. The research of SiC and Si3N4 whiskers reinforced Si3N4 composites to improve its wear and mechanical properties. Key Eng. Mater. 2011, 474–476, 1881–1886. [Google Scholar] [CrossRef]

- Lu, L.M.; Zuo, K.H.; Zeng, Y.P. Fabrication and properties of surface-modified β-Si3N4 whiskers reinforced dental resin composites. J. Appl. Polym. Sci. 2012, 128, 41–46. [Google Scholar] [CrossRef]

- Han, L.; Wang, J.; Li, F.; Wang, H.; Deng, X.; Zhang, H.; Zhang, S. Low-temperature preparation of Si3N4 whiskers bonded/reinforced SiC porous ceramics via foam-gelcasting combined with catalytic nitridation. J. Eur. Ceram. Soc. 2018, 38, 1210–1218. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, X.; Han, W. Effect of Si3N4 nanowires on the mechanical properties and dielectric constant of porous Si3N4 ceramics. J. Ceram. Soc. Jpn. 2019, 127, 602–605. [Google Scholar] [CrossRef]

- Fan, X.; Sun, R.; Dong, J.; Wei, L.; Wang, Q. Fabrication and thermal shock behavior of Si3N4 whiskers toughened γ-Y2Si2O7 coating on porous Si3N4 ceramics. Ceram. Int. 2020, 46, 21681–21688. [Google Scholar] [CrossRef]

- Chen, F.; Yan, K.; Zhou, J.; Zhu, Y.; Hong, J. High toughness Si3N4 ceramic composites synergistically toughened by multilayer graphene/β-Si3N4 whisker: Preparation and toughening mechanism investigation. J. Alloys Compd. 2022, 921, 166183. [Google Scholar] [CrossRef]

- Xing, Y.; Luo, L.; Li, Y.; Wang, D.; Hu, D.; Li, T.; Zhang, H. Exploration of Hierarchical Metal-Organic Framework as Ultralight, High-Strength Mechanical Metamaterials. J. Am. Chem. Soc. 2022, 144, 4393–4402. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Xing, Y.; Song, X.; Liang, X.; Li, Y.; Lin, X.; Zhang, H.; Shi, Y. Size effect and plastic deformation mechanisms of AlON micro/nanopillars with different crystallographic orientations. J. Eur. Ceram. Soc. 2024, 44, 7695–7703. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. An improved technique for determining hardness and elastic modulus using load and displacement sensing indentation experiments. J. Mater. Res. 1992, 7, 1564–1583. [Google Scholar] [CrossRef]

- Oliver, W.C.; Pharr, G.M. Measurement of hardness and elastic modulus by instrumented indentation: Advances in understanding and refinements to methodology. J. Mater. Res. 2004, 19, 3–20. [Google Scholar] [CrossRef]

- Hou, Z.; Wang, H.; Yang, Y.; Song, X.; Chen, S.; Wan, S.; Zhao, X.; Shang, M.; Chen, B. High-pressure synthesis of high-performance submicron-sized polycrystalline β-Si3N4 bulk without additives. Ceram. Int. 2020, 46, 12449–12457. [Google Scholar] [CrossRef]

- Zhao, M.; Slaughter, W.S.; Li, M.; Mao, S.X. Material-length-scale-controlled nanoindentation size effects due to strain-gradient plasticity. Acta Mater. 2003, 51, 4461–4469. [Google Scholar] [CrossRef]

- Lee, H.; Ko, S.; Han, J.; Park, H.; Hwang, W. Novel analysis for nanoindentation size effect using strain gradient plasticity. Scr. Mater. 2005, 53, 1135–1139. [Google Scholar] [CrossRef]

- Nix, W.D.; Gao, H. Indentation size effects in crystalline materials: A law for strain gradient plasticity. J. Mech. Phys. Solids 1998, 46, 411–425. [Google Scholar] [CrossRef]

- Birnbaum, A.J.; Ryou, H.; Steuben, J.C.; Iliopoulos, A.P.; Wahl, K.J.; Michopoulos, J.G. Nested size effects in the nanoindentation response of additively manufactured 316L stainless steel. Mater. Lett. 2020, 280, 128570. [Google Scholar] [CrossRef]

- Ding, K.; Zhang, Y.; Birnbaum, A.J.; Michopoulos, J.G.; McDowell, D.L.; Zhu, T. Strain gradient plasticity modeling of nanoindentation of additively manufactured stainless steel. Extrem. Mech. Lett. 2021, 49, 101503. [Google Scholar] [CrossRef]

- Parthasarathy, T.A.; Rao, S.I.; Dimiduk, D.M.; Uchic, M.D.; Trinkle, D.R. Contribution to size effect of yield strength from the stochastics of dislocation source lengths in finite samples. Scr. Mater. 2007, 56, 313–316. [Google Scholar] [CrossRef]

- Griffith, A.A. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. A 1921, 221, 163–198. [Google Scholar]

- Weibull, W. A statistical distribution function of wide applicability. J. Appl. Mech. 1951, 18, 293–297. [Google Scholar] [CrossRef]

- Song, F.; Huang, G.L.; Park, H.S.; Liu, X.N. A continuum model for the mechanical behavior of nanowires including surface and surface-induced initial stresses. Int. J. Solids Struct. 2011, 48, 2154–2163. [Google Scholar] [CrossRef]

- Tabib-Azar, M.; Nassirou, M.; Wang, R.; Sharma, S.; Kamins, T.I.; Islam, M.S.; Williams, R.S. Mechanical properties of self-welded silicon nanobridges. Appl. Phys. Lett. 2005, 87, 113102. [Google Scholar] [CrossRef]

- Gordon, M.J.; Baron, T.; Dhalluin, F.; Gentile, P.; Ferret, P. Size effects in mechanical deformation and fracture of cantilevered silicon nanowires. Nano Lett. 2009, 9, 525–529. [Google Scholar] [CrossRef]

- Zhang, T.; Luo, M.L.; Chan, W.K. Size-dependent surface stress, surface stiffness, and Young’s modulus of hexagonal prism [111] β-SiC nanowires. J. Appl. Phys. 2008, 103, 104308. [Google Scholar] [CrossRef]

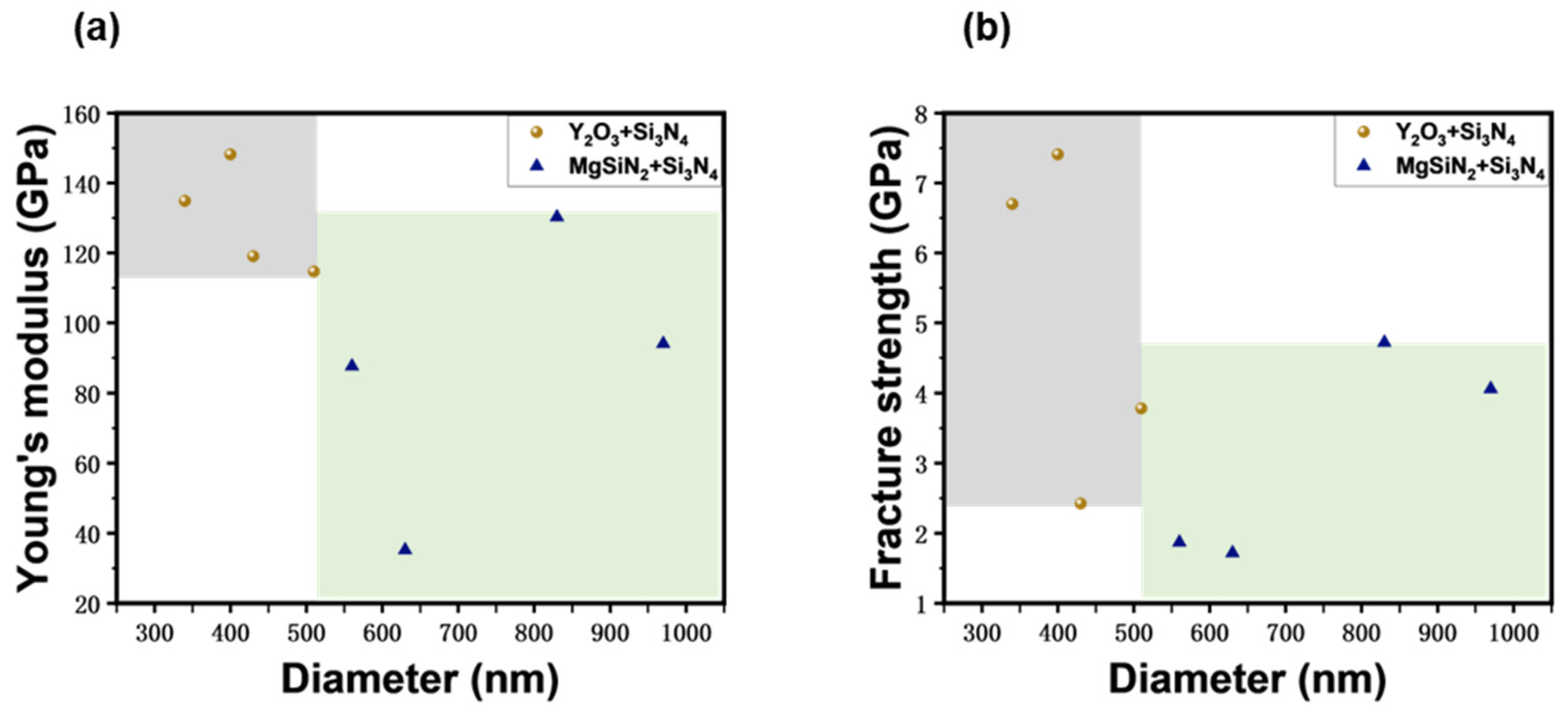

| Diameter (nm) | Young’s Modulus (GPa) | Fracture Strength (GPa) | Fracture Strain | Sintering Aid | |

|---|---|---|---|---|---|

| 1 | 340 | 134.89 | 6.7 | 0.05 | Y2O3 |

| 2 | 400 | 148.18 | 7.41 | 0.05 | Y2O3 |

| 3 | 430 | 119.073 | 2.422 | 0.02 | Y2O3 |

| 4 | 510 | 114.72 | 3.78 | 0.033 | Y2O3 |

| 5 | 560 | 87.66 | 1.87 | 0.021 | MgSiN2 |

| 6 | 630 | 35.23 | 1.72 | 0.049 | MgSiN2 |

| 7 | 830 | 130.29 | 4.56 | 0.035 | MgSiN2 |

| 8 | 970 | 94.05 | 4.06 | 0.043 | MgSiN2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, B.; Bai, T.; Wang, W.; Zhang, H. Mechanical Properties of Silicon Nitride in Different Morphologies: In Situ Experimental Analysis of Bulk and Whisker Structures. Materials 2024, 17, 4549. https://doi.org/10.3390/ma17184549

Wang B, Bai T, Wang W, Zhang H. Mechanical Properties of Silicon Nitride in Different Morphologies: In Situ Experimental Analysis of Bulk and Whisker Structures. Materials. 2024; 17(18):4549. https://doi.org/10.3390/ma17184549

Chicago/Turabian StyleWang, Bokang, Tanglong Bai, Weide Wang, and Hongti Zhang. 2024. "Mechanical Properties of Silicon Nitride in Different Morphologies: In Situ Experimental Analysis of Bulk and Whisker Structures" Materials 17, no. 18: 4549. https://doi.org/10.3390/ma17184549

APA StyleWang, B., Bai, T., Wang, W., & Zhang, H. (2024). Mechanical Properties of Silicon Nitride in Different Morphologies: In Situ Experimental Analysis of Bulk and Whisker Structures. Materials, 17(18), 4549. https://doi.org/10.3390/ma17184549