Investigating the Impact of Substrate Preheating on the Thermal Flow and Microstructure of Laser Cladding of Nickel-Based Superalloy

Abstract

1. Introduction

2. Models and Parameters

- (1)

- The flow of liquid fluid in the molten pool is Newtonian, laminar and incompressible;

- (2)

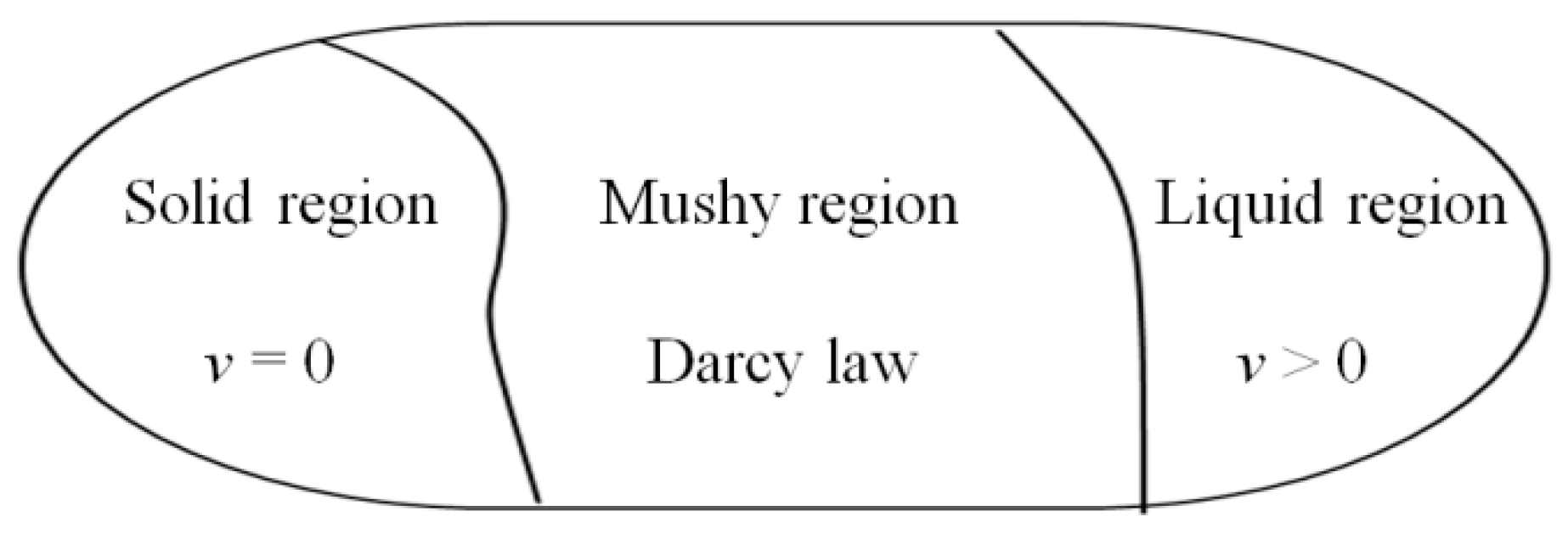

- The mushy region is assumed to be a porous medium with isotropic permeability;

- (3)

- The heat flux generated by the heated powder and the heat loss caused by evaporation are disregarded;

- (4)

- The impact of shielding gas, feeding gas and powder on the melt pool surface is omitted.

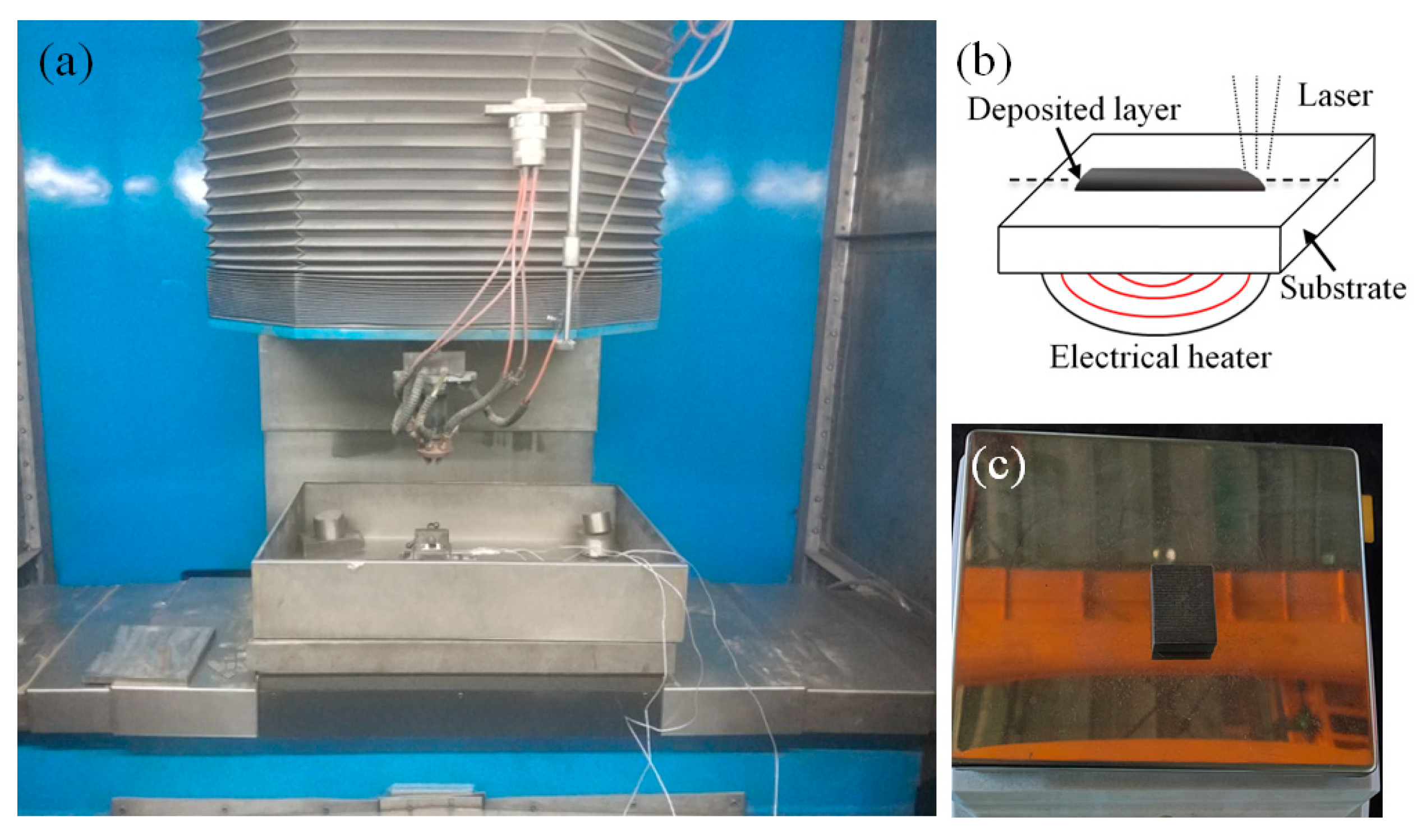

3. Experiment Scheme

4. Results and Discussion

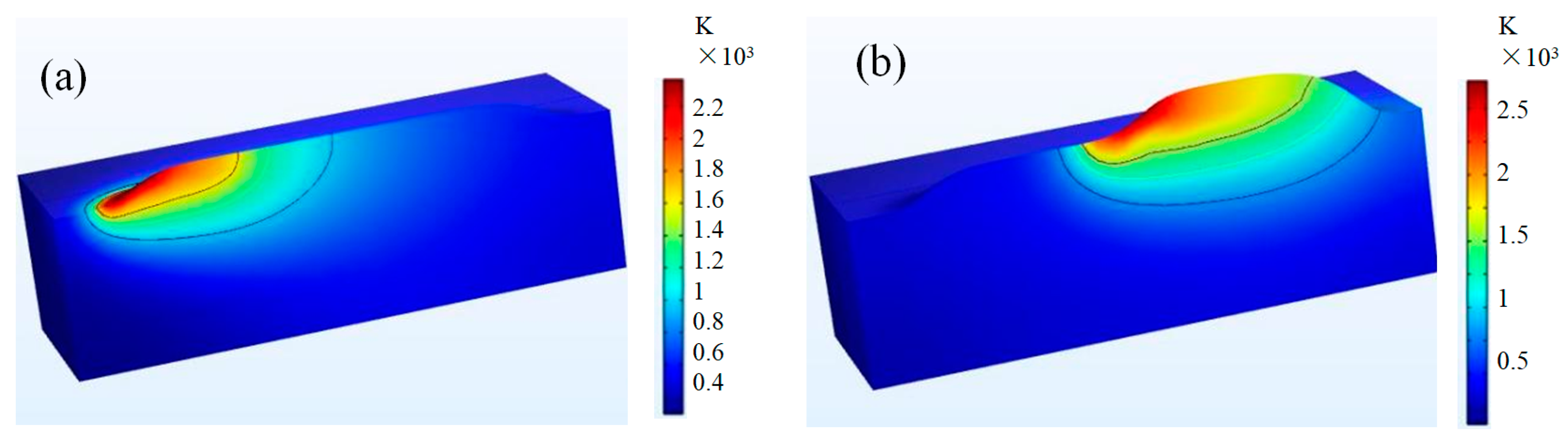

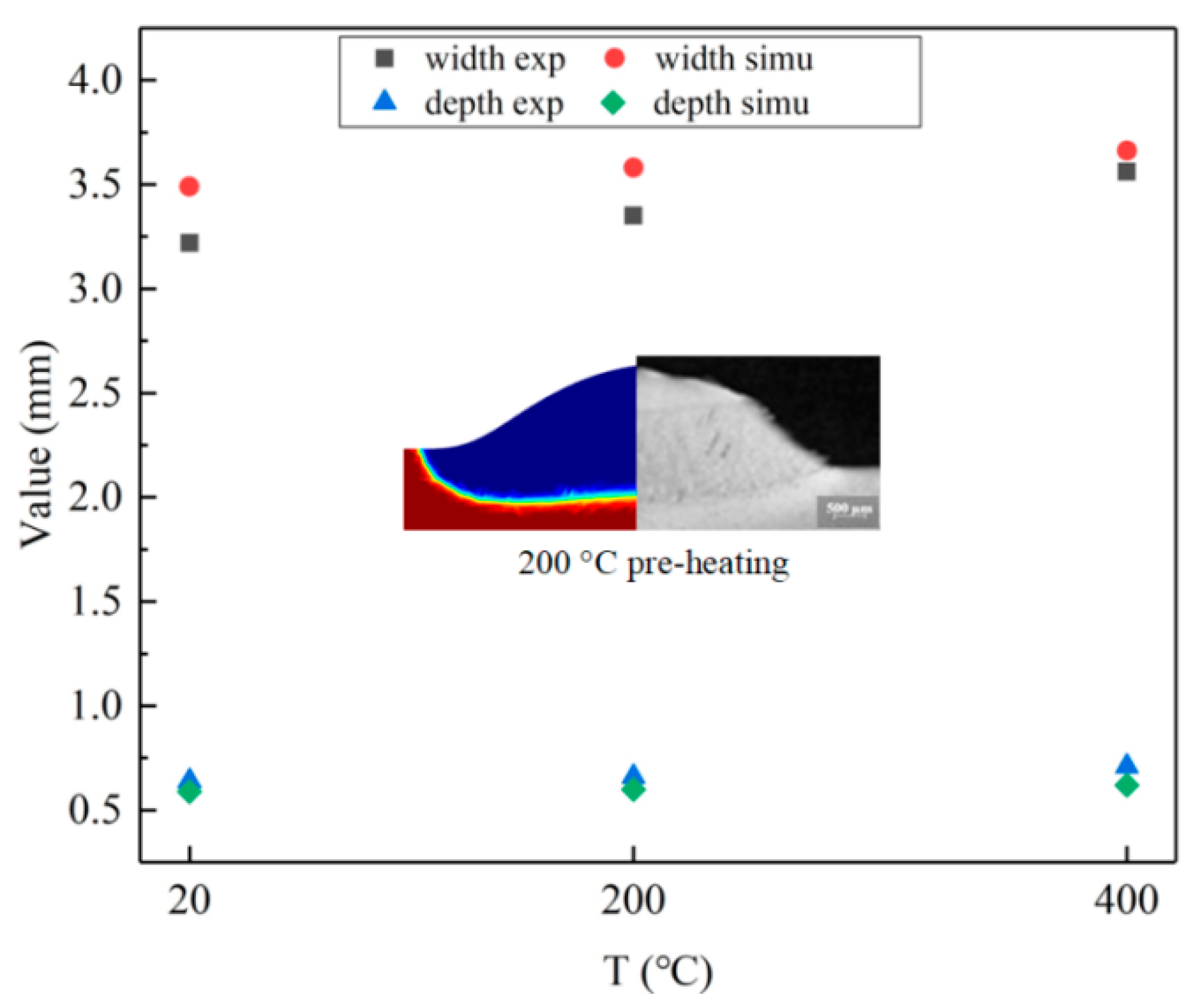

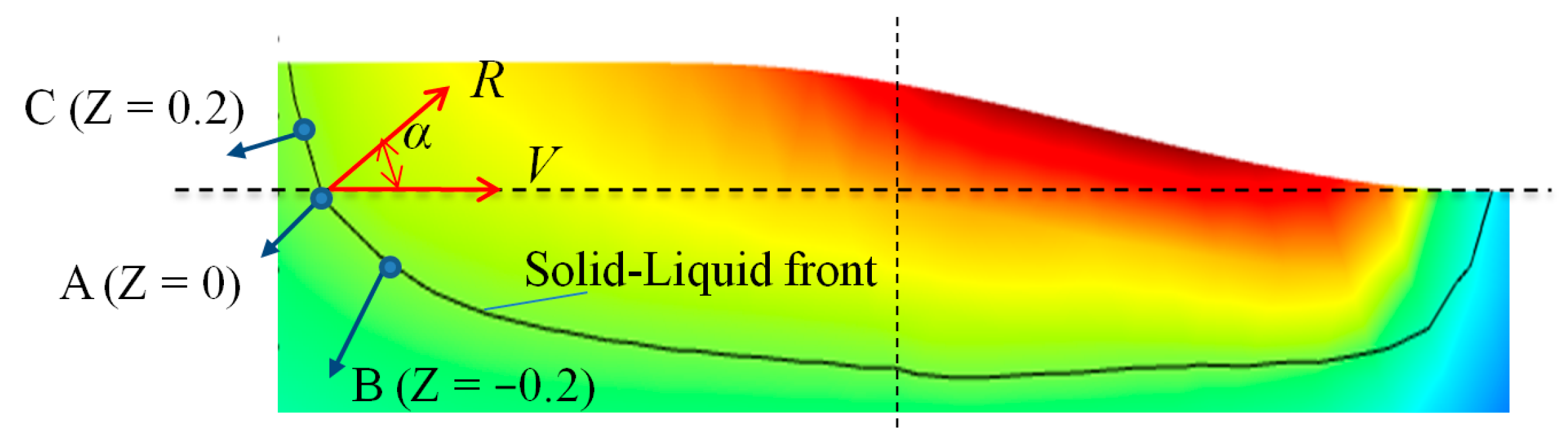

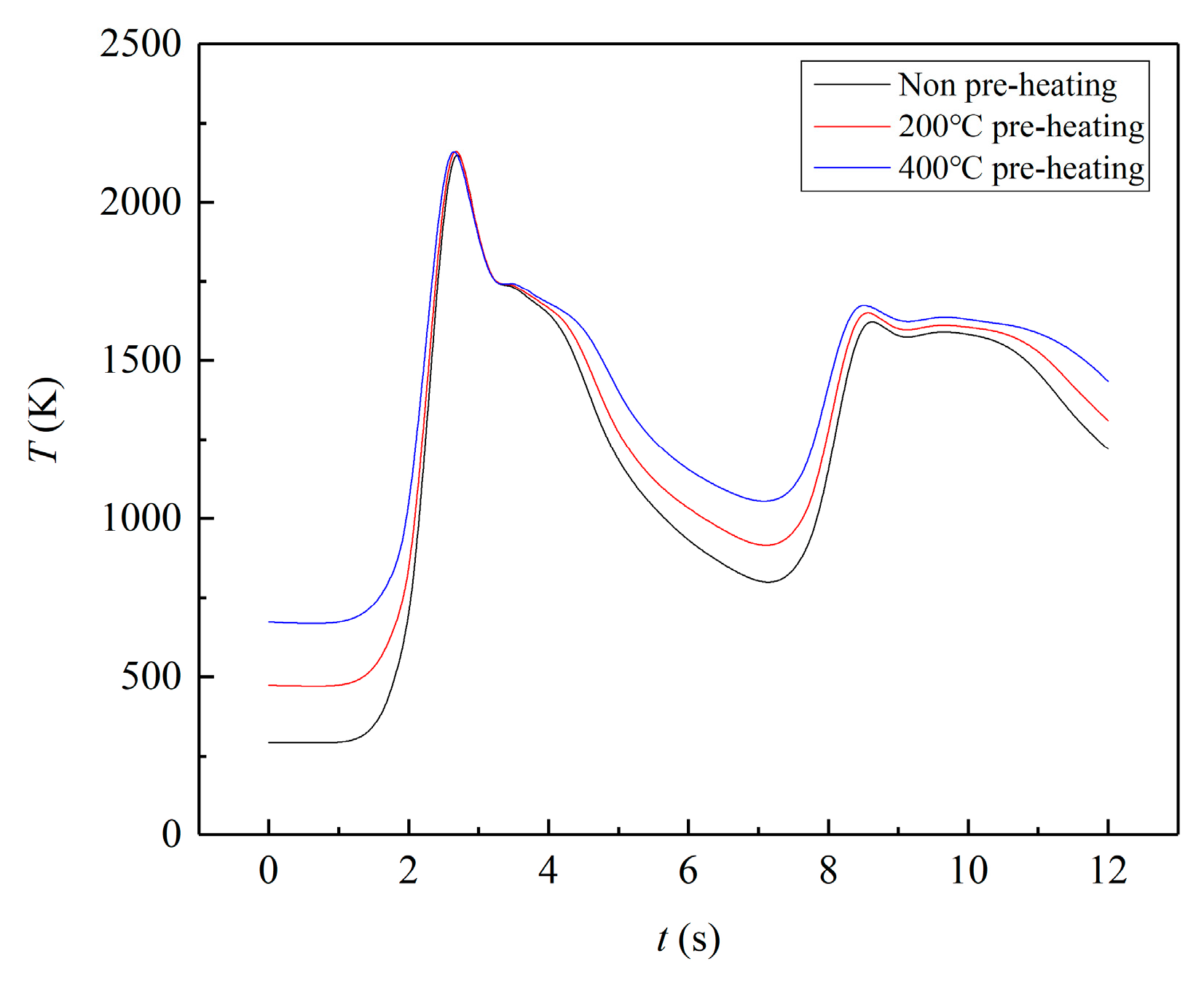

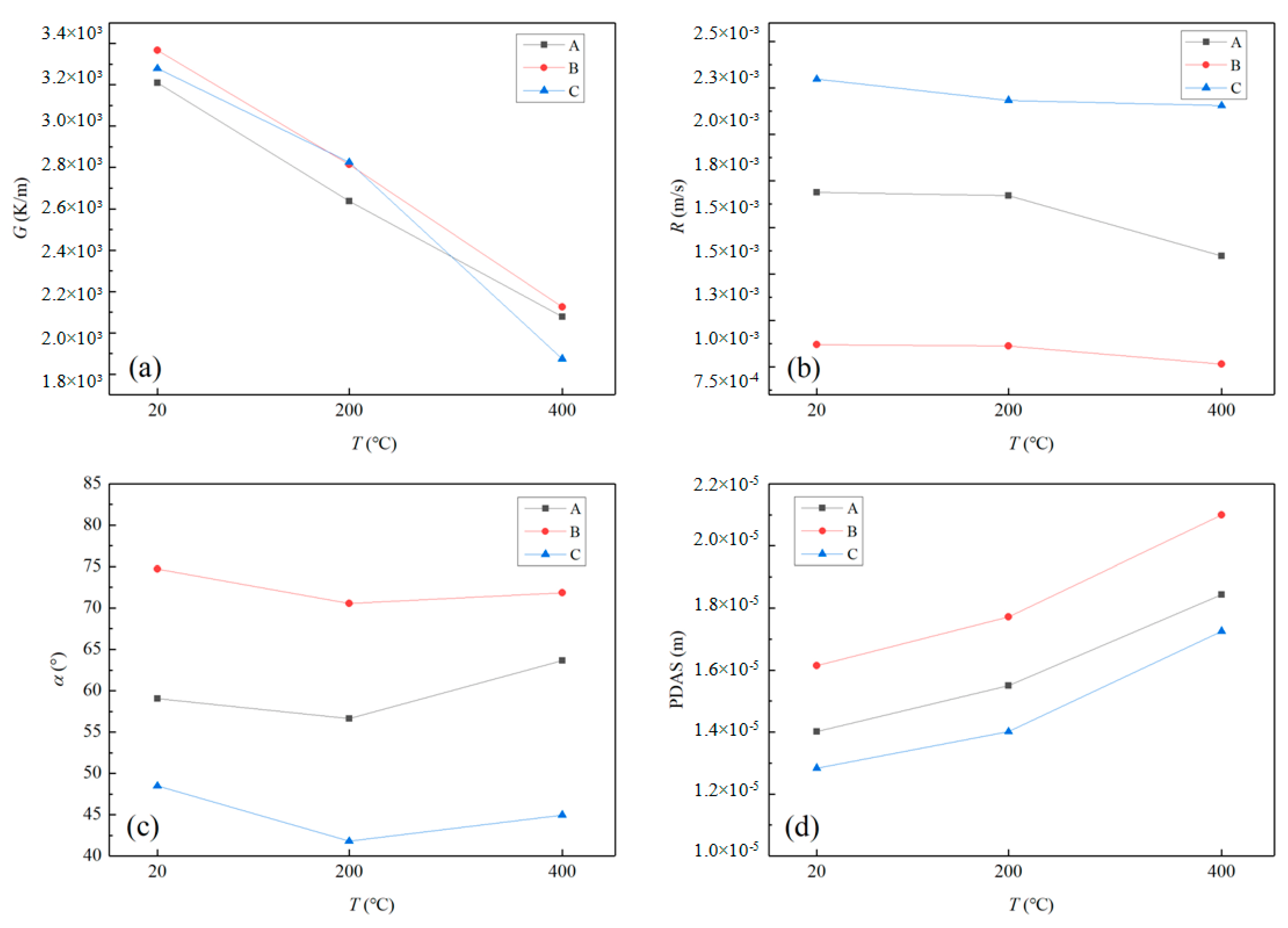

4.1. Temperature Field and Characteristic Parameters

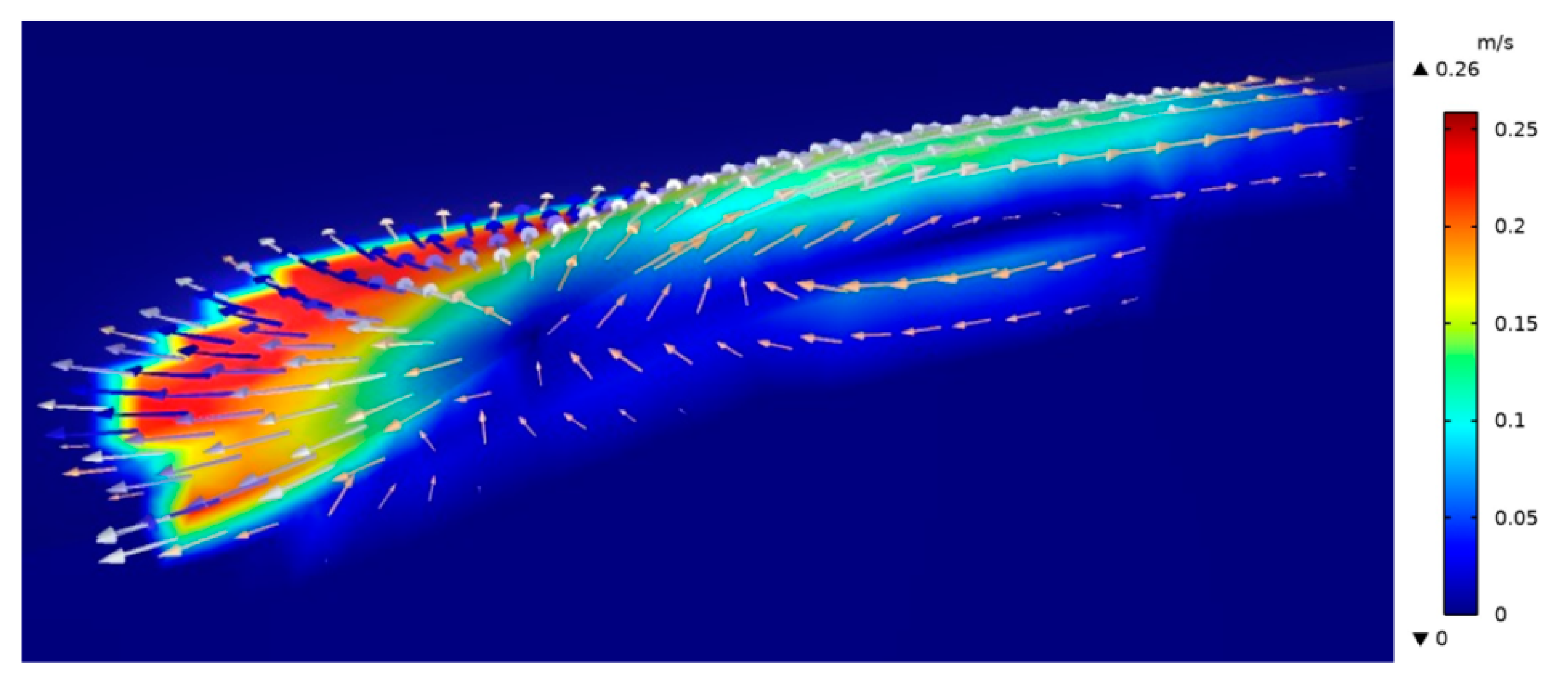

4.2. Flow Field Distribution

4.3. Microstructure Morphology Analysis

5. Conclusions

- (1)

- As the preheating temperature increases, the temperature gradient significantly decreases, leading to a decrease in solidification speed and cooling speed, while PDAS increases accordingly.

- (2)

- In the case of double-layer cladding, the first layer’s heating effect reduces the temperature difference between the substrate and the cladding layer, resulting in a reduction in the second layer of cladding’s temperature gradient. As temperature increases, heat conduction accelerates, and solidification speed significantly increases, which comprehensively affects the increase in PDAS. Preheating the substrate to 400 °C increases PDAS by 31.8% compared to the unheated state.

- (3)

- As the preheating temperature increases, the dendrite spacing gradually increases, the Laves phase precipitates increase, and it is easier to form coarse long-chain Laves phases. And it was discovered that preheating to 400 °C resulted in a 33.5% higher proportion of Laves compared to the unpreheated state.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Baek, G.Y.; Lee, K.Y.; Park, S.H.; Shim, D.S. Effects of substrate preheating during direct energy deposition on microstructure, hardness, tensile strength, and notch toughness. Met. Mater. Int. 2017, 23, 1204–1215. [Google Scholar] [CrossRef]

- Benarji, K.; Kumar, Y.R.; Jinoop, A.N.; Paul, C.P.; Bindra, K.S. Effect of heat-treatment on the microstructure, mechanical properties and corrosion behaviour of SS 316 structures built by laser directed energy deposition based additive manufacturing. Met. Mater. Int. 2021, 27, 488–499. [Google Scholar] [CrossRef]

- Yu, J.H.; Choi, Y.S.; Shim, D.S.; Park, S.H. Repairing casting part using laser assisted additive metal-layer deposition and its mechanical properties. Opt. Laser Technol. 2018, 106, 87–93. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Z.; Choe, C.; Kim, D.; Noh, S.; Sugahara, T.; Suganuma, K. Improvement of the bond strength of Ag sinter-joining on electroless Ni/Au plated substrate by a one-step preheating treatment. J. Electron. Mater. 2019, 48, 1106–1115. [Google Scholar] [CrossRef]

- Hou, X.; Ye, X.; Qian, X.; Zhang, P.; Lu, Q.; Yu, Z.; Shen, C.; Wang, L.; Hua, X. Study on Crack Generation of Ti-Al Alloy Deposited by Plasma Arc Welding Arc. J. Mater. Eng. Perform. 2023, 32, 3571–3576. [Google Scholar] [CrossRef]

- Wu, W.; Ye, S.; Wang, R.; Zhang, C.; Zhang, Y.; Lu, X. Microstructure and wear behavior of plasma cladded Ni-based alloy coating on copper under different preheating temperature. J. Mater. Res. Technol. 2023, 23, 1609–1617. [Google Scholar] [CrossRef]

- Liu, Y.; Ding, Y.; Yang, L.; Sun, R.; Zhang, T.; Yang, X. Research and progress of laser cladding on engineering alloys: A review. J. Manuf. Process. 2021, 66, 341–363. [Google Scholar] [CrossRef]

- Li, C.J.; Tsai, T.W.; Tseng, C.C. Numerical Simulation for Heat and Mass Transfer During Selective Laser Melting of Titanium alloys Powder. Phys. Procedia 2016, 83, 1444–1449. [Google Scholar] [CrossRef]

- He, X.; Mazumder, J. Transport phenomena during direct metal deposition. J. Appl. Phys. 2007, 101, 053113. [Google Scholar] [CrossRef]

- He, X.; Fuerschbach, P.W.; DebRoy, T. Heat transfer and fluid flow during laserspotweldingof304stainlesssteel. J. Phys. D Appl. Phys. 2003, 36, 1388–1398. [Google Scholar] [CrossRef]

- Nie, P.; Ojo, O.A.; Li, Z. Modeling analysis of laser cladding of a nickel-based superalloy. Surf. Coat. Technol. 2014, 258, 1048–1059. [Google Scholar] [CrossRef]

- Akbari, M.; Saedodin, S.; Toghraie, D.; Shoja-Razavi, R.; Kowsari, F. Experimental and numerical investigation of temperature distribution and melt pool geometry during pulsed laser welding of Ti6Al4V alloy. Opt. Laser Technol. 2014, 59, 52–59. [Google Scholar] [CrossRef]

- Ning, J.; Mirkoohi, E.; Dong, Y.; Sievers, D.E.; Garmestani, H.; Liang, S.Y. Analytical modeling of 3D temperature distribution in selective laser melting of Ti-6Al-4V considering part boundary conditions. J. Manuf. Process. 2019, 44, 319–326. [Google Scholar] [CrossRef]

- Shi, Y.; Shen, H.; Yao, Z.; Hu, J. An analytical model based on the similarity in temperature distributions in laser forming. Opt. Lasers Eng. 2007, 45, 83–87. [Google Scholar] [CrossRef]

- Feng, S.; Huang, C.; Wang, J.; Zhu, H.; Yao, P.; Liu, Z. An analytical model for the prediction of temperature distribution and evolution in hybrid laser-waterjet micro-machining. Precis. Eng. 2017, 47, 33–45. [Google Scholar] [CrossRef]

- Kirka, M.M.; Unocic, K.A.; Raghavan, N.; Medina, F.; Dehoff, R.R.; Babu, S.S. Microstructure development in electron beam-melted Inconel 718 and associated tensile properties. Jom 2016, 68, 1012–1020. [Google Scholar] [CrossRef]

- Morville, S.; Carin, M.; Peyre, P.; Gharbi, M.; Carron, D.; Le Masson, P.; Fabbro, R. 2D longitudinal modeling of heat transfer and fluid flow during multilayered direct laser metal deposition process. J. Laser Appl. 2012, 24, 032008. [Google Scholar] [CrossRef]

- Chan, K.C. C. A generalized arbitrary Lagrangian-Eulerian method for incompressible flows with sharp interfaces. J. Comput. Phys. 1975, 17, 311–331. [Google Scholar] [CrossRef]

- Gan, Z.; Yu, G.; He, X.; Li, S. Numerical simulation of thermal behavior and multicomponent mass transfer in direct laser deposition of Co-base alloy on steel. Int. J. Heat Mass Transf. 2017, 104, 28–38. [Google Scholar] [CrossRef]

- Wang, C.; Zhou, J.; Zhang, T.; Meng, X.; Li, P.; Huang, S. Numerical simulation and solidification characteristics for laser cladding of Inconel 718. Opt. Laser Technol. 2022, 149, 107843. [Google Scholar] [CrossRef]

- Salcudean, M.; Abdullah, Z. On the numerical modelling of heat transfer during solidification processes. Int. J. Numer. Methods Eng. 1988, 25, 445–473. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components–process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Hu, Y.; He, X.; Yu, G.; Ge, Z.; Zheng, C.; Ning, W. Heat and mass transfer in laser dissimilar welding of stainless steel and nickel. Appl. Surf. Sci. 2012, 258, 5914–5922. [Google Scholar] [CrossRef]

- Corbin, D.J.; Nassar, A.R.; Reutzel, E.W.; Beese, A.M.; Michaleris, P. Effect of Substrate thickness and preheating on the distortion of laser deposited Ti–6Al–4V. J. Manuf. Sci. Eng. 2018, 140, 061009. [Google Scholar] [CrossRef]

- Liu, H.; Du, X.; Guo, H.; Liu, J.; Chen, P.; Yang, H.; Hao, J. Finite element analysis of effects of dynamic preheating on thermal behavior of multi-track and multi-layer laser cladding. Optik 2021, 228, 166194. [Google Scholar] [CrossRef]

- Khanzadeh, M.; Chowdhury, S.; Marufuzzaman, M.; Tschopp, M.A.; Bian, L. Porosity prediction: Supervised-learning of thermal history for direct laser deposition. J. Manuf. Syst. 2018, 47, 69–82. [Google Scholar] [CrossRef]

- Asai, S.; Muchi, I. Theoretical analysis and model experiments on the formation mechanism of channel-type segregation. Trans. Iron Steel Inst. Jpn. 1978, 18, 90–98. [Google Scholar] [CrossRef]

- Kumar, S.; Roy, S.; Paul, C.; Nath, A. Three-dimensional conduction heat transfer model for laser cladding process. Numer. Heat Transf. Part B Fundam. 2008, 53, 271–287. [Google Scholar] [CrossRef]

| Parameter | Value | Unit |

|---|---|---|

| Inconel 718 liquidus, TL | 1647 | K |

| Inconel 718 solidus, TS | 1571 | K |

| Solid density ρm | 8190 | kg/m3 |

| Specific heat, Cp | 435 | J/kg/K |

| Convective heat transfer coefficient, hc | 10 | W/(m2·K) |

| Latent heat, Lf | 145 | J/kg |

| Dynamic viscosity, μ | 0.006 | kg/(m·s) |

| Surface tension coefficient σ | 1.842 | kg/s2 |

| Temperature coefficient of surface tension dσ/dT | −0.11 | kg/(s2·K) |

| Process Parameter | Value | Unit |

|---|---|---|

| Laser power, P | 2000 | W |

| Scanning speed Vs | 3 | mm/s |

| Spot radius, rl | 1.1 | mm |

| Powderfeedrate, mf | 10 | g/min |

| Powder flow radius, rp | 2.5 | mm |

| Laser absorption rate, ηp | 0.28 | 1 |

| Element | Ni | Cr | Fe | Nb | Mo | Al | Co | C |

|---|---|---|---|---|---|---|---|---|

| Percentage | 52 | 18.7 | 18.1 | 5.16 | 2.94 | 0.53 | 0.1 | 0.037 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jin, Z.; Kong, X.; Ma, L. Investigating the Impact of Substrate Preheating on the Thermal Flow and Microstructure of Laser Cladding of Nickel-Based Superalloy. Materials 2024, 17, 399. https://doi.org/10.3390/ma17020399

Jin Z, Kong X, Ma L. Investigating the Impact of Substrate Preheating on the Thermal Flow and Microstructure of Laser Cladding of Nickel-Based Superalloy. Materials. 2024; 17(2):399. https://doi.org/10.3390/ma17020399

Chicago/Turabian StyleJin, Zhibo, Xiangwei Kong, and Liang Ma. 2024. "Investigating the Impact of Substrate Preheating on the Thermal Flow and Microstructure of Laser Cladding of Nickel-Based Superalloy" Materials 17, no. 2: 399. https://doi.org/10.3390/ma17020399

APA StyleJin, Z., Kong, X., & Ma, L. (2024). Investigating the Impact of Substrate Preheating on the Thermal Flow and Microstructure of Laser Cladding of Nickel-Based Superalloy. Materials, 17(2), 399. https://doi.org/10.3390/ma17020399