Study on the Effect of Hot and Humid Environmental Factors on the Mechanical Properties of Asphalt Concrete

Abstract

:1. Introduction

- This paper mainly explores the change rule of dynamic modulus of return of asphalt mixtures under the combined effect of long-term complex and variable natural factors cycle.

- Probes the first aging after the dry–wet cycle and the first dry–wet cycle after aging of different role orders on the dynamic modulus of resilience of the asphalt mixture change rule of law research.

2. Raw Materials and Gradation Design

2.1. Raw Material

2.2. Grading Design

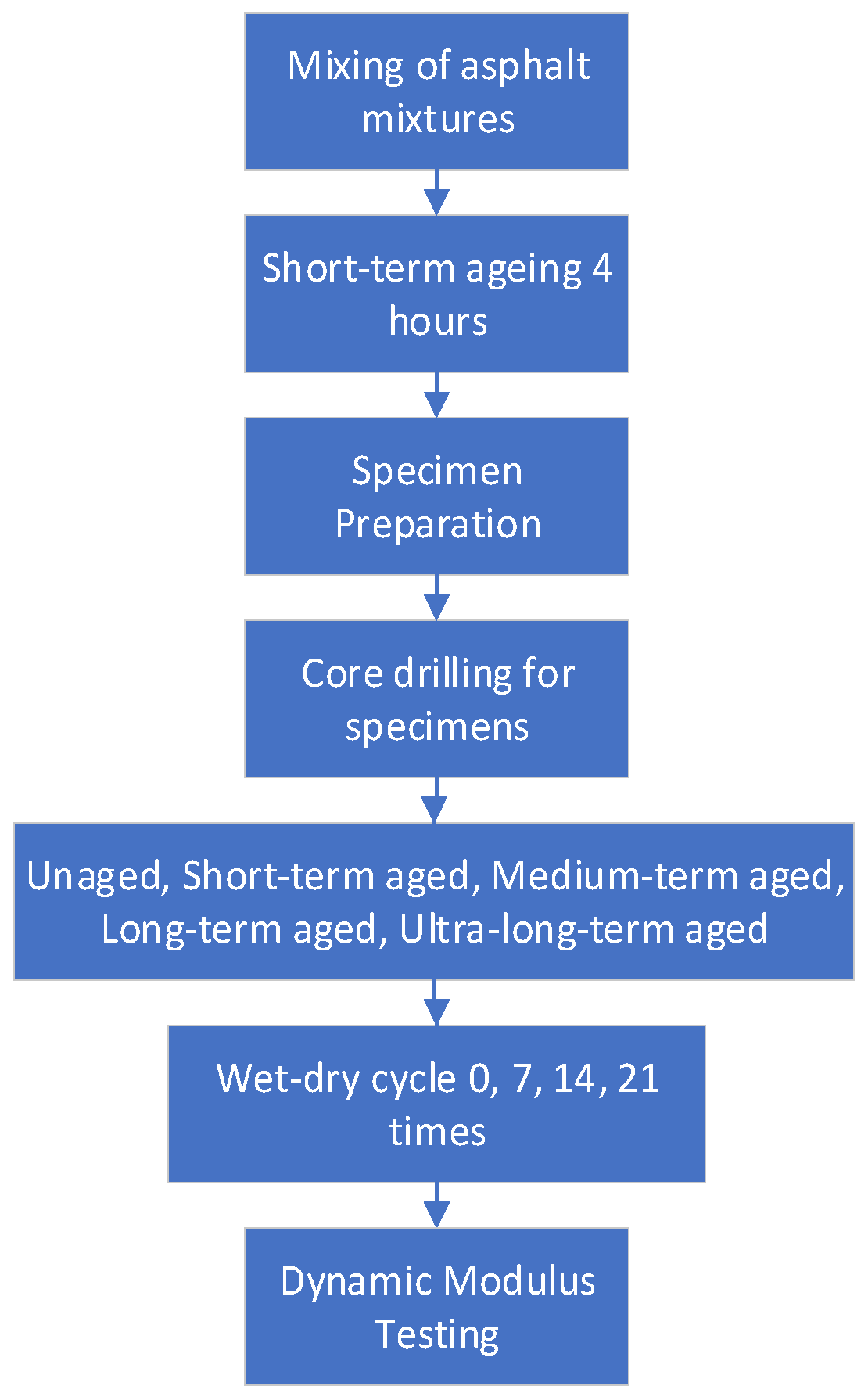

3. Uniaxial Compression Dynamic Modulus Test

3.1. Specimen Preparation

3.2. Test Protocol

- (1)

- Group 0, Group 1, Group 2, Group 3, and Group 4: unaging, short-term, 2 days medium-term, 5 days long-term, and 8 days ultra-long-term aging.

- (2)

- Group 5, Group 6, and Group 7: 7, 14, and 21 dry–wet cycles.

- (3)

- Group 8: 2 days medium-term aging + 7 dry–wet cycles.

- (4)

- Group 9: 7 dry–wet cycles + 2 days medium-term aging.

- (5)

- Group 10: 5 days long-term ag aging + 14 dry–wet cycles.

- (6)

- Group 11: 14 dry–wet cycles + 5 days long-term aging.

- (7)

- Group 12: 2 days ag aging + 7 dry–wet cycles + 3 days aging + 7 dry–wet cycles.

- (8)

- Group 13: 7 dry–wet cycles + 2 days ag aging + 7 dry–wet cycles + 3 days aging.

- (9)

- Group 14: 8 days ultra-long-term ag aging + 21 dry–wet cycles.

- (10)

- Group 15: 21 dry–wet cycles + 8 days ultra-long-term aging.

- (11)

- Group 16: 2 days aging + 7 dry–wet cycles + 3 days aging + 7 dry–wet cycles + 3 days ag aging + 7 dry–wet cycles.

- (12)

- Group 17: 7 dry–wet cycles + 2 days aging + 7 dry–wet cycles + 3 days aging + 7 dry–wet cycles + 3 days aging.

4. Analysis of Test Results

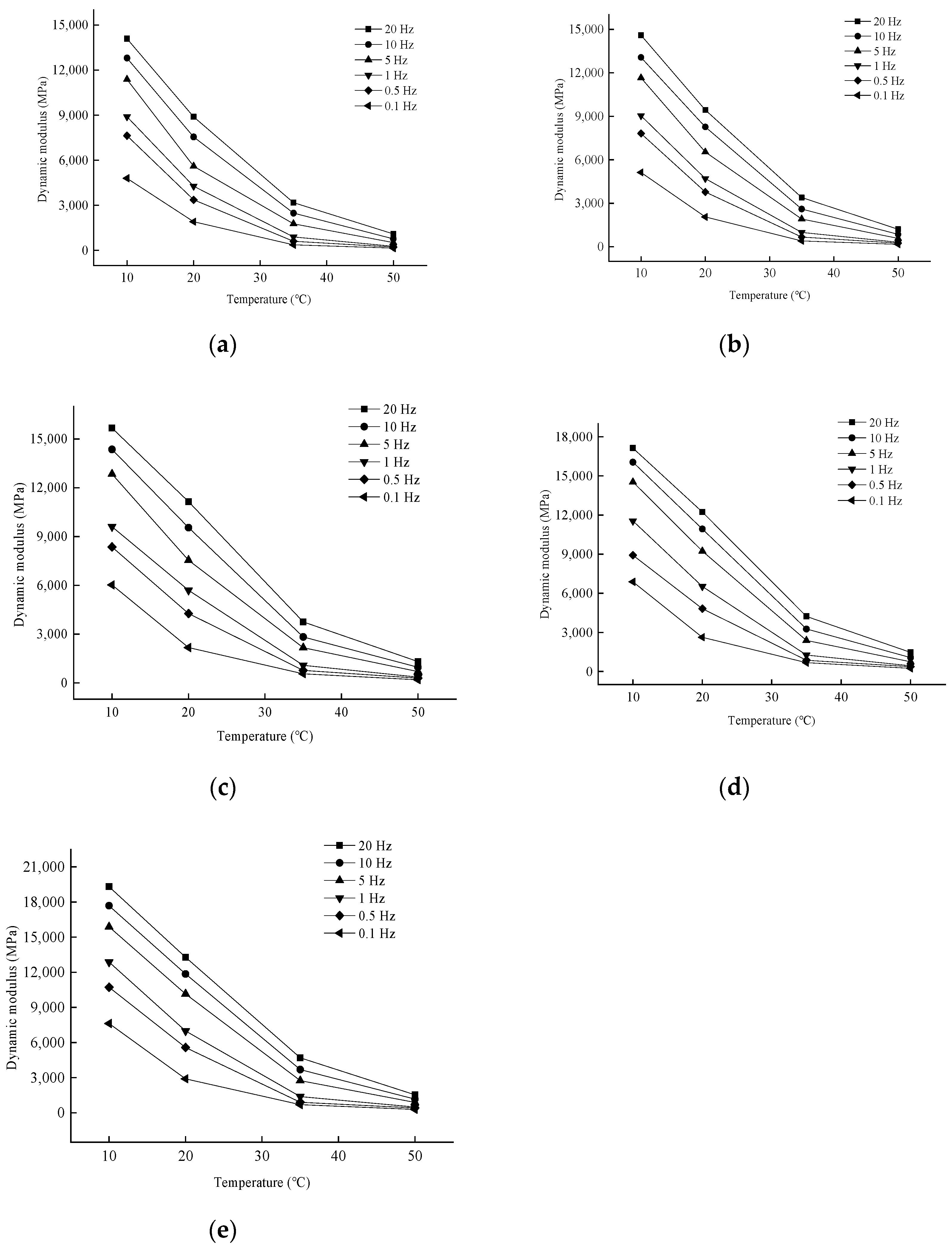

4.1. Analysis of the Effect of Dynamic Modulus of Aged Asphalt Mixtures

- (1)

- Effect of temperature on dynamic modulus

- (2)

- Effect of loading frequency on dynamic modulus

- (3)

- Effect of aging on dynamic modulus

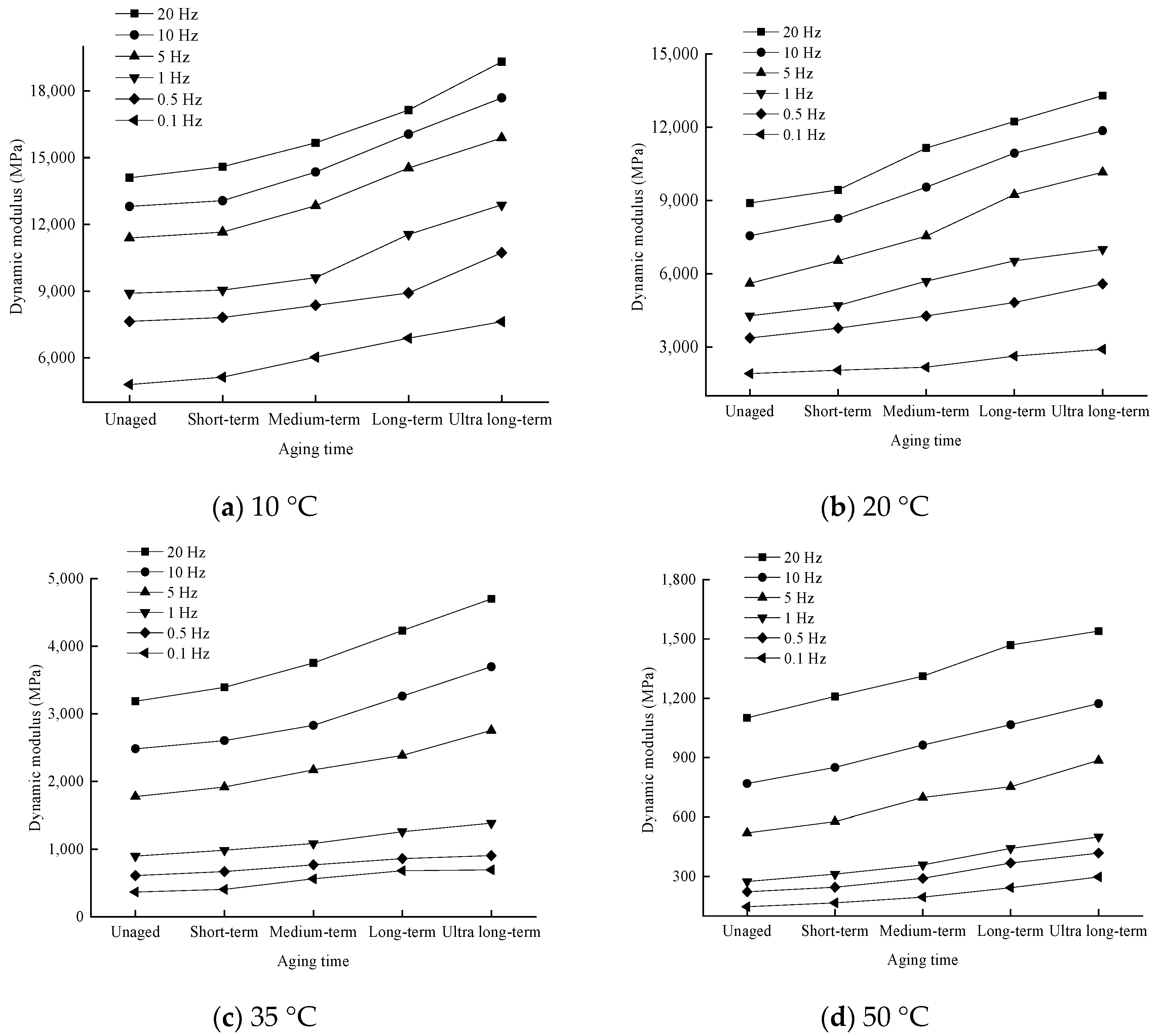

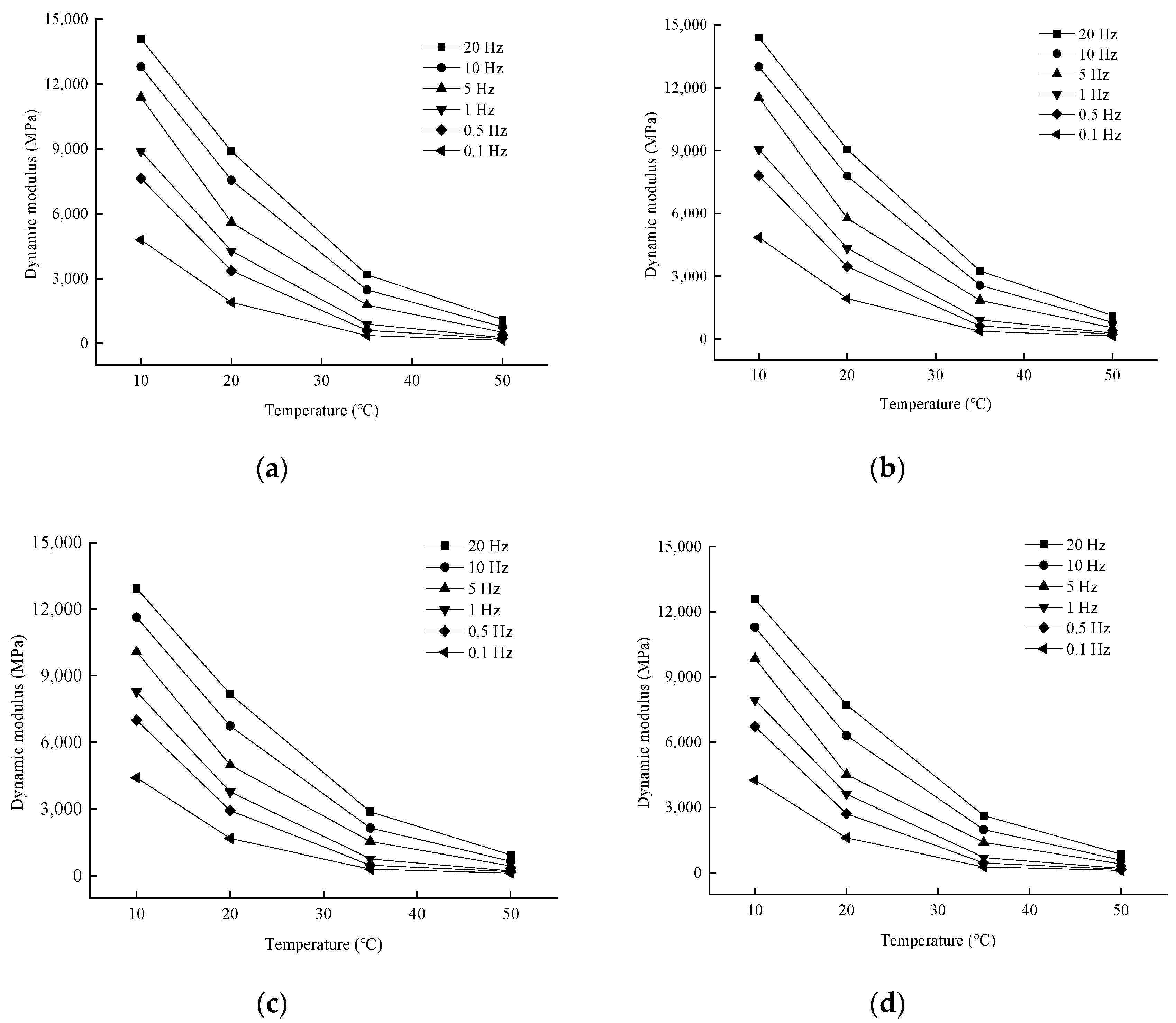

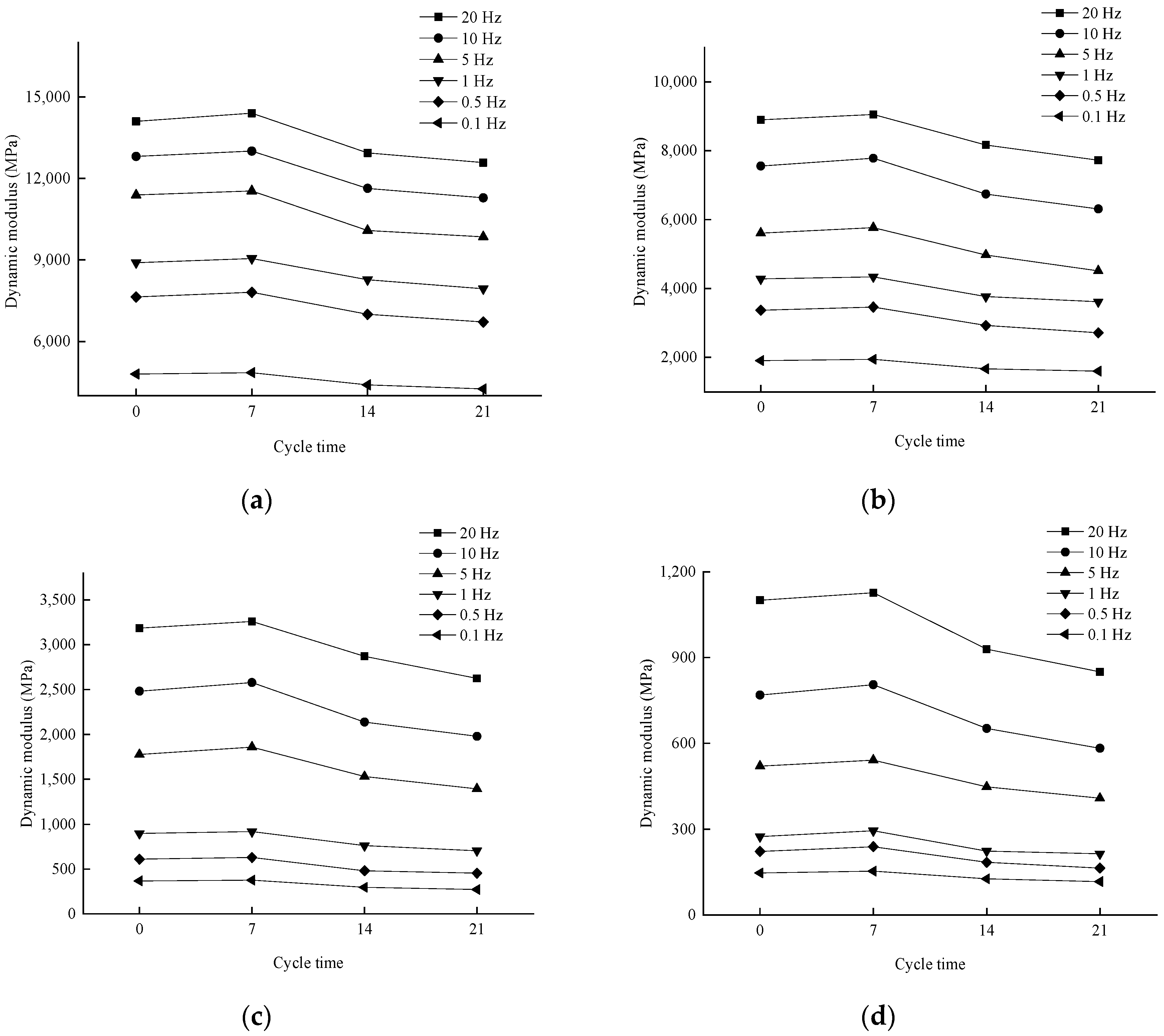

4.2. Analysis of the Effect of Dynamic Modulus of Asphalt Mixtures after Dry–Wet Cycling

- (1)

- Effect of temperature on dynamic modulus

- (2)

- Effect of loading frequency on dynamic modulus

- (3)

- Effect of number of dry–wet cycles on dynamic modulus

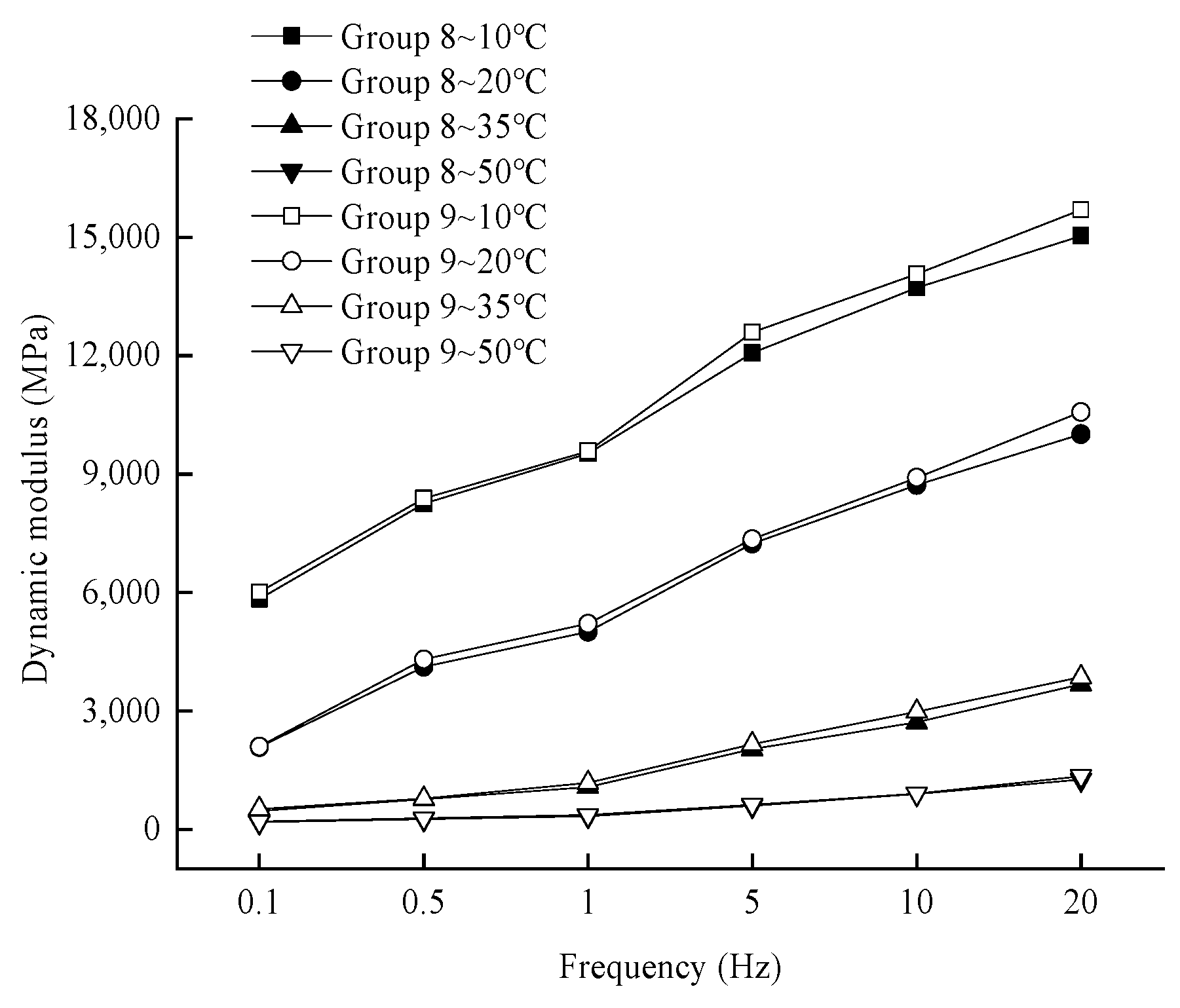

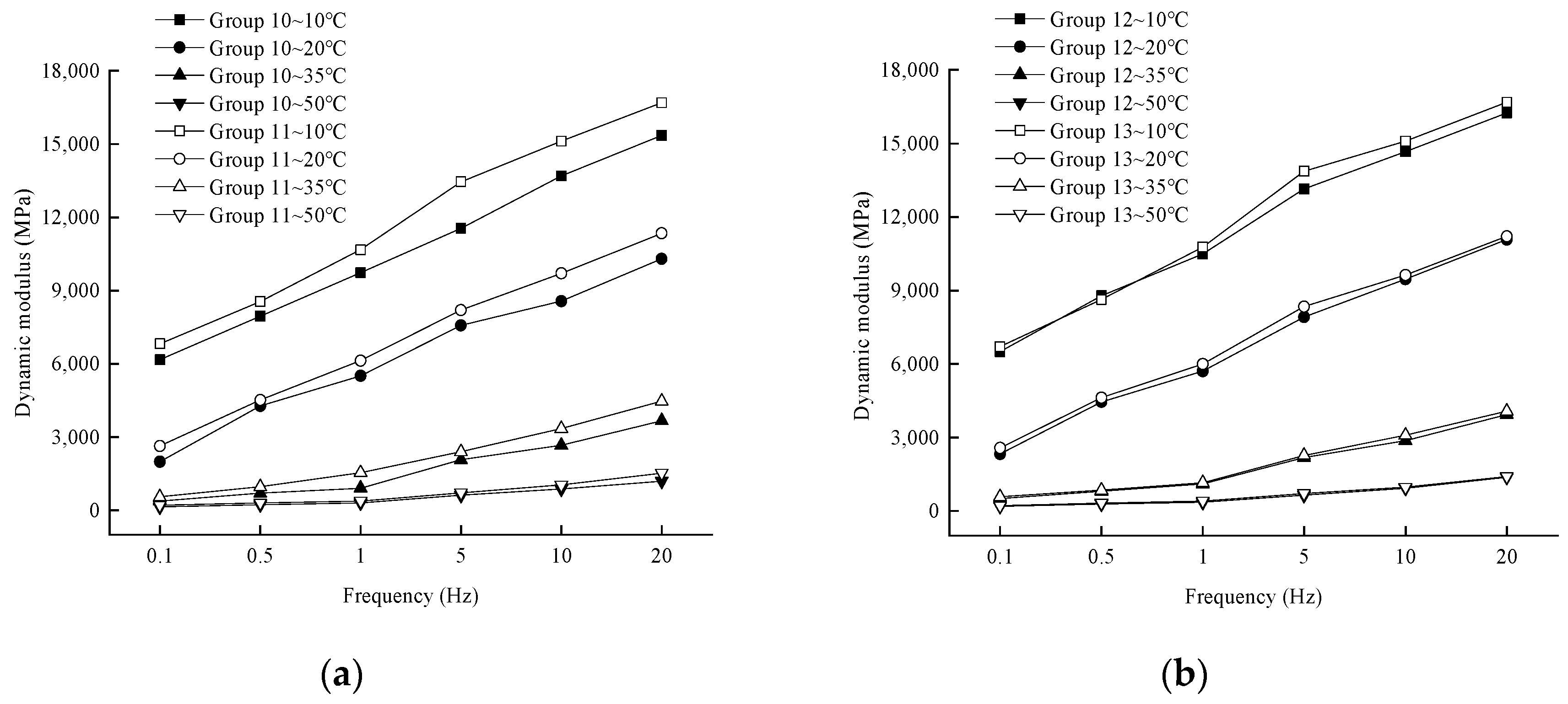

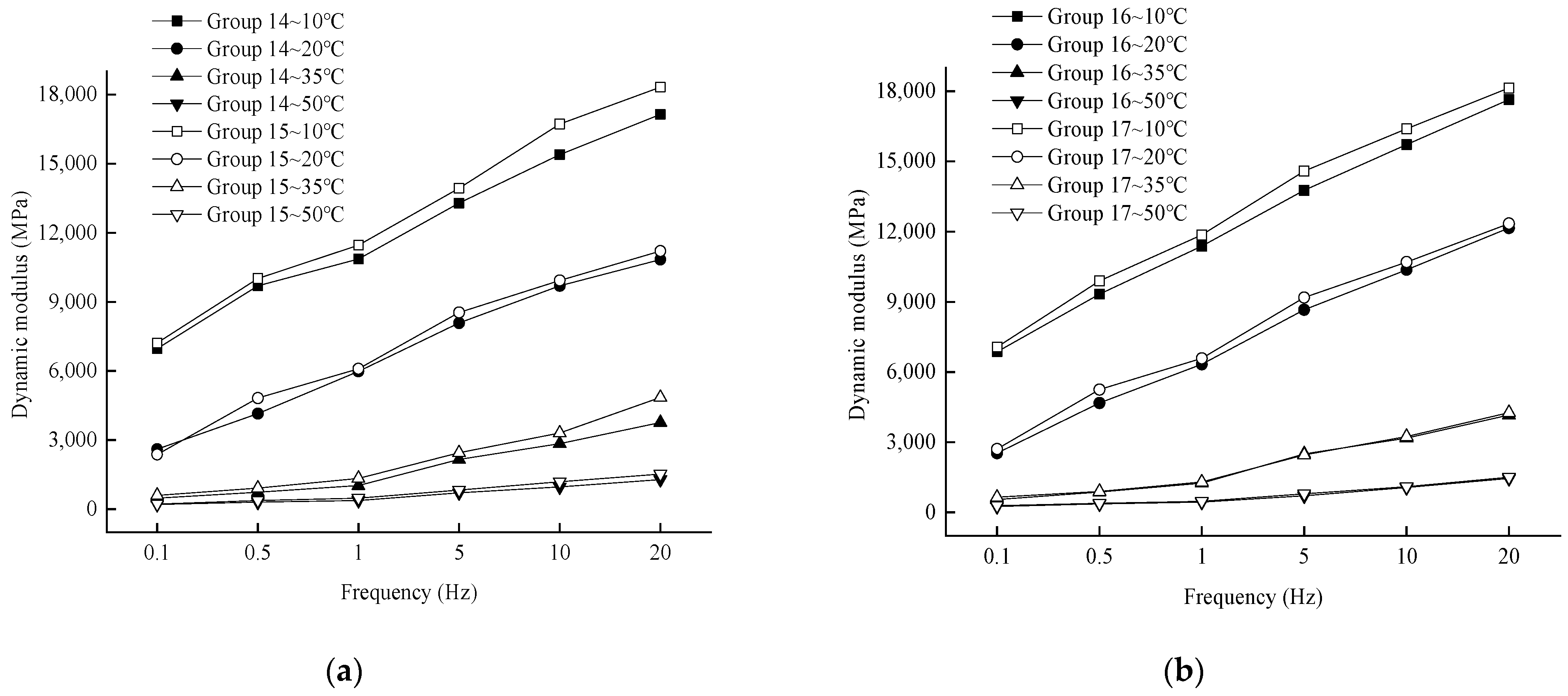

4.3. Effect of Aging and Coupled Dry–Wet Cycling on the Dynamic Modulus of Asphalt Mixtures

- (1)

- Effects of medium-term aging and coupled dry–wet cycling on dynamic modulus

- (2)

- Effects of long-term aging and coupled dry–wet cycling on dynamic modulus

- (3)

- Effects of ultra-long-term aging and coupled dry–wet cycling on dynamic modulus

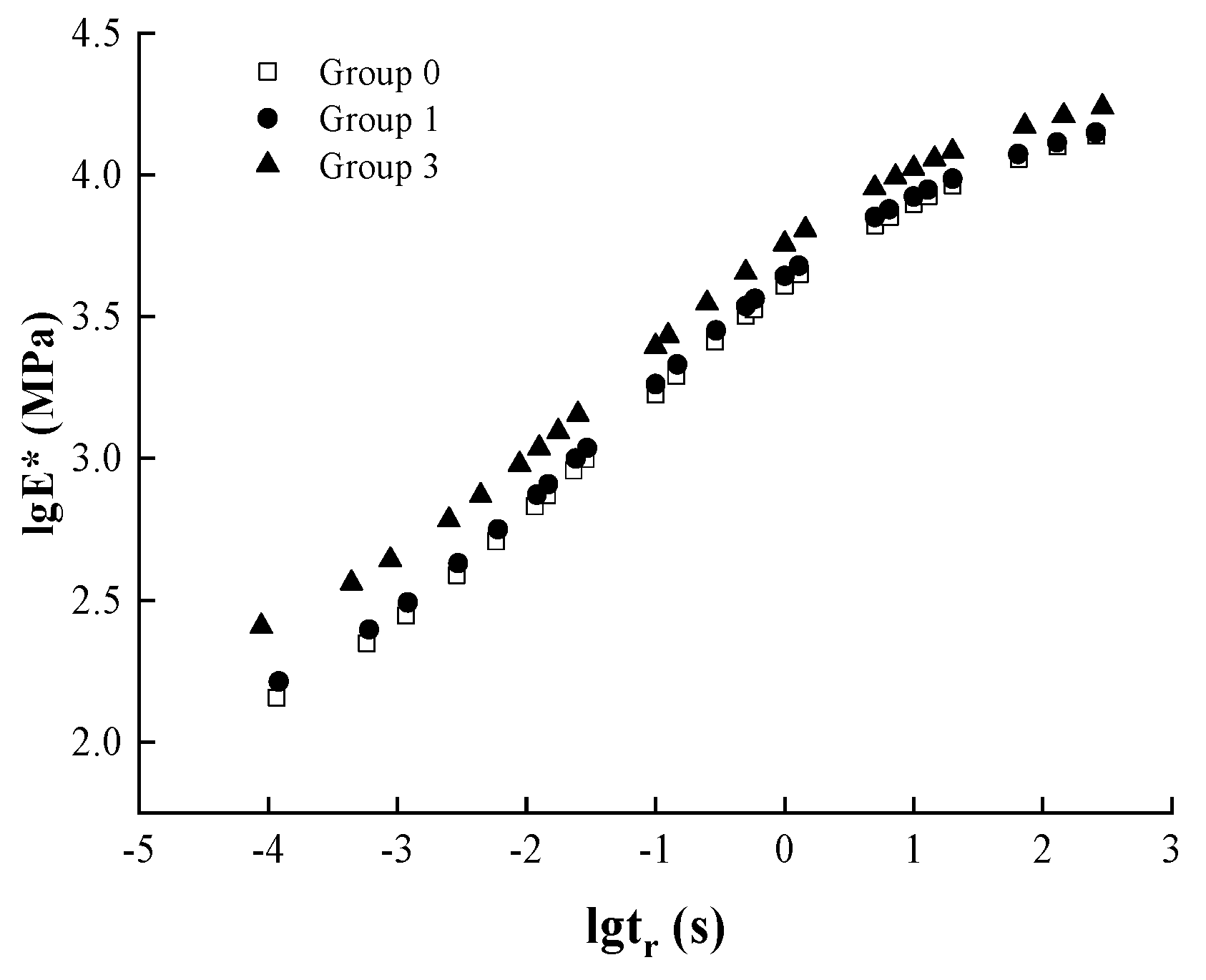

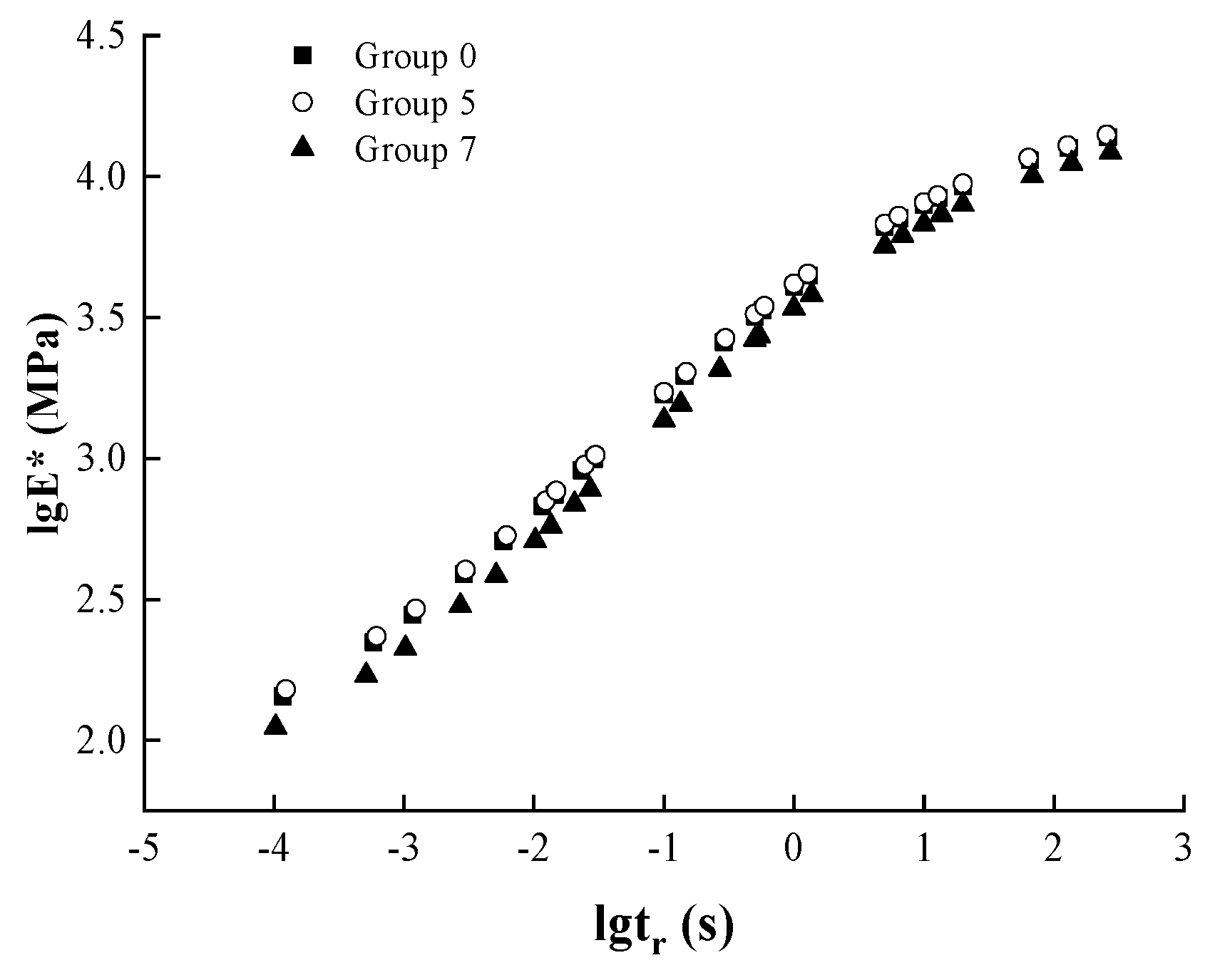

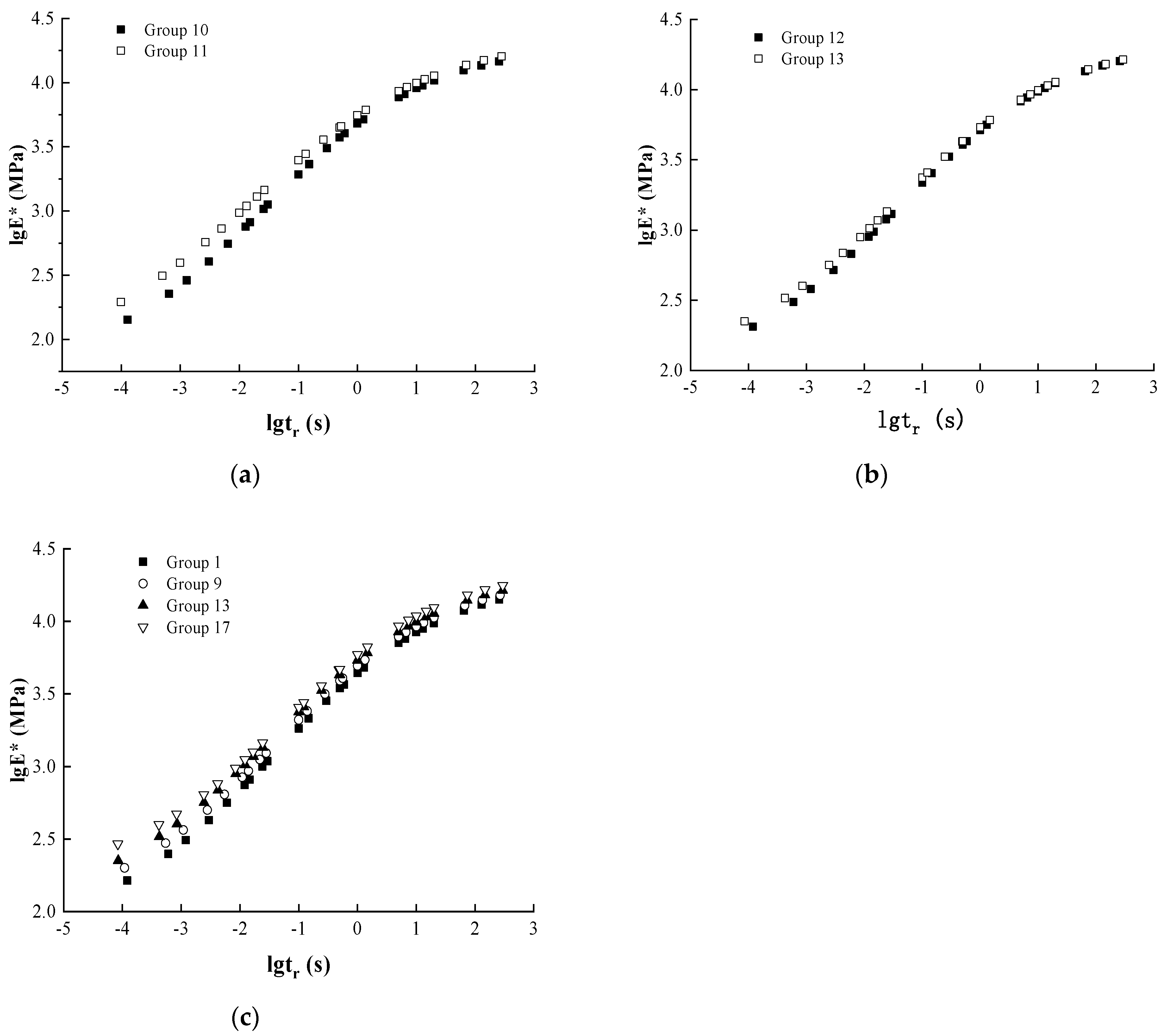

5. Effect of Hot and Humid Environment on the Dynamic Modulus Master Curve of Asphalt Mixtures

5.1. Effect of Aging, and Dry and Wet Cycles on the Dynamic Modulus Master Curve

5.2. Effect of Aging and Coupled Dry–Wet Cycling on the Dynamic Modulus Master Curve

6. Conclusions

- (1)

- The asphalt mixture under the erosion of hot and humid environments is still viscoelastic, the dynamic modulus decreases with the decrease of loading frequency and the increase in temperature, and its main curve is obviously an “S” type.

- (2)

- With aging, asphalt mixture hardening effect is significant, with the deepening of the degree of aging, the dynamic modulus was an upward trend, and the dynamic modulus of short-term aged, medium-term aged, long-term aged, and ultra-long-term aged asphalt mixtures increased by 9.3%, 26.4%, 44.8%, and 57%, respectively, compared to unaged asphalt mixtures at 20 °C and 10 Hz, the mixture of high temperature rutting resistance increased, while the low-temperature crack resistance decreased.

- (3)

- For the dry–wet cycle, the first asphalt water aging effect is more obvious, and the dynamic modulus of the mixture slightly increased. In the process of a long-term dry–wet cycle, the erosion effect of water on asphalt and aggregate increases, the structural bearing capacity attenuation, and the dynamic modulus is greatly reduced, at 20 °C and 10 Hz, for example, the dynamic modulus of asphalt mixtures with seven cycles of wet and dry cycles increased by 3% compared to asphalt mixtures without wet and dry cycles, and the dynamic modulus of asphalt mixtures with 14 cycles of wet and dry cycles and 21 cycles of wet and dry cycles decreased by 10.8% and 16.5% compared to asphalt mixtures without wet and dry cycles respectively, the main curve as a whole shift downward, and the high-temperature performance decreases significantly.

- (4)

- In the aging and dry–wet cycle coupling, the aging asphalt mixture is more susceptible to water erosion, while the first dry–wet cycle after the mix is a relatively small degree of water erosion, the dynamic modulus is relatively larger, the high-temperature performance is relatively better, the low-temperature performance is poor.

- (5)

- In this paper, the dynamic modulus master curves of asphalt mixtures under different operating conditions are investigated to provide a basis for predicting the dynamic modulus of asphalt mixtures under the combined effects of aging, dry and wet cycling, and extreme temperatures. The aging test was carried out using only the thermo-oxidative aging method, which can be further improved by combining with the UV aging method. The asphalt was extracted and analyzed from the perspective of asphalt. It is recommended that the aging mechanism be elaborated on under humid and hot environments with the help of asphalt microtests and that the aging state of the pavement core samples be reasonably assessed in the course of subsequent research. At the same time, new indicators and methods are used to evaluate the mechanical properties of asphalt mixtures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Barraj, F.; Hatoum, A.; Khatib, J.; Assaad, J.; Castro, A.; Elkordi, A. Uncertainty analysis for the dynamic modulus of recycled asphalt mixtures using unclassified fractionated RAP materials. Constr. Build. Mater. 2024, 421, 135721. [Google Scholar] [CrossRef]

- Al-Tawalbeh, A.; Sirin, O.; Sadeq, M.; Sebaaly, H.; Masad, E. Evaluation and calibration of dynamic modulus prediction models of asphalt mixtures for hot climates: Qatar as a case study. Case Stud. Constr. Mater. 2022, 17, e01580. [Google Scholar] [CrossRef]

- Brondani, C.; Vestena, P.M.; Faccin, C.; Schuster, S.L.; Specht, L.P.; Pereira, D.d.S. Moisture susceptibility of asphalt mixtures: 2S2P1D rheological model approach and new index based on dynamic modulus master curve changes. Constr. Build. Mater. 2022, 331, 497–509. [Google Scholar] [CrossRef]

- Karthikeyan, K.; Kothandaraman, S.; Sarang, G. Perspectives on the utilization of reclaimed asphalt pavement in concrete pavement construction: A critical review. Case Stud. Constr. Mater. 2023, 19, e02242. [Google Scholar] [CrossRef]

- Behnood, A.; Golafshani, E.M. Predicting the dynamic modulus of asphalt mixture using machine learning techniques: An application of multi biogeography-based programming. Constr. Build. Mater. 2021, 266, 120983. [Google Scholar] [CrossRef]

- Rueda, E.J.; Caro, S.; Caicedo, B. Influence of Wetting-Drying cycles on the linear viscoelastic properties of asphalt mixtures. Constr. Build. Mater. 2023, 393, 132072. [Google Scholar] [CrossRef]

- Xu, L.; Deng, Y.; Ni, H.; Sun, D.; Ling, S.; Tian, Y. Effect of aging on damping properties of rubberized asphalt binder and rubberized porous asphalt mixture. Constr. Build. Mater. 2024, 411, 134743. [Google Scholar] [CrossRef]

- JTG D50-2017; Chinese Standard. Specifications for Design of Highway Asphalt Pavement. China Communications Press: Beijing, China, 2017. (In Chinese)

- Cui, L.; Xu, J.; Cen, L.; Ren, M.; Cao, F. Molecular engineering and modification of FCC slurry oil residue for improving ageing resistance of high quality paving asphalt. Constr. Build. Mater. 2021, 299, 124234. [Google Scholar] [CrossRef]

- Cui, L.; Xu, J.; Ren, M.; Li, T.; Li, D.; Cao, F. Modification of FCC slurry oil and deoiled asphalt for making high-grade paving asphalt. Chin. J. Chem. Eng. 2022, 44, 300–309. [Google Scholar] [CrossRef]

- Chen, H.; Liu, H.; Luo, R. Study of water stability of asphalt mixtures using dynamic modulus of resilience principal curves. J. Wuhan Univ. Technol. (Transp. Sci. Eng.) 2017, 41, 501–506. (In Chinese) [Google Scholar] [CrossRef]

- Guo, R.; Wang, C.; Niu, Z. A study of the effect of water erosion on the dynamic modulus of resilience of steel slag asphalt mixtures. Bull. Chin. Ceram. Soc. 2018, 37, 166–172. (In Chinese) [Google Scholar] [CrossRef]

- Xiao, Q.; Yu, T.; Chen, X.; Li, Z. Experimental study of dynamic modulus of resilience of iron tailings asphalt mixtures. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2020, 39, 85–90+102. (In Chinese) [Google Scholar]

- Al-Adham, K.; Baig, M.G.; Wahhab, H.A.A. Prediction of Dynamic Modulus for Elastomer-Modified Asphalt Concrete Mixes at Desert Environment. Arab. J. Sci. Eng. 2018, 44, 4141–4149. [Google Scholar] [CrossRef]

- Han, D.; Yuan, M.; Hu, H. Establishing prediction master curve of dynamic modulus of asphalt mixture considering randomness of aggregate morphology. Constr. Build. Mater. 2021, 294, 123575. [Google Scholar] [CrossRef]

- Owais, M.; Moussa, G.S. Global sensitivity analysis for studying hot-mix asphalt dynamic modulus parameters. Constr. Build. Mater. 2024, 413, 134775. [Google Scholar] [CrossRef]

- Arshad, A.K.; Masri, K.A.; Ahmad, J.; Samsudin, M.S. Dynamic Modulus of Nanosilica Modified Porous Asphalt. IOP Conf Ser. Mater. Sci. Eng. 2017, 271, 12008. [Google Scholar] [CrossRef]

- JTG F40-2017; Technical Specifications for Highway Asphalt Pavement Construction, Ministry of Transport. China Communications Press: Beijing, China, 2017.

- JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- JTG E42-2005; Test Methods of Aggregate for Hightway Engineering. China Communications Press: Beijing, China, 2005.

- 17.JTG F40-2017; Technical Specifications for Highway Asphalt Pavement Construction. Ministry of Transport. China Communications Press: Beijing, China, 2017.

- 14.JTG E20-2011; Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering. China Communications Press: Beijing, China, 2011.

- Xiang, H.; He, Z.; Yang, H.; Chen, L. Effects of thermo-oxidative aging on the macrophysical properties and microstructure of asphalt. Constr. Build. Mater. 2023, 395, 1323135. [Google Scholar] [CrossRef]

- Wang, H.; Liu, S.; Liu, G. Investigation on the thermo-oxidative aging resistance of nitrile-butadiene rubber/polyamide elastomer blend and the swelling behaviors in fuels predicted via Hansen solubility parameter method. Polym. Degrad. Stab. 2023, 217, 110512. [Google Scholar] [CrossRef]

- Kong, L.; Wang, Z.; Su, S.; Yue, J.; Luo, W.; Zhou, S.; Ren, D.; Ai, C. Exploring the interplay between thermo-oxidative degradation and asphalt aging in thermoplastic polyurethane-modified asphalt: Mechanisms, properties, and performance evolution. Constr. Build. Mater. 2024, 412, 134694. [Google Scholar] [CrossRef]

| Test Item | Unit | Technical Requirements | Test Results | Test Methods | |

|---|---|---|---|---|---|

| Needle penetration 25 °C | 0.1 mm | 60~80 | 67 | T 0604-2011 [19] | |

| Needle penetration index PI | - | −1.5~+1.0 | −1.34 | T 0604-2011 | |

| Ductility(10 °C, 5 cm/min) | cm | ≥20 | 27.5 | T 0605-2011 | |

| Ductility(15 °C, 5 cm/min) | cm | ≥100 | 150 | T 0605-2011 | |

| Softening point | °C | ≥47 | 47.3 | T 0606-2011 | |

| Power viscosity 60 °C | Pa·s | ≥180 | 190 | T 0620-2011 | |

| Flash point | °C | ≥260 | >260 | T 0611-2011 | |

| Solubility (trichloroethylene) | % | ≥99.5 | >99.5 | T 0607-2011 | |

| After heating the film | Mass change | % | −0.8~+0.8 | 0.03 | T 0609-2011 |

| Needle penetration ratio 25 °C | % | ≥61 | 65 | T 0604-2011 | |

| Ductility 10 °C | cm | ≥6 | 6.3 | T 0605-2011 | |

| Density at 25 °C | g/cm3 | - | 1.04 | T 0603-2011 | |

| Test Item | Unit | Technical Requirements | Test Results | Test Methods |

|---|---|---|---|---|

| Crushing value | % | ≤20 | 13.8 | T 0316-2005 [20] |

| Los Angeles abrasion losses | % | ≤24 | 7.4 | T 0317-2005 |

| Grinding value | PSV | ≥42 | 48 | T 0321-2005 |

| Apparent relative density | g/cm3 | ≥2.6 | 2.920 | T 0304-2005 |

| Water absorption | % | ≤2.0 | 0.2 | T 0304-2005 |

| solidity | % | ≤12 | 1 | T 0314-2005 |

| Content of needle and flake particles | % | ≤15 | 2.0 | T 0312-2005 |

| Mud content (<0.075 mm content) | % | ≤1 | 0.2 | T 0333-2005 |

| Test Item | Unit | Technical Requirements | Test Results | Test Methods |

|---|---|---|---|---|

| Apparent relative density | g/cm3 | ≥2.5 | 2.728 | T 0328-2005 |

| Sand equivalent | % | ≥65 | 78 | T 0334-2005 |

| Angularity | s | ≥30 | 40 | T 0345-2005 |

| Test Item | Unit | Technical Requirements | Test Results | Test Methods | |

|---|---|---|---|---|---|

| Apparent relative density | g/cm3 | ≥2.5 | 2.729 | T 0352-2005 | |

| Hydrophilicity coefficient | % | <1 | 0.71 | T 0353-2005 | |

| Heating stability | - | Measurement records | No colour change | T 0355-2005 | |

| Exterior appearance | - | No agglomeration | No agglomeration | - | |

| Particle size range (%) | <0.6 mm | % | 100 | 100 | T 0351-2005 |

| <0.15 mm | % | 90~100 | 99.4 | T 0312-2005 | |

| <0.075 mm | % | 75~100 | 88.9 | T 0616-2005 | |

| Gradation | Gross Bulk Density | Void Ratio | Bitumen Saturation | Stability | Flow Value | Mineral Gap Ratio |

|---|---|---|---|---|---|---|

| (g/cm3) | (%) | (%) | (kN) | (kN) | (%) | |

| AC-13C | 2.527 | 4.3 | 70.7 | 13.42 | 2.526 | 14.6 |

| technology Specifications | - | 4~6 | 65~75 | ≥8 | 1.5~4 | ≥14 |

| Gradation | Dynamic Stability (Times/min) | Soaked Marshall Stability MS0 (%) | Freeze–Thaw Splitting Tensile Strength TSR (%) |

|---|---|---|---|

| AC-13C | 2831 | 82.6 | 82.1 |

| Technical Specifications | ≥1000 | ≥80 | ≥75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, X.; Zhou, Z.; Fang, Y.; Ma, C.; Yu, G. Study on the Effect of Hot and Humid Environmental Factors on the Mechanical Properties of Asphalt Concrete. Materials 2024, 17, 4942. https://doi.org/10.3390/ma17204942

Yan X, Zhou Z, Fang Y, Ma C, Yu G. Study on the Effect of Hot and Humid Environmental Factors on the Mechanical Properties of Asphalt Concrete. Materials. 2024; 17(20):4942. https://doi.org/10.3390/ma17204942

Chicago/Turabian StyleYan, Xin, Zhigang Zhou, Yingjia Fang, Chongsen Ma, and Guangtao Yu. 2024. "Study on the Effect of Hot and Humid Environmental Factors on the Mechanical Properties of Asphalt Concrete" Materials 17, no. 20: 4942. https://doi.org/10.3390/ma17204942