Assessing the Impact of Shredded Polyethylene Terephthalate (PET) Post-Consumer Plastic as a Partial Replacement for Coarse Aggregates in Unreinforced Concrete

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Experimental Tests

2.2.1. Slump Test

2.2.2. Air Content Test

2.2.3. Compressive Strength Test

2.2.4. Flexural Strength Test

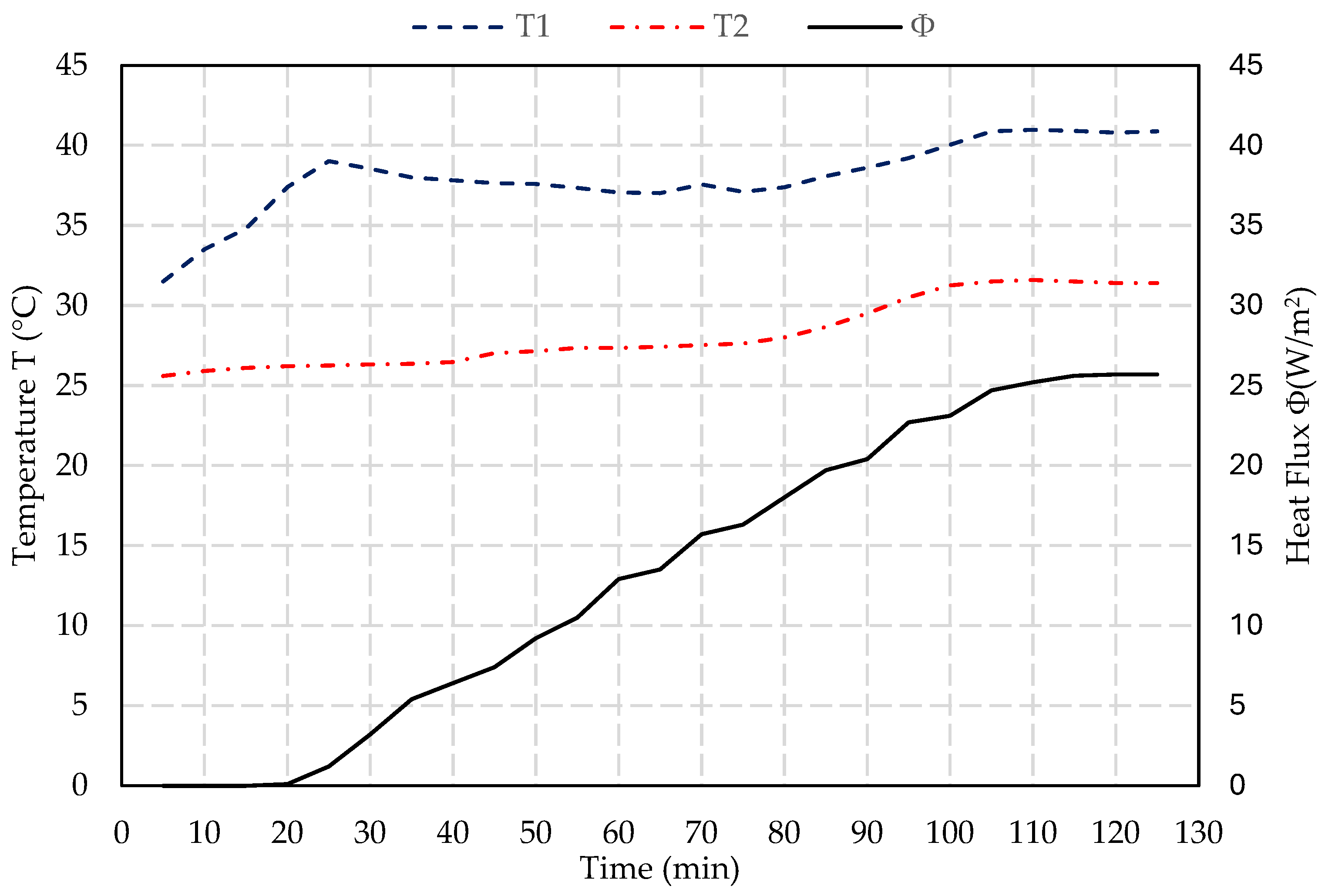

2.2.5. Thermal Conductivity Test

3. Results

3.1. Slump Test Results

3.2. Air Content Test Results

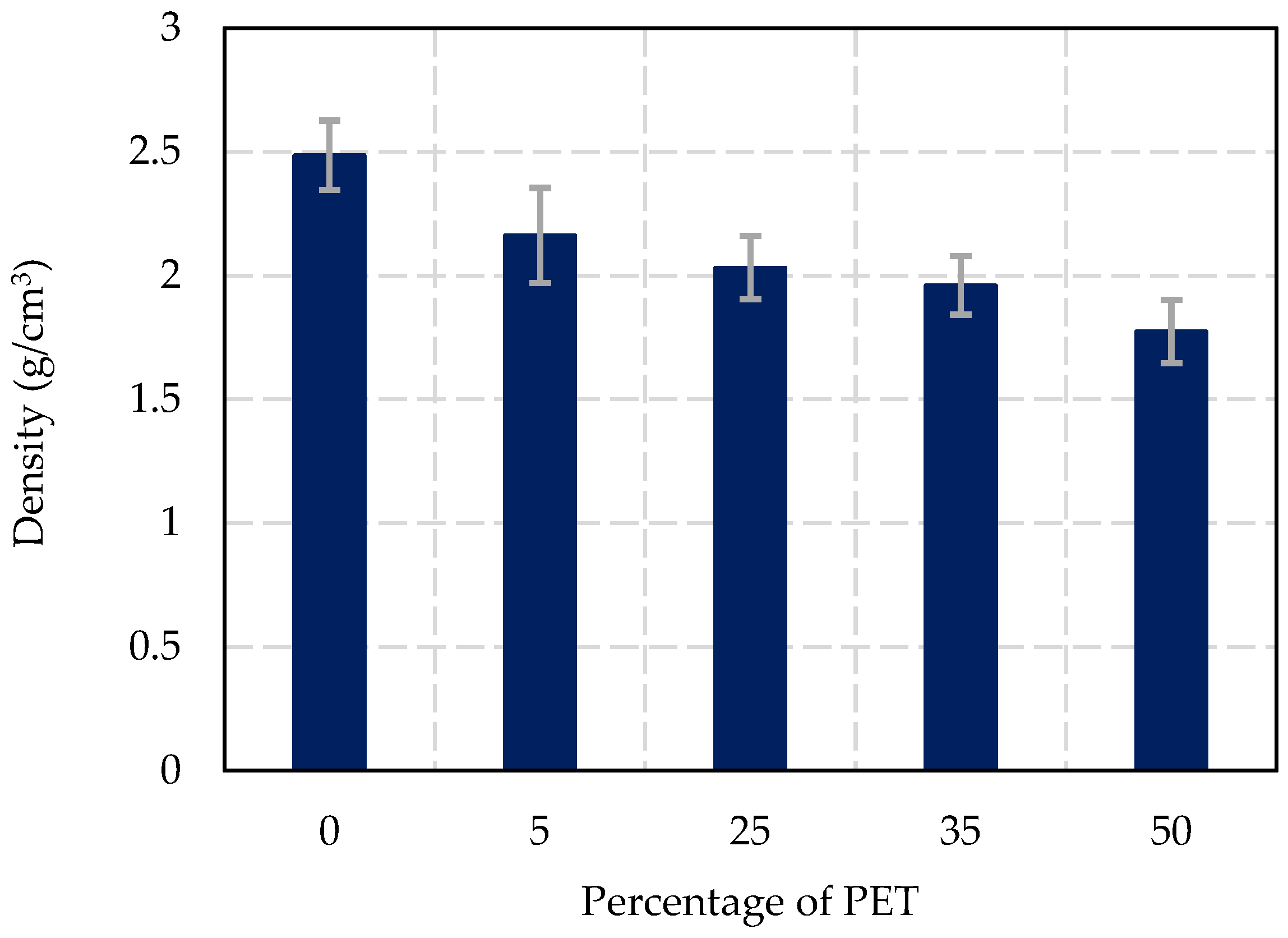

3.3. Density Results

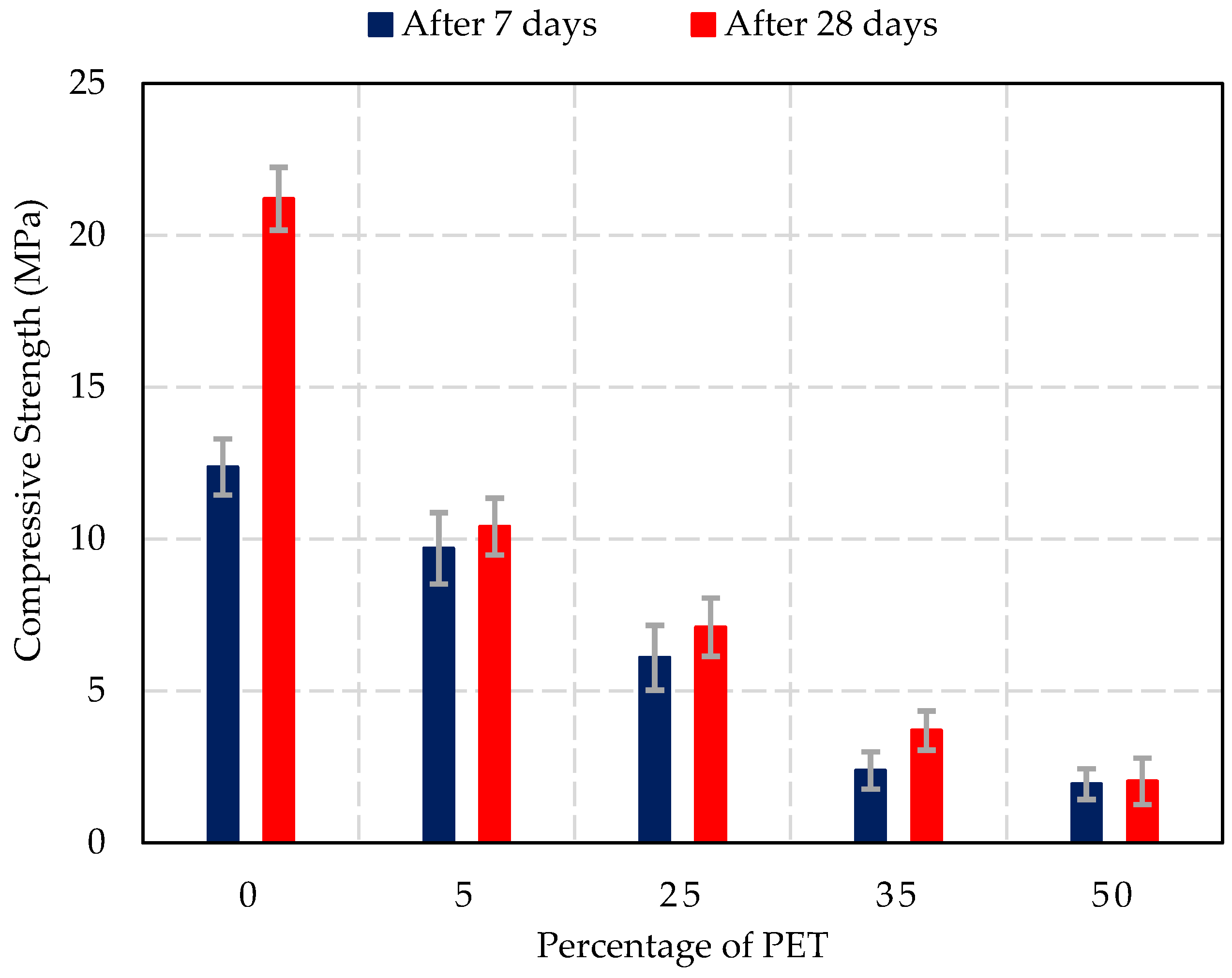

3.4. Compressive Strength Test Results

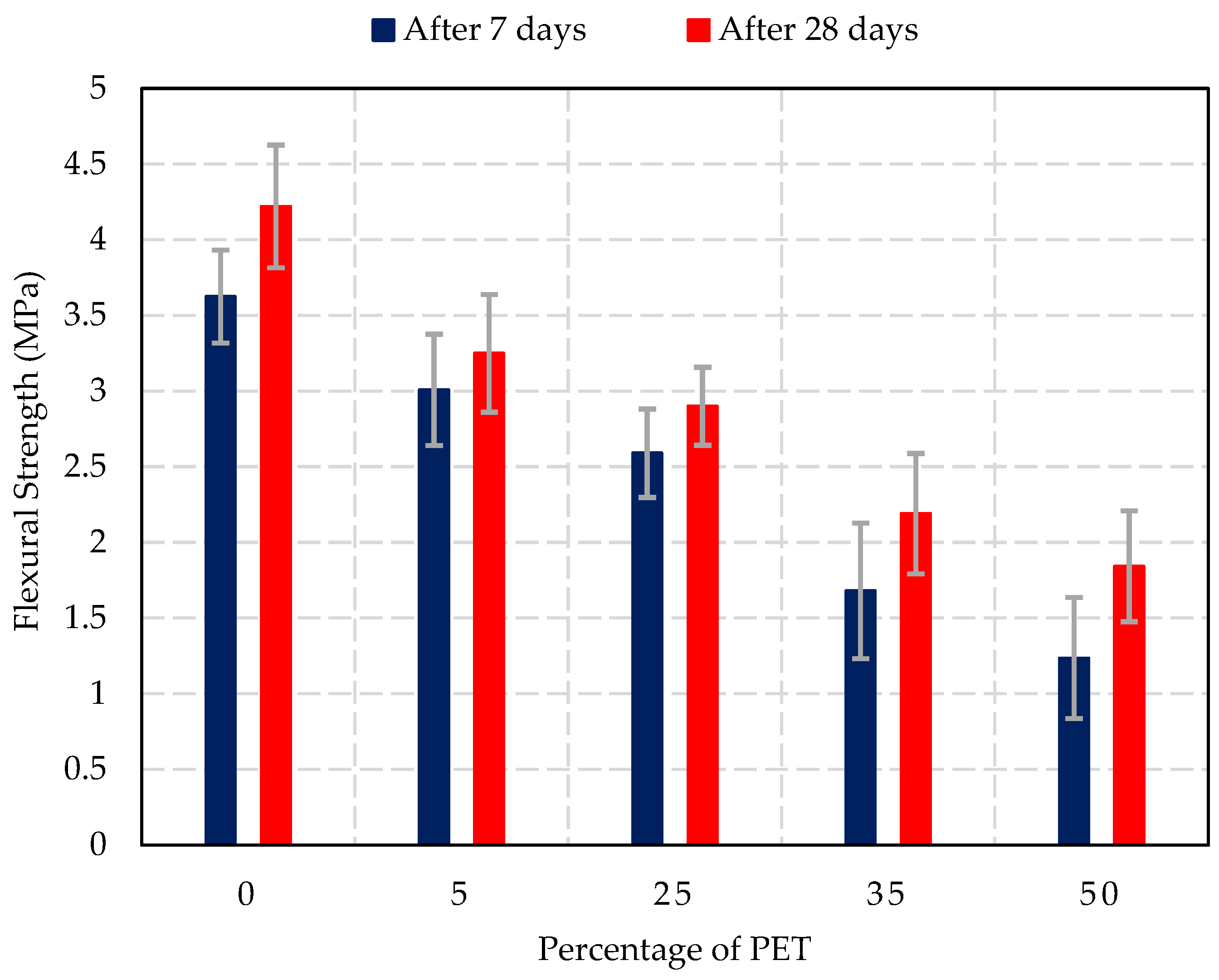

3.5. Flexural Strength Test Results

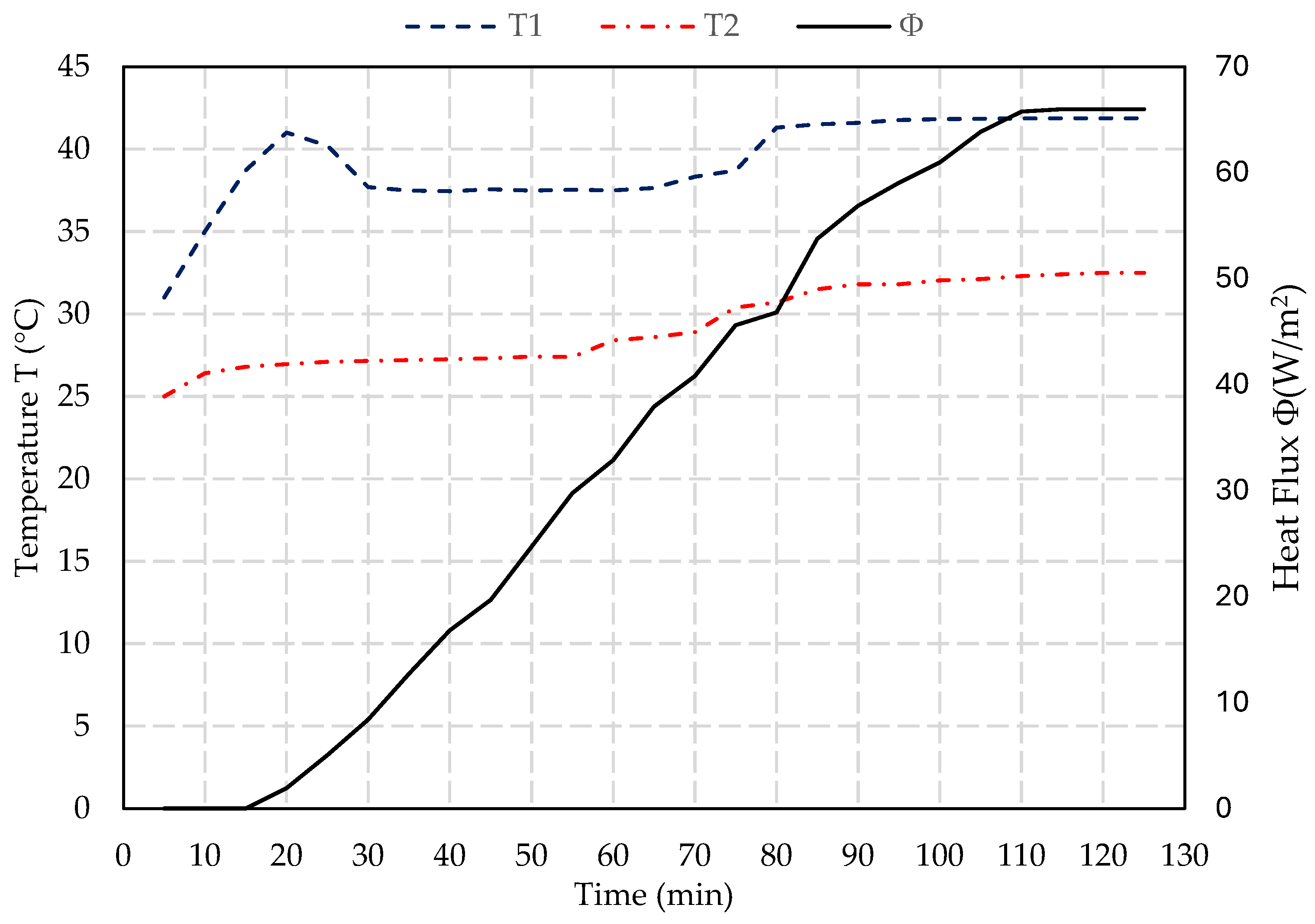

3.6. Thermal Conductivity Test Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geyer, R.; Jambeck, J.R.; Law, K.L. Production, use, and fate of all plastics ever made. Sci. Adv. 2017, 3, e1700782. [Google Scholar] [CrossRef] [PubMed]

- Jahren, P.; Sui, T. Concrete and Sustainability; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ulusu, H.; Aruntas, H.Y.; Gencel, O. Investigation on characteristics of blended cements containing pumice. Constr. Build. Mater. 2016, 118, 11–19. [Google Scholar] [CrossRef]

- Frigione, M. Recycling of PET bottles as fine aggregate in concrete. Waste Manag. 2010, 30, 1101–1106. [Google Scholar] [CrossRef] [PubMed]

- Awoyera, P.O.; Adesina, A. Plastic wastes to construction products: Status, limitations and future perspective. Case Stud. Constr. Mater. 2020, 12, e00330. [Google Scholar] [CrossRef]

- Alghamdi, H. A review of cementitious alternatives within the development of environmental sustainability associated with cement replacement. Environ. Sci. Pollut. Res. 2022, 29, 42433–42451. [Google Scholar] [CrossRef]

- Aslani, F.; Ma, G.; Yim Wan, D.L.; Muselin, G. Development of high-performance self-compacting concrete using waste recycled concrete aggregates and rubber granules. J. Clean. Prod. 2018, 182, 553–566. [Google Scholar] [CrossRef]

- Chen, L.; Yang, M.; Chen, Z.; Xie, Z.; Huang, L.; Osman, A.I.; Farghali, M.; Sandanayake, M.; Liu, E.; Ahn, Y.H.; et al. Conversion of waste into sustainable construction materials: A review of recent developments and prospects. Mater. Today Sustain. 2024, 27, 100930. [Google Scholar] [CrossRef]

- Junaid, M.F.; Rehman, Z.u.; Kuruc, M.; Medveď, I.; Bačinskas, D.; Čurpek, J.; Čekon, M.; Ijaz, N.; Ansari, W.S. Lightweight concrete from a perspective of sustainable reuse of waste byproducts. Constr. Build. Mater. 2022, 319, 126061. [Google Scholar] [CrossRef]

- Moasas, A.M.; Amin, M.N.; Khan, K.; Ahmad, W.; Al-Hashem, M.N.A.; Deifalla, A.F.; Ahmad, A. A worldwide development in the accumulation of waste tires and its utilization in concrete as a sustainable construction material: A review. Case Stud. Constr. Mater. 2022, 17, e01677. [Google Scholar] [CrossRef]

- Silva, R.V.; de Brito, J. 7—Plastic wastes. In Waste and Supplementary Cementitious Materials in Concrete; Siddique, R., Cachim, P., Eds.; Woodhead Publishing: Cambridge, UK, 2018; pp. 199–227. [Google Scholar]

- Lerna, M.; Foti, D.; Petrella, A.; Sabbà, M.F.; Mansour, S. Effect of the Chemical and Mechanical Recycling of PET on the Thermal and Mechanical Response of Mortars and Premixed Screeds. Materials 2023, 16, 3155. [Google Scholar] [CrossRef]

- Babafemi, A.J.; Šavija, B.; Paul, S.C.; Anggraini, V. Engineering Properties of Concrete with Waste Recycled Plastic: A Review. Sustainability 2018, 10, 3875. [Google Scholar] [CrossRef]

- Askar, M.K.; Al-Kamaki, Y.S.S.; Hassan, A. Utilizing Polyethylene Terephthalate PET in Concrete: A Review. Polymers 2023, 15, 3320. [Google Scholar] [CrossRef] [PubMed]

- Meza, A.; Pujadas, P.; Meza, L.M.; Pardo-Bosch, F.; López-Carreño, R.D. Mechanical Optimization of Concrete with Recycled PET Fibres Based on a Statistical-Experimental Study. Materials 2021, 14, 240. [Google Scholar] [CrossRef] [PubMed]

- Coviello, C.G.; Lassandro, P.; Sabbà, M.F.; Foti, D. Mechanical and Thermal Effects of Using Fine Recycled PET Aggregates in Common Screeds. Sustainability 2023, 15, 16692. [Google Scholar] [CrossRef]

- Resende, D.M.; de Carvalho, J.M.F.; Paiva, B.O.; Gonçalves, G.d.R.; Costa, L.C.B.; Peixoto, R.A.F. Sustainable Structural Lightweight Concrete with Recycled Polyethylene Terephthalate Waste Aggregate. Buildings 2024, 14, 609. [Google Scholar] [CrossRef]

- Ferrotto, M.F.; Asteris, P.G.; Borg, R.P.; Cavaleri, L. Strategies for Waste Recycling: The Mechanical Performance of Concrete Based on Limestone and Plastic Waste. Sustainability 2022, 14, 1706. [Google Scholar] [CrossRef]

- Ahmad, F.; Jamal, A.; Mazher, K.M.; Umer, W.; Iqbal, M. Performance Evaluation of Plastic Concrete Modified with E-Waste Plastic as a Partial Replacement of Coarse Aggregate. Materials 2022, 15, 175. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Use of plastic waste as aggregate in cement mortar and concrete preparation: A review. Constr. Build. Mater. 2012, 34, 385–401. [Google Scholar] [CrossRef]

- Oddo, M.C.; Cavaleri, L.; La Mendola, L.; Bilal, H. Integrating Plastic Waste into Concrete: Sustainable Solutions for the Environment. Materials 2024, 17, 3408. [Google Scholar] [CrossRef]

- Sau, D.; Shiuly, A.; Hazra, T. Utilization of plastic waste as replacement of natural aggregates in sustainable concrete: Effects on mechanical and durability properties. Int. J. Environ. Sci. Technol. 2024, 21, 2085–2120. [Google Scholar] [CrossRef]

- Al-Tulaian, B.S.; Al-Shannag, M.J.; Al-Hozaimy, A.R. Recycled plastic waste fibers for reinforcing Portland cement mortar. Constr. Build. Mater. 2016, 127, 102–110. [Google Scholar] [CrossRef]

- Marthong, C.; Sarma, D.K. Influence of PET fiber geometry on the mechanical properties of concrete: An experimental investigation. Eur. J. Environ. Civ. Eng. 2016, 20, 771–784. [Google Scholar] [CrossRef]

- Islam, M.J.; Shahjalal, M. Effect of polypropylene plastic on concrete properties as a partial replacement of stone and brick aggregate. Case Stud. Constr. Mater. 2021, 15, e00627. [Google Scholar] [CrossRef]

- Belmokaddem, M.; Mahi, A.; Senhadji, Y.; Pekmezci, B.Y. Mechanical and physical properties and morphology of concrete containing plastic waste as aggregate. Constr. Build. Mater. 2020, 257, 119559. [Google Scholar] [CrossRef]

- Kurup, A.R.; Kumar, K.S. Novel Fibrous Concrete Mixture Made from Recycled PVC Fibers from Electronic Waste. J. Hazard. Toxic Radioact. Waste 2017, 21, 04016020. [Google Scholar] [CrossRef]

- Kan, A.; Demirboğa, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gu, L.; Gholampour, A. Short-Term Mechanical Properties of Concrete Containing Recycled Polypropylene Coarse Aggregates under Ambient and Elevated Temperature. J. Mater. Civ. Eng. 2017, 29, 04017191. [Google Scholar] [CrossRef]

- Marthong, C.; Marthong, S. An experimental study on the effect of PET fibers on the behavior of exterior RC beam-column connection subjected to reversed cyclic loading. Structures 2016, 5, 175–185. [Google Scholar] [CrossRef]

- Foti, D. Use of recycled waste pet bottles fibers for the reinforcement of concrete. Compos. Struct. 2013, 96, 396–404. [Google Scholar] [CrossRef]

- Irwan, J.M.; Annas, M.M.K.; Aeslina, A.K.; Othman, N.; Koh, K.H.; Asyraf, R.M.; Faisal, S.K. Cracking Propagation of Reinforced Concrete Using Polyethylene Terephtalate (PET) Bottles as Fine Aggregate. Adv. Mater. Res. 2014, 911, 474–478. [Google Scholar] [CrossRef]

- Kim, S.B.; Yi, N.H.; Kim, H.Y.; Kim, J.-H.J.; Song, Y.-C. Material and structural performance evaluation of recycled PET fiber reinforced concrete. Cem. Concr. Compos. 2010, 32, 232–240. [Google Scholar] [CrossRef]

- Choi, Y.-W.; Moon, D.-J.; Chung, J.-S.; Cho, S.-K. Effects of waste PET bottles aggregate on the properties of concrete. Cem. Concr. Res. 2005, 35, 776–781. [Google Scholar] [CrossRef]

- Ferreira, L.; de Brito, J.; Saikia, N. Influence of curing conditions on the mechanical performance of concrete containing recycled plastic aggregate. Constr. Build. Mater. 2012, 36, 196–204. [Google Scholar] [CrossRef]

- Needhidasan, S.; Sai, P. Demonstration on the limited substitution of coarse aggregate with the E-waste plastics in high strength concrete. Mater. Today Proc. 2020, 22, 1004–1009. [Google Scholar] [CrossRef]

- Mustafa, M.A.-T.; Hanafi, I.; Mahmoud, R.; Tayeh, B.A. Effect of partial replacement of sand by plastic waste on impact resistance of concrete: Experiment and simulation. Structures 2019, 20, 519–526. [Google Scholar] [CrossRef]

- Dawood, A.O.; Al-Khazraji, H.; Falih, R.S. Physical and mechanical properties of concrete containing PET wastes as a partial replacement for fine aggregates. Case Stud. Constr. Mater. 2021, 14, e00482. [Google Scholar] [CrossRef]

- Elango, A.; Ashok Kumar, A. Study on partial replacement of plastic waste as fine aggregate in concrete. Int. J. Curr. Eng. Sci. Res. 2018, 5, 1–9. [Google Scholar]

- Claisse, P.A. Chapter 19—Aggregates for concrete and mortar. In Civil Engineering Materials; Claisse, P.A., Ed.; Butterworth-Heinemann: Boston, MA, USA, 2016; pp. 177–188. [Google Scholar]

- ASTM C33/C33M-18; Standard Specification for Concrete Aggregates. ASTM: West Conshohocken, PA, USA, 2018.

- ASTM C143/C143M-12; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM: West Conshohocken, PA, USA, 2012.

- BS 1881-116; Method for Determination of Compressive Strength of Concrete Cubes. The British Standards Institution (BSI): London, UK, 1989.

- ASTM C293/C293M-16; Standard Test Method for Flexural Strength of Concrete (Using Simple Beam with Center-Point Loading). ASTM: West Conshohocken, PA, USA, 2016.

- NF EN 12939:2001; Thermal Performance of Building Materials and Products—Determination of Thermal Resistance by Means of Guarded Hot Plate and Heat Flow Meter Methods—Thick Products of High and Medium Thermal Resistance. The British Standards Institution (BSI): London, UK, 2021.

- ASTM C129-23; Standard Specification for Nonloadbearing Concrete Masonry Units. ASTM: West Conshohocken, PA, USA, 2023.

- Ahmed, M.; Mallick, J.; Abul Hasan, M. A study of factors affecting the flexural tensile strength of concrete. J. King Saud Univ. Eng. Sci. 2016, 28, 147–156. [Google Scholar] [CrossRef]

- Asadi, I.; Shafigh, P.; Abu Hassan, Z.F.B.; Mahyuddin, N.B. Thermal conductivity of concrete—A review. J. Build. Eng. 2018, 20, 81–93. [Google Scholar] [CrossRef]

- Daza-Badilla, L.; Gómez, R.; Díaz-Noriega, R.; Avudaiappan, S.; Skrzypkowski, K.; Saavedra-Flores, E.I.; Korzeniowski, W. Thermal Conductivity in Concrete Samples with Natural and Synthetic Fibers. Materials 2024, 17, 817. [Google Scholar] [CrossRef]

- Rahmani, E.; Dehestani, M.; Beygi, M.H.A.; Allahyari, H.; Nikbin, I.M. On the mechanical properties of concrete containing waste PET particles. Constr. Build. Mater. 2013, 47, 1302–1308. [Google Scholar] [CrossRef]

- Yang, S.; Yue, X.; Liu, X.; Tong, Y. Properties of self-compacting lightweight concrete containing recycled plastic particles. Constr. Build. Mater. 2015, 84, 444–453. [Google Scholar] [CrossRef]

- ASTM C90-23; Standard Specification for Loadbearing Concrete Masonry Units. ASTM: West Conshohocken, PA, USA, 2023.

- Albano, C.; Camacho, N.; Hernández, M.; Matheus, A.; Gutiérrez, A. Influence of content and particle size of waste pet bottles on concrete behavior at different w/c ratios. Waste Manag. 2009, 29, 2707–2716. [Google Scholar] [CrossRef] [PubMed]

- Azhdarpour, A.M.; Nikoudel, M.R.; Taheri, M. The effect of using polyethylene terephthalate particles on physical and strength-related properties of concrete; a laboratory evaluation. Constr. Build. Mater. 2016, 109, 55–62. [Google Scholar] [CrossRef]

- Saikia, N.; de Brito, J. Mechanical properties and abrasion behaviour of concrete containing shredded PET bottle waste as a partial substitution of natural aggregate. Constr. Build. Mater. 2014, 52, 236–244. [Google Scholar] [CrossRef]

- Poonyakan, A.; Rachakornkij, M.; Wecharatana, M.; Smittakorn, W. Potential Use of Plastic Wastes for Low Thermal Conductivity Concrete. Materials 2018, 11, 1938. [Google Scholar] [CrossRef]

| Material | Mass (kg) |

|---|---|

| Cement | 383 |

| Fine aggregate (Sand) | 664 |

| Coarse aggregate (Gravel) | 1185 |

| Water | 191.5 |

| PET% | 0% | 5% | 25% | 35% | 50% | |

|---|---|---|---|---|---|---|

| Tests | ||||||

| Slump (mm) | 34 (±1.2) | 30 (±1.6) | 27 (±1.7) | 15 (±2) | 6 (±2.2) | |

| Variation (%) | −12% | −21% | −56% | −82% | ||

| Air content (%) | 3.5 (±1.1) | 3.3 (±1.1) | 3.7 (±1.4) | 30 (±2.5) | 40 (±2.7) | |

| Variation (%) | −7% | +6% | +757% | +1043% | ||

| Density (g/cm3) | 2.49 (±0.1) | 2.16 (±0.2) | 2.03 (±0.1) | 1.96 (±0.1) | 1.77 (±0.1) | |

| Variation (%) | −13% | −18% | −21% | −29% | ||

| Compressive strength after 7 days (MPa) | 12.4 (±0.9) | 9.7 (±1.1) | 6.1 (±1) | 2.4 (±0.6) | 1.9 (±0.5) | |

| Variation (%) | −22% | −51% | −81% | −84% | ||

| Compressive strength after 28 days (MPa) | 21.2 (±1) | 10.4 (±0.9) | 7.1 (±1) | 3.7 (±0.6) | 2 (±0.8) | |

| Variation (%) | −51% | −67% | −83% | −90% | ||

| Flexural strength after 7 days (MPa) | 3.6 (±0.3) | 3.0 (±0.4) | 2.6 (±0.3) | 1.7 (±0.4) | 1.2 (±0.4) | |

| Variation (%) | −17% | −29% | −54% | −66% | ||

| Flexural strength after 28 days (MPa) | 4.2 (±0.4) | 3.3 (±0.4) | 2.9 (±0.3) | 2.2 (±0.4) | 1.8 (±0.4) | |

| Variation (%) | −23% | −31% | −48% | −56% | ||

| Sample | T1 (°C) | T2 (°C) | φ (W/m2) | R (m2K/W) | λ (W/m.°K) |

|---|---|---|---|---|---|

| 0% PET | 41.88 | 32.50 | 66.0 | 0.14 | 0.70 |

| (±0.5) | (±0.7) | (±3.3) | (±0.007) | (±0.05) | |

| 25% PET | 40.88 | 31.40 | 25.7 | 0.37 | 0.27 |

| (±0.7) | (±0.8) | (±4.2) | (±0.06) | (±0.05) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Farah, E.; Yaacoub, S.; Dgheim, J.; El Hajj, N. Assessing the Impact of Shredded Polyethylene Terephthalate (PET) Post-Consumer Plastic as a Partial Replacement for Coarse Aggregates in Unreinforced Concrete. Materials 2024, 17, 5208. https://doi.org/10.3390/ma17215208

Farah E, Yaacoub S, Dgheim J, El Hajj N. Assessing the Impact of Shredded Polyethylene Terephthalate (PET) Post-Consumer Plastic as a Partial Replacement for Coarse Aggregates in Unreinforced Concrete. Materials. 2024; 17(21):5208. https://doi.org/10.3390/ma17215208

Chicago/Turabian StyleFarah, Elias, Saidé Yaacoub, Joseph Dgheim, and Nemr El Hajj. 2024. "Assessing the Impact of Shredded Polyethylene Terephthalate (PET) Post-Consumer Plastic as a Partial Replacement for Coarse Aggregates in Unreinforced Concrete" Materials 17, no. 21: 5208. https://doi.org/10.3390/ma17215208

APA StyleFarah, E., Yaacoub, S., Dgheim, J., & El Hajj, N. (2024). Assessing the Impact of Shredded Polyethylene Terephthalate (PET) Post-Consumer Plastic as a Partial Replacement for Coarse Aggregates in Unreinforced Concrete. Materials, 17(21), 5208. https://doi.org/10.3390/ma17215208