A Review on Friction Stir Welding of Copper: Tool Geometry, Process Parameters, and Joint Properties

Abstract

:1. Introduction

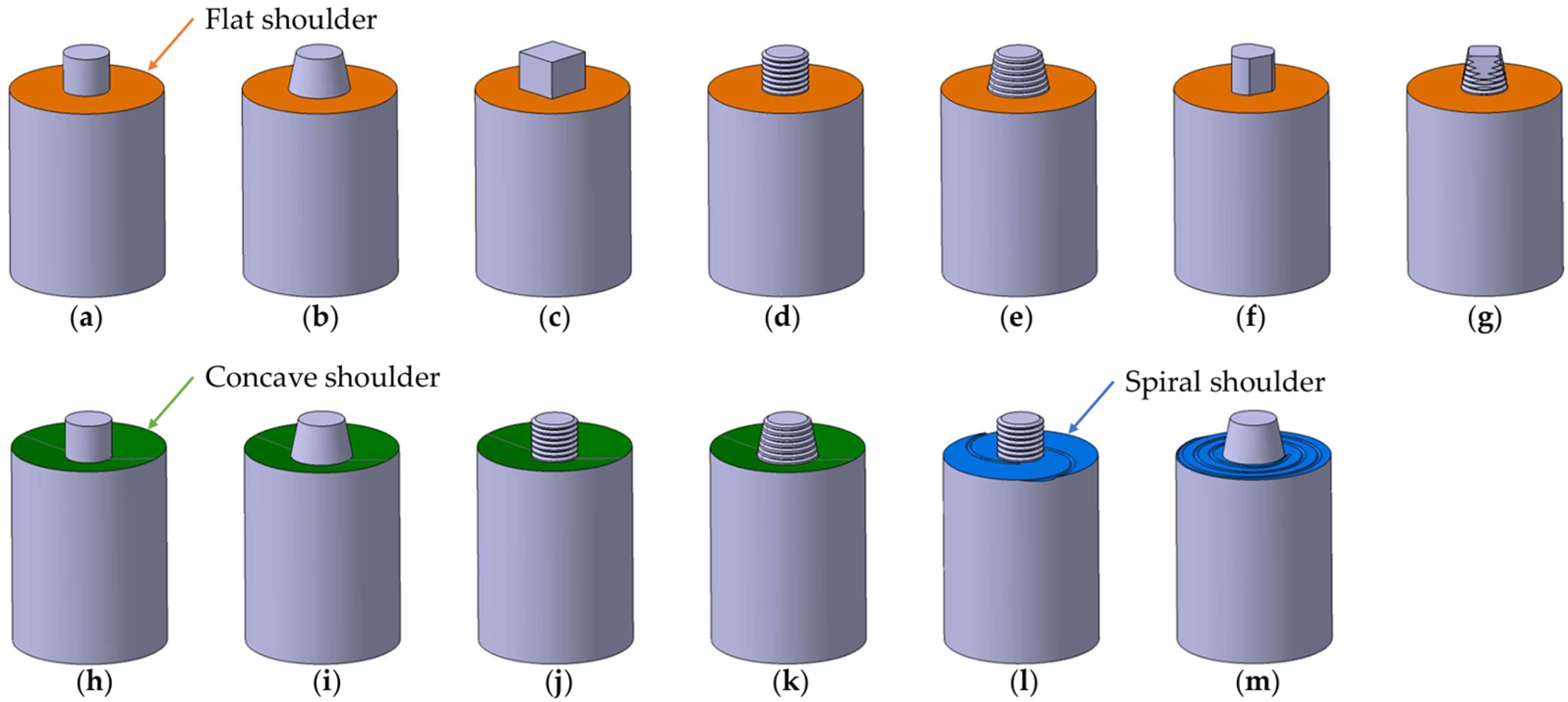

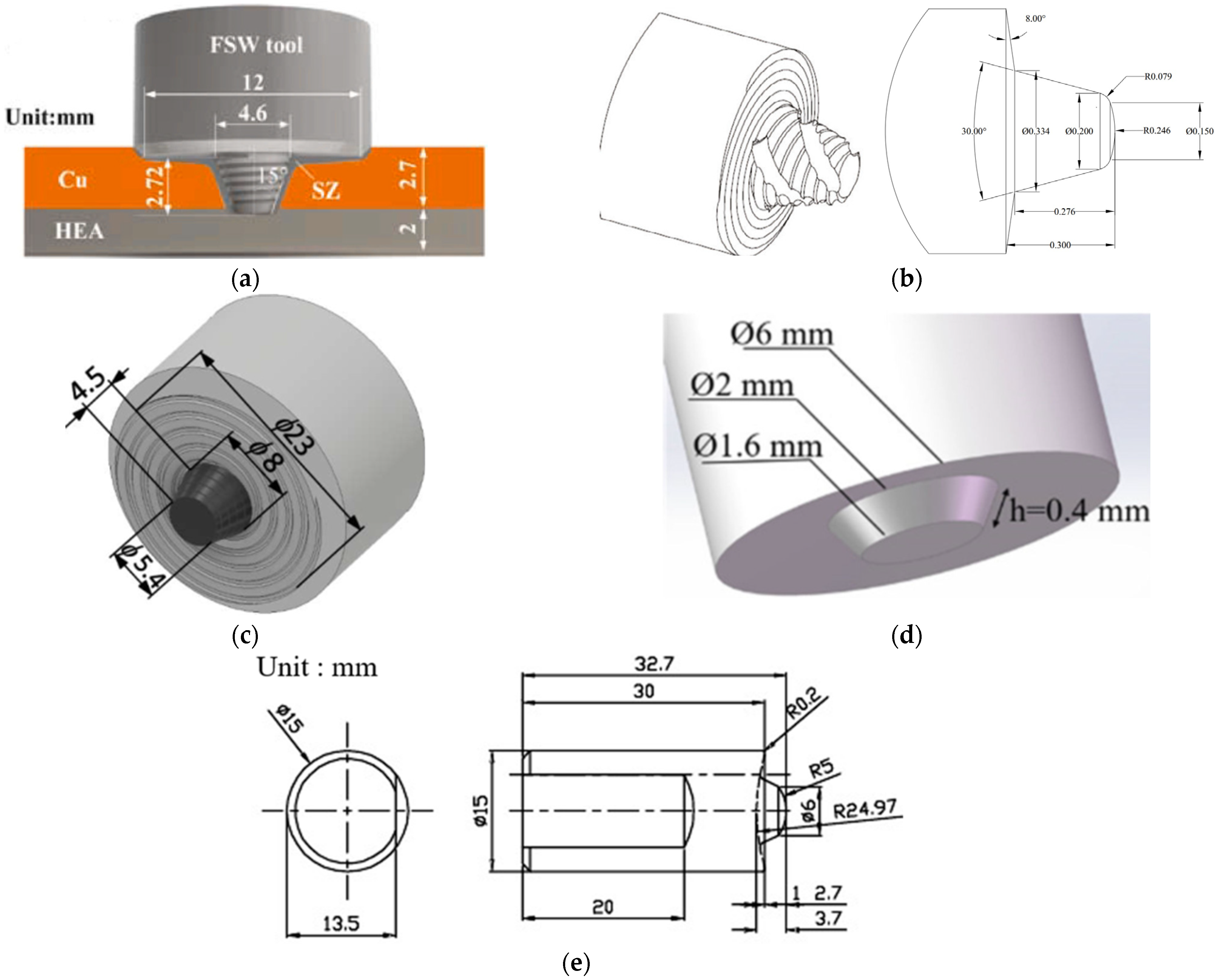

2. Tool Geometry

3. Process Parameters of FSW

- Tools with a flat or concave shoulder and cylindrical or threaded cylindrical pin can be used successfully when welding Cu plates by generating the heat required for joining;

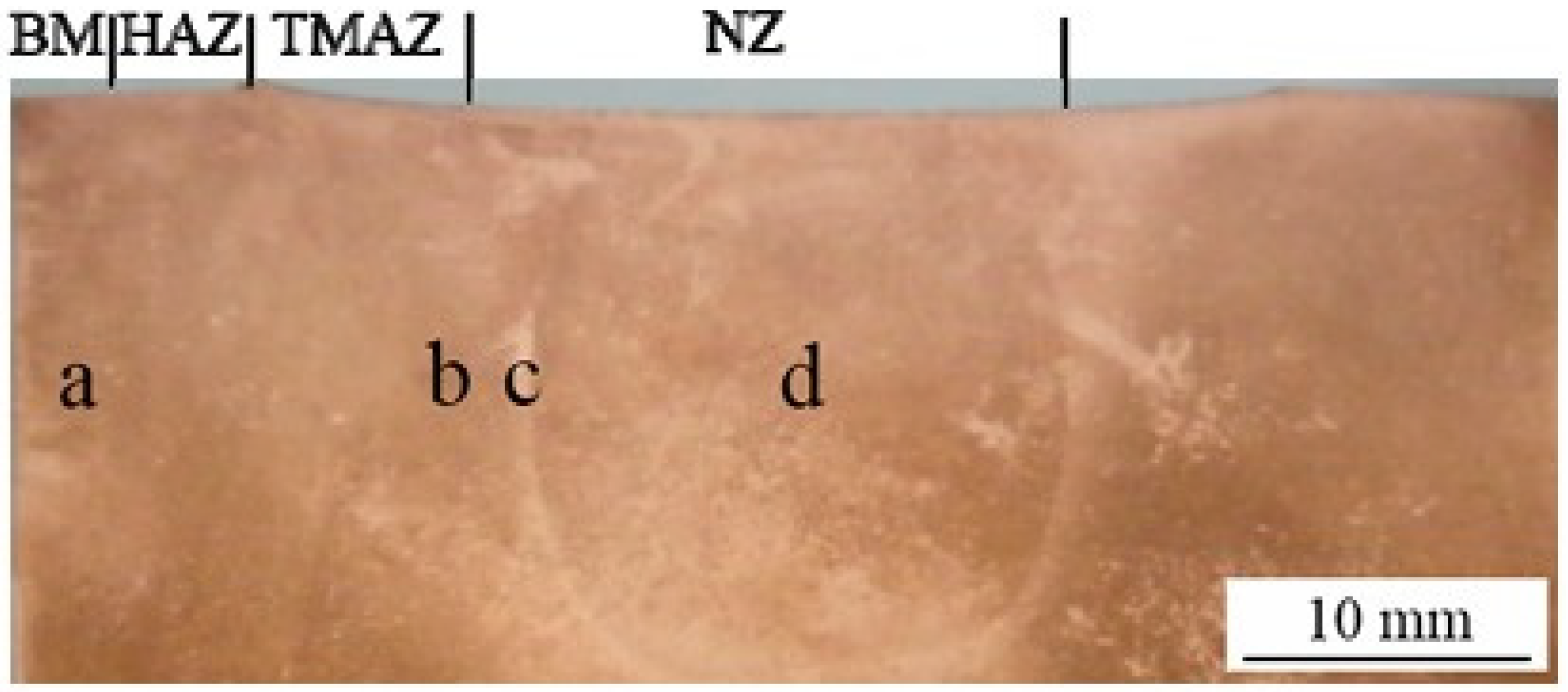

- Regardless of the shape and size of the tool and the values of the technological parameters in the heat-affected zone (HAZ), a microstructure with coarse grains and the poorest mechanical properties are obtained due to incomplete recrystallization;

- The nugget zone (NZ) is usually finer-grained than the heat-affected zone (HAZ) due to complete recrystallization, which leads to higher hardness and strength in the welded zone than in the HAZ;

- A temperature of 550 °C during friction stir welding (FSW) for pure copper is considered ideal for preventing defects and achieving good mechanical properties;

- The material thickness of the joined plates influences the choice of optimal process parameters.

- Zinc content influences grain size in the joint area and joint hardness; a higher zinc content leads to smaller grains and increased hardness;

- The Cu-Cr-Zr alloy joints have improved microstructure and mechanical properties by using post-welding treatments such as rapid water cooling;

- For thin materials, higher rotational speeds (700–1000 rpm) and high traverse speeds are often more effective in ensuring homogeneous mixing and optimal temperature; for thicker materials, rotational speeds and traverse speeds should be reduced to allow optimal heating and prevent material damage;

- Defects such as porosities, cracks, and tunnels occurred when process parameters were incorrectly chosen.

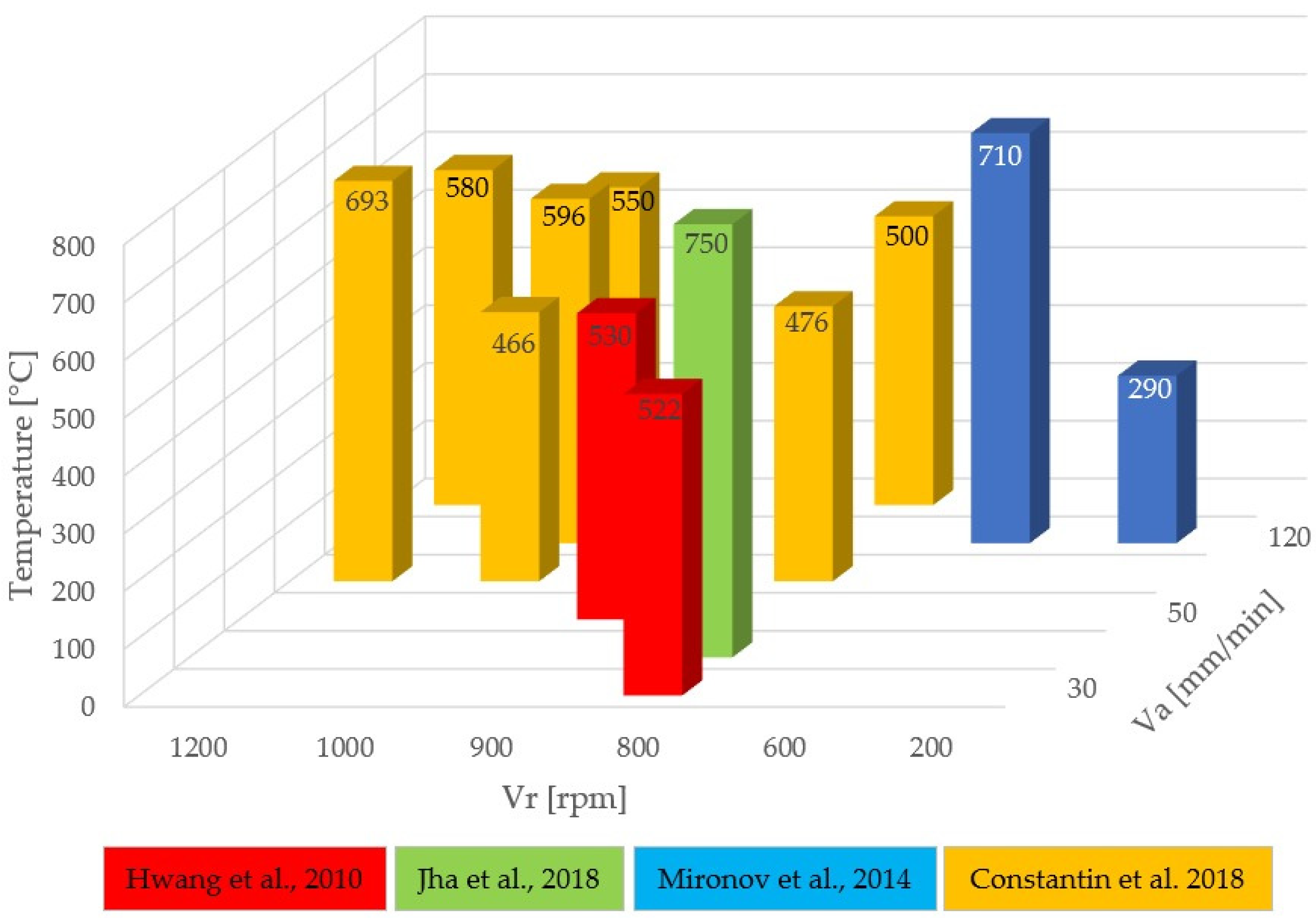

4. Process Temperature

- The temperature in the FSW process influences the recrystallization mechanisms by determining the grain size, grain size distribution in the grain-binding zone, and the homogeneity of the microstructure;

- Higher than optimal temperatures lead to grain growth and decreased mechanical properties;

- For pure copper, the optimum temperature varies between 380 and 600 °C, with most studies recommending around 540–550 °C, i.e., 0.5 × Tm (copper melting temperature), as the optimum welding temperature;

- Copper alloys have a higher maximum temperature during the FSW process (0.8 × Tm) than pure copper.

5. Microstructure

5.1. Nugget Zone

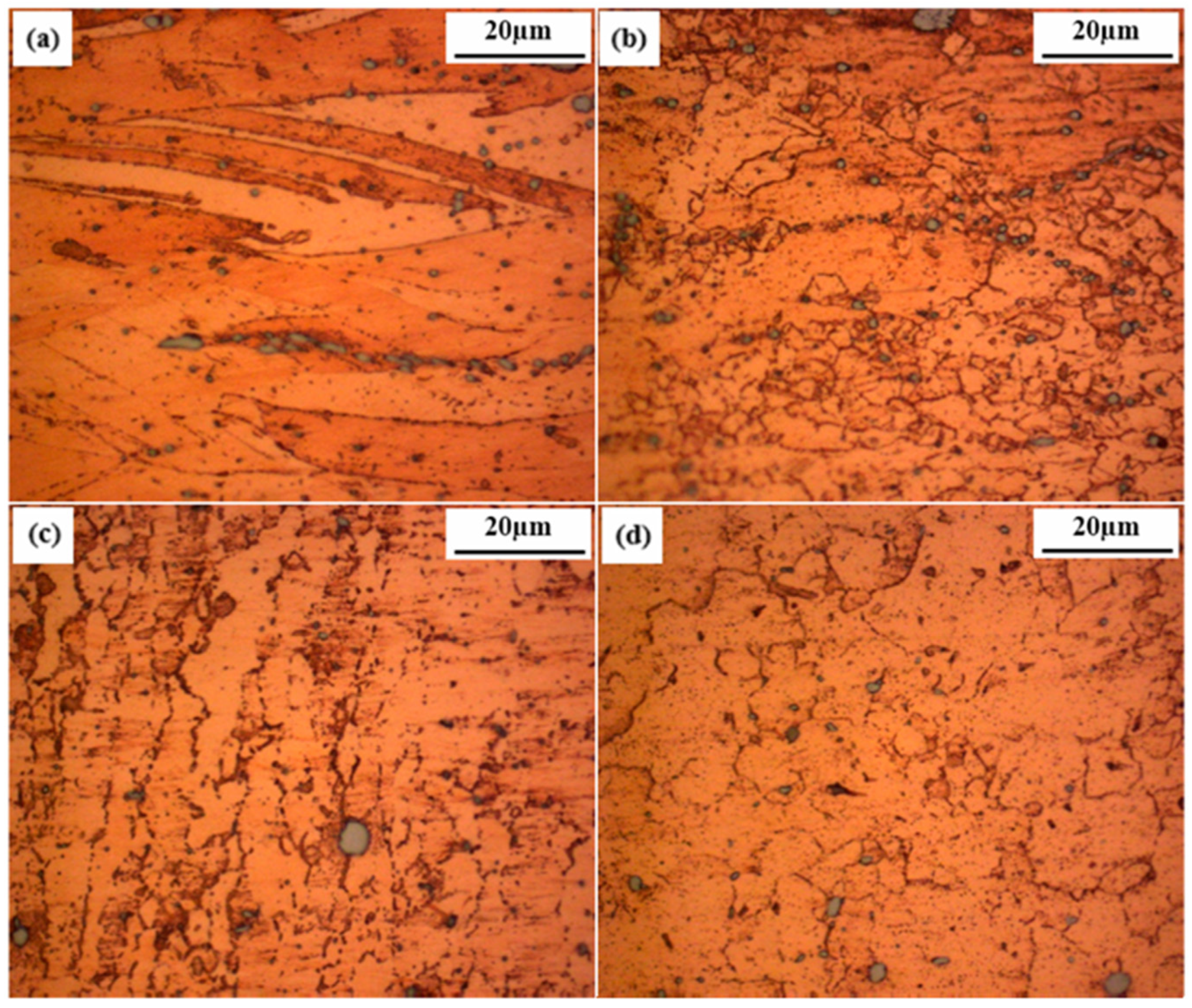

5.2. Thermo-Mechanically Affected Zone

5.3. Heat-Affected Zone

6. Mechanical Properties

6.1. Mechanical Strength

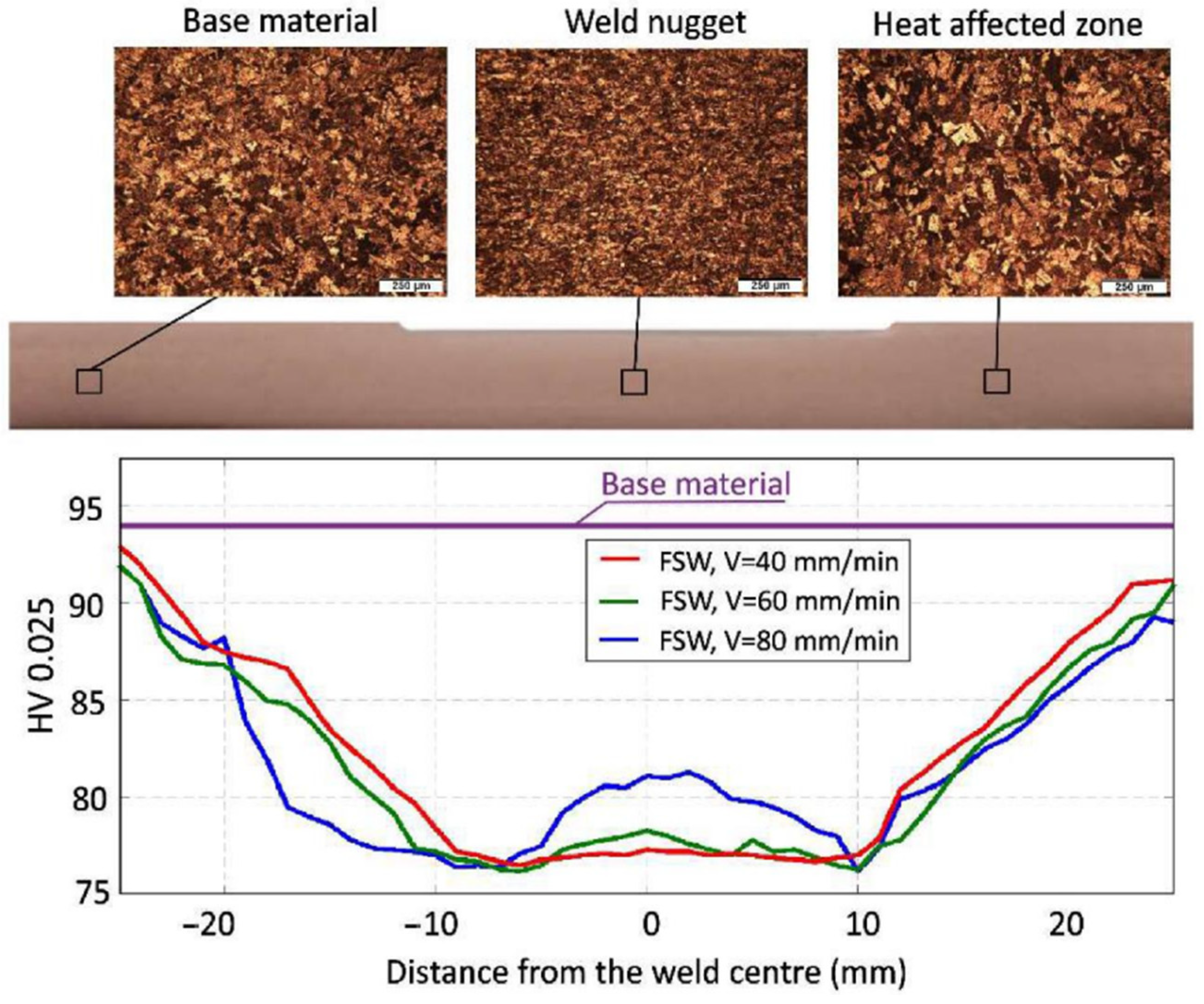

6.2. Microhardness

- In most cases, the mechanical strength values for welded structures are comparable to or even lower than those of the base material (BM). This reduction in resistance is due to several factors, including microstructural changes that lead to material softening, the presence of microscopic defects, and the influence of processing parameters. The mechanical strength is influenced by many factors, including microstructural changes that lead to material softening, the presence of microscopic defects, and the impact of processing parameters.

- In general, the yield strength (YS) and elongation for welded structures are lower than those of the base material due to the modification of the microstructure that occurs during the FSW process.

- Hardness values are typically lower in the joint area than in the base material due to recrystallisation occurring in the joint area.

- The efficiency of FSW is typically high, with values ranging from 70% to above 100%, depending on the material and plate thickness. Welds of thin materials (less than 5 mm) tend to exhibit a higher welding efficiency, often exceeding 90%.

7. Conclusions, Bottlenecks, and Future Development Directions

7.1. Conclusions

7.2. Bottlenecks

7.3. Future Development Direction

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hwang, Y.M.; Fan, P.L.; Lin, C.H. Experimental study on Friction Stir Welding of copper metals. J. Mater. Process Technol. 2010, 210, 1667–1672. [Google Scholar] [CrossRef]

- Dumitra Clej, D.; Popa, D.F.; Popa, G.A.; Jigau, C.; Ghimpusan, M.; Nechifor, A.C. Estimating Performance Parameters to Determine Copper Using Atomic Absorbtion Spectrometry. Bull. Ser. B 2017, 79, 101–110. [Google Scholar]

- Heidarzadeh, A.; Testik, Ö.M.; Güleryüz, G.; Barenji, R.V. Development of a fuzzy logic based model to elucidate the effect of FSW parameters on the ultimate tensile strength and elongation of pure copper joints. J. Manuf. Process. 2020, 53, 250–259. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Friction Welding. United Kingdom; 1995, GB Patent Application No. 9125978, 1991. US Patent No. 5460317, 24 October 1995. [Google Scholar]

- Chen, B.; Chen, K.; Hao, W.; Liang, Z.; Yao, J.; Zhang, L.; Shan, A. Friction stir welding of small-dimension Al3003 and pure Cu pipes. J. Mater. Process Technol. 2015, 223, 48–57. [Google Scholar] [CrossRef]

- Meran, C. The joint properties of brass plates by friction stir welding. Mater. Des. 2006, 27, 719–726. [Google Scholar] [CrossRef]

- Sun, Y.; Gong, W.; Li, Y.; Liu, W.; Sun, S.; Zhu, R.; Feng, J. Effect of rotation speed on microstructure and mechanical properties of bobbin tool friction stir welded T2 copper. Mater. Today Commun. 2023, 35, 106365. [Google Scholar] [CrossRef]

- Jha, K.; Kumar, S.; Nachiket, K.; Bhanumurthy, K.; Dey, G.K. Friction Stir Welding (FSW) of Aged CuCrZr Alloy Plates. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2018, 49, 223–234. [Google Scholar] [CrossRef]

- Sato, Y.S.; Kokawa, H.; Enomoto, M.; Jogan, S. Microstructural Evolution of 6063 Aluminum during Friction-Stir Welding. Met. Mater. Trans. A 1999, 30, 2429–2437. [Google Scholar] [CrossRef]

- Colligan, B.Y.K. Material Flow Behavior during Friction Stir Welding of Aluminum. Weld. Res. 1999, 229–237. [Google Scholar]

- Mishra, R.S.; Ma, Z.Y. Friction stir welding and processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

- Szachogłuchowicz, I.; Śnieżek, L.; Wójcik, A. Mechanical Properties of the AlCu4Mg1 Alloy Joint Manufactured by Underwater Friction Stir Welding. Materials 2024, 17, 1722. [Google Scholar] [CrossRef] [PubMed]

- Sun, Y.F.; Fujii, H. Investigation of the welding parameter dependent microstructure and mechanical properties of friction stir welded pure copper. Mater. Sci. Eng. A 2010, 527, 6879–6886. [Google Scholar] [CrossRef]

- Lai, R.; He, D.; He, G.; Lin, J.; Sun, Y. Study of the microstructure evolution and properties response of a friction-stir-welded copper-chromium-zirconium alloy. Metals 2017, 7, 381. [Google Scholar] [CrossRef]

- Xue, P.; Xie, G.M.; Xiao, B.L.; Ma, Z.Y.; Geng, L. Effect of heat input conditions on microstructure and mechanical properties of friction-stir-welded pure copper. Metall. Mater. Trans. A Phys. Metall. Mater. Sci. 2010, 41, 2010–2021. [Google Scholar] [CrossRef]

- Mironov, S.; Inagaki, K.; Sato, Y.S.; Kokawa, H. Microstructural evolution of pure copper during friction-stir welding. Philos. Mag. 2015, 95, 367–381. [Google Scholar] [CrossRef]

- Kumar, N.; Dhuria, G.K.; Singh, R. Evaluation of Tensile Strength in Friction Stir Welded Aluminum alloy 6101-T6 and commercially pure Copper joints. Mater. Today Proc. 2018, 5, 19230–19236. [Google Scholar] [CrossRef]

- Karrar, G.; Galloway, A.; Toumpis, A.; Li, H.; Al-Badour, F. Microstructural characterisation and mechanical properties of dissimilar AA5083-copper joints produced by friction stir welding. J. Mater. Res. Technol. 2020, 9, 11968–11979. [Google Scholar] [CrossRef]

- Mao, Y.; Ni, Y.; Xiao, X.; Qin, D.; Fu, L. Microstructural characterization and mechanical properties of micro friction stir welded dissimilar Al/Cu ultra-thin sheets. J. Manuf. Process. 2020, 60, 356–365. [Google Scholar] [CrossRef]

- Muhammad, N.A.; Wu, C.S. Evaluation of capabilities of ultrasonic vibration on the surface, electrical and mechanical behaviours of aluminium to copper dissimilar friction stir welds. Int. J. Mech. Sci. 2020, 183, 105784. [Google Scholar] [CrossRef]

- Yaghoubi, S.; Shirazi, A. Mechanical properties and corrosion behavior of friction stir welded copper plates under shielding gas. Int. J. Fatigue 2021, 152, 106419. [Google Scholar] [CrossRef]

- Soni, N.; Yaocheng, Y.; Kumar, A.; Caihong, Y.; Li, L.; Singh, A.; Lin, Y. Electrochemical and surface studies of 0.95 Mg-Al-alloy and pure copper joints prepared using friction stir welding with low-medium-high tool travel speeds. Int. J. Electrochem. Sci. 2019, 14, 8949–8972. [Google Scholar] [CrossRef]

- Zhou, L.; Li, G.H.; Zhang, R.X.; Zhou, W.L.; He, W.X.; Huang, Y.X.; Song, X. Microstructure evolution and mechanical properties of friction stir spot welded dissimilar aluminum-copper joint. J. Alloys Compd. 2019, 775, 372–382. [Google Scholar] [CrossRef]

- Aliha, M.R.M.; Kalantari, M.H.; Ghoreishi, S.M.N.; Torabi, A.R.; Etesam, S. Mixed mode I/II crack growth investigation for bi-metal FSW aluminum alloy AA7075-T6/pure copper joints. Theor. Appl. Fract. Mech. 2019, 103, 102243. [Google Scholar] [CrossRef]

- Osman, N.; Sajuri, Z.; Baghdadi, A.H.; Omar, M.Z. Effect of process parameters on interfacial bonding properties of aluminium–copper clad sheet processed by multi-pass friction stir-welding technique. Metals 2019, 9, 1159. [Google Scholar] [CrossRef]

- Lader, S.K.; Baruah, M.; Ballav, R. Significance of underwater friction stir welding on the weld integrity of thin sheets of aluminum (AA1050-O) and brass (CuZn34) joints. Mater. Sci. Eng. A 2023, 865, 144627. [Google Scholar] [CrossRef]

- Daniela Iordache, M.; Badulescu, C.; Diakhate, M.; Constantin, M.A.; Nitu, E.L.; Demmouche, Y.; Dhondt, M.; Negrea, D. A numerical strategy to identify the FSW process optimal parameters of a butt-welded joint of quasi-pure copper plates: Modeling and experimental validation. Int. J. Adv. Manuf. Technol. 2021, 115, 2505–2520. [Google Scholar] [CrossRef]

- Salahi, S.; Yapici, G.G. Fatigue Behavior of Friction Stir Welded Joints of Pure Copper with Ultra-fine Grains. Procedia Mater. Sci. 2015, 11, 74–78. [Google Scholar] [CrossRef]

- Galvão, I.; Leal, R.M.; Rodrigues, D.M.; Loureiro, A. Influence of tool shoulder geometry on properties of friction stir welds in thin copper sheets. J. Mater. Process Technol. 2013, 213, 129–135. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Laleh, H.M.; Gerami, H.; Hosseinpour, P.; Shabestari, M.J.; Bahari, R. The origin of different microstructural and strengthening mechanisms of copper and brass in their dissimilar friction stir welded joint. Mater. Sci. Eng. A 2018, 735, 336–342. [Google Scholar] [CrossRef]

- Xie, G.M.; Ma, Z.Y.; Geng, L. Development of a fine-grained microstructure and the properties of a nugget zone in friction stir welded pure copper. Scr. Mater. 2007, 57, 73–76. [Google Scholar] [CrossRef]

- Khodaverdizadeh, H.; Heidarzadeh, A.; Saeid, T. Effect of tool pin profile on microstructure and mechanical properties of friction stir welded pure copper joints. Mater. Des. 2013, 45, 265–270. [Google Scholar] [CrossRef]

- Lai, R.; Li, X.; He, D.; Lin, J.; Li, J.; Lei, Q. Microstructures evolution and localized properties variation of a thick friction stir welded CuCrZr alloy plate. J. Nucl. Mater. 2018, 510, 70–79. [Google Scholar] [CrossRef]

- Barenji, R.V. Influence of heat input conditions on microstructure evolution and mechanical properties of friction stir welded pure copper joints. Trans. Indian Inst. Met. 2016, 69, 1077–1085. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Motalleb-nejad, P.; Barenji, R.V.; Khalili, V.; Güleryüz, G. The origin of the maximum hardness of the friction stir welded single-phase Cu-Zn plates: RSM, EBSD, and TEM investigation. Mater. Chem. Phys. 2019, 223, 9–15. [Google Scholar] [CrossRef]

- Sadhu, A.; Sarkar, S.; Chattopadhyay, A.; Mypati, O.; Pal, S.K.; Nath, A.K. Effect of Laser Shock Peening on micro-structure and mechanical properties of Friction Stir Welded CuCrZr sheets. Mater. Sci. Eng. A 2022, 831, 142238. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T.; Klemm, V. Microstructure, texture, and mechanical properties of friction stir welded commercial brass alloy. Mater. Charact. 2016, 119, 84–91. [Google Scholar] [CrossRef]

- Xie, G.M.; Ma, Z.Y.; Geng, L. Effects of friction stir welding parameters on microstructures and mechanical properties of brass joints. Mater. Trans. 2008, 49, 1698–1701. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Barenji, R.V.; Khalili, V.; Güleryüz, G. Optimizing the friction stir welding of the α/β brass plates to obtain the highest strength and elongation. Vacuum 2019, 159, 152–160. [Google Scholar] [CrossRef]

- Mironov, S.; Inagaki, K.; Sato, Y.S.; Kokawa, H. Development of grain structure during friction-stir welding of Cu-30Zn brass. Philos. Mag. 2014, 94, 3137–3148. [Google Scholar] [CrossRef]

- Park, H.S.; Kimura, T.; Murakami, T.; Nagano, Y.; Nakata, K.; Ushio, M. Microstructures and mechanical properties of friction stir welds of 60% Cu-40% Zn copper alloy. Mater. Sci. Eng. A 2004, 371, 160–169. [Google Scholar] [CrossRef]

- Çam, G.; Serindaǧ, H.T.; Çakan, A.; Mistikoglu, S.; Yavuz, H. The effect of weld parameters on friction stir welding of brass plates. Materwiss Werksttech 2008, 39, 394–399. [Google Scholar] [CrossRef]

- Wang, Y.F.; An, J.; Yin, K.; Wang, M.S.; Li, Y.S.; Huang, C.X. Ultrafine-Grained Microstructure and Improved Mechanical Behaviors of Friction Stir Welded Cu and Cu–30Zn Joints. Acta Metall. Sin. (Engl. Lett.) 2018, 31, 878–886. [Google Scholar] [CrossRef]

- Lin, J.W.; Chang, H.C.; Wu, M.H. Comparison of mechanical properties of pure copper welded using friction stir welding and tungsten inert gas welding. J. Manuf. Process. 2014, 16, 296–304. [Google Scholar] [CrossRef]

- Sakthivel, T.; Mukhopadhyay, J. Microstructure and mechanical properties of friction stir welded copper. J. Mater. Sci. 2007, 42, 8126–8129. [Google Scholar] [CrossRef]

- Khodaverdizadeh, H.; Mahmoudi, A.; Heidarzadeh, A.; Nazari, E. Effect of friction stir welding (FSW) parameters on strain hardening behavior of pure copper joints. Mater. Des. 2012, 35, 330–334. [Google Scholar] [CrossRef]

- Raju, L.S.; Venu, B. Meta-heuristic optimization of copper friction stir weldments. INCAS Bull. 2020, 12, 163–171. [Google Scholar] [CrossRef]

- Raju, L.S.; Kumar, A.; Prasad, S.R. Microstructure and mechanical properties of friction stir welded pure copper. Appl. Mech. Mater. 2014, 592–594, 499–503. [Google Scholar] [CrossRef]

- Wang, Y.D.; Xue, P.; Liu, F.C.; Wu, L.H.; Zhang, H.; Zhang, Z.; Ni, D.; Xiao, B.; Ma, Z. Influence of processing innovations on joint strength improvements in friction stir welded high strength copper alloys. Mater. Sci. Eng. A 2023, 872, 144983. [Google Scholar] [CrossRef]

- Liu, H.J.; Shen, J.J.; Huang, Y.X.; Kuang, L.Y.; Liu, C.; Li, C. Effect of tool rotation rate on microstructure and mechanical properties of friction stir welded copper. Sci. Technol. Weld. Join. 2009, 14, 577–583. [Google Scholar] [CrossRef]

- Shen, J.J.; Liu, H.J.; Cui, F. Effect of welding speed on microstructure and mechanical properties of friction stir welded copper. Mater. Des. 2010, 31, 3937–3942. [Google Scholar] [CrossRef]

- Xue, P.; Xiao, B.L.; Zhang, Q.; Ma, Z.Y. Achieving friction stir welded pure copper joints with nearly equal strength to the parent metal via additional rapid cooling. Scr. Mater. 2011, 64, 1051–1054. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Saeid, T. Correlation between process parameters, grain size and hardness of friction-stir-welded Cu–Zn alloys. Rare Metals 2018, 37, 388–398. [Google Scholar] [CrossRef]

- Xie, G.M.; Ma, Z.Y.; Geng, L. Partial recrystallization in the nugget zone of friction stir welded dual-phase Cu-Zn alloy. Philos. Mag. 2009, 89, 1505–1516. [Google Scholar] [CrossRef]

- Machniewicz, T.; Nosal, P.; Korbel, A.; Hebda, M. Effect of FSW traverse speed on mechanical properties of copper plate joints. Materials 2020, 13, 1937. [Google Scholar] [CrossRef]

- Teimurnezhad, J.; Pashazadeh, H.; Masumi, A. Effect of shoulder plunge depth on the weld morphology, macrograph and microstructure of copper FSW joints. J. Manuf. Process. 2016, 22, 254–259. [Google Scholar] [CrossRef]

- Scutelnicu, E.; Birsan, D.; Cojocaru, R. Research on Friction Stir Welding and Tungsten Inert Gas assisted Friction Stir Welding of Copper. Recent Adv. Manuf. Eng. 2012, 1, 97–102. [Google Scholar]

- Sun, Y.F.; Fujii, H. The effect of SiC particles on the microstructure and mechanical properties of friction stir welded pure copper joints. Mater. Sci. Eng. A 2011, 528, 5470–5475. [Google Scholar] [CrossRef]

- Pashazadeh, H.; Teimournezhad, J.; Masoumi, A. Experimental investigation on material flow and mechanical properties in friction stir welding of copper sheets. Int. J. Adv. Manuf. Technol. 2017, 88, 1961–1970. [Google Scholar] [CrossRef]

- Constantin, M.A.; Boşneag, A.; Nitu, E.; Iordache, M. Experimental investigations of tungsten inert gas assisted friction stir welding of pure copper plates. IOP Conf. Ser. Mater. Sci. Eng. 2017, 252, 012038. [Google Scholar] [CrossRef]

- Constantin, M.A.; Bosneag, A.; Nitu, E.; Iordache, M. Orientation of process parameter values of TIG assisted FSW of copper to obtain improved mechanical properties. IOP Conf. Ser. Mater. Sci. Eng. 2018, 400, 022017. [Google Scholar] [CrossRef]

- Constantin, M.A.; Boşneag, A.; Niţu, E.; Iordache, M. Comparative study on microhardness between friction stir welding and tungsten inert gas assisted friction stir welding of pure copper. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018. [Google Scholar]

- Constantin, M.A.; Nitu, E.L.; Iordache, D.M.; Badulescu, C. Study on the influence of technological parameters on the friction stir butt welding process of pure copper plates. IOP Conf. Ser. Mater. Sci. Eng. 2020, 968, 012013. [Google Scholar] [CrossRef]

- Ozer, A.; Sik, A.; Cevik, B.; Ozer, M. The effect of friction stir welding parameters on microstructure and fatigue strength of CuZn37 brass alloys. Kov. Mater.-Met. Mater. 2017, 55, 107–114. [Google Scholar] [CrossRef]

- Krishna, S.C.; Karthick, N.K.; Karthik, G.M.; Damodaram, R.; Jha, A.K.; Pant, B.; Cherian, R.M. Effect of Post-Weld Heat Treatment on the Microstructure and Mechanical Properties of Friction Stir Welds of Cu–Cr–Zr–Ti Alloy. Metallogr. Microstruct. Anal. 2018, 7, 703–710. [Google Scholar] [CrossRef]

- Nia, A.A.; Shirazi, A. Effects of different friction stir welding conditions on the microstructure and mechanical properties of copper plates. Int. J. Miner. Metall. Mater. 2016, 23, 799–809. [Google Scholar] [CrossRef]

- Wang, Y.D.; Zhu, S.Z.; Xie, G.M.; Wu, L.H.; Xue, P.; Ni, D.R.; Xiao, B.L.; Ma, Z.Y. Realising equal-strength welding with good conductivity in Cu–Cr–Zr alloy via friction stir welding. Sci. Technol. Weld. Join. 2021, 26, 448–454. [Google Scholar] [CrossRef]

- Zhang, H.; Miao, J.; Wang, K.; Yu, C.; Mei, R.; Lin, X. Interfacial reaction characteristics and mechanisms during dissimilar friction stir lap welding of pure copper and Al0.1CoCrFeNi alloy. J. Mater. Res. Technol. 2024, 31, 1665–1674. [Google Scholar] [CrossRef]

- Agapiou, J.S. Filling friction stir welding in-process exit holes in copper squirrel cage rotors for electric motors. Procedia Manuf. 2021, 53, 802–813. [Google Scholar] [CrossRef]

- Zhang, C.; Qin, Z.; Rong, C.; Shi, W.; Wang, S. The preliminary exploration of micro-friction stir welding process and material flow of copper and brass ultra-thin sheets. Materials 2020, 13, 2401. [Google Scholar] [CrossRef]

- Lim, Y.; Lee, K.; Moon, S. Effects of a post-weld heat treatment on the mechanical properties and microstructure of a friction-stir-welded beryllium-copper alloy. Metals 2019, 9, 461. [Google Scholar] [CrossRef]

- Nakata, K. Friction stir welding of copper and copper alloy. J. Jpn. Weld. Soc. 2005, 19, 929–933. [Google Scholar] [CrossRef]

- Kumar, R.; Singh, R.; Mehta, N.K.; Avula, D.; Dwivedi, D.K. Effect of Friction Stir Welding on Microstructural and Mechanical Properties of Copper Alloy SEE PROFILE Effect of Friction Stir Welding on Microstructural and Mechanical Properties of Copper Alloy [Internet]. 2011. Available online: https://www.researchgate.net/publication/265408376 (accessed on 17 July 2024).

- Gheisari, Y.; Pashazadeh, H.; Teimournezhad, J.; Masoumi, A. Weld defect formation in FSWed coppers. J. Mater. Eng. Perform. 2014, 23, 2000–2006. [Google Scholar] [CrossRef]

- Surekha, K.; Els-Botes, A. Development of high strength, high conductivity copper by friction stir processing. Mater. Des. 2011, 32, 911–916. [Google Scholar] [CrossRef]

- He, D.; Lai, R.; Xu, S.; Yang, K.; Ye, S.; Wang, J.; Zhu, J.M.; Su, B. Microstructure and mechanical properties of Cu-Cr-Zr alloy by friction stir welding. Adv. Mat. Res. 2013, 602–604, 608–611. [Google Scholar] [CrossRef]

- Kumar, A.; Raju, L.S. Influence of tool pin profiles on friction stir welding of copper. Mater. Manuf. Processes 2012, 27, 1414–1418. [Google Scholar] [CrossRef]

- Saukkonen, T.; Savolainen, K.; Mononen, J.; Hänninen, H.; Koivula, J. Friction Stir Weldability of Copper Alloys [Internet]. 2004. Available online: https://www.researchgate.net/publication/291765614 (accessed on 17 July 2024).

| Material and Plate Thickness | Tool Geometry/Material | Process Parameters | Remarks | Ref. |

|---|---|---|---|---|

| Cu DHP R240: 1 mm | 1. Flat shoulder Ø13 mm; 2. Concave shoulder Ø13 mm, 3. Spiral shoulder Ø13 mm; Cylindrical threaded pin Ø3 mm; Pin length 0.9 mm. | Vr: 400–1000 rpm; Va: 160–250 mm/min; Fa: 7 kN. | When using the flat-shouldered tool, defective joints resulted because little heat was generated and the ability to guide the material flow was poor. The best material flow, mechanical properties, and grain refinement of the NZ were achieved using the spiral-shoulder tool. | [29] |

| Pure Cu 1/2H: 2 mm | Concave shoulder Ø12 mm; Cylindrical pin Ø4 mm; Pin length 2 mm; Material WV alloy. Tilt angle 3°. | Vr: 200–1200 rpm; Va: 200–800 mm/min; Fa: 1000–1500 daN. | Applying a force less than 1200 daN resulted in lower hardnesses than the base material and tensile fractures occurred in the NZ, whereas for 1500 daN the hardness was higher and the specimens broke out of the embedment. At Va = 650 mm/min and Vr = 400–600 rpm and a force of 1500 daN, a refined microstructure without defects was obtained. | [13] |

| Cu 1/2H: 2 mm | Flat shoulder Ø12 mm; Cylindrical pin Ø4 mm; Pin length 2 mm; Material WC. | Vr: 500 rpm; Va: 100 mm/min; Fa: 1000 daN. | The addition of SiC microparticles between the contact surfaces of the plates resulted in a much finer grain structure and the joint hardness increased significantly, but the tensile strength was degraded. | [58] |

| Pure Cu: 3 mm | Flat shoulder Ø12 mm; Cylindrical threaded pin Ø3 mm; Pin length 1.75 mm; Material H13 tool steel. | Vr: 463–1136 rpm; Va: 16–184 mm/min; Fa: 1.66–3.34 kN. | The experimentally validated fuzzy model predicted that, for Vr = 1136 rpm, Va = 46.75 mm/min, and Fa = 3.34 kN, superior mechanical properties would be obtained. Plastic deformation has the greatest influence on grain size in the NZ. Temperatures less than 0.5 of the melting temperature led to good mechanical properties and grain cooling. | [3] |

| Pure Cu 1/2H: 3 mm | Concave shoulder Ø12 mm; Cylindrical threaded pin Ø3 mm; Pin length 2.5 mm; Material HSS tool steel. | Vr: 300–1000 rpm; Va: 100 mm/min. | For lower Va the cracking occurs on the advancing side, and for higher Va the cracking moves to the retreating side. Properties similar to the base material were obtained using Vr = 400 rpm. HAZ is coarse-grained compared to NZ, irrespective of the rotational speed. | [50] |

| Pure Cu 1/2H: 3 mm | Concave shoulder Ø12 mm; Cylindrical threaded pin Ø3 mm; Pin length 2.5 mm; Material HSS tool steel. | Vr: 600 rpm; Va: 25–200 mm/min. | Most defects were identified for lower Va. Tensile strength and joint elongation increased with increasing welding speed, reaching a maximum at Va = 50 mm/min, 100 mm/min, then decreased at higher welding speeds. | [51] |

| Pure Cu: 3 mm | Concave shoulder Ø14 mm; Cylindrical threaded pin Ø4 mm; Pin length 2.7 mm; Tilt angle 2.5°; Additional rapid cooling with flowing water 7 l/min. | Vr: 400–800 rpm; Va: 50 mm/min. | The joint made with Vr = 400 rpm, Va = 50 mm/min, both air cooled and rapidly water cooled, had better hardness than Vr = 800 rpm. The best mechanical properties were obtained with the water-cooled seals. All of the bearings broke in the HAZ during tensile tests. | [52] |

| Cu-DHP: 3 mm | Flat shoulder Ø20 mm; Conical pin Ø4–3 mm; Pin length 2.8 mm. | Vr: 800–1200 rpm; Va: 90–150 mm/min. | Average temperatures in the stability zone ranged between 466 °C and 693 °C. Increasing the rotational speed of the tool resulted in a significant increase in process temperature, while the traverse speed had less influence. Excessive burrs occurred at temperatures above 650 °C. | [27] |

| Pure Cu C11000: 3 mm | Flat shoulder Ø16 mm; Conical pin Ø6–4 mm; Pin length 2.7 mm; Tilt angle 2.5°. | Vr: 1000 rpm; Va: 25 mm/min; Fa: 10 kN. | This study highlights the advantages of FSW over TIG for welding pure copper. FSW joint hardness is much higher than that obtained by TIG. The grain size of NZ is the finest, followed by HAZ. Mechanical properties obtained by FSW are much better than TIG. | [44] |

| Cu: 3 mm | Cylindrical, conical threaded, triangular, square, pentagonal, and hexagonal pins. | Vr: 700–1100 rpm; Va: 30–50 mm/min. | The square shape of the FSW tool pin resulted in joints with very good mechanical properties. With Vr = 900 rpm and Va = 40 mm/min, the best mechanical properties are achieved. | [47] |

| Cu: 3 mm | Flat shoulder Ø24 mm; Cylindrical pin Ø8 mm; Pin length 2.8 mm; Material H13 tool steel. | Vr: 900–1120 rpm; Va: 25–50 mm/min. | Defect-free joints were obtained under all welding conditions. The best mechanical properties and finest grain size was obtained using Vr = 900 rpm and Va = 40 mm/min. | [48] |

| Pure Cu C11000: 3.1 mm | Concave shoulder Ø12 mm; Conical pin Ø3 mm; Pin length 2.8 mm; Material SKH9 high-speed steel. | Vr: 800–900 rpm; Va: 30–50 mm/min. | Defect-free joints were obtained at temperatures between 460 and 530 °C. The advancing part showed higher temperatures than the re-drawing part. The mechanical properties of the TMAZ were about 60% of those of the base material. For Vr = 900 rpm and Va = 50 mm/min and for Vr = 800 rpm and Va = 30 mm/min, good quality joints resulted, with temperatures of 530 °C and 522 °C, respectively. | [1] |

| Pure Cu 1/2H: 4 mm | Concave shoulder Ø12 mm; Cylindrical threaded pin Ø4 mm; Pin length 1.7 mm; Material HSS tool steel. | Vr: 200–1000 rpm; Va: 2 mm/s. | In the cases where the process temperature was below 0.5 of the melting temperature of the base material (Vr = 200–400 rpm), continuous recrystallized granular structures and a material softening were obtained, and for the cases where the temperature was above 0.5, discontinuous recrystallization was accompanied by a material softening. The hardening performed at Vr < 400 rpm (<0.5 × Tm) showed significant hardening of the material due to grain refinement. | [16] |

| Cu: 4 mm | Flat shoulder Ø15 mm; Cylindrical threaded pin Ø6 mm; Pin length 3.7 mm; Tilt angle 2.5°; Blown argon as a shielding gas. | Vr: 600–900 rpm; Va: 40–80 mm/min. | The HAZ was the least resistant. The NZ exhibited a fine grain size due to recrystallization, while the HAZ had a large grain size due to annealing. The corrosion resistance was improved in the NZ. The highest hardness resulted in the NZ for Vr = 600 rpm, Va = 40 mm/min, 2 passes. | [21] |

| Pure Cu: 4 mm | Flat shoulder Ø12 mm; Cylindrical threaded pin Ø5 mm; Pin length 3.4 mm; Material high carbon steel. | Vr: 600 rpm; Va: 45 mm/min. | Defect-free joints with 4 distinct zones were obtained, with fine grains in the NZ and coarse grains in the HAZ. Improved fatigue properties and cyclic hardening and softening behaviors were observed as a function of the strain amplitude, with cracking in the HAZ. | [28] |

| Pure Cu 1/2H: 5 mm | Flat shoulder Ø20 mm; Cylindrical threaded pin Ø6 mm; Pin length 4.7 mm; Tilt angle: 2.5°. | Vr: 400–800 rpm; Va: 50–200 mm/min. | The finest grain was formed in the NZ, and the HAZ had larger holes than the base material. At 400 rpm and 50 mm/min, the hardness in the NZ was significantly higher than that of the base material. The break on impact was in the HAZ for all joints. | [15] |

| Pure Cu: 5 mm | Spiral shoulder Ø20 mm; Cylindrical threaded pin Ø6 mm; Pin length 4.7 mm. | Vr: 400–800 rpm; Va: 50 mm/min. | The grains were smaller and the mechanical properties increased in the NZ for lower rotational speeds (400 rpm). Defect-free bearings were obtained at all rotational speeds investigated. | [31] |

| Pure Cu: 5 mm | Flat shoulder Ø20 mm; 1. Cylindrical threaded pin Ø6 mm; 2. Square pin 6 × 6 mm; Pin length 4.7 mm. | Vr: 600 rpm; Va: 75 mm/min. | The square-pinned tool results in finer recrystallized grains, higher temperatures, and superior mechanical properties. Using a square pine profile can significantly improve the mechanical properties of the joint. | [32] |

| Pure Cu: 5 mm | Flat shoulder Ø20 mm; Square pin 4.3 × 4.3 mm; Pin length 4.7 mm; Material H13 tool steel; Tilt angle: 2.5°. | Vr: 600–1200 rpm; Va: 25–100 mm/min. | High rotational speeds and a low traverse speed resulted in higher temperatures and lower cooling rates, leading to higher heat input. In the NZ the grain size was smaller and larger in the HAZ compared to the base material. The TMAZ showed an equidistant recrystallized grain structure. The NZ’s ductility showed higher values than the base material for Vr = 600 rpm and Va = 75 mm/min. Defect-free joints were obtained at high temperatures (100 mm/min, 1200 rpm) and low temperatures (25–75 mm/min, 600 rpm). | [34] |

| Cu: 5 mm | Flat shoulder Ø20 mm; Cylindrical threaded pin Ø8 mm; Pin length 4.7 mm. | Vr: 500–710 rpm; Va: 56–112 mm/min. | Hardness decreases with increasing temperature. Optimum welding conditions were obtained for Vr = 500 and Va = 56–112 mm/min. The HAZ showed the lowest values of mechanical properties. Charpy tests showed that the impact strength increased in all cases. | [66] |

| Cu: 5 mm | Flat shoulder Ø25 mm; Cylindrical pin Ø5.5 mm; Pin length 4.8 mm. | Vr: 1000 rpm; Va: 80 mm/min; Fa: 25 kN. | FSW was accompanied by an additional TIG heat source, which introduced higher process temperatures than conventional FSW. And this showed that the integration of a heat source brings significant benefits in terms of weld quality, tool wear, and process efficiency. To avoid defects, the maximum temperature should be between 70 and 80% of the melting temperature of the base material. | [57] |

| Cu-ETP R220: 5 mm | Spiral shoulder Ø23 mm; Conical pin Ø8–5.4 mm; Pin length 4.5 mm; Plunging speed 2.5 mm/min; Dwelling time of 5 s. | Vr: 580 rpm; Va: 40–80 mm/min. | The mechanical properties of the joints were significantly lower than those of the base material. The elastic behavior decreased by 60% and the maximum stress by 15% of those of the base material due to excessive heating (800 °C). Joints welded at 60 mm/min exhibited the best mechanical properties, including hardness, tensile strength, and fatigue strength. | [55] |

| Pure Cu: 6 mm | Flat shoulder Ø15 mm; Conical threaded pin Ø6–4 mm; Pin length 5.6 mm; Material H13 tool steel. | Vr: 635 rpm; Va: 8–19 mm/min. | The joint hardnesses were higher than those of the base material. For Va = 19 mm/min, joints with mechanical properties superior to the base material were obtained. | [73] |

| Material and Plate Thickness | Tool Geometry/Material | Process Parameters | Remarks | Ref. |

|---|---|---|---|---|

| Pure Cu–Cu-Zn30%: 2 mm | Flat shoulder Ø12 mm; Cylindrical pin Ø3 mm; Pin length 1.75 mm; Material H13 tool steel. | Vr: 400 rpm; Va: 100 mm/min. | The NZ has a microstructure with small holes. The simultaneous presence of heat and plastic deformation resulted in joints with improved mechanical properties. | [30] |

| Pure Cu–Cu-Zn30%: 2 mm | Flat shoulder Ø12 mm; Cylindrical pin Ø3 mm; Pin length 1.75 mm; Material H13 tool steel. | Vr: 563–1236 rpm; Va: 33–117 mm/min; Fa: 1.16–2.8 kN. | Maximum hardness can be obtained using Vr = 700 rpm, Va = 100 mm/min, and Fa = 1.5 kN. The parameter with the greatest effect on hardness was the rotational speed, followed by axial force and traverse speed. | [35] |

| Cu-Cr-Zr: 2 mm | Flat shoulder Ø18 mm; Cylindrical pin Ø6 mm; Pin length 1.8 mm; Material H13 tool steel; Laser Shock Peening. | Vr: 400–800 rpm; Va: 50–150 mm/min; Energy: 0.8 J; Frequency: 10 Hz. | The NZ shows higher mechanical properties and elongations longer than the base material, and for the HAZ they are similar to those of the base material. Optimum parameters: Vr = 600 rpm, Va = 100 mm/min. LSP significantly improved the mechanical and microstructural properties of the base material and CuCrZr FSW welds. | [36] |

| Cu-Zn: 2 mm | Flat shoulder Ø12 mm; Cylindrical threaded pin Ø3 mm; Pin length 1.75 mm; Material H13 tool steel. | Vr: 463–1136 rpm; Va: 16–184 mm/min; Fa: 1.66–3.34 kN. | Rotational speed had the greatest effect on hardness, followed by axial force and traverse speed. Increasing Vr and Fa or decreasing Va decreased the hardness of the joints due to increased grain size. Maximum hardness was obtained for Vr = 629,2 rpm, Va = 107.2 mm/min and Fa = 2.3 kN. | [39] |

| Pure Cu, Cu-Zn30%, Cu-Zn37%: 2 mm | Flat shoulder Ø12 mm; Cylindrical pin Ø3 mm; Pin length 1.7 mm; Material H13 tool steel. | Vr: 450–900 rpm; Va: 100–300 mm/min. | Higher Zn content led grains to shrink and hardness increased. Higher Vr and lower Va caused an increase in grain size and a decrease in hardness. The developed mathematic models were adequate and accurately predicted grain size and joint hardness. For Vr = 450 rpm and Va = 300 mm/min joints, the best mechanical properties were obtained. | [53] |

| Cu-Zn40%: 2 mm | Flat shoulder Ø12 mm; Cylindrical pin Ø4 mm; Pin length 2 mm; Tilt angle: 2.5°. | Vr: 250–1500 rpm; Va: 500–2000 mm/min. | Joints made with higher Vr showed extremely fine grains in the NZ and TMAZ. Hardnesses ranging from 1.4 to 1.7 of the base material were obtained in the NZ, and for all joints this zone also exhibited the highest stresses. Defect-free joints were obtained in a relatively wide range of welding conditions: Vr = 1000–1500 rpm and Va = 500–2000 mm/min. | [41,72] |

| Pure Cu, Cu-Zn30%: 2 mm | Flat shoulder Ø10 mm; Cylindrical threaded pin Ø3 mm; Pin length 1.3 mm; Material H13 tool steel; Conducted under cold flowing water. | Vr: 1200 rpm; Va: 100–200 mm/min. | Very good strengths and ductility were obtained in the NZs of both materials. The microstructure exhibited ultrafine grains and low dislocation densities. The bond zone showed improved tensile strength and hardness compared to the base materials. | [43] |

| Cu-Cr-Zr: 2.5 mm | 1. Concave shoulder Ø12 mm; Material TiC based cermet; 2. Flat shoulder Ø12 mm; Conical threaded pin Ø5 mm; Pin length 2.3 mm; Material W-Re (Wolfram-Rhenium). | Vr: 400–600 rpm; Vr: 600 rpm for W-Re Va: 50 mm/min. | NZ grains became smaller with decreasing Vr. Strength close to that of the base material was identified using Vr = 400 rpm. Welding with the W-Re tool at Vr = 600 rpm led to the formation of defects in the joint, with a negative impact on the mechanical properties and electrical conductivity. | [67] |

| Cu-Zn30%: 3 mm | Flat shoulder Ø13 mm; Cylindrical threaded pin M5 × 1.5 mm; Pin length 2.9 mm; Material X32CrMoV12-28. | Vr: 2050 rpm; Va: 20–140 mm/min. | Surface defects and tunnel-type defects were encountered. Properties close to those of the base material were obtained by using Va = 112 mm/min. | [6] |

| Cu-Cr-Zr: 3 mm | Flat shoulder Ø20 mm; Conical pin Ø5–3 mm; Pin length 2.7 mm. | Vr: 800–1200 rpm; Va: 40–100 mm/min. | The degree of recrystallization and grain size growth in the NZ had a direct correlation with Vr and an inverse correlation with Va. The tensile strength was about 60% of that of the base material under aging, but higher under annealed conditions. The joints performed at rotation speeds between 800 and 1200 rpm and traverse speeds between 40 and 100 mm/min were defect-free. | [8] |

| Cu-Zn30%: 3 mm | Concave shoulder Ø12 mm; Cylindrical threaded pin Ø4 mm; Pin length 1.7 mm. | Vr: 200–600 rpm; Va: 2 mm/s. | The experiments achieved temperatures between 0.46 and 0.8 of the melting temperature of the base material. In all cases, the grain sizes were smaller in the NZ, which was also the hardest zone. Optimum Vr: 300–600 rpm. | [40] |

| Cu-Zn10%, Cu-Zn30%: 3 mm | Conical pin; Material X32CrMo3 3. | Vr: 1600 rpm; Va: 160–260 mm/min. | In the case of higher Zn content, porosities were formed in the NZ for all Va values. The highest strength and ductility were obtained for Va = 210 mm/min. | [42] |

| Cu-Cr-Zr-Ti: 3.8 mm | Flat shoulder Ø15 mm; Conical threaded pin Ø8–6 mm; Pin length 3 mm; Material Inconel 718. | Vr: 1000 rpm; Va: 30 mm/min; Fa: 10 kN. | The TMAZ showed recrystallized and partially recrystallized fine grains. The flow resistance of the joint was 131% of that of the base material. | [65] |

| Cu (0.7 Ni-0.3 Cr-0.12 Fe-0.04 Ti): 4 mm | Concave shoulder Ø17.8 mm; Conical pin Ø6.5–5.5; Pin length 3.5 mm; The shoulder material T6 grade of tungsten high-speed steel; The pin material C-2 grade of sintered carbide. | Vr: 710 rpm; Va: 40 mm/min. | Voids and cracks were observed on the feed side, caused by low heat input and insufficient material deposition behind the tool. Precise control of the penetration depth can prevent defects and improve the quality of the weld, ensuring uniform material distribution and the formation of a defect-free weld layer. | [56] |

| Cu-Zn37%: 4 mm | Flat shoulder Ø20 mm; Cylindrical threaded pin M6 × 1 mm; Pin length 3.8 mm; Material X210Cr12. | Vr: 750–1000 rpm; Va: 20–60 mm/min. | NZ and TMAZ grain sizes decreased with increasing Va. For Vr = 100 rpm and Va = 20 mm/min, tunnel-type defects appeared. The fatigue life was higher by using Vr = 750 rpm and Va = 20 mm/min. In all cases the fatigue failure was located in the retraction side. | [64] |

| Cu (0.7 Ni-0.3 Cr-0.12 Fe-0.04 Ti): 4 mm | Concave shoulder Ø17.8 mm; Conical pin Ø6.5–5.5; Pin length 3.5 mm; The shoulder material T6 grade of tungsten high-speed steel; The pin material C-2 grade of sintered carbide. | Vr: 500–710 rpm; Va: 20–63 mm/min. | At Vr = 710 rpm and Va = 40 mm/min a good tensile strength was obtained, i.e., a good quality joint without major defects. Onion ring structures could be observed. By increasing the traverse speed or reducing the rotational speed, the mechanical properties were increased and the slip decreased. | [59] |

| Cu-Zn 1/2H: 5 mm | Flat shoulder Ø18 mm; Cylindrical threaded pin Ø6 mm; Pin length 4.7 mm; Tilt angle: 2.5°. | Vr: 400–1000 rpm; Va: 100 mm/min. | Grain recrystallization was incomplete in the NZ. The maximum stresses of the joints were very close to those of the base material, and breakage occurred in the HAZ. The best results were obtained for Vr = 600 rpm. | [38] |

| Cu-Zn 1/2H: 5 mm | Flat shoulder Ø18 mm; Cylindrical threaded pin Ø6 mm; Pin length 4.7 mm; Tilt angle 2.5°. | Vr: 600 rpm; Va: 100 mm/min. | The upper surface and the leading part of the NZ showed fully recrystallized fine grains, while partial dynamic recrystallization was observed in the rest of the bead. The joint zone exhibited increased hardness due to grain refinement and joint cracking occurred in the HAZ. | [54] |

| Cu-Cr-Zr: 7 mm | Concave shoulder Ø20 mm; Conical threaded pin Ø8 mm; Pin length 6.8 mm; Material Ni-base; 1. Solid solution treatment 980 °C for 1.5, followed by rapid water cooling; 2. Peak-aged, 480 °C, 2 h. | Vr: 300–600 rpm; Va: 50–100 mm/min. | The strength was lower than that of the base material for the aged joint and higher for the water-cooled joint. For Vr = 600 rpm and Va = 50 mm/min (welding temperature 481 °C) the best mechanical strength and electrical conductivity resulted due to efficient temperature control and the use of water cooling. | [49] |

| Material and Plate Thickness | Tool Geometry | Process Parameters | Measuring Procedure | Measuring Zone | Value | Ref. |

|---|---|---|---|---|---|---|

| Cu-DHP: 3 mm | Flat shoulder; Conical pin. | Vr: 800 rpm; Va: 150 mm/min. | Infrared thermographic camera | Constant distance from the welding zone, continuously monitoring the temperature near the tool. | 500 °C | [63] |

| Cu-Cr-Zr: 3 mm | Flat shoulder; Conical pin. | Vr: 800 rpm; Va: 40 mm/min. | Thermocouples | At 2 mm from the shoulder. | ≈750 °C | [8] |

| Cu-Zn30%: 3 mm | Concave shoulder; Cylindrical conical pin; | Vr: 600 rpm; Va: 2 mm/s. | Thermocouples | Integrated directly into the workpiece and positioned so as to be destroyed by the passage of the tool. | ≈700 °C | [40] |

| Pure Cu C11000: 3.1 mm | Flat shoulder; Conical pin. | Vr: 800; 900 rpm; Va: 30; 50 mm/min. | Thermocouples | At 6 mm from the joint line, on both the forward (AS) and rear (RS). | 460–530 °C | [1] |

| Pure Cu 1/2H: 4 mm | Concave shoulder; Cylindrical conical pin; | Vr: 500 rpm; Va: 2 mm/s. | Thermocouples | Integrated directly into the workpiece and positioned so as to be destroyed by the passage of the tool. | ≈550 °C (0.5 × Tm) | [16] |

| Pure Cu: 4 mm | Concave shoulder; Conical pin. | Vr: 710 rpm; Va: 40 mm/min. | Thermocouples, FEM analysis | At 6 mm from the line of trim and at a depth of 2 mm from the upper surface, on (AS). | ≈500 °C | [74] |

| Pure Cu: 5 mm | Flat shoulder; 1. Cylindrical conical pin; 2. Square pin. | Vr: 600 rpm; Va: 75 mm/min. | Thermocouples | Close to the finishing line at several points. | 1. ≈ 380 °C 2. ≈ 450 °C | [32] |

| Pure Cu: 5 mm | Flat shoulder; Square pin. | Vr: 1200 rpm; Va: 100 mm/min. | Thermocouples | Close to the joint line, 120 mm from the end of the plate. | 492 °C | [34] |

| Cu-ETP R220: 5 mm | Spiral shoulder; Conical pin. | Vr: 580 rpm; Va: 60 mm/min. | Thermal imaging camera | On the surface of the plate near the shoulder. | ≈600 °C | [55] |

| Cu-Cr-Zr: 7 mm | Concave shoulder; Conical threaded pin. | Vr: 600 rpm; Va: 50 mm/min. | K-type thermocouples | At the edge of the NZ. | 481 °C | [49] |

| Rotation Rate [rpm] | Traverse Speed [mm/min] | Temperature [°C] | Morphological Surface Joints |

|---|---|---|---|

| 1200 | 90 | 693 |  |

| 1000 | 90 | 466 |  |

| 1200 | 150 | 580 |  |

| 1000 | 150 | 550 |  |

| 800 | 90 | 476 |  |

| 800 | 150 | 500 |  |

| 1000 | 120 | 596 |  |

| Material and Plate Thickness [mm] | Tool Geometry | Rotation Rate [rpm] | Traverse Speed [mm/min] | Grain Size [μm] | Ref. |

|---|---|---|---|---|---|

| Cu-DHP R240: 1 | Cylindrical threaded pin | 400–1000 | 160–250 | 1–8 | [29] |

| Pure Cu–Brass: 2 | Cylindrical pin | 400 | 100 | 2.7–3.6 | [30] |

| Cu-Zn: 2 | Cylindrical pin | 563–1236 | 33–117 | 6.6–19.8 | [35] |

| Cu-Cr-Zr: 2 | Cylindrical pin | 400–800 | 50–150 | 1.45 | [36] |

| Pure Cu 1/2H: 2 | Cylindrical pin | 200–1200 | 200–800 | 3.77–24.1 | [13] |

| Cu-Zn: 2 | Cylindrical threaded pin | 463–1136 | 16–184 | 4.2–15.6 | [39] |

| Pure Cu, Cu-Zn30%, Cu-Zn37%: 2 | Cylindrical pin | 450–900 | 100–300 | 1.6–17.1 | [53] |

| Cu-Zn40%: 2 | Cylindrical pin | 250–1500 | 500–2000 | 0.8–22.5 | [41,72] |

| Pure Cu, Cu-Zn30%: 2 | Cylindrical threaded pin | 1200 | 100–200 | 0.98; 0.54 | [43] |

| Cu: 2 | – | 1000 | 30 | 11 | [45] |

| Cu 1/2H: 2 | Cylindrical pin | 500 | 100 | 2–8 | [58] |

| Cu-Cr-Zr: 2.5 | Conical threaded pin | 400–600 | 50 | 4.5–8.2 | [67] |

| Pure Cu: 3 | Cylindrical threaded pin | 463–1136 | 16–184 | 46 | [3] |

| Pure Cu 1/2H: 3 | Cylindrical threaded pin | 300–1000 | 100 | 4 | [50] |

| Pure Cu 1/2H: 3 | Cylindrical threaded pin | 600 | 25–200 | 4.27–5.26 | [51] |

| Cu-Cr-Zr: 3 | Conical pin | 800–1200 | 40–100 | 3–20 | [8] |

| Cu-Zn30%: 3 | Cylindrical threaded pin | 200–600 | 120 | 0.4–3 | [40] |

| Cu-Zn10%, Cu-Zn30%: 3 | Conical pin | 1600 | 160–260 | 0.3 | [42] |

| Pure Cu C11000: 3 | Conical pin | 1000 | 25 | 110.5–150 | [44] |

| Cu: 3 | Cylindrical pin | 300 | 50–250 | 3–9.3 | [75] |

| Cu-Cr-Zr-Ti: 3.8 | Conical threaded pin | 1000 | 30 | 65 ± 9 | [65] |

| Cu: 4 | Cylindrical threaded pin | 600–900 | 40–80 | 2.3–16.1 | [21] |

| Cu T2: 4 | Cylindrical pin | 600–1200 | 50 | 22.51–57.61 | [7] |

| Pure Cu 1/2H: 4 | Cylindrical threaded pin | 200–1000 | 2 | 1–30 | [16] |

| Pure Cu: 5 | Cylindrical threaded pin/square pin | 600 | 75 | 10–15 | [32] |

| Cu: 5 | Cylindrical threaded pin | 500–710 | 56–112 | 2.4–17.3 | [66] |

| Cu-ETP R220: 5 | Conical pin | 580 | 40–80 | 10 | [55] |

| Pure Cu: 5 | – | 600–900 | 25–75 | 9–14 | [46] |

| Pure Cu 1/2H: 5 | Cylindrical threaded pin | 400–800 | 50–200 | 3–16 | [15] |

| Pure Cu: 5 | Cylindrical threaded pin | 400–800 | 50 | 3.5–12 | [31] |

| Pure Cu: 6 | Conical threaded pin | 635 | 8–19 | 12.59–15.62 | [73] |

| Cu-Cr-Zr: 7 | Conical threaded pin | 300–600 | 50–100 | 20 | [49] |

| Cu-Cr-Zr: 12 | – | – | – | 10–15 | [76] |

| Material and Plate Thickness [mm] | Tool Geometry | Process Parameters | UTS [MPa]/YS [MPa] | Microhardness [HV] | Elongation [%] | Joint Efficiency [%] | Ref. |

|---|---|---|---|---|---|---|---|

| Cu DHP R240: 1 | Cylindrical threaded pin | Vr: 400–1000 rpm; Va: 160–250 mm/min. | BM: 320 FSW: 287–325 | BM: 92 FSW: 90–130 * | – | 90–102 | [29] |

| Cu T2: 2 | Cylindrical pin | Vr: 600–1200 rpm; Va: 50 mm/min. | FSW: 190–233.25/65.04–137.45 | FSW: 75–85 * | FSW: 8.84–47.64 | – | [7] |

| Pure Cu 1/2H: 2 | Cylindrical pin | Vr: 200–1200 rpm; Va: 200–800 mm/min. | BM: 266/194 FSW: 225–266/101–255 | BM: 100 * FSW: 65–103 * | BM: 47 FSW: 20–47 | 85–100 | [13] |

| Pure Cu: 2 | Cylindrical threaded pin | Vr: 1200 rpm; Va: 100–200 mm/min. | BM: 210 */70 * FSW: 310 */275 | BM: 71.3 FSW: 108.4 | – | 68 | [43] |

| Cu: 2 | - | Vr: 1000 rpm; Va: 30 mm/min. | BM: 273 FSW: 231 | BM: 101–111 FSW: 128–136 | BM: 3.1 FSW: 1.2 | 85 | [45] |

| Cu 1/2H: 2 | Cylindrical pin | Vr: 500 rpm; Va: 100 mm/min. | FSW: 125–228 | FSW: 70–110 | – | – | [58] |

| Pure Cu C11000: 3 | Conical pin | Vr: 1000 rpm; Va: 25 mm/min. | BM: 212/68 FSW: 194/70 | BM: 95 * FSW: 80 * | BM: 28.1 FSW: 22.8 | 92 | [44] |

| Cu: 3 | Cylindrical, conical threaded, triangular, square, pentagonal, and hexagonal pins | Vr: 700–1100 rpm; Va: 30–50 mm/min. | FSW: 158.29–212.07/90.88–167.06 | FSW: 77.89–98.94 | FSW: 3.01–15.09 | – | [47] |

| Cu: 3 | Cylindrical pin | Vr: 900–1120 rpm; Va: 25–50 mm/min. | BM: 260/231 FSW: 121–168/95–112 | BM: 110 FSW: 62–85 | BM: 31 FSW: 8.8–13.5 | 47–65 | [48] |

| Pure Cu 1/2H: 3 | Cylindrical threaded pin | Vr: 600 rpm; Va: 25–200 mm/min. | FSW: 258–272 * | FSW: 88–108 * | FSW: 1.5–11.5 * | – | [51] |

| Pure Cu: 3 | Cylindrical threaded pin | Vr: 400–800 rpm; Va: 50 mm/min. | BM: 350/330 FSW: 220–340/100–315 | BM: 115 FSW: 70–105 * | BM: 9 FSW: 8–21 | 63–97% | [52] |

| Cu: 3 | Cylindrical pin | Vr: 300 rpm; Va: 50–250 mm/min. | BM: 270/209 FSW: 319–328/236–261 | BM: 84.6 FSW: 101.9–113.6 | BM: 22 FSW: 23–24 | 118–121 | [75] |

| Cu: 3 | Cylindrical, conical threaded, triangular, square, pentagonal, and hexagonal pins | Vr: 900 rpm; Va: 40 mm/min. | BM: 260/231 FSW: 168–218/109–182 | BM: 110 FSW: 85–105 | BM: 31 FSW: 3–16 | 65–85 | [77] |

| Pure Cu C11000: 3.1 | Conical pin | Vr: 800–900 rpm; Va: 30–50 mm/min. | BM: 282 * FSW: 192–219 * | BM: 104 * FSW: 75–85* | – | 68–78 | [1] |

| Cu: 4 | Cylindrical threaded pin | Vr: 600–900 rpm; Va: 40–80 mm/min. | BM: 352/151 FSW: 249–346/117–146 | BM: 91 FSW: 107–130 * | – | 71–98 | [21] |

| Cu: 4 | Conical pin | Vr: 500–710 rpm; Va: 20–63 mm/min. | BM: 301.6/232 FSW: 290–368/144–331 | BM: 120–130 FSW: 105–155 | BM: 18.9 FSW: 4–18 | 96–122 | [59] |

| Pure Cu 1/2H: 5 | Cylindrical threaded pin | Vr: 400–800 rpm; Va: 50–200 mm/min. | BM: 236.7/222.9 FSW: 228.7–236.3/122.1–207.7 | BM: 81 * FSW: 62–99 * | BM: 27.7 FSW: 15.1–24.7 | 97–100 | [15] |

| Pure Cu: 5 | Cylindrical threaded pin | Vr: 400–800 rpm; Va: 50 mm/min. | BM: 236 */224 * FSW: 239–240 */142–174 * | BM: 82.2 FSW: 63.1–99.6 | BM: 28 * FSW: 39–45 * | 101 | [31] |

| Pure Cu: 5 | Cylindrical threaded pin/square pin | Vr: 600 rpm; Va: 75 mm/min. | BM: 234/178 FSW: 202–221/115–134 | BM: 107 FSW: 87–99 | – | 86–94 | [32] |

| Pure Cu: 5 | Square pin | Vr: 600–1200 rpm; Va: 25–100 mm/min. | FSW: 222–267 */114–127 * | BM: 74 * FSW: 63–87 * | FSW: 35–44 * | – | [34] |

| Pure Cu: 5 | Conical threaded pin | Vr: 300–600 rpm; Va: 50–100 mm/min. | BM: 234/178 FSW: 216–221/118–127 | BM: 107 FSW: 81–88 | BM: 47 FSW: 36–43 | 92–94 | [49] |

| Cu-ETP R220: 5 | Conical pin | Vr: 580 rpm; Va: 40–80 mm/min. | BM: 252.7–262.2/232–242 FSW: 209–220.7/82–101.3 | BM: 94 * FSW: 77–82 * | BM: 67.3–69.2 FSW: 40.3–70.5 | 83–85 | [55] |

| Cu: 5 | Cylindrical threaded pin | Vr: 700–710 rpm; Va: 56–112 mm/min. | BM: 331/137 FSW: 235–326/106–134 | BM: 77 * FSW: 90–110 * | BM: 29 FSW: 31–38 | 71–98 | [66] |

| Pure Cu: 6 | Conical threaded pin | Vr: 635 rpm; Va: 8–19 mm/min. | BM: 273.2/240.7 FSW: 138.8–256.9/93.8–165.4 | BM: 97 | BM: 33.54 FSW: 5.51–24.44 | 58–107 | [73] |

| CuCrZr: 2 | Cylindrical pin | Vr: 400–800 rpm; Va: 50–150 mm/min. | BM: 244–250 */174–230 * FSW: 230–240 */168–225 * | BM: 95–114 * FSW: 121–135 | BM: 34–39 * FSW: 25–28 * | 94–96 | [36] |

| Cu70%-Zn30%: 2 | Cylindrical pin | Vr: 450 rpm; Va: 100 mm/min. | BM: 230 * FSW: 300 * | BM: 90 * FSW: 125 * | – | 130 | [37] |

| Cu60%-Zn40%: 2 | Cylindrical pin | Vr: 250–1500 rpm; Va: 500–2000 mm/min. | BM: 380 */195 * FSW: 370–385 */190–210 * | BM: 100 * FSW: 130–160 * | BM: 60 * FSW: 21–51 * | 97–101 | [41] |

| Cu-Zn30: 2 | Cylindrical threaded pin | Vr: 1200 rpm; Va: 100–200 mm/min. | BM: 360 */110 * FSW: 490 */408 | BM: 96.7 FSW: 155.2 | – | 136 | [43] |

| Cu-Cr-Zr: 2 | Conical threaded pin | Vr: 400–600 rpm; Va: 50 mm/min. | BM: 488/437 FSW: 382–488/320–439 | BM: 151 FSW: 107–173 | BM: 17.6 FSW: 8.9–11.8 | 78–100 | [67] |

| CuZn30%: 3 | Cylindrical threaded pin | Vr: 2050 rpm; Va: 20–140 mm/min. | BM: 360/215 FSW: 175–340/130–210 | BM: 95 * FSW: 155 * | BM: 67 | 49–94 | [6] |

| Cu-Zn: 3 | Cylindrical threaded pin | Vr: 463–1136 rpm; Va: 16–184 mm/min. | FSW: 272–319 | FSW: 90–135 | FSW: 27–56 | – | [39] |

| Cu90%-Zn10%: 3 | Conical pin | Vr: 1600 rpm; Va: 160–260 mm/min. | BM: 249/139 FSW: 233–252/137–143 | BM: 75 FSW: 110 * | BM: 19 FSW: 11–16 | 94–101 | [42] |

| Cu70%-Zn30%: 3 | Conical pin | Vr: 1600 rpm; Va: 160–260 mm/min. | BM: 341/217 FSW: 329–400/166–283 | BM: 82 FSW: 85 * | BM: 17 FSW: 3–14 | 96–117 | [42] |

| Cu-Cr-Zr-Ti: 3.8 | Conical threaded pin | Vr: 1000 rpm; Va: 30 mm/min. | BM: 240/74 FSW: 221–272 */64–171 | BM: 70 * FSW: 65–85 * | BM: 38 FSW: 13–42 | 92–113 | [65] |

| Cu-Zn 1/2H: 5 | Cylindrical threaded pin | Vr: 400–1000 rpm; Va: 100 mm/min. | BM: 400 */230 * FSW: 400 */180–190 * | BM: 110 * FSW: 123–136 * | BM: 50 * FSW: 39–46 * | 100 | [38] |

| Cu-Cr-Zr: 7 | Conical threaded pin | Vr: 300–600 rpm; Va: 50–100 mm/min. | BM: 239–437 FSW: 240–437 | BM: 80–135.8 FSW: 89–152.1 | – | 71–120 | [49] |

| Cu-OF: 10–11 | Pin triflate | Vr: 1400 rpm; Va: 600 mm/min. | BM: 298/292 FSW: 217/120–128 | BM: 100 * FSW: 65 * | BM: 13 FSW: 38 | 73 | [78] |

| Cu-DHP: 10–11 | Pin triflate | Vr: 1000–1125 rpm; Va: 200–400 mm/min. | BM: 208/66 FSW: 215–230/103–115 | BM: 70 * FSW: 67–73 * | BM: 56 FSW: 44–50 | 103–111 | [78] |

| CuAl5Zn5Sn: 10–11 | Pin triflate | Vr: 350–500 rpm; Va: 70–100 mm/min. | BM: 433/170 FSW: 439–443/175–195 | BM: 90 * FSW: 105–130 * | BM: 71 FSW: 59–66 | 101–102 | [78] |

| Cu-Cr-Zr: 12 | - | - | BM: 449.736 FSW: 266.451 | BM: 136–148 FSW: 88–99 | BM: 29.733 FSW: 25.412 | 59 | [76] |

| Cu-Cr-Zr: 21 | Conical pin | Vr: 1500 rpm; Va: 150 mm/min. | BM: 450 * FSW: 260–280 | BM: 150 * FSW: 65–80 * | BM: 12 * FSW: 16–21 * | 57–62 | [14] |

| Cu-Cr-Zr: 30 | Conical threaded pin | Vr: 1500 rpm; Va: 30 mm/min. | BM: 450 */400 * FSW: 260–280 */205–230 * | BM: 150 * FSW: 65–82 * | BM: 13 * FSW: 16–21 * | 58–62 | [33] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bulacu, R.N.; Dhondt, M.; Demmouche, Y.; Bădulescu, C.; Nițu, E.L.; Iordache, D.M. A Review on Friction Stir Welding of Copper: Tool Geometry, Process Parameters, and Joint Properties. Materials 2024, 17, 5374. https://doi.org/10.3390/ma17215374

Bulacu RN, Dhondt M, Demmouche Y, Bădulescu C, Nițu EL, Iordache DM. A Review on Friction Stir Welding of Copper: Tool Geometry, Process Parameters, and Joint Properties. Materials. 2024; 17(21):5374. https://doi.org/10.3390/ma17215374

Chicago/Turabian StyleBulacu, Răducu Nicolae, Matthieu Dhondt, Younes Demmouche, Claudiu Bădulescu, Eduard Laurențiu Nițu, and Daniela Monica Iordache. 2024. "A Review on Friction Stir Welding of Copper: Tool Geometry, Process Parameters, and Joint Properties" Materials 17, no. 21: 5374. https://doi.org/10.3390/ma17215374

APA StyleBulacu, R. N., Dhondt, M., Demmouche, Y., Bădulescu, C., Nițu, E. L., & Iordache, D. M. (2024). A Review on Friction Stir Welding of Copper: Tool Geometry, Process Parameters, and Joint Properties. Materials, 17(21), 5374. https://doi.org/10.3390/ma17215374