Study on Wear and Corrosion Resistance of Ni60/WC Coating by Laser Cladding on Reciprocating Pump Plunger: Comparison with Flame-Sprayed Plungers

Abstract

:1. Introduction

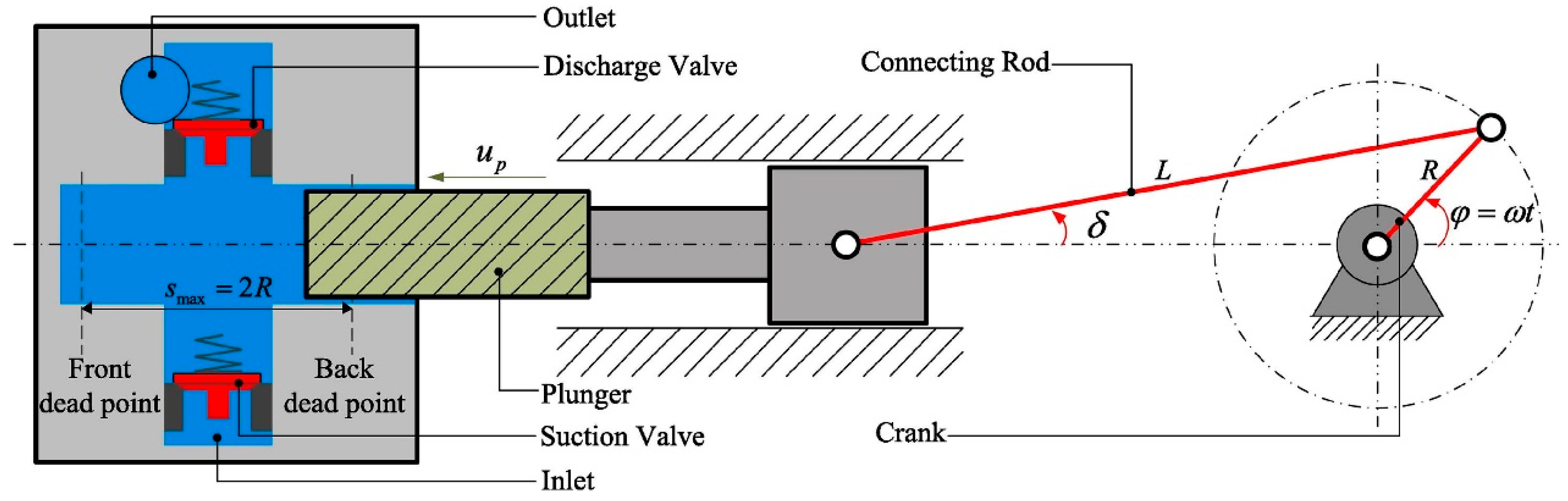

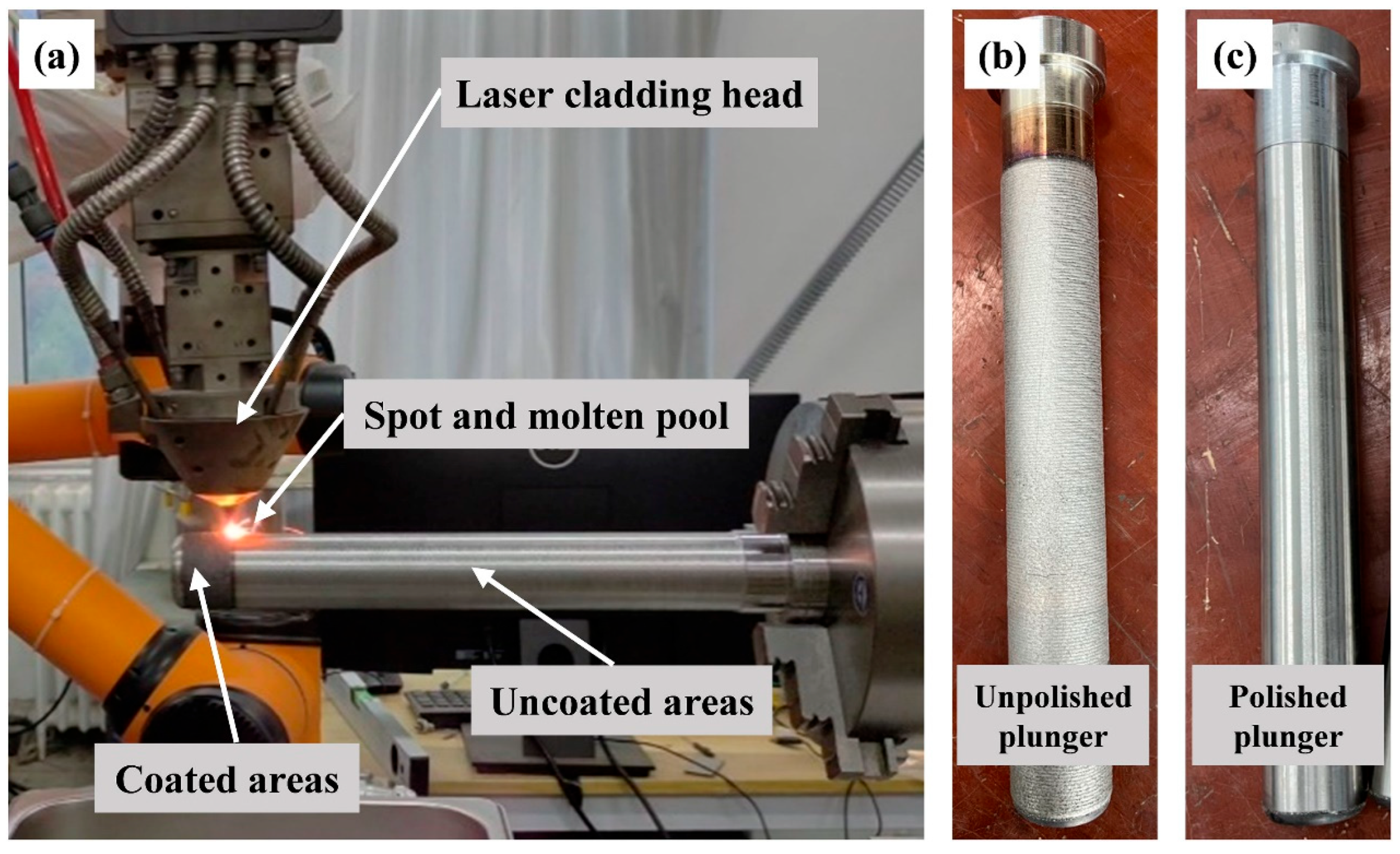

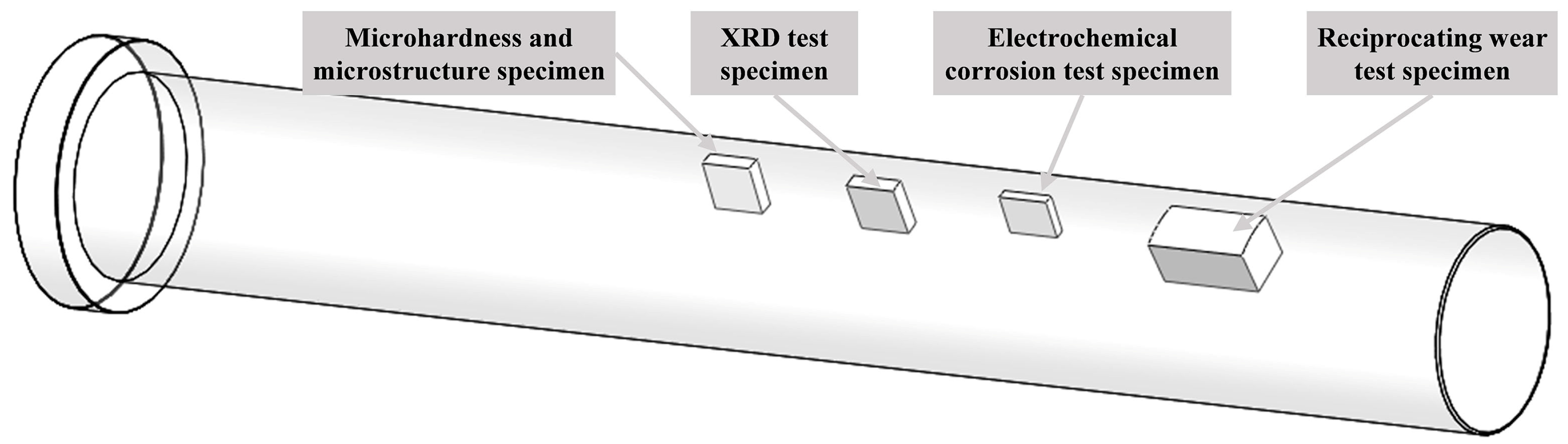

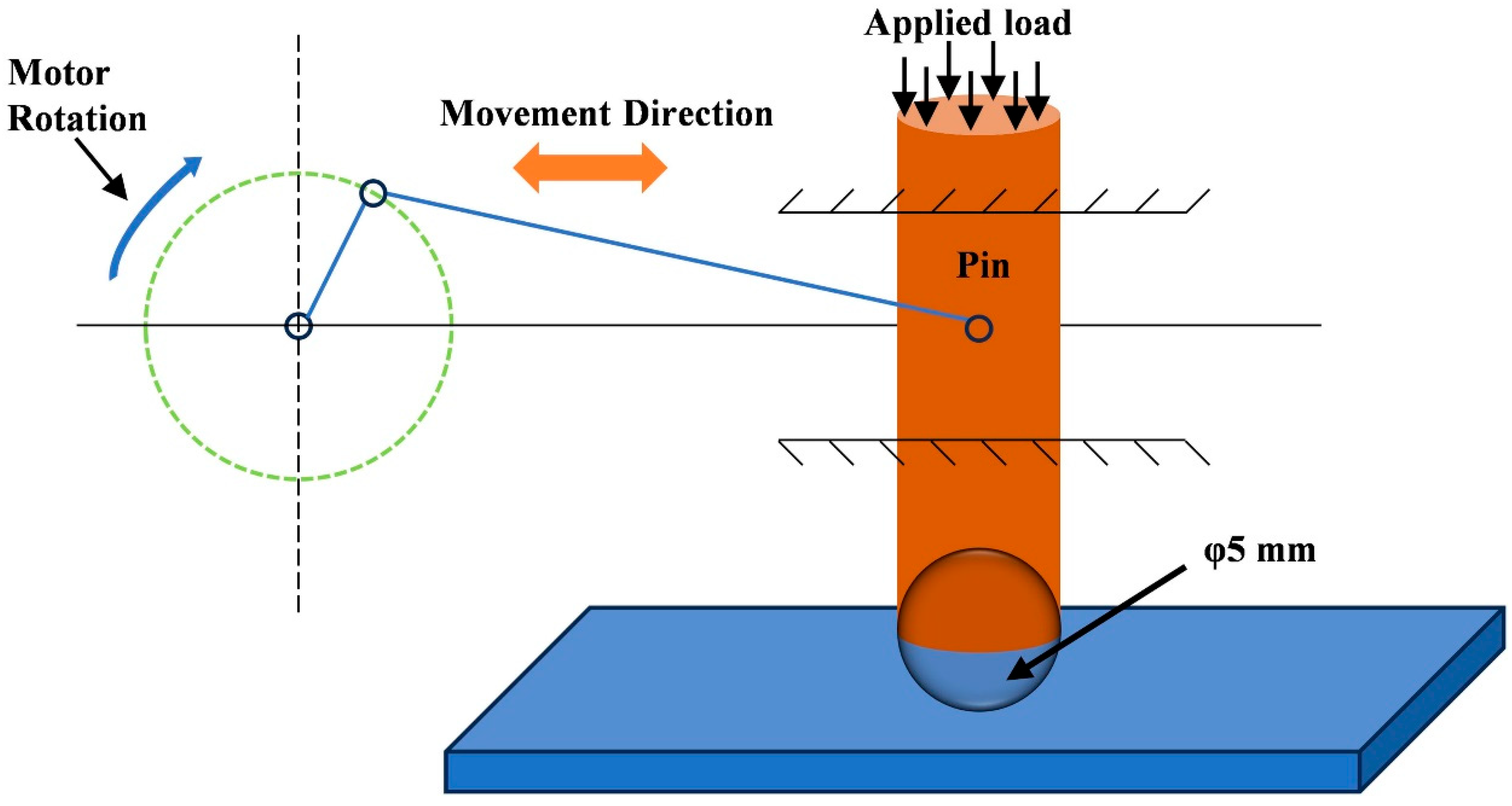

2. Experimental Procedures

3. Results and Discussion

3.1. Morphology and Phase Composition

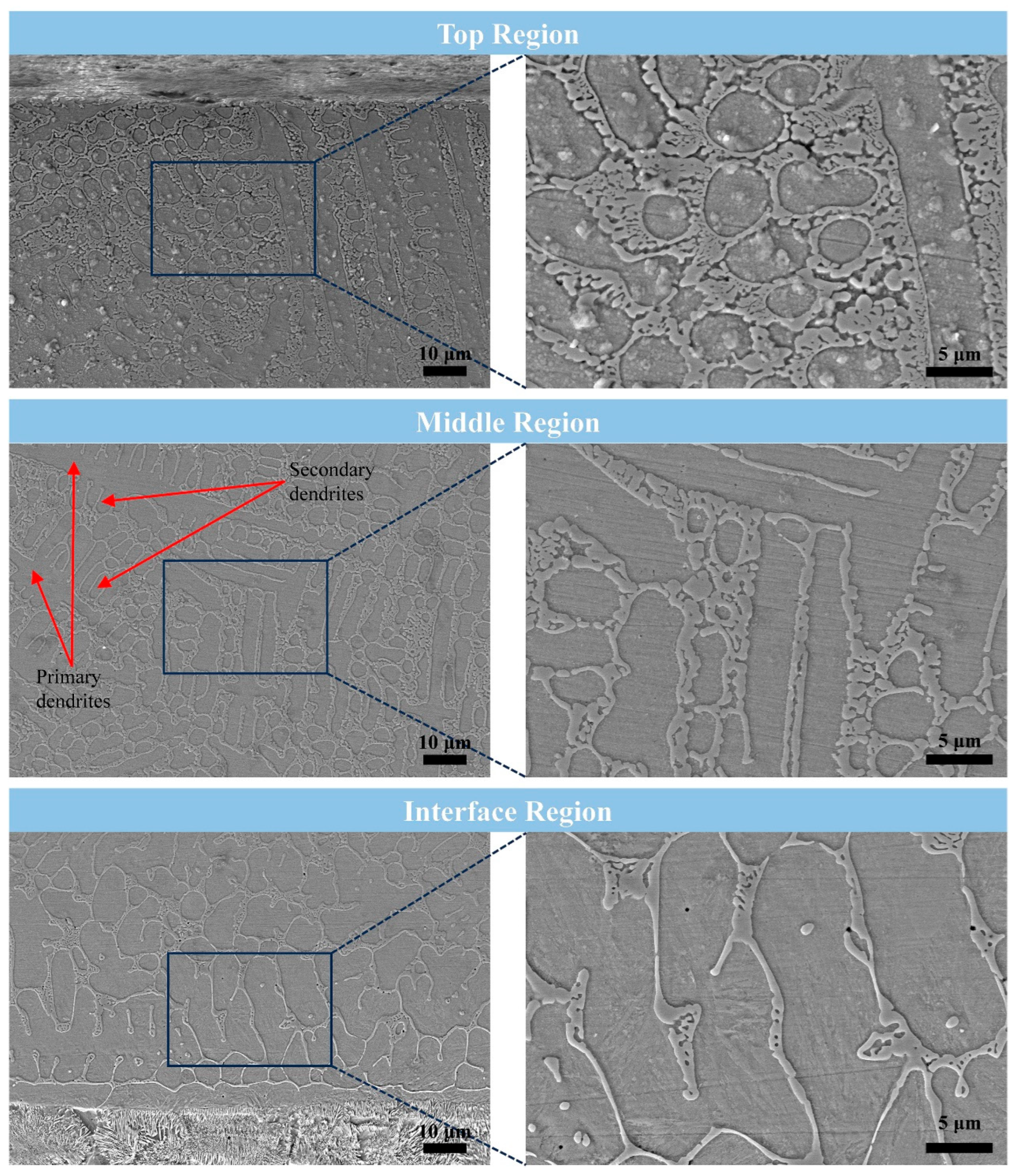

3.2. Microstructure

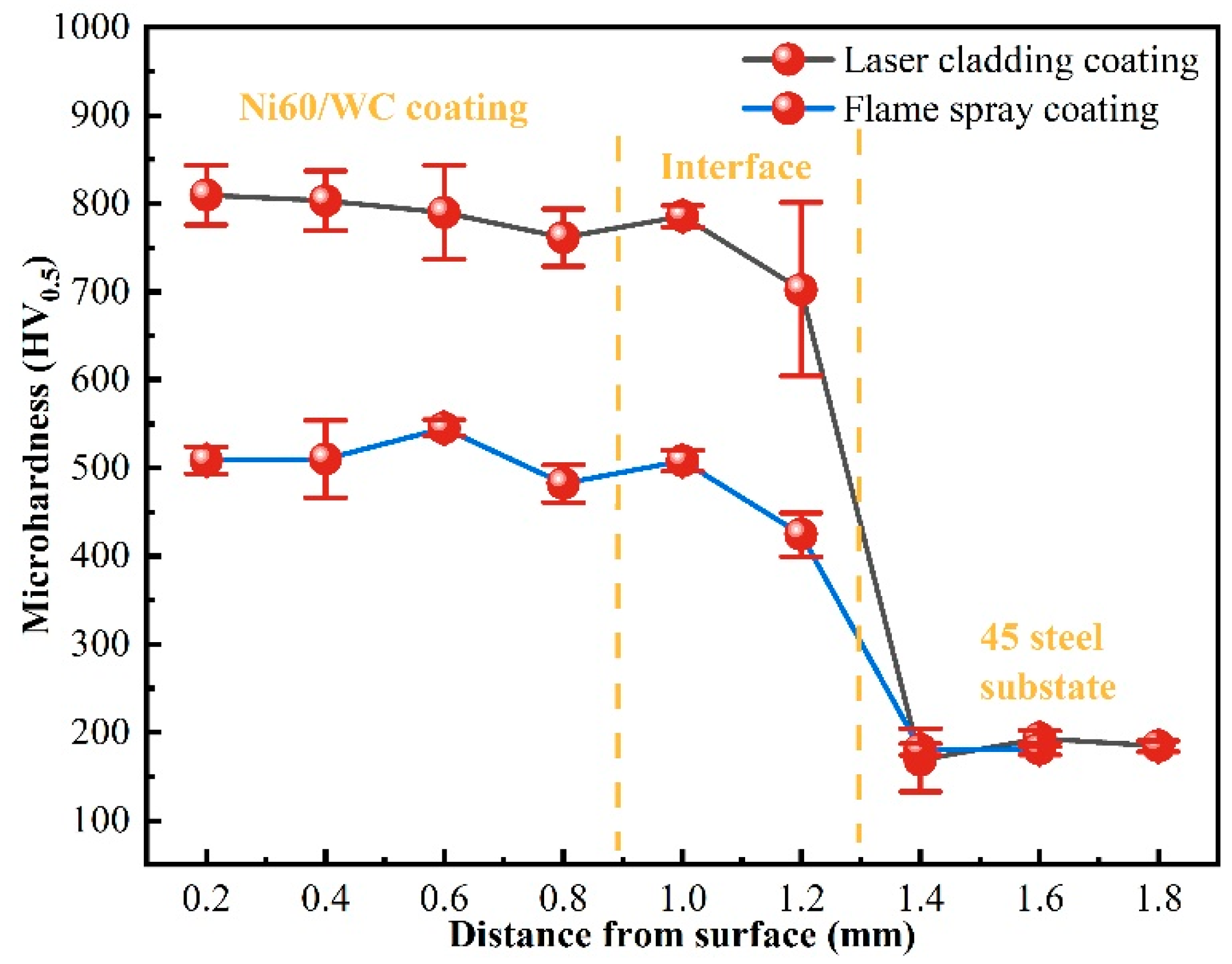

3.3. Microhardness Distribution

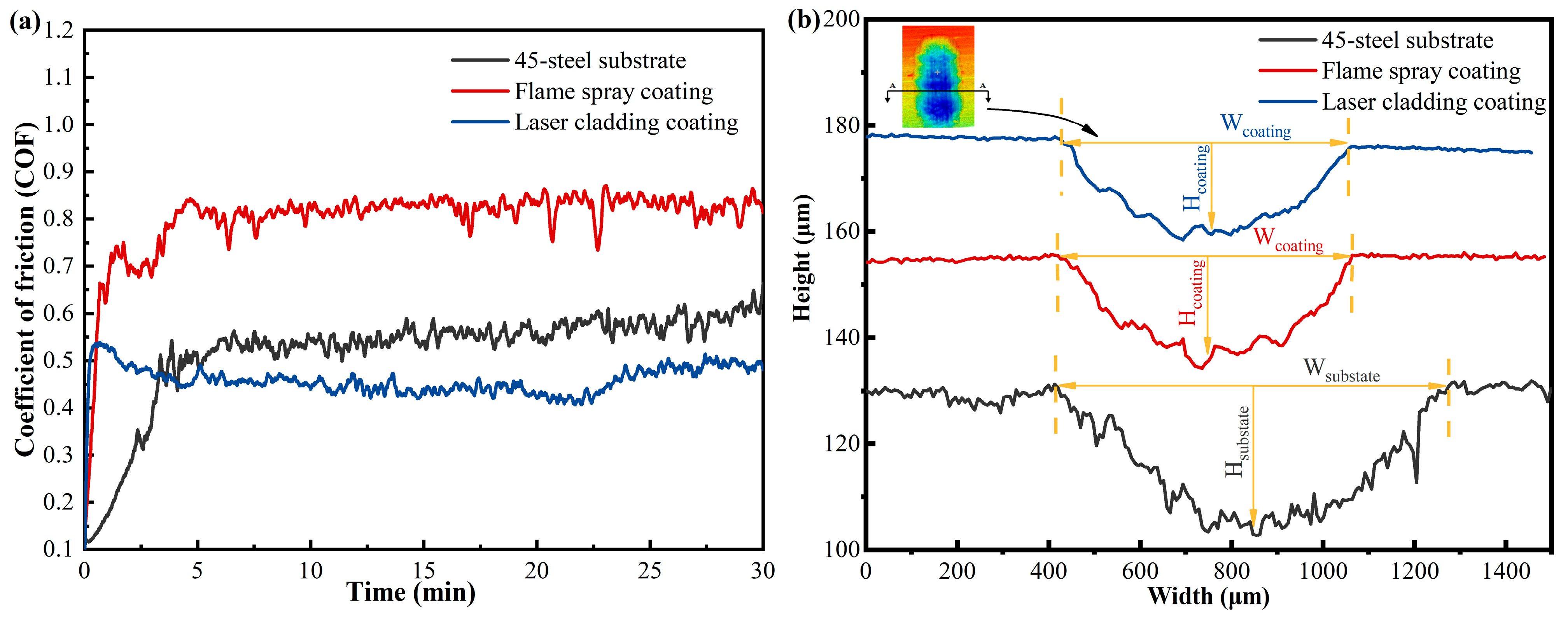

3.4. Wear Resistance

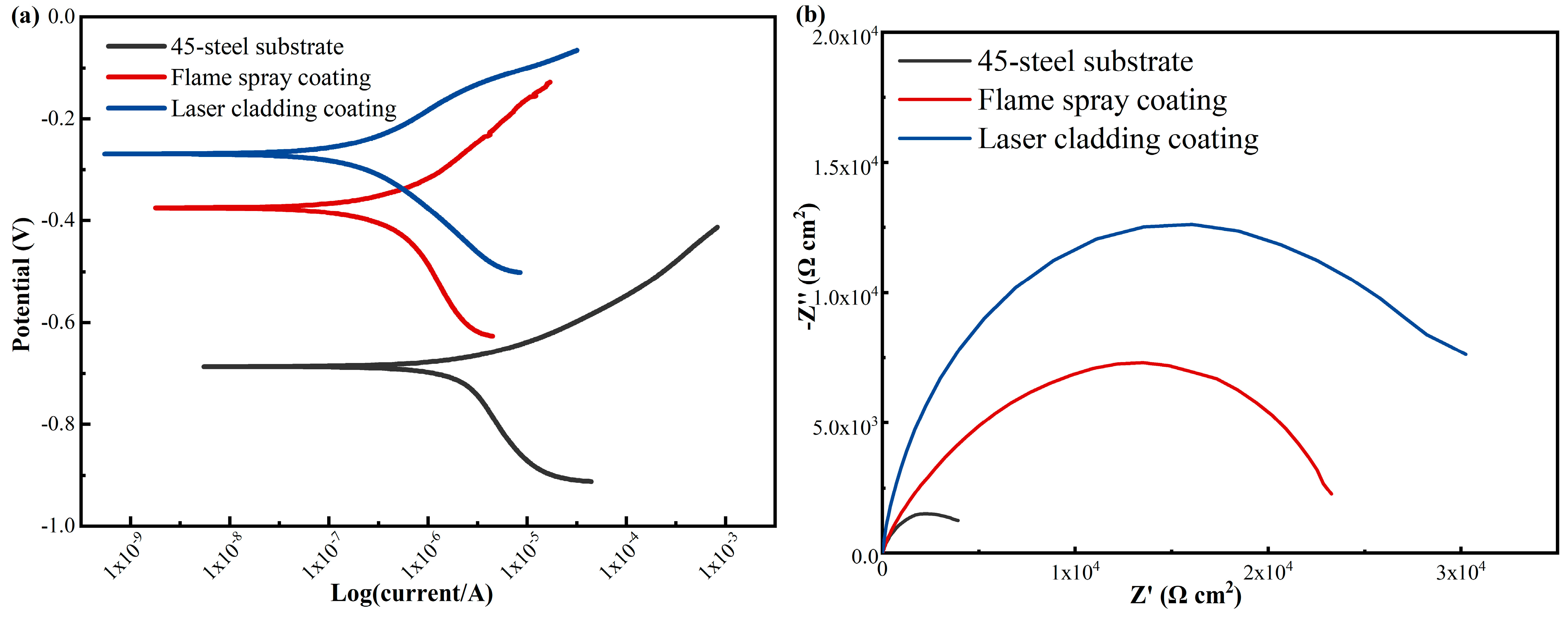

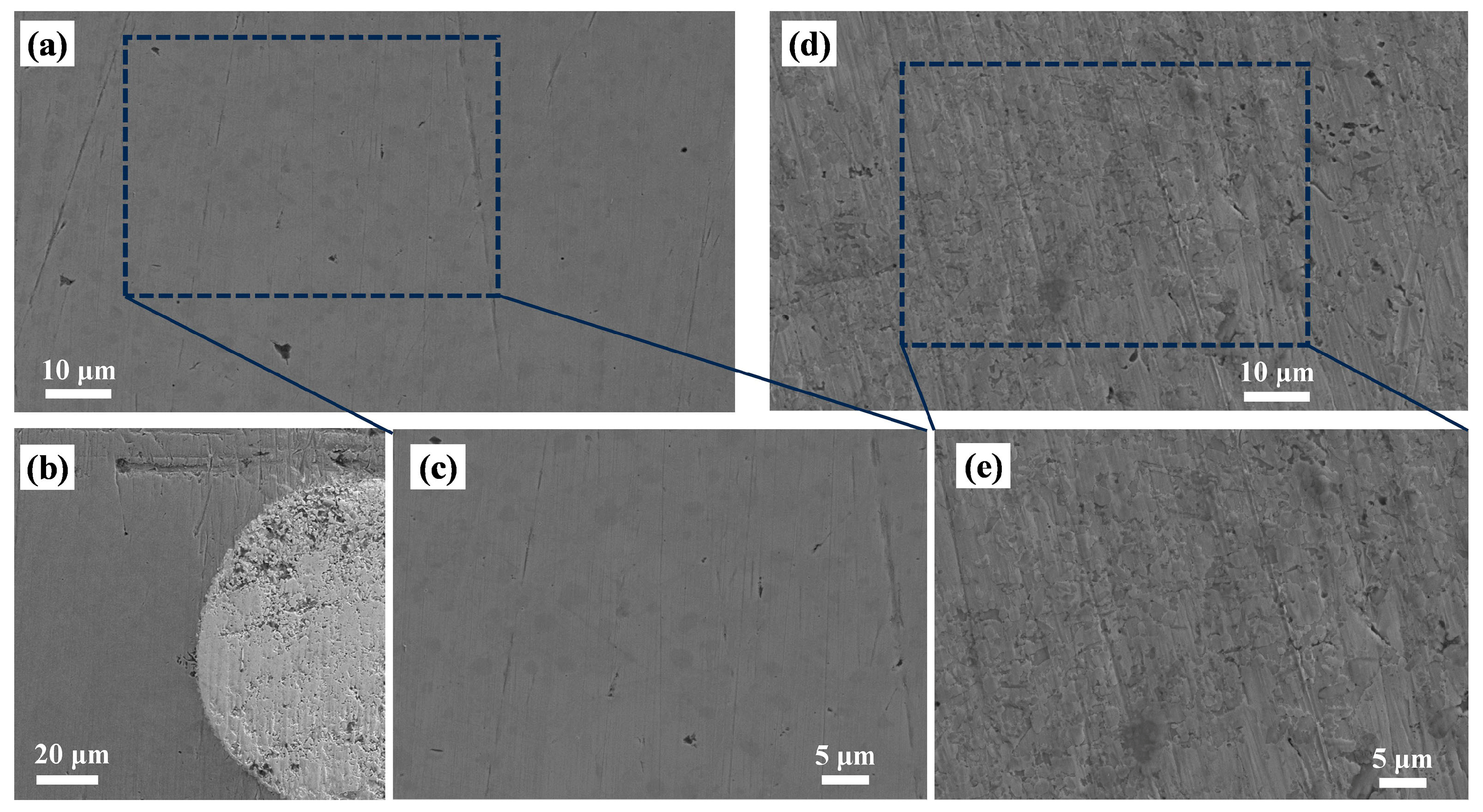

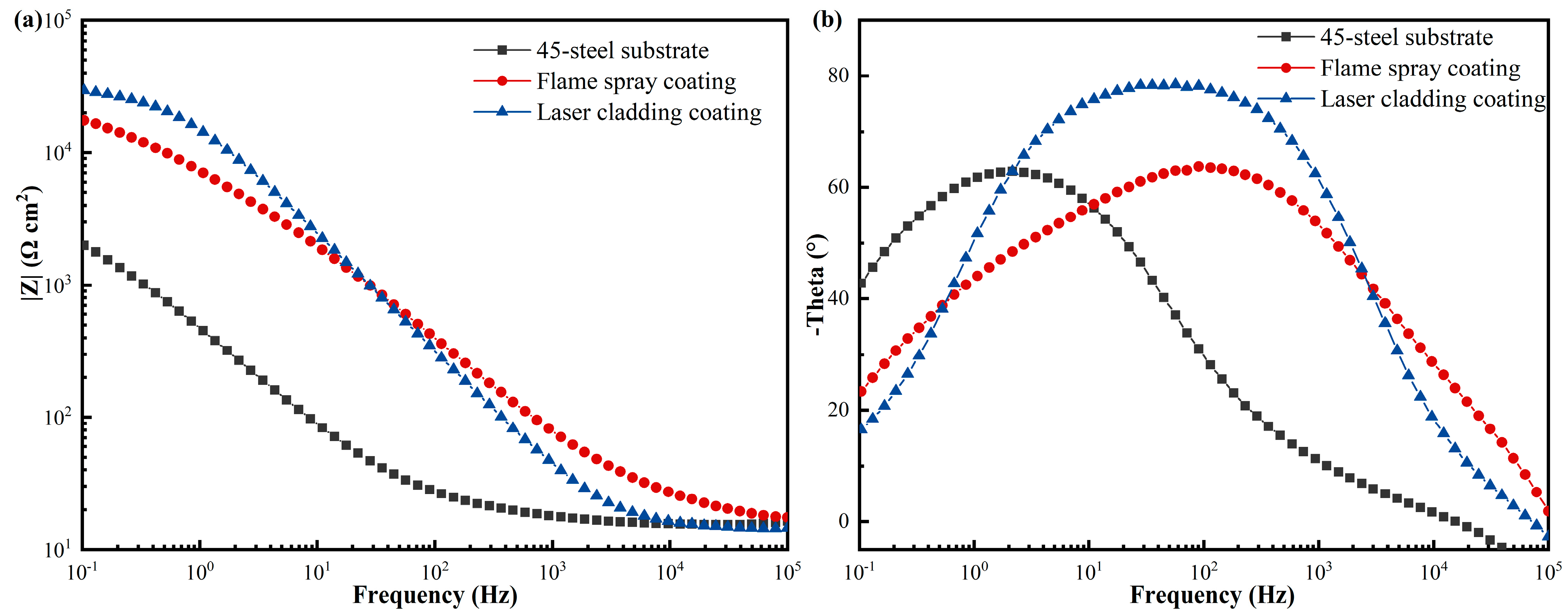

3.5. Corrosion Resistance

4. Conclusions

- The laser heat source irradiated the surface of the 45-steel plunger to form a liquid molten pool, which melted Ni60/WC powder and solidified rapidly, and the coating without defects, such as microcracks and porosity, was prepared in the plunger indication. The coatings prepared via laser cladding showed excellent metallurgical bonding with the substrate, and elemental analysis revealed that elemental diffusion occurred between the WC particles and the melted Ni60 alloy after irradiation by the laser heat source.

- The Ni60/WC prepared via laser cladding is mainly composed of the γ-(Ni, Fe) phase, while the 45-steel matrix is mainly composed of the α-Fe phase, and the WC particles are only present in the interior of the coating, not on the surface. Microstructural analysis reveals that the top region of the coating is dominated by equiaxed crystals and equiaxed-like crystals, the middle region shows a typical dendritic crystal structure, and the bottom region of the cytosolic crystals shows the phenomenon of elongation along the perpendicular direction of the fusion line between the coating and the substrate; the grain size of the cytosolic crystals is significantly larger compared with that of the top region.

- The highest microhardness value of the coating is 821.8 HV0.5, which is 310.9% higher compared to the 45-steel substrate (~200 HV0.5) and is superior to the microhardness of the flame-sprayed plunger coating of 545.5 HV0.5. The laser cladding coatings have a lower coefficient of friction than 45-steel substrates and flame-sprayed coatings and a lower volumetric wear rate over the same period of time. Both coatings showed uniform corrosion characteristics in the solution, and the surface of the laser cladding coating after corrosion was smoother than that of the flame-sprayed coating. The laser cladding coating had the highest wear resistance and excellent corrosion resistance. In addition, the laser cladding coating had a much smaller corrosion current density and corrosion rate of 3.5 wt.% NaCl solution, which is promising for reciprocating pump plunger applications.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wang, T.; Wang, G.; Dai, L.; Chen, L.; Qiu, S.; Li, R. Motion mechanism study on the valve disc of an ultra-high pressure reciprocating pump. Mech. Syst. Signal Process. 2021, 160, 107942. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, Z.; Bu, Y.; Qiu, C.; Yuan, Y. Simulation studies on drilling mud pump plunger seal failure under ultrahigh pressure and ultradeep conditions. Eng. Fail. Anal. 2014, 45, 142–150. [Google Scholar] [CrossRef]

- Meng, L.; Zhu, B.; Liu, X.; Zeng, X. Investigation on the Ni60-WC composite coatings deposited by extreme-high-speed laser-induction hybrid cladding technology: Forming characteristics, microstructure and wear behaviors. Surf. Coat. Technol. 2023, 473, 130033. [Google Scholar] [CrossRef]

- Kumar, S.; Mandal, A.; Das, A.K. The effect of process parameters and characterization for the laser cladding of cBN based composite clad over the Ti6Al4V alloy. Mater. Chem. Phys. 2022, 288, 126410. [Google Scholar] [CrossRef]

- Paul, C.P.; Alemohammad, H.; Toyserkani, E.; Khajepour, A.; Corbin, S. Cladding of WC–12 Co on low carbon steel using a pulsed Nd:YAG laser. Mater. Sci. Eng. A 2007, 464, 170–176. [Google Scholar] [CrossRef]

- Yuan, W.; Li, R.; Chen, Z.; Gu, J.; Tian, Y. A comparative study on microstructure and properties of traditional laser cladding and high-speed laser cladding of Ni45 alloy coatings. Surf. Coat. Technol. 2021, 405, 126582. [Google Scholar] [CrossRef]

- Ding, Y.; Bi, W.; Zhong, C.; Wu, T.; Gui, W. A Comparative Study on Microstructure and Properties of Ultra-High-Speed Laser Cladding and Traditional Laser Cladding of Inconel625 Coatings. Materials 2022, 15, 6400. [Google Scholar] [CrossRef]

- Guo, Y.X.; Liu, Q.B.; Zhou, F. Microstructure and properties of Fe5Cr5SiTiCoNbMoW coating by laser cladding. Surf. Eng. 2018, 34, 283–288. [Google Scholar] [CrossRef]

- Lu, P.-Z.; Jia, L.; Zhang, C.; Heng, X.; Xi, X.-C.; Duan, M.-F.; Lu, Z.-L.; Zhou, Y.-X. Optimization on laser cladding parameters for preparing Ni60 coating along with its friction and wear properties. Mater. Today Commun. 2023, 37, 107162. [Google Scholar] [CrossRef]

- Zhou, S.; Dai, X.; Zheng, H. Microstructure and wear resistance of Fe-based WC coating by multi-track overlapping laser induction hybrid rapid cladding. Opt. Laser Technol. 2012, 44, 190–197. [Google Scholar] [CrossRef]

- Erfanmanesh, M.; Shoja-Razavi, R.; Abdollah-Pour, H.; Mohammadian-Semnani, H.; Barekat, M.; Hashemi, S.H. Friction and wear behavior of laser cladded WC-Co and Ni/WC-Co deposits at high temperature. Int. J. Refract. Metals Hard Mater. 2019, 81, 137–148. [Google Scholar] [CrossRef]

- Paul, C.P.; Mishra, S.K.; Tiwari, P.; Kukreja, L.M. Solid-Particle Erosion Behaviour of WC/Ni Composite Clad layers with Different Contents of WC Particles. Opt. Laser Technol. 2013, 50, 155–162. [Google Scholar] [CrossRef]

- Aramian, A.; Razavi, N.; Sadeghian, Z.; Berto, F. A review of additive manufacturing of cermets. Addit. Manuf. 2020, 33, 101130. [Google Scholar] [CrossRef]

- Chen, C.; Feng, A.; Wei, Y.; Wang, Y.; Pan, X.; Song, X. Effects of WC particles on microstructure and wear behavior of laser cladding Ni60 composite coatings. Opt. Laser Technol. 2023, 163, 109425. [Google Scholar] [CrossRef]

- Feng, M.; Ma, Y.; Tian, Y.; Cao, H. Microstructure and Wear Resistance of Ti6Al4V Titanium Alloy Laser-Clad Ni60/WC Composite Coating. Materials 2024, 17, 264. [Google Scholar] [CrossRef]

- Miao, X.; Wu, M.; Wang, H.; Zhao, Y.; Cui, C.; He, R.; Jie, D. Effects of La content on microstructure and tribological properties of laser clad Ni60/WC/La2O3 composite coatings on Cr12MoV. J. Mater. Res. Technol. 2024, 29, 2667–2678. [Google Scholar] [CrossRef]

- Qunshuang, M.; Yajiang, L.; Juan, W.; Kun, L. Microstructure evolution and growth control of ceramic particles in wide-band laser clad Ni60/WC composite coatings. Mater. Des. 2016, 92, 897–905. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Y.; Fan, K.; Wang, Q.; Li, Y.; Teng, X. Microstructure and elastocaloric effect of NiTi shape memory alloy in-situ synthesized by laser directed energy deposition additive manufacturing. Mater. Charact. 2024, 210, 113831. [Google Scholar] [CrossRef]

- Jia, D.; Yi, P.; Liu, Y.; Sun, J.; Yue, S.; Zhao, Q. Effect of laser-textured groove wall interface on molybdenum coating diffusion and metallurgical bonding. Surf. Coat. Technol. 2021, 405, 126561. [Google Scholar] [CrossRef]

- Qunshuang, M.; Yajiang, L.; Juan, W. Effects of Ti addition on microstructure homogenization and wear resistance of wide-band laser clad Ni60/WC composite coatings. Int. J. Refract. Met. Hard Mater. 2017, 64, 225–233. [Google Scholar] [CrossRef]

- Venkatesh, L.; Samajdar, I.; Tak, M.; Doherty, R.D.; Gundakaram, R.C.; Prasad, K.S.; Joshi, S.V. Microstructure and phase evolution in laser clad chromium carbide-NiCrMoNb. Appl. Surf. Sci. 2015, 357, 2391–2401. [Google Scholar] [CrossRef]

- Paydas, H.; Mertens, A.; Carrus, R.; Lecomte-Beckers, J.; Tchuindjang, J.T. Laser cladding as repair technology for Ti–6Al–4V alloy: Influence of building strategy on microstructure and hardness. Mater. Des. 2015, 85, 497–510. [Google Scholar] [CrossRef]

- Bartkowski, D.; Młynarczak, A.; Piasecki, A.; Dudziak, B.; Gościański, M.; Bartkowska, A. Microstructure, microhardness and corrosion resistance of Stellite-6 coatings reinforced with WC particles using laser cladding. Opt. Laser Technol. 2015, 68, 191–201. [Google Scholar] [CrossRef]

- Qi, C.; Zhan, X.; Gao, Q.; Liu, L.; Song, Y.; Li, Y. The influence of the pre-placed powder layers on the morphology, microscopic characteristics and microhardness of Ti-6Al-4V/WC MMC coatings during laser cladding. Opt. Laser Technol. 2019, 119, 105572. [Google Scholar] [CrossRef]

- Zhang, P.; Pang, Y.; Yu, M. Effects of WC Particle Types on the Microstructures and Properties of WC-Reinforced Ni60 Composite Coatings Produced by Laser Cladding. Metals 2019, 9, 583. [Google Scholar] [CrossRef]

| Elements | C | Si | Cr | Mn | Fe | B | Ni | Cu |

|---|---|---|---|---|---|---|---|---|

| 45-steel substrate | 0.45 | 0.2 | 0.24 | 0.5 | Bal | - | 0.22 | 0.25 |

| Ni60 alloy powder | 0.72 | - | 16.34 | - | 4.13 | 2.87 | Bal | - |

| Parameters | Laser Power (W) | Spot Diameter (mm) | Axial Speed (mm/s) | Rotational Speed (r/min) | Powder Feeding Speed (g/min) | Argon Flow Rate (L/min) |

|---|---|---|---|---|---|---|

| Values | 1700 | 3 | 0.14 | 5 | 17 | 25 |

| Position | Elements (at.%) | |||||

|---|---|---|---|---|---|---|

| C | W | Mn | Cr | Fe | Ni | |

| A | 52.35 | 47.65 | - | - | - | - |

| B | 58.39 | 41.61 | - | - | - | - |

| C | 26.93 | 1.16 | 0.37 | 11.56 | 48.76 | 10.78 |

| D | 22.49 | 0.73 | 2.41 | 4.10 | 47.70 | 22.55 |

| E | 27.03 | 1.11 | 0.36 | 8.15 | 47.10 | 16.24 |

| Samples | Corrosion Potential (Ecorr/V) | Corrosion Current Density (Icorr/Acm−2) | Corrosion Rate (mmPY) |

|---|---|---|---|

| 45-steel substrate | −0.687 | 3.99 × 10−6 | 46.9 × 10−3 |

| Flame spray coating | −0.375 | 4.27 × 10−7 | 5.02 × 10−3 |

| Laser cladding coating | −0.270 | 2.52 × 10−7 | 2.96 × 10−3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Qi, J.; Zhang, H.; Zhao, N.; Shao, Z.; Wang, S. Study on Wear and Corrosion Resistance of Ni60/WC Coating by Laser Cladding on Reciprocating Pump Plunger: Comparison with Flame-Sprayed Plungers. Materials 2024, 17, 5183. https://doi.org/10.3390/ma17215183

Wang X, Qi J, Zhang H, Zhao N, Shao Z, Wang S. Study on Wear and Corrosion Resistance of Ni60/WC Coating by Laser Cladding on Reciprocating Pump Plunger: Comparison with Flame-Sprayed Plungers. Materials. 2024; 17(21):5183. https://doi.org/10.3390/ma17215183

Chicago/Turabian StyleWang, Xiaogang, Jingjing Qi, Hao Zhang, Ning Zhao, Zhangbin Shao, and Shuyao Wang. 2024. "Study on Wear and Corrosion Resistance of Ni60/WC Coating by Laser Cladding on Reciprocating Pump Plunger: Comparison with Flame-Sprayed Plungers" Materials 17, no. 21: 5183. https://doi.org/10.3390/ma17215183

APA StyleWang, X., Qi, J., Zhang, H., Zhao, N., Shao, Z., & Wang, S. (2024). Study on Wear and Corrosion Resistance of Ni60/WC Coating by Laser Cladding on Reciprocating Pump Plunger: Comparison with Flame-Sprayed Plungers. Materials, 17(21), 5183. https://doi.org/10.3390/ma17215183