Preparation and Oil Adsorption of Cellulose-graft-poly(butyl acrylate-N,N′-methylene Bisacrylamide)

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials and Reagents

2.2. Adsorbent Preparation and Characterization

2.3. Adsorption Capacity of Oils and Organic Solvents

2.4. Oil–Water Separation Performance

2.5. Regeneration Performance

3. Results and Discussion

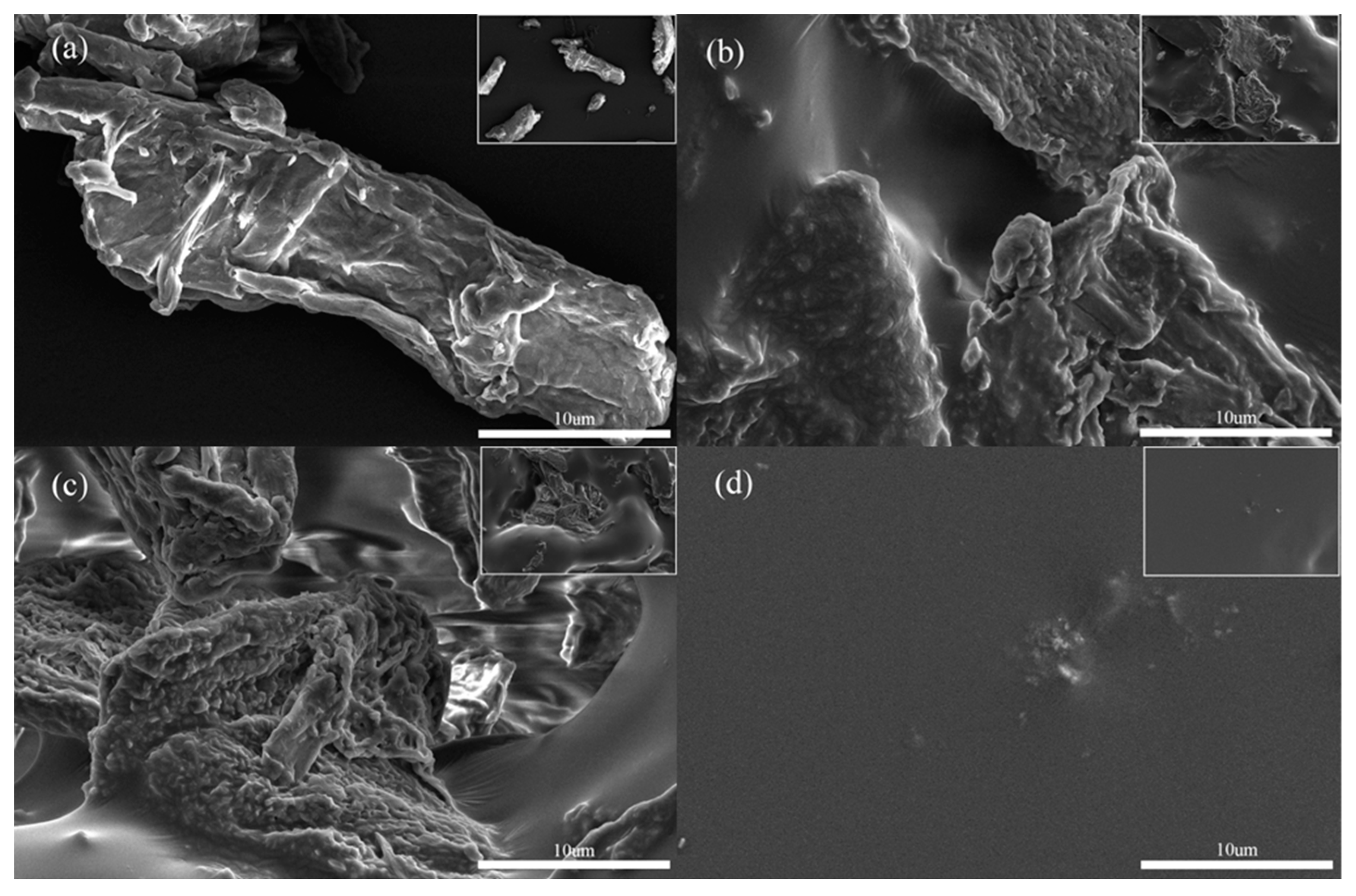

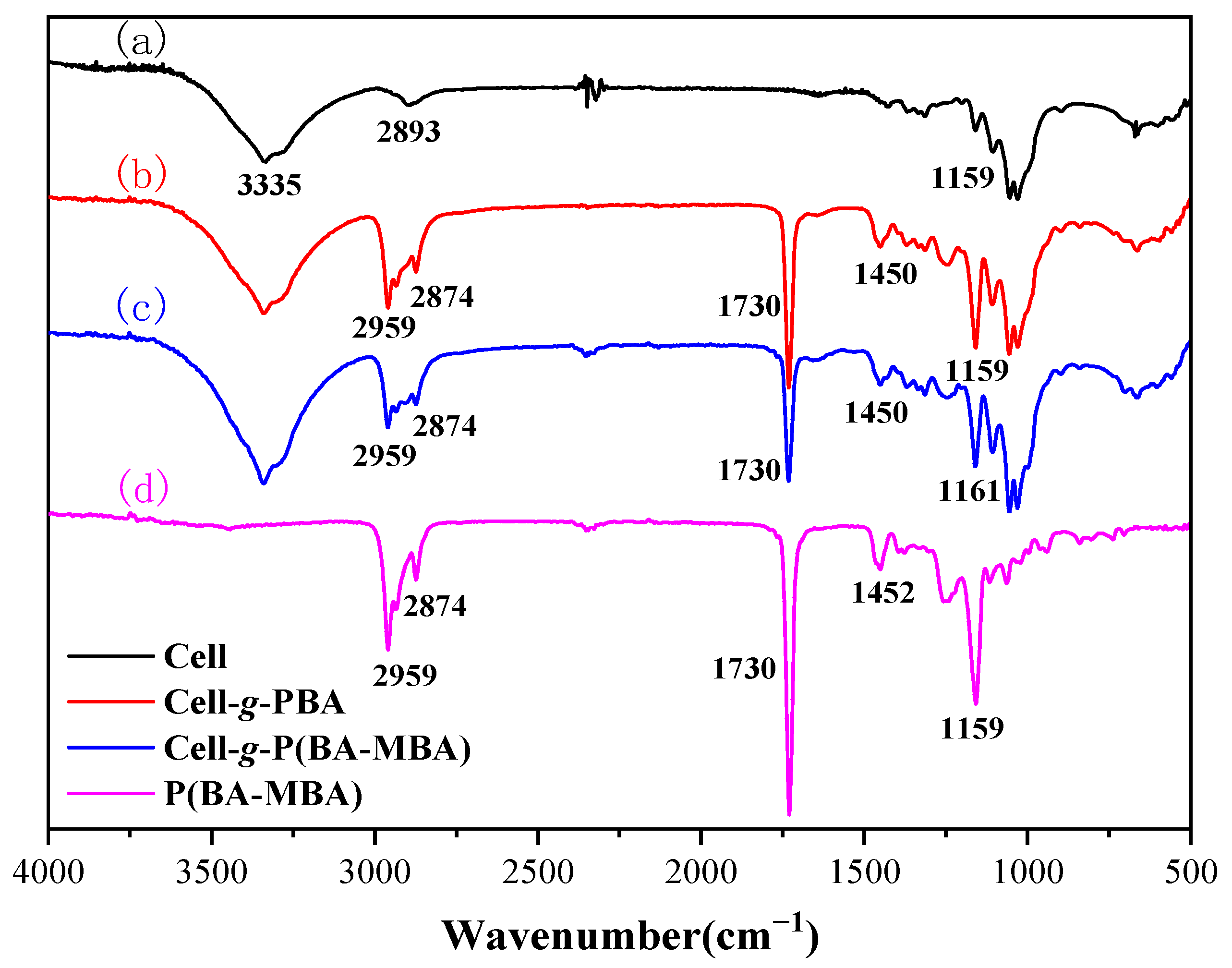

3.1. Characterization of Polymers

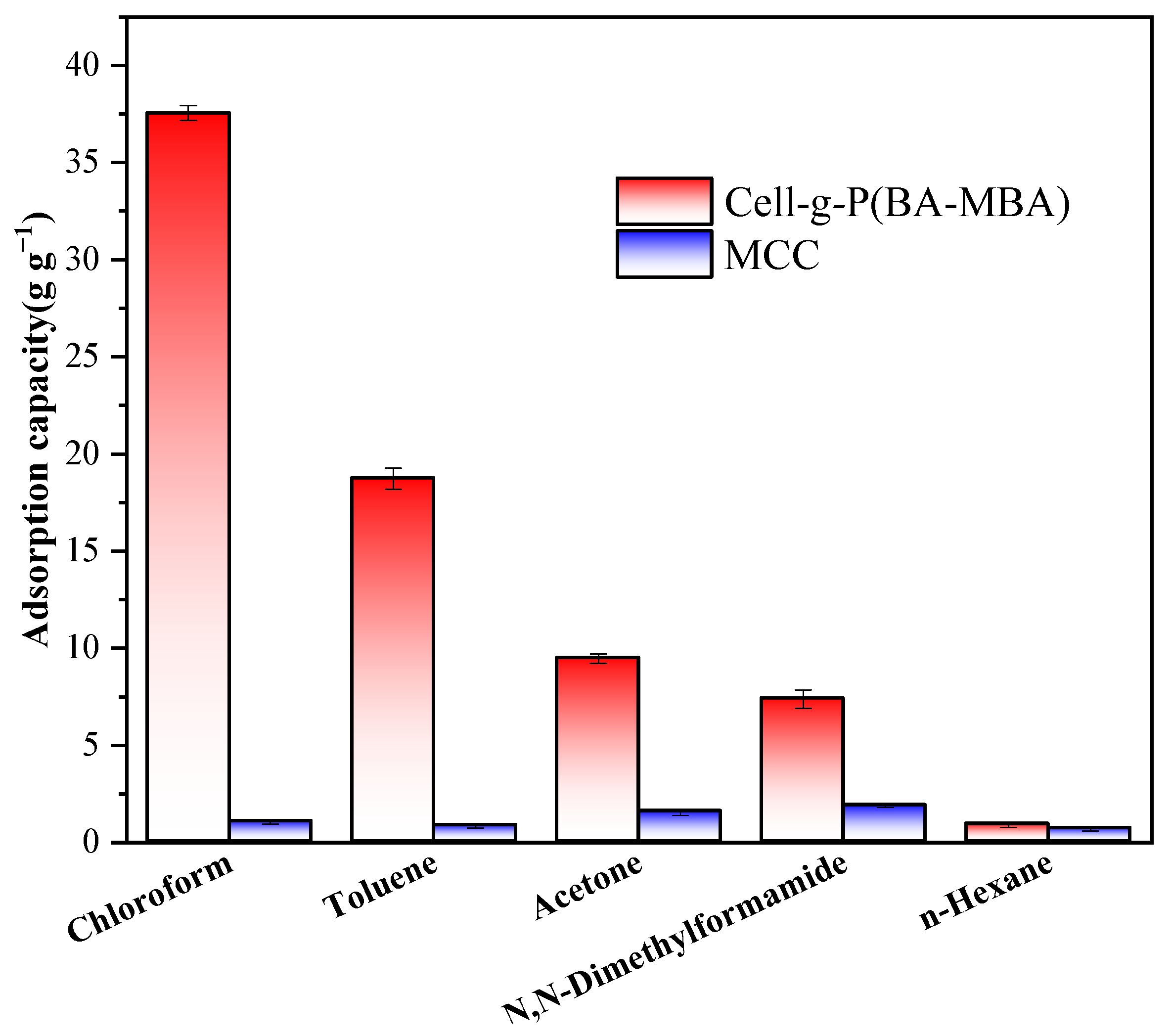

3.2. Adsorption Property Testing

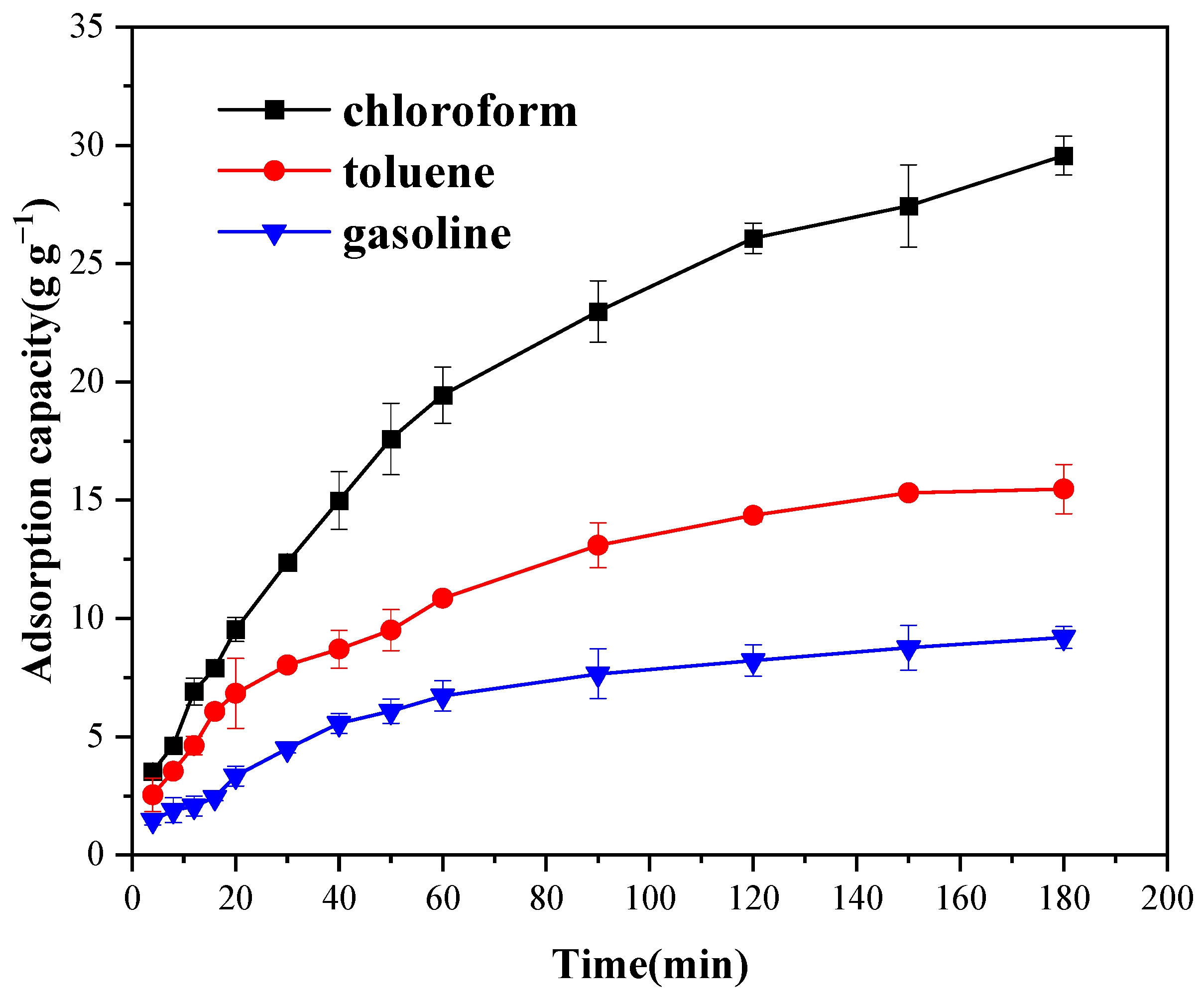

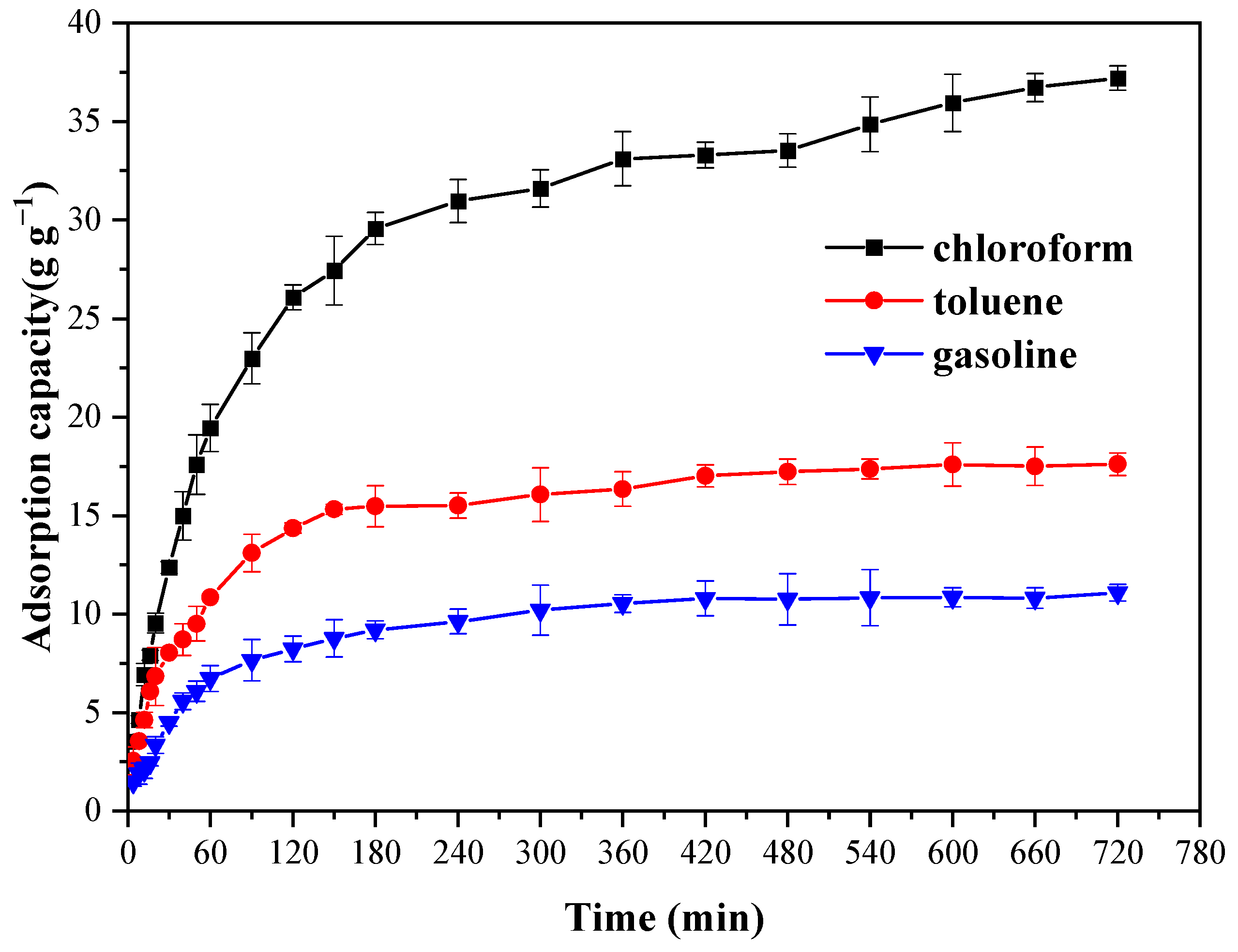

3.3. Adsorption Kinetics

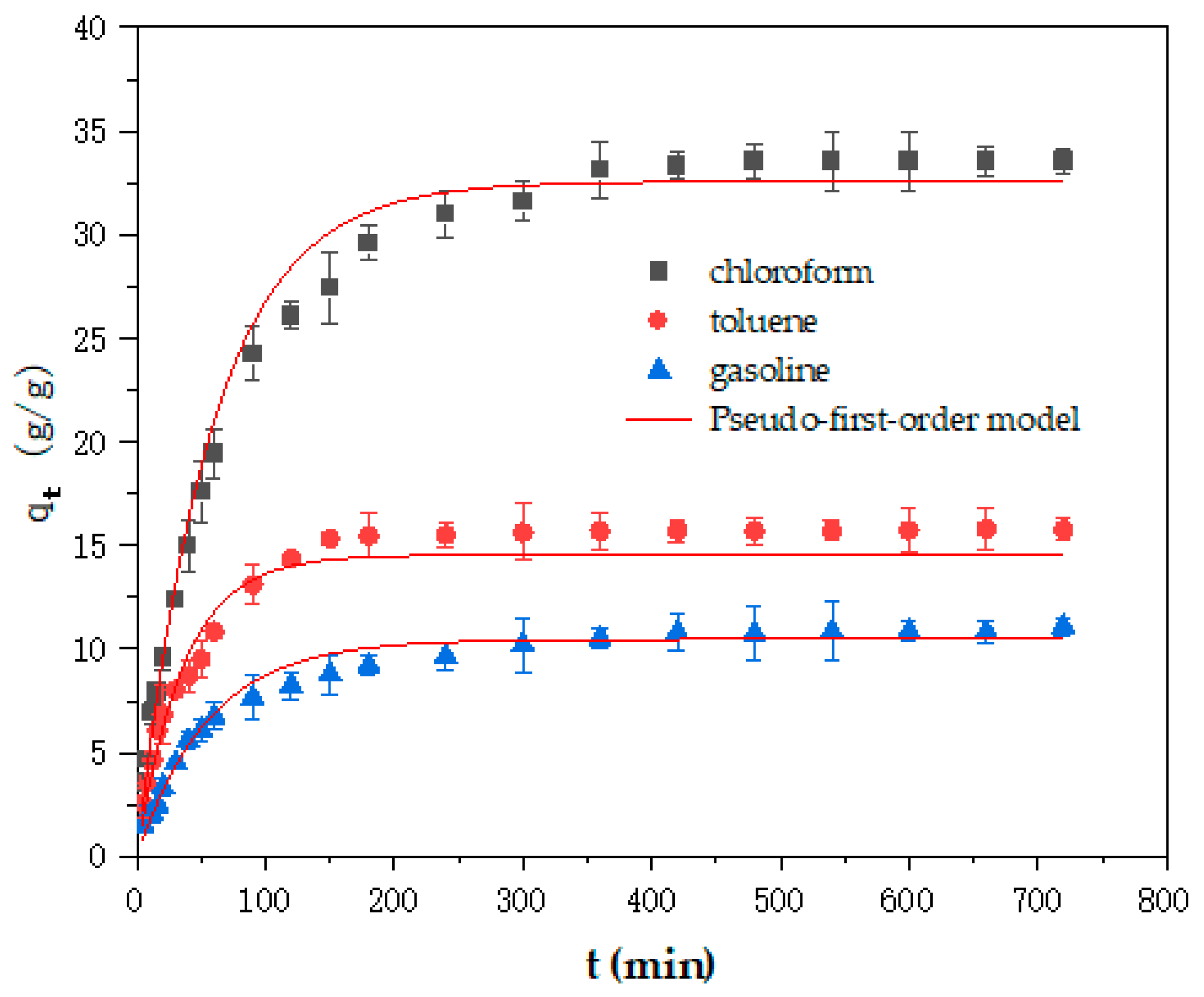

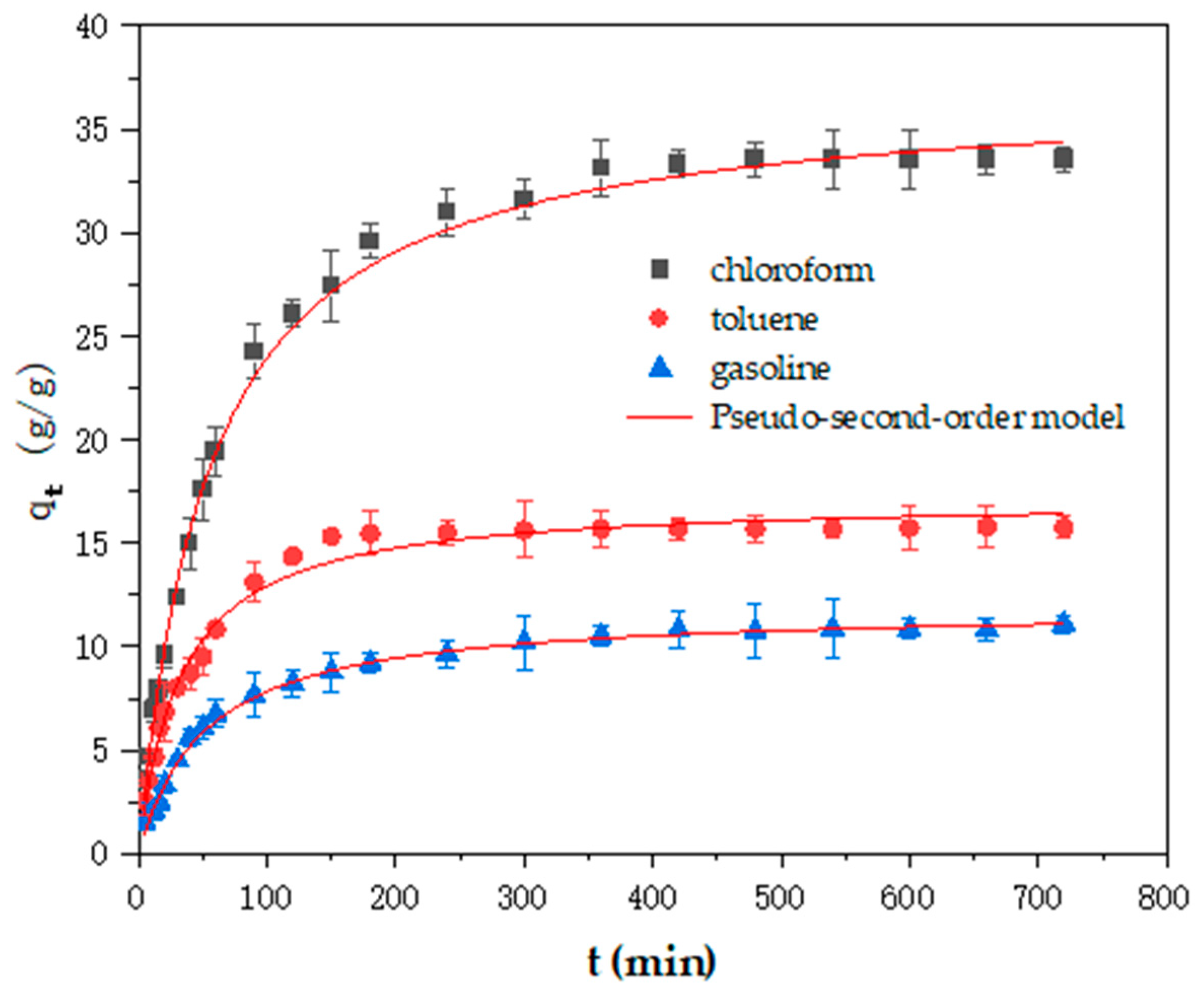

3.4. Adsorption Isotherm

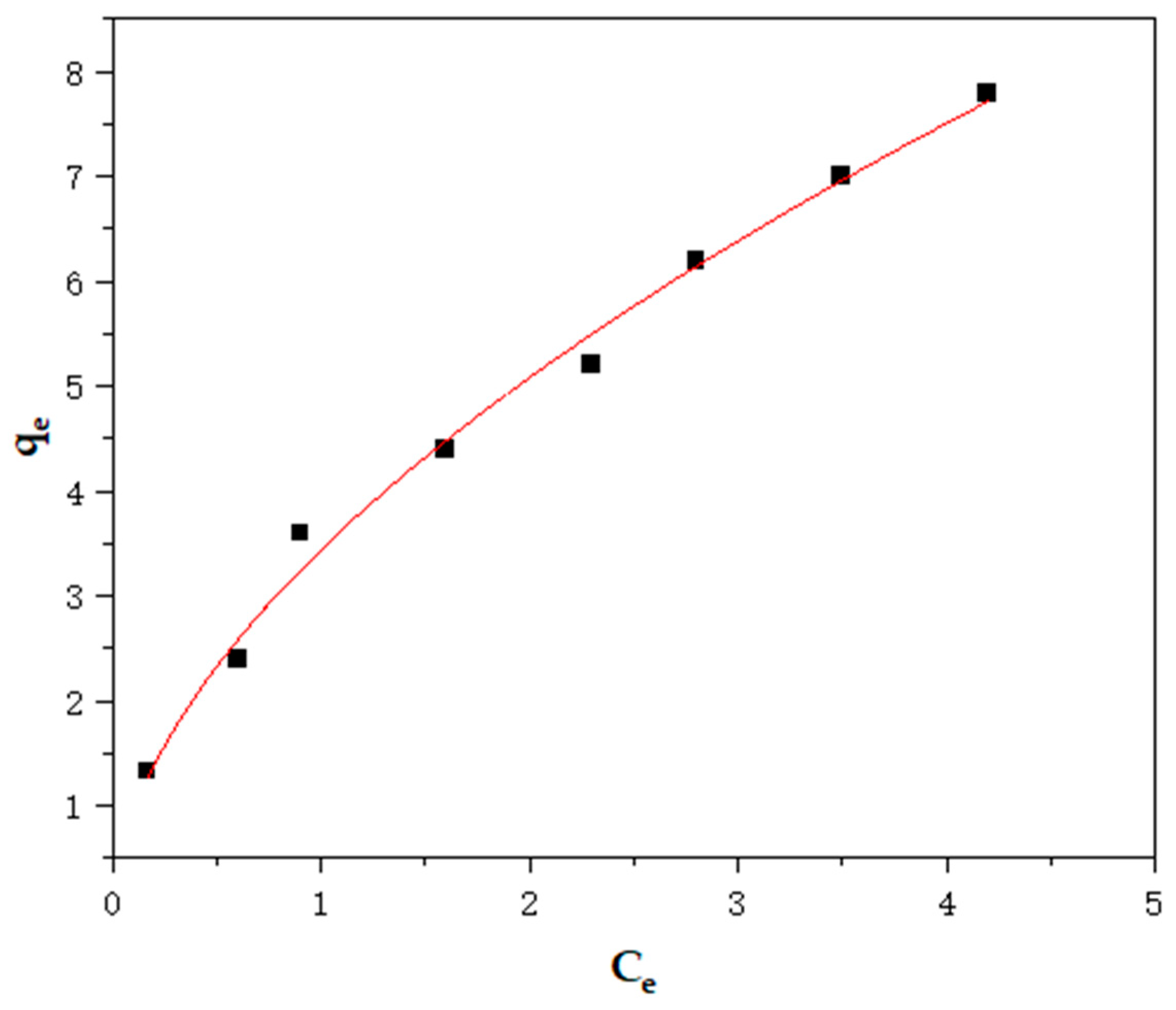

3.5. Adsorption Thermodynamics

3.6. Oil-Water Separation Performance

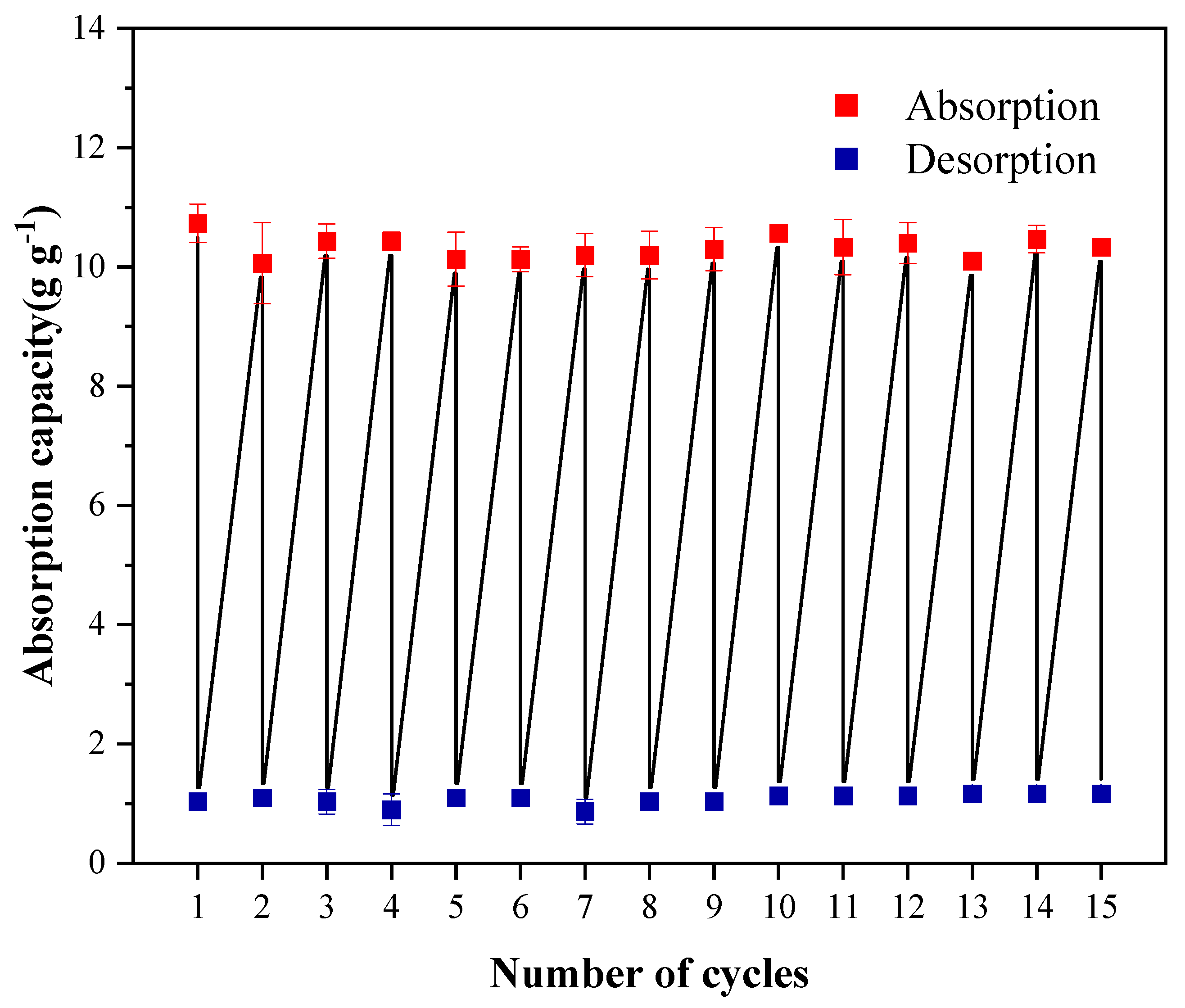

3.7. Regeneration Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hubbe, M.A.; Rojas, O.J.; Fingas, M.; Gupta, B.S. Cellulosic Substrates for Removal of Pollutants from Aqueous Systems: A Review. 3. Spilled Oil and Emulsified Organic Liquids. BioResources 2013, 8, 3038–3097. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Z.; Lu, Y.; Liu, Y.; Yang, D.; Li, Q.; Qiu, F. Recent progress and future prospects of oil-absorbing materials. Chin. J. Chem. Eng. 2019, 27, 1282–1295. [Google Scholar] [CrossRef]

- Atlas, R.M.; Hazen, T.C. Oil Biodegradation and Bioremediation: A Tale of the Two Worst Spills in US History. Environ. Sci. Technol. 2011, 45, 6709–6715. [Google Scholar] [CrossRef] [PubMed]

- Barron, M.G. Ecological Impacts of the Deepwater Horizon Oil Spill: Implications for Immunotoxicity. Toxicol. Pathol. 2012, 40, 315–320. [Google Scholar] [CrossRef] [PubMed]

- Scarlett, A.G.; Nelson, R.K.; Gagnon, M.M.; Holman, A.I.; Reddy, C.M.; Sutton, P.A.; Grice, K. MV Wakashio grounding incident in Mauritius 2020: The world’s first major spillage of Very Low Sulfur Fuel Oil. Mar. Pollut. Bull. 2021, 171, 112917. [Google Scholar] [CrossRef] [PubMed]

- Oliveira, L.M.T.M.; Saleem, J.; Bazargan, A.; Duarte, J.L.D.S.; McKay, G.; Meili, L. Sorption as a rapidly response for oil spill accidents: A material and mechanistic approach. J. Hazard. Mater. 2021, 407, 124842. [Google Scholar] [CrossRef] [PubMed]

- Patalano, A.; Villalobos, F.; Pena, P.; Jauregui, E.; Ozkan, C.; Ozkan, M. Scaling sorbent materials for real oil-sorbing applications and environmental disasters. MRS Energy Sustain. 2019, 6, e3. [Google Scholar] [CrossRef]

- Dave, D.; Ghaly, A.E. Remediation technologies for marine oil spills: A critical review and comparative analysis. Am. J. Environ. Sci. 2011, 7, 423–440. [Google Scholar] [CrossRef]

- Ifelebuegu, A.O.; Johnson, A. Nonconventional low-cost cellulose- and keratin-based biopolymeric sorbents for oil/water separation and spill cleanup: A review. Crit. Rev. Environ. Sci. Technol. 2017, 47, 964–1001. [Google Scholar] [CrossRef]

- Karan, C.P.; Rengasamy, R.S.; Das, D. Oil spill cleanup by structured fibre assembly. Indian J. Fibre Text. Res. 2011, 36, 190–200. [Google Scholar]

- Nyankson, E.; Rodene, D.; Gupta, R.B. Advancements in Crude Oil Spill Remediation Research after the Deepwater Horizon Oil Spill. Water Air Soil Pollut. 2016, 227, 29. [Google Scholar] [CrossRef]

- Zhang, N.; Qi, Y.; Zhang, Y.; Luo, J.; Cui, P.; Jiang, W. A Review on Oil/Water Mixture Separation Material. Ind. Eng. Chem. Res. 2020, 59, 14546–14568. [Google Scholar] [CrossRef]

- Dhaka, A.; Chattopadhyay, P. A review on physical remediation techniques for treatment of marine oil spills. J. Environ. Manag. 2021, 288, 112428. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Dong, L.; Zhang, D.; Chen, X.; Xue, Y.; Guan, Y.; Li, Y. Mesoporous carbon spheres modified polyurethane sponge/phase change material composites: Photothermal conversion, thermal storage and efficient recovery of high-viscosity crude oil. Carbon 2023, 214, 118372. [Google Scholar] [CrossRef]

- Lee, H.; Trinh, B.M.; Crawford, E.A.; Mekonnen, T.H. Thermoplastic elastomer melt-blown fiber mats for oil spill remediation: Fabrication, oil uptake, and gel formation studies. Sep. Purif. Technol. 2023, 326, 124761. [Google Scholar] [CrossRef]

- El Allaoui, B.; Chakhtouna, H.; Zari, N.; Benzeid, H.; Qaiss, A.E.; Bouhfid, R. Superhydrophobic alkylsilane functionalized cellulose beads for efficient oil/water separation. J. Water Process. Eng. 2023, 54, 104015. [Google Scholar] [CrossRef]

- Mahmodi, G.; Bafti, R.R.; Boroujeni, N.I.; Pradhan, S.; Dangwal, S.; Sengupta, B.; Vatanpour, V.; Sorci, M.; Fathizadeh, M.; Bikkina, P.; et al. Improving cellulose acetate mixed matrix membranes by incorporating hydrophilic MIL-101(Cr)-NH2 nanoparticles for treating dye/salt solution. Chem. Eng. J. 2023, 477, 146736. [Google Scholar] [CrossRef]

- Kadili, J.A.; Abdullah, A.H.; Johari, I.S.; Zainuddin, N.; Jamil, S. Highly efficient and reusable superhydrophobic 3D polyurethane nanocomposite foam for remediation of oil polluted water. J. Porous Mater. 2023. [Google Scholar] [CrossRef]

- Quoc Ba, T.; Son Truong, N.; Duong Khanh, H.; Tuan Du, T.; Dat Minh, H.; Do, N.H.N.; Thao Phuong, L.; Le, P.K.; Le, D.K.; Nhan, P.-T.; et al. Cellulose-based aerogels from sugarcane bagasse for oil spill-cleaning and heat insulation applications. Carbohydr. Polym. 2020, 228, 115365. [Google Scholar]

- Omran, A.A.B.; Mohammed, A.A.B.A.; Sapuan, S.M.; Ilyas, R.A.; Asyraf, M.R.M.; Rahimian Koloor, S.S.; Petru, M. Micro- and Nanocellulose in Polymer Composite Materials: A Review. Polymers 2021, 13, 231. [Google Scholar] [CrossRef]

- Teli, M.D.; Valia, S.P. Grafting of Butyl Acrylate on to Banana Fibers for Improved Oil Absorption. J. Nat. Fibers 2016, 13, 470–476. [Google Scholar] [CrossRef]

- Krishnan, M.R.; Almohsin, A.; Alsharaeh, E.H. Syntheses and fabrication of mesoporous styrene-co-methyl methacrylate-graphene composites for oil removal. Diam. Relat. Mater. 2022, 130, 109494. [Google Scholar] [CrossRef]

- Iordanskii, A.; Karpova, S.; Olkhov, A.; Borovikov, P.; Kildeeva, N.; Liu, Y. Structure-morphology impact upon segmental dynamics and diffusion in the biodegradable ultrafine fibers of polyhydroxybutyrate-polylactide blends. Eur. Polym. J. 2019, 117, 208–216. [Google Scholar] [CrossRef]

- Viju, S.; Brindha, R.; Thilagavathi, G. Surface modification of nettle fibers by grafting to improve oil sorption capacity. J. Ind. Text. 2019, 50, 1314–1329. [Google Scholar] [CrossRef]

- Yue, X.; Zhang, T.; Yang, D.; Qiu, F.; Rong, J.; Xu, J.; Fang, J. The synthesis of hierarchical porous Al2O3/acrylic resin composites as durable, efficient and recyclable absorbents for oil/water separation. Chem. Eng. J. 2017, 309, 522–531. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Kang, Y.; Wang, A. Investigation of oil sorption capability of PBMA/SiO2 coated kapok fiber. Chem. Eng. J. 2013, 223, 632–637. [Google Scholar] [CrossRef]

- Littunen, K.; Hippi, U.; Johansson, L.-S.; Osterberg, M.; Tammelin, T.; Laine, J.; Seppala, J. Free radical graft copolymerization of nanofibrillated cellulose with acrylic monomers. Carbohydr. Polym. 2011, 84, 1039–1047. [Google Scholar] [CrossRef]

- Wang, J.; Zheng, Y.; Wang, A. Preparation and properties of kapok fiber enhanced oil sorption resins by suspended emulsion polymerization. J. Appl. Polym. Sci. 2013, 127, 2184–2191. [Google Scholar] [CrossRef]

- Rani, K.; Gomathi, T.; Vijayalakshmi, K.; Saranya, M.; Sudha, P.N. Banana fiber Cellulose Nano Crystals grafted with butyl acrylate for heavy metal lead (II) removal. Int. J. Biol. Macromol. 2019, 131, 461–472. [Google Scholar]

- Siddiqui, M.N.; Redhwi, H.H.; Charitopoulou, D.; Achilias, D.S. Effect of organomodified clay on the reaction kinetics, properties and thermal degradation of nanocomposites based on poly(styrene-co-ethyl methacrylate). Polym. Int. 2014, 63, 766–777. [Google Scholar] [CrossRef]

- Devi, P.; Singh, J.; Rehmaan, H.; Kaushik, R.D. Novel Aloe-Vera and allyl methacrylate-based antimicrobial copolymer nanoemulsion for coating: An in-situ approach. J. Polym. Res. 2022, 29, 511. [Google Scholar] [CrossRef]

- Zhu, Q.; Chu, Y.; Wang, Z.; Chen, N.; Lin, L.; Liu, F.; Pan, Q. Robust superhydrophobic polyurethane sponge as a highly reusable oil-absorption material. J. Mater. Chem. A 2013, 1, 5386–5393. [Google Scholar] [CrossRef]

- Rizvi, A.; Chu, R.K.M.; Lee, J.H.; Park, C.B. Superhydrophobic and Oleophilic Open-Cell Foams from Fibrillar Blends of Polypropylene and Polytetrafluoroethylene. ACS Appl. Mater. Interfaces 2014, 6, 21131–21140. [Google Scholar] [CrossRef] [PubMed]

- Koroleva, M.Y.; Yurtov, E.V. Pickering emulsions: Structure, properties and the use as colloidosomes and stimuli-responsive emulsions. Russ. Chem. Rev. 2022, 91, RCR5024. [Google Scholar] [CrossRef]

- Yan, L.; Li, Q.; Wang, X.; Song, H.; Chi, H.; Qiao, Y.; Zhai, Y.; Liu, D. Synthesis and Absorption Performance of Acrylic Ester and Hollow Fiber MgO Nanoparticle Resin Composite. Polym.-Plast. Technol. Eng. 2017, 56, 1857–1865. [Google Scholar] [CrossRef]

- Krishnan, M.R.; Aldawsari, Y.F.; Alsharaeh, E.H. Three-dimensionallycross-linkedstyrene-methyl methacrylate-divinylbenzene terpolymer networks for organic solvents and crude oil absorption. J. Appl. Polym. Sci. 2021, 138, 9. [Google Scholar] [CrossRef]

- Foo, K.Y.; Hameed, B.H. Insights into the modeling of adsorption isotherm systems. Chem. Eng. J. 2010, 156, 2–10. [Google Scholar] [CrossRef]

- Wang, X.; Jiang, C.; Hou, B.; Wang, Y.; Hao, C.; Wu, J. Carbon composite lignin-based adsorbents for the adsorption of dyes. Chemosphere 2018, 206, 587–596. [Google Scholar] [CrossRef]

- Mohammadpour, R.; Mir Mohamad Sadeghi, G. Effect of Liquefied Lignin Content on Synthesis of Bio-based Polyurethane Foam for Oil Adsorption Application. J. Polym. Environ. 2020, 28, 892–905. [Google Scholar] [CrossRef]

- Ashrafi, S.D.; Safari, G.H.; Sharafi, K.; Kamani, H.; Jaafari, J. Adsorption of 4-Nitrophenol on calcium alginate-multiwall carbon nanotube beads: Modeling, kinetics, equilibriums and reusability studies. Int. J. Biol. Macromol. 2021, 185, 66–76. [Google Scholar] [CrossRef]

| Sample Name | H (%) | C (%) | N (%) |

|---|---|---|---|

| MCC | 6.66 | 42.23 | 0 |

| Cell-g-PBA | 9.32 | 62.77 | 0 |

| Cell-g-P(BA-MBA) | 9.25 | 65.40 | <0.1 |

| P(BA-MBA) | 9.78 | 65.56 | <0.1 |

| Adsorbents | Oil Adsorption Capacity (g/g) | References |

|---|---|---|

| PS-PMMA/DVB | 1.5–12.1 | [32] |

| PP/PTFE fibrillar blend | 5–24 | [33] |

| Supermacroporous Polystyrene materials | 29.5 | [34] |

| Porous Al2O3/acrylic resin composites | 6.8–30.1 | [25] |

| Hollow Fiber MgO Nanoparticle Resin composite | 10.4–28.2 | [35] |

| Cell-g-P(BA-MBA) | 0.5–37.6 | This work |

| Pseudo-First-Order | Pseudo-Second-Order | ||||||

|---|---|---|---|---|---|---|---|

| Oil | qe,exp (g/g) | k1 (min−1) | qe,calc (g/g) | R2 | k2 (g/g min−1) | qe,calc (g/g) | R2 |

| Chloroform | 37.55 | 0.0176 | 32.55 | 0.98695 | 0.0021 | 36.98 | 0.99353 |

| Toluene | 18.72 | 0.0278 | 14.53 | 0.95609 | 0.0018 | 17.16 | 0.9869 |

| Gasoline | 10.45 | 0.0180 | 10.46 | 0.98089 | 0.0016 | 11.88 | 0.9882 |

| Oil | Langmuir Isotherm | Freundlich Isotherm | ||||

|---|---|---|---|---|---|---|

| qmax (g/g) | KL (L/g) | R2 | KF (g/g) | n | R2 | |

| gasoline | 10.12 | 0.57 | 0.94653 | 3.44 | 1.78 | 0.99094 |

| T (K) | ∆G0 (kJ mol−1) | ∆H0 (kJ mol−1) | ∆S0 (J mol−1 K−1) | R2 |

|---|---|---|---|---|

| 293.15 | −1.3547 | |||

| 303.15 | −1.1151 | −9.7099 | −0.0285 | 0.9970 |

| 313.15 | −0.8162 | |||

| 323.15 | −0.5027 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, P.-X.; Wang, X.-G.; Yang, M.-Q.; Wang, J.-X.; Meng, F.-J. Preparation and Oil Adsorption of Cellulose-graft-poly(butyl acrylate-N,N′-methylene Bisacrylamide). Materials 2024, 17, 325. https://doi.org/10.3390/ma17020325

Guo P-X, Wang X-G, Yang M-Q, Wang J-X, Meng F-J. Preparation and Oil Adsorption of Cellulose-graft-poly(butyl acrylate-N,N′-methylene Bisacrylamide). Materials. 2024; 17(2):325. https://doi.org/10.3390/ma17020325

Chicago/Turabian StyleGuo, Peng-Xiang, Xin-Gang Wang, Mao-Qian Yang, Jian-Xin Wang, and Fan-Jun Meng. 2024. "Preparation and Oil Adsorption of Cellulose-graft-poly(butyl acrylate-N,N′-methylene Bisacrylamide)" Materials 17, no. 2: 325. https://doi.org/10.3390/ma17020325

APA StyleGuo, P.-X., Wang, X.-G., Yang, M.-Q., Wang, J.-X., & Meng, F.-J. (2024). Preparation and Oil Adsorption of Cellulose-graft-poly(butyl acrylate-N,N′-methylene Bisacrylamide). Materials, 17(2), 325. https://doi.org/10.3390/ma17020325