Mechanical Behavior of Oxide Dispersion Strengthened Steel Directly Consolidated by Rotary Swaging

Abstract

:1. Introduction

2. Materials and Methods

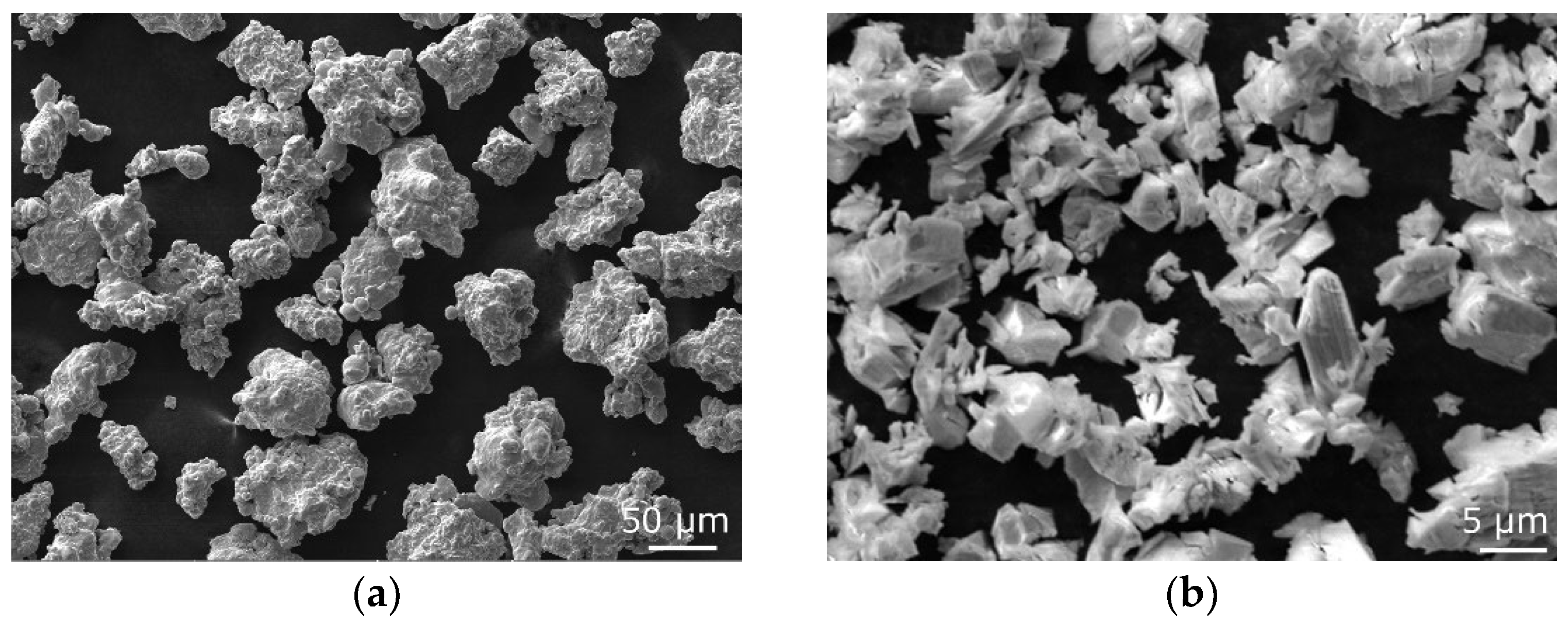

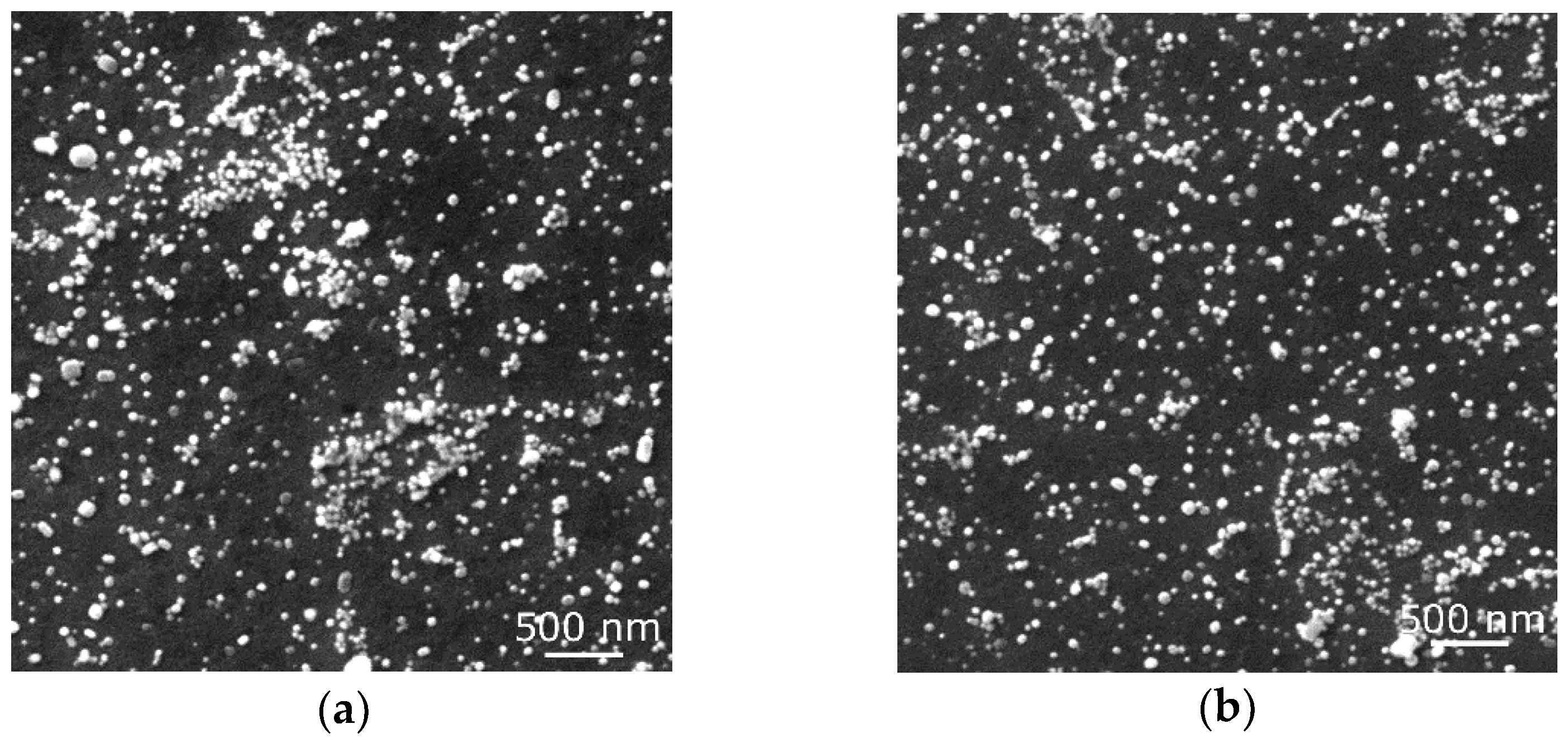

2.1. Experimental Material

2.2. Analyses

3. Results

3.1. Microstructure Homogeneity

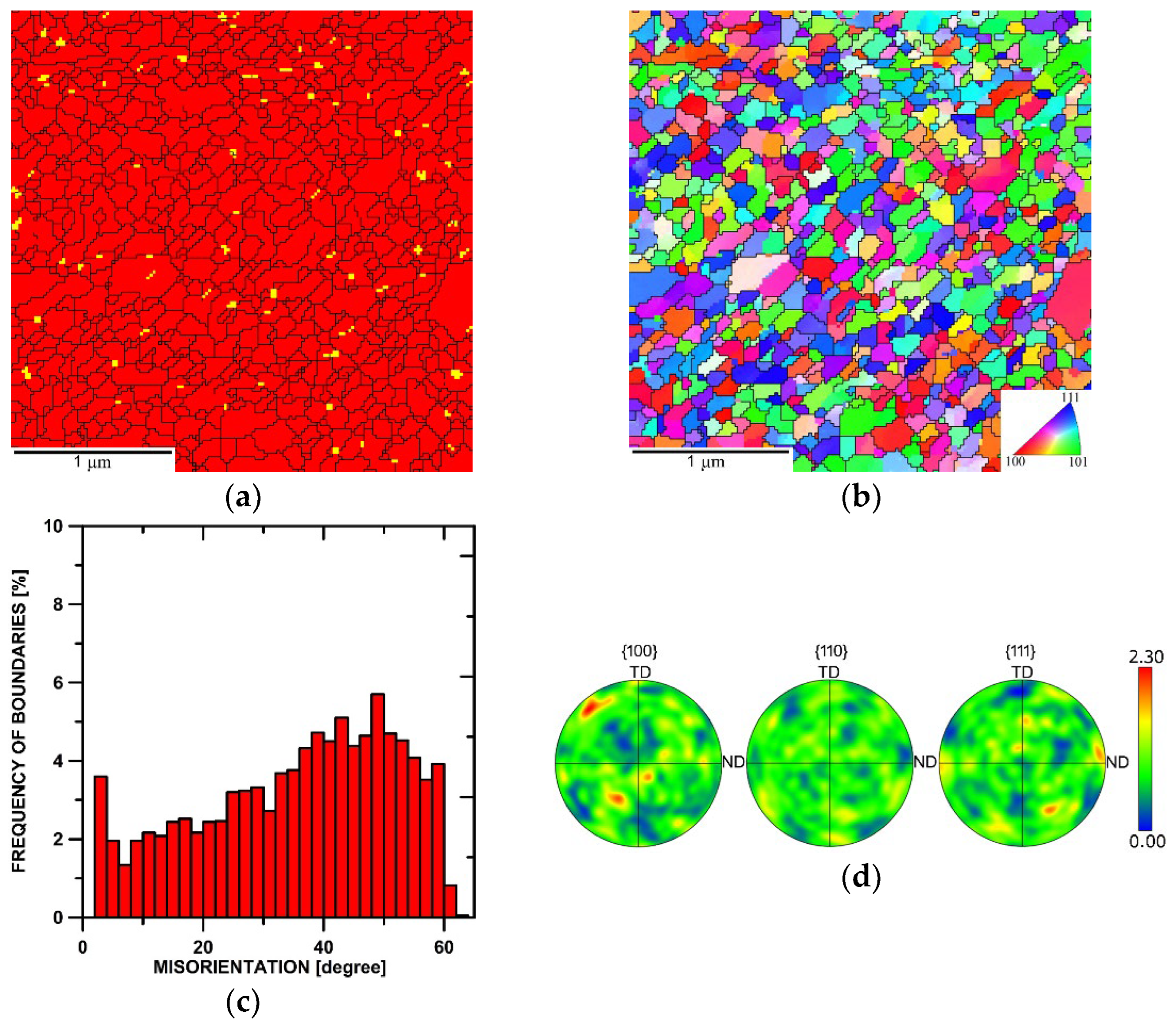

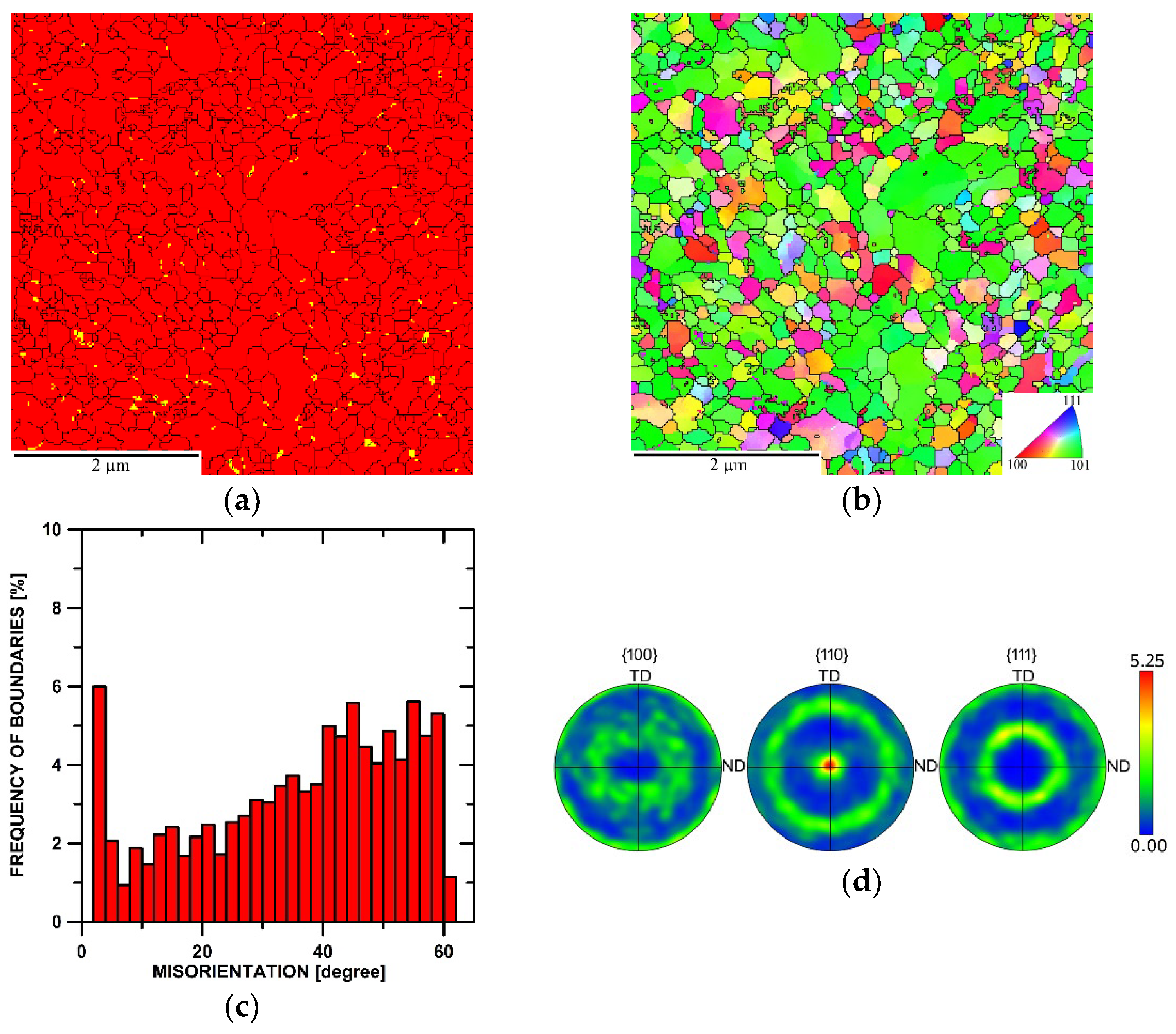

3.2. Microstructure Assessment

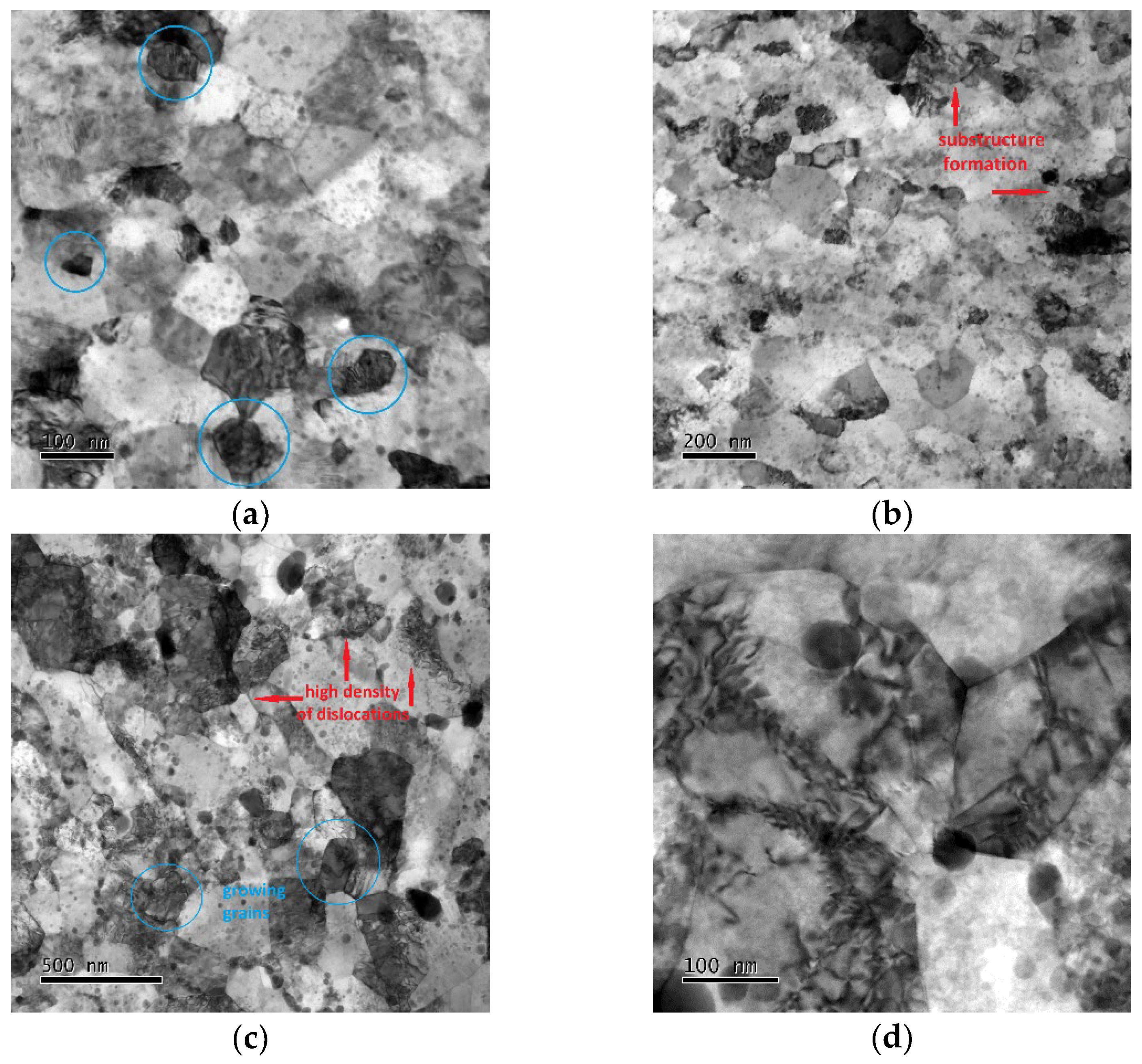

3.3. Substructure Development

3.4. Mechanical Properties at Room Temperature

3.5. Mechanical Properties at Elevated Temperature

4. Discussions

5. Conclusions

- -

- swaging ratio of 1.4 resulted in a consolidated microstructure featuring ultra-fine grains and advantageous mechanical properties (microhardness of 690 HV0.5), but the consolidated workpiece still featured local inhomogeneities in Y2O3 particles distribution;

- -

- swaging ratio of 2.5 substantially contributed to the homogenization of Y2O3 particle distribution and thus homogeneity of the mechanical properties. Mechanical properties exhibited lower absolute values given by occurring recrystallization and a lower extent of accumulation of lattice defects;

- -

- testing at 1300 °C and multiple strain rates revealed generally higher absolute flow stress values, but flow stress decreased after reaching peak strain for the workpiece with a swaging ratio of 1.4 (development of dynamic recrystallization), and lower flow stress values but steady state-like behavior for workpiece with a swaging ratio of 2.5 (development of dynamic recovery)

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kuranova, N.N.; Makarov, V.V.; Pushin, V.G.; Ustyugov, Y.M. Influence of Heat Treatment and Deformation on the Structure, Phase Transformation, and Mechanical Behavior of Bulk TiNi-Based Alloys. Metals 2022, 12, 2188. [Google Scholar] [CrossRef]

- Gordienko, A.I.; Malikov, A.G.; Volochaev, M.N.; Panyukhina, A.D. Influence of Chemical Composition and Thermomechanical Treatment of Low-Carbon Steels on the Microstructure and Mechanical Properties of Their Laser Welded Joints. Mater. Sci. Eng. A 2022, 839, 142845. [Google Scholar] [CrossRef]

- Radionova, L.V.; Perevozchikov, D.V.; Makoveckii, A.N.; Eremin, V.N.; Akhmedyanov, A.M.; Rushchits, S.V. Study on the Hot Deformation Behavior of Stainless Steel AISI 321. Materials 2022, 15, 4057. [Google Scholar] [CrossRef] [PubMed]

- Kunčická, L.; Kocich, R.; Lowe, T.C. Advances in Metals and Alloys for Joint Replacement. Prog. Mater. Sci. 2017, 88, 232–280. [Google Scholar] [CrossRef]

- Macháčková, A.; Krátká, L.; Petrmichl, R.; Kunčická, L.; Kocich, R. Affecting Structure Characteristics of Rotary Swaged Tungsten Heavy Alloy via Variable Deformation Temperature. Materials 2019, 12, 4200. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Optimizing Electric Conductivity of Innovative Al-Cu Laminated Composites via Thermomechanical Treatment. Mater. Des. 2022, 215, 110441. [Google Scholar] [CrossRef]

- Tikhonova, M.; Kaibyshev, R.; Belyakov, A. Microstructure and Mechanical Properties of Austenitic Stainless Steels after Dynamic and Post-Dynamic Recrystallization Treatment. Adv. Eng. Mater. 2018, 20, 1700960. [Google Scholar] [CrossRef]

- Wang, X.; Kustov, S.; Van Humbeeck, J. A Short Review on the Microstructure, Transformation Behavior and Functional Properties of NiTi Shape Memory Alloys Fabricated by Selective Laser Melting. Materials 2018, 11, 1683. [Google Scholar] [CrossRef]

- Maznichevskii, A.N.; Goikhenberg, Y.N.; Sprikut, R.V. Electron-Microscopy Investigation of Excess-Phase Precipitates Affecting the Intergranular Corrosion of Chromium–Nickel Austenitic Steels. Phys. Met. Metallogr. 2021, 122, 362–369. [Google Scholar] [CrossRef]

- Zhurerova, L.G.; Rakhadilov, B.K.; Popova, N.A.; Kylyshkanov, M.K.; Buranich, V.V.; Pogrebnjak, A.D. Effect of the PEN/C Surface Layer Modification on the Microstructure, Mechanical and Tribological Properties of the 30CrMnSiA Mild-Carbon Steel. J. Mater. Res. Technol. 2020, 9, 291–300. [Google Scholar] [CrossRef]

- Ukai, S.; Hatakeyama, K.; Mizuta, S.; Fujiwara, M.; Okuda, T. Consolidation Process Study of 9Cr-ODS Martensitic Steels. J. Nucl. Mater. 2002, 307–311, 758–762. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Kozlov, K.A.; Kataeva, N.V. Oxide-Dispersion Strengthened Radiation-Resistant Steels. Phys. Met. Metallogr. 2018, 119, 1350–1353. [Google Scholar] [CrossRef]

- Raman, L.; Gothandapani, K.; Murty, B.S. Austenitic Oxide Dispersion Strengthened Steels: A Review. Def. Sci. J. 2016, 66, 316. [Google Scholar] [CrossRef]

- Macháčková, A.; Kocich, R.; Bojko, M.; Kunčická, L.; Polko, K. Numerical and Experimental Investigation of Flue Gases Heat Recovery via Condensing Heat Exchanger. Int. J. Heat Mass Transf. 2018, 124, 1321–1333. [Google Scholar] [CrossRef]

- Verma, L.; Dabhade, V.V. Synthesis of Fe-15Cr-2W Oxide Dispersion Strengthened (ODS) Steel Powders by Mechanical Alloying. Powder Technol. 2023, 425, 118554. [Google Scholar] [CrossRef]

- Meng, B.; Xiong, Y.; Zhong, W.; Duan, S.; Li, H. Progressive Collapse Behaviour of Composite Substructure with Large Rectangular Beam-Web Openings. Eng. Struct. 2023, 295, 116861. [Google Scholar] [CrossRef]

- Gerasimidis, S.; Ellingwood, B. Twenty Years of Advances in Disproportionate Collapse Research and Best Practices since 9/11/2001. J. Struct. Eng. 2023, 149, 02022002. [Google Scholar] [CrossRef]

- Razumovskii, I.; Bokstein, B.; Logacheva, A.; Logachev, I.; Razumovsky, M. Cohesive Strength and Structural Stability of the Ni-Based Superalloys. Materials 2021, 15, 200. [Google Scholar] [CrossRef]

- Dmitrieva, A.; Mukin, D.; Sorokin, I.; Stankevich, S.; Klimova-Korsmik, O. Laser-Directed Energy Deposition of Ni-Based Superalloys with a High Content of γ’-Phase Using Induction Heating. Mater. Lett. 2023, 353, 135217. [Google Scholar] [CrossRef]

- Atrazhev, V.V.; Burlatsky, S.F.; Dmitriev, D.V.; Furrer, D.; Kuzminyh, N.Y.; Lomaev, I.L.; Novikov, D.L.; Stolz, S.; Reynolds, P. The Mechanism of Grain Boundary Serration and Fan-Type Structure Formation in Ni-Based Superalloys. Metall. Mater. Trans. A 2020, 51, 3648–3657. [Google Scholar] [CrossRef]

- Sundar, R.S.; Deevi, S.C. High-Temperature Strength and Creep Resistance of FeAl. Mater. Sci. Eng. A 2003, 357, 124–133. [Google Scholar] [CrossRef]

- Miller, M.K.; Hoelzer, D.T.; Kenik, E.A.; Russell, K.F. Stability of Ferritic MA/ODS Alloys at High Temperatures. Intermetallics 2005, 13, 387–392. [Google Scholar] [CrossRef]

- Ramar, A.; Schäublin, R. Analysis of Hardening Limits of Oxide Dispersion Strengthened Steel. J. Nucl. Mater. 2013, 432, 323–333. [Google Scholar] [CrossRef]

- Schaeublin, R.; Leguey, T.; Spätig, P.; Baluc, N.; Victoria, M. Microstructure and Mechanical Properties of Two ODS Ferritic/Martensitic Steels. J. Nucl. Mater. 2002, 307–311, 778–782. [Google Scholar] [CrossRef]

- Ates, H.; Turker, M.; Kurt, A. Effect of Friction Pressure on the Properties of Friction Welded MA956 Iron-Based Superalloy. Mater. Des. 2007, 28, 948–953. [Google Scholar] [CrossRef]

- Zhang, Z.; Saleh, T.A.; Maloy, S.A.; Anderoglu, O. Microstructure Evolution in MA956 Neutron Irradiated in ATR at 328 °C to 4.36 Dpa. J. Nucl. Mater. 2020, 533, 152094. [Google Scholar] [CrossRef]

- Wilshire, B.; Lieu, T.D. Deformation and Damage Processes during Creep of Incoloy MA957. Mater. Sci. Eng. A 2004, 386, 81–90. [Google Scholar] [CrossRef]

- Miller, M.; Hoelzer, D.; Kenik, E.; Russell, K. Nanometer Scale Precipitation in Ferritic MA/ODS Alloy MA957. J. Nucl. Mater. 2004, 329–333, 338–341. [Google Scholar] [CrossRef]

- Capdevila, C.; Miller, M.K.; Russell, K.F.; Chao, J.; González-Carrasco, J.L. Phase Separation in PM 2000TM Fe-Base ODS Alloy: Experimental Study at the Atomic Level. Mater. Sci. Eng. A 2008, 490, 277–288. [Google Scholar] [CrossRef]

- Tang, Q.; Hoshino, T.; Ukai, S.; Leng, B.; Hayashi, S.; Wang, Y. Refinement of Oxide Particles by Addition of Hf in Ni-0.5 Mass%Al-1 Mass%Y2O3 Alloys. Mater. Trans. 2010, 51, 2019–2024. [Google Scholar] [CrossRef]

- Ngala, W.O.; Maier, H.J. Creep–Fatigue Interaction of the ODS Superalloy PM 1000. Mater. Sci. Eng. A 2009, 510–511, 429–433. [Google Scholar] [CrossRef]

- Lu, C.; Lu, Z.; Wang, X.; Xie, R.; Li, Z.; Higgins, M.; Liu, C.; Gao, F.; Wang, L. Enhanced Radiation-Tolerant Oxide Dispersion Strengthened Steel and Its Microstructure Evolution under Helium-Implantation and Heavy-Ion Irradiation. Sci. Rep. 2017, 7, 40343. [Google Scholar] [CrossRef]

- Allen, T.R.; Gan, J.; Cole, J.I.; Miller, M.K.; Busby, J.T.; Shutthanandan, S.; Thevuthasan, S. Radiation Response of a 9 Chromium Oxide Dispersion Strengthened Steel to Heavy Ion Irradiation. J. Nucl. Mater. 2008, 375, 26–37. [Google Scholar] [CrossRef]

- Fu, A.; Liu, B.; Liu, B.; Cao, Y.; Wang, J.; Liao, T.; Li, J.; Fang, Q.; Liaw, P.K.; Liu, Y. A Novel Cobalt-Free Oxide Dispersion Strengthened Medium-Entropy Alloy with Outstanding Mechanical Properties and Irradiation Resistance. J. Mater. Sci. Technol. 2023, 152, 190–200. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, B.; Luo, L.; Oliveira, J.P.; Li, B.; Yan, H.; Liu, T.; Zhao, J.; Wang, L.; Su, Y.; et al. Effects of Process Atmosphere on Additively Manufactured FeCrAl Oxide Dispersion Strengthened Steel: Printability, Microstructure and Tensile Properties. Mater. Sci. Eng. A 2023, 882, 145438. [Google Scholar] [CrossRef]

- Staltsov, M.S.; Chernov, I.I.; Bogachev, I.A.; Kalin, B.A.; Olevsky, E.A.; Lebedeva, L.J.; Nikitina, A.A. Optimization of Mechanical Alloying and Spark-Plasma Sintering Regimes to Obtain Ferrite–Martensitic ODS Steel. Nucl. Mater. Energy 2016, 9, 360–366. [Google Scholar] [CrossRef]

- Sagaradze, V.V.; Litvinov, A.V.; Shabashov, V.A.; Vil’danova, N.F.; Mukoseev, A.G.; Kozlov, K.A. New Method of Mechanical Alloying of ODS Steels Using Iron Oxides. Phys. Met. Metallogr. 2006, 101, 566–576. [Google Scholar] [CrossRef]

- Owusu-Mensah, M.; Jublot-Leclerc, S.; Gentils, A.; Baumier, C.; Ribis, J.; Borodin, V.A. In Situ TEM Thermal Annealing of High Purity Fe10wt%Cr Alloy Thin Foils Implanted with Ti and O Ions. Nucl. Instrum. Methods Phys. Res. Sect. B Beam Interact. Mater. At. 2019, 461, 219–225. [Google Scholar] [CrossRef]

- Xu, H.; Lu, Z.; Wang, D.; Liu, C. Effect of Zirconium Addition on the Microstructure and Mechanical Properties of 15Cr-ODS Ferritic Steels Consolidated by Hot Isostatic Pressing. Fusion Eng. Des. 2017, 114, 33–39. [Google Scholar] [CrossRef]

- Shulga, A.V. A Comparative Study of the Mechanical Properties and the Behavior of Carbon and Boron in Stainless Steel Cladding Tubes Fabricated by PM HIP and Traditional Technologies. J. Nucl. Mater. 2013, 434, 133–140. [Google Scholar] [CrossRef]

- Hary, B.; Logé, R.; Ribis, J.; Mathon, M.-H.; Van Der Meer, M.; Baudin, T.; de Carlan, Y. Strain-Induced Dissolution of Y–Ti–O Nano-Oxides in a Consolidated Ferritic Oxide Dispersion Strengthened (ODS) Steel. Materialia 2018, 4, 444–448. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Shan, Y.; Yan, W.; Shi, Q.; Yang, K.; Shen, J.; Nagasasa, T.; Muroga, T.; Yang, H.; et al. Anisotropy in Creep Properties and Its Microstructural Origins of 12Cr Oxide Dispersion Strengthened Ferrite Steels. J. Nucl. Mater. 2019, 517, 307–314. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, J.; Liu, B.; Chen, Y.; Li, D.; Wang, H.; Shen, Y. Nanosized Oxide Phases in Oxide-Dispersion-Strengthened Steel PM2000. Philos. Mag. 2021, 101, 2514–2527. [Google Scholar] [CrossRef]

- Leng, B.; Ukai, S.; Sugino, Y.; Tang, Q.; Narita, T.; Hayashi, S.; Wan, F.; Ohtsuka, S.; Kaito, T. Recrystallization Texture of Cold-Rolled Oxide Dispersion Strengthened Ferritic Steel. ISIJ Int. 2011, 51, 951–957. [Google Scholar] [CrossRef]

- Wu, S.; Li, J.; Li, C.; Li, Y.; Xiong, L.; Liu, S. Preliminary Study on the Fabrication of 14Cr-ODS FeCrAl Alloy by Powder Forging. J. Mater. Sci. Technol. 2021, 83, 49–57. [Google Scholar] [CrossRef]

- Kumar, D.; Prakash, U.; Dabhade, V.V.; Laha, K.; Sakthivel, T. High Yttria Ferritic ODS Steels through Powder Forging. J. Nucl. Mater. 2017, 488, 75–82. [Google Scholar] [CrossRef]

- Li, Y.; Shen, J.; Li, F.; Yang, H.; Kano, S.; Matsukawa, Y.; Satoh, Y.; Fu, H.; Abe, H.; Muroga, T. Effects of Fabrication Processing on the Microstructure and Mechanical Properties of Oxide Dispersion Strengthening Steels. Mater. Sci. Eng. A 2016, 654, 203–212. [Google Scholar] [CrossRef]

- Jayasankar, K.; Pandey, A.; Mishra, B.K.; Das, S. In-Situ Formation of Complex Oxide Precipitates during Processing of Oxide Dispersion Strengthened Ferritic Steels. Fusion Eng. Des. 2016, 102, 14–20. [Google Scholar] [CrossRef]

- Böhmermann, F.; Hasselbruch, H.; Herrmann, M.; Riemer, O.; Mehner, A.; Zoch, H.-W.; Kuhfuss, B. Dry Rotary Swaging–Approaches for Lubricant Free Process Design. Int. J. Precis. Eng. Manuf. Technol. 2015, 2, 325–331. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R. Effect of Activated Slip Systems on Dynamic Recrystallization during Rotary Swaging of Electro-Conductive Al-Cu Composites. Mater. Lett. 2022, 321, 10–13. [Google Scholar] [CrossRef]

- Strunz, P.; Kunčická, L.; Beran, P.; Kocich, R.; Hervoches, C. Correlating Microstrain and Activated Slip Systems with Mechanical Properties within Rotary Swaged WNiCo Pseudoalloy. Materials 2020, 13, 208. [Google Scholar] [CrossRef] [PubMed]

- Kunčická, L.; Kocich, R.; Németh, G.; Dvořák, K.; Pagáč, M. Effect of Post Process Shear Straining on Structure and Mechanical Properties of 316 L Stainless Steel Manufactured via Powder Bed Fusion. Addit. Manuf. 2022, 59, 103128. [Google Scholar] [CrossRef]

- Kocich, R.; Szurman, I.; Kursa, M.; Fiala, J. Investigation of Influence of Preparation and Heat Treatment on Deformation Behaviour of the Alloy NiTi after ECAE. Mater. Sci. Eng. A 2009, 512, 100–104. [Google Scholar] [CrossRef]

- Hlaváč, L.M.; Kocich, R.; Gembalová, L.; Jonšta, P.; Hlaváčová, I.M. AWJ Cutting of Copper Processed by ECAP. Int. J. Adv. Manuf. Technol. 2016, 86, 885–894. [Google Scholar] [CrossRef]

- Kocich, R.; Greger, M.; Macháčková, A. Finite Element Investigation of Influence of Selected Factors on ECAP Process. In Proceedings of the METAL 2010: 19th International Metallurgical and Materials Conference, Roznov pod Radhostem, Czech Republic, 18–20 May 2010; pp. 166–171. [Google Scholar]

- Valiev, R.Z.; Straumal, B.; Langdon, T.G. Using Severe Plastic Deformation to Produce Nanostructured Materials with Superior Properties. Annu. Rev. Mater. Res. 2022, 52, 357–382. [Google Scholar] [CrossRef]

- Lim, S.J.; Choi, H.J.; Yoon, D.J.; Jeong, H.G.; Lee, C.H. Product Geometry for Process Parameter during Rotary Swaging Process as Chipless Forming Process. Mater. Sci. Forum 2007, 544–545, 439–442. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L. Optimizing Structure and Properties of Al/Cu Laminated Conductors via Severe Shear Strain. J. Alloys Compd. 2023, 953, 170124. [Google Scholar] [CrossRef]

- Kuhfuss, B.; Moumi, E.; Piwek, V. Micro Rotary Swaging: Process Limitations and Attempts to Their Extension. Microsyst. Technol. 2008, 14, 1995–2000. [Google Scholar] [CrossRef]

- Chen, X.; Liu, C.; Jiang, S.; Chen, Z.; Wan, Y. Fabrication of Nanocrystalline High-Strength Magnesium−Lithium Alloy by Rotary Swaging. Adv. Eng. Mater. 2022, 24, 2100666. [Google Scholar] [CrossRef]

- Chen, X.; Liu, C.; Wan, Y.; Jiang, S.; Han, X.; Chen, Z. Formation of Nanocrystalline AZ31B Mg Alloys via Cryogenic Rotary Swaging. J. Magnes. Alloys 2023, 11, 1580–1591. [Google Scholar] [CrossRef]

- Suryanarayana, C. Mechanical Alloying: A Critical Review. Mater. Res. Lett. 2022, 10, 619–647. [Google Scholar] [CrossRef]

- Kocich, R.; Kunčická, L.; Benč, M. Development of Microstructure and Properties within Oxide Dispersion Strengthened Steel Directly Consolidated by Hot Rotary Swaging. Mater. Lett. 2023, 353, 135276. [Google Scholar] [CrossRef]

- Mao, X.; Oh, K.H.; Jang, J. Evolution of Ultrafine Grained Microstructure and Nano-Sized Semi-Coherent Oxide Particles in Austenitic Oxide Dispersion Strengthened Steel. Mater. Charact. 2016, 117, 91–98. [Google Scholar] [CrossRef]

- Xu, R.; Geng, Z.; Wu, Y.; Chen, C.; Ni, M.; Li, D.; Zhang, T.; Huang, H.; Liu, F.; Li, R.; et al. Microstructure and Mechanical Properties of In-Situ Oxide-Dispersion-Strengthened NiCrFeY Alloy Produced by Laser Powder Bed Fusion. Adv. Powder Mater. 2022, 1, 100056. [Google Scholar] [CrossRef]

- Verlinden, B.; Driver, J.; Samajdar, I.; Doherty, R.D. Thermo-Mechanical Processing of Metallic Materials; Elsevier: Amsterdam, The Netherlands, 2007; ISBN 9780080444970. [Google Scholar]

- Chou, T.S. Recrystallisation Behaviour and Grain Structure in Mechanically Alloyed Oxide Dispersion Strengthened MA956 Steel. Mater. Sci. Eng. A 1997, 223, 78–90. [Google Scholar] [CrossRef]

- Kunčická, L.; Kocich, R.; Strunz, P.; Macháčková, A. Texture and Residual Stress within Rotary Swaged Cu/Al Clad Composites. Mater. Lett. 2018, 230, 88–91. [Google Scholar] [CrossRef]

- Strunz, P.; Kocich, R.; Canelo-Yubero, D.; Macháčková, A.; Beran, P.; Krátká, L. Texture and Differential Stress Development in W/Ni-Co Composite after Rotary Swaging. Materials 2020, 13, 2869. [Google Scholar] [CrossRef]

- Kunčická, L.; Macháčková, A.; Lavery, N.P.; Kocich, R.; Cullen, J.C.T.; Hlaváč, L.M. Effect of Thermomechanical Processing via Rotary Swaging on Properties and Residual Stress within Tungsten Heavy Alloy. Int. J. Refract. Met. Hard Mater. 2020, 87, 105120. [Google Scholar] [CrossRef]

- Bartsch, M.; Wasilkowska, A.; Czyrska-Filemonowicz, A.; Messerschmidt, U. Dislocation Dynamics in the Oxide Dispersion Strengthened Alloy INCOLOY MA956. Mater. Sci. Eng. A 1999, 272, 152–162. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kocich, R.; Kunčická, L.; Král, P.; Dvořák, K. Mechanical Behavior of Oxide Dispersion Strengthened Steel Directly Consolidated by Rotary Swaging. Materials 2024, 17, 4831. https://doi.org/10.3390/ma17194831

Kocich R, Kunčická L, Král P, Dvořák K. Mechanical Behavior of Oxide Dispersion Strengthened Steel Directly Consolidated by Rotary Swaging. Materials. 2024; 17(19):4831. https://doi.org/10.3390/ma17194831

Chicago/Turabian StyleKocich, Radim, Lenka Kunčická, Petr Král, and Karel Dvořák. 2024. "Mechanical Behavior of Oxide Dispersion Strengthened Steel Directly Consolidated by Rotary Swaging" Materials 17, no. 19: 4831. https://doi.org/10.3390/ma17194831

APA StyleKocich, R., Kunčická, L., Král, P., & Dvořák, K. (2024). Mechanical Behavior of Oxide Dispersion Strengthened Steel Directly Consolidated by Rotary Swaging. Materials, 17(19), 4831. https://doi.org/10.3390/ma17194831