Self-Healing Composites: A Path to Redefining Material Resilience—A Comprehensive Recent Review

Abstract

:1. Introduction

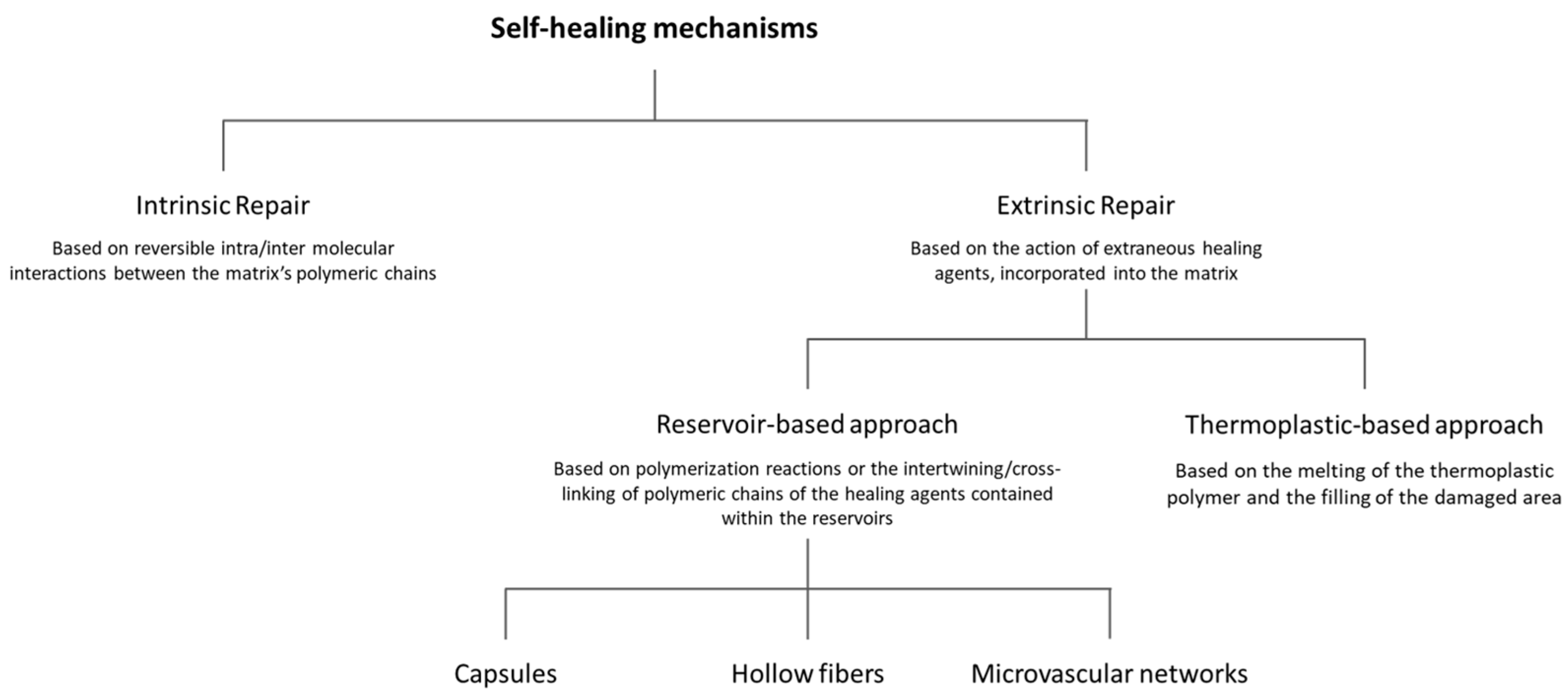

2. Approaches to Self-Healing

2.1. Healing Efficiency

2.2. Self-Healing through Reservoirs

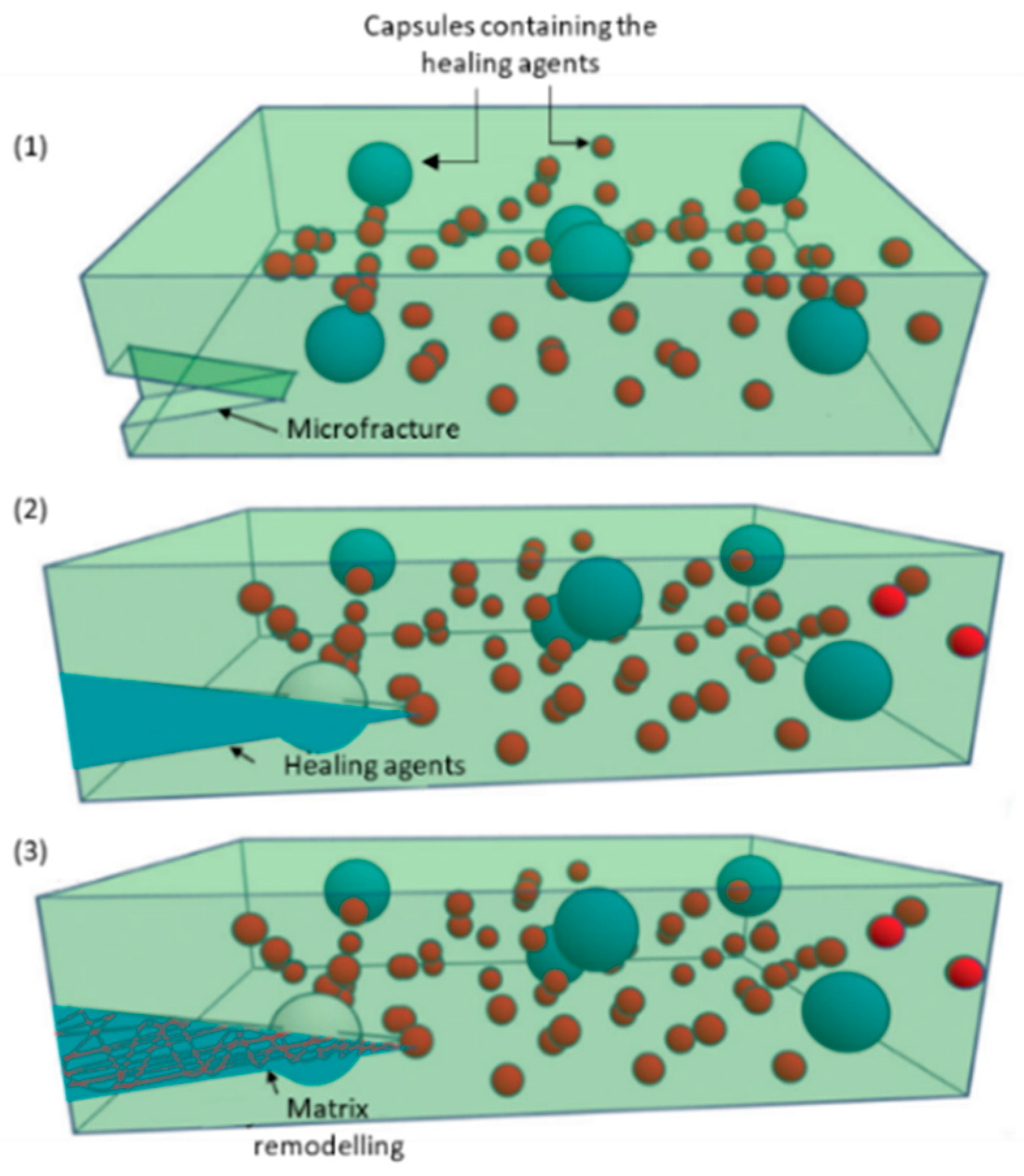

2.2.1. Capsules

| Composite | Healing Agents | Healing Conditions | Healing Efficiency | Other Notable Findings | Reference |

|---|---|---|---|---|---|

| Epoxy matrix composite | Two types of microcapsules containing: - Same polymer as the matrix (12 wt%) - Amine curing agent (8 wt%) | 24 h at room temperature, followed by 6 h at 50 °C | 80.4% (Fracture toughness) | H. Hu et al. [36] | |

| Epoxy matrix composite | Two types of microcapsules containing: - Styrene (15 wt%) - Benzoyl peroxide (3 wt%) | 24 h at 25 °C | 65% (Impact tests) | Multi-repairability reduced efficiency by 20% to 30% after second and third repairs | C. Y. Zhang et al. [37] |

| Epoxy matrix composite | - Microcapsules containing: monomers of 5-ethylidene-2-norbornene with multi-walled carbon nanotubes (10 wt%) - Matrix dispersed Ruthenium Grubbs catalyst | 48 h at room temperature | 97% (Fracture toughness) | Carbon nanotubes improved healing efficiency | H. H. Zamal et al. [38] |

| Epoxy matrix composite | Microcapsules containing epoxy resin inside and curing initiator catalyst (Scandium triflate (III)) on the outer surface (20 wt%) | 24 h at 120 °C | 79.1% (Fracture toughness) | Microcapsule structure improved reaction probability between resin and catalyst | R. Rodriguez et al. [39] |

| Epoxy-based foams | Multi-core-like bilayer calcium-alginate capsules (15% vol.) containing: - Epoxy resin on the inner core - Curing agent on the outer core | >80% in the first cycle (Elastic modulus) | Multi-core capsules provided a better mixing of the healing agents, increasing performance | Shunze Cao et al. [23] | |

| Carbon fiber/epoxy composite | Microcapsules containing an epoxy resin-solvent solution | 24 h at room temperature | 91% (Interfacial shear strength) | Usage of a binder stabilized the microcapsules on the fibers’ surface | Amanda R. Jones et al. [41] |

| Polymer matrix with carbon fibers | - Microcapsules containing an epoxy resin, mercaptan (15 wt%) - Modified silver nanoparticles on the surface of the reinforcing fibers | 24 h at room temperature | 80% (Fracture toughness) 74% (Interface shear strength) | Coordination bond between mercaptan and silver nanoparticles regenerated fiber/matrix interface | Wrihao Yuan et al. [42] |

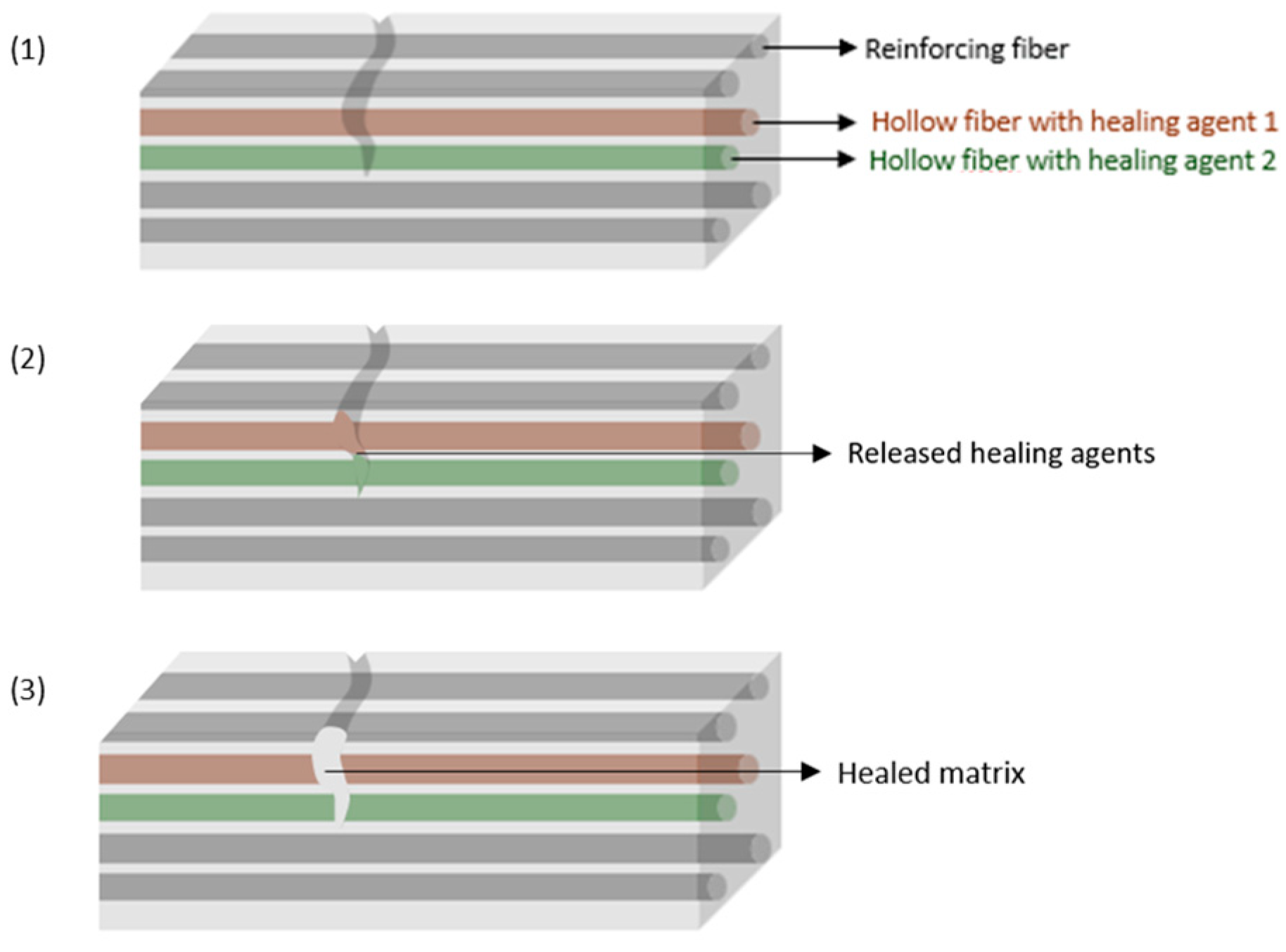

2.2.2. Hollow Fibers

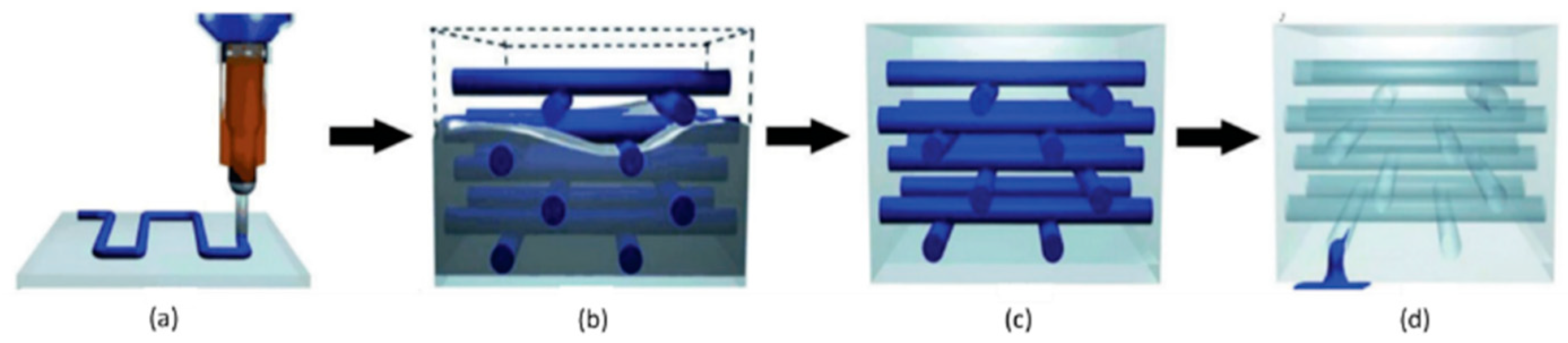

2.2.3. Microvascular Networks

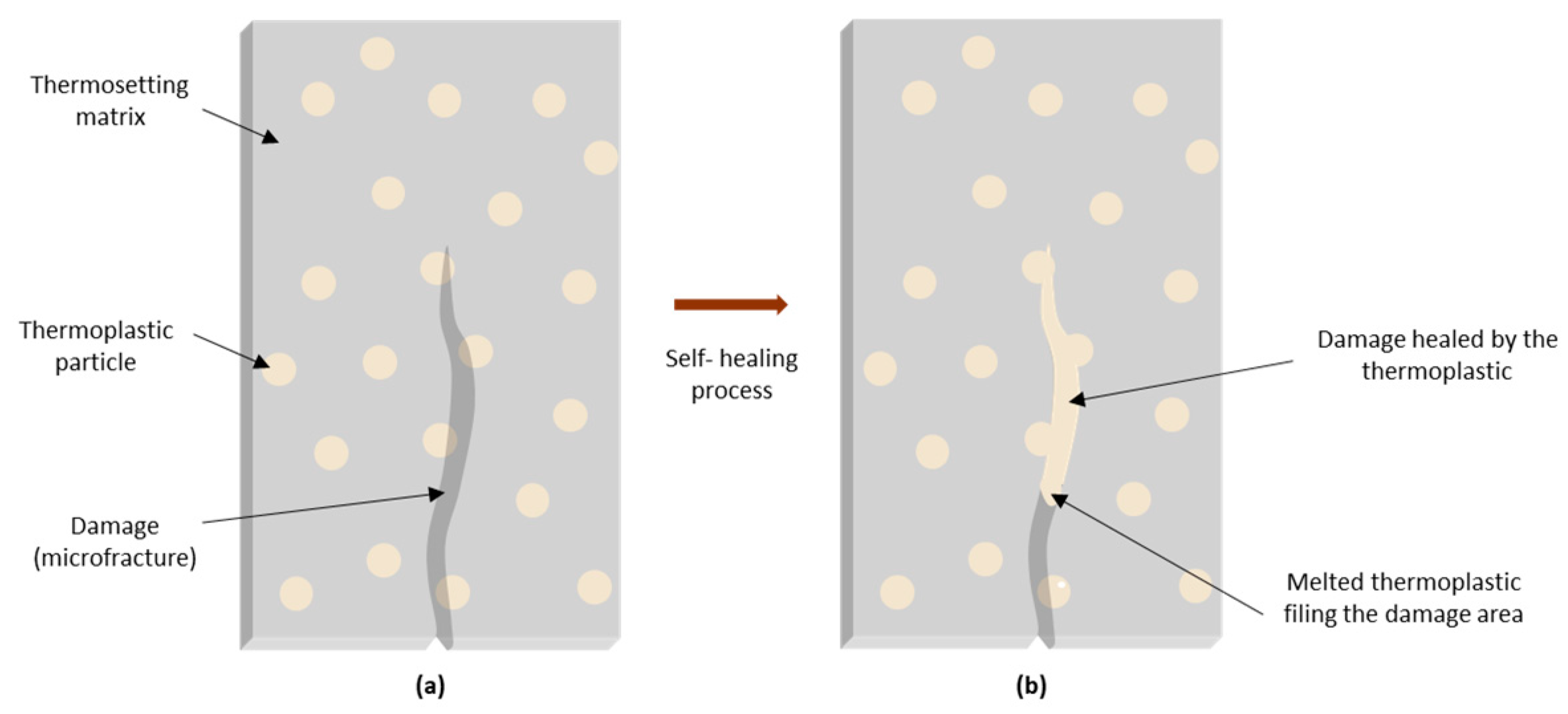

2.3. Self-Healing through Thermoplastic Polymers

3. Applications

4. Challenges, Opportunities and Future Prospects

5. Conclusions

- Two general approaches exist for preparing self-healing composites, namely, through the incorporation of either reservoirs containing the healing agents or thermoplastics.

- Among the reservoir-based approaches, capsules are the most extensively investigated due to their ease of application and the fact that they are the focus of groundbreaking research aimed at increasing their efficiency.

- Hollow fibers and microvascular networks are emerging as promising options due to their wider coverage of the materials’ volume and the ability to be refilled. Such reservoirs are also under intense study, with alternatives emerging to facilitate their integration into the composites’ structure.

- Thermoplastics have also been widely explored, particularly considering their theoretically unlimited healing cycles. However, research is committed to developing alternative polymer melting mechanisms that allow for the complete independence of the healing process.

- Globally, all the methods tend to jeopardize mechanical properties, requiring a balance between this loss and the self-healing ability.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Islam, S.; Bhat, G. Progress and Challenges in Self-Healing Composite Materials. Mater. Adv. 2021, 2, 1896–1926. [Google Scholar] [CrossRef]

- Priyadarsini, M.; Rekha Sahoo, D.; Biswal, T. A New Generation Self-Healing Composite Materials. Mater. Today Proc. 2021, 47, 1229–1233. [Google Scholar] [CrossRef]

- Mercy, J.L.; Prakash, S. Self Healing Composite Materials: A Review. Int. J. ChemTech Res. 2016, 9, 316–324. [Google Scholar]

- Cioffi, M.O.H.; Bomfim, A.S.C.; Ambrogi, V.; Advani, S.G. A Review on Self-healing Polymers and Polymer Composites for Structural Applications. Polym. Compos. 2022, 43, 7643–7668. [Google Scholar] [CrossRef]

- Zhang, Z.P.; Rong, M.Z.; Zhang, M.Q. Self-Healable Functional Polymers and Polymer-Based Composites. Progress Polym. Sci. 2023, 144, 101724. [Google Scholar] [CrossRef]

- Nik Md Noordin Kahar, N.N.F.; Osman, A.F.; Alosime, E.; Arsat, N.; Mohammad Azman, N.A.; Syamsir, A.; Itam, Z.; Abdul Hamid, Z.A. The Versatility of Polymeric Materials as Self-Healing Agents for Various Types of Applications: A Review. Polymers 2021, 13, 1194. [Google Scholar] [CrossRef]

- Kausar, A. Self-Healing Polymer/Carbon Nanotube Nanocomposite: A Review. J. Plast. Film Sheeting 2021, 37, 160–181. [Google Scholar] [CrossRef]

- Vintila, I.S.; Badea, T.; Draghici, S.; Petrescu, H.A.; Cucuruz, A.; Iovu, H.; Hadar, A. Mechanical Characterization of DCPD and ENB Healing Systems in Glass Fibre Composites. Mater. Plast. 2020, 57, 278–289. [Google Scholar] [CrossRef]

- Srinivas, M.; Yelamasetti, B.; Vishnu Vardhan, T.; Mohammed, R. A Critical Review on Self-Healing Composites. Mater. Today Proc. 2021, 46, 890–895. [Google Scholar] [CrossRef]

- Ahmed, A.; Ali, A.; Alzahrani, B.; Sanada, K. Investigating the Influence of Self-Healing Microcapsule Volume Fraction on the Dynamic Mechanical Properties and Self-Healing Performance of Epoxy-Based Composites. J. Polym. Res. 2024, 31, 201. [Google Scholar] [CrossRef]

- Jadoun, S. Synthesis, Mechanism, and Applications of Self-Healing Materials. Biomed. Mater. Devices 2024, 2, 225–240. [Google Scholar] [CrossRef]

- Guadagno, L.; Raimondo, M.; Naddeo, C.; Longo, P. Application of Self-Healing Materials in Aerospace Engineering. In Self-Healing Polymers; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2013; pp. 401–412. ISBN 978-3-527-67018-5. [Google Scholar]

- Zamal, H.H.; Barba, D.; Aïssa, B.; Haddad, E.; Rosei, F. Recovery of Electro-Mechanical Properties inside Self-Healing Composites through Microencapsulation of Carbon Nanotubes. Sci. Rep. 2020, 10, 2973. [Google Scholar] [CrossRef] [PubMed]

- Rb, J.R.; M, J.A.; D, R.; A, S.; Kennedy, S.M. A Complete Overview of Self-Healing Composites Including Its Models in Aeronautical Systems. Polym.-Plast. Technol. Mater. 2024, 63, 1143–1174. [Google Scholar] [CrossRef]

- Kontiza, A.; Kartsonakis, I.A. Smart Composite Materials with Self-Healing Properties: A Review on Design and Applications. Polymers 2024, 16, 2115. [Google Scholar] [CrossRef]

- Pandey, S.K.; Mishra, S.; Ghosh, S.; Rohan, R.; Maji, P.K. Self-Healing Polymers for Aviation Applications and Their Impact on Circular Economy. Polym. Eng. Sci. 2024, 64, 951–987. [Google Scholar] [CrossRef]

- Garcia, S.J. Effect of Polymer Architecture on the Intrinsic Self-Healing Character of Polymers. Eur. Polym. J. 2014, 53, 118–125. [Google Scholar] [CrossRef]

- Self-Healing Materials Market-Global Industry Analysis and Forecast (2022–2029)-by Product Type, Technology, Application, and Region. Maximize Market Research. Available online: www.maximizemarketresearch.com/market-report/global-self-healing-materials-market/65964/ (accessed on 20 December 2023).

- Kanu, N.J.; Gupta, E.; Vates, U.K.; Singh, G.K. Self-Healing Composites: A State-of-the-Art Review. Compos. Part A Appl. Sci. Manuf. 2019, 121, 474–486. [Google Scholar] [CrossRef]

- Kadam, S.; Chavan, S.; Kanu, N.J. An Insight into Advance Self-Healing Composites. Mater. Res. Express 2021, 8, 052001. [Google Scholar] [CrossRef]

- Song, M.-M.; Wang, Y.-M.; Liang, X.-Y.; Zhang, X.-Q.; Zhang, S.; Li, B.-J. Functional Materials with Self-Healing Properties: A Review. Soft Matter 2019, 15, 6615–6625. [Google Scholar] [CrossRef]

- Je, P.C.; Sultan, M.T.; Selvan, C.P.; Irulappasamy, S.; Mustapha, F.; Basri, A.A.; Safri, S.N.A. Manufacturing Challenges in Self-Healing Technology for Polymer Composites—A Review. J. Mater. Res. Technol. 2020, 9, 7370–7379. [Google Scholar] [CrossRef]

- Cao, S.; Zhu, W.; Liu, T. Bio-Inspired Self-Healing Polymer Foams with Bilayered Capsule Systems. Compos. Sci. Technol. 2020, 195, 108189. [Google Scholar] [CrossRef]

- Ghorbanpour Arani, A.; Miralaei, N.; Farazin, A.; Mohammadimehr, M. An Extensive Review of the Repair Behavior of Smart Self-Healing Polymer Matrix Composites. J. Mater. Res. 2023, 38, 617–632. [Google Scholar] [CrossRef]

- Kosarli, M.; Bekas, D.G.; Tsirka, K.; Baltzis, D.; Vaimakis-Tsogkas, D.Τ.; Orfanidis, S.; Papavassiliou, G.; Paipetis, A.S. Microcapsule-Based Self-Healing Materials: Healing Efficiency and Toughness Reduction vs. Capsule Size. Compos. Part B Eng. 2019, 171, 78–86. [Google Scholar] [CrossRef]

- Xue, Y.; Li, C.; Liu, J.; Tan, J.; Su, Z.; Yang, Y.; Zhang, G.; Zhang, Q. Fabrication and Characterization of Hierarchical Microcapsules with Multi-Storage Cells for Repeatable Self-Healing. Colloids Surf. A Physicochem. Eng. Asp. 2020, 603, 125201. [Google Scholar] [CrossRef]

- Scheiner, M.; Dickens, T.J.; Okoli, O. Progress towards Self-Healing Polymers for Composite Structural Applications. Polymer 2016, 83, 260–282. [Google Scholar] [CrossRef]

- Mauldin, T.C.; Kessler, M.R. Self-Healing Polymers and Composites. Int. Mater. Rev. 2010, 55, 317–346. [Google Scholar] [CrossRef]

- Wang, J.; Tang, J.; Chen, D.; Xing, S.; Liu, X.; Hao, J. Intrinsic and Extrinsic Self-healing Fiber-reinforced Polymer Composites: A Review. Polym. Compos. 2023, 44, 6304–6323. [Google Scholar] [CrossRef]

- Fifo, O.; Ryan, K.; Basu, B. Glass Fibre Polyester Composite with in Vivo Vascular Channel for Use in Self-Healing. Smart Mater. Struct. 2014, 23, 095017. [Google Scholar] [CrossRef]

- Jones, A.R.; Watkins, C.A.; White, S.R.; Sottos, N.R. Self-Healing Thermoplastic-Toughened Epoxy. Polymer 2015, 74, 254–261. [Google Scholar] [CrossRef]

- Radovic, I.; Stajcic, A.; Radisavljevic, A.; Veljkovic, F.; Cebela, M.; Mitic, V.V.; Radojevic, V. Solvent Effects on Structural Changes in Self-Healing Epoxy Composites. Mater. Chem. Phys. 2020, 256, 123761. [Google Scholar] [CrossRef]

- Wu, X.; Zhang, Y.; Chen, H.; Zhang, L.; Xie, G. Solvent Effect of Microcapsules Endows Self-Lubricating Polymer Composites with Wear in-Situ Self-Healing Function. Colloids Surf. A Physicochem. Eng. Asp. 2023, 676, 132158. [Google Scholar] [CrossRef]

- Icduygu, M.G.; Asilturk, M.; Altan, M.C. Microcapsules of Poly(Methyl Metharcylate) Containing Epoxy Resin and Multi-Walled Carbon Nanotubes. AIP Conf. Proc. 2017, 1914, 030017. [Google Scholar]

- Caruso, M.M.; Schelkopf, S.R.; Jackson, A.C.; Landry, A.M.; Braun, P.V.; Moore, J.S. Microcapsules Containing Suspensions of Carbon Nanotubes. J. Mater. Chem. 2009, 19, 6093–6096. [Google Scholar] [CrossRef]

- Hu, H.; Zhang, L.; Yu, R.; Yuan, L.; Yang, Y.; He, X.; Wang, J.; Li, Z. Microencapsulation of Ethylenediamine and Its Application in Binary Self-Healing System Using Dual-Microcapsule. Mater. Des. 2020, 189, 108535. [Google Scholar] [CrossRef]

- Zhang, C.Y.; Jiang, X.B.; Rong, M.Z.; Zhang, M.Q. Free Radical Polymerization Aided Self-Healing. J. Intell. Mater. Syst. Struct. 2014, 25, 31–39. [Google Scholar] [CrossRef]

- Zamal, H.H.; Barba, D.; Aïssa, B.; Haddad, E.; Rosei, F. Failure Analysis of Self-Healing Epoxy Resins Using Microencapsulated 5E2N and Carbon Nanotubes. Smart Mater. Struct. 2021, 30, 025011. [Google Scholar] [CrossRef]

- Rodriguez, R.; Bekas, D.G.; Flórez, S.; Kosarli, M.; Paipetis, A.S. Development of Self-Contained Microcapsules for Optimised Catalyst Position in Self-Healing Materials. Polymer 2020, 187, 122084. [Google Scholar] [CrossRef]

- Quadrini, F.; Bellisario, D.; Iorio, L.; Santo, L.; Pappas, P.; Koutroumanis, N.; Anagnostopoulos, G.; Galiotis, C. Shape Memory Composite Sandwich Structures with Self-Healing Properties. Polymers 2021, 13, 3056. [Google Scholar] [CrossRef]

- Jones, A.R.; Cintora, A.; White, S.R.; Sottos, N.R. Autonomic Healing of Carbon Fiber/Epoxy Interfaces. ACS Appl. Mater. Interfaces 2014, 6, 6033–6039. [Google Scholar] [CrossRef]

- Yuan, W.; Zhang, Z.; Li, Y.; Huang, Y.; Zhong, Z.; Hu, Z. Self-Healing and in-Situ Real-Time Damage-Reporting Fiber-Reinforced Composite. Compos. Sci. Technol. 2024, 245, 110344. [Google Scholar] [CrossRef]

- Gao, C.; Ruan, H.; Yang, C.; Wang, F. Investigation on Microcapsule Self-Healing Mechanism of Polymer Matrix Composites Based on Numerical Simulation. Polym. Compos. 2021, 42, 3619–3631. [Google Scholar] [CrossRef]

- Wang, X.; Ding, T. A Review on the Current State of Microcapsule-Based Self-Healing Dental Composites. J. Funct. Biomater. 2024, 15, 165. [Google Scholar] [CrossRef] [PubMed]

- Li, C.; Tan, J.; Liu, Y.; Zhang, B.; Fan, X.; Zhang, Q. Facile Fabrication of Multihollow Polymer Microspheres via Novel Two-Step Assembly of P(St-Co-nBA-Co-AA) Particles. Colloid. Polym. Sci. 2015, 293, 993–1001. [Google Scholar] [CrossRef]

- Mookhoek, S.D.; Blaiszik, B.J.; Fischer, H.R.; Sottos, N.R.; White, S.R.; Zwaag, S. van der Peripherally Decorated Binary Microcapsules Containing Two Liquids. J. Mater. Chem. 2008, 18, 5390–5394. [Google Scholar] [CrossRef]

- Wang, R.; Hu, H.; Liu, W.; He, X.; Guo, Q. The Effect of Synthesis Condition on Physical Properties of Epoxy-containing Microcapsules. J. Appl. Polym. Sci. 2012, 124, 1866–1879. [Google Scholar] [CrossRef]

- Hia, I.L.; Pasbakhsh, P.; Chan, E.-S.; Chai, S.-P. Electrosprayed Multi-Core Alginate Microcapsules as Novel Self-Healing Containers. Sci. Rep. 2016, 6, 34674. [Google Scholar] [CrossRef]

- Gan, S.N.; Shahabudin, N.; Gan, S.N.; Shahabudin, N. Applications of Microcapsules in Self-Healing Polymeric Materials. In Microencapsulation—Processes, Technologies and Industrial Applications; IntechOpen: London, UK, 2019; ISBN 978-1-83881-870-8. [Google Scholar]

- Ning, K.; Loomans, B.; Yeung, C.; Li, J.; Yang, F.; Leeuwenburgh, S. Influence of Microcapsule Parameters and Initiator Concentration on the Self-Healing Capacity of Resin-Based Dental Composites. Dent. Mater. 2021, 37, 403–412. [Google Scholar] [CrossRef]

- Adli, A.; Shelesh-Nezhad, K.; Khoshravan Azar, M.; Mohammadi-Aghdam, M. The Effect of Vascular Self-Healing Pattern on Mechanical Behaviour and Healing Performance of Epoxy/Glass Composite. Plast. Rubber Compos. 2020, 49, 79–90. [Google Scholar] [CrossRef]

- Kling, S.; Czigány, T. Damage Detection and Self-Repair in Hollow Glass Fiber Fabric-Reinforced Epoxy Composites via Fiber Filling. Compos. Sci. Technol. 2014, 99, 82–88. [Google Scholar] [CrossRef]

- Sadeghi, S.A.M.; Borhani, S.; Zadhoush, A.; Dinari, M. Self-healing Performance of Hybrid Core-shell Nanofibers Mat Containing Epoxy-mercaptan at Subroom Temperature. Polym. Compos. 2021, 42, 2422–2431. [Google Scholar] [CrossRef]

- Zhu, Y.; Ye, X.J.; Rong, M.Z.; Zhang, M.Q. Self-Healing Glass Fiber/Epoxy Composites with Polypropylene Tubes Containing Self-Pressurized Epoxy and Mercaptan Healing Agents. Compos. Sci. Technol. 2016, 135, 146–152. [Google Scholar] [CrossRef]

- Mohammadi, M.A.; Eslami-Farsani, R.; Ebrahimnezhad-Khaljiri, H. Experimental Investigation of the Healing Properties of the Microvascular Channels-Based Self-Healing Glass Fibers/Epoxy Composites Containing the Three-Part Healant. Polym. Test. 2020, 91, 106862. [Google Scholar] [CrossRef]

- Patrick, J.F.; Hart, K.R.; Krull, B.P.; Diesendruck, C.E.; Moore, J.S.; White, S.R.; Sottos, N.R. Continuous Self-Healing Life Cycle in Vascularized Structural Composites. Adv. Mater. 2014, 26, 4302–4308. [Google Scholar] [CrossRef] [PubMed]

- Hansen, C.J.; Wu, W.; Toohey, K.S.; Sottos, N.R.; White, S.R.; Lewis, J.A. Self-Healing Materials with Interpenetrating Microvascular Networks. Adv. Mater. 2009, 21, 4143–4147. [Google Scholar] [CrossRef]

- Eslami-Farsani, R.; Khalili, S.M.R.; Khademoltoliati, A.; Saeedi, A. Tensile and Creep Behavior of Microvascular Based Self-Healing Composites: Experimental Study. Mech. Adv. Mater. Struct. 2021, 28, 384–390. [Google Scholar] [CrossRef]

- Amano, R.S.; Lewinski, G.; Shen, R. Imprinted Glass Fiber-Reinforced Polymer Vascular Networks for Creating Self-Healing Wind Turbine Blades. J. Energy Resour. Technol. 2022, 144, 062107. [Google Scholar] [CrossRef]

- Lee, M.W. Prospects and Future Directions of Self-Healing Fiber-Reinforced Composite Materials. Polymers 2020, 12, 379. [Google Scholar] [CrossRef]

- Meure, S.; Wu, D.Y.; Furman, S. Polyethylene-Co-Methacrylic Acid Healing Agents for Mendable Epoxy Resins. Acta Mater. 2009, 57, 4312–4320. [Google Scholar] [CrossRef]

- Ladani, R.B.; Pingkarawat, K.; Nguyen, A.T.T.; Wang, C.H.; Mouritz, A.P. Delamination Toughening and Healing Performance of Woven Composites with Hybrid Z-Fibre Reinforcement. Compos. Part A Appl. Sci. Manuf. 2018, 110, 258–267. [Google Scholar] [CrossRef]

- Peñas-Caballero, M.; Chemello, E.; Grande, A.M.; Hernández Santana, M.; Verdejo, R.; Lopez-Manchado, M.A. Poly(Methyl Methacrylate) as Healing Agent for Carbon Fibre Reinforced Epoxy Composites. Polymers 2023, 15, 1114. [Google Scholar] [CrossRef]

- Azevedo Do Nascimento, A.; Fernandez, F.; Da Silva, F.S.; Ferreira, E.P.C.; Melo, J.D.D.; Cysne Barbosa, A.P. Addition of Poly (Ethylene-Co-Methacrylic Acid) (EMAA) as Self-Healing Agent to Carbon-Epoxy Composites. Compos. Part A Appl. Sci. Manuf. 2020, 137, 106016. [Google Scholar] [CrossRef]

- Chen, B.; Cai, H.; Mao, C.; Gan, Y.; Wei, Y. Toughening and Rapid Self-healing for Carbon Fiber/Epoxy Composites Based on Electrospinning Thermoplastic Polyamide Nanofiber. Polym. Compos. 2022, 43, 3124–3135. [Google Scholar] [CrossRef]

- Ladani, R.B.; Nguyen, A.T.T.; Wang, C.H.; Mouritz, A.P. Mode II Interlaminar Delamination Resistance and Healing Performance of 3D Composites with Hybrid Z-Fibre Reinforcement. Compos. Part A Appl. Sci. Manuf. 2019, 120, 21–32. [Google Scholar] [CrossRef]

- Chang, K.M.; Sottos, N.R. Self-Healing of Transverse Crack Damage in Carbon Fiber Composites. Compos. Sci. Technol. 2023, 242, 110158. [Google Scholar] [CrossRef]

- European Space Agency Develops Self-Healing Materials. Assem. Autom. 2006, 26. [CrossRef]

- Srivastava, A.; Usha, P.; Al-Alawachi, S.F.A.; Kansal, L.; Koithyar, A.; Arora, D. Self-Healing Materials: Mechanisms, Characterization, and Applications: A Detailed Review. E3S Web Conf. 2024, 505, 01019. [Google Scholar] [CrossRef]

- Saini, S.; Jain, D. The Effect of Healing Time on the Self-Healing Efficiency of Carbon Fibre Reinforced Polymer Composites. Mater. Today Proc. 2017, 4, 2903–2909. [Google Scholar] [CrossRef]

- Everitt, D.T.; Luterbacher, R.; Coope, T.S.; Trask, R.S.; Wass, D.F.; Bond, I.P. Optimisation of Epoxy Blends for Use in Extrinsic Self-Healing Fibre-Reinforced Composites. Polymer 2015, 69, 283–292. [Google Scholar] [CrossRef]

- Hia, I.L.; Vahedi, V.; Pasbakhsh, P. Self-Healing Polymer Composites: Prospects, Challenges, and Applications. Polym. Rev. 2016, 56, 225–261. [Google Scholar] [CrossRef]

- Wang, Y.; Pham, D.T.; Ji, C. Self-Healing Composites: A Review. Cogent Eng. 2015, 2, 1075686. [Google Scholar] [CrossRef]

- Pernigoni, L.; Lafont, U.; Grande, A.M. Self-Healing Materials for Space Applications: Overview of Present Development and Major Limitations. CEAS Space J. 2021, 13, 341–352. [Google Scholar] [CrossRef]

- Feng, H.; Yu, F.; Zhou, Y.; Li, M.; Xiao, L.; Ao, Y. Fabrication of Microcapsule-Type Composites with the Capability of Underwater Self-Healing and Damage Visualization. RSC Adv. 2020, 10, 33675–33682. [Google Scholar] [CrossRef] [PubMed]

| Composite | Healing Agents | Healing Conditions | Healing Efficiency | Other Notable Findings | Reference |

|---|---|---|---|---|---|

| Epoxy resin matrix with glass fibers | Two types of glass fibers containing: - Epoxy resin - Amine curing agent | 48 h at 70 °C | 42% (Tensile strength) | Smaller fiber distances and angled fibers (45° increased efficiency | A. Adili et al. [51] |

| Epoxy resin matrix with glass fibers | Two types of glass fibers containing: - Unsaturated polyester resin - Methyl ethyl ketone peroxide initiator, dissolved in dimethyl phthalate | 120 h at 23 °C | S. Kling [52] | ||

| Epoxy resin matrix with hollow fibers | Two types of hollow fibers containing: - Dicyclopentadiene, dissolved in N, N′-dimethylformamide - First-gen Grubbs catalyst dissolved in toluene | 24 h at 25 °C | 53%, (Impact tests) | Filled fibers acted as reinforcing agents | I. Radovic et al. [32] |

| Epoxy matrix composite | Core–shell nanofibers mat containing: - Epoxy resin - Mercaptan-based hardener | 200 min at 10 °C | The material was able to self-heal and restore flexural modulus and strength | Good adhesion between matrix and nanofiber mat | S. A. M. Sadeghi et al. [53] |

| Epoxy composite with glass fibers and polypropylene (PP) tubes | PP tubes containing: - Epoxy resin - Thiol and amine mixture + foaming agent | 93% (Flexural strength) | PP tubes contributed to overcome filling difficulties. PP tubes were UV - irradiated to break upon damage | Y. Zhu et al. [54] |

| Composite | Healing Agents | Healing Conditions | Healing Efficiency | Other Notable Findings | Reference |

|---|---|---|---|---|---|

| Epoxy resin matrix with glass fibers | Two subnetworks containing: - Epoxy resin - Curing agent | 7 days at ambient conditions | 89% (Tensile strength) | Microvascular network reduces tensile strength but could be improved with a more rigid material | R. Eslami-Farsani et al. [58] |

| Epoxy resin matrix with glass fibers | Network filled with dicyclopentadiene Matrix dispersed Grubbs catalyst | Nearly doubled strength after recovery (Three-point bending test) | Hexagonal grid favors healing agent access | R. S. Amano et al. [59] | |

| Polyester matrix with glass fibers | Two-dimensional vascular network containing single-part cyanoacrylate adhesive | 24 h at ambient conditions | 84% (Flexural stiffness) 46% (Loading strength) | Channels located in mid-plane for dual-surface damage access | O. Fifo et al. [30] |

| Epoxy matrix with fiber reinforcement | Network containing: -Epoxy resin - Amine-based curing agent (low viscosity) | 48 h at 30 °C | Over 100% due to higher fracture toughness of healed polymer | Two patterns (parallel and herringbone) analyzed: herringbone pattern showed better efficiency and toughness; Three successive healing cycles increased load resistance | J. F. Patrick et al. [56] |

| Composite | Healing Agents | Healing Conditions | Healing Efficiency | Other Notable Findings | Reference |

|---|---|---|---|---|---|

| Epoxy matrix with carbon fiber reinforcement | Poly(ethylene-co-methacrylic acid) microparticles (5 wt%) | 150 °C for 30 min | Complete recovery of interlaminar shear strength | Slight increase in glass transition temperature but decrease in interlaminar shear strength and storage modulus | A. Azevedo et al. [64] |

| Epoxy matrix with carbon fiber reinforcement | Poly(methyl methacrylate) (20 wt%) | 150 °C for 120 min | 53% (Fracture toughness) | Softening and flow of polymer drives healing; Zinc acetate catalyst enhances interface adhesion but reduces mechanical properties | M. Peñas-Caballero et al. [63] |

| Epoxy matrix with carbon fiber reinforcement | Electrospun polyamine nanofibers (1.2 wt%) | 130 °C for 20 min (3 cycles | 110.44% (Interlaminar shear strength recovery for first cycle) | Improved interfacial adhesion and bending properties without affecting storage modulus or glass transition temperature | B. Chen et al. [65] |

| Epoxy matrix with carbon fiber reinforcement | Through-the-thickness Z-binders: - Carbon fiber - Poly(ethylene-co-methacrylic acid)) | 150 °C for 30 min | 35–40% (Mode I fracture toughness) 25% (Mode II fracture toughness) | Hybrid composite improves mode I and II fracture toughness (1200% and 75%, respectively) | R. B. Ladani et al. [62,66] |

| Epoxy matrix with carbon fiber reinforcement | Matrix dispersed poly(bisphenol A-co-epichlorohydrin) resin-encapsulated solvent | 57% (Tensile tests) | No significant differences between solvent-based and temperature-based methods for healing | K. M. Chang [67] |

| Self-Healing Mechanism | Pros | Cons |

|---|---|---|

| Capsules | - Simple and well-studied - Effective for small, localized damage | - Typically one-time healing only - Limited healing agent storage - Distribution and uniformity of capsules can be uneven, limiting efficiency - Presence of empty microcapsules after damage can compromise material’s integrity |

| Hollow fibers | - Larger storage capacity for healing agents compared to capsules - Can provide healing over a larger area - Controlled release of healing agents upon fiber rupture | - Still tendentially a one-time healing system - Fibers may compromise materials’ structural integrity - Difficult to repair fibers once damaged, limiting repeated healing |

| Microvascular Networks | - Continuous supply of healing agents, allowing for multiple healing events - Can provide healing to larger, more complex areas - More durable than capsules or fibers | - Complex fabrication and integration into composite materials - Prone to clogging or blockage, which can disrupt the healing mechanism - Potential for pressure build-up within the network, causing system failure |

| Thermoplastics | - Simple to implement - Reversible - Multiple healing events possible | - Often requires external stimuli (like heat) to trigger healing - Healing may not be as effective at the nanoscale or for severe damage |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Durão, M.L.; Nobre, L.; Mota, C.; Bessa, J.; Cunha, F.; Fangueiro, R. Self-Healing Composites: A Path to Redefining Material Resilience—A Comprehensive Recent Review. Materials 2024, 17, 4681. https://doi.org/10.3390/ma17194681

Durão ML, Nobre L, Mota C, Bessa J, Cunha F, Fangueiro R. Self-Healing Composites: A Path to Redefining Material Resilience—A Comprehensive Recent Review. Materials. 2024; 17(19):4681. https://doi.org/10.3390/ma17194681

Chicago/Turabian StyleDurão, Maria Luísa, Luís Nobre, Carlos Mota, João Bessa, Fernando Cunha, and Raúl Fangueiro. 2024. "Self-Healing Composites: A Path to Redefining Material Resilience—A Comprehensive Recent Review" Materials 17, no. 19: 4681. https://doi.org/10.3390/ma17194681

APA StyleDurão, M. L., Nobre, L., Mota, C., Bessa, J., Cunha, F., & Fangueiro, R. (2024). Self-Healing Composites: A Path to Redefining Material Resilience—A Comprehensive Recent Review. Materials, 17(19), 4681. https://doi.org/10.3390/ma17194681