Evaluation on Preparation and Performance of a Low-Carbon Alkali-Activated Recycled Concrete under Different Cementitious Material Systems

Abstract

1. Introduction

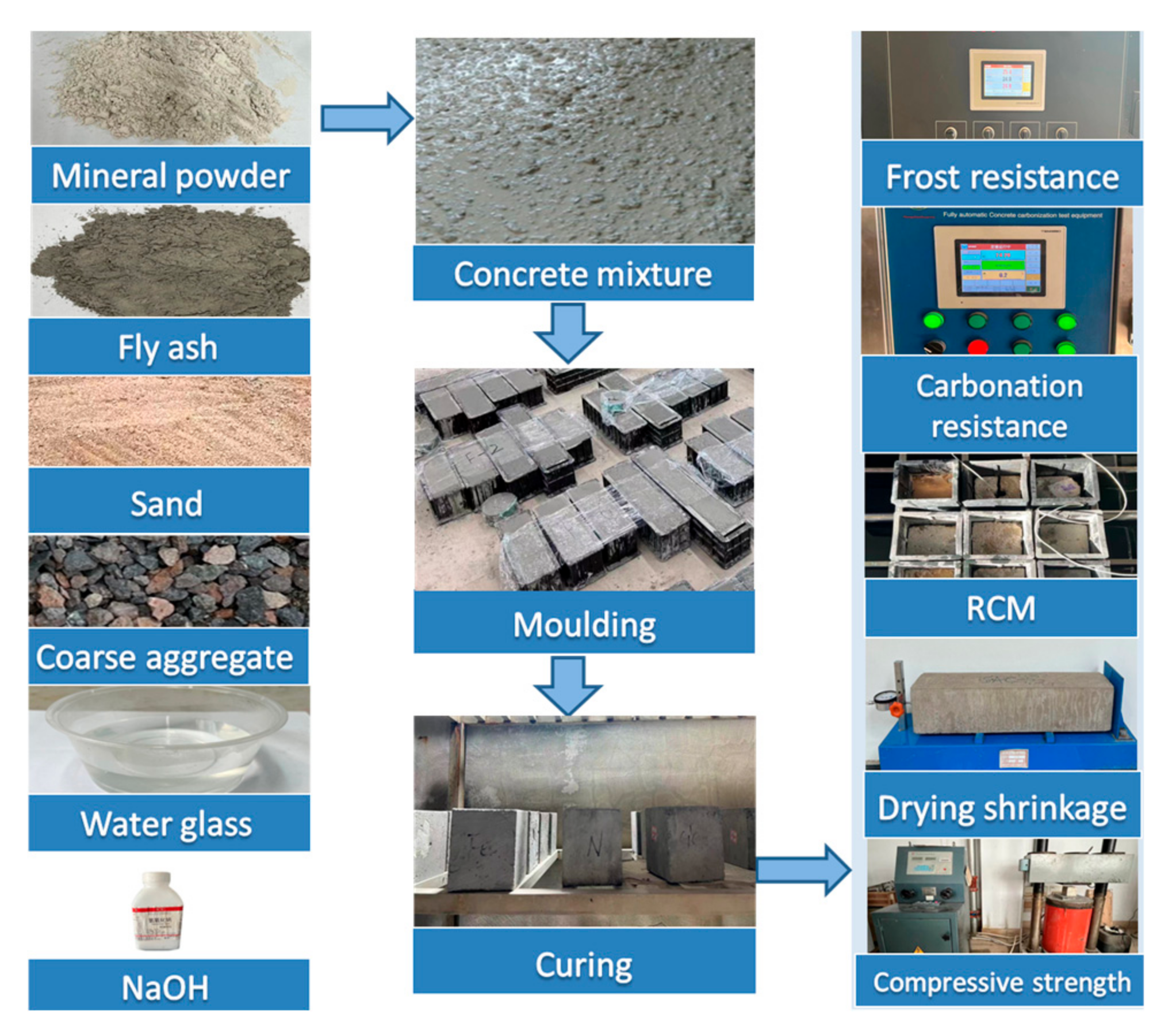

2. Experiment Program

2.1. Raw Material

2.2. Mix Proportion of Concrete

2.3. Test Methods

3. Results and Discussion

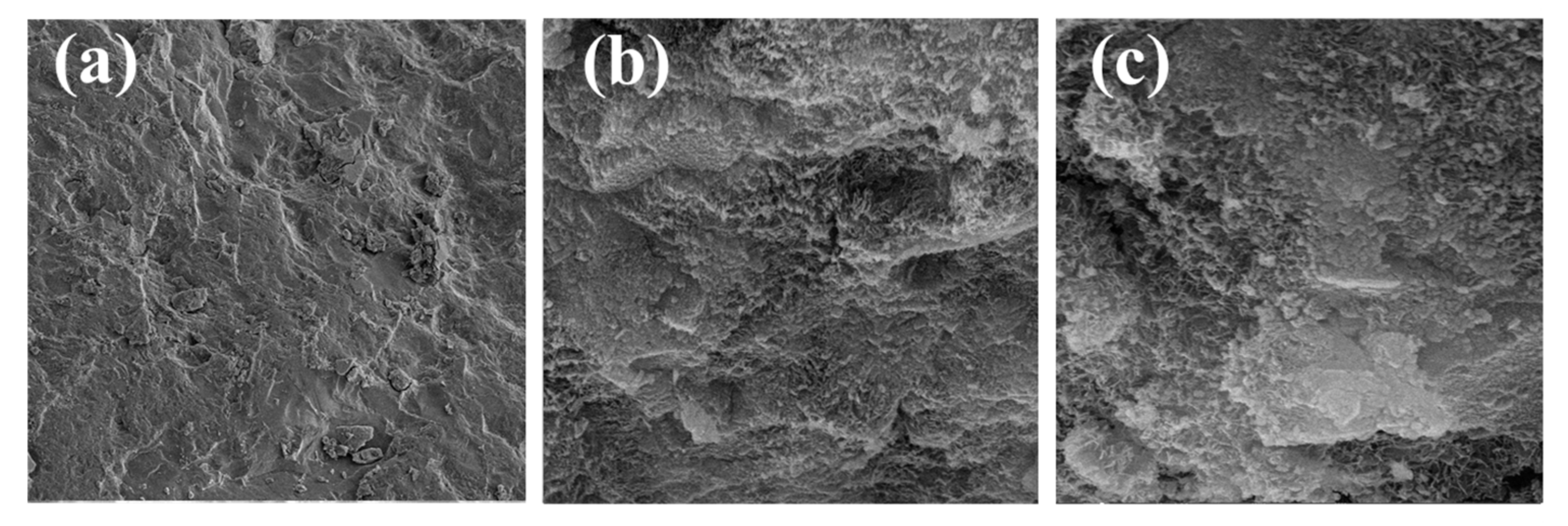

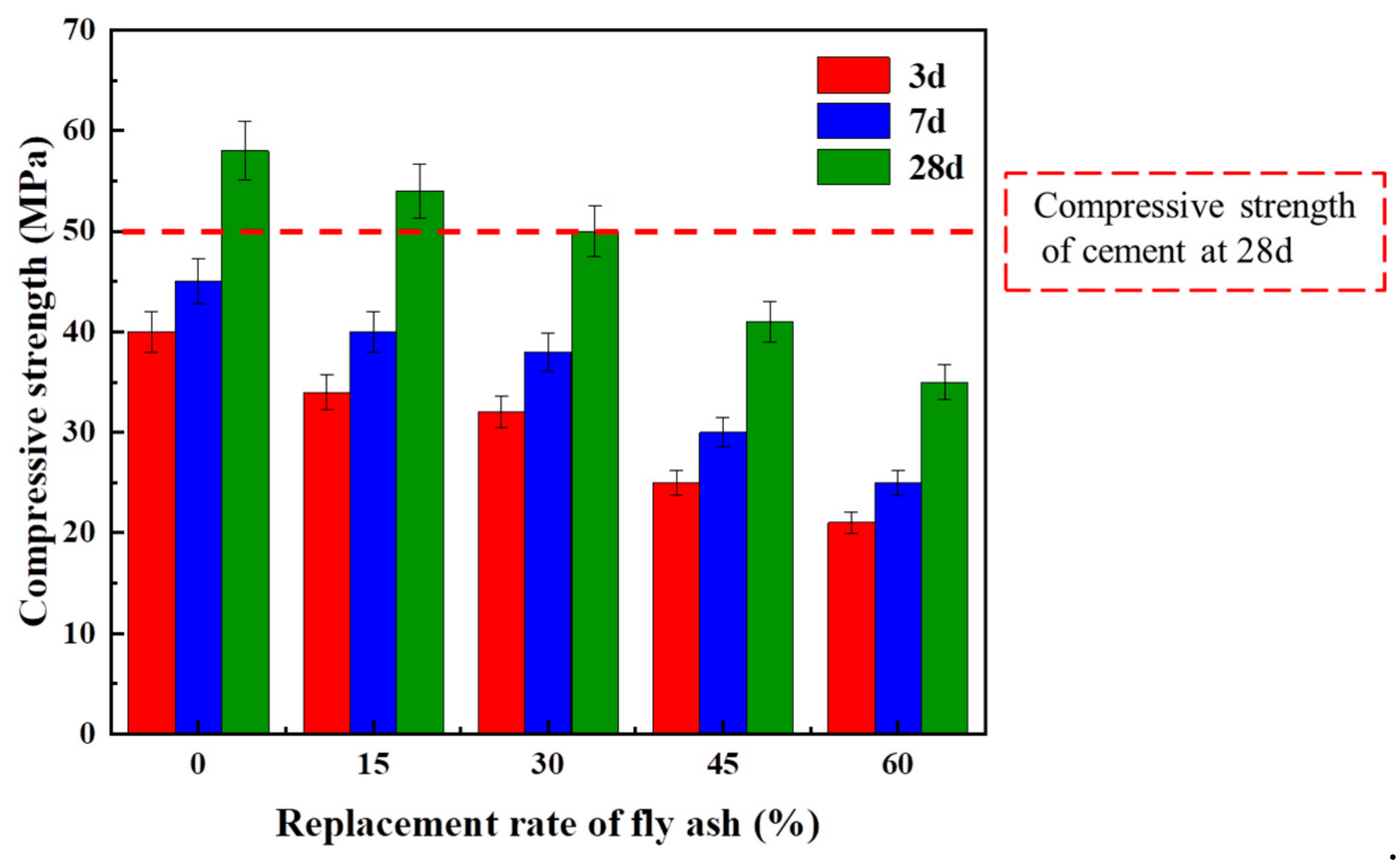

3.1. Optimum Content Determination of FA

3.2. Workability of Alkali-Activated Recycled Concrete

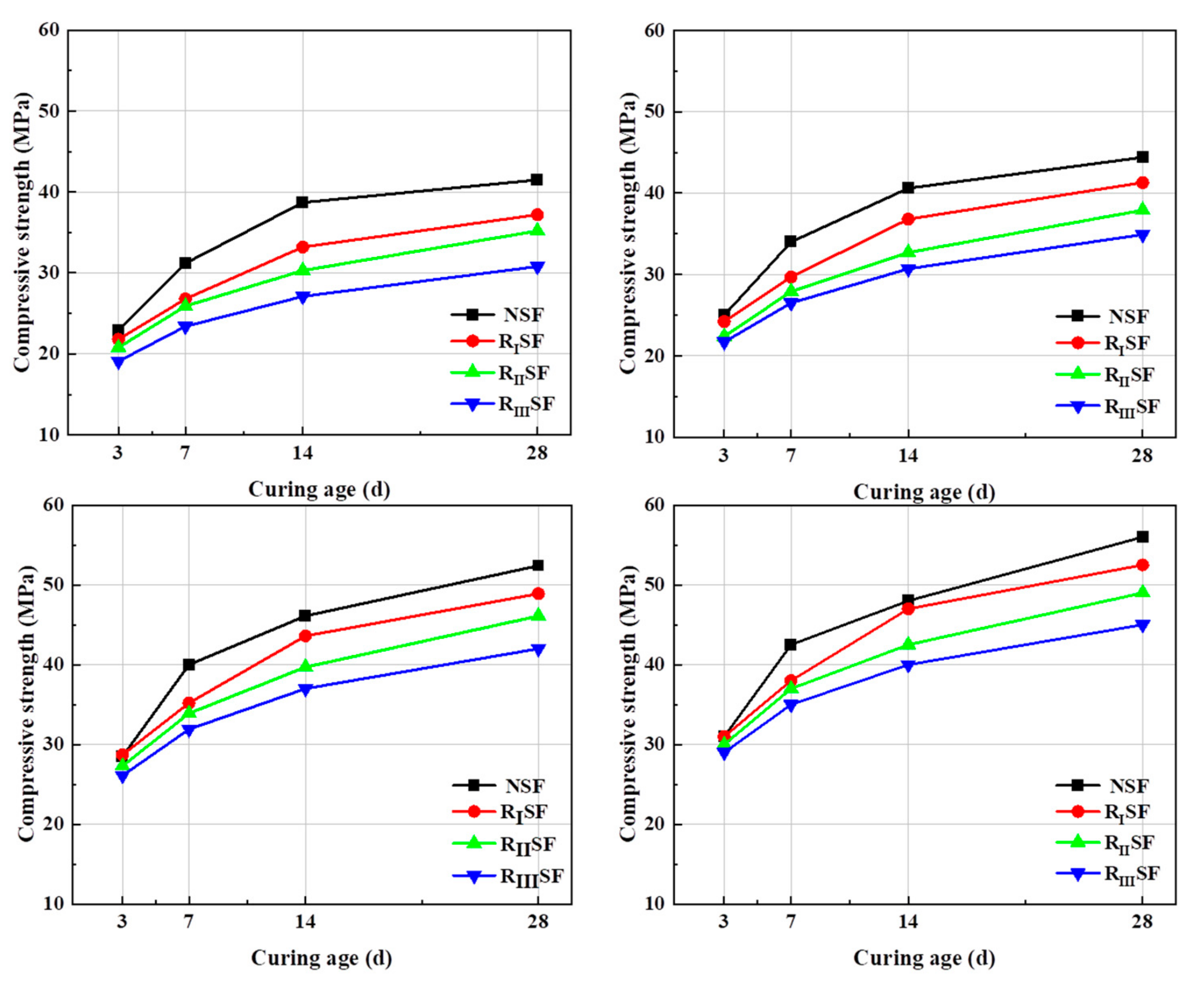

3.3. Mechanical Property of AARC

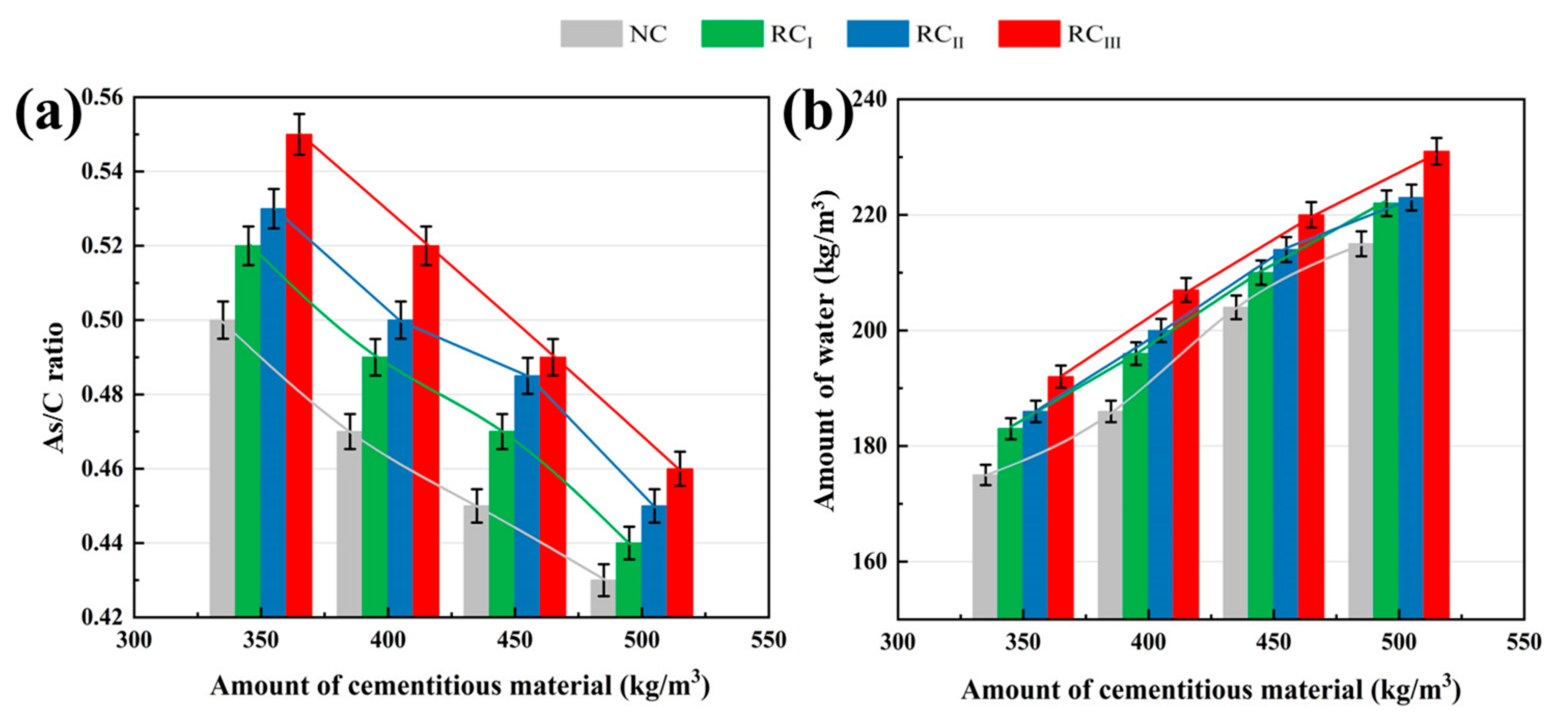

3.4. Mix Proportion Ratio Optimization

3.4.1. Confirmation of Base Mix Proportion Ratio

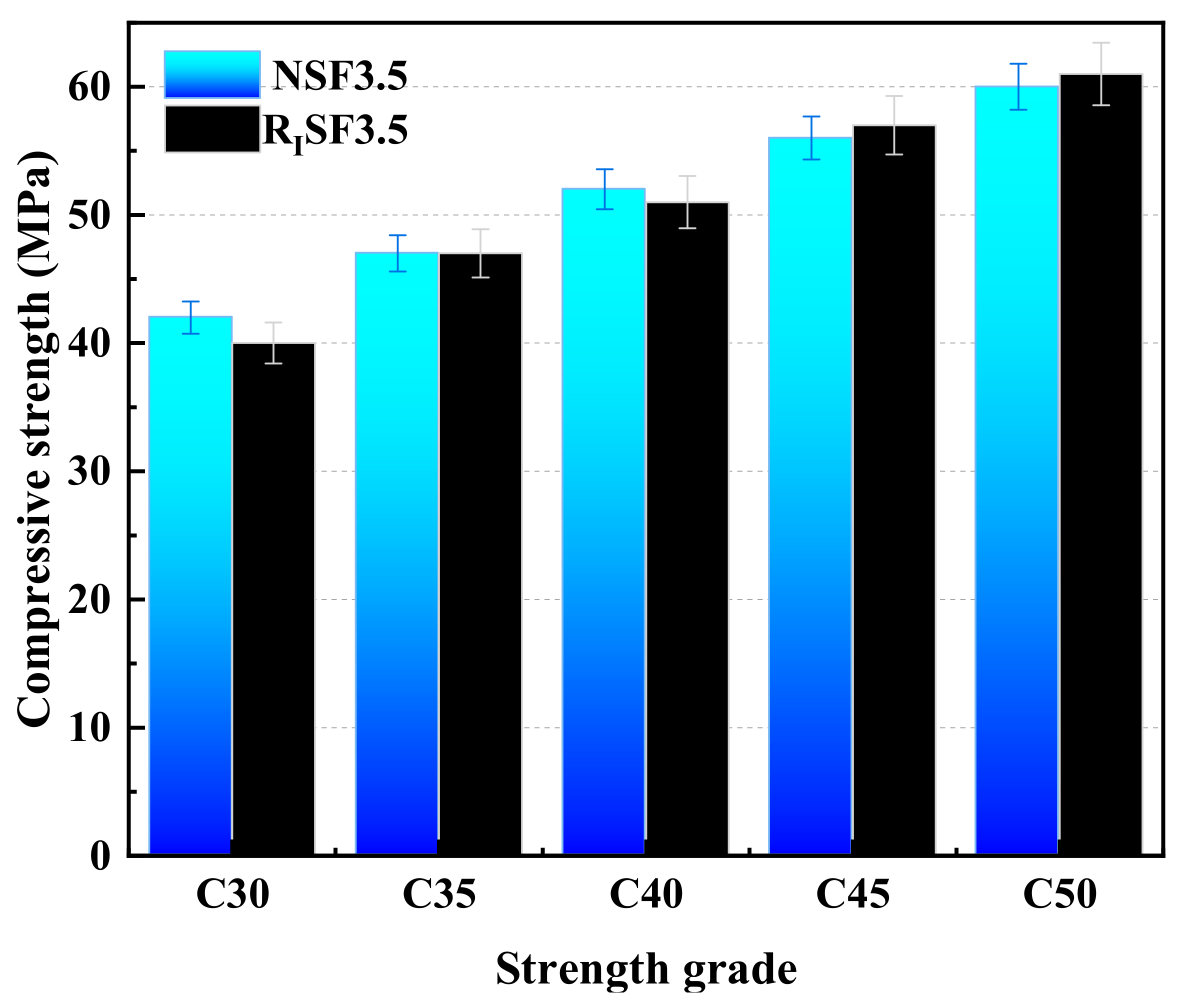

3.4.2. Verification of Reference Ratio Strength

3.5. Durability of Recycled Concrete

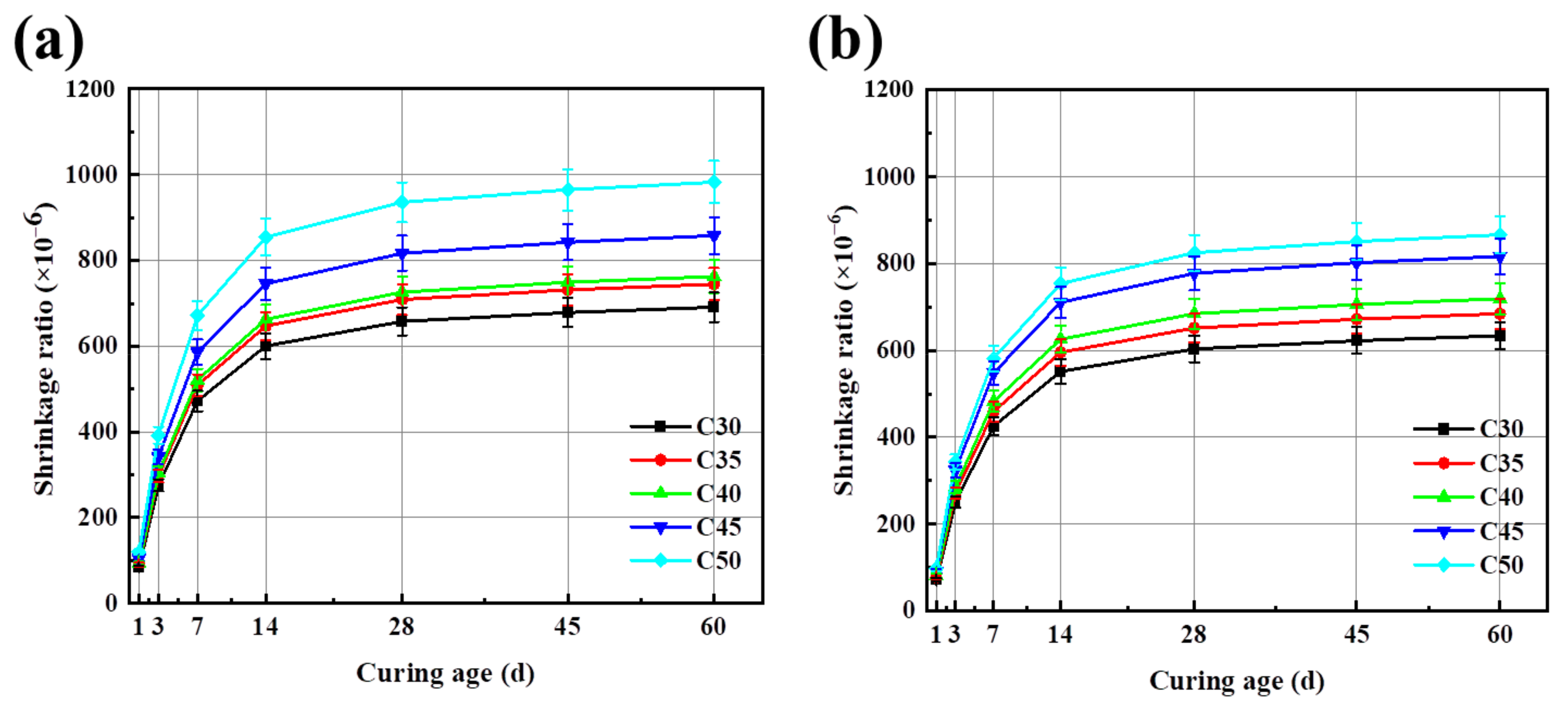

3.5.1. Shrinkage of Different Concrete

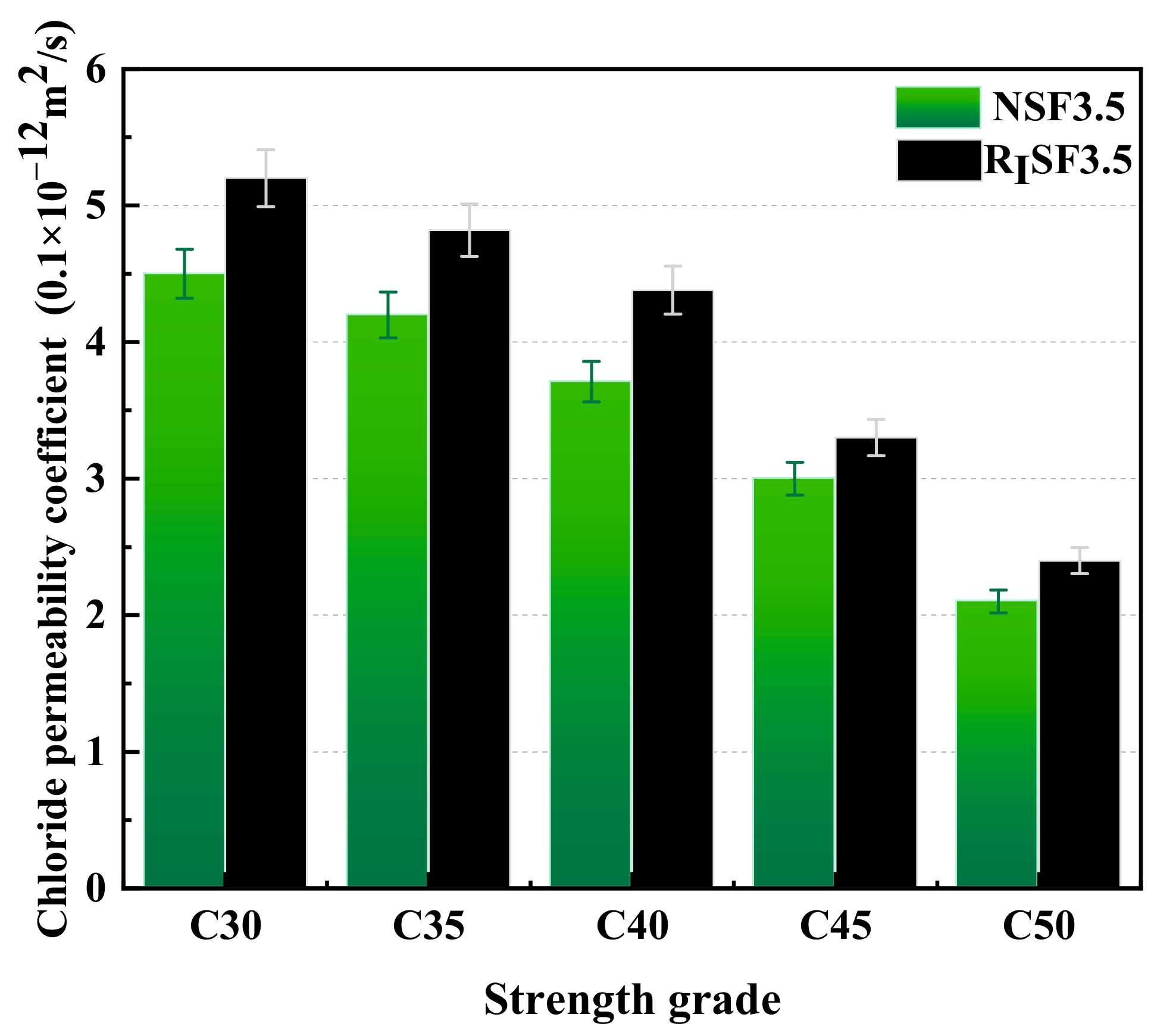

3.5.2. Chloride Ion Permeability of Different Types of Concrete

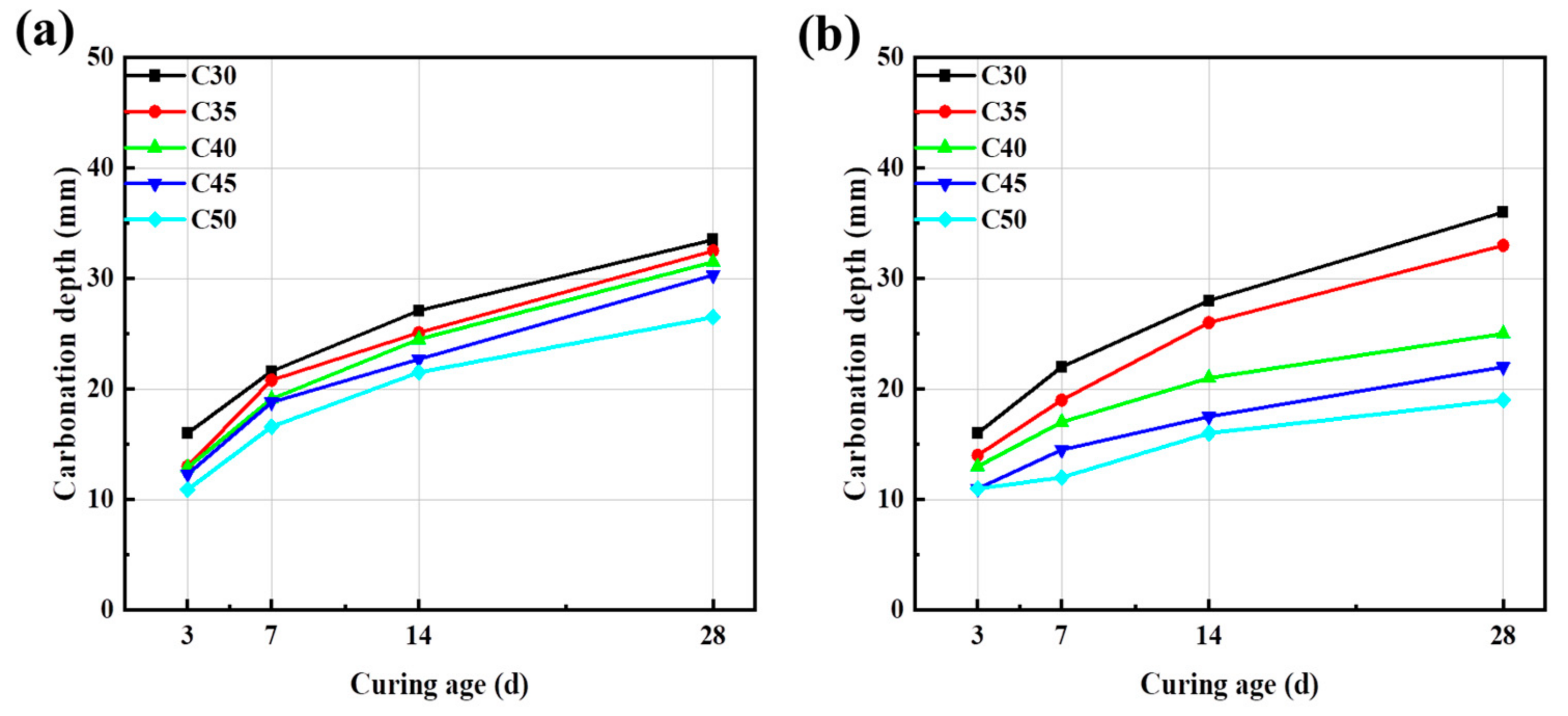

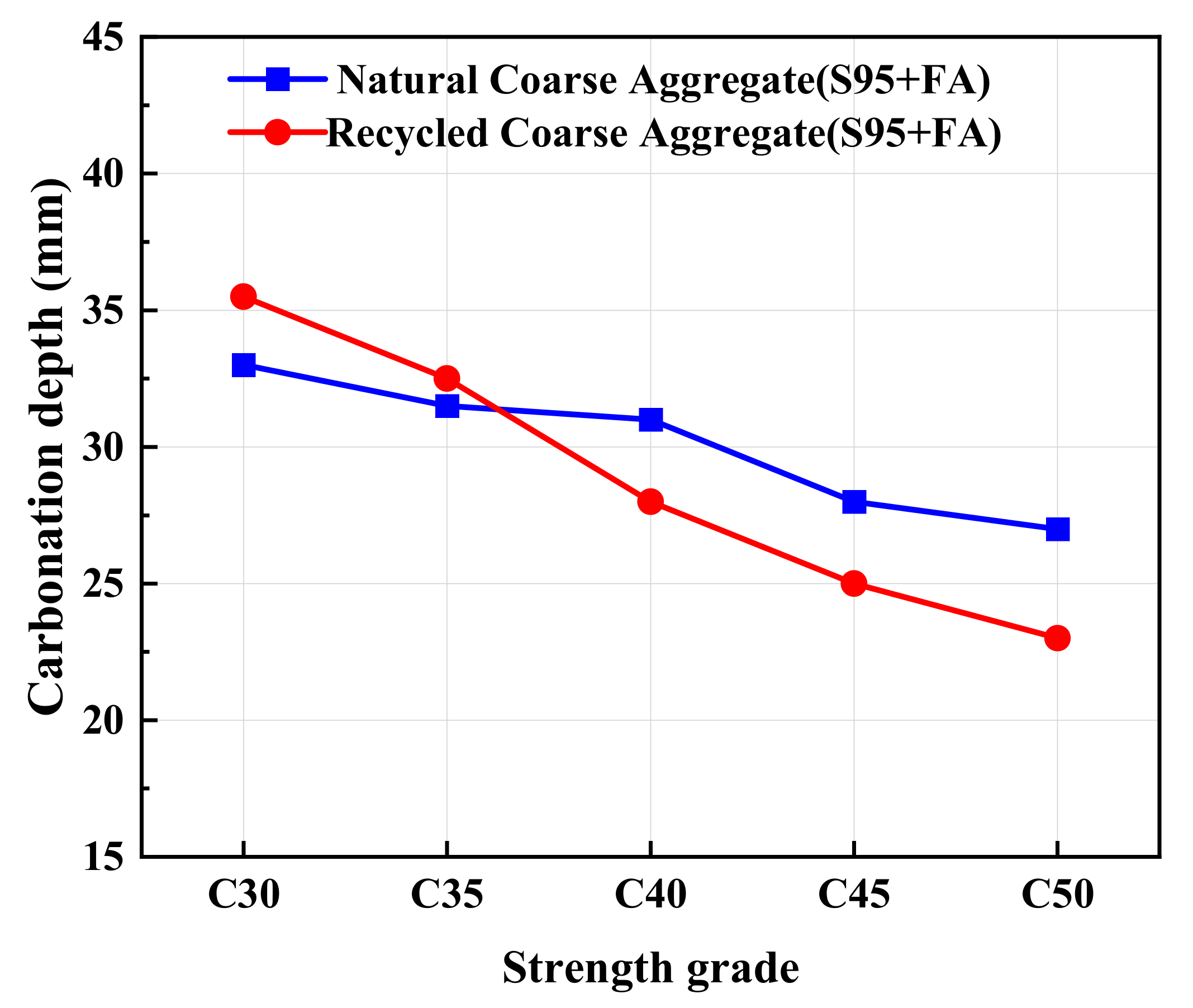

3.5.3. Carbonization Resistance of Different Concrete

3.5.4. Frost Resistance of Different Concrete

4. Conclusions

- (1)

- Through the analysis of the mechanical properties and microstructure of alkali-activated mortar, the concentration and modulus of activator were adjusted to make the 28 d compressive strength consistent with the strength of cement mortar. The optimum content of FA was determined to be 30%, and the solid waste-based alkali-activated cementitious material system was optimized.

- (2)

- Based on the mechanical properties of AARC with different aggregate quality, the linear relationship between 28 d compressive strength and alkali-activated cementitious material system and sol ratio was established, and the mix ratio of AARC with different strength grades was optimized.

- (3)

- The 28 d compressive strength of AARC after optimization can meet the standard requirements. Its shrinkage performance, chloride ion penetration resistance, and frost resistance are similar to NAC, but the carbonation resistance of AARC above strength grade C40 is significantly improved.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Feng, C.H.; Huang, Y.H.; Cui, B.W.; Zhu, J.; Li, D.; Guo, H. Research progress on strengthening methods of building recycled aggregates. Mater. Rep. 2022, 36, 88–95. [Google Scholar]

- Yang, H.; Xia, J. Urban construction and demolition waste and landfill failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.Q.; Yu, L.; Zhang, J.J. Production forecast, comprehensive utilization, management measures and visualization analysis of construction waste. Sustain. Chem. Pharm. 2024, 41, 101720. [Google Scholar] [CrossRef]

- Sun, Z.; Gao, Y.; Yang, J.J.; Chen, Y.X.; Guo, B.H.W. Development of urban building energy models for Wellington city in New Zealand with detailed survey data on envelope thermal characteristics. Energy Build. 2024, 321, 114647. [Google Scholar] [CrossRef]

- Guo, H.; Shi, C.J.; Guan, X.M.; Zhu, J.P.; Ding, Y.H.; Zhang, H.B. Durability of recycled aggregate concrete: A review. Cem. Concr. Compos. 2018, 89, 251–259. [Google Scholar] [CrossRef]

- Kabirifar, K.; Mojtahedi, M.; Wang, C.X.; Tam, V.W.Y. Construction and demolition waste management contributing factors coupled with reduce, reuse, and recycle strategies for effective waste management: A review. J. Clean. Prod. 2020, 263, 121265. [Google Scholar] [CrossRef]

- Pan, Y.; Wang, L.L.; Chen, B.; Zhang, J.; Cheng, G.; Zhao, Y. Study on the influence of impurities in recycled aggregate of construction waste on its performance in preparing recycled concrete. Sichuan Environ. 2023, 42, 33–39. [Google Scholar]

- Gu, L.G.; Liu, Y.; Zeng, J.J.; Zhang, Z.Y.; Pham, P.N.; Liu, C.; Zhuge, Y. The synergistic effects of fibres on mechanical properties of recycled aggregate concrete: A comprehensive review. Constr. Build. Mater. 2024, 436, 137011. [Google Scholar] [CrossRef]

- Ding, Z.K.; Yang, Q.F.; Zhang, Z.Y.; Chen, J.Y. Interfering implicit attitudes of adopting recycled products from construction wastes. J. Clean. Prod. 2024, 464, 142775. [Google Scholar] [CrossRef]

- Wu, J.C. Application and promotion of recycled aggregate of construction waste in green concrete. Build. Technol. Dev. 2022, 49, 75–77. [Google Scholar]

- Liang, C.; Ma, Z. Utilization of CO2 curing to enhance the properties of recycled aggregate and prepared concrete: A review. Cem. Concr. Compos. 2020, 105, 103446. [Google Scholar] [CrossRef]

- Wang, X.; Yan, Y.R.; Tong, X.F.; Gong, Y.F. Investigation of Mineral Admixtures on Mechanical Properties of Alkali-Activated Recycled Concrete Powders Cement. Buildings 2022, 12, 1234. [Google Scholar] [CrossRef]

- Liu, X.L. Research progress of construction waste treatment and resource recycling. Leather Prod. Environ. Prot. Sci. Technol. 2022, 3, 88–90. [Google Scholar]

- Lippiatt, N.; Ling, T.C.; Pan, S.Y. Towards carbon-neutral construction materials: Carbonation of cement-based materials and the future perspective. J. Build. Eng. 2020, 28, 101062. [Google Scholar] [CrossRef]

- Wang, H.R. Study on heat flow model of fly ash and sodium hydroxide alkali activation: A case study of alkali activated cement. Real Estate World 2023, 384, 33–37. [Google Scholar]

- Jin, Z.Q.; Zhao, X.; Du, Y.J.; Yang, S.Y.; Wang, D.Q.; Zhao, T.J.; Bai, Y. Comprehensive properties of passive film formed in simulated pore solution of alkali-activated concrete. Constr. Build. Mater. 2022, 319, 126142. [Google Scholar] [CrossRef]

- Heikal, M.; Abd El Aleem, S.; Morsi, W.M. Durability of composite cements containing granulated blast-furnace slag and silica nano-particles. Indian J. Eng. Mater. Sci. 2016, 23, 88–100. [Google Scholar]

- Zheng, W.Z.; Wu, M.N.; Wang, Y. Research progress of alkali-inspired cementitious materials. J. Build. Struct. 2019, 40, 28–39. [Google Scholar]

- Yu, S.Y.; He, J.; Sang, G.C.; Yang, S.Q.; Liu, G.Y. Study on hydration process of alkali-activated slag cement activated by weakly alkaline components. Constr. Build. Mater. 2024, 413, 134716. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Z.X.; Cao, S.J.; Rong, X.; Shi, Z.Y.; Wang, H. Study on axial compressive stress-strain relationship of alkali-activated slag lightweight aggregate concrete. Constr. Build. Mater. 2023, 364, 129991. [Google Scholar] [CrossRef]

- Tang, L.; Zhang, H.G.; Huang, Q.; Wang, Q.; Shi, X.S. Study on sulfate resistance of fly ash base polymer recycled concrete. J. Sichuan Univ. (Eng. Sci. Ed.) 2015, 47, 164–170. [Google Scholar]

- Raghav, M.; Park, T.; Yang, H.M.; Lee, S.Y.; Karthick, S.; Lee, H.S. Review of the Effects of Supplementary Cementitious Materials and Chemical Additives on the Physical, Mechanical and Durability Properties of Hydraulic Concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef] [PubMed]

- Vo, D.H.; Thi, K.D.T.; Hwang, C.L.; Liao, M.C.; Hsu, W.L.; Yehualaw, M.D. Mechanical properties of concrete produced with alkali-activated slag-fly ash and recycled concrete aggregate and designed using the densified mixture design algorithm (DMDA) method: Effects of recycled aggregate content and alkaline solution. Dev. Built Environ. 2023, 14, 100125. [Google Scholar] [CrossRef]

- Aldandooh, M.A.A.; Bunnori, N.M.; Johari, M.A.M.; Jamrah, A.; Alnuaimi, A. Retrofitting of damaged reinforced concrete beams with a new green cementitious composites material. Compos. Struct. 2016, 142, 27–34. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Yu, R.; Zhang, J.; Shui, Z. A low-carbon alkali activated slag based ultra-high performance concrete (UHPC): Reaction kinetics and microstructure development. Journal of Cleaner Production 2022, 363, 132416. [Google Scholar] [CrossRef]

- Song, W.L. Analysis of the development direction and innovative ideas of construction management of construction engineering. Jiangxi Build. Mater. 2021, 268, 153–154. [Google Scholar]

- Wei, Z.F.; Wei, Y.F. Application study on inhibition of alkali active aggregate. Sichuan Hydroelectr. Power 2023, 42, 104–107. [Google Scholar]

- Hsu, S.; Chi, M.; Huang, R. Effect of fineness and replacement ratio of ground fly ash on properties of blended cement mortar. Constr. Build. Mater. 2018, 176, 250–258. [Google Scholar] [CrossRef]

- Li, J.; Deng, X.; Lu, Z.Y.; Li, X.Y.; Hou, L.; Jiang, J.; Yang, F.Y.; Zhang, J.J.; He, K.W. Recycled concrete fines as a supplementary cementitious material: Mechanical performances, hydration, and microstructures in cementitious systems. Case Stud. Constr. Mater. 2024, 21, e03575. [Google Scholar] [CrossRef]

- Wang, J.H.; Huang, Y.; Yang, G.T.; Wei, Q.A.; Liu, W.Z. Research progress on compressive properties of recycled concrete. Mater. Rep. 2022, 36, 278–286. [Google Scholar]

- Lee, J.S.; Kim, E.S.; Jang, K.P.; Park, C.K.; Kwon, S.H. Prediction of concrete pumping based on correlation between slump and rheological properties. Adv. Concr. Constr. 2022, 13, 395–410. [Google Scholar]

- GB/T 50081-2019; Standard for test methods of concrete physical and mechanical properties. China Architecture & Building Press: Beijing, China, 2019.

- Kou, S.C.; Zhan, B.J.; Poon, C.S. Feasibility study of using recycled fresh concrete waste as coarse aggregates in concrete. Constr. Build. Mater. 2012, 28, 549–556. [Google Scholar] [CrossRef]

- GB/T 50082-2009; Standard for test methods of long-term performance and durability of ordinary concrete. China Architecture & Building Press: Beijing, China, 2009.

- Yu, Z.X.; Li, Q.Y.; Su, D.L. Research progress on self-generated shrinkage and drying shrinkage properties of recycled concrete. Concrete 2022, 388, 6–9. [Google Scholar]

- Yu, Q.; Wan, X.M.; Zhao, T.J.; Wang, T.; Han, X.; Sun, Z.T. Study on chloride ion permeability resistance and electrical test method of alkali-excited slag concrete. Mater. Rep. 2022, 36, 100–105. [Google Scholar]

- Bai, W.F.; Ye, D.Q.; Ye, S.; Yuan, C.Y.; Guan, J.F.; Yang, G.; Xie, C.P. Study on mechanical properties and damage mechanism of alkali-activated slag concrete. J. Build. Eng. 2024, 96, 110357. [Google Scholar] [CrossRef]

- Wang, D.P.; Chen, P.Y.; Wang, L.; Li, X.K.; Shen, Q.H. Study on shrinkage characteristics of fly ash content on alkali-excited slag mortar. Bull. Chin. Ceram. Soc. 2018, 37, 701–705. [Google Scholar]

- Hameed, R.; Tahir, M.; Abbas, S.; Sheikh, H.U.; Kazmi, S.M.S.; Munir, M.J. Mechanical and Durability Characterization of Hybrid Recycled Aggregate Concrete. Materials 2024, 17, 1571. [Google Scholar] [CrossRef]

- Liu, X.; Wu, J.; Zhao, X.; Yan, P.P.; Ji, W.Y. Effect of brick waste content on mechanical properties of mixed recycled concrete. Constr. Build. Mater. 2021, 292, 123320. [Google Scholar] [CrossRef]

- Wang, Y.Y.; Yuan, H.; Chen, S.Y. Study on the ratio of alkali-inspired cementitious materials prepared from solid waste. Chem. Miner. Process. 2022, 51, 1–6. [Google Scholar]

- Moussadik, A.; El Fadili, H.; Saadi, M.; Diouri, A. Lightweight aerated concrete based on activated powders of coal gangue and fly ash. Constr. Build. Mater. 2024, 417, 135333. [Google Scholar] [CrossRef]

- JGJ/T 439-2018; Technical standard for application of alkali-activated slag concrete. Beijing Architecture & Building Press: Beijing, China, 2018.

- JGJ 55-2011; Specification for mix proportion design of ordinary concrete. China Architecture & Building Press: Beijing, China, 2011.

- JGJ/T 240-2011; Technical specification for application of recycled aggregate. China Architecture & Building Press: Beijing, China, 2011.

- Gan, W. Study on the effect of fly ash content on the properties of recycled concrete of construction waste. West. Transp. Sci. Technol. 2022, 182, 43–45. [Google Scholar]

- Yue, G.B.; Ma, Z.M.; Liu, M.; Liang, C.F.; Ba, G.Z. Damage behavior of the multiple ITZs in recycled aggregate concrete subjected to aggressive ion environment. Constr. Build. Mater. 2020, 245, 118419. [Google Scholar] [CrossRef]

- Bayraktar, O.Y.; Eshtewi, S.S.T.; Benli, A.; Kaplan, G.; Toklu, K.; Gunek, F. The impact of RCA and fly ash on the mechanical and durability properties of polypropylene fibre-reinforced concrete exposed to freeze-thaw cycles and MgSO4 with ANN modeling. Constr. Build. Mater. 2021, 313, 125508. [Google Scholar] [CrossRef]

- Mi, R.J.; Pan, G.H. Research progress on carbonization resistance of recycled concrete. J. Harbin Eng. Univ. 2020, 41, 473–480. [Google Scholar]

- Zhang, S.F.; Qi, H.J. Research progress on durability of recycled concrete. Concrete 2021, 383, 56–62. [Google Scholar]

- Martinez-Molina, W.; Chavez-Garcia, H.L.; Perez-Lopez, T.; Alonso-Guzman, E.M.; Arreola-Sanchez, M.; Navarrete-Seras, M.A.; Borrego-Perez, J.A.; Sanchez-Calvillo, A.; Guzman-Torres, J.A.; Perez-Quiroz, J.T. Effect of the Addition of Agribusiness and Industrial Wastes as a Partial Substitution of Portland Cement for the Carbonation of Mortars. Materials 2021, 14, 7276. [Google Scholar] [CrossRef]

- Zheng, X.C.; Liu, F.; Luo, T.; Duan, Y.F.; Yi, Y.; Hua, C. Study on Durability and Pore Characteristics of Concrete under Salt Freezing Environment. Materials 2021, 14, 7228. [Google Scholar] [CrossRef]

- Wu, J.C.; Cheng, Y.D.; Zhong, T.; Lai, D.J.; Chen, Z.W. Review of research on the strengthening of recycled aggregates for construction waste. Environ. Sanit. Eng. 2022, 30, 53–62. [Google Scholar]

| SiO2 | Al2O3 | Fe2O3 | CaO | Na2O | MnO | MgO | SO3 | TiO2 | BaO | SrO |

|---|---|---|---|---|---|---|---|---|---|---|

| 56.12 | 30.25 | 5.65 | 4.59 | 0.38 | 0.05 | 0.43 | 0.91 | 1.43 | 0.07 | 0.12 |

| Projects | Standard Regulations | Recycled Coarse Aggregates | |||||

|---|---|---|---|---|---|---|---|

| NC | I | II | III | I | II | III | |

| Micro-powder content (%) | <0.5 | <1.0 | <2.0 | <3.0 | 0.6 | 1.4 | 1.8 |

| Water absorption rate (%) | <2 | <3.0 | <5.0 | <8.0 | 2.3 | 4.2 | 7.0 |

| Needle flake particle content (%) | <8 | <10.0 | 1.7 | 3.4 | 6.2 | ||

| Impurity content (%) | <1 | <1.0 | 0.2 | 0.7 | 0.8 | ||

| Robustness (%) | <5 | <5.0 | <10.0 | <15.0 | 3.8 | 7.4 | 14.5 |

| Crushing index (%) | <10 | <12.0 | <20.0 | <30.0 | 9.5 | 18.0 | 28.7 |

| Apparent density (kg/m3) | >2500 | >2450 | >2350 | >2250 | 2469 | 2452 | 2313 |

| Void ratio (%) | <45 | <47.0 | <50.0 | <53.0 | 42.0 | 44.0 | 45.0 |

| Mark | Replacement Ratio (%) | Alkali Equivalent (%) | Modulus | Mineral Powder (kg/m3) | FA (kg/m3) | Sand (kg/m3) | As/C Ratio |

|---|---|---|---|---|---|---|---|

| FA-0 | 0 | 3.5 | 1.00 | 400 | 0 | 724 | 0.45 |

| FA-15 | 15 | 3.5 | 1.00 | 340 | 60 | 724 | 0.45 |

| FA-30 | 30 | 3.5 | 1.00 | 280 | 120 | 724 | 0.45 |

| FA-45 | 45 | 3.5 | 1.00 | 220 | 180 | 724 | 0.45 |

| FA-60 | 60 | 3.5 | 1.00 | 160 | 240 | 724 | 0.45 |

| Mark | Mineral Powder | Fly Ash | Alkali Equivalent | Sand | Coarse Aggregate | Water Glass | NaOH |

|---|---|---|---|---|---|---|---|

| SF1-1 | 245 | 105 | 3.0 | 742 | 1113 | 36.46 | 9.57 |

| SF1-2 | 280 | 120 | 3.0 | 724 | 1086 | 41.67 | 10.93 |

| SF1-3 | 315 | 135 | 3.0 | 706 | 1059 | 46.88 | 12.30 |

| SF1-4 | 350 | 150 | 3.0 | 688 | 1032 | 52.09 | 13.66 |

| SF2-1 | 245 | 105 | 3.5 | 742 | 1113 | 42.54 | 11.16 |

| SF2-2 | 280 | 120 | 3.5 | 724 | 1086 | 48.62 | 12.75 |

| SF2-3 | 315 | 135 | 3.5 | 706 | 1059 | 54.69 | 14.35 |

| SF2-4 | 350 | 150 | 3.5 | 688 | 1032 | 60.77 | 15.94 |

| Strength Grade | C20 | C25–C45 | C50–C55 |

|---|---|---|---|

| Standard value () | 4.0 | 5.0 | 6.0 |

| Aggregate Type | Cementitious System | Regression Equation | Correlation Coefficient |

|---|---|---|---|

| Natural aggregate | S95 + FA | y = 0.1084x + 3.03 | R2 = 0.9817 |

| I-class RCA | S95 + FA | y = 0.1148x − 3.49 | R2 = 0.9813 |

| II-class RCA | S95 + FA | y = 0.1080x − 3.15 | R2 = 0.9792 |

| III-class RCA | S95 + FA | y = 0.1102x − 8.21 | R2 = 0.9851 |

| Aggregate Type | Cementitious System | Regression Equation | Correlation Coefficient |

|---|---|---|---|

| Natural aggregate | S95 + FA | y = −227.9439x + 154.80 | R2 = 0.9760 |

| I-class RCA | S95 + FA | y = −217.6471x + 149.77 | R2 = 0.9482 |

| II-class RCA | S95 + FA | y = −200.8824x + 140.51 | R2 = 0.9442 |

| III-class RCA | S95 + FA | y = −183.6667x + 131.38 | R2 = 0.9851 |

| Mark | Strength Grade | S95 | FA | Fine Aggregate | Coarse Aggregate | Water Glass | NaOH | Additional Water | Solubility Ratio |

|---|---|---|---|---|---|---|---|---|---|

| NSF | C30 | 227.1 | 97.3 | 743.8 | 1115.8 | 39.4 | 10.3 | 116.1 | 0.51 |

| C35 | 259.4 | 111.2 | 723.2 | 1084.8 | 45.0 | 11.8 | 124.5 | 0.49 | |

| C40 | 291.7 | 125.0 | 703.4 | 1055.1 | 50.6 | 13.3 | 130.9 | 0.47 | |

| C45 | 324.0 | 138.8 | 684.4 | 1026.5 | 56.3 | 14.8 | 135.2 | 0.45 | |

| C50 | 367.2 | 157.4 | 658.8 | 988.2 | 63.8 | 16.7 | 137.8 | 0.42 | |

| RISF | C30 | 254.2 | 108.9 | 716.3 | 1074.4 | 44.1 | 11.6 | 130.4 | 0.51 |

| C35 | 284.7 | 122.0 | 697.7 | 1046.5 | 49.4 | 13.0 | 136.7 | 0.49 | |

| C40 | 315.2 | 135.1 | 679.8 | 1019.8 | 54.7 | 14.4 | 141.0 | 0.47 | |

| C45 | 345.7 | 148.1 | 662.8 | 994.2 | 60.0 | 15.7 | 143.3 | 0.44 | |

| C50 | 386.5 | 165.7 | 639.9 | 959.9 | 67.1 | 17.6 | 143.2 | 0.41 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, C.; Wang, X.; Li, Y.; Li, Q.; Yue, G. Evaluation on Preparation and Performance of a Low-Carbon Alkali-Activated Recycled Concrete under Different Cementitious Material Systems. Materials 2024, 17, 4869. https://doi.org/10.3390/ma17194869

Liu C, Wang X, Li Y, Li Q, Yue G. Evaluation on Preparation and Performance of a Low-Carbon Alkali-Activated Recycled Concrete under Different Cementitious Material Systems. Materials. 2024; 17(19):4869. https://doi.org/10.3390/ma17194869

Chicago/Turabian StyleLiu, Cheng, Xinyan Wang, Yujiao Li, Qiuyi Li, and Gongbing Yue. 2024. "Evaluation on Preparation and Performance of a Low-Carbon Alkali-Activated Recycled Concrete under Different Cementitious Material Systems" Materials 17, no. 19: 4869. https://doi.org/10.3390/ma17194869

APA StyleLiu, C., Wang, X., Li, Y., Li, Q., & Yue, G. (2024). Evaluation on Preparation and Performance of a Low-Carbon Alkali-Activated Recycled Concrete under Different Cementitious Material Systems. Materials, 17(19), 4869. https://doi.org/10.3390/ma17194869